Abstract

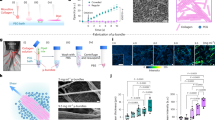

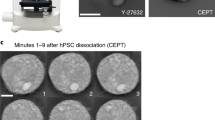

This paper describes a protocol to encapsulate cells in sub-millimeter-sized cylindrical collagen modules and to assemble these modules into a tissue-engineered construct within a continuous loop flow circuit. Modules are fabricated by gelling a solution of collagen, that contains suspended cells, within the lumen of a small-bore polyethylene tube. The tubing is then cut into short lengths using an automated cutter and gently vortexed to remove the cell-containing collagen modules from the tubing lumen. Modules are then randomly assembled into a modular construct by pipetting a suspension of modules into a larger tube that is positioned within a continuous flow circuit. A range of cylinder aspect ratios are achievable; therefore, this method could potentially be used to create short discs or, alternatively, long threads of soft gels, with or without encapsulated cells, for a variety of tissue-engineering applications. Module fabrication requires 1 d and assembly of a modular construct requires 2 h.

NOTE: The title of the article is incorrect as published. It should read: "Fabrication of cell-containing gel modules to assemble modular tissue-engineered constructs".

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

269,00 € per year

only 22,42 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

08 March 2007

The title of the article is incorrect as published. It should read: "Fabrication of cell-containing gel modules to assemble modular tissue-engineered constructs".

References

Langer, R. & Vacanti, J.P. Tissue engineering. Science 260, 920 (1993).

Nomi, M., Atala, A., Coppi, P.D. & Soker, S. Principals of neovascularization for tissue engineering. Mol. Aspects Med. 23, 463 (2002).

Carmeliet, P. & Jain, R. K. Angiogenesis in cancer and other diseases. Nature 407, 249 (2000).

Kim, B.S., Putnam, A.J., Kulik, T.J. & Mooney, D.J. Optimizing seeding and culture methods to engineer smooth muscle tissue on biodegradable polymer matrices. Biotechnol. Bioeng. 57, 46–54 (1998).

McGuigan, A.P. & Sefton, M.V. Vascularized organoid engineered by modular assembly enables blood perfusion. Proc. Natl. Acad. Sci. USA 103, 11461 (2006).

Sosnik, A. & Sefton, M.V. Biomaterials 26, 7425–7435 (2005).

Lahooti, S. & Sefton, M.V. Methods for Microencapsulation with HEMA-MMA. Methods in Molecular Medicine. Vol 18: Tissue Engineering Methods and Protocols (eds. Morgan, J.R. & Yamush, M.L.) 331–348 (Humana Press Inc., Totowa, New Jersey, USA, 1999).

Acknowledgements

We would like to acknowledge Z. Fang, of FCS Technologies Inc., and T. Fixler for technical assistance; and the National Institute of Health (EB001013, co-investigators E. Yeo and A. Gotlieb) and the Natural Sciences and Engineering Research Council for funding. A.P.M. and B.L. acknowledge the fellowship support of the Province of Ontario and the Canadian Institutes of Health Research Training Program in Regenerative Medicine.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Figure 1

Automatic cutter concept drawing (PDF 74 kb)

Supplementary Figure 2

[a–d] Module fabrication process (PDF 1089 kb)

Supplementary Figure 3

Preliminary Assembly of the Flow Circuit for gas sterilization (PDF 71 kb)

Rights and permissions

About this article

Cite this article

McGuigan, A., Leung, B. & Sefton, M. Fabrication of cells containing gel modules to assemble modular tissue-engineered constructs. Nat Protoc 1, 2963–2969 (2006). https://doi.org/10.1038/nprot.2006.443

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2006.443