Abstract

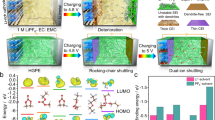

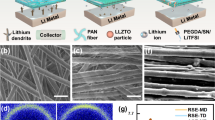

Increasing the energy density of batteries can accelerate the deployment of electric vehicles, expand the utilization of renewable energy and, in turn, reduce greenhouse gas emissions. Different from commercially available lithium-ion batteries, high-energy-density lithium-metal batteries use metallic lithium instead of graphite as the negative electrode. The commercialization of lithium-metal batteries is hindered by the electrochemical instability of lithium metal. Polymer coatings have shown promise in addressing issues related to each step of heterogeneous lithium deposition. Here we summarize the current understanding of key design principles and highlight relevant coating compositions. Moreover, we discuss high-performing coating–electrolyte pairs and provide an outlook on interface design for novel electrolytes.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

27,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

118,99 € per year

only 9,92 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019). This paper proposed practical guidelines for the characterization of LMBs.

Whittingham, M. History, evolution, and future status of energy storage. Proc. IEEE 100, 1518–1534 (2012).

Tikekar, M. D., Choudhury, S., Tu, Z. & Archer, L. A. Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat. Energy 1, 16114 (2016). This paper highlights challenges related to the instability of Li-metal anodes.

Gong, H. et al. Fast-charging of hybrid lithium-ion/lithium-metal anodes by nanostructured hard carbon host. ACS Energy Lett. 7, 4417–4426 (2022).

Yan, K. et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016).

Xu, R. et al. Artificial interphases for highly stable lithium metal anode. Matter 1, 317–344 (2019).

Yan, C. et al. Dual-layered film protected lithium metal anode to enable dendrite-free lithium deposition. Adv. Mater. 30, 1707629 (2018).

Sun, S. et al. Facile ex situ formation of a LiF–polymer composite layer as an artificial SEI layer on Li metal by simple roll-press processing for carbonate electrolyte-based Li metal batteries. J. Mater. Chem. A 8, 17229–17237 (2020).

Basile, A., Bhatt, A. I. & O’Mullane, A. P. Stabilizing lithium metal using ionic liquids for long-lived batteries. Nat. Commun. 7, ncomms11794 (2016).

Zheng, G. et al. Interconnected hollow carbon nanospheres for stable lithium metal anodes. Nat. Nanotechnol. 9, 618–623 (2014).

Chen, L. et al. Lithium metal protected by atomic layer deposition metal oxide for high performance anodes. J. Mater. Chem. A 5, 12297–12309 (2017).

Chen, L. et al. Directly formed alucone on lithium metal for high-performance Li batteries and Li–S batteries with high sulfur mass loading. ACS Appl. Mater. Interfaces 10, 7043–7051 (2018).

Zhou, H., Yu, S., Liu, H. & Liu, P. Protective coatings for lithium metal anodes: recent progress and future perspectives. J. Power Sources 450, 227632 (2020).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Stalin, S. et al. Ultrathin zwitterionic polymeric interphases for stable lithium metal anodes. Matter 4, 3753–3773 (2021).

Stalin, S. et al. Designing polymeric interphases for stable lithium metal deposition. Nano Lett. 20, 5749–5758 (2020).

Kim, J.-M. et al. High current-density-charging lithium metal batteries enabled by double-layer protected lithium metal anode. Adv. Funct. Mater. 32, 2207172 (2022).

Zhang, Q.-K. et al. Homogeneous and mechanically stable solid–electrolyte interphase enabled by trioxane-modulated electrolytes for lithium metal batteries. Nat. Energy 8, 725–735 (2023).

Zheng, G. et al. High-performance lithium metal negative electrode with a soft and flowable polymer coating. ACS Energy Lett. 1, 1247–1255 (2016).

Huang, Z. et al. Effects of polymer coating mechanics at solid–electrolyte interphase for stabilizing lithium metal anodes. Adv. Energy Mater. 12, 2103187 (2022).

Liu, K. et al. Lithium metal anodes with an adaptive “solid–liquid” interfacial protective layer. J. Am. Chem. Soc. 139, 4815–4820 (2017).

Yu, Z. et al. A dynamic, electrolyte-blocking, and single-ion-conductive network for stable lithium-metal anodes. Joule 3, 2761–2776 (2019).

Li, N.-W. et al. A flexible solid electrolyte interphase layer for long-life lithium metal anodes. Angew. Chem. Int. Ed. 57, 1505–1509 (2018).

Weng, Y.-T. et al. An ultrathin ionomer interphase for high efficiency lithium anode in carbonate based electrolyte. Nat. Commun. 10, 5824 (2019).

Liu, F. et al. Fabrication of hybrid silicate coatings by a simple vapor deposition method for lithium metal anodes. Adv. Energy Mater. 8, 1701744 (2018).

Xu, R. et al. Artificial soft–rigid protective layer for dendrite-free lithium metal anode. Adv. Funct. Mater. 28, 1705838 (2018).

Gao, Y. et al. Polymer–inorganic solid–electrolyte interphase for stable lithium metal batteries under lean electrolyte conditions. Nat. Mater. 18, 384–389 (2019).

Zhao, Y. et al. Natural SEI-inspired dual-protective layers via atomic/molecular layer deposition for long-life metallic lithium anode. Matter 1, 1215–1231 (2019).

Tu, Z. et al. Designing artificial solid–electrolyte interphases for single-ion and high-efficiency transport in batteries. Joule 1, 394–406 (2017).

Kozen, A. C. et al. Stabilization of lithium metal anodes by hybrid artificial solid electrolyte interphase. Chem. Mater. 29, 6298–6307 (2017).

Huang, Z., Choudhury, S., Gong, H., Cui, Y. & Bao, Z. A cation-tethered flowable polymeric interface for enabling stable deposition of metallic lithium. J. Am. Chem. Soc. 142, 21393–21403 (2020).

Baran, M. J. et al. Diversity-oriented synthesis of polymer membranes with ion solvation cages. Nature 592, 225–231 (2021).

Zhu, B. et al. Poly(dimethylsiloxane) thin film as a stable interfacial layer for high-performance lithium-metal battery anodes. Adv. Mater. 29, 1603755 (2017).

Liu, Y. et al. An artificial solid electrolyte interphase with high Li-ion conductivity, mechanical strength, and flexibility for stable lithium metal anodes. Adv. Mater. 29, 1605531 (2017).

Sun, Y. et al. A novel organic “polyurea” thin film for ultralong-life lithium-metal anodes via molecular-layer deposition. Adv. Mater. 31, 1806541 (2019).

Zhou, H. et al. Quantification of the ion transport mechanism in protective polymer coatings on lithium metal anodes. Chem. Sci. 12, 7023–7032 (2021).

Luo, J., Fang, C.-C. & Wu, N.-L. High polarity poly(vinylidene difluoride) thin coating for dendrite-free and high-performance lithium metal anodes. Adv. Energy Mater. 8, 1701482 (2018).

Fu, C. et al. Universal chemomechanical design rules for solid-ion conductors to prevent dendrite formation in lithium metal batteries. Nat. Mater. 19, 758–766 (2020).

Fu, C. & Battaglia, C. Polymer–inorganic nanocomposite coating with high ionic conductivity and transference number for a stable lithium metal anode. ACS Appl. Mater. Interfaces 12, 41620–41626 (2020).

Liu, H.-J. et al. Engineering lithiophilic silver sponge integrated with ion-conductive PVDF/LiF protective layer for dendrite-free and high-performance lithium metal batteries. ACS Appl. Energy Mater. 6, 519–529 (2023).

Jang, E. K., Ahn, J., Yoon, S. & Cho, K. Y. High dielectric, robust composite protective layer for dendrite-free and LiPF6 degradation-free lithium metal anode. Adv. Funct. Mater. 29, 1905078 (2019).

Choudhury, S. et al. Ion conducting polymer interfaces for lithium metal anodes: impact on the electrodeposition kinetics. Adv. Energy Mater. 13, 2301899 (2023).

Guo, Q. et al. CNT/PVDF composite coating layer on Cu with a synergy of uniform current distribution and stress releasing for improving reversible Li plating/stripping. ACS Appl. Mater. Interfaces 14, 46043–46055 (2022).

Guo, S. et al. PVDF-HFP/LiF composite interfacial film to enhance the stability of Li-metal anodes. ACS Appl. Energy Mater. 3, 7191–7199 (2020).

Wang, G. et al. Self-stabilized and strongly adhesive supramolecular polymer protective layer enables ultrahigh-rate and large-capacity lithium-metal anode. Angew. Chem. Int. Ed. 59, 2055–2060 (2020).

Gao, Y. et al. Interfacial chemistry regulation via a skin-grafting strategy enables high-performance lithium-metal batteries. J. Am. Chem. Soc. 139, 15288–15291 (2017).

Zhao, Y. et al. Stable Li metal anode by a polyvinyl alcohol protection layer via modifying solid–electrolyte interphase layer. Nano Energy 64, 103893 (2019).

Liu, Y. et al. Solubility-mediated sustained release enabling nitrate additive in carbonate electrolytes for stable lithium metal anode. Nat. Commun. 9, 3656 (2018).

Huang, Z. et al. A salt-philic, solvent-phobic interfacial coating design for lithium metal electrodes. Nat. Energy 8, 577–585 (2023).

Aurbach, D., Zinigrad, E., Cohen, Y. & Teller, H. A short review of failure mechanisms of lithium metal and lithiated graphite anodes in liquid electrolyte solutions. Solid State Ion. 148, 405–416 (2002).

Lopez, J. et al. Effects of polymer coatings on electrodeposited lithium metal. J. Am. Chem. Soc. 140, 11735–11744 (2018).

Monroe, C. & Newman, J. The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J. Electrochem. Soc. 152, A396 (2005). This work links the Li deposition morphology to interfacial mechanical properties.

Cao, D. et al. Lithium dendrite in all-solid-state batteries: growth mechanisms, suppression strategies, and characterizations. Matter 3, 57–94 (2020).

Kong, X., Rudnicki, P. E., Choudhury, S., Bao, Z. & Qin, J. Dendrite suppression by a polymer coating: a coarse-grained molecular study. Adv. Funct. Mater. 30, 1910138 (2020).

Khurana, R., Schaefer, J. L., Archer, L. A. & Coates, G. W. Suppression of lithium dendrite growth using cross-linked polyethylene/poly(ethylene oxide) electrolytes: a new approach for practical lithium-metal polymer batteries. J. Am. Chem. Soc. 136, 7395–7402 (2014).

Hallinan, D. T. Jr & Balsara, N. P. Polymer electrolytes. Annu. Rev. Mater. Res. 43, 503–525 (2013).

Mavila, S., Eivgi, O., Berkovich, I. & Lemcoff, N. G. Intramolecular cross-linking methodologies for the synthesis of polymer nanoparticles. Chem. Rev. 116, 878–961 (2016).

Utomo, N. W. et al. Solid-state polymer–particle hybrid electrolytes: structure and electrochemical properties. Sci. Adv. 10, eado4719 (2024).

Zhao, Q., Liu, X., Stalin, S., Khan, K. & Archer, L. A. Solid-state polymer electrolytes with in-built fast interfacial transport for secondary lithium batteries. Nat. Energy 4, 365–373 (2019).

Zheng, J. et al. In-situ polymerization with dual-function electrolyte additive toward future lithium metal batteries. Mater. Today Energy 26, 100984 (2022).

Aurbach, D., Youngman, O. & Dan, P. The electrochemical behavior of 1,3-dioxolane–LiClO4 solutions—II. Contaminated solutions. Electrochim. Acta 35, 639–655 (1990).

Wojtecki, R. J., Meador, M. A. & Rowan, S. J. Using the dynamic bond to access macroscopically responsive structurally dynamic polymers. Nat. Mater. 10, 14–27 (2011).

Stukalin, E. B., Cai, L.-H., Kumar, N. A., Leibler, L. & Rubinstein, M. Self-healing of unentangled polymer networks with reversible bonds. Macromolecules 46, 7525–7541 (2013).

Mackanic, D. G. et al. Decoupling of mechanical properties and ionic conductivity in supramolecular lithium ion conductors. Nat. Commun. 10, 5384 (2019).

Bai, P., Li, J., Brushett, F. R. & Bazant, M. Z. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ. Sci. 9, 3221–3229 (2016).

Chazalviel, J.-N. Electrochemical aspects of the generation of ramified metallic electrodeposits. Phys. Rev. A 42, 7355–7367 (1990). This work describes how charge imbalance leads to heterogeneous metal deposition.

Ding, F. et al. Dendrite-free lithium deposition via self-healing electrostatic shield mechanism. J. Am. Chem. Soc. 135, 4450–4456 (2013).

Wang, X. et al. Poly(ionic liquid)s-in-salt electrolytes with co-coordination-assisted lithium-ion transport for safe batteries. Joule 3, 2687–2702 (2019).

Zhou, X. et al. Electrical breakdown and ultrahigh electrical energy density in poly(vinylidene fluoride–hexafluoropropylene) copolymer. Appl. Phys. Lett. 94, 162901 (2009).

Liu, Y. et al. Insight into the critical role of exchange current density on electrodeposition behavior of lithium metal. Adv. Sci. 8, 2003301 (2021).

Boyle, D. T. et al. Correlating kinetics to cyclability reveals thermodynamic origin of lithium anode morphology in liquid electrolytes. J. Am. Chem. Soc. 144, 20717–20725 (2022).

Ren, X. et al. Localized high-concentration sulfone electrolytes for high-efficiency lithium-metal batteries. Chem 4, 1877–1892 (2018).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4418 (2004). This work summarizes common salts and solvents for Li batteries.

Wang, H. et al. Liquid electrolyte: the nexus of practical lithium metal batteries. Joule 6, 588–616 (2022).

Etacheri, V. et al. Effect of fluoroethylene carbonate (FEC) on the performance and surface chemistry of Si-nanowire Li-ion battery anodes. Langmuir 28, 965–976 (2012).

Qian, J. et al. High rate and stable cycling of lithium metal anode. Nat. Commun. 6, 6362 (2015).

Yu, Z. et al. Rational solvent molecule tuning for high-performance lithium metal battery electrolytes. Nat. Energy 7, 94–106 (2022).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Hobold, G. M. et al. Moving beyond 99.9% Coulombic efficiency for lithium anodes in liquid electrolytes. Nat. Energy 6, 951–960 (2021).

Adams, B. D., Zheng, J., Ren, X., Xu, W. & Zhang, J.-G. Accurate determination of Coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2018).

Kim, S. C. et al. Data-driven electrolyte design for lithium metal anodes. Proc. Natl Acad. Sci. USA 120, e2214357120 (2023).

Xiao, J. et al. Understanding and applying coulombic efficiency in lithium metal batteries. Nat. Energy 5, 561–568 (2020).

Song, Y. et al. The significance of imperceptible crosstalk in high-energy batteries. Energy Storage Mater. 63, 103018 (2023).

Meng, Y. S., Srinivasan, V. & Xu, K. Designing better electrolytes. Science 378, eabq3750 (2022).

Acknowledgements

The authors acknowledge support from the Assistant Secretary for Energy Efficiency and Renewable Energy (EERE), Office of Vehicle Technologies (VTO) of the US Department of Energy (DOE) under the Battery Materials Research (BMR) Program and Battery 500 Consortium.

Author information

Authors and Affiliations

Contributions

All authors contributed to the writing and revision of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Jia-Qi Huang, Wei-Hong Lai and the other, anonymous, reviewer for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, Z., Lyu, H., Greenburg, L.C. et al. Stabilizing lithium-metal electrodes with polymer coatings. Nat Energy (2025). https://doi.org/10.1038/s41560-025-01767-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41560-025-01767-z