Abstract

Microwaves offer volumetric heating with a higher energy efficiency than conductive–convective heat transfer in conventional approaches. The emerging application of microwave heating in biorefineries is a low-emission strategy to produce bio-based chemicals and materials. In this Review, we discuss the use of microwaves in biorefinery applications, including lignocellulose pretreatment, bioactive substance extraction, pyrolysis and hydrothermal treatment. Experimental evidence suggests that microwaves increase reaction rates, product yield and selectivity; however, these outcomes do not always occur. It is important that microwave-assisted techniques are assessed under controlled conditions to allow a fair comparison with conventional processing. Microwaves can induce hotspots in heterogeneous, multiphasic systems, which have reaction-specific impacts on the chemistry of the system. If not controlled, hotspot generation might cause potential catalyst deactivation or risk of reactor explosion. Pilot-scale systems for solid-phase processing such as pyrolysis have already been demonstrated, whereas large-scale microwave-assisted liquid-phase processing could face problems such as low microwave absorptivity in hot water and limited microwave penetration for large volumes. Further work is needed to develop standard protocols to clarify the advantages of microwaves in wide-ranging biorefinery systems to lay the foundation of technological transfer.

Key points

-

Microwave processing could enable the development of energy-efficient biorefineries for lignocellulose pretreatment, extraction of bioactive substances, pyrolysis, hydrothermal treatment and fine chemical production.

-

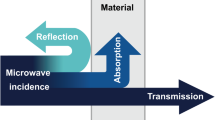

Unlike conventional heating methods, the reacting matrix, including the feedstocks, solvents and additives, needs to be strong microwave absorbers for effective heating to occur under microwaves.

-

Non-equilibrium localized heating under microwaves, known as the hotspot effect, has been widely linked to the increased reaction rate and selective production observed in microwave experiments; however, there is not yet any empirical evidence on the universality of this link.

-

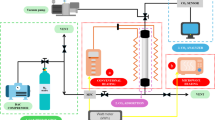

The feasibility of pilot-scale and field-scale microwave-assisted biorefineries has been experimentally demonstrated, especially for solid-phase processing such as pyrolysis.

-

Techno-economic assessments and life-cycle analyses indicate that microwave processing potentially has a lower cost and carbon footprint than conventional techniques; however, such a conclusion cannot be extrapolated to contexts outside the discussed studies and independent assessments are still required for new projects in real-life scenarios.

-

Hotspot monitoring and control alongside advances in microwave reactors could help to expedite the industrial-scale use of microwave-assisted biorefineries.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

118,99 € per year

only 9,92 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

UK Department for Energy Security & Net Zero. Biomass Strategy 2023. GOV.UK https://www.gov.uk/government/publications/biomass-strategy (2023).

Bioenergy Technologies Office, US Department of Energy. 2023 Multi-Year Program Plan. US Department of Energy https://www.energy.gov/eere/bioenergy/articles/2023-multi-year-program-plan (2023).

Federal Ministry of Education and Research (BMBF) & Federal Ministry of Food and Agriculture (BMEL), Germany. National Bioeconomy Strategy. BMBF & BMEL https://www.bmbf.de/SharedDocs/Publikationen/de/bmbf/FS/31617_Nationale_Biooekonomiestrategie_Langfassung_en.pdf?__blob=publicationFile&v=5 (2020).

Vogt, E. T. C. & Weckhuysen, B. M. The refinery of the future. Nature 629, 295–306 (2024).

Chong, C. T. & Ng, J.-H. Limitations to sustainable renewable jet fuels production attributed to cost than energy-water-food resource availability. Nat. Commun. 14, 8156 (2023).

Sanchez-Gutierrez, M. et al. Valorisation of Olea europaea L. olive leaves through the evaluation of their extracts: antioxidant and antimicrobial activity. Foods 10, 966 (2021).

Ho, S. H., Zhang, C., Chen, W. H., Shen, Y. & Chang, J. S. Characterization of biomass waste torrefaction under conventional and microwave heating. Bioresour. Technol. 264, 7–16 (2018).

Mi, J., Cheng, J., Ng, K. H. & Yan, N. Biomass to green surfactants: microwave-assisted transglycosylation of wheat bran for alkyl glycosides production. Bioresour. Technol. 401, 130738 (2024).

Yu, I. K. M. et al. Evidences of starch–microwave interactions under hydrolytic and pyrolytic conditions. Green Chem. 22, 7109–7118 (2020).

Robinson, J. et al. Unravelling the mechanisms of microwave pyrolysis of biomass. Chem. Eng. J. 430, 132975 (2022).

Tsukahara, Y. et al. In situ observation of nonequilibrium local heating as an origin of special effect of microwave on chemistry. J. Phys. Chem. C 114, 8965–8970 (2010).

Horikoshi, S., Osawa, A., Sakamoto, S. & Serpone, N. Control of microwave-generated hot spots. Part V. Mechanisms of hot-spot generation and aggregation of catalyst in a microwave-assisted reaction in toluene catalyzed by Pd-loaded AC particulates. Appl. Catal. A: Gen. 460–461, 52–60 (2013).

Petricci, E., Risi, C., Ferlin, F., Lanari, D. & Vaccaro, L. Avoiding hot-spots in microwave-assisted Pd/C catalysed reactions by using the biomass derived solvent gamma-Valerolactone. Sci. Rep. 8, 10571 (2018).

Ke, L. et al. Microwave catalytic pyrolysis of biomass: a review focusing on absorbents and catalysts. npj Mater. Sustain. 2, 24 (2024).

Zou, R. et al. Advancements and applications of microwave-assisted deep eutectic solvent (MW-DES) lignin extraction: a comprehensive review. Green Chem. 26, 1153–1169 (2024).

Gao, Y., Remón, J. & Matharu, A. S. Microwave-assisted hydrothermal treatments for biomass valorisation: a critical review. Green Chem. 23, 3502–3525 (2021).

Kaza, S., Yao, L. C., Bhada-Tata, P. & Van Woerden, F. in What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050 17–37 (World Bank, 2018).

Moorhouse, J. & Minier, Q. Bioenergy — Tracking Bioenergy. IEA https://www.iea.org/energy-system/renewables/bioenergy#tracking (2023).

Naidoo, J. C. et al. Microwave-assisted sequential green liquor-inorganic salt pretreatment for enhanced sugar recovery from sorghum leaves towards bioethanol and biohydrogen production. Renew. Energy 225, 120225 (2024).

Dharmaraja, J. et al. Lignocellulosic biomass conversion via greener pretreatment methods towards biorefinery applications. Bioresour. Technol. 369, 128328 (2023).

Jönsson, L. J., Alriksson, B. & Nilvebrant, N.-O. Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol. Biofuels 6, 16 (2013).

Kłosowski, G. & Mikulski, D. Changes in various lignocellulose biomasses structure after microwave-assisted hydrotropic pretreatment. Renew. Energy 219, 119387 (2023).

Wang, N. et al. An efficient microwave-assisted method using ethyl lactate/water cosolvent for lignocellulosic biomass fractionation. Chem. Eng. J. 494, 152724 (2024).

Aguilar-Reynosa, A. et al. Comparison of microwave and conduction–convection heating autohydrolysis pretreatment for bioethanol production. Bioresour. Technol. 243, 273–283 (2017).

Taherzadeh, M. J. & Karimi, K. in Biofuels (eds Pandey, A. et al.) 287–311 (Academic Press, 2011).

Gabhane, J., Prince William, S. P. M., Vaidya, A. N., Mahapatra, K. & Chakrabarti, T. Influence of heating source on the efficacy of lignocellulosic pretreatment — a cellulosic ethanol perspective. Biomass Bioenergy 35, 96–102 (2011).

Muley, P. D. et al. Rapid microwave-assisted biomass delignification and lignin depolymerization in deep eutectic solvents. Energy Convers. Manage. 196, 1080–1088 (2019).

Cutz, L. et al. Microstructural degradation during the storage of biomass pellets. Commun. Mater. 2, 2 (2021).

Wu, N., Niu, Q., Pieters, J. & Ronsse, F. Influence of torrefaction as pretreatment on the fast pyrolysis of sugarcane trash. Energy Conv. Manag. 291, 117291 (2023).

Sui, H. et al. Effect of oxidative torrefaction on fuel and pelletizing properties of agricultural biomass in comparison with non-oxidative torrefaction. Renew. Energy 226, 120423 (2024).

Zhou, Q., Shen, Y. & Gu, X. Progress in torrefaction pretreatment for biomass gasification. Green Chem. 26, 9652–9670 (2024).

Yan, B. et al. Investigation on microwave torrefaction: parametric influence, TG-MS-FTIR analysis, and gasification performance. Energy 220, 119794 (2021).

Yek, P. N. Y. et al. Microwave co-torrefaction of waste oil and biomass pellets for simultaneous recovery of waste and co-firing fuel. Renew. Sust. Energy Rev. 152, 111699 (2021).

Agu, O. S., Tabil, L. G., Mupondwa, E., Emadi, B. & Dumonceaux, T. Impact of biochar addition in microwave torrefaction of camelina straw and switchgrass for biofuel production. Fuels 3, 588–606 (2022).

Arpia, A. A. et al. Catalytic microwave-assisted torrefaction of sugarcane bagasse with calcium oxide optimized via Taguchi approach: product characterization and energy analysis. Fuel 305, 121543 (2021).

Fan, P. et al. Nanopore analysis of salvianolic acids in herbal medicines. Nat. Commun. 15, 1970 (2024).

Huang, J. et al. Effect of microwave pretreatment of perilla seeds on minor bioactive components content and oxidative stability of oil. Food Chem. 388, 133010 (2022).

Pintać, D. et al. Solvent selection for efficient extraction of bioactive compounds from grape pomace. Ind. Crop. Prod. 111, 379–390 (2018).

Lucchesi, M. E., Smadja, J., Bradshaw, S., Louw, W. & Chemat, F. Solvent free microwave extraction of Elletaria cardamomum L.: a multivariate study of a new technique for the extraction of essential oil. J. Food Eng. 79, 1079–1086 (2007).

Saleh, I. A. et al. Extraction of silymarin from milk thistle (Silybum marianum) seeds — a comparison of conventional and microwave-assisted extraction methods. J. Microw. Power Electromagn. Energy 51, 124–133 (2017).

Taqi, A., Farcot, E., Robinson, J. P. & Binner, E. R. Understanding microwave heating in biomass-solvent systems. Chem. Eng. J. 393, 124741 (2020).

Oufnac, D. S. et al. Extraction of antioxidants from wheat bran using conventional solvent and microwave-assisted methods. Cereal Chem. 84, 125–129 (2007).

Baker-Fales, M., Chen, T.-Y., Bhalode, P., Wang, Z. & Vlachos, D. G. Microwave enhancement of extractions and reactions in liquid–liquid biphasic systems. Chem. Eng. J. 476, 146552 (2023).

Chen, T.-Y., Baker-Fales, M., Goyal, H. & Vlachos, D. G. Microwave heating-induced temperature gradients in liquid–liquid biphasic systems. Ind. Eng. Chem. Res. 61, 3011–3022 (2022).

Zengin, G. et al. A comparative exploration of the phytochemical profiles and bio-pharmaceutical potential of Helichrysum stoechas subsp. barrelieri extracts obtained via five extraction techniques. Proc. Biochem. 91, 113–125 (2020).

Tsubaki, S., Sakamoto, M. & Azuma, J.-I. Microwave-assisted extraction of phenolic compounds from tea residues under autohydrolytic conditions. Food Chem. 123, 1255–1258 (2010).

Ibraeva, K. et al. Comparative analysis of conventional and microwave pyrolysis of raw materials with different degree of metamorphism. Energy Conv. Manag. 301, 118067 (2024).

Jiang, Y. et al. Pyrolysis of banana peel with microwave and furnace as the heating sources: the distinct impacts on evolution of the pyrolytic products. Process. Saf. Environ. Prot. 173, 373–383 (2023).

Lin, J. et al. Comparison of microwave pyrolysis and conventional pyrolysis of Eupatorium adenophorum. Environ. Prog. Sustain. Energy 42, e13978 (2022).

Lin, B.-J. & Chen, W.-H. Sugarcane bagasse pyrolysis in a carbon dioxide atmosphere with conventional and microwave-assisted heating. Front. Energy Res. 3, 1–9 (2015).

Shi, K. et al. Production of H(2)-rich syngas from lignocellulosic biomass using microwave-assisted pyrolysis coupled with activated carbon enabled reforming. Front. Chem. 8, 3 (2020).

Parvez, A. M. et al. Conventional and microwave-assisted pyrolysis of gumwood: a comparison study using thermodynamic evaluation and hydrogen production. Fuel Process. Technol. 184, 1–11 (2019).

Domínguez, A. et al. Conventional and microwave induced pyrolysis of coffee hulls for the production of a hydrogen rich fuel gas. J. Anal. Appl. Pyrolysis 79, 128–135 (2007).

Shi, K., Yan, J., Lester, E. & Wu, T. Catalyst-free synthesis of multiwalled carbon nanotubes via microwave-induced processing of biomass. Ind. Eng. Chem. Res. 53, 15012–15019 (2014).

Halim, S. A., Mohd, N. A. & Razali, N. A. A comparative assessment of biofuel products from rice husk and oil palm empty fruit bunch obtained from conventional and microwave pyrolysis. J. Taiwan Inst. Chem. Eng. 134, 104305 (2022).

Suriapparao, D. V., Vinu, R., Shukla, A. & Haldar, S. Effective deoxygenation for the production of liquid biofuels via microwave assisted co-pyrolysis of agro residues and waste plastics combined with catalytic upgradation. Bioresour. Technol. 302, 122775 (2020).

Zhang, Z. et al. Low-temperature microwave-assisted pyrolysis of waste office paper and the application of bio-oil as an Al adhesive. Green Chem. 17, 260–270 (2015).

Li, D., Zhu, L., Berruti, F. & Briens, C. Autothermal fast pyrolysis of waste biomass for wood adhesives. Ind. Crop. Products 170, 113711 (2021).

Nzediegwu, C., Arshad, M., Ulah, A., Naeth, M. A. & Chang, S. X. Fuel, thermal and surface properties of microwave-pyrolyzed biochars depend on feedstock type and pyrolysis temperature. Bioresour. Technol. 320, 124282 (2021).

Omoriyekomwan, J. E., Tahmasebi, A., Zhang, J. & Yu, J. Formation of hollow carbon nanofibers on bio-char during microwave pyrolysis of palm kernel shell. Energy Conv. Manag. 148, 583–592 (2017).

Omoriyekomwan, J. E., Tahmasebi, A., Zhang, J. & Yu, J. Mechanistic study on direct synthesis of carbon nanotubes from cellulose by means of microwave pyrolysis. Energy Conv. Manag. 192, 88–99 (2019).

Wang, Z. et al. Nanocarbons from rice husk by microwave plasma irradiation: from graphene and carbon nanotubes to graphenated carbon nanotube hybrids. Carbon 94, 479–484 (2015).

Ferrera-Lorenzo, N., Fuente, E., Bermudez, J. M., Suarez-Ruiz, I. & Ruiz, B. Conventional and microwave pyrolysis of a macroalgae waste from the agar–agar industry. Prospects for bio-fuel production. Bioresour. Technol. 151, 199–206 (2014).

Lahijani, P., Zainal, Z. A., Mohamed, A. R. & Mohammadi, M. Microwave-enhanced CO2 gasification of oil palm shell char. Bioresour. Technol. 158, 193–200 (2014).

Mašek, O. et al. Microwave and slow pyrolysis biochar — comparison of physical and functional properties. J. Anal. Appl. Pyrolysis 100, 41–48 (2013).

Mohamed, B. A., Kim, C. S., Ellis, N. & Bi, X. Microwave-assisted catalytic pyrolysis of switchgrass for improving bio-oil and biochar properties. Bioresour. Technol. 201, 121–132 (2016).

Li, M. et al. The impact of heating rate on the decomposition kinetics and product distribution of algal waste pyrolysis with in-situ weight measurement. Chem. Eng. J. 457, 141368 (2023).

Zhang, X., Wu, K. & Yuan, Q. Comparative study of microwave and conventional hydrothermal treatment of chicken carcasses: bio-oil yields and properties. Energy 200, 117539 (2020).

Zhuang, X., Liu, J., Wang, C., Zhang, Q. & Ma, L. Microwave-assisted hydrothermal liquefaction for biomass valorization: insights into the fuel properties of biocrude and its liquefaction mechanism. Fuel 317, 123462 (2022).

Tran, K.-Q. et al. Fast hydrothermal liquefaction of native and torrefied wood. Energy Proc. 105, 218–223 (2017).

Yang, J. et al. Microwave-assisted hydrothermal liquefaction of biomass model components and comparison with conventional heating. Fuel 277, 118202 (2020).

Shao, Y. et al. Synthesis of improved hydrochar by microwave hydrothermal carbonization of green waste. Fuel 266, 117146 (2020).

Soroush, S. et al. Microwave assisted and conventional hydrothermal treatment of waste seaweed: comparison of hydrochar properties and energy efficiency. Sci. Total Environ. 878, 163193 (2023).

Dai, L. et al. Comparative study on microwave and conventional hydrothermal pretreatment of bamboo sawdust: hydrochar properties and its pyrolysis behaviors. Energy Convers. Manag. 146, 1–7 (2017).

Zhu, Z. et al. Microwave synthesis of amphiphilic carbon dots from xylose and construction of luminescent composites with shape recovery performance. J. Lumin. 213, 474–481 (2019).

Balakrishnan, T., Ang, W. L., Mahmoudi, E., Mohammad, A. W. & Sambudi, N. S. Formation mechanism and application potential of carbon dots synthesized from palm kernel shell via microwave assisted method. Carbon Resour. Convers. 5, 150–166 (2022).

Liu, Y. et al. Non-thermal effect of microwave on the chemical structure and luminescence properties of biomass-derived carbon dots via hydrothermal method. Appl. Surf. Sci. 552, 149503 (2021).

Remón, J., Li, T., Chuck, C. J., Matharu, A. S. & Clark, J. H. Toward renewable-based, food-applicable prebiotics from biomass: a one-step, additive-free, microwave-assisted hydrothermal process for the production of high purity xylo-oligosaccharides from beech wood hemicellulose. ACS Sustain. Chem. Eng. 7, 16160–16172 (2019).

Remón, J., Danby, S. H., Clark, J. H. & Matharu, A. S. A new step forward nonseasonal 5G biorefineries: microwave-assisted, synergistic, co-depolymerization of wheat straw (2G biomass) and Laminaria saccharina (3G biomass). ACS Sustain. Chem. Eng. 8, 12493–12510 (2020).

Trubetskaya, A. et al. Microwave hydrolysis, as a sustainable approach in the processing of seaweed for protein and nanocellulose management. Algal Res. 78, 103406 (2024).

Remón, J., Matharu, A. S. & Clark, J. H. Simultaneous production of lignin and polysaccharide rich aqueous solutions by microwave-assisted hydrothermal treatment of rapeseed meal. Energy Conv. Manag. 165, 634–648 (2018).

Fan, J. et al. Direct microwave-assisted hydrothermal depolymerization of cellulose. J. Am. Chem. Soc. 135, 11728–11731 (2013).

Yu, I. K. M. et al. NaCl-promoted phase transition and glycosidic bond cleavage under microwave heating for energy-efficient biorefinery of rice starch. Green Chem. 22, 7355–7365 (2020).

Velaga, B. & Peela, N. R. Levulinic acid production from furfural: process development and techno-economics. Green Chem. 24, 3326–3343 (2022).

Ji, T. et al. Niobium-doped TiO2 solid acid catalysts: strengthened interfacial polarization, amplified microwave heating and enhanced energy efficiency of hydroxymethylfurfural production. Appl. Catal. B 243, 741–749 (2019).

Zhang, Q. et al. Sustainable production of gluconic acid and glucuronic acid via microwave-assisted glucose oxidation over low-cost Cu-biochar catalysts. Green Chem. 24, 6657–6670 (2022).

Lin, J.-Y., Thanh, B. X., Kwon, E. & Lin, K.-Y. A. Enhanced catalytic conversion of 5-hydroxymethylfurfural to 2,5-diformylfuran by HKUST-1/TEMPO under microwave irradiation. Biomass Convers. Biorefin. 11, 2829–2836 (2021).

Omri, M., Pourceau, G., Becuwe, M. & Wadouachi, A. Improvement of gold-catalyzed oxidation of free carbohydrates to corresponding aldonates using microwaves. ACS Sustain. Chem. Eng. 4, 2432–2438 (2016).

Zhang, Q. et al. Efficient microwave-assisted mineralization of oxytetracycline driven by persulfate and hypochlorite over Cu-biochar catalyst. Bioresour. Technol. 372, 128698 (2023).

Horikoshi, S., Kamata, M., Mitani, T. & Serpone, N. Control of microwave-generated hot spots. 6. Generation of hot spots in dispersed catalyst particulates and factors that affect catalyzed organic syntheses in heterogeneous media. Ind. Eng. Chem. Res. 53, 14941–14947 (2014).

Druzhinina, T., Weltjens, W., Hoeppener, S. & Schubert, U. S. The selective heating of iron nanoparticles in a single-mode microwave for the patterned growths of carbon nanofibers and nanotubes. Adv. Funct. Mater. 19, 1287–1292 (2009).

Ramirez, A., Hueso, J. L., Mallada, R. & Santamaria, J. In situ temperature measurements in microwave-heated gas–solid catalytic systems. Detection of hot spots and solid–fluid temperature gradients in the ethylene epoxidation reaction. Chem. Eng. J. 316, 50–60 (2017).

De Bruyn, M. et al. Subtle microwave-induced overheating effects in an industrial demethylation reaction and their direct use in the development of an innovative microwave reactor. J. Am. Chem. Soc. 139, 5431–5436 (2017).

Zhao, Z. et al. Watching microwave-induced microscopic hot spots via the thermosensitive fluorescence of europium/terbium mixed-metal organic complexes. Angew. Chem. Int. Ed. 61, e202114340 (2022).

Suguro, T., Kishimoto, F., Movick, W. J. & Takanabe, K. Coherent evaluation of energy efficiency for microwave catalytic reactors based on reaction equilibrium. ChemCatChem 16, e202301598 (2024).

Horikoshi, S., Mura, H. & Serpone, N. Three-dimensional observations of the electric field distribution of variable frequency microwaves, and scaling-up organic syntheses. Commun. Chem. 6, 261 (2023).

Khattak, H. K., Bianucci, P. & Slepkov, A. D. Linking plasma formation in grapes to microwave resonances of aqueous dimers. Proc. Natl Acad. Sci. USA 116, 4000–4005 (2019).

Kappe, C. O., Pieber, B. & Dallinger, D. Microwave effects in organic synthesis: myth or reality? Angew. Chem. Int. Ed. 52, 1088–1094 (2013).

Obermayer, D. et al. Design and performance validation of a conductively heated sealed-vessel reactor for organic synthesis. J. Org. Chem. 81, 11788–11801 (2016).

Luo, H. et al. Microwave-assisted low-temperature biomass pyrolysis: from mechanistic insights to pilot scale. Green Chem. 23, 821–827 (2021).

Mari Selvam, S., Balasubramanian, P., Chintala, M. & Gujjala, L. K. S. Techno-economic analysis of microwave pyrolysis of sugarcane bagasse biochar production. Biomass Convers. Biorefin. https://doi.org/10.1007/s13399-024-06232-7 (2024).

Haeldermans, T. et al. A comparative techno-economic assessment of biochar production from different residue streams using conventional and microwave pyrolysis. Bioresour. Technol. 318, 124083 (2020).

Lam, S. S. et al. Microwave vacuum pyrolysis of waste plastic and used cooking oil for simultaneous waste reduction and sustainable energy conversion: recovery of cleaner liquid fuel and techno-economic analysis. Renew. Sustain. Energy Rev. 115, 109359 (2019).

Xu, J. et al. Catalytic co-pyrolysis characteristics and kinetics analysis of food waste and chinar leaves, and the large-scale microwave disposal feasibility. Biomass Convers. Biorefin. 14, 15949–15967 (2023).

Lee, C. S., Chong, M. F., Binner, E., Gomes, R. & Robinson, J. Techno-economic assessment of scale-up of bio-flocculant extraction and production by using okra as biomass feedstock. Chem. Eng. Res. Des. 132, 358–369 (2018).

Parthasarathy, P., Tahir, F., Pradhan, S., Al-Ansari, T. & McKay, G. Life cycle assessment of biofuel production from waste date stones using conventional and microwave pyrolysis. Energy Conv. Manag. X 21, 100510 (2024).

Baker-Fales, M., Chen, T.-Y. & Vlachos, D. G. Scale-up of microwave-assisted, continuous flow, liquid phase reactors: application to 5-hydroxymethylfurfural production. Chem. Eng. J. 454, 139985 (2023).

Deng, C. et al. Co-production of hydrochar, levulinic acid and value-added chemicals by microwave-assisted hydrothermal carbonization of seaweed. Chem. Eng. J. 441, 135915 (2022).

Makepa, D. C., Chihobo, C. H. & Musademba, D. Techno-economic analysis and environmental impact assessment of biodiesel production from bio-oil derived from microwave-assisted pyrolysis of pine sawdust. Heliyon 9, e22261 (2023).

Mohamed, B. A. et al. Phenolic-rich bio-oil production by microwave catalytic pyrolysis of switchgrass: experimental study, life cycle assessment, and economic analysis. J. Clean. Prod. 366, 132668 (2022).

Ren, J., La, X., Wang, J. & Jiang, J. Beyond microwave susceptors: exploring 5525 MHz frequency for efficient biomass pyrolysis. Fuel 372, 132220 (2024).

Luo, J. et al. In-depth exploration of the energy utilization and pyrolysis mechanism of advanced continuous microwave pyrolysis. Appl. Energy 292, 116941 (2021).

Fan, Y. et al. Microwave-induced carbonization of rapeseed shell for bio-oil and bio-char: multi-variable optimization and microwave absorber effect. Energy Conv. Manag. 191, 23–38 (2019).

Terigar, B. G., Balasubramanian, S., Sabliov, C. M., Lima, M. & Boldor, D. Soybean and rice bran oil extraction in a continuous microwave system: from laboratory- to pilot-scale. J. Food Eng. 104, 208–217 (2011).

Peng, H., Luo, H., Jin, S., Li, H. & Xu, J. Improved bioethanol production from corn stover by alkali pretreatment with a novel pilot-scale continuous microwave irradiation reactor. Biotechnol. Bioprocess. Eng. 19, 493–502 (2014).

Longanesi, L. et al. Scaled-up microwave-assisted pretreatment and continuous fermentation to produce yeast lipids from brewery wastes. Ind. Eng. Chem. Res. 59, 19803–19816 (2020).

Gaber, M. A. F. M. et al. Improved canola oil expeller extraction using a pilot-scale continuous flow microwave system for pre-treatment of seeds and flaked seeds. J. Food Eng. 284, 110053 (2020).

Garcia-Garcia, G., Rahimifard, S., Matharu, A. S. & Dugmore, T. I. J. Life-cycle assessment of microwave-assisted pectin extraction at pilot scale. ACS Sustain. Chem. Eng. 7, 5167–5175 (2019).

Nadar, C. G., Arora, A. & Shastri, Y. Sustainability challenges and opportunities in pectin extraction from fruit waste. ACS Eng. Au 2, 61–74 (2022).

Dávila, J. A., Rosenberg, M. & Cardona, C. A. Techno-economic and environmental assessment of p-cymene and pectin production from orange peel. Waste Biomass Valor. 6, 253–261 (2015).

Filly, A. et al. Solvent-free microwave extraction of essential oil from aromatic herbs: from laboratory to pilot and industrial scale. Food Chem. 150, 193–198 (2014).

Périno, S., Pierson, J. T., Ruiz, K., Cravotto, G. & Chemat, F. Laboratory to pilot scale: microwave extraction for polyphenols lettuce. Food Chem. 204, 108–114 (2016).

Petigny, L. et al. Simultaneous microwave extraction and separation of volatile and non-volatile organic compounds of boldo leaves. From lab to industrial scale. Int. J. Mol. Sci. 15, 7183–7198 (2014).

Zhang, Y. et al. Organosolv fractionation of a lignocellulosic biomass feedstock using a pilot scale microwave-heating reactor. Ind. Crop. Prod. 180, 114700 (2022).

Lin, Q., Chen, G. & Liu, Y. Scale-up of microwave heating process for the production of bio-oil from sewage sludge. J. Anal. Appl. Pyrolysis 94, 114–119 (2012).

Lin, Q. H., Cheng, H. & Chen, G. Y. Preparation and characterization of carbonaceous adsorbents from sewage sludge using a pilot-scale microwave heating equipment. J. Anal. Appl. Pyrolysis 93, 113–119 (2012).

Zhao, X. et al. Microwave pyrolysis of straw bale and energy balance analysis. J. Anal. Appl. Pyrolysis 92, 43–49 (2011).

Salema, A. A., Afzal, M. T. & Bennamoun, L. Pyrolysis of corn stalk biomass briquettes in a scaled-up microwave technology. Bioresour. Technol. 233, 353–362 (2017).

Zhou, N. et al. Syngas production from biomass pyrolysis in a continuous microwave assisted pyrolysis system. Bioresour. Technol. 314, 123756 (2020).

Dufour, A., Girods, P., Masson, E., Rogaume, Y. & Zoulalian, A. Synthesis gas production by biomass pyrolysis: effect of reactor temperature on product distribution. Int. J. Hydrog. Energy 34, 1726–1734 (2009).

Muniyappan, D., Lima, G. R., Pereira, A. O., Gopi, R. & Ramanathan, A. Multivariate combined optimization strategy and comparative life-cycle assessment of biomass and plastic residues via microwave co-pyrolysis approach towards a sustainable synthesis of renewable hydrocarbon fuel. J. Environ. Chem. Eng. 11, 111436 (2023).

Özeler, D., Yetiş, Ü. & Demirer, G. N. Life cycle assessment of municipal solid waste management methods: Ankara case study. Environ. Int. 32, 405–411 (2006).

Huang, C., Mohamed, B. A. & Li, L. Y. Comparative life-cycle assessment of pyrolysis processes for producing bio-oil, biochar, and activated carbon from sewage sludge. Resour. Conserv. Recycling 181, 106273 (2022).

Mong, G. R. et al. Multivariate optimisation study and life cycle assessment of microwave-induced pyrolysis of horse manure for waste valorisation and management. Energy 216, 119194 (2021).

Yang, J. et al. Is it feasible to replace freshwater by seawater in hydrothermal liquefaction of biomass for biocrude production? Fuel 282, 118870 (2020).

Shao, Y. et al. Acidic seawater improved 5-hydroxymethylfurfural yield from sugarcane bagasse under microwave hydrothermal liquefaction. Environ. Res. 184, 109340 (2020).

Rosso, D. et al. Conventional and microwave assisted hydrolysis of urban biowastes to added value lignin-like products. Green Chem. 17, 3424–3435 (2015).

Hu, Y., Ma, D. & Ma, J. Microwave hotspots: thermal nonequilibrium dynamics from the perspective of quantum states. J. Phys. Chem. A 125, 2690–2696 (2021).

Wang, K. et al. Learning to detect local overheating of the high-power microwave heating process with deep learning. IEEE Access 6, 10288–10296 (2018).

Yang, R., Wang, Z. & Chen, J. An integrated approach of mechanistic-modeling and machine-learning for thickness optimization of frozen microwaveable foods. Foods 10, 763 (2021).

Horikoshi, S. et al. Application of variable frequency microwaves in microwave-assisted chemistry: relevance and suppression of arc discharges on conductive catalysts. Catalysts 10, 777 (2020).

Neha, S., Prasanna Kumar Ramesh, K. & Remya, N. Techno-economic analysis and life cycle assessment of microwave co-pyrolysis of food waste and low-density polyethylene. Sustain. Energy Technol. Assess. 52, 102356 (2022).

Wang, N. et al. The comparative techno-economic and life cycle assessment for multi-product biorefinery based on microwave and conventional hydrothermal biomass pretreatment. J. Clean. Prod. 474, 143562 (2024).

Silva, M. B. D. O., de Oliveira, S. A. & Rosa, D. D. S. Comparative study on microwave-assisted and conventional chitosan production from shrimp shell: process optimization, characterization, and environmental impacts. J. Clean. Prod. 440, 140726 (2024).

Sathendra, E. R., Praveenkumar, R., Gurunathan, B., Chozhavendhan, S. & Jayakumar, M. in Biofuels and Bioenergy (eds Gurunathan, B., Sahadevan, R. & Zakaria Z. A.) Ch. 5, 87–110 (Elsevier, 2022).

Hah Young, Y. & Seung Wook, K. The next-generation biomass for biorefining. BioResources 16, 2188–2191 (2021).

Morris, B. A. in The Science and Technology of Flexible Packaging 2nd edn (ed. Morris, B. A.) Ch. 4, 85–138 (William Andrew Publishing, 2022).

Haji Esmaeili, S. A., Szmerekovsky, J., Sobhani, A., Dybing, A. & Peterson, T. O. Sustainable biomass supply chain network design with biomass switching incentives for first-generation bioethanol producers. Energy Policy 138, 111222 (2020).

Makepa, D. C., Chihobo, C. H. & Musademba, D. Microwave-assisted pyrolysis of pine sawdust (Pinus patula) with subsequent bio-oil transesterification for biodiesel production. Biofuels 15, 317–325 (2024).

Nolte, M. W., Zhang, J. & Shanks, B. H. Ex situ hydrodeoxygenation in biomass pyrolysis using molybdenum oxide and low pressure hydrogen. Green Chem. 18, 134–138 (2016).

Nguyen, V. G. et al. Recent advances in hydrogen production from biomass waste with a focus on pyrolysis and gasification. Int. J. Hydrog. Energy 54, 127–160 (2024).

O’Connor, S. et al. Biogas production from small-scale anaerobic digestion plants on European farms. Renew. Sustain. Energy Rev. 139, 110580 (2021).

Jha, A. K. & Sit, N. Extraction of bioactive compounds from plant materials using combination of various novel methods: a review. Trends Food Sci. Technol. 119, 579–591 (2022).

Kappe, C. O., Dallinger, D. & Murphree, S. S. Microwave theory. in Practical Microwave Synthesis for Organic Chemists 11–44 (Wiley-VCH Verlag GmbH & Co. KGaA, 2008).

Namazi, A. B., Allen, D. G. & Jia, C. Q. Probing microwave heating of lignocellulosic biomasses. J. Anal. Appl. Pyrolysis 112, 121–128 (2015).

Peng, Z., Hwang, J.-Y., Mouris, J., Hutcheon, R. & Huang, X. Microwave penetration depth in materials with non-zero magnetic susceptibility. ISIJ Int. 50, 1590–1596 (2010).

Ao, W. et al. Microwave assisted preparation of activated carbon from biomass: a review. Renew. Sustain. Energy Rev. 92, 958–979 (2018).

Wang, Z. et al. Carbon-enabled microwave chemistry: from interaction mechanisms to nanomaterial manufacturing. Nano Energy 85, 106027 (2021).

Zhou, H. et al. Engineering the Cu/Mo2CTx (MXene) interface to drive CO2 hydrogenation to methanol. Nat. Catal. 4, 860–871 (2021).

Ma, Y., Wei, S., Liu, R., Sun, L. & Wang, W. A review on MXene-based microwave absorption composites: engineering, component optimization and structure regulation. J. Mater. Chem. C 12, 9068–9093 (2024).

Wang, N. et al. Performance of green solvents in microwave-assisted pretreatment of lignocellulose. Chem. Eng. J. 482, 148786 (2024).

Acknowledgements

I.K.M.Y. acknowledges the financial support provided by Tsinghua-NUS Joint Research Initiative Fund (WBS: A-8002524-00-00).

Author information

Authors and Affiliations

Contributions

Q.Z., Z. Li, Z. Liu and Y.D.P. researched data for the article. All authors contributed substantially to discussion of the content. W.K.O. specifically contributed to discussion related to scale-up of biorefineries. All authors wrote the article. I.K.M.Y. reviewed and/or edited the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

W.K.O. is the Manager Director of Sobono Private Limited, which focuses on sustainable technologies including bioresource utilization for renewable energy production. The other authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Clean Technology thanks Avtar Matharu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

PlaWave: https://mwcc.jp/post_seed_en/bio-oil-production-by-pyrolysis/

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Q., Li, Z., Liu, Z. et al. Microwave-assisted biorefineries. Nat. Rev. Clean Technol. 1, 269–287 (2025). https://doi.org/10.1038/s44359-025-00033-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44359-025-00033-5