Abstract

Proton exchange membrane water electrolysis stands as a promising technology for sustainable hydrogen production, although its viability hinges on minimizing platinum (Pt) usage without sacrificing catalytic efficiency. Central to this challenge is enhancing the intrinsic activity of Pt while ensuring the stability of the catalyst. We herein present a Mo2TiC2 MXene-supported Pt nanocluster catalyst (Mo2TiC2-PtNC) that requires a minimal Pt content (36 μg cm−2) to function, yet remains highly active and stable. Operando spectroscopy and theoretical simulation provide evidence for anomalous charge transfer from the MXene substrate to PtNC, thus generating highly efficient electron-rich Pt sites for robust hydrogen evolution. When incorporated into a proton exchange membrane electrolyzer, the catalyst affords more than 8700 h at 200 mA cm−2 under ambient temperature with a decay rate of just 2.2 μV h−1. All the performance metrics of the present Mo2TiC2-PtNC catalysts are on par with or even surpass those of current hydrogen evolution electrocatalysts under identical operation conditions, thereby challenging the monopoly of high-loading Pt/C-20% in the current electrolyzer design.

Similar content being viewed by others

Introduction

The escalating importance of renewable green hydrogen as an energy vector represents an undeniable facet of the evolving energy landscape1,2. A pressing target in the U.S. Department of Energy’s (DOE’s) Energy Earthshots initiative is to reduce the cost of clean hydrogen to $1 per kilogram in a decade, known as the “111” target3. Central to realizing this vision is the application of proton exchange membrane (PEM) water electrolysis technology, noted for its low electrical resistance, high current density, high H2 purity, and swift device response4,5. However, the viability of its commercialization within the hydrogen market is contingent upon the reduction in capital costs. The DOE’s 2026 target mandates a total Pt-group metal (PGM) loading below 0.5 mg cm−2 for PEM devices6. Currently, the Pt content in the cathode alone falls within the range of 0.4–0.6 mg cm−2 7. This highlights the urgent need to implement low Pt-group metal cathodes, thereby reserving the PGM budget for iridium (Ir) incorporation into the anode (typically more than 5 times the Pt content)7,8,9,10,11,12. Despite progress in developing nonprecious materials for cost efficiency13,14,15, Pt remains the material of choice for facilitating the acidic hydrogen evolution reaction (HER) in current commercial PEM water electrolyzers, owing to its unmatched intrinsic activity and stability16,17,18,19.

The HER on metal surfaces such as Pt involves protons from a solution combined with electrons at an electrode. This HER reaction proceeds in two main steps: forming chemisorbed hydrogen atoms on the electrode, followed by H2 gas evolution. This simple mechanism allows enhancing the HER through two main strategies: maximizing the intrinsic catalytic efficiency and optimizing the exposure of active sites on the catalyst. Nørskov et al. showed the intrinsic HER activity in a “volcano plot” using the binding free energy (∆GH) of hydrogen (*H)20. They found the highest activity when ∆GH was near zero, demonstrating that the optimal electrocatalytic sites for the HER should bind *H slightly weaker than metals such as Pd, Rh, or Pt. This could correspond to a more negative chemical state than metallic states21. On the other hand, a surface-to-volume ratio can be achieved, for instance, by downsizing bulk catalysts to nanoclusters (NCs) and even to isolated single atoms (SAs). This approach is particularly attractive because it leverages nearly all available platinum atoms, thereby optimizing their effectiveness and enhancing the overall efficiency22,23,24. However, this strategy also exposes more low-coordinate Pt atoms, which have been shown to strongly adsorb *H, consequently reducing the intrinsic activity of Pt. Balancing the metal particle size and maintaining the desired binding energy are critical for developing effective HER catalysts. Moreover, stability is another key factor that must be considered in the utilization of Pt for the HER, as extended electrolysis or a higher current increases the likelihood of Pt agglomeration and thus the degradation of active sites.

Given that the electronic properties of Pt can be fine-tuned by selective bonding with proper supports25, and that Pt agglomeration can be mitigated through spatial confinement or geometric shielding26, we envisioned that the intrinsic activity and stability of Pt nanoclusters (PtNC) could be concurrently modulated by designing supported Pt islands surrounded by functional groups that have high diffusion barriers to isolate these Pt islands. MXenes, first reported by Gogotsi et al. in 201027,28,29, are a class of well-known two-dimensional transition metal carbides or nitrides with layered structures that may serve as an ideal model to validate our hypothesis. In MXenes, early transition metals (M layers) are sandwiched between conductive carbon layers, with abundant surface termination groups, such as O and OH, on the outer M layers30. Pursuing this line of inquiry, we synthesized a highly stable and efficient electrocatalyst composed of PtNC supported on MXene (Mo2TiC2-PtNC) for use in PEM water electrolysis. From our experimental and theoretical evidence, we found anomalous charge transfer from the MXene substrate to PtNC, which generated highly efficient electron-rich Pt sites for robust hydrogen evolution. The as-synthesized Mo2TiC2-PtNC matches the performance of commercial Pt/C-20%, requiring only an overpotential of 13 ± 3.6 mV to reach 10 mA cm−2 while maintaining stability at this current density for more than 280 h. Impressively, our Mo2TiC2-PtNC-based device showcased a robust capability to electrolyze pure water splitting for more than 8700 h at 200 mA cm−2 under ambient temperature, when coupled with a commercial oxygen evolution catalyst (IrO2) in a PEM electrolyzer. Notably, the device delivered a high current density of 1 A cm−2 at a low average applied voltage of ~1.65 V and maintained steady operation for over 4800 h under real-world operating conditions (80 °C, 1 bar). Notably, the Pt loading on the cathode in our assembled PEM device is merely 36 μg cm−2, far less than one-tenth of the loading in commercial design. Our Mo2TiC2-PtNC catalyst holds great promise as a viable alternative to commercial Pt/C-20%, representing a prime candidate for satisfying the operational demands of next-generation PEM devices.

Results and discussion

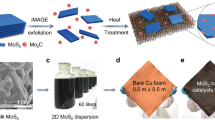

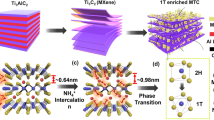

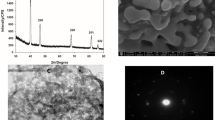

We adopted a straightforward hydrothermal method to synthesize the Mo2TiC2-PtNC catalysts (see details in the Methods and Fig. 1a). The first step involved the synthesis of multi-layered Mo2TiC2 (denoted as Mo2TiC2-M) via the HF etching method, in which the Al layers were selectively removed from the parent Mo2TiAlC2 powder (illustrated in Supplementary Figs. 1–3). Following this, the structure was intercalated with the organic molecule tetrabutylammonium hydroxide (TBAOH), thereby yielding the few-layered Mo2TiC2 MXene29,31. The process was completed with a thorough washing step to remove any residual TBAOH. The layered structure of Mo2TiC2 was evident from the scanning electron microscopy (SEM) image (Fig. 1b). The interlayer spacing of Mo2TiC2 was calculated to be 1.8 nm (inset of Fig. 1b) from transmission electron microscopy (TEM), which corresponds to the (002) plane from the X-ray diffraction (XRD) results (Fig. 1f). Finally, by employing Mo2TiC2 as a support, we facilitated the deposition of PtNC via a hydrothermal protocol, incorporating chloroplatinic acid hexahydrate (H2PtCl6·6H2O) and Mo2TiC2 in the process (see Methods for additional details). Quantitative analysis via inductively coupled plasma optical emission spectroscopy (ICP-OES) indicated that the as-prepared Mo2TiC2-PtNC catalyst had a Pt loading of 3.6 ± 0.1 wt% (Supplementary Table 1).

a Schematic of the synthesis process of Mo2TiC2-PtNC. b SEM and TEM images of few-layer Mo2TiC2. c TEM image of Mo2TiC2-PtNC. d Size distribution of the Pt nanoclusters. e HADDF-STEM image of the nanoclusters. f XRD spectra of Mo2TiAlC2, Mo2TiC2, and Mo2TiC2-PtNC. g Normalized XANES spectra at the Pt L3-edge of PtO2, Mo2TiC2-PtSA, Mo2TiC2-PtNC, rGO-PtNC and Pt foil. h k3-weighted Fourier transform of EXAFS spectra derived from the EXAFS spectra of PtO2, Mo2TiC2-PtSA, Mo2TiC2-PtNC, rGO-PtNC, and Pt foil. R is the interatomic distance. i High-resolution XPS spectra (Pt 4f) of Mo2TiC2-PtSA, Mo2TiC2-PtNC, rGO-PtNC and Pt foil. (The circles represent raw data, and the lines represent fitting data and base line.) j DEMS measurements of Mo2TiC2-PtSA, Mo2TiC2-PtNC, rGO-PtNC and Pt/C-20%, the onset potentials were determined at points where the signal-to-noise ratio exceeded 5. Source data are provided as a Source Data file.

After the hydrothermal reaction, TEM and high-angle annular dark-field scanning TEM (HAADF-STEM) images (Fig. 1c–e) confirmed that the PtNC were homogeneously sized, with an average diameter of approximately 1.7 nm (Fig. 1d). Furthermore, the results from the high-resolution HAADF-STEM image revealed that the exposed crystal facet of the experimentally prepared PtNC is the (111) facet (Fig. 1e). The two-dimensional crystal structure of Mo2TiC2 was also well maintained (Fig. 1f), suggesting that the incorporation of the Pt precursor into the precursor solution had no discernible effect on the morphology of the MXene structure. For comparison, we also synthesized MXene-supported Pt single atoms (Mo2TiC2-PtSA, 2.7 wt% Pt) and reduced graphene oxide (rGO)-supported PtNC (rGO-PtNC, Pt size ~1.5 nm, 4.1 wt% Pt) as controls. The HAADF-STEM images, in conjunction with energy-dispersive spectroscopy (EDS) elemental mapping, unveiled a uniform dispersion of PtSA or PtNC across the support structure for the controls (Supplementary Figs. 4–5). Multiple spectra, including XRD and Raman spectroscopy, revealed that both Mo2TiC2-PtSA and Mo2TiC2-PtNC exhibited peak patterns similar to those of Mo2TiC2 MXene, indicating the structural stability of the MXene substrate (Supplementary Figs. 6–7). Additionally, PtSA and PtNC on the support were distinguished using CO adsorption diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS; see details in Methods). The spectra primarily displayed a strong band at 2105 cm−1 for Mo2TiC2-PtSA and 2051 cm−1 for Mo2TiC2-PtNC, further substantiating the distinctions in the electronic structure between the two samples (Supplementary Fig. 8)32.

To reveal the electronic structure of the Pt species within the catalysts, we employed X-ray absorption fine structure (XAFS) and X-ray photoelectron spectroscopy (XPS) analyses. The normalized X-ray absorption near-edge structure (XANES) depicted in Fig. 1g indicated that the white line intensity of the Mo2TiC2-PtNC catalysts was even lower than that of the bulk Pt foil, suggesting a possibly reduced oxidation state. Figure 1h shows the k3-weighted Fourier transform of the extended X-ray absorption fine structure (EXAFS) at the Pt L3-edge. We observed a dominant peak at 1.72 Å for Mo2TiC2-PtSA, which corresponded to the Pt-O bond, and no Pt-Pt bonds were observed. This result confirmed that Pt atoms were dispersed as single sites in Mo2TiC2-PtSA, and the evident Pt-O coordination was consistent with previous reports33,34. Since the first shell scattering peak in the Pt L3-edge of Mo₂TiC₂-PtNC is located within the same distance region as the Pt-Pt scattering peak of Pt foil (R = 1.5–3.2 Å, which corresponds to metal-metal bonding)35, and the difference in the main peak position is less than 0.1 Å36,37, distinguishing Pt-Mo and Pt-Pt coordination signals solely through observation of the EXAFS spectrum is challenging. We subsequently performed fitting of the L3-edge EXAFS of the Mo2TiC2-PtNC and Pt foil. Compared with those of the Pt foil (Supplementary Fig. 9 and Supplementary Table 2), the EXAFS fitting results of Mo2TiC2-PtNC (Supplementary Table 3) reveal a Pt-Mo coordination signal at 2.69 Å, which aligns well with the fitting results of Pt-Mo coordination in other articles35,36,37. Notably, the absence of a Pt-O signal in the Mo2TiC2-PtNC spectrum suggested that the PtNC on the MXene surface was directly bonded to the MXene lattice rather than to surface oxygen functionalities. Interestingly, the high-resolution Pt 4f XPS spectrum revealed that the Mo2TiC2-PtNC catalyst featured a negatively shifted binding energy (70.5 eV and 73.8 eV for the Pt 4f 7/2 and 4f 5/2 doublets, respectively) in comparison to that of the bulk Pt foil (71 eV and 74.3 eV)38, in good agreement with the XANES analysis. To validate the robustness of our data, we also calibrated our XPS spectra using Si 2p lines as the internal standard. These results were consistent with those obtained using the C 1s calibration method (Supplementary Fig. 10). This phenomenon is intriguing, as Pt on most carbon or oxide substrates generally exists in an oxidized or metallic state (Fig. 1i and Supplementary Fig. 11)39,40,41. As expected, Pt in Mo2TiC2-PtSA shows a more positively shifted binding energy than does bulk Pt, which aligns well with previous reports18,34,42,43,44,45. These findings underscore the size effect on the electronic state of Pt. In contrast, rGO-PtNC displays more positive binding energy than Pt foil does, highlighting the unique role of the MXene substrate. Taken together, the above results demonstrate that the direct bonding of PtNC with the MXene lattice results in anomalous electron transfer to Pt atoms, creating an electron-rich Pt surface. Furthermore, the high-resolution Mo 3d XPS spectrum shows that Mo2TiC2-PtNC displays more pronounced high-valence Mo signals than Mo2TiC2 does (Supplementary Fig. 12), further confirming electron transfer from Mo to PtNC. This shifts the d-band center of Pt downwards from −3.62 (Pt foil) to −3.77 eV (Mo2TiC2-PtNC) (Supplementary Fig. 13), resulting in closer thermal-neutral binding of *H (∆GH = 0). Furthermore, we employed operando differential electrochemical mass spectrometry (DEMS) to assess the HER capabilities of the different catalysts (Fig. 1j). Impressively, the Mo2TiC2-PtNC catalyst manifested a much lower onset potential than did its counterparts, drawing closer to the commercial benchmark Pt/C-20% catalyst. Simply replacing the MXene substrate with carbon (rGO-PtNC, with similar Pt dimensions and loading) or decreasing the particle size from PtNC to PtSA (Mo2TiC2-PtSA, with similar Pt loading) results in much lower HER activity than Mo2TiC2-PtNC does. This finding implies that the HER activity is closely dependent on the synergistic effect between the Pt metal and MXene substrates. We deduce that the intrinsic activity of the Mo2TiC2-PtNC catalyst is significantly influenced by the unique electron-rich electronic structure of the Pt center due to Pt-MXene interactions.

The HER performances of the different catalysts were then evaluated in detail using a three-electrode setup with Hg/Hg2SO4 as the reference electrode and a graphite rod as the counter electrode in H2-saturated 0.5 M H2SO4. Prior to the experimental tests, the reference electrode was meticulously calibrated to a reversible hydrogen electrode (RHE). Linear sweep voltammetry (LSV) curves revealed that the as-prepared Mo2TiC2-PtNC catalyst exhibited effective HER activity with an overpotential of only 13 ± 3.6 mV at 10 mA cm−2, similar to the benchmark Pt/C-20% (14.7 ± 0.6 mV at 10 mA cm−2; Fig. 2a). To further compare the intrinsic HER activity of Mo2TiC2-PtNC with that of the benchmark material, we measured the hydrogen underpotential deposition (H-UPD) features to exclude the contribution of different electrochemical surface area (ECSA, Fig. 2b, c). In a clear demonstration of electrocatalytic performance, a comparison of the LSV curves, normalized using H-UPD, revealed a substantial difference between the two materials. Specifically, Mo2TiC2-PtNC showed an intrinsic performance of 1.55 ± 0.4 mA cm−2ECSA (the specific value in Fig. 2c is 1.99 mA cm−2ECSA) which was 4.8 times greater than that of the benchmark Pt/C-20% of 0.32 ± 0.04 mA cm−2ECSA, measured at an overpotential of 31 mV. Additionally, Mo2TiC2-PtNC demonstrated a Tafel slope of 24 mV dec−1, a value that was comparable to the Tafel slope observed for Pt/C-20% (Fig. 2d). This similarity in the Tafel slopes suggested that the kinetic rate-step process of Mo2TiC2-PtNC was consistent with that of Pt/C-20%, following the same mechanism referred to as the Tafel step. To further describe the elementary reaction in the HER process on Mo2TiC2-PtNC, we conducted operando electrochemical impedance spectroscopy (EIS) experiments (Fig. 2e and Supplementary Figs. 15, 16). Specifically, we observed that Mo2TiC2-PtNC exhibited only one phase angle, indicative of the same Volmer-Tafel kinetic process that characterizes commercial Pt/C-20%. This finding stands in stark contrast to the two-phase angles typically observed in the Volmer-Heyrovsky kinetic process46,47.

a The iR-corrected polarization curves of glass carbon (GC), Mo2TiC2 (R = 3.378 Ω), Mo2TiC2-PtSA (R = 2.18 Ω), Mo2TiC2-PtNC (R = 1.763 Ω) and Pt/C-20% (R = 1.433 Ω) acquired using a graphite rod as the counter electrode in 0.5 M H2SO4 (GCE electrode surface area: 1.13 cm2, catalyst loading: 1 mg cm−2, rotation rate: 1600 rpm, pH value of the electrolyte (H2SO4): 0.43 ± 0.02, and all measurements were conducted at ambient temperature. All error bars in Fig. 2 represent the standard deviation. All potentials are 100% iR compensated, and all non-iR corrected data and corresponding resistance values for three independent samples are shown in Supplementary Fig. 14 and Supplementary Table 4, respectively). b H-UPD region of Mo2TiC2-PtNC and Pt/C-20% obtained from the cyclic voltammetry curve (Scan rate: 50 mV s−1). c ECSA-normalized (H-UPD) HER polarization curves of Mo2TiC2-PtNC and Pt/C-20% in 0.5 M H2SO4. d Tafel slopes of Mo2TiC2, Mo2TiC2-PtSA Mo2TiC2-PtNC and Pt/C-20%. e Operando EIS tests of Mo2TiC2-PtNC. f Calculated TOF and mass activity values at an overpotential of 60 mV in 0.5 M H2SO4. g Stability test of Mo2TiC2-PtNC through chronopotentiometry at a current density of 10 mA cm−2 in 0.5 M H2SO4. Source data are provided as a Source Data file.

We further quantitatively analyzed HER activity in terms of mass activity and turnover frequency (TOF, normalized to the active site density) (Fig. 2f). Specifically, at an overpotential of 60 mV, the mass activity of Mo2TiC2-PtNC was estimated to be 3.3 ± 1.31 A mg−1, which was substantially greater than that of Pt/C-20% (0.72 ± 0.19 A mg−1) and Mo2TiC2-PtSA (0.35 ± 0.07 A mg−1). At the same overpotential, a significant difference in the TOF was observed. Specifically, the TOF of Mo2TiC2-PtNC was found to be 9.45 ± 3.71 s−1. This value not only outperforms the benchmark Pt/C-20% (1.82 ± 0.48 s−1) but also surpasses Mo2TiC2-PtSA (0.36 ± 0.07 s−1). Notably, the TOF represents a lower bound for the true activity of Mo2TiC2-PtNC because a subset of the Pt atoms remains inaccessible within the bulk, coupled with the constraints posed by mass transport limitations48.

In addition to the above performance, maintaining robust electrolytic stability is the key. We further evaluated the stability of Mo2TiC2-PtNC and found that it maintained a hydrogen Faradaic efficiency (FE) close to 100% across different current densities (Supplementary Fig. 17). Additionally, stable hydrogen production was achieved through electrolysis at 10 mA cm−2 for over 280 h (Fig. 2g). Accelerated stability tests revealed virtually no decay after 10,000 cycles (Supplementary Fig. 18). Structural characterization via XRD, SEM, XPS, TEM and XAFS (XANES and EXAFS) further demonstrated that the structure was almost unchanged after the durability test (Supplementary Figs. 19, 20). Consequently, the aforementioned attributes of Mo2TiC2-PtNC, including its low overpotential, reduced Tafel slope, and slow decay rate, were found to surpass those of most previously reported Pt-based catalysts (Supplementary Fig. 21 and Supplementary Table 5).

To explore the impact of the substrate on the loaded PtNC, the HER mechanism was further analyzed utilizing the equivalent circuit depicted in Supplementary Fig. 22. This approach allowed for a detailed examination of the underlying electrochemical processes, providing insights into the specific interactions and dynamics that govern the reaction kinetics. The intermediate coverage on the catalyst surface can be represented by two parallel components (Cφ and R2, which represent the hydrogen adsorption pseudo-capacitance and resistance, respectively) in the equivalent circuit49. As illustrated in Supplementary Figs. 23, 24, the adsorption charges of hydrogen on the surfaces of Mo2TiC2-PtNC and rGO-PtNC were obtained through EIS fitting. Notably, Mo2TiC2-PtNC exhibited more hydrogen adsorption charges (750 μC) than did rGO-PtNC (624 μC). This result indicates a much greater surface intermediate coverage on Mo2TiC2-PtNC, despite its quite similar Pt dimensions and content to those of rGO-PtNC. Such a difference highlights the critical role of electron enrichment on the Pt surface of Mo2TiC2-PtNC.

Additionally, we compared the in situ attenuated total reflection surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS) of Mo2TiC2-PtSA, rGO-PtNC, and Mo2TiC2-PtNC under different applied potentials (0.1 to −0.1 V) (Supplementary Fig. 25). Among these catalysts, Mo2TiC2-PtNC exhibited the highest vO-H wavenumber, indicating the weakest degree of hydrogen bonding in its interfacial water50,51. This characteristic facilitates more efficient intermediate transport, thereby increasing the reaction kinetics. We further investigated the effect of the substrate by comparing the activity and stability of Mo2TiC2-PtNC and rGO-PtNC. A comparison was made under identical conditions, with both substrates having similar particle sizes of PtNC and Pt loading. As shown in Supplementary Figs. 26, 27, the performance of rGO-PtNC was found to be inferior, and its stability at a current density of 10 mA cm−2 clearly decreased over a period of 70 h. These results collectively affirm that the high structural stability of Mo2TiC2-PtNC can be attributed to the unique interaction between the Pt and MXene supports.

Density functional theory (DFT) calculations were performed to elucidate the origin of the high stability and high HER activity of Mo2TiC2-PtNC, where unique metal-support interactions play a pivotal role, as indicated by comparisons with controls. Considering the computational consumption and experimental size of PtNC, a Pt31 model was chosen for simulation, which mostly exposes the (111) facet, as revealed by the previous HAADF-STEM image in Fig. 1e. Although the supported model involving metal binding to surface oxygen (Fig. 3a) is a common alternative, a model in which Pt31 binds to Mo (Fig. 3b) was employed here due to the absence of a Pt-O signal for Mo2TiC2-PtNC from experimental observations (Fig. 1h). DFT calculations revealed that the two different models resulted in opposite charge transfer directions (Fig. 3a, b). In contrast to the commonly observed charge transfer from the metal to the support, the latter model showed a significant charge transfer reversal from the support to the metal, which is consistent with the XPS observations (Fig. 1i). Thus, both the experimental and theoretical findings corroborate the hypothesis that PtNC binds to outer Mo sites, which aligns with the fact that TiC2 layers are sandwiched between Mo layers in Mo2TiC230. Moreover, this model showed a much stronger metal-support interaction (−2.81 eV per interacting atom; Fig. 3b) than that of the model in which Pt31 bound to the surface oxygen (−0.79 eV per interacting atom; Fig. 3a), which even surpassed the binding strength between Pt31 and the Pt (111) surface (−2.11 eV per interacting atom; Fig. 3c). This result indicates that Mo2TiC2 with oxygen functional groups can act as a bifunctional heteroenergetic support. The Mo-block anchors and secures the PtNC in place, resulting in anomalous charge transfer, while the O-block isolates the PtNC, preventing particle migration and coalescence and inhibiting Ostwald ripening26. Therefore, the unique structure of Mo2TiC2-PtNC enables the achievement of high stability for nanoscale PtNC, which is consistent with experimental observations (Fig. 2g).

The models for PtNC are supported on the (a) surface oxygen of Mo2TiC2, (b) Mo of Mo2TiC2, and (c) Pt (111) surface. ΔEMSI: strength of the metal-support interaction. d The d-electron structure of on-surface Pt atoms on the Pt (111) surface and Mo2TiC2-PtNC, including LC-Pt and MoC-Pt, respectively. e Free energy diagram of hydrogen evolution at zero potential and pH 0 for the Pt (111) surface and Mo2TiC2-PtNC, including LC-Pt and MoC-Pt. Atomic coordinate dataset is provided as Supplementary Data 1, other source data are provided as a Source Data file.

As indicated by the charge transfer observed in both the experimental (Fig. 1i) and theoretical (Fig. 3b) results, the unique metal-support interaction also significantly tunes the electronic structure of PtNC and thus the HER activity. Figure 3d shows the d-electron structures of the surface Pt atoms on Mo2TiC2-PtNC, which included low-coordinate Pt (LC-Pt) and Mo-coordinate Pt (MoC-Pt). Compared with that of the surface Pt on the Pt (111) slab, the d-band center of LC-Pt is upshifted as expected, whereas that of MoC-Pt is downshifted. This is consistent with the downshift in the d-band center of Mo2TiC2-PtNC observed via XPS (−3.77 eV) compared with that of the Pt foil (−3.62 eV; Supplementary Fig. 13). A downshift of the d-band center weakens the binding of *H and moves it toward the optimal value, which is subsequently evidenced by the calculated adsorption-free energy of *H (Fig. 3e). The weakened *H binding increases the intrinsic HER activity by accelerating the Tafel steps, which has been identified as the rate-determining step for both Pt/C and Mo2TiC2-PtNC (Fig. 2e and Supplementary Fig. 15). Conversely, for the model with PtNC supported on graphene instead of Mo2TiC2-PtNC (Supplementary Fig. 28), Pt atoms at the interface were found to bind *H as strongly as LC-Pt. Therefore, the metal-support interaction of Mo2TiC2-PtNC enables us to overcome the disadvantage of decreasing the Pt size, where increasing the exposure of LC-Pt would strengthen *H binding and decrease the intrinsic HER activity.

Finally, to assess the capacity of our Mo2TiC2-PtNC to electrolyze water in an industrial setting, we utilized PEM devices assembled with a membrane electrode assembly (MEA) specifically for the electrolysis of pure water (Fig. 4a). A commercial PEM device (Pt/C-20%||IrO2) with a loading of 500 μg cm−2 Pt was included for comparison. Although we lack the specific expertise and equipment to fabricate industrial-grade, high-quality membrane electrodes with minimal ionic resistance between the cathode and anode, this does not compromise the validity of the performance comparison. We sandwiched the Nafion 117 membrane between Mo2TiC2-PtNC and commercial IrO2 for PEM water electrolysis, with a loading of 36 μg cm−2 Pt (1 mg cm−2 catalyst, see Supplementary Fig. 29 for Pt load optimization). We assessed stable electrolytic hydrogen production at room temperature. Although the Pt loading in our case is substantially lower than that in commercial designs, the performance of our device, when directly compared, aligns with the levels observed in contemporary commercial designs, operating under an equivalent bias voltage (Fig. 4b). Moreover, our Mo2TiC2-PtNC based cell was able to electrolyze hydrogen for more than 8700 h at 200 mA cm−2. This was achieved with an overpotential of ~1.97 V and a degradation rate of only 2.2 μV h−1 (Fig. 4c), which matches the DOE’s 2026 target (2.3 μV h−1).

a Photograph and schematic of the PEMWE device. b Chronopotentiometry test of a 4 cm2 Pt/C-20%||IrO2 PEMWE device at 200 mA cm−2 (25 °C, ambient pressure), compared with a Mo2TiC2-PtNC device. c Long-term electrolytic test of PEMs assembled with Mo2TiC2-PtNC at 200 mA cm−2 and 1 A cm−2 using commercial IrO2 as the anode catalyst, at 25 °C and 80 °C, respectively. Discontinuities in voltage arise from the unexpected power off. d Photograph of the 49 cm2 device and MEA membrane together with the Mo2TiC2-PtNC cathode and IrO2 anode layers. e Long-term stability of the 49 cm2 device at ambient pressure. All the performance tests of the aforementioned PEMWE devices were conducted without iR correction. Source data are provided as a Source Data file.

In addition, the stability of such devices was better than that of recently reported precious metal catalysts (Supplementary Table 6). We further conducted electrolysis experiments on the Mo2TiC2-PtNC based cell under industrial working conditions (1 A cm−2, 1 bar at 80 °C). By constantly regulating the parameters during the assembly process of the device, the impedance between the cathode and anode in our device can be reduced to 15–20 mΩ cm−2; as a result, the device can run stably for hydrogen production for 4800 h at 1 A cm−2 (Fig. 4c). According to the calculation from DOE’s suggestion (see details in Note 1), note that the clean electricity price of $0.03 per kWh, as proposed by the DOE, was employed in our calculation52,53, only US$ 1.327 was required to produce 1 kg H2 with this device, well below the DOE goal of 2026 (<US$ 2 kg−1 H2). Compared with other membrane electrode assembly water electrolyzers (MEAWEs) with cathodic PGM catalysts, the observed superiority of Mo2TiC2-PtNC as a cathode catalyst underscores its potential for industrial applications (Table 1). This potential is further emphasized by our ability to achieve gram-scale synthesis of the catalyst (Supplementary Fig. 30). To demonstrate the availability of our catalyst in mass hydrogen generation, we also conducted a constant electrolytic hydrogen production test on an extended electrode area (49 cm2) of the Mo2TiC2-PtNC based cell, which outputs over 4.09-liter pure hydrogen per hour, and the stability exceeded 3600 h (Fig. 4d, e). The findings reported here could contribute to future developments in large-area membrane electrode assembly and reactor implementation, highlighting its potential for industrial applications.

In conclusion, to alleviate the usage of Pt-group precious metals in acidic water electrolysis, we developed a catalyst (Mo2TiC2-PtNC), featuring a low Pt mass loading on MXenes. The interaction between Pt and the support induces electron enrichment on the Pt surface, enabling thermo-neutral hydrogen adsorption. Consequently, the catalyst achieved electrolytic performance and stability on par with commercial Pt/C-20%. Notably, our Mo2TiC2-PtNC catalyst demonstrated a robust capacity for hydrogen production at 200 mA cm−2 over 8700 h in a PEM device, and even under industrial conditions (1 A cm−2, 1 bar at 80 °C), it maintained stability for more than 4800 hours. Therefore, we identified a catalyst with the potential to replace commercial Pt/C-20% for water electrolysis in industrial-scale PEM devices. This advancement could help reduce catalyst costs and support the broader adoption of PEM reactors and grid implementations.

Methods

Materials synthesis

Chemicals

Ethanol, Nafion 117 perfluorinated resin solution (5 wt%), chloroplatinic acid hexahydrate (H2PtCl6·6H2O) and tetrabutylammonium hydroxide (C16H37NO) were purchased from Macklin. Graphene oxide (GO) was purchased from Suzhou Tanfeng Graphene Technology Co., Ltd. Pt/C (nominally 20 wt% on carbon black) was purchased from Johnson Matthey. All reagents were used without further purification. All aqueous solutions were prepared with Millipore water (resistivity of 18.2 MΩ cm). The detailed parameters are provided in Supplementary Table 7.

Synthesis of multilayer Mo2TiC2 MXene

Mo2TiAlC2 MAX-phase powder (2.0 g) was slowly added to an HF (40%, 20 ml) solution in a Teflon beaker under continuous stirring for 120 h at 55 °C. The product was centrifuged and washed several times in argon-saturated water until the pH approached 6 or 7. The suspension was freeze-dried at −59 °C for 48 h to obtain dry multilayer Mo2TiC2 powders.

Synthesis of fewer-layer Mo2TiC2 MXene

Multilayer Mo2TiC2 MXene (1.0 g) was added to 20 ml of organic solvent (54–56 wt% TBAOH ((C4H9)4NOH)) and stirred at 50 °C for 24 h. The resulting mixture was centrifuged and washed three times in deionized water to separate the MXene from TBAOH. After the upper layer was emptied, 100 ml of deionized water was added, and the mixture was sonicated for 1 h in an ice bath, followed by centrifugation for 1 h at 3500 rpm (~1370 × g) to obtain fewer-layer MXenes with uniform dispersion.

Synthesis of Mo2TiC2-PtNC

The sample was prepared using a standard hydrothermal technique. Specifically, 50 mg of few-layered Mo2TiC2 MXene was uniformly dispersed in 25 ml of deionized water with 7.65 mg of H2PtCl6·6H2O. This mixture was then subjected to ultrasonic agitation to achieve a homogenous solution. The mixture was transferred to a 50 ml Teflon-lined autoclave and reacted at 180 °C for 0.5 h. After naturally cooling to room temperature, the products were washed and centrifuged three times with deionized water to obtain the Mo2TiC2-PtNC catalysts.

Synthesis of Mo2TiC2-PtSA and rGO-PtNC

The synthesis of Mo2TiC2-PtSA was performed via a hydrothermal method similar to that used for Mo2TiC2-PtNC. First, 5.5 mg of [Pt(NH3)4](NO3)2 was added to a 50 ml solution of 50 mg of Mo2TiC2 and heated at 140 °C for 1 h to obtain Mo2TiC2-PtSA after centrifugation and washing. The preparation of rGO-PtNC was achieved by a simple impregnation method. Specifically, 7.65 mg of H2PtCl6·6H2O was added to 25 ml of aqueous solution containing 50 mg of GO to form a uniform dispersion. The mixture was further freeze-dried for 48 h at −59 °C, Following this, it was transferred to a tube furnace and reacted at 450 °C under a 5% H2/Ar atmosphere for 2 h, resulting in the rGO-PtNC product.

Characterizations

Scanning electron microscopy (SEM) was performed on a GeminiSEM300 electron microscope. Powder X-ray diffraction (PXRD) was performed using Cu Kα radiation (λ = 1.54178 Å) by a Philips X’Pert Pro Super diffractometer. Raman spectra were obtained using a LabRAM HR laser Raman analyzer with an excitation wavelength of 785 nm. Transmission electron microscopy (TEM) was performed on a Tecnai G2 F20 S-Twin TMP transmission electron microscope with an acceleration voltage of 200 kV. X-ray photoelectron spectroscopy (XPS) was performed on an Axis Supra photoelectron spectrometer using an exciting source of Al Kα radiation (1486.6 eV), and the binding energy of the C 1s peak (284.8 eV) was selected as the actual reference. HADDF–STEM and EDS elemental mapping were performed on a Themis Z field-emission transmission electron microscope at an acceleration voltage of 200 kV. The Pt concentrations of all the samples were measured using inductively coupled plasma optical emission spectroscopy (ICP-OES, Avio 500). In situ diffuse reflectance Fourier transform infrared spectroscopy (DRIFTS) experiments were conducted on a Thermo Scientific Nicolet iS50 FTIR spectrometer with ZnSe as the prismatic window at room temperature. XAS measurements at the Pt L3-edge of the samples were carried out on the BL14W1 beamline of the Shanghai Synchrotron Radiation Facility, operated in fluorescent mode on all samples. XAFS data processing and fitting were carried out with Demeter software.

CO DRIFTS

The adsorption behavior of CO on the Mo2TiC2-PtSA and Mo2TiC2-PtNC catalysts was studied by diffuse reflectance Fourier transform infrared spectroscopy (DRIFTS). DRIFTS spectra were collected on a Thermo Scientific Nicolet iS50 FTIR spectrometer at a resolution of 8 cm−1. The infrared cell was first partially filled with inert KBr powder and filled with catalysts on the KBr holder. For fresh catalysts, pretreatment at 100 °C and Ar for 30 min was performed to remove impurities (H2O) that may be adsorbed on the surface. Then, the background spectrum was recorded after the reaction cell was cooled to 25 °C. Then, CO adsorption was conducted with a mixture of 10% CO/Ar (15 ml min−1) and Ar (30 ml min−1) for 20 min. Furthermore, gas-phase CO in the reaction cell was removed by Ar purging at a flow rate of 30 ml min−1, after which the desorption spectrum of the catalyst-adsorbed CO was recorded. CO adsorption experiments were carried out at 25 °C.

In situ DEMS tests

For the in situ DEMS test, 2 mg of each catalyst was mixed with 5 wt% Nafion (20 µl) in 980 µl of ethanol and then sonicated for 20 min to form a homogeneous solution. A 0.01 ml of ink was drop-cast onto a glassy carbon (diameter of 0.3 cm) working electrode. The electrodes were dried at room temperature for at least 30 min. In situ differential electrochemical mass spectrometry (DEMS) was performed using a custom capillary electrochemical mass spectrometer single cell. A capillary was inserted into the in situ cell, close to the side above the working electrode. The gaseous product was introduced into a DEMS sensor (PrismaPro). Linear sweep voltammetry was performed on the cathode at a scan rate of 1 mV s−1. A photograph of the in situ DEMS setup is provided in Supplementary Fig. 31.

In situ ATR-SEIRAS test

4 mg of each catalyst was mixed with 40 μl of Nafion (5 wt%) and 960 μl of ethanol and then sonicated for 20 min to form a homogeneous solution. A 0.238 ml of ink was dropped on a gold-plated silicon crystal (usable area of 0.95 cm2) with a typical catalyst loading (~1 mg cm−2). For constant potential testing, the potential was varied from 0.1 to −0.1 V versus RHE, and the infrared spectral data were recorded. A photograph of the in situ ATR-SEIRAS setup is provided in Supplementary Fig. 32.

All the detailed configurations of the in situ electrochemical cells used are provided in Supplementary Table 8.

Electrochemical measurements

Calibration of the reference electrode and conversion to RHE scale

A mercury-mercurous sulfate reference electrode (Hg/Hg2SO4) was used in all the measurements. The calibration of the reference electrode was performed in the standard three-electrode configuration. Polished platinum foil was used as the working and counter electrode, and Hg/Hg2SO4 was used as the reference electrode. The electrolyte was purged and saturated with high-purity H2 before measurement and was kept flowing during the calibration process. Cyclic voltammetry (CV) was then run at a scan rate of 1 mV s−1, and the average potential at which the current crossed zero was taken as the thermodynamic potential for the hydrogen electrode reactions. In our experiment, in 0.5 M H2SO4, the zero current point was calculated to be 0.697 V.

Therefore, E(RHE) = E(Hg/Hg2SO4) + 0.697 V

Measurement of the electrode material

All the electrochemical performance tests were performed at room temperature by a BioLogic VMP3 electrochemical workstation with a typical three-electrode system. A glass carbon electrode with a diameter of 1.2 cm was selected as the working electrode, Hg/HgSO4 was used as the reference electrode, and a graphite rod was used as the counter electrode. An H-type cell was used as the electrolytic cell (a Nafion membrane was used to separate the anode and cathode chambers). The Hg/HgSO4 electrode was calibrated in a H2-saturated 0.5 M H2SO4 electrolyte. The preparation, storage and pH values of the electrolyte (0.5 M H2SO4, pH value: 0.43 ± 0.02) are provided in Supplementary Fig. 33 and Note 2.

To prepare the working electrode ink, 4 mg of each catalyst was mixed with 40 μl of Nafion (5 wt%) and 960 μl of ethanol and then sonicated for 20 min to form a homogeneous solution. A 0.283 ml of ink was dropped on glass carbon (area of 1.13 cm2) with a typical catalyst loading (~1 mg cm−2). Additionally, the cathode chamber was separated from the anode chamber (counter electrode: graphite rod) by a Nafion 117 membrane (the activation process of the Nafion membrane is provided in Note 3). For the performance test, the cathode chamber was placed on a magnetic stirring table (~1600 rpm) to facilitate the rapid desorption of H2 gas bubbles. Linear sweep voltammetry was carried out in 0.5 M H2SO4 at a scan rate of 5 mV s−1, deaerated with Ar. Cyclic voltammetry was performed in the potential window from 0.15 V to −1.5 V (versus RHE) for 10000 cycles (scan rate of 50 mV s−1). Electrochemical resistance measurements were performed at the OCV with the frequency range from 0.01 Hz to 106 Hz (operando EIS tests were performed at potentials ranging from 0.02 V to −0.05 V (versus RHE), and the resistance values were calculated from the high frequency intercepts with the X-axis on the Nyquist plot. The Tafel test was performed by chronoamperometry54, which is more accurate than the Tafel value obtained from the polarization curve. Cyclic voltammetry and potential-time stability tests were conducted with a catalyst loading of ~1 mg cm−2 on 1 cm2 carbon paper.

Additionally, the constant potential test was conducted using the “Chronoamperometry” function in BioLogic VMP3, whereas the constant current test was performed using the “Chronopotentiometry” function in BioLogic VMP3. Data acquisition and processing were carried out using the corresponding software, “EC-Lab”, via a USB serial connection.

The FE of Mo2TiC2-PtNC was calculated using the following Eq. (1).

where n represents the number of electron transfer involved in the HER, F denotes the Faraday constant (96,485 C mol−1), \({n}_{({H}_{2})}\) denotes the number of moles of H2 detected by gas chromatography (GC) during HER electrolysis (using GC to detect the volume of H2, applying the ideal gas equation to convert to \({n}_{({H}_{2})}\)), i represents the applied current, and t represents the reaction time of HER electrocatalysis.

The ECSA of Pt was estimated by measuring the H-UPD characteristics. CV measurements were performed in a three-electrode system (with an Ar-saturated 0.5 M H2SO4 solution) collected from 0 to 0.6 V versus RHE at a scan rate of 50 mV s−1. Calculated from the region of hydrogen desorption charge (~0–0.5 V versus RHE) on the CV curves. Calculate ECSA using the following Eq. (2).

where SQ is the integral area of the hydrogen desorption charge region in the CV curve. v is the scan rate and 210 μC cmPt–2 for a monolayer H-UPD at Pt.

The TOF values were calculated based on the number of surface active Pt atoms in each catalyst (the TOF value of Mo2TiC2-PtSA was calculated from the mass of Pt) on the electrode according the following Eq. (3).

where i represents the current recorded from the LSV curves.

The mass activity was determined using the following Eq. (4).

where \({m}_{{Pt}}\) is the mass of Pt in each catalyst on the electrode.

Performance of the membrane electrode devices

To prepare the membrane electrode device, the anodic catalyst IrO2 was selected for the oxygen evolution reaction (OER), and Pt/C (20 wt%, Johnson Matthey) or Mo2TiC2-PtNC was used as the cathode HER catalyst. For commercial design, a slurry composed of Pt/C, Nafion (5 wt%) and ethanol was evenly sprayed on both sides of the proton exchange membrane (Nafion 117), with mass loading of 1 mg cm−2 Ir and 0.5 mg cm−2 Pt. The PEM device with Mo2TiC2-PtNC catalyst is prepared in the same procedure and the mass loadings of IrO2 and Mo2TiC2-PtNC were controlled to be 1 mg cm−2 Ir and 36 μg cm−2 Pt, respectively. After drying, the membrane electrode was hot-pressed (100 °C) at a pressure of 2 MPa for 10 min. Titanium felt and carbon paper were used as the anode and cathode gas diffusion layers, and a peristaltic pump (2.5 ml min−1) was used for pure water circulation to the anodic side. A Fumasep FS-990-PK membrane was used to fabricate the 49 cm2 PEM device following the same preparation procedures described previously. All the cell tests were performed at ambient pressure, and none of the measured cell voltages were iR compensated. The details of the catalyst loading calculation and the geometric dimensions of the electrodes are provided in Note 4.

In a PEM water electrolyzer test, a DC current power supply (DCPS0614, 30 V/20 A) was employed as a constant potentiostat. Stability tests were performed in constant current mode, with data collected and processed using the “DC Power Supply” software connected via a USB serial port.

Computational methods

The Vienna ab initio simulation package (VASP)55,56,57 was used for all density functional theory (DFT) calculations. In these simulations, the valence electrons were defined as follows: the 1s electron in H, the 2s and 2p electrons in C and O, the 3d and 4s electrons in Ti, the 4d, 4p, and 5s electrons Mo, and the 5d and 6s electrons in Pt58. A plane-wave basis set was employed with a kinetic energy cutoff of 450 eV. Core electrons were treated using the projector augmented-wave (PAW) method59. Monkhorst–Pack meshes60 of 2 × 2 × 1 sampling in the Brillouin zone were employed for the slab models.

For pristine Mo2TiC2-O2, a 6 × 6 supercell with one layered structure was chosen. For pristine graphene, an 8 × 8 supercell was chosen. For pristine Pt(111), a 6 × 6 supercell with four layers was chosen. Except for the bottom two layers of the Pt(111)-based cases, all the atoms were relaxed. Convergence of the geometry optimization was assumed when the force on each atom was less than 0.02 eV Å−161. The Perdew-Burke-Ernzerhof (PBE) functional, within the generalized gradient approximation (GGA), was employed for all calculations62. Dispersion interactions were accounted for using the DFT + D3 method with Becke-Jonson (BJ) damping63,64.

The free energy of the adsorbed state was calculated using Eq. (5):

where ΔEH is the adsorption energy of hydrogen, ΔEZPE is the difference corresponding to the zero point energy between the adsorbed state and the gas phase, and TΔS is the term corresponding to the entropy correction of hydron adsorption. As reported in previous work, a value of ΔEZPE -TΔS of 0.24 eV is employed here65.

In the free energy diagram of the HER, the Gibbs free energy change (ΔG) of the proton-coupled electron transfer (PCET) step was calculated using the computational hydrogen electrode (CHE) model20,66, which defines the chemical potential of the proton-electron pair as half of the chemical potential of hydrogen.

Note 1 | Techno-economic analysis

Considering that the cost of noble metals in the cathode accounts for a high proportion of the total MEA cost (0.4–0.6 mg cm−2), cost accounting of the cathodic noble metals is necessary. The price of the noble metal (Pt) was obtained from the Johnson Matthey Price Charts.

1) The cathodic noble metal content of our PEM electrolyzer is 0.036 mg cm−2, which is much lower than the reported cathode platinum load (0.4–0.6 mg cm−2). Our cathodic platinum metal cost is only $0.01181 cm−2.

2) The energy efficiency of a PEM electrolyzer can be calculated by the following equation:

where 1.23 V represents the theoretical energy of the products and \({U}_{{cell}}\) is the cell voltage (V) required to deliver a current density of 1 A cm−2.

3) The energy consumption of a PEM electrolyzer is calculated by the following equation:

where \({I}_{{cell}}\) is the current delivered (A), t is the operation time (h), and \({m}_{{H}_{2}}\) is the mass of hydrogen produced in a t duration, which can be calculated by Faraday’s laws of electrolysis:

z in Eq. (8) is the number of electrons transferred to produce one hydrogen molecule, \({M}_{{H}_{2}}\) is the relative molecular mass (2 g mol−1).

The energy efficiency and energy consumption of our PEM electrolyzer are superior to those of the targets (69% and 48 kWh kg−1H2 for 2026) set by the US Department of Energy.

4) Cost of H2 per kilogram of hydrogen:

Cost (H2/kg) = energy consumption × electricity price

=44.22 kWh/kg H2 × $0.03/kWh

=$1.327/kg H2

Our H2 production cost is much lower than the target ($2/kg H2 for 2026) set by the US Department of Energy.

Note 2|Preparation and storage of the electrolyte

The 0.5 M H2SO4 electrolyte was freshly prepared before each use using the following procedure. First, 486.4 ml of deionized water was measured and transferred into a 500 ml volumetric flask. Next, 13.6 ml of concentrated H2SO4 (98%) was carefully measured using a 20 ml pipette and slowly added to the volumetric flask while gently swirling the solution to ensure thorough mixing. The solution was then allowed to cool to room temperature. Once cooled, deionized water was gradually added to the volumetric flask until the solution’s meniscus reached the calibration mark. The solution was then sealed and stored in a cool, dry place for use.

Note 3|Activation process of the Nafion 117 membrane

The Nafion 117 membrane, with a thickness of 183 μm, was used when fabricating the three-electrode and MEA device and underwent an activation process prior to use: the membrane was first treated in a 5% hydrogen peroxide solution at 80 °C for 1 h to remove organic impurities. It was then rinsed by soaking in deionized water for 30 minutes to eliminate any residual peroxide. The membrane was subsequently treated in a 5% dilute sulfuric acid solution at 80 °C for 1 h to increase its proton conductivity, followed by a final rinse in deionized water for 30 min to remove any remaining acid.

Note 4|Details of the catalyst loading calculation and geometric dimensions of the electrodes

In a three-electrode test, the catalyst slurry concentration (c) was 4 mg ml−1, and the glassy carbon electrode area (s) was 1.13 cm2 (diameter of 1.2 cm). A catalyst drop volume (v) of 0.283 ml was applied, resulting in a catalyst loading (m) on the electrode calculated as

In situ DEMS tests, for a catalyst slurry concentration of 2 mg ml−1, a glassy carbon electrode area of 0.0707 cm2 (diameter of 0.3 cm), and a catalyst drop volume of 0.01 ml, the catalyst loading (excessive loading of the catalyst on such an electrode can cause catalyst detachment, leading to unreliable experimental results) was calculated as

In situ ATR-SEIRAS test, for a catalyst slurry concentration of 4 mg ml−1, a usable gold-plated silicon crystal area of 0.95 cm2 (diameter of 1.1 cm), and a catalyst drop volume of 0.238 ml, the catalyst loading was calculated as

Data availability

All data were available in the main text or the supplementary materials. Source data are provided with this paper.

References

van Renssen, S. The hydrogen solution? Nat. Clim. Chang. 10, 799–801 (2020).

Dresselhaus, M. S. & Thomas, I. L. Alternative energy technologies. Nature 414, 332–337 (2001).

Hydrogen Shot|Department of Energy. https://www.energy.gov/eere/fuelcells/hydrogen-shot.

Terlouw, T., Bauer, C., McKenna, R. & Mazzotti, M. Large-scale hydrogen production via water electrolysis: a techno-economic and environmental assessment. Energy Environ. Sci. 15, 3583–3602 (2022).

King, L. A. et al. A non-precious metal hydrogen catalyst in a commercial polymer electrolyte membrane electrolyser. Nat. Nanotechnol. 14, 1071–1074 (2019).

Technical Targets for Proton Exchange Membrane Electrolysis | Department of Energy. https://www.energy.gov/eere/fuelcells/technical-targets-proton-exchange-membrane-electrolysis.

Yu, H. & Yi, B. Hydrogen for energy storage and hydrogen production from electrolysis. Chin. J. Eng. Sci. 20, 58 (2018).

Minke, C., Suermann, M., Bensmann, B. & Hanke-Rauschenbach, R. Is iridium demand a potential bottleneck in the realization of large-scale PEM water electrolysis? Int J. Hydrog. Energy 46, 23581–23590 (2021).

An, L. et al. Recent development of oxygen evolution electrocatalysts in acidic environment. Adv. Mater. 33, 2006328 (2021).

Chen, Z. et al. Advances in oxygen evolution electrocatalysts for proton exchange membrane water electrolyzers. Adv. Energy Mater. 12, 2103670 (2022).

Liang, Q. & Li, D. Activating localized lattice oxygen for durable acidic water oxidation. Chem. Catal. 1, 506–508 (2021).

Tymoczko, J., Calle-Vallejo, F., Schuhmann, W. & Bandarenka, A. S. Making the hydrogen evolution reaction in polymer electrolyte membrane electrolysers even faster. Nat. Commun. 7, 10990 (2016).

Pan, S. et al. Efficient and stable noble-metal-free catalyst for acidic water oxidation. Nat. Commun. 13, 2294 (2022).

Staszak-Jirkovský, J. et al. Design of active and stable Co–Mo–Sx chalcogels as pH-universal catalysts for the hydrogen evolution reaction. Nat. Mater. 15, 197–203 (2016).

Zhang, X.-L. et al. Efficient acidic hydrogen evolution in proton exchange membrane electrolyzers over a sulfur-doped marcasite-type electrocatalyst. Sci. Adv. 9, eadh2885 (2023).

Yang, H. et al. Metastable-phase platinum oxide for clarifying the Pt–O active site for the hydrogen evolution reaction. Energy Environ. Sci. 16, 574–583 (2023).

Subbaraman, R. et al. Enhancing hydrogen evolution activity in water splitting by tailoring Li+-Ni(OH)2-Pt interfaces. Science 334, 1256–1260 (2011).

Shi, Y. et al. Electronic metal–support interaction modulates single-atom platinum catalysis for hydrogen evolution reaction. Nat. Commun. 12, 3021 (2021).

Hansen, J. N. et al. Is there anything better than Pt for HER? ACS Energy Lett. 6, 1175–1180 (2021).

Nørskov, J. K. et al. Trends in the exchange current for hydrogen evolution. J. Electrochem Soc. 152, J23 (2005).

Yan, Q.-Q. et al. Reversing the charge transfer between platinum and sulfur-doped carbon support for electrocatalytic hydrogen evolution. Nat. Commun. 10, 4977 (2019).

Wang, A., Li, J. & Zhang, T. Heterogeneous single-atom catalysis. Nat. Rev. Chem. 2, 65–81 (2018).

Liu, L. & Corma, A. Metal catalysts for heterogeneous catalysis: from single atoms to nanoclusters and nanoparticles. Chem. Rev. 118, 4981–5079 (2018).

Chen, Y. et al. Single-atom catalysts: synthetic strategies and electrochemical applications. Joule 2, 1242–1264 (2018).

Rong, H., Ji, S., Zhang, J., Wang, D. & Li, Y. Synthetic strategies of supported atomic clusters for heterogeneous catalysis. Nat. Commun. 11, 5884 (2020).

Hu, S. & Li, W.-X. Sabatier principle of metal-support interaction for design of ultrastable metal nanocatalysts. Science 374, 1360–1365 (2021).

Naguib, M., Mochalin, V. N., Barsoum, M. W. & Gogotsi, Y. 25th anniversary article: mxenes: a new family of two-dimensional materials. Adv. Mater. 26, 992–1005 (2014).

Gogotsi, Y. & Anasori, B. The rise of MXenes. ACS Nano 13, 8491–8494 (2019).

Naguib, M. et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 23, 4248–4253 (2011).

Anasori, B. et al. Two-dimensional, ordered, double transition metals carbides (MXenes). ACS Nano 9, 9507–9516 (2015).

Naguib, M., Unocic, R. R., Armstrong, B. L. & Nanda, J. Large-scale delamination of multi-layers transition metal carbides and carbonitrides “MXenes”. Dalton Trans. 44, 9353–9358 (2015).

Bazin, P. et al. FT-IR study of CO adsorption on Pt/CeO2: characterisation and structural rearrangement of small Pt particles. Phys. Chem. Chem. Phys. 7, 187–194 (2005).

Zhao, D. et al. MXene (Ti3C2) vacancy-confined single-atom catalyst for efficient functionalization of CO2. J. Am. Chem. Soc. 141, 4086–4093 (2019).

Zhang, J. et al. Single platinum atoms immobilized on an MXene as an efficient catalyst for the hydrogen evolution reaction. Nat. Catal. 1, 985–992 (2018).

Li, Z. et al. Direct methane activation by atomically thin platinum nanolayers on two-dimensional metal carbides. Nat. Catal. 4, 882–891 (2021).

Mao, J. et al. Design of ultrathin Pt-Mo-Ni nanowire catalysts for ethanol electrooxidation. Sci Adv 3 (2017).

Zhang, X. et al. A stable low-temperature H2-production catalyst by crowding Pt on α-MoC. Nature 589, 396–401 (2021).

Moulder, J. F., Stickle, W. F., Sobol, P. E., Bomben, K. D. & Chastain, J. Handbook of X-Ray Photoelectron Spectroscopy A Reference Book of Standard Spectra for Identification and Interpretation of XPS Data (Physical Electronics Division, Perkin-Elmer Corporation, 1979).

Zhao, Y. et al. Modulating Pt-O-Pt atomic clusters with isolated cobalt atoms for enhanced hydrogen evolution catalysis. Nat. Commun. 13, 2430 (2022).

Xiong, M. et al. In situ tuning of electronic structure of catalysts using controllable hydrogen spillover for enhanced selectivity. Nat. Commun. 11, 4773 (2020).

Wang, X. et al. Atomic-precision Pt6 nanoclusters for enhanced hydrogen electro-oxidation. Nat. Commun. 13, 1596 (2022).

Zhou, K. L. et al. Platinum single-atom catalyst coupled with transition metal/metal oxide heterostructure for accelerating alkaline hydrogen evolution reaction. Nat. Commun. 12, 3783 (2021).

Cheng, N. et al. Platinum single-atom and cluster catalysis of the hydrogen evolution reaction. Nat. Commun. 7, 13638 (2016).

Liu, D. et al. Atomically dispersed platinum supported on curved carbon supports for efficient electrocatalytic hydrogen evolution. Nat. Energy 4, 512–518 (2019).

Fang, S. et al. Uncovering near-free platinum single-atom dynamics during electrochemical hydrogen evolution reaction. Nat. Commun. 11, 1029 (2020).

Yan, P. et al. One stone five birds” plasma activation strategy synergistic with Ru single atoms doping boosting the hydrogen evolution performance of metal hydroxide. Adv. Funct. Mater. 33, 2301343 (2023).

Chen, W. et al. Deciphering the alternating synergy between interlayer Pt single-atom and NiFe layered double hydroxide for overall water splitting. Energy Environ. Sci. 14, 6428 (2021).

Zalitis, C. M., Kramer, D., Sharman, J., Wright, E. & Kucernak, A. R. Pt nano-particle performance for PEFC reactions at low catalyst loading and high reactant mass transport. ECS Trans. 58, 39–47 (2013).

Li, J. et al. Ethylene-glycol ligand environment facilitates highly efficient hydrogen evolution of Pt/CoP through proton concentration and hydrogen spillover. Energy Environ. Sci. 12, 2298–2304 (2019).

Sun, K. et al. Interfacial water engineering boosts neutral water reduction. Nat. Commun. 13, 6260 (2022).

Li, P. et al. Hydrogen bond network connectivity in the electric double layer dominates the kinetic pH effect in hydrogen electrocatalysis on Pt. Nat. Catal. 5, 900–911 (2022).

Hao, S. et al. Torsion strained iridium oxide for efficient acidic water oxidation in proton exchange membrane electrolyzers. Nat. Nanotechnol. 16, 1371–1377 (2021).

Shi, Z. et al. Customized reaction route for ruthenium oxide towards stabilized water oxidation in high-performance PEM electrolyzers. Nat. Commun. 14, 843 (2023).

Anantharaj, S. et al. The pitfalls of using potentiodynamic polarization curves for tafel analysis in electrocatalytic water splitting. ACS Energy Lett. 6, 1607–1611 (2021).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for open-shell transition metals. Phys. Rev. B 48, 13115–13118 (1993).

Kresse, G. & Furthmüller, J. Efficiency of ab initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B. 54, 11169–11186 (1996).

Niu, W. et al. Pb-rich Cu grain boundary sites for selective CO-to-n-propanol electroconversion. Nat. Commun. 14, 4882 (2023).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Sun, S. et al. Potassium-promoted limestone for preferential direct hydrogenation of carbonates in integrated CO2 capture and utilization. JACS Au 4, 72–79 (2024).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Grimme, S., Ehrlich, S. & Goerigk, L. Effect of the damping function in dispersion corrected density functional theory. J. Comput. Chem. 32, 1456–1465 (2011).

Chen, Z. et al. Accurate descriptions of molecule-surface interactions in electrocatalytic CO2 reduction on the copper surfaces. Nat. Commun. 14, 936 (2023).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Dong, S. et al. Overall design of anode with gradient ordered structure with low iridium loading for proton exchange membrane water electrolysis. Nano Lett. 22, 9434–9440 (2022).

Liu, W. et al. Single‐layer platinum cluster catalyst for efficient hydrogen electro‐production. Adv. Funct. Mater. 33, 2212752 (2023).

Shi, Z. et al. Phase-dependent growth of Pt on MoS2 for highly efficient H2 evolution. Nature 621, 300–305 (2023).

Gao, L. et al. Engineering a local potassium cation concentrated microenvironment toward the ampere-level current density hydrogen evolution reaction. Energy Environ. Sci. 16, 285–294 (2023).

Zhao, J. et al. Activating Ru-O-Co interaction on the a-Co(OH)2 @Ru interface for accelerating the volmer step of alkaline hydrogen evolution. Small Methods 7, 2201362 (2023).

Zhang, T. et al. Pinpointing the axial ligand effect on platinum single-atom-catalyst towards efficient alkaline hydrogen evolution reaction. Nat. Commun. 13, 6875 (2022).

Zheng, X. et al. Tailoring a local acid-like microenvironment for efficient neutral hydrogen evolution. Nat. Commun. 14, 4209 (2023).

Acknowledgements

The authors acknowledge the National Key Research and Development Program of China (2024YFB4105700, 2022YFA1504402), National Natural Science Foundation of China (22405035, 52171201, 22233002, 22103014), Natural Science Foundation of Sichuan Province (2025NSFJQ0017, 24NSFSC5779), the Innovation Program for Quantum Science and Technology (2021ZD0303305), the China Postdoctoral Science Foundation funded project (2022M710601), and the Huzhou Science and Technology Bureau (2023GZ02). We thank beamline BL14W1 of the Shanghai Synchrotron Radiation Facility for providing the facilities.

Author information

Authors and Affiliations

Contributions

The project was conceptualized by C.X. and supervised by C.X., X.X. and Q.J. H.Z. prepared the catalysts. H.Z., Q.Z., J.L. and C.L. performed the catalytic tests. H.Z., Y.J., R.Z., Z.Z., Z.X., Y.C. and D.Z. performed the catalyst characterizations. X.Xiong, Zhao.C., Y.D. and C.L. performed the XAFS measurements. Yi.C., J.T., T.Z. and X.L. helped in the analysis of the data. Z.C. and X.X. performed the DFT calculations. C.X., Q.J., X.X., Z.C. and H.Z. wrote the paper with input from all the authors. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

A China provisional patent application (202310633252.7) based on the technology described in this work was filed in July 2023 by C.X., H.Z. and Q.J. at the University of Electronic Science and Technology of China. The other authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Min-Rui Gao, Xiong Peng and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zeng, H., Chen, Z., Jiang, Q. et al. Sustainable and cost-efficient hydrogen production using platinum clusters at minimal loading. Nat Commun 16, 4314 (2025). https://doi.org/10.1038/s41467-025-59450-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-59450-6