Abstract

Polymers crosslinked by covalent bonds suffer from a conflict: dense covalent crosslinks increase modulus but decrease fatigue threshold. Polymers crosslinked by physical bonds commonly have large hysteresis. Here we simultaneously achieve high modulus, high fatigue threshold, and low hysteresis in a network of unusually long polymer chains crosslinked by domains of physical bonds. When the network without precrack is pulled by a moderate stress, chains in the domains slip negligibly, so that the domains function like hard particles, leading to high modulus and low hysteresis. When the network with a precrack is stretched, the chains in the domains at the crack tip slip but do not pull out. This enables high tension to transmit over long segments of chains, leading to a high fatigue threshold.

Similar content being viewed by others

Introduction

Biopolymers, such as proteins1 and nucleic acids2, are architectures of covalent bonds and physical bonds. Covalent bonds define primary structures. Physical bonds, including hydrogen bonds and hydrophobic interactions, define higher order structures that are strong enough to provide functions, yet weak enough to reassemble in response to stimuli.

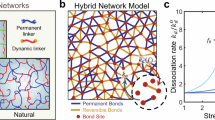

Inspired by these biological architectures of covalent bonds and physical bonds, here we design a network of unusually long chains of covalent bonds crosslinked by domains of physical bonds (Fig. 1a). The network is designed with four key features. First, the chains outside the domains are flexible, densely entangled, and have low interchain friction. Second, each physical bond is weak, but a ___domain of many physical bonds is strong enough to function like hard particles under moderate stress. Third, the physical bonds between chains are much weaker than the covalent bonds along individual chains, so that chains slip in the domains under high stress. Fourth, each chain is so long that it is crosslinked through multiple domains to other chains, ensuring that the chain can slip but not be pulled out of the domains.

a Undeformed network. b When the network without precut crack is subject to a moderate stress, the chains in the domains slip negligibly, and domains function like hard particles. c When the network with a precut crack is stretched, at the crack tip, the chains in the domains slip, transmitting high tension over a long distance.

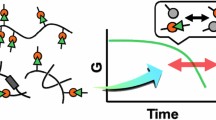

In this design, stress acts as a stimulus. The chains in the domains slip negligibly when stress is moderate, but slip when stress is large. That is, a ___domain behaves like a metal with a yield strength. This yield-like molecular characteristic profoundly affects the mechanical behaviors of the network. When the network without precut crack is subjected to a moderate stress, the domains function like hard particles, so that the network has high modulus and low hysteresis (Fig. 1b). The chains outside the domains are stretchable by entropic elasticity. Near a crack tip, the stress is high, and the chains in the domains slip relative to one another (Fig. 1c). A chain slipping in a ___domain differs from a chain splitting from the ___domain, in that the tension in the chain is balanced by the interchain friction. This effect is called shear lag3,4, which enables the chain to slip but not pull out. Consequently, at the crack tip, the high tension can be transmitted to a segment of the chain longer than the segment between neighboring domains, leading to high fatigue threshold.

Many applications of polymer networks require high modulus to resist excessive deformation, high fatigue threshold to resist crack growth under cyclic loads, and low hysteresis to reduce energy loss during deformation. Polymers crosslinked by covalent bonds suffer from a conflict: dense covalent crosslinks increases modulus, but decrease fatigue threshold5,6,7,8. Specifically, when the number of monomers between two crosslinks is n, the modulus scales as E ∼ n−1, but the fatigue threshold scales as Gth ∼ n1/2. On the other hand, polymers crosslinked by physical bonds commonly have large hysteresis8,9. That is, the physical bonds unzip when the network is stretched, but do not rezip fast enough when the network is unstretched. This results in stress-stretch curves that differ upon loading and unloading. The large hysteresis leads to high toughness to resist crack growth under monotonic stretch9,10, but does not enhance fatigue threshold to resist crack growth under cyclic stretch11,12. Furthermore, the unzip of physical bonds lowers modulus over cyclic stretch11,13.

Simultaneously achieving high modulus, high fatigue threshold, and low hysteresis has been a challenge among established materials (Supplementary Fig. 1). For example, natural rubber has low hysteresis, but low modulus and low fatigue threshold14. As a second example, thermoplastic polyurethanes have high fatigue threshold and high modulus, but high hysteresis15,16. As a third example, polyvinyl alcohol hydrogels have high fatigue threshold and high modulus, but large hysteresis17,18,19. As a fourth example, elastomers and gels reinforced by rigid particles have high toughness, high fatigue threshold, and high modulus20,21,22. Under large deformation, detachment and reattachment between polymers and particles increase hysteresis22. Recently demonstrated materials have created excitement in the field, but do not simultaneously achieve high modulus, high fatigue threshold, and low hysteresis. The double-network polymers achieve high modulus, high fatigue threshold, and low hysteresis; the high modulus and low hysteresis, however, have been limited to small stretches23,24,25,26,27. Polymer networks containing physical crosslinks have high hysteresis and low fatigue threshold. Examples include hydrogels of polyacrylamide-alginate10,28, polyelectrolytes29, and polyampholytes30,31,32, as well as ionogels33,34.

In this work, we demonstrate the principle outlined above by using two species of polymer that can form a ___domain of physical bonds in water. We first homogenize a mixture of long polymer chains, monomers, and photoinitiators through kneading and annealing. This homogeneous mixture is subsequently polymerized to form a blend of two species of long-chain polymers. The two species form complexes through hydrogen bonds. Upon swelling in water to equilibrium, the blend develops into a hydrogel, where hydrophobic interactions drive the aggregation of multiple complexes into domains. These domains physically crosslink the long polymer chains into a network. The resulting hydrogel exhibits a high modulus, a high fatigue threshold, and low hysteresis.

Results

We demonstrate our design by fabricating a hydrogel using two species of polymers (Supplementary Movie 1). The fabrication begins with a powder of one species of polymer, poly(ethylene glycol) (PEG) (Fig. 2a), and a liquid monomer precursor of another species of polymer, poly(acrylic acid) (PAAc) (Fig. 2b). Polymer powder and the monomer liquid are mixed into a polymer-monomer mixture, which is initially heterogeneous and opaque (Fig. 2c). The mixture is kneaded at an elevated temperature (80 °C) without breaking the PEG chains. After kneading, the polymer-monomer mixture becomes homogeneous, transparent, and readily deforms by viscoplasticity (Supplementary Fig. 2). We will call the polymer-monomer mixture in this state a dough. The dough is annealed at an elevated temperature (65 oC), and the PEG chains relax and entangle (Fig. 2d). Upon exposure to ultraviolet light, the AAc monomers link into PAAc chains (Fig. 2e). The two species of polymers, PEG and PAAc, zip together through hydrogen bonds. A sequence of the ether-carboxyl hydrogen bonds constitutes a complex. Both polymers are hydrophilic. Once a complex forms, the backbones of the two polymers are hydrophobic. The polymer-polymer mixture remains transparent, and feels like dried, stiff bubble gum. Submerged in water, the polymer-polymer mixture swells. The hydrophobic interactions, in the presence of water, aggregate multiple complexes into a ___domain35 (Fig. 2f). Outside the domains, the polymers form hydrogen bonds with water and are flexible, highly entangled, and have low interchain friction. The PEG-PAAc-water mixture is a hydrogel, which is transparent (Fig. 2g), and elastically stretchable (Fig. 2h).

a Powder of one species of long polymers. b Liquid of monomer precursor of another species of long polymers. c Mix the polymer powder and the liquid monomer precursor. d Knead and anneal the polymer-monomer mixture to form a homogeneous dough. e When the monomers are polymerized, the two species of polymers are zipped by hydrogen bonds. f Submerge the polymer-polymer mixture in water to form a hydrogel. g The hydrogel is transparent. h The hydrogel is stretchable. i A dough can be made into various shapes, such as helix, mobius strip, kirigami, and origami. The shapes retain after the monomers are polymerized and the polymer-polymer mixtures are swollen into hydrogel. Scale bars represent 5 mm.

The dough of polymer-monomer readily undergoes plastic deformation, which facilitates shaping by molding, extrusion, and printing. Once the monomer polymerizes, the shape of the polymer-polymer mixture is fixed. Furthermore, submerged in water, the mixture swells but retains the shape. These processes fabricate hydrogel into various shapes, such as helix, mobius strip, kirigami, and origami (Fig. 2i).

We use Irgacure 2959 as the initiator, which is commonly decomposed by ultraviolet light, but not by elevated temperature. That is, Irgacure 2959 is commonly used as a photoinitiator, but not a thermal initiator. This fact is significant for the design of our process, in which the dough is kneaded at 80 °C for 20 min and annealed at 65 °C for four hours. Will such periods of elevated temperatures decompose some of Irgacure 2959, and partially polymerize AAc monomers? Such polymerization would be undesirable, as polymerization would prevent the dough from deformation to form shapes. To ascertain that thermal initiation does not take place in our process window, after kneading and annealing, we show that the monomer conversion to be nearly zero by evaporating the monomer and measuring the weight (Supplementary Fig. 3). Furthermore, after kneading and annealing, we submerge the dough in water, and the dough completely dissolves. Incidentally, the melting temperature of Irgacure 2959 is ~88 °C. Apparently thermal decomposition is negligible below this temperature.

We characterize the materials in several stages, beginning with the PEG-AAc dough. The dough is soft and plastically deformable (Supplementary Movie 2). The dough flows at a low frequency and maintains a plateau of storage modulus (~200 kPa) in a wide range of high frequencies (Supplementary Fig. 4). The broad plateau of low storage modulus indicates that the long polymers, dissolved in the monomer liquid, are rubbery and entangled.

By contrast, the polymer-polymer mixture is a transparent and plastically deformable material of high stiffness, strength, and viscosity (Supplementary Figs. 5, 6, Supplementary Movie 3). The newly formed PAAc chains are densely entangled among themselves and with the PEG chains. The ether groups -CH2OCH2- of PEG and carboxyl groups -COOH of PAAc are known to form hydrogen bonds. A sequence of the hydrogen bonds between two polymer chains is called a polymer complex36,37,38,39. However, some of the ether groups of PEG and carboxyl groups of PAAc do not form hydrogen bonds, as shown by the Fourier-transform infrared (FTIR) spectroscopy (Supplementary Figs. 7, 8, and Supplementary Table 1). This coexistence of complex and noncomplex segments of two polymer chains has been reported by a 13C NMR study39. The scanning electron cryomicroscopy (cryo-SEM, Supplementary Fig. 9) show that the PEG-PAAc mixture forms domains of ~10–50 nm. This kind of heterogeneous structure may be called “semi-complex”, analogous to a semi-crystalline polymer. Thermodynamically, the two polymers tend to form complexes. However, complexation cannot happen in some regions due to the steric hindrance of long polymer chains. The “semi-complexed” polymers are also observed in other systems, such as stereocomplex polylactides40. The PEG-PAAc mixture has a single glass transition at 9 °C, while the glass transition temperature is ~−50 °C for the pure PEG, ~100 °C for the pure PAAc (Supplementary Fig. 10). This single glass transition of PEG-PAAc mixtures has been reported in the literature, indicating that the two polymers are mixed at the molecular scale39,41,42.

Submerged in water, the PEG-PAAc mixture swells to form a hydrogel. The hydrogel is transparent, elastic, and stretchable (Supplementary Movie 4). The domains are of sizes of ~30–60 nm (Supplementary Fig. 11). Both pure PEG and pure PAAc can dissolve in water. The PEG and PAAc, once zipping together into a complex, become hydrophobic. The particle-like phase is likely the ___domain of the PEG-PAAc complex. The ___domain size in the PEG-PAAc hydrogel is larger than that in the PEG-PAAc mixture, likely because the hydrophobic interactions drive phase coarsening. Both PEG and PAAc are unusually long, so that each long chain is crosslinked through multiple domains to other chains. For the PEG of molecular weight of 8 × 106 g mol−1, the root-mean-square end-to-end distance is estimated to be 265 nm. For PAAc, the molecular weight is ~2 × 106 g mol−1 (Supplementary Fig. 12), and the root-mean-square end-to-end distance is estimated to be 118 nm. Both are larger than the size of a ___domain of ~30–60 nm.

To demonstrate roles of the domains, we prepare another hydrogel, PEG hydrogel, in which unusually long polymers are highly entangled and sparsely crosslinked by covalent bonds. The PEG hydrogel is prepared by mixing the PEG powder of long chains with a small amount of water and photoinitiator, kneading the mixture into dough, crosslinking the polymers, and submerging the crosslinked network in water to equilibrium43. The PEG hydrogel is flaccid, whereas PEG-PAAc hydrogel is turgid (Fig. 3a). The PEG hydrogel contains 7 wt.% of polymers, and PEG-PAAc hydrogel contains 48 wt.% of polymers. The PEG hydrogel is highly entangled and sparsely crosslinked by covalent bonds, so that the swelling ratio is mainly set by entanglements (Fig. 3b). The PEG-PAAc hydrogel is highly entangled and crosslinked by the domains. The domains absorb water negligibly, so that the swelling ratio is set by entanglements and the volume fraction of domains (Fig. 3c). The domains act as high-functionality crosslinks, like reinforcing hard particles linked to the flexible chains.

a Stress-stretch curves, along with photos of the two hydrogels. b When the PEG hydrogel is stretched, the covalent crosslinks prevent the entanglements from disentangling. c When the PEG-PAAc hydrogel is stretched, the domains remain intact, and act as high-functionality crosslinks, which also prevent the entanglements from disentangling. d The properties of PEG hydrogel (black columns) and PEG-PAAc hydrogel (red columns). Data with error bars in (d) are presented as mean values ± standard deviations (s.d.) of n = 3 replicates.

We measure stress-stretch curves of the two types of hydrogels (Fig. 3a). The PEG hydrogel has a low modulus of ~55 kPa, and the PEG-PAAc hydrogel has a high modulus of ~510 kPa (Fig. 3d). The high modulus of the latter indicates that the volume fraction of domains is high. This aligns with elastomers reinforced by a high concentration of hard particles, where an order of magnitude amplification of modulus is commonly reported20,21,44,45. The domains also amplify other properties determined by the stretch-stretch curves, including strength, stretchability, and work of fracture (Fig. 3d). As a demonstration, when an iron ball is dropped from a height onto the hydrogels, the PEG hydrogel ruptures, but PEG-PAAc hydrogel bounces the ball (Supplementary Movie 5).

In a rheometer, the loss tangent tan δ of PEG-PAAc hydrogel is ~0.06, which is comparable to that of PEG hydrogel (~0.03). This finding is remarkable considering that the polymer content of PEG-PAAc hydrogel is seven times that of PEG hydrogel. Furthermore, when subjected to a stretch of two and unloaded, the PEG-PAAc hydrogel has a low hysteresis of 13% (Supplementary Fig. 13). These findings indicate that, though each physical bond is weak, a ___domain is strong enough to slip negligibly when the network is under moderate stress.

Under cyclic stretch, the crack growth per cycle is measured as a function of the amplitude of energy release rate (Fig. 4a, b). The linear regression of data extrapolates the fatigue threshold, Gth. The fatigue threshold is 6.5 J m−2 for the PEG hydrogel (Fig. 4a) and is 184 J m−2 for the PEG-PAAc hydrogel (Fig. 4b). For the PEG hydrogel, at the crack tip, the high tension is transmitted over the entire polymer strand between neighboring covalent crosslinks (Fig. 4c). Once a single bond in the polymer strand breaks, the energy stored in the entire strand is dissipated. This classic Lake-Thomas picture accounts for the observed fatigue threshold of the PEG hydrogel. In contrast, for the PEG-PAAc hydrogel, the hydrogen bonds and hydrophobic interactions in a ___domain are much weaker than covalent bonds along the polymers, so that near the crack tip, the polymers in the domains can slip relative to one another (Fig. 4d). The tension in the chain is balanced by the interchain friction of shear lag effect3,4. This effect enables the long chains to slip but not pull out. Consequently, at the crack tip, the high tension can be transmitted to a polymer segment longer than the polymer strand between neighboring domains.

Crack growth per cycle as a function of the amplitude of energy release rate for a PEG hydrogel and b PEG-PAAc hydrogel. c For a PEG hydrogel, at the crack tip, the high tension is transmitted over the polymer strand between neighboring covalent crosslinks. d For a PEG-PAAc hydrogel, at the crack tip, polymer chains in the domains slip and transmit high tension over a long distance.

The impact of covalent crosslinks on limiting the extent of stress deconcentration is further illustrated by another experiment. When the PAAc is crosslinked by covalent bonds, the PEA-PAAc hydrogel still shows a high modulus and low hysteresis but becomes brittle (Supplementary Fig. 14).

Under monotonic stretch, the PEG hydrogel has a toughness of ~1600 J m−2, and the PEG-PAAc hydrogel has a toughness of ~4200 J m−2. Note that for each of the two hydrogels, the toughness is much higher than the fatigue threshold. Such a difference between toughness and fatigue threshold has been reported for many materials, including a polyacrylamide hydrogel46,47. Under monotonic stretch, crack growth is resisted by a synergy of two mechanisms: scission of polymer strands crossing the crack plane, and inelastic deformation in a volume of material off the crack plane. In the PEG hydrogel, inelastic deformation off the crack plane is likely due to scission of some of the polymer strands. In the PEG-PAAc hydrogel, inelastic deformation off the crack plane is likely due to chain slip in the domains, as well as chain scission.

The PEG-PAAc hydrogel is wear-resistant. When the hydrogel under a normal force rubs against a sandpaper cyclically, the weight loss per cycle of PEG-PAAc hydrogel is ~10 times lower than that of PEG hydrogel (Fig. 3d). High modulus, strength, fatigue threshold, and toughness may contribute to this high wear resistance. Wear resistance is important to applications including artificial cartilage and hydrogel coatings48.

To illustrate the importance of unusually long polymers, we prepare a hydrogel in which both PEG and PAAc chains are shorter than those in the PEG-PAAc hydrogel described above. We call them short-chain hydrogel and long-chain hydrogel. The short-chain PEG refers to a polymer with molecular weight of ~4 × 105 g mol−1, which is 1/20 that of the long-chain PEG. The short-chain PAAc is fabricated by adding the initiator 30-times that in the long-chain PAAc. The molecular weight of short-chain PAAc is 1/7 that of the long-chain PAAc (Supplementary Fig. 12).

The long-chain hydrogel is much stiffer, stronger, and more elastic than the short-chain hydrogel (Fig. 5a and Supplementary Fig. 15). The two hydrogels have a similar polymer content, but markedly different modulus and strength (Fig. 5b). As frequency decreases, the storage modulus of the long-chain hydrogel remains nearly constant, but that of the short-chain hydrogel reduces significantly (Fig. 5c). When held at a constant stretch of three, the long-chain hydrogel relaxes less stress than the short-chain hydrogel (Fig. 5d). We hang a weight onto the two hydrogels (Supplementary Movie 6), during which the short-chain hydrogel creeps to rupture, but the long-chain hydrogel bears the load and behaves elastically.

a Stress-stretch curves. Photos of the two hydrogels subject to the same hanging weight. b Polymer content, modulus, and strength of the two hydrogels. Data in (b) are presented as mean values ± standard deviations (s.d.) of n = 3 replicates. c Storage moduli of the two hydrogels as functions of frequency. d Stress relaxation of the two hydrogels. e Schematic of the hydrogel of unusually long chains under stretch. f Schematic of the hydrogel of short chains under stretch.

The root-mean-square end-to-end distance is 265 nm for unusually long-chain PEG, and 59 nm for short-chain PEG. The root-mean-square end-to-end distance is 118 nm for unusually long-chain PAAc, and 45 nm for short-chain PAAc. The two hydrogels exhibit a similar morphology with a ___domain size of 30–60 nm (Supplementary Figs. 11, 16). Each long chain is crosslinked by multiple domains with few dangling ends (Fig. 5e). Each short chain can only be crosslinked by one or two domains with many dangling ends (Fig. 5f). Within each ___domain, long chains can cross the whole domains, but the many short chains do not. The long-chain hydrogel will rupture mainly by chain scission. A long chain crosses multiple domains of high friction, so that multiple domains participate in resisting the chain pullout. By contrast, the short-chain hydrogel will rupture by chain pullout, with negligible chain scission. In other experiments, we keep the PEG chains long and vary the length of PAAc chains, or fix the chain length of PAAc chains and vary the length of PEG chains (Supplementary Figs. 17, 18). Longer chains always lead to higher modulus, higher strength, and lower hysteresis.

The domains can be further strengthened by designing chemistry. We prepare a hydrogel composed of unusually long polymers of PEG and poly(methacrylic acid) (PMAAc) (Supplementary Fig. 19). The methyl groups in PMAAc enhance the hydrophobic interaction and hence strengthen the domains. The PEG-PMAAc hydrogel achieves a high modulus of ~1.9 MPa, a high strength of ~3.5 MPa, and a high fatigue threshold of ~230 J m−2. The principles of chain slips and shear lag are maintained, because the physical interactions between the polymers are still weaker than the covalent bonds along the polymers.

Discussion

The polymer network based on self-assembled domains has been explored previously49,50,51. This network achieves high modulus and toughness, yet typically large hysteresis due to the pullout of short chains from the domains. The current design presents an approach to achieve high modulus, high toughness, high fatigue threshold, while maintaining low hysteresis simultaneously.

A recent approach to resolve the conflict of modulus, fatigue threshold, and hysteresis is to introduce mechanophore crosslinks of intermediate strength into an elastomer52. The mechanophore crosslinks remain intact upon a moderate stretch, leading to a high modulus and low hysteresis. The mechanophore crosslinks break before the polymer chains, releasing the chain length of a bridging strand at the crack tip to achieve a high fatigue threshold. However, the broken mechanophore crosslinks do not reform, and cause permanent damage in the material.

The principle of long chains of covalent bonds crosslinked by domains of physical bonds may be used to re-engineer broadly used materials to simultaneously achieve high modulus, high fatigue threshold, and low hysteresis. For example, triblock copolymers, in which rubbery chains are crosslinked by glassy domains, commonly have large hysteresis and low fatigue threshold53, likely due to the chain pullout from the glassy domains. Multiblock copolymers, in which long polymer chains are crosslinked through multiple glassy domains, show a higher strength than triblock copolymers54. Such a material holds promise to achieve a high fatigue threshold.

In many applications, hydrogels are used in contact with water, and are therefore commonly prepared using relatively short chains to avoid excessive swelling. Our design principle requires that the polymer chains used in the PEG-PAAc hydrogel be much longer than those commonly used in PEG and PAAc hydrogels. PEG hydrogels are commonly prepared from relatively short chains of Mn < 1 × 105 g mol−1. Here we use PEG chains of molecular weight ~8 × 106 g mol−1. PAAc hydrogels are commonly prepared using a relatively large ratio of photoinitiator to monomer (~10−2). Here we use an unusually low ratio (~10−4) to achieve high molecular weight ~2 × 106 g mol−1. Both polymers have molecular weights over 106 g mol−1, generally regarded as ultra-high molecular weight polymers. In contact with water, the PEG-PAAc hydrogel of unusually long chains avoids excessive swelling by forming domains of physical bonds. Our design principle requires that each polymer chain be long enough to be incorporated into multiple domains of physical bonds, so that the chain can slip in the domains, but not pull out from the domains.

We demonstrate that unusually long chains of covalent bonds crosslinked by domains of physical bonds simultaneously achieve high modulus, high fatigue threshold, and low hysteresis. The domains are strong enough so that polymers in the domains slip negligibly under moderate stress, and the network achieves high modulus and low hysteresis. At the crack tip, the high tension along the polymers reaches the strength of the covalent bonds, which is much stronger than the physical bonds between polymers, so that the domains at the crack tip slip. Unlike a covalent crosslink, the ___domain of physical bonds slips but does not break. Polymer chains do not pull out due to the shear lag effect. Consequently, the high tension at the crack tip is transmitted over the long segments of the polymer chains, leading to high fatigue threshold. Moreover, the domains of physical bonds can be designed to dissociate on demand. This combination of attributes holds promise for developing polymers that contributes to sustainability.

Methods

Materials

Poly(ethylene glycol) (PEG, Mv = 400,000 and 8,000,000 g mol−1), acrylic acid (AAc), methacrylic acid (MAAc), Irgacure 2959, N,N′-Methylenebis(acrylamide) (MBA), benzophenone, ethanol, and isopropyl alcohol (IPA) are purchased from Sigma-Aldrich and used without further purification. Distilled water is purchased from Poland Spring.

Preparation of hydrogels crosslinked by domains of physical bonds

We dissolve a certain amount of UV initiator Irgacure 2959 into the liquid of monomer (acrylic acid or methacrylic acid) to form a homogenous solution. The solution is dripped onto the powder of PEG. The weight of the monomer is calculated to let the molar ratio of the monomer and the repeat unit of PEG to be equivalent. The solution and the polymer powder are mixed by hand, and the mixture is heterogeneous. The mixture is then homogenized by a kneading process (Supplementary Fig. 2). Each cycle of kneading includes three steps: hot-press the sample between two rigid plates of 80 °C into a sheet of thickness of 0.5 mm by using a spacer, hold the press for five minutes, and then fold the sheet twice. We repeat the process for four cycles. During pressing and holding, the dough is kept in a plastic bag (reclosable zip bag, VWR) to prevent the evaporation of monomer. After kneading, we anneal the dough at elevated temperature to further homogenize the dough, relax the polymer chains and let the chains entangle. The annealing process is as follows. We sandwich the sheet of dough between two glass plates and press it to the thickness of 0.4 mm by using a spacer. The sheet of dough is kept at 65 °C for four hours. After cooling down to room temperature, the sandwiched sample is exposed to ultraviolet light for three hours to polymerize the monomers in the dough. After polymerization, the polymer-polymer mixture is then submerged into water for at least two days to obtain a fully-swollen hydrogel.

Preparation of the PEG hydrogel

We prepare an ethanol solution of benzophenone photocrosslinker (10 wt.%). We dissolve 130 μL of this photocrosslinker solution in ~1.5 g of isopropyl alcohol (IPA), drip the solution onto 2.5 g of PEG powder, and then mix them by hand to form a mixture. The mixture is left in an oven at 65 °C for 15 min to evaporate the IPA. Then, we drip 2.5 g of water onto the dried mixture of PEG and benzophenone. We use the same process of kneading and annealing above to homogenize the mixture and form a homogeneous dough. Note that water molecules evaporate somewhat during the kneading process. After annealing, the water content of the dough is ~40%. The homogenized dough is exposed to ultraviolet light for 1.3 h in a nitrogen environment. When ultraviolet light is irradiated, benzophenone molecules are activated to abstract hydrogen atoms from PEG chains and create radicals. Two radicals couples to form a chemical bond, crosslinking PEG chains43. The cross-linked dough is submerged in water for at least two days to obtain a fully-swollen PEG hydrogel.

Tensile test

The stress-stretch curve and loading-unloading curve are measured by uniaxial tensile tests at a constant stretch rate of 0.05 s−1. The sample is cut into a dumbbell shape by a die cutter (Ace steel rule dies, ISO 527-2-5B). The total length of the sample is 35 mm, and the neck width is 2 mm. The gauge length is ~20 mm and is regarded as the initial length of the sample. The sample is tested by Instron 5966 with a 100 N load cell. The stress-stretch curve is measured by stretching the sample until it fractures. The initial slope of the stress-stretch curve is recorded as modulus. The stress and stretch at fracture are recorded as the strength and the stretchability, respectively. The work of fracture is calculated by integrating the stress-stretch curve. Hysteresis is measured by the loading-unloading curve with a maximum stretch of two. We define hysteresis as the ratio of the area between the loading and unloading curves divided by the area under the loading curve. During all tensile tests for hydrogels, a humidifier is used to prevent the hydrogel from losing water.

Pure shear test

The toughness and fatigue threshold are measured by a pure shear test. The sample dimensions for the pure shear test are 63.5 mm in width and 10 mm in height. The sample is adhered to grippers of acrylic slides using Krazy glue. One sample is cut by a fresh razor blade (VWR, 55411-050) to form a 25 mm precrack, and the other one remains intact. When measuring toughness, the intact sample is stretched to obtain the strain energy density as a function of stretch W(λ), and the precracked sample is stretched to fracture to obtain the critical stretch λc. The toughness was calculated by W(λc)H0, where H0 was the initial height of the sample. The loading rate is 0.05 s−1 for toughness measurement. For the fatigue test, the strain energy density is measured from the stress-stretch curve of intact sample after 500 cycles of loading and unloading. The precracked sample is applied to a cyclic stretch of fixed amplitude. An amplitude of the stretch corresponds to an amplitude of energy release rate. Around 500 cycles are applied ahead of the measurement to form a consistent crack tip. The crack growth is measured by an optical microscope after additional 10,000 cycles and divided by the number of cycles to get the crack advance per cycle dc/dn. Based on the resolution of the microscope, the minimum crack growth rate we can detect is ~1 nm cycle−1. Each cycle of loading and unloading takes 1 s.

Stretch relaxation test

The hydrogel is cut into a rectangle shape with 20 mm in width and ~15 mm in length. We stretch the sample to a stretch of three using a loading rate of 5 mm s−1. We then hold the sample at this stretch and monitor the stress with time.

Rheology test

We use a rheometer (DHR-3, TA Instruments) to test linear dynamic viscoelasticity of samples including annealed PEG-AAc dough and hydrogels. The sample is cut into a disk with a diameter of 20 mm. A stainless-steel plate with a diameter of 20 mm is used. Frequency sweeps from 600 to 0.0001 rad s−1 with a linear deformation strain of 0.3% at 25 °C. For PEG-AAc dough, the sample is gradually compressed to a thickness of 500 µm and held for 30 min to ensure a good adhesion to the steel plate and the substrate. The dough is sticky and capable of viscoplastic deformation. For hydrogels, we use Krazy glue to adhere the hydrogels to the steel plate and substrate. We hold the adhered hydrogels for 30 min to ensure a good adhesion. Before all rheological measurements, a sweep of strain amplitude is used to validate a limit of strain amplitude, below which sample does not slip, as well as shows a linear deformation. We use a dynamic mechanical analyzer (DMA, Q800, TA Instruments) to test the dynamic behavior of the PEG-PAAc mixture. We use the tensile mode and sweep the frequency from 200 to 0.01 Hz at the temperatures of 25, 45, and 65 °C, respectively. The principle of time-temperature superposition is applied to overlap the mechanical spectra of different temperatures to establish a master curve at a reference temperature of 25 °C.

Cryogenic scanning electron microscopy (Cryo-SEM)

To preserve microstructures, samples are quenched in liquid nitrogen and transferred to a high-vacuum sputter coater (Leica EM ACE600) maintained at −160 °C. In the coater, samples are fractured to expose cross-sections, after which the temperature is raised to −90 °C and held for 5 min to sublimate surface water. The samples are then cooled back to −160 °C and sputter-coated with a ~5 nm platinum layer. Finally, they are transferred to a cryogenic scanning electron microscope (Helios Nanolab G3 UC) for microstructure observation, with the temperature maintained at −140 °C.

Fourier-transform infrared spectroscopy (FTIR)

We use FTIR, attenuated total reflectance (ATR) mode (Nicolet iS-50 FTIR equipped with a diamond ATR crystal) to identify the functional groups within PEG, PAAc and PEG-PAAc mixtures. The spectra are recorded from 4000 to 500 cm−1 at 4 cm−1 resolution and 32 sample/background scans. To investigate the hydrogen bonds within PAAc and PEG-PAAc mixtures, the carbonyl region (1800–1650 cm−1) was deconvoluted based on a Gaussian function.

Differential scanning calorimetry (DSC)

We use a differential scanning calorimetry (TA, Discovery 250) to characterize the phase transition behaviors of PEG-PAAC mixture. The sample of 5 mg is placed in an aluminum pan. Temperature sweeps from −85 to 160 °C is used with a heating rate of 5 °C min−1.

Molecular weight characterization of PAAc

We use Agilent gel permeation chromatography (GPC) coupled with Wyatt Multi-Angle Light Scattering (MALS) to characterize the molecular weight of PAAc. To dissolve the samples in water, we synthesize PEG-PAAc mixture using PEG with a low molecular weight of 200 g mol−1, instead of the high molecular weight of 8,000,000 g mol−1. This short-chain PEG is known to be unable to form complexes with PAAc55. The short PEG chains are also used to avoid the signals of the PEG and PAAc from overlapping. Aqueous solution of sodium nitrate (0.1 mol L−1) is used as a mobile phase. The mobile phase is ultrasonically degassed and filtered with 0.2 μm filter paper before injection into columns. The gel chromatography columns of Shodex 804 and 806 M are used in series. The injection volume of the sample is 30 μL and the flow rate of mobile phase is 0.5 mL min−1. The temperatures of the column and detector are set to 45 °C. The refractive index of the mobile phase and polyacrylic acid is 1.4785 and 0.171 g mL−1, respectively. The test results are processed using Astra software. Here we use the photoinitiator-to-monomer ratios of 10−4 and 3 × 10−3. The measurements of GPC yield molecular weights of ~2 × 106 g mol−1 and ~3 × 105 g mol−1.

Data availability

The authors declare that the data supporting the findings of this study are available within the Article and its Supplementary Information files. All data are available from the corresponding author upon request.

References

Branden, C. I. & Tooze, J. Introduction to protein structure (Garland Science, 2012).

Saenger, W. Principles of nucleic acid structure (Springer Science & Business Media, 2013).

Lavoie, S. R., Hassan, S., Kim, J., Yin, T. & Suo, Z. Toughness of a composite in which sliding between fibers and matrix is rate-sensitive. Extreme Mech. Lett. 46, 101317 (2021).

Hassan, S. & Kim, J. Polyacrylamide hydrogels. IV. Near-perfect elasticity and rate-dependent toughness. J. Mech. Phys. Solids 158, 104675 (2022).

Zhou, Y. et al. The stiffness-threshold conflict in polymer networks and a resolution. J. Appl. Mech. 87, 031002 (2020).

Creton, C. 50th anniversary perspective: networks and gels: soft but dynamic and tough. Macromolecules 50, 8297–8316 (2017).

Li, X. & Gong, J. P. Design principles for strong and tough hydrogels. Nat. Rev. Mater. 9, 380–398 (2024).

Zhao, X. et al. Soft materials by design: unconventional polymer networks give extreme properties. Chem. Rev. 121, 4309–4372 (2021).

Zhao, X. Multi-scale multi-mechanism design of tough hydrogels: building dissipation into stretchy networks. Soft Matter 10, 672–687 (2014).

Sun, J.-Y. et al. Highly stretchable and tough hydrogels. Nature 489, 133–136 (2012).

Bai, R., Yang, J. & Suo, Z. Fatigue of hydrogels. Eur. J. Mech. A Solids 74, 337–370 (2019).

Lake, G. & Thomas, A. The strength of highly elastic materials. Proc. R. Soc. Lond. Ser. Math. Phys. Sci 300, 108–119 (1967).

Bai, R., Yang, J., Morelle, X. P., Yang, C. & Suo, Z. Fatigue fracture of self-recovery hydrogels. ACS Macro Lett. 7, 312–317 (2018).

Lake, G. & Yeoh, O. Measurement of rubber cutting resistance in the absence of friction. Int. J. Fract. 14, 509–526 (1978).

Scetta, G. et al. Self-organization at the crack tip of fatigue-resistant thermoplastic polyurethane elastomers. Macromolecules 54, 8726–8737 (2021).

Scetta, G. et al. Strain induced strengthening of soft thermoplastic polyurethanes under cyclic deformation. J. Polym. Sci. 59, 685–696 (2021).

Stauffer, S. R. & Peppast, N. A. Poly (vinyl alcohol) hydrogels prepared by freezing-thawing cyclic processing. Polymer 33, 3932–3936 (1992).

Lin, S. et al. Anti-fatigue-fracture hydrogels. Sci. Adv. 5, eaau8528 (2019).

Hua, M. et al. Strong tough hydrogels via the synergy of freeze-casting and salting out. Nature 590, 594–599 (2021).

Steck, J., Kim, J., Kutsovsky, Y. & Suo, Z. Multiscale stress deconcentration amplifies fatigue resistance of rubber. Nature 624, 303–308 (2023).

Wang, M.-J. Effect of polymer-filler and filler-filler interactions on dynamic properties of filled vulcanizates. Rubber Chem. Technol. 71, 520–589 (1998).

Lin, W.-C., Fan, W., Marcellan, A., Hourdet, D. & Creton, C. Large strain and fracture properties of poly(dimethylacrylamide)/silica hybrid hydrogels. Macromolecules 43, 2554–2563 (2010).

Gong, J. P., Katsuyama, Y., Kurokawa, T. & Osada, Y. Double‐network hydrogels with extremely high mechanical strength. Adv. Mater. 15, 1155–1158 (2003).

Ducrot, E., Chen, Y., Bulters, M., Sijbesma, R. P. & Creton, C. Toughening elastomers with sacrificial bonds and watching them break. Science 344, 186–189 (2014).

Zhang, W. et al. Fatigue of double-network hydrogels. Eng. Fract. Mech. 187, 74–93 (2018).

Sanoja, G. E. et al. Why is mechanical fatigue different from toughness in elastomers? The role of damage by polymer chain scission. Sci. Adv. 7, eabg9410 (2021).

Fang, Y. et al. Toughening hydrogels with fibrillar connected double networks. Adv. Mater. 36, 2402282 (2024).

Bai, R. et al. Fatigue fracture of tough hydrogels. Extreme Mech. Lett. 15, 91–96 (2017).

Luo, F. et al. Oppositely charged polyelectrolytes form tough, self-healing, and rebuildable hydrogels. Adv. Mater. 27, 2722–2727 (2015).

Sun, T. L. et al. Physical hydrogels composed of polyampholytes demonstrate high toughness and viscoelasticity. Nat. Mater. 12, 932–937 (2013).

Li, X. et al. Effect of mesoscale phase contrast on fatigue-delaying behavior of self-healing hydrogels. Sci. Adv. 7, eabe8210 (2021).

Li, X. & Gong, J. P. Role of dynamic bonds on fatigue threshold of tough hydrogels. Proc. Natl. Acad. Sci. 119, e2200678119 (2022).

Wang, M. et al. Tough and stretchable ionogels by in situ phase separation. Nat. Mater. 21, 359–365 (2022).

Wang, M. et al. Glassy gels toughened by solvent. Nature, https://doi.org/10.1038/s41586-024-07564-0 (2024).

Khutoryanskiy, V. V. Hydrogen-bonded interpolymer complexes as materials for pharmaceutical applications. Int. J. Pharm. 334, 15–26 (2007).

Khutoryanskiy, V. V., Dubolazov, A. V., Nurkeeva, Z. S. & Mun, G. A. pH effects in the complex formation and blending of poly (acrylic acid) with poly (ethylene oxide). Langmuir 20, 3785–3790 (2004).

Ikawa, T., Abe, K., Honda, K. & Tsuchida, E. Interpolymer complex between poly (ethylene oxide) and poly (carboxylic acid). J. Polym. Sci. Polym. Chem. Ed 13, 1505–1514 (1975).

Bailey, F. Jr, Lundberg, R. & Callard, R. Some factors affecting the molecular association of poly (ethylene oxide) and poly (acrylic acid) in aqueous solution. J. Polym. Sci. A 2, 845–851 (1964).

Miyoshi, T., Takegoshi, K. & Hikichi, K. High-resolution solid state 13C n.m.r. study of the interpolymer interaction, morphology and chain dynamics of the poly(acrylic acid)/poly(ethylene oxide) complex. Polymer 38, 2315–2320 (1997).

Bai, H., Deng, S., Bai, D., Zhang, Q. & Fu, Q. Recent advances in processing of stereocomplex‐type polylactide. Macromol. Rapid Commun. 38, 1700454 (2017).

Smith, K., Winslow, A. & Petersen, D. Association reactions for poly (alkylene oxides) and polymeric poly (carboxylic acids). Ind. Eng. Chem. 51, 1361–1364 (1959).

Li, J. et al. Highly elastic fibers made from hydrogen-bonded polymer complex. ACS Macro Lett 5, 814–818 (2016).

Nian, G., Kim, J., Bao, X. & Suo, Z. Making highly elastic and tough hydrogels from doughs. Adv. Mater. 34, 2206577 (2022).

Bergstrom, J. S. & Boyce, M. C. Mechanical behavior of particle filled elastomers. Rubber Chem. Technol. 72, 633–656 (1999).

Chen, Z., Zhang, G., Luo, Y. & Suo, Z. Rubber-glass nanocomposites fabricated using mixed emulsions. Proc. Natl. Acad. Sci. 121, e2322684121 (2024).

Yang, C., Yin, T. & Suo, Z. Polyacrylamide hydrogels. I. Network imperfection. J. Mech. Phys. Solids 131, 43–55 (2019).

Liu, J. et al. Polyacrylamide hydrogels. II. Elastic dissipater. J. Mech. Phys. Solids 133, 103737 (2019).

Adibnia, V. et al. Bioinspired polymers for lubrication and wear resistance. Prog. Polym. Sci. 110, 101298 (2020).

Ye, Y. N. et al. Molecular mechanism of abnormally large nonsoftening deformation in a tough hydrogel. Proc. Natl. Acad. Sci. 118, e2014694118 (2021).

Zhang, H. J. et al. Tough physical double‐network hydrogels based on amphiphilic triblock copolymers. Adv. Mater. 28, 4884–4890 (2016).

Ye, Y. N. et al. Tough and self‐recoverable thin hydrogel membranes for biological applications. Adv. Funct. Mater. 28, 1801489 (2018).

Wang, S. et al. Facile mechanochemical cycloreversion of polymer cross-linkers enhances tear resistance. Science 380, 1248–1252 (2023).

Mars, W. & Ellul, M. Fatigue characterization of a thermoplastic elastomer. Rubber Chem. Technol. 90, 367–380 (2017).

Hotta, A. et al. Semicrystalline thermoplastic elastomeric polyolefins: Advances through catalyst development and macromolecular design. Proc. Natl. Acad. Sci. 103, 15327–15332 (2006).

Osada, Y. Equilibrium study of polymer–polymer complexation of poly (methacrylic acid) and poly (acrylic acid) with complementary polymers through cooperative hydrogen bonding. J. Polym. Sci. Polym. Chem. Ed 17, 3485–3498 (1979).

Acknowledgements

This work was supported by the National Science Foundation under MRSEC (DMR-2011754). Z.S. acknowledges the support of the Air Force Office of Scientific Research under award number FA9550-20-1-0397. M.W.M.T. gratefully acknowledges the financial support under the College of Engineering (CoE) International Postdoctoral Fellowship (IPF), which is jointly provided by the Ministry of Education, Singapore, and Nanyang Technological University, Singapore.

Author information

Authors and Affiliations

Contributions

X.B., Z.C., and G.N. contributed equally. X.B., Z.C., and G.N. conceived the project. X.B., Z.C., G.N., M.W.M.T., Y.K., and Z.S. designed the study and interpreted the results. X.B., Z.C., G.N., M.W.M.T., and C.A. conducted the experiments. All authors contributed to the writing of the manuscript. Y.K. and Z.S. supervised the research.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Hang Zhang and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bao, X., Chen, Z., Nian, G. et al. Unusually long polymers crosslinked by domains of physical bonds. Nat Commun 16, 4749 (2025). https://doi.org/10.1038/s41467-025-59875-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-59875-z