Abstract

Aqueous zinc-ion batteries offer sustainable large-scale storage potential with inherent safety and low cost, yet suffer from limited energy density and cycle life due to aqueous electrolyte constraints. Here, we introduce affordable, stable electrolyte (0.33 $·kg−1) incorporating minimal multi-halogen anions (Cl−, Br−, and I−) to create a high-entropy solvation structure enabling high-performance zinc batteries. Despite the small amount, the diversified mono-halogenated contact ion pair and multi-halogenated aggregate solvation structures create the unique high-entropy solvation structure, to form the lean-water halogenated interfacial environment, suppressing the hydrogen evolution reaction, while facilitating cascade desolvation. Multi-halogen additives generate diverse contact ion pairs (Zn-X, X = Cl/Br/I) with compact solvation shells accelerating ion transport. In this way, the high-entropy solvation structure breaks the trade-off between plating overpotential (energy efficiency) and plating/stripping reversibility (Coulombic efficiency). As a result, the high-entropy solvation-based electrolyte enables practical zinc metal battery with 152.2 Wh kg−1electrode for 120 cycles at lean electrolyte of 2.4 μL mg−1 and an Ah-level pouch cell is validated with high Coulombic efficiency of over 99.90% for over 250 cycles. Our findings emphasize the importance of electrolyte design for the precise control of anion-cation interactions for stable Zn/electrolyte interface and enable practical zinc metal battery with high energy and low cost.

Similar content being viewed by others

Introduction

Rechargeable aqueous zinc ion batteries with low-cost, non-flammable, and sustainable features have gained popularity in grid-scale energy storage application1,2,3,4. However, the aqueous zinc ion battery is hindered by the limited reversibility of Zn0/Zn2+ due to the parasitic reactions, including hydrogen evolution and dendrite formation. The hydrogen evolution would release flammable gas (H2) and increase the internal pressure of the cell, causing a safety concern, while the dendrite formation would result in dead Zn0, leading to low utilization of zinc anode, reducing the energy density of the cell5,6,7,8. Therefore, it is crucial to build a robust Zn/electrolyte interface against the dendrite formation and serious corrosion reactions to enable the long lifespan zinc metal battery, especially at practical conditions, where the zinc anode and electrolyte are limited.

Electrolyte design over solvation structure has been demonstrated to effectively change the Zn0 electrodeposition process. Tuning the solvation structure into a lean-water state is widely adopted since it reduces the water activity by driving water molecules from disordered and free state to coordinated state. The lean water electrolyte is usually composed of a superhigh fraction of salt (LiTFSI9,10, EMIMTSFI11, ZnCl212,13, Zn(OAc)214, etc.), polymer15,16, or gel with a very limited amount of water. They have been demonstrated to show expanded electrochemical working window, while maintaining a pretty high ionic conductivity. However, the cost of the electrolyte would rise by over 10 times due to the use of expensive salt compared to a dilute and cheap benchmark electrolyte (2 M ZnSO4, 0.32 $·kg−1)17. To design a practical zinc battery, a low-cost, while effective, electrolyte design strategy would be critical18.

In a dilute benchmark electrolyte, Zn(OH)62+ is regarded as the main solvation shell and the solvated water is regarded as a major factor for corrosion of zinc metal. By replacing the solvated water with other anions (e.g., Cl−, Br−, and I−) has been proven to be quite effective to create water-free halogenated solvation shell19,20,21 to hinder the hydrogen evolution at expense of increased overpotential in Zn plating/stripping, sacrificing the rate capability of the cell. The introduction of halogen ions would create a water-free (less) solvation shell, which inhibits the water decomposition from the solvation shell13,22. According to the charge delocalization and polarizability of ions, it is ranked in the Hofmeister series (Fig. S1). However, considering the strong Zn-X (Cl, Br, and I) bonding compared with Zn-H2O (Fig. 1a), halogen anions would reach the Zn/electrolyte interface rather than the solvated water during the desolvation process. A substantial amount of Cl− in the electrolyte would facilitate the formation ZnCl42− aggregated solvation complexes12,22, which serves as strong energy barrier for desolvation. The Zn-halide association strength weakens with the trends of Cl− > Br− > I−23,24 leads to decreased overpotentials for Zn deposition in halogen electrolyte. Despite the increased overpotentials, the strong interaction between Zn2+ and Cl− anion would facilitate the lean water interface, and therefore, result in the highest plating/stripping efficiency. The addition of chaotropic halogen is expected to enhance the hydrophobicity of Zn2+ ions. The stronger the charge delocalization and polarizability, the higher the Zn-X dissociation energy. Therefore, a trade-off between plating overpotential (energy efficiency) and plating/stripping efficiency (utilization of zinc metal) can be drawn in the halogenated electrolyte (Fig. 1b).

Entropy tuning has been regarded as a route to improve material properties such as high-entropy alloys and ceramics25, corrosion retardant cathode26, solid electrolytes27, and all temperature zinc battery electrolyte13,28. Herein, we propose a high-entropy solvation structure through introducing mixed halogen anions to break the trade-off between overpotential and Coulombic efficiency, and therefore, achieve practical energy dense zinc metal battery, while maintaining an affordable price (0.33 $·kg−1 vs. 2 M ZnSO4, 0.32 $·kg−1). The high entropy solvation electrolyte (HESE) is composed of major amounts of mono-halogenated CIP and small amount of multi-halogenated AGG and the diversity increase accounts for the entropy increase from 902.22 to 1172.43. The mono-halogenated CIP accounts for the major component, which gets rid of the high desolvation energy of the multi-halogenated AGG. Moreover, the HESE shows the smaller ion clusters due to the high amount of mono-halogenated CIP, which yields an improved diffusion rate. In this way, concentration gradients are alleviated during high-rate cycling and denser and more uniform metal deposition is achieved (Fig. 1c). Moreover, the intimate Zn-X contact ion pair promotes the lean water and I−-rich interface in the electric double layer (EDL) as revealed by in situ Raman. In this way, the water decomposition is greatly inhibited, and the I−-rich interface suggests the facile desolvation process. By taking those advantages of the HESE above, a full cell based on Zn/NVO achieved a high areal capacity of over 9.23 mAh cm−2 at low NP ratio of ~2 and lean electrolyte (E/C = 6 μL mAh−1), yielding a high specific energy of 152.2 Wh kg−1(cathode & anode). Additionally, as a proof-of-concept, the pouch cell at a practical capacity of 1 Ah sustains over 250 cycles with almost unity average Coulombic efficiency of over 99.90%.

Results

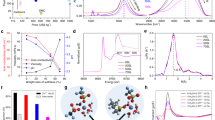

Entropy is controlled by increasing the amount of halogen anions in the electrolyte. It should be noted that, unlike traditional high-entropy materials, the composition ratios at the macroscopic level are close to each other. The proposed HESE electrolyte is composed of a mixed 0.02 M halogen anion (Cl−, Br−, and I−) system (0.06 M in total). The standard Aurbach’s method29 is first applied to compare the electrochemical response of the proposed HESE electrolyte. The trade-off between the average Coulombic efficiency (CE) and the overpotential is observed in different testing conditions, including Aurbach’s method, 5 mA cm−2, 1 mAh cm−2; 10 mA cm−2, 5 mAh cm−2; and 20 mA cm−2, 10 mAh cm−2 (Figs. 1d, S2, S3). Cl−-containing electrolyte shows the highest CEs and overpotential compared to Br− and I− containing electrolyte (Fig. 1e, f). In the HESE electrolyte, it exhibits an almost unity average CE of 99.94% at a current density of 5 mA cm−2, while the voltage hysteresis is as low as 29 mV. Even when the current density is up to 20 mA cm−2, it can still maintain a CE of 99.76% and an overpotential of 69 mV. It is important to highlight that optimal concentration (2HESE) was determined based on the cyclic stability (Fig. S4) and reversibility (Fig. S5, Table S1) test results. Persistent low overpotential (46 mV) during 1000 h cycling and high CE proved that the HESE electrolyte breaks the usual observed trade-off between the average CE and the overpotential in the halogenated electrolyte, which is expected to enable higher performance zinc ion batteries. Furthermore, it should be noted that the incorporation of halogen ions did not result in any substantial corrosive impact on the other battery components (Fig. S6).

To understand the effects of HESE in breaking the trade-off, we first gain molecular understanding through Molecular dynamics (MD). Figure 2a illustrates the 3D molecular configuration of the typical solvation structure in HESE. Here, Zn2+, H2O molecules, and anions tend to aggregate and form ion pairs or ion clusters30,31,32. In the baseline electrolyte, Zn2+ is mostly coordinated by six H2O molecules (with a minor amount of SO42−), which are consistent with the previous calculation results33,34. The dominant solvation structures are Zn-6H2O and Zn-5H2O-SO42−, accounting for 30.3% and 62.4%, respectively. In HESE, more than 18 kinds of solvation structures are observed (Fig. 2b, Tables S2, S3). Here, we classified those solvation structures into multi-halogenated aggregate (AGG), mono-halogenated contact ion pair (CIP), and non-halogenated solvation structure. In HESE, the majority of the solvation structure is composed of mono-halogenated CIP (~72%), while multi-halogenated AGG only accounts for ~23%. The introduced halogen anion participates in most (over 95%) of the Zn2+ primary solvation structure due to the strong interaction between Zn2+ and X−. The introduction of Cl−, Br−, and I− in the HESE leads to greatly increased varieties (from 2 to 18) of primary Zn2+ solvation shell. The electrostatic potential and formation energy data for certain characteristic solvation structures have been calculated using Density Functional Theory (DFT) and are presented in detail within Table S4. Here, the diversified solvation structure in HESE suggests the increased components in the HESE system. Entropy primarily refers to configurational entropy (Sconf), where the introduction of multiple components increases local disorder and thus enhances Sconf:

where R is the ideal gas constant, and xi is the molar fraction of the i-th component35. Based on the calculation, HESE showed a configurational entropy value of 1172.43, higher than the baseline electrolyte (902.22) in Fig. S7, suggesting the high entropy state of HESE with various halogenated Zn2+ primary solvation shells.

a 3D snapshots of HESE and partially enlarged snapshots for the solvation structure of Zn2+. b Distribution of first solvation structures. c Zn K-edge XANES spectra, d Wavelet transform contour plots of Zn K-edge at R-space, and e EXAFS analysis of the k-space spectrum. f The proportion of three types of V-O-H bonds obtained from Raman spectral fitting. g The radial distribution functions and coordination number of Zn2+-O, h Average Zn2+ cluster sizes at 300 K. i Wide-angle X-ray scattering (WAXS) curves. j The Zn-ion self-diffusion coefficient (DZn) means squared displacement collected from MD simulations in two electrolyte solutions. k A summary of image snapshot with side and frontal view of the anode-electrolyte interface of HESE at negative potential, zero potential, and positive potential, respectively.

The diversified solvation structure is further validated by the experimental results. The Zn K-edge X-ray absorption near-edge structure (XANES) spectra of Zn foil and different electrolytes are compared in Fig. 2c. The extended Zn K-edge XANES spectra (inset) reveal a higher average charge density in the solvation shell near Zn compared to the base electrolyte in the HESE, indicating changes in the local solvation shell36, which is due to the multi-solvation structures of AGG and CIP formed by different halogen ions. The Fourier-transformed extended X-ray absorption fine structure (FT-EXAFS) spectra in Fig. 2d display the different coordination scattering of Zn-O, Zn-Cl, Zn-Br, Zn-I, displaying abundant coordination of Zn2+. The reduced peak intensity indicates a decrease in Zn-O coordination, indicating the effect of H2O molecules being excluded. The splitting peak within 1.3–2 Å indicates distinct atomic spacing between Zn2+ and solvated species, which is the solvated shell with the participation of heterogeneous anions (Fig. 2e). The above characterization elucidates the chaotic zinc coordination environment, which increases the entropy of the electrolyte. The O-H stretching vibrations of the electrolytes in the Raman spectra in Figs. 2f and S8 in the range of 2800 to 3800 cm−1 are fitted into three peaks, corresponding to strong, medium, and weak hydrogen bonds (H-bonds). MD results also show that the number of hydrogen bonds in the three charge states fluctuates with time, which reflects the dynamic change of intermolecular interaction during the charging and discharging process of the electrolyte (Fig. S9). In the HESE, the proportion of strong H-bonds is lower (43.07% vs. 49.03%), while the strength of weak H-bonds is higher than in the baseline electrolyte (25.99% vs. 22.98%). This indicates that the introduction of halogens as structure breakers effectively disrupts the interactions between H2O molecules. In addition, the effects of adding a single halogen ion of the same concentration (0.06 M) on the H-bond in the electrolyte were also analyzed by Raman spectrum (Fig. S10). According to the fitting results, a single halogen anion can break some strong H-bonds, reduced from 49.03% of baseline electrolyte to 42.33% (Cl−), 42.52% (Br−), and 45.11% (I−), respectively, converting them into medium-strength hydrogen bonds. However, at the same concentration, the proportion of weak H-bonds is still lower than HESE, further indicating stronger interactions between mixed halogen anions and H2O molecule.

The average solvation structure size is further compared. In the baseline electrolyte (Fig. S11), the radial distribution functions (RDFs) and coordination number distribution functions (CNDFs) reveal that the bonding distance of Zn2+-solvated H2O is approximately 0.2 nm, with an average coordination number of approximately 5.63 (Fig. 2g). The average number of H2O, Cl, Br, and I in the solvation shell is approximately 3.10, 0.94, 0.40, and 0.37, respectively (Fig. S12). Meanwhile, in electrolytes with mono-halogen anion (such as I−), the coordination numbers of H2O and I are 3.76 and 0.68, respectively (Fig. S13). This kind of contact ion pair between Zn2+ and halogen anions results in a denser contact ion solvation shell37,38, resulting in a smaller solvation shell (0.706 nm vs. 1.125 nm, at 300 K). Besides, the average size of Zn2+ clusters decreased from 12.39 (baseline) to 9.15, which is even smaller than mono halogen electrolyte (10.86) (Figs. 2h and S14). The influence of the anions on the solvation shell of Zn2+ was investigated using XAFS analysis. Furthermore, this is consistent with the WAXS spectra in Fig. 2i. The diffusion coefficient is directly related to the cluster size, and the decrease in cluster size leads to a reduction in the hydrodynamic radius and an increase in the ion diffusion coefficient. The results of the probability distribution function (PDF) analysis (Fig. S15) indicate that the bonding length between Zn2+ and H2O in the HESE increases from 0.76 to 0.85 Å, which also suggests a weakened interaction between Zn2+ and H2O molecules in the first shell39. The difference in scattering intensity at low Q range in the WAXS spectra indicates a higher concentration of large-sized ion clusters in the baseline electrolyte, while the diversity of anions in the HESE reduces the presence of large-sized clusters40,41.

The large number of mono-halogenated CIPs compared to the multi-halogenated AGGs is expected to promote the desolvation energy penalty. This is also verified by the experimental results by the Arrhenius equation according to the EIS curves under the temperature of 30–70 °C. The HESE shows an apparent energy barrier of 24.22 kJ mol−1, which is much lower than the baseline electrolyte (34.59 kJ mol−1) in Fig. S16. In summary, the HESE exhibits high entropy and diversified solvation configurations with intense mono-halogenated Zn-X CIPs, promoting the facile desolvation process42,43. Furthermore, the varieties of the HESE are expected to favor the general trend of mixing, which is applicable to our electrolyte44,45. Therefore, the HESE with diverse anions tends to have high ion migration rates thermodynamically46. The self-diffusion rate of zinc ions in the HESE reaches 1.96 × 10−4 cm2 S−1, while the corresponding value in the baseline electrolyte is only 0.89 × 10−4 cm2 S−1 (Fig. 2j), which is consistent with experimental data (Fig. S17) where 10 % enhancement in the ionic conductivity is observed in HESE. Moreover, the Zn2+ transference number has increased to 0.568 compared to the baseline electrolyte (0.367), which favors the fast zinc ion transport kinetics (Fig. S18).

The plating/stripping behavior of Zn2+ to Zn0 is expected to be influenced by the diversified solvation structure from the HESE. Cyclic voltammetry (CV) analysis of the Zn||Cu cell revealed that halogen anions in the electrolytes reduce nucleation overpotential, thereby enhancing nucleation kinetics. The HESE system showed a more pronounced effect, with a larger enclosed area and peak current in the HESE indicating increased active nucleation sites. The overpotential of the mixed anionic electrolyte was significantly lower (∆V = 47 mV) than the baseline (∆V = 68 mV), decreasing with halide binding strength (Cl > Br > I, ∆V = 66, 63, and 57 mV, respectively) (Fig. S23). These findings suggest that the competitive coordination of Cl−, Br−, and I− activate additional solution species, improving the rate capability for zinc plating/stripping in mixed anionic electrolytes.

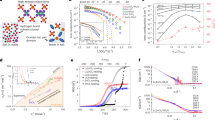

Chronoamperometry (CA) at −150 mV was applied to study the nucleation and growth kinetics of Zn (Fig. S24). The current density of the zinc anode in the baseline electrolyte consistently increased within 500 s, demonstrating preferential two-dimensional (2D) diffusion paths due to vertical zinc growth. This self-amplifying deposition behavior toward the minimum surface energy direction exacerbates Zn dendrite growth. In contrast, in the HESE, the increase in current density only persisted for a brief nucleation period, with a stable low current density indicating uniform zinc deposition. Besides, the fitting of the typical 3D nucleation models based on jm and the corresponding tm to the experimental results was performed in Fig. 3a, b. Initially, the increased current value reflects the expansion of the electroactive region due to the increase in zinc nucleus size and the generation of new nuclei. The subsequent current decrease toward steady-state indicates a diffusion-controlled growth process due to nucleus overlap and diffusion zone merging. The observed nucleation behavior in the baseline electrolyte correlates closely with the predicted response from the 3DI model, where nucleation sites are relatively limited. Conversely, the nucleation behavior observed in the HESE follows a different pattern, initially exhibiting characteristics of the 3DI model, and transitioning to a mixed mode controlled by both 3DI and 3DP when t > tm. In this scenario, smaller particle sizes are typically formed, and the model fitting results align well with the morphological differences observed in ex situ SEM analysis (Fig. 3c). The morphology of rapidly formed zinc nuclei is mainly determined by the nucleation process. In the baseline electrolyte solution, the nucleation of Zn tends to be random, occurring only at grain boundaries or in locally energy-favored area. As the deposition progresses, these sparse and rare zinc nuclei continue to grow and merge, resulting in the formation of distinct protrusions, leading to the typical 3D growth of the zinc dendrite. The zinc dendrites are prone to exacerbating corrosion reactions. The uneven distribution of initial nucleation sites and the early growth process directly contribute to the tendency of localized Zn deposition due to the higher electrostatic force from Zn2+ 47. In contrast, in the HESE, time-resolved SEM images show that the initial nucleation sites are well dispersed, and the surface deposition appears granular, almost covering the entire surface at 20 s. The abundant Zn nuclei guide the subsequent growth process, and as adjacent Zn nuclei meet each other, they gradually merge into a dense Zn deposition layer that covers the entire substrate surface. Macroscopic digital photographs of the nucleation and growth process can be found in Fig. S25. The incorporation of Zn-X (X = Cl, Br, and I) would intrinsically decrease the electrostatic force, facilitating the more active sites from zinc plating and moreover, the halogen ion is believed to promote the 2D growth of zinc through formation of parallel zinc sheet on the zinc plate, thereby inhibiting the dendrite formation. The rich nucleation sites and 2D growth mechanism would also decrease overpotential, as reflected through transient currents48. The differences in nucleation patterns will inevitably restructure the localized electrochemical environment, thereby influencing subsequent growth behavior. A schematic representation of the processes is presented in Fig. 3d.

Experimental dimensionless transients in comparison with the theoretical nucleation models of a baseline and b HESE solution. c Time-series SEM images of Zn in two electrolytes about Zn nucleation and initial growth. d Schematic illustration of the Zn nucleation and growth mechanisms. Surface flatness mapping of deposited zinc in e baseline and f HESE solution. In situ Raman spectra of the Zn/electrolyte interface in HESE during g plating and h stripping. i SEM images of plated Zn on Cu (A–E) in baseline electrolyte and (F–J) in HESE with a plating capacity from 0.2 mAh cm−2 to 5 mAh cm−2. In situ microscopy images of the Zn plating process in j baseline electrolyte and k in HESE at 10 mA cm−2. l, m Cross-section SEM images of 10 mAh cm−2 deposited zinc in baseline electrolyte and HESE, respectively.

Figure 3e, f illustrate the surface characteristics of zinc deposits. In the baseline electrolyte, the irregular red protrusions on the surface reflect uneven deposition, resulting in island-like height variations. The poor initial nucleation state leads to completely different zinc deposition morphologies. Due to the influences of the dissolution process, hexagonal zinc with a diameter of about 5–10 μm in vertical or inclined states grows randomly and sparsely in the baseline electrolyte, inducing dendrites. On the contrary, the rapid transport kinetics and multi-halogen ion-mediated lean-water interface in HESE result in dense stacking of zinc deposition with increasing capacity, while its size is smaller, which is related to smaller zinc ion clusters. Furthermore, regardless of the deposit substrate or the current density used, the morphologies and distribution coverage of the deposited zinc in the two electrolytes exhibit consistent patterns (Figs. S26, S27).

The interfacial solvation structure of the zinc anode is then tracked by in situ Raman spectroscopy to track material specificity at the interface. The initial Raman spectra of the two electrolytes are shown in Fig. S28, which were used to determine the characteristic Raman peaks that need special attention. As shown in Figs. 3l, m and S29, the in situ Raman peak at ~160 cm−2 corresponds to the solvation structure characteristic peak of [ZnClx]2−x 49, which is not surprising since the Zn-Cl bonding strength is strongest compared to Zn-H2O. The intensity at the interface gradually appears with the increase of deposition time, while it becomes stable afterward, indicating the major role of Zn-Cl solvation at the interface and therefore, a lean-water interface. The time interval may come from the low concentration of halogen anions in the electrolyte. Meanwhile, during stripping, the [ZnClx]2−x structure gradually disappears, suggesting the depletion of Zn-related species due to the electrostatic effect. Moreover, the Raman peak at ~3000–3800 cm−2 corresponds to v-O-H bonds (Fig. S30), and its variation reflects the decomposition of free water in the electrolyte that triggers the hydrogen evolution reaction (HER). In the baseline electrolyte, a red shift of v-O-H was observed during the Zn stripping process, and the intensity of S-H (Strong H-bond) increased with the solvation of Zn2+. On the contrary, during the plating process, a blue shift of v-O-H was observed (Fig. S31), accompanying the decrease of the S-H contribution, which suggests that the plating of zinc would minimize the Zn2+ concentration and trigger the water-rich zone at interface50. The formation of the water-rich zone during the plating process is regarded as having a major role in the corrosion of zinc metal. However, in the HESE, the intensity of S-H is greatly stronger compared to the benchmark electrolyte (below 29%) and more importantly, the intensity remains constant at ~34% from 6 to 30 min (Fig. S32). Higher S-H accounts for the reduced hydrogen evolution. It is believed that the phenomenon that frees HESE from the water-rich zone in HESE suggests that fast zinc ion transport in the diverse solvation structure in HESE51,52. This is further verified inhibited HER in HESE with benchmark baseline electrolyte using LSV. Under the same current density, the potential of HER shifted from −1.688 to −1.738 V (vs. Zn/Zn2+) in baseline electrolyte and HESE, respectively (Fig. S33), indicating the suppressed HER (Fig. S34). In situ pH testing (Fig. S35) of the charge and discharge process demonstrated the inhibition of side reactions by the HESE electrolyte during the cell cycle, which was manifested by smaller pH fluctuations (from 4.41 to 4.49) compared to the baseline electrolyte (from 4.27 to 4.61). This suggests the minimum corrosion reaction in HESE. Based on the observations above, the HESE electrolyte provides a lean water interface through the cascaded desolvation process to [ZnClx]2−x, and fast Zn2+ ion transport to inhibit the water-rich zone during plating, which suppresses the HER and corrosion reaction in HESE.

We further understand the nucleation and growth behavior of Zn on Cu substrates in HESE. Figure S36 shows characteristic voltage distribution maps of the zinc plating process on Cu substrates under different electrolytes. Compared to the baseline electrolyte (−270 mV), the nucleation overpotential in the HESE is reduced to approximately −149 mV, due to the smaller ion clusters leading to lower energy barriers for zinc deposition, thereby promoting more uniform, smaller, and denser zinc nuclei. SEM observations were conducted on the sampling points indicated in the voltage distribution maps, yielding Fig. 3g. In the baseline electrolyte, the obtained zinc deposits consist of numerous loosely distributed and separated lamellar structures, with the size of these lamellar structures increasing as the amount of zinc deposits increases. The newly deposited Zn preferentially deposits on partially formed lamellae, which is the primary cause of dendrite formation and potential short-circuiting. The morphology of the zinc deposit in the HESE is markedly different from that in the baseline electrolyte. As the amount of zinc deposition increases, the size of the zinc lamellae increases, while the nano-scale lamellae formed are smaller and densely packed in the deposition interstices, rather than expanding upward. This demonstrates that the high-entropy environment regulates the uniform distribution of Zn2+ and significantly increases the preferred sites for Zn deposition on the electrode surface. These findings emphasize the importance of initial deposition quality for subsequent electroplating/reversible stripping processes. Then, the zinc deposition process was observed using an in situ optical system at a current density of 10 mA cm−2. In the baseline electrolyte, as the plating capacity gradually increased, the initially uneven deposition led to the formation of disordered Zn dendrites (Fig. 3h). In contrast, in HESE, a dense and uniform Zn surface was obtained (Fig. 3i). The final morphology of the deposited zinc is shown in Fig. 3j and k, respectively. The morphology of zinc deposition is an important determinant of cyclic stability, and the above loose and dense deposition morphologies, as well as the crystal face orientation of deposited zinc, were further verified in cross-sectional SEM images (Fig. S37) and ex situ XRD (Fig. S38) at different deposition amounts. Mossy-like deposition in the baseline electrolyte will lead to dendrites and rampant side reactions, ultimately causing short circuits. The deposition of zinc in HESE is dense, also effectively balances the interface concentration field and zinc ion flux, achieving preferred orientation and high stability.

A practical zinc metal battery requires a high depth of discharge (DOD > 50%); thus, the cycling performance at a demanding 68.4% DOD was investigated to verify practicability. The cell exhibited cycling performance within 220 h at a current density of 40 mA cm−2 and an areal capacity of 20 mAh cm−2 (Fig. 4a). The cycling stability of Zn||Zn symmetric batteries under conventional conditions has also been tested and compared (Figs. S39, 40). At a higher rate of 1 mAh cm−2 and 10 or 20 mA cm−2, the Zn||Zn symmetric cells containing the HESE could cycle over 10,000 cycles, accumulating an areal capacity of 10 Ah cm−2 (Figs. 4b, S41). Encouragingly, under diverse testing conditions, the HESE consistently demonstrated outstanding performance, surpassing the results of most previously reported Zn||Zn batteries53,54,55,56,57,58,59,60,61,62,63,64,65,66,67 (Fig. S42, Table S5). These results indicate that the unique, diverse solvation configuration and smaller zinc ion clusters effectively enhance the reversibility and utilization efficiency of the Zn anode, achieving uniform Zn deposition during repeated stripping/plating processes.

Galvanostatic cycling of Zn||Zn symmetric cells in different electrolytes at a 40 mA cm−2 and 20 mAh cm−2 (DOD = 68.4%), and b 20 mA cm−2 and 1 mAh cm−2. c Coulombic efficiencies and time-voltage profiles of Zn||Cu cells using different electrolytes at 1 mA cm−2 and 1 mAh cm−2 and d 5 mA cm−2 and 1 mAh cm−2. e Coulombic efficiencies of the Zn||Ti cells at 20 mA cm−2, 10 mA h cm−2.

Further investigation was conducted into the cycling reversibility and stability of the zinc anode. Zn||Cu asymmetric cells were assembled and tested at current densities of 1 or 5 mA cm−2 with an areal capacity of 1 mAh cm−2. The Zn||Cu half-cell in HESE exhibited a cycle life of over 1400 cycles (3000 h), with an average CE of 99.67% (Fig. 4c), whereas the cell with baseline electrolyte lasted only around 60 h. Notably, the cell voltage with the HESE remained stable throughout cycling. At 5 mA cm−2 and 1 mAh cm−2, the cell with the baseline electrolyte operates for 450 cycles, with significant CE fluctuations, a sign of zinc corrosion68. In contrast, the Zn||Cu cell with the HESE exhibited an average CE as high as 99.94% over more than 7800 cycles with a low voltage hysteresis of 63 mV (Fig. 4d). Furthermore, the results under other conditions (40 mA cm−2, 10 mAh cm−2) are shown in Fig. S43, the cell cycled 250 times (CPC = 2500 mAh cm−2) with an average CE of 99.83%. Comparison based on the average CE and cumulative capacity index showed the state-of-the-art performance53,54,55,56,57,58,59,60,63,65,66,69 (Fig. S44 and Table S6). To further verify the reversibility of the zinc anode in HESE, we assembled Zn||Ti asymmetric cells using a Ti substrate. As shown in Fig. 4g, even at high current densities of 20 mA cm−2 and 10 mA h cm−2, the cell delivered a high CPC of 2400 mAh cm−2 with an average CE of 99.64%. Figure S45 and Table S7 show a comparison of the cycling reversibility performance of the Zn||Ti cell with other literature reports58,62,65,67,70,71,72,73. Undoubtedly, regardless of whether Cu or Ti electrodes were used, the HESE significantly improved the CEs, especially at high current densities.

The HESE is further evaluated at full cell configuration (both coin cell and pouch cell) to estimate the practicability. NaV3O8 (NVO) nanosheets were selected as the cathode material (Fig. S46). High mass loading (19.0 mg cm−2) of NVO (Fig. S47) is used to achieve a commercial-level battery with an areal capacity over 2 mAh cm−2. To achieve a low N/P ratio of approximately 1.52, a thin zinc foil of 20 μm (11.7 mAh cm−2) is used. In the practical condition, the Zn||NVO full cell with HESE achieved 80.4% capacity retention after 1500 cycles at 4 A g−1, while the cell using baseline electrolyte failed within 300 cycles (Fig. 5a). Despite the slight improvement compared with the baseline electrolyte (16.1 mAh g−1), the full cells in HESE show the highest capacity retention (60 % in Fig. S48) for 2000 cycles at 1 A g−1 compared to the single halogen component as well as baseline electrolyte. To further showcase the advantages of HESE, the loading of the cathode electrode material is further increased to 37 mg cm−2, yielding a high areal capacity, with a thickness of approximately 400 μm (Fig. S49) while the electrolyte is limited to a smaller amount (E/C = ~6 μL mAh−1). A high areal capacity of over 9.23 mAh cm−2 at 1 A g−1 is achieved with capacity retention of 93.0% after 120 cycles (Fig. 5b), representing the state-of-the-art performance (Table S7). Compared to state-of-the-art performance53,54,55,56,57,58,64,66,70,74,75, which typically employ lower loadings (<3 mg cm−2) and excess zinc foil, resulting in high NP ratios (>50:1) and low weight energy densities (<10 Wh kg−1), the obtained data in this study are at an advanced level in Fig. 5c, where high-loading cathodes and thin zinc anodes are used for the full cell. Table S8 summarizes and compares the long-term cycling performance of the cells at different N/P ratios. By limiting the mass of each component, the energy density of the cell would reach 152.2 Wh/Kgelectrode and 57.6 Wh/Kgelectrode+electrolyte, which represents the state-of-the-art performance (Fig. 5d and Table S9). The failure of the baseline electrolyte is characterized by ex situ SEM of the zinc anode. The pulverization of the zinc plate from the uncontrolled dendrite growth at high DOD is the major problem (Fig. 5e). In the HESE, a dense and smooth deposition layer facilitates the deeply cycled zinc anode.

a Long-cycling performance of Zn||NVO coin cell at 4 A g−1. b Cycling stability of the Zn||NVO cell under harsh conditions (mass loading of 37 mg cm−2, E/C = ~6 μL mAh−1), the inset shows two cell models. c Dependence of energy density on N/P ratio in Zn||NVO full cell. d Comparison of the proposed Zn||NVO cell with other reported low N/P and E/C ratio cells. e SEM images of zinc anode after 200 cycles. f Rate performance of the Zn||NVO cell (mass loading of 19 mg cm−2, N/P = ~1.52) in two electrolytes. g CV curves of Zn||NVO full cell at 0.1 mV s−1. h, i DRT fitted curves of Zn||NVO full cell. j The cycle performance and k Ah-level multi-layer pouch cell model using HESE.

The rate performance of the full cells shows discharge of specific capacities of 371.0, 293.6, 256.5, 215.4, 157.7, and 88.2 mA h g−1 at specific currents from 0.1 to 10 A g−1, and a capacity recovery of 359.0 mA h g−1 upon returning to 0.1 A g−1 (Fig. 5f). The HESE exhibited stronger rate capability than baseline electrolyte, especially at high current densities, demonstrating higher current adaptability. Figure 5g shows that the full cell using the HESE exhibits broader redox peaks and smaller polarization compared to the baseline electrolyte, from 256/233 mV reduced to 210/195 mV, indicating that the energy storage process has faster reaction kinetics. Based on the cyclic voltammetry (CV) curves at different scan rates (Fig. S50), paired redox peaks were observed at all scan rates, attributed to the vanadium reactions. The b values of the four peaks were 0.614, 0.869, 0.670, and 0.816, indicating that the electrochemical process is jointly controlled by capacitive and diffusion behaviors. The DRT measurements further demonstrated that the full cell assembled with the HESE displayed smaller semicircles in the high-frequency region, corresponding to lower charge-transfer resistance and indicating fast electron transport capability, which allows for faster zinc plating/stripping and ion diffusion (Figs. 5 h, i, and S51). As illustrated in Fig. S52, after 48 h of resting, the capacity retention of the Zn||NVO battery using a HESE (97.4%) is higher than that of the battery using a baseline electrolyte (87.2%). Further extending the rest time to 72 h and 96 h, the capacity retention remains as high as 91.8% and 86.4%, respectively, indicating effective control of the self-discharge rate in HESE and lower capacity loss caused by spontaneous side reactions.

Furthermore, to validate the practical potential of HESE, multi-layer pouch cell with a size of 8.5 × 8.5 cm was assembled (Fig. 5j, k), the pouch cell (Fig. S53) with a cathode electrode loading of 28.1 mg cm−2 provided an initial capacity of 1.0 Ah without any ballooning phenomenon after 250 cycles. The manufacturing cost consumption of HESE is evaluated based on the current market price of materials (Table S10), the results of this analysis show that the electrolyte has a comparatively low cost (0.33 $·kg−1).

Discussion

In summary, we successfully introduced mixed halogen anions to create a high-entropy solvation structure with large proportions of mono-halogenated contact ion pairs (CIPs) to break the trade-off between the overpotential and average CE in common halogenated electrolyte. The HESE breaks the trade-off by creating mono-halogenated CIPs instead of multi-halogenated AGGs to eliminate the high desolvation energy of Zn-X complexes. Moreover, the HESE creates a lean water interface with I−-rich electric double layer interface to block the active water molecules, thus suppressing the HER and enabling the high CE. In this way, the HESE realizes a simultaneous reduction in plating overpotential and enhancement CE, thereby achieving practical energy-dense zinc metal battery. By taking advantage of the high-entropy electrolyte, full cell based on Zn/NVO achieved a high areal capacity of over 9.23 mAh cm−2 at a low N/P ratio of ~2 and lean electrolyte (E/C = 6 μL mAh−1), yielding a high energy density of 152.2 Wh/kg(anode+cathode). Additionally, as a proof-of-concept, the pouch cell at a practical capacity of 1 Ah could sustain over 250 cycles with near-unity average Coulombic efficiency exceeding 99.90%. This work provides a vast unexplored design space for high-entropy electrolytes, stimulates efforts to develop other HESEs, further advances other facets of high-performance electrolytes, and accelerates practical deployment of zinc metal batteries.

Methods

Preparation of the electrolytes

2 M ZnSO4 electrolyte was prepared by dissolving zinc sulfate (ZnSO4·7H2O, Sinopharm Chemical Reagent Co., Ltd., ≥99.5%) into deionized (DI) water. For the high entropy solvation electrolyte (HESE), different amounts of ZnCl2, ZnBr2, and ZnI2 (abbreviated as Ad.) were added to the 2 M ZnSO4 electrolyte. The concentrations of Ad. in the corresponding electrolytes were calculated at 0.01, 0.02, 0.03, and 0.05 M (noted as 1HESE, HESE, 3HESE, and 5HESE), respectively. The electrolyte for Zn||NaV3O8 full cells was 2 M ZnSO4 aqueous solution with/without 0.02 M Ad additive (2HESE).

Preparation of the electrodes

2 g of V2O5 powder was added to 60 mL of 2 M NaCl aqueous solution. After stirring for 72 h at 30 °C, the suspension was washed with deionized water and alcohol 3 times. Finally, the black red NaV3O8 powder was obtained by freeze-drying for 3 days. The powder was ground repeatedly before use until there was no agglomeration/particle present.

The cathode slurry was composed of 70 wt.% as-prepared active material, 20 wt.% conductive agent (super P, Timcal) and 10 wt.% polymer binder (60 wt.% Polytetrafluoroethylene preparation, Aladdin). Then the cathode was prepared by mixing and pressing, and was dried at 80 °C under vacuum for 12 h. The mass loading of the active materials is about 10–40 mg cm−2 by controlling different thicknesses. The anode was served by Zn foil (φ = 12 mm) only. To achieve different N/P ratios, the zinc foil thickness was replaced with 10, 20, and 50 μm.

For Zn||Cu and Zn||Ti asymmetric batteries, both copper and titanium foils have a diameter of 16 μm and a thickness of 10 μm.

Materials characterization

Scanning electron microscope (SEM, JEOL JSM-7500F) was used to acquire the morphology of materials and elemental mapping images. The XRD (Burker, D8 Advance) tests were conducted to analyze the crystallographic structure of samples with Cu Kα radiation in steps of 0.02°. Raman spectra were collected by a Renishaw Raman RE01 utilizing a 633 nm laser. The SAXS testing instrument is Xeuss 2.0 (Xenocs, France), with a light tube power of 30 W and a wavelength of 1.54189 Å, Detector Pilatus 3 R 300 K, single pixel size 172 μm; the distance between the detector and the sample was 98 mm; exposure time of 300 s. XAS measurements were collected at beamline 12-BM of the Advanced Photon Source (APS) at Argonne National Laboratory (ANL). PDF data were collected at beamline 11-ID-C of APS at ANL.

Electrochemical measurements

All testing CR2016-type coin cells were assembled in an open-air environment by using a glass fiber filter (φ = 19 mm, GF/A, Whatman, Canrd Technology Co. Ltd) as the separator. The electrolyte amount used in each cell was 100 μL, unless otherwise specified. The electrochemical performance of the batteries was conducted on the Neware battery tester (According to literature reports12, the accuracy of the testing system was calculated, when we test the average CEs value of 50 cycles, whereas if a power law of the square root was applied, the error is 0.03889%.) and an electrochemical workstation (Versa, STAT-3). All cycling data were acquired from a minimum of 3 parallel cells per electrolyte formulation and 2 independent electrolyte batches. For Zn||NaV3O8 full cells, CV was tested in the voltage range of 0.3–1.6 V (vs. Zn2+/Zn) at different scan rates. LSV was measured using Zn as working electrode, platinum wire electrode as counter electrode, Hg/KCl (vs. SCE) as reference electrode at a scan rate of 1 mV s−1 in 1 M Na2SO4. Chronoamperometry (CA) plots were carried out with the abovementioned three electrodes at an overpotential of −150 mV and a duration of 200 s. EIS spectra were recorded with a frequency ranging from 0.1 Hz to 100 kHz (seven data points per decade of frequency) with an amplitude of 5 mV under the stable open-circuit voltage condition.

The Zn2+ transference number was obtained according to the typical Evans method, which should be described as the following formula (2):

Where I0/Is and R0/Rs represent the initial/final current density and charge-transfer resistance before and after the polarization test, ΔV (20 mV) is the constant polarization potential for the chronoamperometry test.

Current transient curve was measured by the chronoamperometric technique with three electrode cells with a Zn metal reference. Cu-based conventional electrodes were applied as working electrodes to avoid the influence of the direct growth current of the original Zn crystal on the total current. 1 M Na2SO4 (introduced to balance concentration polarization during Zn plating) and 0.1 M ZnSO4 with/without 0.02 M Ad. aqueous electrolytes were applied as electrolytes. The experiment was carried out by stepping the potential from open circuit potential to different potentials. The original curves were reported to determine the maximum point and further plot (I/Im)2 to t/tm dimensionless curves. The dimensionless curves were fitted with theoretical instantaneous (3DI) and progressive (3DP) nucleation curves described by the Scharifker-Hills’ models described in the following Eqs. (3–4)48.

Where Im and tm are the maximum current density and its corresponding time.

DRT analysis

Distribution relaxation times (DRT) from the EIS data were calculated by MatlabR2023b with a toolbox of DRT-TOOLS developed by the research group of Professor Francesco Ciucci. DRT-TOOLS is freely available from the following site: https://github.com/ciuccislab.

Molecular dynamics (MD) simulations and DFT methods

The solid-liquid interface calculations for 2 M ZSO/0.02 M (ZnCl2, ZnBr2, ZnI2) aqueous solution on Zn(002) surface were conducted with COMPASS III force field using the Forcite Module in Materials Studio (MS) 2020. The dimensional lengths of the rectangular Zn(002) slab are 42.64 × 41.54 Å in plane, which contains 5 layers of Zn. 2 M ZSO/0.02 M (ZnCl2, ZnBr2, ZnI2) aqueous solution model is composed of 400 ZnSO4, 40 ZnCl2, 40 ZnBr2, 40 ZnI2 and 4000 H2O molecules in a rectangular box with length scales of 42.64 × 41.54 × 38.31 Å. After geometry optimization, the aqueous solution was placed on the Zn (002) surface. The voltage was controlled by adjusting the charge density of the top layer Zn. All MD calculations were performed under the NVT ensemble (T = 298.0 K) with a time step of 1 fs and a total simulation time of 800 ps, during which simulation trajectories were recorded every 8000 steps. The running time was long enough for the system energy and temperature to reach stability. The temperature was controlled by a Nose-Hoover thermostat. The Ewald scheme and atom-based cutoff method (i.e., a radius of 12.5 Å) were applied to treat electrostatic and van der Waals (vdW) interactions, respectively. The concentration profiles of Zn2+, Cl−, Br−, I− and H2O along the perpendicular direction were analyzed. The solid-liquid interface snapshots were displayed. The criteria for hydrogen bond length are less than 2.7 Å and for angle is more than 120°.

The electrostatic potential (ESP), formation energy and size of solvation sheaths were respectively calculated by DMol3 module in Materials Studio (MS) 2020. Firstly, the generalized gradient approximation (GGA) with Perdew–Burke–Ernzerhof (PBE) exchange-correlation functional was employed to fully relax each solvation structure. The double-numeric quality basis sets with polarization functions were used. The iterative tolerances for energy change, force and displacements were 1 × 10−5 Ha, 0.002 Ha Å−1 and 0.005 Å, respectively. In the self-consistent field (SCF) procedure, 10−6 a.u. was used for the convergence standard electron density. After structure optimization, single point energy calculation was executed, and meanwhile, electron density and ESP were outputted. The size of each solvation sheath was calculated by Atom Volumes and Surfaces tool in MS. The formation energies Ef were calculated according to the following Eq. (5):

where ESS, EZn2+ and EB are the energies of the solvation structure, isolated Zn2+ and solvents or anions in the solvation sheath, respectively.

The number of atoms or molecules contained in different electrolyte systems of MD simulation is shown in Table 1.

Data availability

All data that support the findings of this study are presented in the manuscript and Supplementary Information, or are available from the corresponding author upon request. Source data are provided with this paper.

References

Liang, Y. & Yao, Y. Designing modern aqueous batteries. Nat. Rev. Mater. 8, 109–122 (2023).

Chao, D. et al. Roadmap for advanced aqueous batteries: from design of materials to applications. Sci. Adv. 6, eaba4098 (2020).

Liu, S. et al. Design of electrolyte for boosted aqueous battery performance: a critical review and perspective. Appl. Phys. Rev. https://doi.org/10.1063/5.0140107 (2023).

Nie, W. et al. Design strategies toward high-performance Zn metal anode. Small Methods 8, 2201572 (2024).

Duan, T. et al. A multifunctional Janus layer for LLZTO/PEO composite electrolyte with enhanced interfacial stability in solid-state lithium metal batteries. Energy Storage Mater. 65, 103091 (2024).

Nie, W. et al. Oriented-electrochemical etching of Zn crystal edges in deep eutectic solvent for enhancing stability and reversibility of Zn anodes. Adv. Funct. Mater. 34, 2403305 (2024).

Ji, X. & Nazar, L. F. Best practices for zinc metal batteries. Nat. Sustain.7, 98–99 (2024).

Chang, L. et al. Innovative zinc anodes: advancing metallurgy methods to battery applications. Small 27, 2408124 (2024).

Wang, F. et al. Highly reversible zinc metal anode for aqueous batteries. Nat. Mater. 17, 543–549 (2018).

Suo, L. et al. Water-in-salt” electrolyte enables high-voltage aqueous lithium-ion chemistries. Science 350, 938–943 (2015).

Liu, C. et al. Electrochemical hydrophobic tri-layer interface rendered mechanically graded solid electrolyte interface for stable zinc metal anode. Angew. Chem. Int. Ed. 63, e202318063 (2024).

Jiang, H. et al. Chloride electrolyte enabled practical zinc metal battery with a near-unity Coulombic efficiency. Nat. Sustain.6, 806–815 (2023).

Yang, C. et al. All-temperature zinc batteries with high-entropy aqueous electrolyte. Nat. Sustain.6, 325–335 (2023).

Dong, D., Wang, T., Sun, Y., Fan, J. & Lu, Y.-C. Hydrotropic solubilization of zinc acetates for sustainable aqueous battery electrolytes. Nat. Sustain.6, 1474–1484 (2023).

Yang, J.-L., Yang, P., Xiao, T. & Fan, H. J. Designing single-ion conductive electrolytes for aqueous zinc batteries. Matter 7, 1928–1949 (2024).

Chen, Z. et al. Polymer hetero-electrolyte enabled solid-state 2.4-V Zn/Li hybrid batteries. Nat. Commun. 15, 3748 (2024).

Innocenti, A., Bresser, D., Garche, J. & Passerini, S. A critical discussion of the current availability of lithium and zinc for use in batteries. Nat. Commun. 15, 4068 (2024).

Ma, L. et al. Realizing high zinc reversibility in rechargeable batteries. Nat. Energy 5, 743–749 (2020).

Zhang, Q. et al. Halogenated Zn2+ solvation structure for reversible Zn Metal Batteries. J. Am. Chem. Soc. 144, 18435–18443 (2022).

Zhang, Q. et al. Modulating electrolyte structure for ultralow temperature aqueous zinc batteries. Nat. Commun. 11, 4463 (2020).

Zhang, Q., Lu, Y., Liu, X., Xie, W. & Chen, J. Nonaggregated anions enable the undercooled aqueous electrolyte for low-temperature applications. J. Am. Chem. Soc. 146, 12743–12749 (2024).

Zhang, Q. et al. Designing anion-type water-free Zn2+ solvation structure for robust Zn metal anode. Angew. Chem. Int. Ed. 60, 23357–23364 (2021).

Driscoll, D. M. et al. Emergent solvation phenomena in non-aqueous electrolytes with multiple anions. Chem 9, 1955–1971 (2023).

Lavan, S. N. et al. Generalizable, tunable control of divalent cation solvation structure via mixed anion contact ion pair formation. J. Mater. Chem. A 12, 6768–6776 (2024).

Ye, Y. F., Wang, Q., Lu, J., Liu, C. T. & Yang, Y. High-entropy alloy: challenges and prospects. Mater. Today 19, 349–362 (2016).

Lun, Z. et al. Cation-disordered rocksalt-type high-entropy cathodes for Li-ion batteries. Nat. Mater. 20, 214–221 (2021).

Zeng, Y. et al. High-entropy mechanism to boost ionic conductivity. Science 378, 1320–1324 (2022).

Qiu, M. et al. Tailoring water structure with high-tetrahedral-entropy for antifreezing electrolytes and energy storage at −80 °C. Nat. Commun. 14, 601 (2023).

Adams, B. D., Zheng, J., Ren, X., Xu, W. & Zhang, J.-G. Accurate determination of Coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2018).

Ahmad, N. & Day, M. C. Cation solvation: the conversion of contact ion pairs to solvent separated ion pairs. J. Am. Chem. Soc. 99, 941–942 (1977).

Belch, A. C., Berkowitz, M. & McCammon, J. A. Solvation structure of a sodium chloride ion pair in water. J. Am. Chem. Soc. 108, 1755–1761 (1986).

Kim, M. et al. Cationic additive with a rigid solvation shell for high-performance zinc ion batteries. Angew. Chem. Int. Ed. 61, e202211589 (2022).

Dong, J. et al. Spontaneous molecule aggregation for nearly single-ion conducting sol electrolyte to advance aqueous zinc metal batteries: the case of tetraphenylporphyrin. Angew. Chem. Int. Ed. 63, e202401441 (2024).

Lin, H. et al. Interfacial regulation via configuration screening of a disodium naphthalenedisulfonate additive enabled high-performance wide-pH Zn-based batteries. Energy Environ. Sci. https://doi.org/10.1039/D4EE04212C (2025).

Xie, B. et al. Ultrastable electrolyte (>3500 hours at high current density) achieved by high-entropy solvation toward practical aqueous zinc metal batteries. Energy Environ. Sci. 17, 7281–7293 (2024).

Wang, D. et al. Localized anion-cation aggregated aqueous electrolytes with accelerated kinetics for low-temperature zinc metal batteries. Angew. Chem. Int. Ed. 62, e202315834 (2023).

Kropman, M. F. & Bakker, H. J. Dynamics of water molecules in aqueous solvation shells. Science 291, 2118–2120 (2001).

Kumar, P., Buldyrev, S. V. & Stanley, H. E. A tetrahedral entropy for water. Proc. Natl. Acad. Sci. USA 106, 22130–22134 (2009).

Tang, P. et al. Understanding pseudocapacitance mechanisms by synchrotron X-ray analytical techniques. Energy Environ. Mater. 6, e12619 (2023).

Kim, S. C. et al. High-entropy electrolytes for practical lithium metal batteries. Nat. Energy 8, 814–826 (2023).

Dubouis, N. et al. Tuning water reduction through controlled nanoconfinement within an organic liquid matrix. Nat. Catal. 3, 656–663 (2020).

Zhang, H. et al. Low-enthalpy and high-entropy polymer electrolytes for Li-metal battery. Energy Environ. Mater. 7, e12514 (2024).

Zhao, X. et al. More is better: high-entropy electrolyte design in rechargeable batteries. Energy Environ. Sci. 17, 2406–2430 (2024).

Lu, Z. et al. Step-by-step desolvation enables high-rate and ultra-stable sodium storage in hard carbon anodes. Proc. Natl. Acad. Sci. USA 119, e2210203119 (2022).

Self, J. et al. Ion pairing and redissociaton in low-permittivity electrolytes for multivalent battery applications. J. Phys. Chem. Lett. 11, 2046–2052 (2020).

Chen, X. et al. Dominant solvent-separated ion pairs in electrolytes enable superhigh conductivity for fast-charging and low-temperature lithium ion batteries. ACS Nano 18, 8350–8359 (2024).

Wang, S. et al. Bifunctional Zn2+-solvation structure electrolyte for highly reversible zinc anodes. Nano Energy 126, 109661 (2024).

Zhao, Y. et al. Tailoring grain boundary stability of zinc-titanium alloy for long-lasting aqueous zinc batteries. Nat. Commun. 14, 7080 (2023).

Jin, S. et al. Production of fast-charge Zn-based aqueous batteries via interfacial adsorption of ion-oligomer complexes. Nat. Commun. 13, 2283 (2022).

Yu, X. et al. Unlocking dynamic solvation chemistry and hydrogen evolution mechanism in aqueous zinc batteries. J. Am. Chem. Soc. https://doi.org/10.1021/jacs.4c02558 (2024).

Xu, D. et al. Water catchers within sub-nano channels promote step-by-step zinc-ion dehydration enable highly efficient aqueous zinc-metal batteries. Adv. Mater. 36, 2403765 (2024).

Yoo, H. D. et al. Fast kinetics of magnesium monochloride cations in interlayer-expanded titanium disulfide for magnesium rechargeable batteries. Nat. Commun. 8, 339 (2017).

An, Y. et al. Stable aqueous anode-free zinc batteries enabled by interfacial engineering. Adv. Funct. Mater. 31, 2101886 (2021).

Zhao, K. et al. Boosting the kinetics and stability of Zn anodes in aqueous electrolytes with supramolecular cyclodextrin additives. J. Am. Chem. Soc. 144, 11129–11137 (2022).

Yin, J. et al. Integrated electrolyte regulation strategy: trace trifunctional tranexamic acid additive for highly reversible Zn metal anode and stable aqueous zinc ion battery. Energy Storage Mater. 59, 102800 (2023).

Luo, J. et al. Regulating the inner Helmholtz plane with a high donor additive for efficient anode reversibility in aqueous Zn-ion batteries. Angew. Chem. Int. Ed. 62, e202302302 (2023).

Wang, S. et al. Low-concentration redox-electrolytes for high-rate and long-life zinc metal batteries. Small 20, 2207664 (2024).

Lv, Y. et al. Engineering a self-adaptive electric double layer on both electrodes for high-performance zinc metal batteries. Energy Environ. Sci. 15, 4748–4760 (2022).

Lin, C. et al. High-rate, large capacity, and long life dendrite-free Zn metal anode enabled by trifunctional electrolyte additive with a wide temperature range. Adv. Sci. 9, 2201433 (2022).

Hu, Z. et al. A self-regulated electrostatic shielding layer toward dendrite-free Zn batteries. Adv. Mater. 34, 2203104 (2022).

Miao, L. et al. Aqueous electrolytes with hydrophobic organic cosolvents for stabilizing zinc metal anodes. ACS Nano 16, 9667–9678 (2022).

Yu, H. et al. Reversible adsorption with oriented arrangement of a zwitterionic additive stabilizes electrodes for ultralong-life Zn-ion batteries. Energy Environ. Sci. 16, 2684–2695 (2023).

Peng, M. et al. Polycation-regulated electrolyte and interfacial electric fields for stable zinc metal batteries. Angew. Chem. Int. Ed. 62, e202302701 (2023).

Li, C. et al. Enabling selective zinc-ion intercalation by a eutectic electrolyte for practical anodeless zinc batteries. Nat. Commun. 14, 3067 (2023).

Li, J. et al. Dextran: a multifunctional and universal electrolyte additive for aqueous Zn ion batteries. Adv. Energy Mater. 13, 2301743 (2023).

Wang, X. et al. Highly reversible zinc metal anodes enabled by solvation structure and interface chemistry modulation. Adv. Energy Mater. 13, 2301670 (2023).

Zhou, K., Li, Z., Qiu, X., Yu, Z. & Wang, Y. Boosting Zn anode utilization by trace iodine ions in organic-water hybrid electrolytes through formation of anion-rich adsorbing layers. Angew. Chem. Int. Ed. 62, e202309594 (2023).

Wu, Z., Li, Y. & Liu, J. Coulombic efficiency for practical zinc metal batteries: critical analysis and perspectives. Small Methods 8, 2300660 (2024).

Tian, C. et al. Improved interfacial ion migration and deposition through the chain-liquid synergistic effect by a carboxylated hydrogel electrolyte for stable zinc metal anodes. Angew. Chem. Int. Ed. 62, e202310970 (2023).

Li, D., Cao, L., Deng, T., Liu, S. & Wang, C. Design of a solid electrolyte interphase for aqueous Zn batteries. Angew. Chem. Int. Ed. 60, 13035–13041 (2021).

Zhao, R. et al. Lanthanum nitrate as aqueous electrolyte additive for favourable zinc metal electrodeposition. Nat. Commun. 13, 3252 (2022).

Cao, J. et al. Interfacial double-coordination effect guiding uniform electrodeposition for reversible zinc metal anode. Adv. Energy Mater. 14, 2302770 (2024).

Hu, N. et al. A double-charged organic molecule additive to customize electric double layer for super-stable and deep-rechargeable Zn metal pouch batteries. Adv. Funct. Mater. 34, 2311773 (2024).

Zhao, Z. et al. Horizontally arranged zinc platelet electrodeposits modulated by fluorinated covalent organic framework film for high-rate and durable aqueous zinc ion batteries. Nat. Commun. 12, 6606 (2021).

Yang, H. et al. Sustainable high-energy aqueous zinc–manganese dioxide batteries enabled by stress-governed metal electrodeposition and fast zinc diffusivity. Energy Environ. Sci. 16, 2133–2141 (2023).

Acknowledgements

This work was supported by the Guangdong Basic and Applied Basic Research Foundation (K.N. Zhao 2024A1515140075), the National Natural Science Foundation of China (Q.C. Sun 52404423, X.G. Lu 52334009, H.W. Cheng 51874196), the Open Research Fund of Songshan Lake Materials Laboratory (H.W. Cheng 2023SLABFK12), and the Science and Technology Commission of Shanghai Municipality (H.W. Cheng 23ZR1421600, 21DZ1208900, 19DZ2270200). This research used resources of the Advanced Photon Source (beamline 12-BM and beamline 11-ID-C), a U.S. DOE Office of Science User Facility, operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02- 06CH11357.

Author information

Authors and Affiliations

Contributions

L.H. Chang and K.N. Zhao conceived the idea, performed the experiment, and wrote the manuscript. L. Zhang, B.M. Zhang, L.H. Zheng and J.T. Li provided some important experimental insights. J.M. Li and Q.C. Sun conducted some electrochemical analysis. H.W. Cheng, X.G. Lu and K.N. Zhao supervised and supported this work. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Kanghoon Yim and the other anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chang, L., Cheng, H., Li, J. et al. High-entropy solvation chemistry towards affordable and practical Ah-level zinc metal battery. Nat Commun 16, 6134 (2025). https://doi.org/10.1038/s41467-025-61456-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-61456-z