Abstract

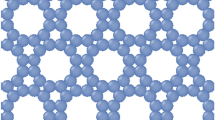

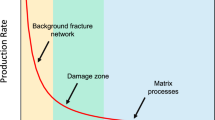

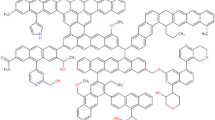

Storage and transportation of methane (CH4) remains challenging as it cannot be liquefied at ambient temperature and instead must be stored as compressed gas at high pressures (approximately 25 MPa). Alternatively, it can be stored within nanoporous materials at moderate pressures (for example, 3.5 MPa) but this ‘adsorbed natural gas’ approach can suffer from substantial desorption with only minor temperature increases. Both methods therefore necessitate additional safety measures. Here we report graphene-coated porous carbon materials that can be charged with CH4 at high pressure and retain it at ambient pressure and temperature (below 318 K), thereby enhancing storage safety. Our data suggest that graphene serves as a thermally controllable lock that obstructs or activates pores to trap or release CH4, enabling a pressure-equivalent loading of 19.9 MPa at 298 K, and release upon heating to 473 K. The resulting reversible CH4 volumetric capacity reaches 142 v/v, exceeding that of various adsorbed natural gas materials at 3.5 MPa and 298 K when considering container space utilization.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

27,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

118,99 € per year

only 9,92 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in the published article and its Supplementary Information and source data files. Source data are provided with this paper.

References

Methane Opportunities for Vehicular Energy DE-FOA-0000672 (DOE, 2012); https://arpa-e-foa.energy.gov/

Alezi, D. et al. MOF crystal chemistry paving the way to gas storage needs: aluminum-based soc-MOF for CH4, O2, and CO2 storage. J. Am. Chem. Soc. 137, 13308–13318 (2015).

Tian, T. et al. A sol-gel monolithic metal–organic framework with enhanced methane uptake. Nat. Mater. 17, 174–179 (2018).

Chen, Z. et al. Balancing volumetric and gravimetric uptake in highly porous materials for clean energy. Science 368, 297–303 (2020).

Rozyyev, V. et al. High-capacity methane storage in flexible alkane-linked porous aromatic network polymers. Nat. Energy 4, 604–611 (2019).

Peng, Y. et al. Methane storage in metal–organic frameworks: current records, surprise findings, and challenges. J. Am. Chem. Soc. 135, 11887–11894 (2013).

Lozano-Castelló, D., Alcañiz-Monge, J., De La Casa-Lillo, M. A., Cazorla-Amorós, D. & Linares-Solano, A. Advances in the study of methane storage in porous carbonaceous materials. Fuel 81, 1777–1803 (2002).

He, Y., Zhou, W., Qian, G. & Chen, B. Methane storage in metal-organic frameworks. Chem. Soc. Rev. 43, 5657–5678 (2014).

Casco, M. E. et al. High-pressure methane storage in porous materials: are carbon materials in the pole position? Chem. Mater. 27, 959–964 (2015).

Kumar, K. V., Preuss, K., Titirici, M. M. & Rodríguez-Reinoso, F. Nanoporous materials for the onboard storage of natural gas. Chem. Rev. 117, 1796–1825 (2017).

Simon, C. M. et al. The materials genome in action: identifying the performance limits for methane storage. Energy Environ. Sci. 8, 1190–1199 (2015).

Gedeon, G. Hazards of Chemicals and Gases (Continuing Education & Development, Inc., 2023).

Gao, Q., Xu, J., Cao, D., Chang, Z. & Bu, X.-H. A rigid nested metal–organic framework featuring a thermoresponsive gating effect dominated by counterions. Angew. Chem. 128, 15251–15254 (2016).

Mason, J. A. et al. Methane storage in flexible metal–organic frameworks with intrinsic thermal management. Nature 527, 357–361 (2015).

Li, G. et al. Temperature-regulated guest admission and release in microporous materials. Nat. Commun. 8, 15777 (2017).

Chen, K. et al. Gating effect for gas adsorption in microporous materials—mechanisms and applications. Chem. Soc. Rev. 51, 1139–1166 (2022).

Kim, H. et al. Temperature-triggered gate opening for gas adsorption in microporous manganese formate. Chem. Commun. https://doi.org/10.1039/b811087e (2008).

Zammit, M. et al. Future Automotive Aftertreatment Solutions: The 150 °C Challenge Workshop Report (PNNL, 2012); https://www.pnnl.gov/main/publications/external/technical_Reports/PNNL-22815.pdf

Papapetrou, M., Kosmadakis, G., Cipollina, A., La Commare, U. & Micale, G. Industrial waste heat: estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl. Therm. Eng. 138, 207–216 (2018).

Waste Heat Recovery: Technology and Opportunities in U.S. Industry (DOE, 2008); https://www1.eere.energy.gov/manufacturing/intensiveprocesses/pdfs/waste_heat_recovery.pdf

de Tomas, C. et al. Structural prediction of graphitization and porosity in carbide-derived carbons. Carbon 119, 1–9 (2017).

Vallejos-Burgos, F. et al. 3D nanostructure prediction of porous carbons via gas adsorption. Carbon 215, 118431 (2023).

Fan, J. et al. Control of hole opening in single-wall carbon nanotubes and single-wall carbon nanohorns using oxygen. J. Phys. Chem. B 110, 1587–1591 (2006).

Utsuimi, S. et al. Opening mechanism of internal nanoporosity of single-wall carbon nanohorn. J. Phys. Chem. B 109, 14319–14324 (2005).

Kaneko, K., Shimizu, K. & Suzuki, T. Intrapore field‐dependent micropore filling of supercritical N2 in slit‐shaped micropores. J. Chem. Phys. 97, 8705–8711 (1992).

Murata, K. et al. Pore structure of single-wall carbon nanohorn aggregates. Chem. Phys. Lett. 331, 14–20 (2000).

Howe, J. Y., Rawn, C. J., Jones, L. E. & Ow, H. Improved crystallographic data for graphite. Powder Diffr. 18, 150–154 (2003).

Wang, S. et al. The subtracting pore effect method for an accurate and reliable surface area determination of porous carbons. Carbon 175, 77–86 (2021).

Malard, L. M., Pimenta, M. A., Dresselhaus, G. & Dresselhaus, M. S. Raman spectroscopy in graphene. Phys. Rep. 473, 51–87 (2009).

Graf, D. et al. Spatially resolved raman spectroscopy of single- and few-layer graphene. Nano Lett. 7, 238–242 (2007).

Duane, W. & Shimizu, T. The relation between the intensity of general X-radiation and the atomic number of the anticathode. Phys. Rev. 14, 525–529 (1919).

Pelletier, M. J. Quantitative analysis using Raman spectrometry. Appl. Spectrosc. 57, 20A–42A (2003).

Ferrari, A. C. & Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 61, 14095–14107 (2000).

Liu, H.-N., Cong, X., Lin, M.-L. & Tan, P.-H. The intrinsic temperature-dependent Raman spectra of graphite in the temperature range from 4 K to 1,000 K. Carbon 152, 451–458 (2019).

Sharma, M. et al. Temperature dependent Raman modes of reduced graphene oxide: effect of anharmonicity, crystallite size and defects. Carbon 184, 437–444 (2021).

Akikubo, K., Kurahashi, T., Kawaguchi, S. & Tachibana, M. Thermal expansion measurements of nano-graphite using high-temperature X-ray diffraction. Carbon 169, 307–311 (2020).

Tsang, D. K. L., Marsden, B. J., Fok, S. L. & Hall, G. Graphite thermal expansion relationship for different temperature ranges. Carbon 43, 2902–2906 (2005).

Zakharchenko, K. V., Los, J. H., Katsnelson, M. I. & Fasolino, A. Atomistic simulations of structural and thermodynamic properties of bilayer graphene. Phys. Rev. B 81, 235439 (2010).

Webster, C. E., Drago, R. S. & Zerner, M. C. Molecular dimensions for adsorptives. J. Am. Chem. Soc. 120, 5509–5516 (1998).

Webster, C. E., Cottone, A. & Drago, R. S. Multiple equilibrium analysis description of adsorption on Na-mordenite and H-mordenite. J. Am. Chem. Soc. 121, 12127–12139 (1999).

Wang, S. et al. Activation routes for high surface area graphene monoliths from graphene oxide colloids. Carbon 76, 220–231 (2014).

Marsh, H. & Rodriguez-Reinoso, F. Activated Carbon (Elsevier, 2006).

Kawabuchi, Y., Kishino, M., Kawano, S., Whitehurst, D. & Mochida, I. Carbon deposition from benzene and cyclohexane onto active carbon fiber to control its pore size. Langmuir 12, 4281–4285 (1996).

Moreira, R. F. P. M., José, H. J. & Rodrigues, A. E. Modification of pore size in activated carbon by polymer deposition and its effects on molecular sieve selectivity. Carbon 39, 2269–2276 (2001).

Vallejos-Burgos, F., Coudert, F.-X. & Kaneko, K. Air separation with graphene mediated by nanowindow-rim concerted motion. Nat. Commun. 9, 1812 (2018).

Urita, K., Suenaga, K., Sugai, T., Shinohara, H. & Iijima, S. In situ observation of thermal relaxation of interstitial-vacancy pair defects in a graphite gap. Phys. Rev. Lett. 94, 155502 (2005).

Shah, J. K. et al. Cassandra: an open source Monte Carlo package for molecular simulation. J. Comput. Chem. 38, 1727–1739 (2017).

Acknowledgements

This work was supported by the Japan Science and Technology Agency (JST) Open Innovation Platform with Enterprise, Research Institute and Academia (OPERA), under project number JPMJOP1722 (K.K.). J.S.-A. acknowledges financial support from the Ministerio de Ciencia e Innovación (Project PID2019-108453GB-C21) and the Conselleria de Innovación, Universidades, Ciencia y Sociedad Digital (Project CIPROM/2021/022) (J.S.-A.). K.K. was also financially supported by Takagi Co. S.W. acknowledges partial support from JST funds. We thank AD’ALL Co. for providing activated carbon fibre samples. We also thank Y. Gogotsi (Drexel University) for providing valuable suggestions for the revision of the manuscript.

Author information

Authors and Affiliations

Contributions

S.W. and K.K. developed the study concept and designed the methodology. S.W., F.V.-B, H.T. and K.K. wrote the paper. S.W. synthesized the samples. S.W., A.F., H.O., M.N., Y.K., T.O., H.K., K.U., H.N., I.M. and T.H. contributed to sample characterization. F.V.-B. and H.T. built the simulation model. F.V.-B. performed the Grand Canonical Monte Carlo calculations. H.T. performed the MD simulations. S.W., J.P.M.-L. and J.S.-A. performed the CH4 adsorption measurements. A.F., H.O., K.U., H.T. and J.S.-A. contributed to the discussion and editing of the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–10, Figs. 1–38 and Tables 1–15.

Supplementary Video 1

Temperature-dependent TEM observations of graphene-coated carbon at elevated temperatures.

Supplementary Video 2

Stable graphene layer contact responsible for pore locking at 298 K.

Supplementary Video 3

Movement of the graphene coating layers corresponding to pore unlocking at 473 K.

Source data

Source Data Fig. 1

Structural characterizations of graphene-coated carbon.

Source Data Fig. 2

Methane storage performance of graphene-coated carbon and reported ANG.

Source Data Fig. 3

Temperature-dependent characterizations of pore obstruction/activation.

Source Data Fig. 4

Methane storage performance of graphene-coated carbons prepared under different conditions.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, S., Vallejos-Burgos, F., Furuse, A. et al. Ambient pressure storage of high-density methane in nanoporous carbon coated with graphene. Nat Energy (2025). https://doi.org/10.1038/s41560-025-01783-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41560-025-01783-z