Abstract

Water chestnut is a characteristic aquatic vegetable in China, and its demand for peeling fresh fruit is increasing rapidly. Aiming at the existing problems of high labor intensity and low efficiency of manual peeling, a combined water chestnut peeling machine was designed, which used a rotary knife to remove bud and root, and a differential friction belts to remove side peel. The performance of the peeling machine was tested with water chestnut from Xiaogan, Hubei Provence. Under the conditions of 200 g feeding mass and 10 r/min rotation speed, the single factor test was carried out with cutting speed as the influencing factor and the cutting rate of bud and root as the evaluation index. The results showed that the cutting rate of fresh fruit of water chestnut bud and root were 79.04% and 83.77% respectively when the cutting speed of rotary knife was 1.2 m/s. In the differential friction belts, high and low linear velocities were taken as the influencing factors, and the side peel removal rate was used as the evaluation index. The side peel removal rate was 84.93% at the high-speed linear velocity of 2.1 m/s and the low-speed linear velocity of 1.58 m/s. The performance of the whole machine was evaluated, and the results showed that the working loss of the combined water chestnut peeling machine was 43.03% and the comprehensive peeling rate was 77.43%, which reached the design requirements. This study can provide a reference for the research and development of water chestnut peeling device.

Similar content being viewed by others

Introduction

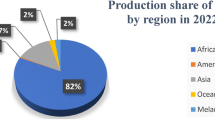

Water chestnut, also known as Eleocharis, is one of the important aquatic vegetables in China. It is widely planted in Hubei, Guangxi, Zhejiang, Hunan, and other places, with a total area of 50,000 hm2, and the annual output of fresh fruit of water chestnut is 600,000–800,000 tons1,2. At present, centering on the implementation of the national rural revitalization strategy and the needs of "one county, one product" county economic development, the planting of water chestnut in Guangxi, Hubei and other places is developing rapidly3,4,5. Fresh water chestnut after peeling can be used for the processing of candied fruit and canned fruit, which can achieve higher economic value6,7. However, water chestnut peeling is still mainly manually operated, with high labor intensity, low efficiency, and high production cost, which is difficult to meet the requirements of industrial development. The peeling technology has become one of the bottlenecks in the development of water chestnut industry.

Domestic and foreign scholars have studied common fruit and vegetable peeling technologies8,9,10,11, mainly including chemical peeling, steam peeling, mechanical peeling, etc.12,13,14,15. Steam peeling will make water chestnut cooked and lose their fresh flavor16,17, so this method is not feasible. Chemical peeling is soaked in lye, which is highly polluted by waste liquid and prone to lye residue and has an impact on food safety18,19,20. Mechanical peeling is the earliest and longest applied peeling method for fruit and vegetable, and it is also a more efficient and environmentally friendly method21,22,23. Chemical peeling and steam peeling can input a large number of target fruits at one time, so it can achieve high work efficiency. However, at present, the problem of pulp ripening or harmful liquid residues cannot be solved. Mechanical peeling will not cause potential safety and health hazards to fruits, and meets the food requirements. Therefore, the peeling industry generally focuses on machinery, such as Cao Chengmao, who designed a knife-cutting and rolling friction feeding bamboo shoots peeling machine, mechanized peeling of bamboo shoots24; Zeng Rong designed a multi-channel integrated shelling machine for fresh lotus seeds. The multi-channel profiling groove wheel was used to realize the single discharge of fresh lotus seeds, the circular cutting of internal and external cutters, and the separation of rolling shells and kernels, so as to realize the shelling of fresh lotus seeds25; Yu Guohong designed a flexible adaptive profiling sweet potato peeler based on the physical characteristics of sweet potatoes to achieve better sweet potato peeling performance26. Xu Xieqing designed a fresh lotus seed peeling machine based on the water jet peeling method to reduce manual work and improve peeling efficiency27.

The above peeling devices have realized the peeling function of agricultural materials in their respective fields, but cannot be applied to water chestnuts. Based on the status quo, the water chestnut mechanical peeling technology was studied in this paper, we designed a kind of combined water chestnut peeling machine, using the rotary knife to remove bud and root, differential friction belts to remove the side peel. Through the theoretical analysis of the main technical route such as blanking, positioning and transmitted through. The structure and parameter range of key components were determined, and the performance test was carried out, to provide a reference for the research and development of water chestnut peeling machine.

Materials and methods

Determination of the peeling scheme

The overall shape of water chestnut is similar to that of a lantern, but its shape is irregular. There is bud on the upper part, protruding upward and outward, and root on the bottom, with both bud and root sunken into the flesh (Fig. 1). Considering the shape of water chestnut, proposed the following technical scheme: the whole process of fruit peel can be divided into the removal of bud and root, and friction to remove side peel two phases in combination, to use a rotary knife center axis perpendicular to the water chestnut, at the same time close to bud and root, got removal of bud and root, then to remove side peel by friction way, to maximize the pulp of water chestnut. When bud and root were removed, the maximum thickness of pulp was retained according to the size h shown in Fig. 1. When rubbing the side peel, retain the maximum diameter pulp according to the size φ as shown in Fig. 1.

Working principle

The combined water chestnut peeling machine mainly consists of feeding, positioning, cutting, transmission, friction, unloading, etc. To improve the working efficiency, the machine adopts double-channel operation at the same time (Fig. 2).

When the peeling machine works, the water chestnut enters the feeding funnel by the feeding mechanism, and the discharging end of the funnel is brush. The water chestnut can be centralized and moved into the positioning hole of the positioning mechanism; the positioning mechanism is provided with an adjustable supporting plate, and the vibration source is installed below the supporting plate. When the water chestnut is rotated by the positioning mechanism, the supporting plate vibration makes the bud up and the root down. After alignment, the water chestnut moves to the cutting place driven by the positioning disk, and the rotary knife turns to remove the water chestnut bud and root at the same time; After the bud and root are removed, the water chestnut with side peel which is similar to drum enters the transmission mechanism, and then entered the conveying channel composed of differential friction belts and conveying flat belt under its guidance. Then, under the action of differential rubbing of friction belts on both sides, the side peel of water chestnut is removed, and the peeled water chestnut is uniformly recycled at the unloading place. The working process of the whole machine is shown in Fig. 3.

Design of main working parts

Blanking and cutting device

The positioning mechanism of the peeling machine is shown in Fig. 4. Its working process is as follows: Water chestnut falls to the upper surface of the positioning disk with the opening hole through the feeding hopper, and the positioning disk rotates under the drive of the motor. Under the action of the friction on the surface of the positioning disk and auxiliary pulling of the brush at the bottom of the hopper, the water chestnut falls into the positioning hole in turn. The diameter of the positioning hole is designed to ensure that only one water chestnut can enter, so the brush will send the redundant water chestnut fed by the subsequent hopper along the surface of the positioning disk and make it slide along the surface of the disk into the next positioning hole.

In addition, the brush can also adjust the posture of the water chestnut. According to the shape characteristics, there are only two ways to place the water chestnut: ① When the bud is upward and the bottom is downward, the water chestnut is relatively stable and will not be affected by the brush; ② When the bud is facing down, the water chestnut is extremely unstable. Under the effect of the brush, it will automatically turn over to place the bud facing up.

The cutting mechanism is shown in Fig. 5. A stainless-steel supporting plate was arranged at the lower side of the positioning disk to hold the water chestnut falling into the positioning hole. There was a gap δ between the supporting plate and the disk, which can be set by adjusting the installation position of the supporting plate. When working, the lower knife rotated close to the lower surface of the positioning disk to remove the water chestnut root, while the upper knife rotated close to the upper surface of the positioning disk to remove the water chestnut bud part; It can be seen from Fig. 1 that both bud and root of water chestnut have depression, and bud (root) cutting rate can be controlled by adjusting gap δ and disk thickness h1. To give consideration to higher bud (root) cutting rate and flesh thickness h, this study focused on the average size of water chestnut, the gap was set at 3 mm, and disk thickness was set at 15 mm.

After removing the bud and root, the pulp entered the next procedure; bud and root left the disk area under the impact and friction of the knife, fell naturally, and were recycled uniformly. To compact the structure and reduce the external size of the whole machine, the diameter of the positioning disk was set as 380 mm, the number of positioning holes on the disk was 8, and the distance from the center of each positioning hole to the center of the rotating axis was 140 mm.

Analysis of transmission process of water chestnut

After the bud and root were cut off by the rotary knife, the water chestnut continued to move in a circular motion with the positioning disk, and when it moved to the opening of the supporting plate, it fell into the friction peeling device by gravity. To ensure that the water chestnut can fall smoothly from the opening to enter the next item of the friction mechanism, the process was analyzed. The movement model of the process is established as shown in Fig. 6.

Analysis of the falling process of water chestnut (1) Positioning disk; (2) Supporting plate; (3) Conveyor; Water chestnut running track is A → B → C, A indicates the initial position of the water chestnut, B indicates that the water chestnut has just fallen into the opening, and C indicates that the water chestnut is in contact with the water chestnut conveyor; h2 is the thickness of the supporting plate, h3 is the distance between the supporting plate and the conveying mechanism, L1 is the distance from A to B, L2 is the distance from A to C, H1 is the height from A to B for the water chestnut, H2 is the falling height of water chestnut from A to C, d1 is the diameter of water chestnut blanking hole, d2 is the conveying mechanism and the spacing of blanking hole of supporting plate.

The falling process of water chestnut is a flat throwing movement, and its horizontal velocity v is:

The formula for calculating the size d1 at the opening of the vibration plate is as follows:

The calculation formula for the installation size of water chestnut transfer mechanism is as follows:

where v is the linear velocity of the water chestnut in the positioning hole in a circular motion with the positioning disk, m/s; ω is the angular velocity of the disk, rad/s; n is the disk rotary speed, r/min; r is rotation radius of positioning hole, m; t1 is the time required for water chestnut to move from A to B, s; t2 is the time required for water chestnut to move from A to C.

The design range of disk rotary speed was 10–60 r/min; The thickness of the supporting plate had no direct influence on the working process, so the thickness was 2 mm which was the commonly used stainless steel plate; To make the whole machine structure compacted, the distance between the supporting plate and the transmission mechanism h3 was 100 mm; According to Eqs. (2) and (3), the dimension of the opening d1 ≥ 82 mm, and the distance between the installation position of the transmission mechanism and the left end of the opening of the support plate d2 ≤ 43 mm.

Profiling positioning block

After the water chestnut entered the positioning hole, to make it rotate steadily with the positioning disk in the positioning hole and prevent it from popping out from the hole during cutting, a profiling positioning block is designed. The structural design process was as follows.

Established the x-axis along the water chestnut midpoint horizontal transverse, and y-axis vertical longitudinal established (Fig. 7), the water chestnut dimension was measured along the longitudinal section contour, random measuring 20 sizes close to the average water chestnut, measuring the contour size, the water chestnut outer contour curve was obtained by MATLAB simulation data, established according to the outline curve contour locating piece, can make the water chestnut and its internal fit closely.

The contour parameters of the profiling positioning block were taken from a part of the contour curve of the water chestnut, as shown in the red rectangle in Fig. 7. Because of its complex curve form, the positioning profiling block was manufactured by 3D printing, and its outboard cylindrical surface was stuck and fixed on the inner wall of the positioning hole, as shown in Fig. 8, with the upper surface flushed with the positioning disk. When the water chestnut entered the positioning hole, its side fitted with the positioning block under the action of centrifugal force, compared with the cylindrical through-hole, the designed profiling positioning block not only increased the force contact area, but also facilitated the formation of stable supporting cutting.

Side peel removal device

After cutting the bud and root, the water chestnut fell into the Y-shaped feeding port at the blanking hole of the supporting plate, as shown in Fig. 9, the side peel removal process was continued. A conveyor belt is arranged below the Y-shaped feeding port, and the water chestnut was fed to the differential friction belts by the joint action of the guide plates on both sides. To ensure that water chestnut was better imported from the Y-shaped port, the conveyor belt is designed in an inclined state. After several tests, the inclined angle was set to 10°, and the effect of water chestnut entering the conveyor belt was the best.

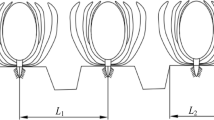

The friction belt spacing d3 can be adjusted by the installation position of the synchronous belt axle, and its size was the same as that Φ shown in Fig. 1, set the friction belt spacing d3 = 40 mm according to the size of the test object. The water chestnut was squeezed and rubbed by two differential friction belts and rotates forward in the channel to realize peeling all around. The principle was shown in Fig. 10.

Principle of friction peeling (1) Friction belt I; (2) Water chestnut; (3) Friction belt II; vI > vI; vI is the velocity direction of the friction belt I; vII is the velocity direction of the friction belt II; vIII is actual running direction of water chestnut; ωIII is actual angular velocity direction of water chestnut.

The water chestnut rotated and advanced under the clamping effect of two differential friction belts, and its speed was ωIII, the forward speed was vIII; vI and vII were the linear velocity of high-speed belt and low-speed belt respectively, which were controlled by motor speed and adjustable; When the difference between the linear velocity of the differential friction belt vI and vII was larger, the forward speed of water chestnut vIII was larger; during the test, the linear speed of the differential belt was controlled by adjusting the motor speed, and then the forward speed of the water chestnut was changed to explore the corresponding working speed for the best peeling effect.

The friction belt was developed by the team and consisted of a synchronous belt, sponge layer, and friction particles (Fig. 11). Synchronous belt and motor pulley connected, and plays a driving role; in combination with the external contour size of water chestnut, the sponge layer thickness h4 = 4 mm was set. By adding the sponge layer, it can play a role of buffering and decompression, effectively reduced the crushing damage of friction belt on water chestnut during peeling, reduced the loss of pulp, and ensured high peeling quality. Friction particles are composed of sand particles of different sizes. In order to ensure a better peeling effect, the average particle size of friction particles h5 = 2 mm, which is set based on the actual experiment, and the particle shape is polyhedral with sharp edges and corners, to quickly remove the side peel of water chestnut.

Experimental design and analysis of results

Test materials

The test material was the local traditional water chestnut variety widely cultivated in Xiaogan city, Hubei Province. The size and specifications were relatively consistent after classification and screening before the test. The average mass of single fruit was 29.03 g, the average maximum transverse diameter Φ0 was 44.99 mm, the average total pulp height h0 was 29.66 mm, and the average wet base moisture content was 83.32%. The test equipment included water content measuring instrument, electronic scale, speed calibration instrument, vernier caliper, box cutter, grid paper, marker pen, etc.

Cutting test of bud and root

According to the pre-test, continuous feeding can be guaranteed when the single feeding was 200 g and the disk rotation speed was 10 r/min. Under these conditions, the knife rotation speed was taken as the influencing factor, the range of knife rotation speed n was set from 100 to 300 r/min, and the cutting rate of bud and root was taken as the evaluation index to carry out the single factor experiment on the optimal cutting speed of the peeling machine to cut root and bud.

It was found that water chestnut would be repeatedly cut when cutting at high speed (Fig. 12). Repeated cutting results in the reduced thickness of water chestnut (Fig. 12b) or fragmentation of water chestnut (Fig. 12c), which increased additional peeling losses.

Analysis of the reason was that the cutting speed was large, the positioning disk did not send the water chestnut after cutting out of the cutting range in time, which led to secondary cutting. The main influencing factors were the knife speed, the rotation speed of the positioning disk, the center distance of the positioning hole, etc. In this study, the rotation speed of the knife and disk were taken as the influence factor.

The cutting speed v1 is the sum of the linear velocity of the positioning disk and the knife:

where ω is the angular velocity of the disk, rad/s; r is the rotation radius of the positioning hole, m; ω1 is the angular velocity of the knife, rad/s; r1 is the knife length, m.

The cutting rate of water chestnut bud (root) was calculated by the following formula:

where y1 is the cutting rate of bud (root), %; Sa is the section area after bud (root) excision, mm2; Sr is residual bud (root) area, mm2.

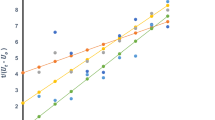

The test result was shown in Fig. 13. Variance analysis was performed for the bud and root excision test of water chestnut as shown in Table 1. It can be seen that the cutting speed has no significant effect on the cutting of bud and root of water chestnut in the test range, and the difference in cutting rate is small with the increase of cutting speed.

Within the test range, according to the mean value analysis, when the cutting speed was 1.2 m/s, the removal effect of water chestnut bud and root was relatively the best.

Removal test of side peel

Since there is no quality evaluation standard for water chestnut peeling at present, an evaluation method was proposed based on the current research situation. The removal rate of water chestnut side peel can be calculated by the following formula:

where y2 is the side peel removal rate, %; S1 is the cuticular area of water chestnut before removing side peel, mm2; S2 is the epidermal area of water chestnut after removing side peel, mm2.

In order to investigate the effect of working parameters on side peel removal by friction, a full factor experiment was carried out with water chestnut with bud and root removed as the object and the speed of differential belt as the influencing factor. The main function of the synchronous belt is to smoothly guide the water chestnut into the Y-shaped port and to ensure that water chestnut is always between the two belts during friction peeling, according to the actual test, when removing side peel, the water chestnut is mainly affected by friction between the two friction belts and is not in contact with the nether synchronous belt, so the speed of it had no effect, so did not take it as test factor.

The factors and levels of this test were shown in Table 2. According to the structure size, the rotation speed of the friction belt was converted to linear velocity. Belt I was the high-speed belt, and belt II was the low-speed belt. The test results were shown in Fig. 14.

The appearance of water chestnut after peeling was shown in Fig. 15. The results of variance analysis were shown in Table 3. The speed of the two friction belts had no significant influence on the peeling effect (P > 0.05), but with high-speed belt velocity increased, the side peel removal rate had a downward trend, mainly due to: When the side peel of water chestnut was removed between the differential channels of the two friction belts, the relative sliding distance between the side peel and the friction belts was always longer than the outer circumference of the water chestnut, and a certain amount of side peel can be removed. However, with the increase of the high-speed belt velocity, the relative sliding distance between the water chestnut and the friction belts decreased slightly, so the removal rate decreased. In the test range, according to the mean value analysis of test data, when vI = 2.1 m/s and vII = 1.58 m/s, the highest removal rate of water chestnut side peel was 84.93%.

Overall performance evaluation

The combined water chestnut peeling machine was shown in Fig. 16. The parameters of the machine were adjusted according to the above tests, and the performance of the whole machine was evaluated under the optimal parameter combination of each project. The experiment was repeated 20 times, and the peeling loss rate and comprehensive peeling rate were obtained respectively.

The rate of peeling loss was calculated by the following formula:

where y3 is the loss rate, %; m1 is the total mass of water chestnut before peeling, g; m2 is the mass of water chestnut after peeling, g.

The comprehensive peeling rate was calculated by the following formula:

where y4 is the comprehensive peeling rate, %; y1 is the cutting rate of bud (root), %; y2 is the removal rate of side peel, %.

To prevent mass variation of water chestnut from water loss, an electronic scale was used to weigh the water chestnut immediately after the test. The results showed that under the optimal parameters, the working efficiency of the machine exceeded 6 kg/min, which was much higher than that of manual peeling; as for peeling quality, the peeling loss rate of the combined water chestnut peeling machine was 43.03%, and the comprehensive peeling rate was 77.43%. The peeling rate of the whole machine was different from that of the single bud, root, and side peel test. The main reason was that the peeling process of the whole machine was completed automatically, so there may be deviation in the transfer of water chestnut in different processes, which resulted in a poor effect.

Data showed that the peel of mature water chestnut accounted for a high proportion, about 20–25% of the total fruit mass28,29,30. Considering that the irregular shape of water chestnut will cause overcutting loss31,32 during mechanical peeling, combined with the actual investigation, the mass loss of manual peeling is about 40%. This peeling machine can realize the peeling loss of 43.03% and the comprehensive peeling rate of 77.43% respectively, achieving the design goal of initial replacement of the manual. However, the surface of water chestnut after peeling is rough and the perception is poor, which needs to be improved.

Conclusion

In this study, a combined water chestnut peeling machine was designed, which used rotary knife to remove bud and root and differential friction belts group to remove side peel. The combined operation mode was adopted to remove bud and root and side peel of water chestnut in turn. Through the theoretical analysis of the process of blanking positioning and transmission, the structural form and parameter range of the device were determined.

Bench tests were carried out on the bud and root cutting and side peel friction of water chestnut. The results showed that when the cutting speed was 1.2 m/s, the cutting rate of bud and root of water chestnut could reach 79.04% and 83.77%; High speed belt vI = 2.1 m/s, low speed belt vII = 1.58 m/s, and the removal rate of water chestnut side peel was 84.93%. The performance of the whole machine was evaluated under the optimal parameter combination of each link. The results showed that the working efficiency of the machine can exceed 6 kg/min, and the peeling loss rate of the whole machine was 43.03%, and the comprehensive cleaning rate is 77.43%. The working indexes of the whole machine basically meet the design goal of replacing manual work. However, the peeled water chestnut has rough surface and high loss, which needs to be improved in the next study.

Data availability

All data generated or analyzed during this study are included in this published article and all data included in this study are available upon request by contact with the corresponding author.

References

Li, F. et al. Screening of evaluation on main agronomic and economic characters in Chinese water chestnut germplasm resources. China Veg. 4, 48–52 (2017).

O, K. et al. Current status of Guangxi water chestnut industrial development and its developing suggestions. J. South. Agric. 44(2), 356–359 (2013).

Liu, X. & Meng, X. Progress research on resource development and utilization of water chestnut. Food Res. Dev. 42(3), 212–217 (2021).

M, G. & Duan, Y. Review and prospects of international water chestnut trade—An empirical study based on ESCP paradigm and trade data from 1988 to 2007. Issues Agric. Econ. 12, 86–92 (2008).

Wu, M., Zong, Y. & Zhao, B. Trade pattern and prospect of lotus root and water chestnut in the world. Agric. Outlook 15(3), 66–72 (2019).

Chen, Z., Xia, J. & Zhan, P. The compression feature research of water chestnut. J. Anhui Agric. Univ. 44(1), 171–176 (2017).

Chen, L. et al. Characteristics of new water chestnut varieties and key techniques for high-yield and high-efficiency cultivation. J. Changjiang Veg. 16, 117–119 (2011).

Chen, H. et al. Process parameter optimization of dual-roller peeling device for satsuma mandarin peeling machine. Trans. Chin. Soc. Agric. Eng. 31(4), 293–298 (2015).

Li, C. et al. Design and experiment of litchi denucleating and decorticating machine. Trans. Chin. Soc. Agric. Mach. 45(8), 93–100 (2014).

Gong, X., Wang, G. & Liu, H. Improvement and regression test of double knife type hami melon peeler. J. China Agric. Mech. 42(8), 115–120 (2021).

Xu, M. & Zhang, Y. The study of sugarcane peeler based on the PLC. J. Agric. Mech. Res. 11, 115–118 (2014).

Gong, X. et al. Design and experiment of double dnife automatic peeler for hami melon. J. Agric. Mech. Res. 44(6), 176–181 (2022).

He, X. & Wang, D. Tensile property of corn stalk rind based on analysis of fiber morphology. Trans. Chin. Soc. Agric. Eng. 31(10), 92–98 (2015).

Chen, W. et al. Experimental study and parameter analysis on buckwheat huller. J. China Agric. Univ. 22(7), 107–114 (2017).

Liu, M. et al. Research status of key technologies and devices for walnut by-products processing. J. China Agric. Mech. 42(05), 55–74 (2021).

Chen, H., Liu, Q. & Zeng, S. Technological on peeling kiwifruit by steam blanching. Food Sci. Technol. 41(6), 117–120 (2016).

Sui, W. et al. Research on utilization status and classification management of solid waste in fruit processing in China. Trans. Chin. Soc. Agric. Eng. 34(S1), 172–180 (2018).

Xiang, J. & Hu, T. Study on the peeling of water chestnut and the extraction of red pigment. Sci. Technol. Food Ind. 28(7), 159–161 (2007).

Wang, F. et al. Effect of peeling methods on drying characteristics and physico-chemical properties of yellow peach prepared by combined osmotic dehydration and drying. J. Chin. Inst. Food Sci. Technol. 21(9), 121–129 (2021).

Wang, L. et al. Effect of different peeling methods on the peeling efficiency and quality of tomatoes. Food Sci. 38(5), 26–31 (2017).

Du, Y. et al. Design of corn ear peeling device based on knowledge-based engineering. Trans. Chin. Soc. Agric. Mach. 51(S02), 249–260 (2020).

Shi, N. et al. Peeling and shearing mechanical performance test of cotton stalks in extrusion state. Trans. Chin. Soc. Agric. Eng. 33(18), 51–58 (2017).

Cao, J. et al. Design and test of cutter plate potato peeling device. Agric. Eng. 10(10), 48–54 (2020).

Cao, C. et al. Design and experiment of bamboo shoots peeling machine with rolling friction feeding based on knife-cutting method. Trans. Chin. Soc. Agric. Mach. 53(09), 142–150 (2022).

Zeng, R. et al. Design and experiment of multi-channel integrated shelling mechanism for fresh lotus seed. Trans. Chin. Soc. Agric. Mach. 53(04), 79–88 (2022).

Guo, Z. Design and Testing of Combined Water Chestnut Peeling Machine (Huazhong Agricultural University, 2020).

Xu, X. et al. Design and parameter optimization of fresh lotus seeds peeling machine. Trans. Chin. Soc. Agric. Mach. 52(01), 338–349 (2021).

Xie, L. et al. Study on accumulation characteristics of heavy metals of cadmium, mercury, copper and lead in water chestnut. Southwest China J. Agric. Sci. 31(8), 1712–1716 (2018).

Feng, B. Study on Physical Characteristics and Damage of Potato Tubers at Harvesting Stage (Gansu Agricultural University, 2018).

Liang, F. et al. Design and experiment of water chestnut peeler. J. Huazhong Agric. Univ. 39(4), 163–168 (2020).

Wang, F. et al. Development of comb type leaves clearing and top cutting machine for beets. Trans. Chin. Soc. Agric. Eng. 37(4), 69–79 (2021).

Chen, H. et al. Experimental study on mechanical properties and peel separation characteristics of citrus reticulate blanco with peel clamped moving. Trans. Chin. Soc. Agric. Eng. 33(14), 25–31 (2017).

Funding

Funding was provided by Special subsidy project of national characteristic vegetable industry technology system.

Author information

Authors and Affiliations

Contributions

G.Z. provided ideas and writing guidance; L.C. conducted experiment and writed the first draft; Z.G. assembled the machine; L.H. and D.Z. provided equipment support; L.F. provided design ideas; All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, G., Chen, L., Guo, Z. et al. Design and experiment of a combined peeling machine for water chestnut. Sci Rep 13, 2393 (2023). https://doi.org/10.1038/s41598-023-28472-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-28472-9

This article is cited by

-

Design and experiment of key components for self-propelled harvester for Chinese cabbage

Scientific Reports (2025)