Abstract

The current study investigated the primary and secondary compressibility characteristics of organic clay with two biopolymers, Chitosan (Dch) and Casein (Dca) at dosages of 0.5%, 1%, 2%, and 4%. The primary compression index (Cc) values were reduced by 18% and 59% at dosage (Dch and Dca) of 4% at a consolidation pressure of 800 kPa. The secondary compression indices of chitosan and casein-treated soils fell below the normal range specified for organic soils and lay in the range of 0.01–0.017. The biopolymers also accelerated the consolidation process at all dosages (Dch) and 2% Dca. The hydraulic conductivity increased for all dosages of chitosan whereas it declined for all dosages of casein compared to untreated soil. The reliability analysis was conducted for biopolymer-treated soils and presented a rational approach toward the selection of a suitable liner. Chitosan failed to achieve a target reliability index of 3 whereas casein-amended samples attained values equal to and greater than 3 at all dosages and consolidation pressures at COV of Kmax = 20%. At all dosages, the casein-treated soils exhibited reliability index values greater than 3 up to COV of Kmax = 40% indicating the higher stability of casein mixes as a liner material.

Similar content being viewed by others

Introduction

Since time immemorial, waste disposal and management have been a pertinent issue for mankind. The situation is aggravated by rapid urbanization and dwindling waste processing1. The major environmental issue faced by geoenvironmental engineers is the potential contamination of groundwater and surrounding ecosystems by the leachate produced by solid waste2. The contaminant transport and the associated mechanisms within soil and water pose a significant threat and are key issues to be addressed3. Retardation of contaminants within the landfill facility is the immediate and promising solution to delaying the environmental contamination from municipal solid waste (MSW) landfills. Landfill liners form an integral part of the waste management facilities by retarding the migration of organic and inorganic contaminants4,5. The material serving as a liner has to comply with the design requirements by satisfying the required values of unconfined compressive strength (200 kPa), hydraulic conductivity (< 10−7 cm/s), and volumetric shrinkage (< 4%)6,7.

Locally available soils may not always satisfy the liner design specifications. The presence of vulnerable soils as in situ soils poses a threat to the structural integrity and serviceability of the intended application8. However, the amendment of soils using appropriate materials will render them effective barriers9. Partial or complete replacement of local soil by bentonite can significantly modify properties such as hydraulic conductivity, consistency, and compaction characteristics10. However, the higher shrinkage, low compressive strength, and high-cost render bentonite an unreliable liner material11. In the past, industrial waste products such as fly ash have also been proposed as barrier materials owing to their significantly better mechanical and hydraulic properties12. Regardless of their benefits, fly ash has proven to be unsuitable in field application owing to the difficulty in compacting, leading to higher hydraulic conductivities13. The environmental suitability of fly ash is also questionable due to the presence of heavy metals13. The inclusion of silica fume (10–25%) in clayey soil led to increased cation exchange capacity and a reduction in hydraulic conductivity. The percentage removal of copper was achieved around 90% with silica fume at 25% dosage14. Due to the disposal challenge posed by waste tire textile fibers (WTTF), these materials were utilized in expansive soils to investigate the consolidation, desiccation cracking, and tensile strength. The efficacy of soil-WTTF mixes as a suitable liner material was proved by the reduction in compressibility and desiccation cracking15.

The structural integrity of compacted clay liners is sometimes compromised by the rainfall infiltration caused by desiccation cracking. Under this phenomenon, the hydraulic conductivity increased by manifold and affected the liner functionality16. Chitosan has effectively controlled the desiccation cracking in fine-grained soils for dosages of 0.5–4%17. Steadily, a paradigm shift has been witnessed from the usage of chemical amendments to novel materials in recent years18,19,20,21,22,23. Hydrophobic and waste-derived biopolymers such as chitosan have proven their worth in amending the soil to suit liner requirements at optimal dosages17,23. By natural selection, these materials tend to be resilient and relatively sustainable compared to other chemical stabilizers24. The filler characteristics of chitosan have modified the soil structure to have lower hydraulic conductivities (< 10−7 cm/s) at lower dosages (< 2%) in organic silts. Additionally, the compression index was reduced by 50% at 0.5% chitosan25. Another emerging biopolymer in the field of soft soil stabilization is a protein-based biopolymer named casein. The casein structure facilitates reduced interactions with water molecules due to the presence of hydrophobic bonds inside the casein micelles and aids in reducing the compressibility of the soil by 71% at a dosage of 2% in clayey soil26.

It is important to understand that biopolymers are degradable and will be subjected to changes in the measured properties upon contact with the heavy metals and leachate produced by the landfill. The hydraulic conductivity (K) of the biopolymer amended liner is subjected to variations due to factors such as construction techniques, overburden pressure from waste, rainfall infiltration, and interaction with other organic matter. The dosages selected for liner amendment will have a profound impact on the hydraulic characteristics of the material. It becomes imperative to evaluate the safety of the liners against K failure by conducting a reliability-based design optimization (RBDO). The reliability analysis is useful in handling complex information such as multivariate correlated data and leads to sound engineering judgment by verifying the reasonability of results9,27,28,29. This rational approach is beneficial to providing a comparison of probabilities of failure for different designs and also demonstrates the role of different components to uncertainty in the probability of failure27,30,31,32,33.

The current study investigated the possibility of using a Silty Clay amended by including a polysaccharide (chitosan) and protein-based (casein) biopolymer by experimental data, multivariate statistical models, and RBDO. The manuscript also discusses the mechanism between soil and the selected biopolymers leading to the desired requirements. The initial part of the manuscript discusses the results from an incremental consolidation test performed on various soil-biopolymer mixes (Dch and Dca) leading to the selection of an optimal mix. The reliability of the optimal mixes was determined by performing RBDO and evaluation of reliability indices.

Materials and methodology

Soil

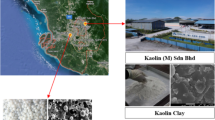

The soil sample was procured from Meenapally, Kuttanad, India (9° 50.9′ 50.2″ N, 76° 39′ 40.28″ E) at a depth of 1.5 m. The organic content was obtained as 13% as per AASHTO T 26734. The liquid limit and plasticity index values under air-dried conditions were determined as 73% and 29.4%, respectively, by ASTM D4318-17e1 (ASTM 2017)35. The Maximum Dry Density and Optimum Moisture Content were determined as 1.48 g/cm3 and 31.1%, respectively, as per ASTM D698-12e2 (ASTM 2021)36. The soil can be classified as organic clay of high plasticity as per ASTM D2487-17 (ASTM 2020)37. Further, the one-dimensional incremental consolidation test was conducted by following ASTM D2435-04 (ASTM 2011)38 to assess the compressibility characteristics.

Biopolymers

The biopolymers considered for the current study were chitosan and casein. The aforementioned biopolymers were procured from Swakit Biotech Private Limited, Karnataka, India, and Marine Hydrocolloids, Cochin, Kerala, India. Owing to their hydrophobic properties and significant improvement in engineering properties, the biopolymers were considered for amendment at dosages (Dch and Dca) of 0.5%, 1%, 2%, and 4%. The dosages were fixed considering the previous studies of Chitosan and Casein on cohesive soils with different mineralogy and composition25,39,40,41. The dosages were limited to 4% as any further increase in dosage resulted in increased viscosity of the biopolymer gels formed due to interaction with water, thereby affecting the bonding between soil and biopolymer39. The high viscosity of the biopolymer gels will lead to poor workability and accelerate the formation of air voids resulting in weak planes21. Owing to the scarcity of studies on organic soils amended using biopolymers, the influence of biopolymers, and particularly the effect of chitosan and casein on cohesive soils were referred for understanding the range of dosages to be selected for the current study.

One-dimensional consolidation test

The raw and biopolymer-amended soils were evaluated for their compressibility characteristics by conducting a conventional one-dimensional fixed ring consolidation test following ASTM D2435-04 (ASTM 2011)38. The samples were prepared in the consolidation ring of dimension 60 mm × 20 mm at a maximum dry density of 1.48 g/cm3. Following the sample preparation within the consolidation ring, sample saturation was initiated under a seating pressure of 6.25 kPa. The consolidation test was conducted with a load increment up to 800 kPa followed by unloading at a decrement ratio of four. Based on the experimental data, the parameters such as coefficient of consolidation (Cv), hydraulic conductivity (K), primary compression index (Cc), and secondary compression index (Cα) were calculated at consolidation pressures (\(\sigma_{cp}\)) of 100, 200, 400, and 800 kPa. From the previous experimental studies, it was observed that the completion time for primary and secondary consolidation of organic soils is exponentially related to the load or stress applied42. Furthermore, when soils are ameliorated using biopolymers or such organic materials, the compressibility behaviour will deviate from that of untreated soil21. It was observed that above a load of 400 kPa, the secondary consolidation behaviour does not change much for soils with organic content in the range of 10–50%. In the initial studies conducted on the collected soil, there was negligible variation in deformation observed beyond 800 kPa. Additionally, the compressibility behaviour of Kaolinite cohesive soils modified using biopolymers compacted at maximum dry density was also conducted for the pressure range of 12.5–800 kPa43,44,45. Hence the stress range for the current study was limited to 800 kPa. The tests were conducted in triplicates and the average values were considered for analysis.

Multivariate nonlinear regression models for consolidation parameters

The parameters derived from the consolidation data such as the primary compression index (Cc), secondary compression index (Cα), coefficient of consolidation (Cv), and hydraulic conductivity (K) of organic clay treated with Chitosan (Dch) and Casein (Dca) were modelled using twelve non-linear regression models. The statistical software package (DataFit, Oakdale Engineering, PA), which contains 298 2D and 242 3D regression models was utilized to develop the multivariate regression equations. The independent variables considered are dosages of Chitosan (Dch) and Casein (Dca), and consolidation pressure (\(\sigma_{cp}\)). From the statistical analysis of the experimental data, it was observed that the non-linear regression models predicted the behaviour accurately compared to linear models. The models having the highest coefficient of determination (R2) and lower root mean square error (RMSE) were selected as the best-fitting non-linear relationships. A 95% confidence was used to evaluate the regression coefficients. The probability of liner material failure, the factors of safety, and the limit state function for the hydraulic conductivity failure with unamended organic clay are given in Eqs. 1, 2, and 3 respectively.

The appendix presents the multivariate non-linear regression models developed for untreated and biopolymer-treated organic clay for predicting the values of primary compression index (Cc), secondary compression index (Cα), coefficient of consolidation (Cv), and hydraulic conductivity (K). The nonlinear regression models for primary compression indices of untreated organic clay (\(C_{c\_ut\_fit}\)), organic clay amended with Chitosan (\(C_{c\_Chi\_fit}\)), and Casein (\(C_{c\_Ca\_fit}\)) are displayed in Eqs. 4, 5, and 6. The equations (7, 8, and 9) are determined to predict secondary compression indices of untreated organic clay (\(C_{\alpha \_ut\_fit}\)), treated with Chitosan (\(C_{\alpha \_Chi\_fit}\)), and Casein (\(C_{\alpha \_Ca\_fit}\)). The Appendix also presents the equations (10, 11, and 12) for coefficients of consolidation of untreated organic clay (\(C_{v\_ut\_fit}\)), treated with Chitosan (\(C_{v\_Chi\_fit}\)), and Casein (\(C_{v\_Ca\_fit}\)). Lastly, the equations (13, 14, and 15) to predict the hydraulic conductivity (\(K_{ut\_fit}\)) of untreated organic clay, treated with Chitosan (\(K_{Chi\_fit}\)), and Casein (\(K_{Ca\_fit}\)) are shown in Appendix.

Tables S1 to S12 summarized the non-linear regression analysis of the primary compression index (Cc), secondary compression index (Cα), coefficient of consolidation (Cv), and hydraulic conductivity (K) for organic clay, Chitosan (Dch), and Casein (Dca) treated organic clay under supplementary material. Tables S1 to S12 established a good correlation between experimental findings and values proposed using the multivariate regression equations. The effect of adding Chitosan content (Dch) and Casein content (Dca) to organic clay on the factors of safety (\(FS_{{D_{ch} }}\) and \(FS_{{D_{ca} }}\)) and reliability indices against liner material failure (\(\beta_{Dch}\) and \(\beta_{Dca}\)) was discussed in the results and discussion section.

Reliability-based design optimization of liner material for MSW landfills

The reliability-based design optimization (RBDO) approach was utilized to assess the integrity of MSW liners against the possibility of hydraulic conductivity failure. The ideal value of hydraulic conductivity of liners is considered to be less than 10−7 cm/s. The probability of liner material failure (Pf) in terms of hydraulic conductivity (K) failure is defined in Eq. (1):

The limiting value of hydraulic conductivity defined to prevent failure is Kmax. To ensure serviceability of liners, Kmax is considered as 10−8 cm/s. The factors of safety against hydraulic conductivity failure of unamended organic clay (\(FS\)) is given by Eq. (2).

The factors of safety against hydraulic conductivity failure of chitosan-treated organic clay (\(FS_{{D_{ch} }}\)), and casein-treated organic clay (\(FS_{{D_{ca} }}\)) can be computed by substituting \(K_{fit}\) = \(K_{{D_{ch} \_fit}}\), and \(K_{fit}\) = \(K_{{D_{ca} \_fit}}\) in Eq. (2).

The limit state function for the hydraulic conductivity failure of liner material with unamended organic clay is given by Eq. (3).

Similarly, limit state functions for the hydraulic conductivity failure of liner material with Chitosan treated soil (\(g_{1} \left( x \right)\)) and Casein treated soil (\(g_{2} \left( x \right)\)) can be written by substituting \(FS\) = \(FS_{{D_{ch} }}\) and \(FS\) = \(FS_{{D_{ca} }}\) in Eq. (3).

The optimization in the standard normal space \(U\, = \,\left\{ {u_{k} } \right\}_{k = 1}^{n}\) is defined as follows:

-

Determine the reliability index against hydraulic conductivity failure (\(\beta_{Dch}\)) of Chitosan-treated liner material, which minimizes \(g_{1} (u)\) and is subjected to \(\sqrt {u^{T} u}\).

-

Determine the reliability index against hydraulic conductivity failure (\(\beta_{Dca}\)) of Casein-treated liner material which minimizes \(g_{2} (u)\) and is subjected to \(\sqrt {u^{T} u}\).

The conditions, \(g_{1} (u) = 0\) and \(g_{2} (u) = 0\) represent the linearized first-order limit state functions in the U space related to the risk of hydraulic conductivity failure in liner material made of organic clay treated with Chitosan and Casein, respectively.

Target reliability index for RBDO analysis

The target reliability levels used in geotechnical and geoenvironmental engineering designs are influenced by guidelines from various national and international codes of practice. However, these recommendations are not always consistent across different standards46. The selection of an appropriate target reliability index balances safety and economic considerations, and specific values are often chosen based on project requirements and codal provisions. A target reliability index of 3.0 for above-average performance, 4.0 for good performance, and 5.0 for high performance is recommended by the US Army Corps of Engineers47. Whereas, Eurocode 7 recommends a target reliability level of 95%48. The target reliability index is chosen to meet codal provisions and to ensure safety while also considering economic factors. The design of liners for high-reliability index implies a very safe design but may lead to conservative and costly solutions. The design of liners for low-reliability index may result in an unsafe design, though it could be less expensive. A reliability index of 3.0 corresponds to a probability of failure of approximately 0.00135 (or 0.135%) is commonly prescribed in geotechnical and geoenvironmental design practices49. This level of risk is deemed acceptable for many geotechnical engineering applications where the consequences of failure are significant but not catastrophic. This value is seen as a rational compromise between safety and cost. The importance of selecting project-specific target reliability indices has been emphasized by researchers, as different projects may have varying requirements for safety and cost-effectiveness50. The target reliability index is particularly critical in designs such as landfill liners, where a high-reliability index ensures safety but can be conservative and costly. Conversely, a lower reliability index might reduce costs but at the risk of compromising safety. Therefore, a target reliability index of 3.0 is chosen in the present study as it is a well-established benchmark that balances safety, cost, and practicality.

Results and discussions

Variation in void ratio with consolidation pressure

As depicted in Fig. 1, the untreated soil exhibited a marginal decrease in void ratio up to a pressure of 50 kPa beyond which the void ratio sustained a steep decrease with an increase in pressure up to 800 kPa. Upon unloading at 800 kPa, the rebound was found to be marginal indicating the presence of Kaolinite mineral in the studied soil. As shown in Fig. 1, the inclusion of chitosan led to a reduction in the void ratio at all dosages and consolidation pressures. At a consolidation pressure of 100 kPa, the void ratio decreased by 10.6%, 23.5%, 42.4%, and 18.8% at 0.5%, 1%, 2%, and 4% Dch respectively. The soil modified using casein also exhibited a similar decrease in void ratio and was reduced by 30.5%, 24.7%, 43.5%, and 42.3% at 0.5%, 1%, 2%, and 4% Dca respectively as shown in Fig. 2. For the same dosages, it can be observed from Figs. 1 and 2 that casein overpowered chitosan in reducing the compressibility at all dosages. The chitosan and casein-treated soils exhibited a marginal rebound upon unloading. The chitosan and casein modified the soil structure to a flocculated and aggregated structure as shown in Fig. 3. Casein-treated soils exhibited a denser structure compared to chitosan-treated soil and this was also reflected in the compressibility of the treated soils. The steep decrease in void ratio beyond a pressure of 100 kPa indicated the disruption of the stable structures formed as a result of soil-biopolymer bonding. For chitosan and casein-treated soils, it was observed that the void ratio increased at 4% dosage compared to the void ratios at lower dosages indicating the formation of higher interaggregate voids within the structure as depicted in Fig. 3.

Variation in primary compression index (C c) and secondary compression index (C α)

The effect of dosage and consolidation pressure on the primary compression index (Cc) is depicted in Fig. 4a. The untreated soils exhibited Cc of 0.284, 0.289, 0.299, and 0.358 at consolidation pressure of 100, 200, 400, and 800 kPa respectively. The addition of chitosan reduced the volume of the soil matrix by the interaction between the chitosan and soil particles. The neutrally charged chitosan particles replaced the water molecules existing near the clay surface and reduced the void space between the soil particles. The soil matrix transformed from flocculated to flocculated and aggregated structure and thereby reduced the volume of the soil-biopolymer matrix. This led to the reduction in the primary compression index (Cc) by 0.72, 0.35, 0.27, and 0.35 times at Dch = 0.5%, 1%, 2%, and 4% respectively at a consolidation pressure of 100 kPa. When the consolidation pressure was increased to 800 kPa, the disruption of the stable matrices increased the compressibility and attained higher values of Cc at a particular dosage (Dch). The inclusion of casein micelles led to an interaction between the negatively charged casein and positively charged edges of clay particles leading to a uniform coating around the soil particles. The casein coating reduced the compressibility more effectively compared to chitosan particles. At a consolidation pressure of 100 kPa, the compressibility (Cc) reduced by 0.13, 0.11, 0.08, and 0.21 times compared to untreated soil at dosages of Dca = 0.5%, 1%, 2%, and 4% respectively as shown in Fig. 4b.

The effect of chitosan and casein in reducing the creep deformation is depicted in Fig. 5a and b. The raw soil exhibited secondary compression index (Cα) values of 0.0121, 0.0171, 0.0199, and 0.021 at \(\sigma_{cp}\) = 100, 200, 400, and 800 kPa respectively. Soil with Cα greater than or equal to 0.064 is considered to be highly organic39. The studied soil exhibited low values of Cα around 0.01 due to the lower organic content of the soil. At \(\sigma_{cp}\) = 100 kPa, the chitosan-treated soil reduced Cα by 1.07%, 12.35%, 13.67%, and 19.24% for dosages of (Dch) 0.5%, 1%, 2%, and 4% respectively. Whereas, the casein-treated soil reduced Cα by 61.11%, 61.77%, 63.59%, and 80.35% for dosages (Dca) of 0.5%, 1%, 2%, and 4% respectively. The reduction in secondary compression after amendment with chitosan and casein will aid in mitigating the detrimental effects of secondary settlement in the field.

Variations in coefficient of consolidation (C v)

The variation of Cv in chitosan-treated (Dch) soils is presented in Fig. 6a. The untreated soils attained Cv values of 6.24, 5.95, 5.68, and 5.34 m2/year at consolidation pressures of 100 kPa, 200 kPa, 400 kPa, and 800 kPa respectively. From Fig. 6a, it was observed that the addition of chitosan (Dch) accelerated the consolidation process and facilitated the easy expulsion of water from the soil structure at all dosages (Dch). At a consolidation pressure of 100 kPa, the Cv values increased by 1.62, 3.09, 6.94, and 1.72 times at Dch = 0.5%, 1%, 2%, and 4% respectively. For a particular consolidation pressure, the Cv values increased up to 2% and thereafter declined at Dch = 4%. The casein-treated (Dca) soils exhibited a drop in Cv for all dosages except for Dca = 2%. At a consolidation pressure of 100 kPa, the Cv values dropped by 0.57, 0.78, and 0.78 times for dosages of Dca = 0.5%, 1%, and 4% as shown in Fig. 6b. Similar to the trend observed for chitosan, the casein-treated soil also displayed a decrement in Cv with a rise in consolidation pressure.

Variation in hydraulic conductivity (K)

Figure 7a depicts the variation in hydraulic conductivity of soil-chitosan mixes for varying dosages (Dch) and consolidation pressures (\(\sigma_{cp}\)). The untreated soils attained K values of 6.29, 6.01, 5.74, and 5.39 (× 10−8 cm/s) indicating the lower permeability of the raw soil for consolidation pressures of 100, 200, 400, and 800 kPa. The K values declined as the consolidation pressure increased. After amending with chitosan (Dch), the K value increased by 1.57, 1.75, 4.15, and 1.13 times for dosages of 0.5%, 1%, 2%, and 4% at a consolidation pressure of 100 kPa. The hydraulic conductivity of soil treated with 4% (Dch) decreased by 0.27 times compared to chitosan amendment at 2%. However, at all dosages, the K values of soil-chitosan mixes were higher than those of raw soil. With a rise in consolidation pressure, the K values declined by 0.95, 0.89, and 0.84 times at Dch = 0.5% at consolidation pressure of 200, 400, and 800 kPa. For Dch > 0.5%, the K values decreased with an increase in consolidation pressure up to 800 kPa.

For the case of casein-treated soil, the hydraulic conductivity decreased by 0.32, 0.41, 0.43, and 0.28 times for Dca = 0.5%, 1%, 2%, and 4% at \(\sigma_{cp}\) = 100 kPa as shown in Fig. 7b. With a rise in consolidation pressure, the K values further dropped for all dosages (Dca). Considering the liner requirement as per K value, the casein-treated soils have exhibited a drop in K value at all dosages (Dca) whereas, the chitosan amendment brought a rise in K value at all dosages (Dch) compared to untreated soil. As displayed in Fig. 3, chitosan and casein amended samples took up an aggregated and flocculated structure. The interaction of chitosan and casein is due to the electrostatic force of attraction between them and clay particles. Unlike chemical stabilization, the soil-biopolymer bond does not contribute to the formation of any new compounds within the structure. For neutral biopolymers such as chitosan, the adsorption on the clay surface is largely entropy-driven and leads to the desorption of water molecules. The increase in entropy can be attributed to the breaking of sequential hydrogen bonding extending from the clay surface51. Anionic polymers or polyanions such as Casein are effective flocculants, especially while accompanying polyvalent cations such as exposed Aluminium ions at the clay surface52. The aforementioned interactions between chitosan and casein with clay particles led to the formation of a flocculated and aggregated structure. Chitosan acted as a voluminous filler material and increased the hydraulic conductivity with an increase in dosage. Whereas, casein formed a uniform coating over the soil particles and relatively led to the formation of a denser structure. This aided in reducing the value of hydraulic conductivity of soil-casein mixes.

Effect of dosage on factors of safety (\(FS_{{D_{ch} }}\) and \(FS_{{D_{ca} }}\)) of chitosan (D ch) and casein-treated (D ca) soils

The effect of dosage on the factors of safety modified using chitosan (\(FS_{{D_{ch} }}\)) and casein (\(FS_{{D_{ca} }}\)) is presented in Fig. 8. A factor of safety (FS) of 1.589 was attained for untreated soil at a consolidation pressure (\(\sigma_{cp}\)) of 100 kPa. As \(\sigma_{cp}\) rose to 200, 400, and 800 kPa, the factor of safety increased by 4.78%, 9.75%, and 16.61% respectively. The increase in FS with an increase in \(\sigma_{cp}\) can be attributed to the decrease in Kch observed in Fig. 7a. On adding chitosan to the raw soil, the factors of safety against K failure decreased to 1.026, 1.058, 1.107, and 1.165 at \(\sigma_{cp}\) = 100, 200, 400, and 800 kPa for dosage of 5% (Dch). The increase in hydraulic conductivity upon the addition of Dch = 0.5% as shown in Fig. 7a can be a contributing factor to the decrease in \(FS_{{D_{ch} }}\). The hydraulic conductivity values further increased at Dch = 1% and this was reflected in the \(FS_{{D_{ch} }}\) values attained for different \(\sigma_{cp}\) at the same dosage. Beyond a dosage of 1%, the factors of safety decreased below 1 indicating the negative influence of higher dosages of chitosan.

However, \(FS_{{D_{ch} }}\) started increasing beyond Dch = 3.5% and attained values of \(FS_{{D_{ch} }}\) = 1.412, 1.456, 1.534, and 1.633 at \(\sigma_{cp}\) = 100, 200, 400, and 800 kPa respectively at Dch = 4%. This is in agreement with the increase in hydraulic conductivity up to 2% and a decrease at 4% Dch as shown in Fig. 7a. From Fig. 8, it can be observed that, unlike chitosan, casein has displayed a significant peak in \(FS_{{D_{ca} }}\) after treating with dosage of 0.5% (Dca). This can be attributed to the decrease in hydraulic conductivity at the same dosage of casein as displayed in Fig. 7b. The rise in \(FS_{{D_{ca} }}\) was increased by a factor of 3.05, 3.07, 3.08, and 3.05 times at \(\sigma_{cp}\) = 100, 200, 400, and 800 kPa respectively. Beyond Dca = 0.5%, a slight increase in hydraulic conductivity was observed (Fig. 7b) which led to a decrease in \(FS_{{D_{ca} }}\) up to a dosage of 2%. Beyond Dca = 2%, \(FS_{{D_{ca} }}\) displayed a continuous increase up to the highest dosage of 4%. The highest \(FS_{{D_{ca} }}\) of 8.272, 8.37, 8.348, and 8.643 were attained at Dca = 4% for \(\sigma_{cp}\) = 100, 200, 400, and 800 kPa respectively.

Effect of dosage on reliability indices (\(\beta_{Dch}\) and \(\beta_{Dca}\)) of chitosan (D ch) and casein-treated (D ca) soils

The feasibility of utilizing the biopolymers, chitosan, and casein as a liner amendment for cohesive deposits was evaluated using the reliability indices. Figure 9 depicts the effect of biopolymer dosages on the reliability indices (\(\beta_{Dch}\) and \(\beta_{Dca}\)). A reliability index of 3 is regarded as the optimum value to consider a material appropriate for the intended application. In the case of untreated soil, the material exhibited positive values (\(\beta\)) of 2.24, 2.475, 2.709, and 3.015 for \(\sigma_{cp}\) = 100, 200, 400, and 800 kPa respectively. For untreated and biopolymer-treated soils, the samples exhibited an increase in reliability index with an increase in consolidation pressure. After amending the soil with Dch = 0.5%, the reliability indices (\(\beta_{Dch}\)) reduced to 0.032, 0.187, 0.415, and 0.669 for an increase in \(\sigma_{cp}\) from 100 to 800 kPa. The increase in permeability at Dch = 0.5% as shown in Fig. 7a led to a dip in reliability indices. Further, the reliability indices dropped to negative values beyond Dch = 0.5% indicating the detrimental effects of chitosan as a liner material.

For casein-treated soils, the reliability indices increased by 3.54, 3.28, 3.09, and 2.85 times after mixing soil with Dca of 0.5% for \(\sigma_{cp}\) = 100, 200, 400, and 800 kPa respectively. The reliability index achieved a value of greater than 3 for the different dosages of casein (Dca) admixed with soil. Even though the reliability indices (\(\beta_{Dca}\)) witnessed a drop at Dca = 1% and 2%, the values further increased at Dca = 4%. Casein proved to be an excellent liner material at all dosages by attaining \(\beta_{Dca}\) > 3. The above reliability indices were compared for chitosan and casein-treated soils at COV of Kmax = 20%.

Comparison of reliability index of casein treated soil (\(\beta_{Dca}\)) for different COV of K max for different consolidation pressures

After evaluating the reliability indices for chitosan and casein-treated soils for the different consolidation pressures, it was observed that casein completely outperformed chitosan as a liner material against K failure. Considering the performance of casein and reliability indices achieved at different dosages and consolidation pressures, the casein-treated soils were only considered for assessing the effect of COV of Kmax. The effect of COV of Kmax on the reliability indices of casein-treated soils for all dosages at a consolidation pressure of 100 kPa is shown in Fig. 10. The untreated soil exhibited reliability indices of 4.595, 2.24, 1.431, 1.01, 0.745, and 0.558 at COV of Kmax = 10%, 20%, 30%, 40%, 50%, and 60% respectively. As the COV of Kmax increased, the reliability indices dropped indicating detrimental effects due to the uncertainties involved within the environmental conditions. The general trend for reliability index was a steep increase at Dca = 0.5%, followed by a drop at 1% and 2% and further an increase in reliability index up to the highest dosage of 4%. At Dca = 0.5%, a reliability index (\(\beta_{Dca}\)) of 3 was attained for COV of Kmax upto 50%. At COV of Kmax = 60%, the highest value achieved is 2.83 for a dosage of 4%.

As the consolidation pressure was increased to 200 kPa, the trend remains the same. However, the reliability indices were observed to attain a rise at each dosage as shown in Fig. 11, compared to the values obtained at 100 kPa. This can be attributed to the decrease in K value with increase in consolidation pressure for the same dosage as shown in Fig. 7b. The peak values of reliability indices were attained as 16.076, 8.111, 5.404, 4.04, 3.185, and 2.665 at Dca = 0.5% at COV of Kmax = 10, 20, 30, 40, 50, and 60% respectively. Similar to the observation made for Fig. 10, a reliability index of 3 could not be achieved when the COV of Kmax exceeded 50%.

At consolidation pressure of 400 kPa and 800 kPa, \(\beta_{Dca}\) > 3 was attained at Dca = 0.5% for COV of Kmax up to 50% as displayed in Figs. 12 and 13. From Figs. 10, 11, 12 and 13, the importance of assessing the stability of the mixes under different uncertainties quantified in the form of COV on the hydraulic conductivity was established. Different factors such as compaction process, change in moisture content, influence of leachate concentrations, presence of organic and inorganic contaminants, can be considered as the varying factors affecting the liner integrity. These varying factors were quantified using COV of Kmax in the current study. From analyzing the effect of COV of Kmax on the reliability indices of casein-treated soils, it has been understood that the target reliability index of 3 can be achieved at the minimum dosage (Dca) of 0.5% and up to COV of Kmax value of 50%. Thus, Dca = 0.5% can be considered as the optimum dosage requirement for casein as a liner material amendment in soft soil.

Conclusions

The influence of two hydrophobic biopolymers, namely chitosan and casein on the consolidation parameters of an organic clay has been investigated in the current study. Non-linear multivariate regression models were developed to predict the coefficient of consolidation (Cv), hydraulic conductivity (K), primary compression index (Cc), and secondary compression index (Cα) values. To assess the feasibility of the biopolymer as a liner material, the probability of the liner against hydraulic conductivity failure was evaluated by conducting a reliability analysis. The following conclusions are drawn from the current study:

-

The interaction between chitosan and casein with the soil particles led to the formation of an aggregated and flocculated structure and reduced the soil volume. At the highest consolidation pressure of 800 kPa, the primary compressibility (Cc) was reduced by 18% and 59% at a maximum dosage (Dch and Dca) of 4%.

-

The secondary compression index (Cα) was reduced by 32% and 47% for chitosan and casein-amended samples at 4% (Dch and Dca) at a consolidation pressure of 800 kPa. The compressibility indices (Cc and Cα) increased with a rise in consolidation pressure due to the disruption of the stable structures.

-

The hydrophobic biopolymers also accelerated the consolidation process and increased the coefficient of consolidation (Cv) at all dosages (Dch) and 2% Dca. The Cv values were found to reduce with a rise in consolidation pressure at all dosages (Dch and Dca).

-

In the case of chitosan-amended samples, the hydraulic conductivity increased compared to untreated soil whereas the casein-amended samples exhibited hydraulic conductivities lower than those of untreated soil. Thus, casein exhibited a potential application as a liner material.

-

The addition of chitosan rendered factors of safety below 1 between dosages (Dch) of 0.5% and 3.5%, beyond which factors of safety attained values greater than 1 at all consolidation pressures. However, casein-amended samples exhibited factors of safety greater than 1 at all dosages and consolidation pressures.

-

Chitosan amended liner material failed to achieve the target reliability index of 3 at all dosages. Whereas, the casein amended samples attained the target reliability index of 3 at all dosages and consolidation pressures at COV of Kmax = 20%.

-

At all consolidation pressures, the highest reliability indices (> 3) were attained at a dosage of 0.5% (Dca) for the different COV of Kmax from 10 to 60%. Thus, the optimum dosage of casein required for liner amendment can be considered as Dca = 0.5%.

Among the selected biopolymers for the current study, casein proved to be an excellent material for amending liner materials and exhibited higher factors of safety (> 1) and reliability indices (> 3) for all dosages (Dca). Biopolymers have proven to be environment friendly and non-polluting by virtue of the natural materials used for their synthesis. Either dry mixing method or wet mixing method can be adopted for achieving a homogeneous soil-biopolymer mix. As a future scope of work, the interaction of casein with various contaminants can be explored.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

Abbreviations

- COV :

-

Coefficient of variation

- FS :

-

Factors of safety against hydraulic conductivity failure of untreated soil

- \(FS_{{D_{ch} }}\) :

-

Factors of safety against hydraulic conductivity failure of Chitosan treated soil

- \(FS_{{D_{ca} }}\) :

-

Factors of safety against hydraulic conductivity failure of Casein treated soil

- D ch :

-

Chitosan content

- g 1(x):

-

The limit state function for Chitosan-treated soil

- D ca :

-

Casein content

- g 2(x):

-

The limit state function for Casein-treated soil

- K :

-

Hydraulic conductivity of soil

- \(K_{ut\_\exp }\) :

-

Hydraulic conductivity of untreated soil obtained from the experiment

- \(K_{ut\_fit}\) :

-

Hydraulic conductivity of untreated soil obtained from curve fitting

- \(K_{Chi\_\exp }\) :

-

Hydraulic conductivity of Dch modified soil obtained from experiment

- \(K_{Chi\_fit}\) :

-

Hydraulic conductivity of Dch modified soil obtained from curve fitting

- \(K_{Ca\_\exp }\) :

-

Hydraulic conductivity of Dca modified soil obtained from experiment

- \(K_{Ca\_fit}\) :

-

Hydraulic conductivity of Dca modified soil obtained from curve fitting

- K max :

-

Maximum specified value of hydraulic conductivity as per the regulatory standards

- \(C_{v\_ut\_\exp }\) :

-

Coefficient of consolidation of untreated soil obtained from experiment

- \(C_{v\_ut\_fit}\) :

-

Coefficient of consolidation of untreated soil obtained from curve fitting

- \(C_{v\_Chi\_\exp }\) :

-

Coefficient of consolidation of Dch modified soil obtained from experiment

- \(C_{v\_Chi\_fit}\) :

-

Coefficient of consolidation of Dch modified soil obtained from curve fitting

- \(C_{v\_Ca\_\exp }\) :

-

Coefficient of consolidation of Dca modified soil obtained from experiment

- \(C_{v\_Ca\_fit}\) :

-

Coefficient of consolidation of Dca modified soil obtained from curve fitting

- \(C_{c\_ut\_\exp }\) :

-

Primary compression index of untreated soil obtained from experiment

- \(C_{c\_ut\_fit}\) :

-

Primary compression index of untreated soil obtained from curve fitting

- \(C_{c\_Chi\_\exp }\) :

-

Primary compression index of Dch modified soil obtained from experiment

- \(C_{c\_Chi\_fit}\) :

-

Primary compression index of Dch modified soil obtained from curve fitting

- \(C_{c\_Ca\_\exp }\) :

-

Primary compression index of Dca modified soil obtained from experiment

- \(C_{c\_Ca\_fit}\) :

-

Primary compression index of Dca modified soil obtained from curve fitting

- \(C_{\alpha \_ut\_\exp }\) :

-

Secondary compression index of untreated soil obtained from experiment

- \(C_{\alpha \_ut\_fit}\) :

-

Secondary compression index of untreated soil obtained from curve fitting

- \(C_{\alpha \_Chi\_\exp }\) :

-

Secondary compression index of Dch modified soil obtained from experiment

- \(C_{\alpha \_Chi\_fit}\) :

-

Secondary compression index of Dch modified soil obtained from curve fitting

- \(C_{\alpha \_Ca\_\exp }\) :

-

Secondary compression index of Dca modified soil obtained from experiment

- \(C_{\alpha \_Ca\_fit}\) :

-

Secondary compression index of Dca modified soil obtained from curve fitting

- \(\beta\) :

-

Reliability index

- \(\beta_{Dch}\) :

-

Reliability index against hydraulic conductivity failure of Chitosan treated soil

- \(\beta_{Dca}\) :

-

Reliability index against hydraulic conductivity failure of Casein treated soil

- \(\sigma_{cp}\), P :

-

Consolidation pressure

References

Singh, A. Managing the uncertainty problems of municipal solid waste disposal. J. Environ. Manag. 240, 259–265. https://doi.org/10.1016/j.jenvman.2019.03.025 (2019).

Vaverková, M. D. et al. Impact of municipal solid waste landfill on environment–A case study. J. Ecol. Eng. 19(4), 55–68. https://doi.org/10.12911/22998993/89664 (2018).

Rowe, R. K. Long-term performance of contaminant barrier systems. Geotechnique 55(9), 631–678. https://doi.org/10.1680/geot.2005.55.9.631 (2005).

Lo, I. M., Mak, R. K. & Lee, S. C. Modified clays for waste containment and pollutant attenuation. J. Environ. Eng. 123(1), 25–32. https://doi.org/10.1061/(ASCE)0733-9372(1997)123:1(25) (1997).

Scalia, I. V. et al. Enhanced bentonites for containment of inorganic waste leachates by GCLs. Geosynth. Int. 25(4), 392–411. https://doi.org/10.1680/jgein.18.00024 (2018).

Kayabali, K. Engineering aspects of a novel landfill liner material: Bentonite-amended natural zeolite. Eng. Geol. 46(2), 105–114. https://doi.org/10.1016/S0013-7952(96)00102-0 (1997).

Ojuri, O. O. & Oluwatuyi, O. E. Strength and hydraulic conductivity characteristics of sand-bentonite mixtures designed as a landfill liner. Jordan J. Civ. Eng. 11(4), 614–622 (2017).

Rasheed, R. M. & Moghal, A. A. B. Critical appraisal of the behavioral geo-mechanisms of peats/organic soils. Arab. J. Geosci. 15(12), 1123. https://doi.org/10.1007/s12517-022-10396-9 (2022).

Vydehi, K. V., Moghal, A. A. B. & Basha, B. M. Reliability-based design optimization of biopolymer-amended soil as an alternative landfill liner material”. J. Hazard. Toxic Radioact. Waste 26(3), 04022011. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000697 (2022).

Shariatmadari, N., Salami, M. & Fard, M. K. Effect of inorganic salt solutions on some geotechnical properties of soil-bentonite mixtures as barriers. Int. J. Civ. Eng. 9(2), 103–110 (2011).

Sivapullaiah, P. V. & Baig, M. A. A. Gypsum treated fly ash as a liner for waste disposal facilities. Waste Manag. 31(2), 359–369. https://doi.org/10.1016/j.wasman.2010.07.017 (2011).

Edil, T. B., Sandstrom, L. K. & Berthouex, P. M. Interaction of inorganic leachate with compacted pozzolanic fly ash. J. Geotech. Eng. 118(9), 1410–1430. https://doi.org/10.1061/(ASCE)0733-9410(1992)118:9(1410) (1992).

Palmer, B. G., Edil, T. B. & Benson, C. H. Liners for waste containment constructed with class F and C fly ashes. J. Hazard. Mater. 76(2–3), 193–216. https://doi.org/10.1016/S0304-3894(00)00199-0 (2000).

Nambiar, N., Remya, N. & Varghese, G. K. Effective reuse of waste material as an amendment in composite landfill liner: Assessment of geotechnical properties and pollutant retention capacity. Waste Manag. Res. 38(2), 134–141. https://doi.org/10.1177/0734242X19886920 (2020).

Narani, S. S., Abbaspour, M., Hosseini, S. M., Aflaki, E. & Nejad, F. M. Sustainable reuse of Waste Tire Textile Fibers (WTTFs) as reinforcement materials for expansive soils: With a special focus on landfill liners/covers. J. Clean. Prod. 247, 119151. https://doi.org/10.1016/j.jclepro.2019.119151 (2020).

Tran, K. M., Bui, H. H., Kodikara, J. & Sánchez, M. Soil curling process and its influencing factors. Can. Geotech. J. 57(3), 408–422. https://doi.org/10.1139/cgj-2018-0489 (2019).

Rasheed, R. M., Moghal, A. A. B., Jannepally, S. S. R., Rehman, A. U. & Chittoori, B. C. S. Shrinkage and consolidation characteristics of chitosan-amended soft soil—A sustainable alternate landfill liner material. Buildings 13, 2230. https://doi.org/10.3390/buildings13092230 (2023).

Amulya, G., Moghal, A. A. B. & Almajed, A. Sustainable binary blending for low-volume roads—Reliability-based design approach and carbon footprint analysis. Materials 16(5), 2065. https://doi.org/10.3390/ma16052065 (2023).

Ashfaq, M., Moghal, A. A. B. & Basha, B. M. Reliability-based design optimization of chemically stabilized coal gangue. J. Test. Eval. 50(6), 3116–3130. https://doi.org/10.1520/JTE20210176 (2022).

Kumar, M. A., Moghal, A. A. B., Vydehi, K. V. & Almajed, A. Embodied energy in the production of guar and xanthan biopolymers and their cross-linking effect in enhancing the geotechnical properties of cohesive soil. Buildings 13(9), 2304. https://doi.org/10.3390/buildings13092304 (2023).

Vydehi, K. V. & Moghal, A. A. B. Effect of biopolymeric stabilization on the strength and compressibility characteristics of cohesive soil. J. Mater. Civ. Eng. 34(2), 04021428. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004068 (2022).

Rasheed, R. M. & Moghal, A. A. B. Compressibility and durability characteristics of protein-based biopolymer amended organic soil. J. Mater. Civ. Eng. https://doi.org/10.1061/JMCEE7/MTENG-17285 (2024).

Rasheed, R. M., Moghal, A. A. B., Rambabu, S. & Almajed, A. Sustainable assessment and carbon footprint analysis of polysaccharide biopolymer-amended soft soil as an alternate material to canal lining. Front. Environ. Sci. 11, 1214988. https://doi.org/10.3389/fenvs.2023.1214988 (2023).

Kavazanjian, E. Jr. If It’s biogeotechnical, it must be sustainable (Right?). GeoStrata Mag. Arch. 27(4), 12–13. https://doi.org/10.1061/geosek.0000498 (2023).

Kannan, G. & Sujatha, E. R. Crustacean polysaccharides for the geotechnical enhancement of organic silt: A clean and green alternative. Carbohydr. Polym. 299, 120227. https://doi.org/10.1016/j.carbpol.2022.120227 (2023).

Ni, J., Li, S. S. & Geng, X. Y. Mechanical and biodeterioration behaviours of a clayey soil strengthened with combined carrageenan and casein. Acta Geotech. 17, 5411–5427. https://doi.org/10.1007/s11440-022-01588-4 (2022).

Basha, B. M. & Babu, G. S. Optimum design for external seismic stability of geosynthetic reinforced soil walls: Reliability-based approach. J. Geotech. Geoenviron. Eng. 136(6), 797–812. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000289 (2010).

Phoon, K. K. Role of reliability calculations in geotechnical design. Georisk Assess. Manag. Risk Eng. Syst. Geohazards 11(1), 4–21. https://doi.org/10.1080/17499518.2016.1265653 (2017).

Vydehi, K. V., Moghal, A. A. B. & Basha, B. M. Target reliability-based design of embankments using biopolymer-modified cohesive soil. Int. J. Geomech. 22(8), 04022115. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002429 (2022).

Christian, J. T. Geotechnical engineering reliability: How well do we know what we are doing?. J. Geotech. Geoenviron. Eng. 130(10), 985–1003. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:10(985) (2004).

Moghal, A. A. B., Basha, B. M. & Ashfaq, M. Probabilistic study on the geotechnical behavior of fiber reinforced soil. In Frontiers in Geotechnical Engineering Developments in Geotechnical Engineering (eds Latha, G. & M.) (Springer, 2019). https://doi.org/10.1007/978-981-13-5871-5_17.

Moghal, A. A. B., Chittoori, B. C., Basha, B. M. & Al-Shamrani, M. A. Target reliability approach to study the effect of fiber reinforcement on UCS behavior of lime treated semiarid soil. J. Mater. Civ. Eng. 29(6), 04017014. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001835 (2017).

Syed, M., Moghal, A. A. B., & Chittoori, B. C. S. Reliability analysis of polyvinyl alcohol fiber-reinforced soft subgrade soil treated with lime and alkali activated stabilizer: A comparative study. In Geo-Congress 422–432. https://doi.org/10.1061/9780784484661.044 (2023).

AASHTO T 26. Standard Method of Test for Determination of Organic Content in Soils by Loss on Ignition (2022). Accessed May 2024

ASTM. Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM D4318–17el. (ASTM, 2017) (Accessed on May 2024)

ASTM. Standard test methods for laboratory compaction characteristics of soil using standard effort (12400 ft-lbf=ft3 (600 kN-m=m3)). ASTM D698–12e2. (ASTM, 2021). (Accessed on May 2024)

ASTM. 2020. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM D2487–17 (American Society for Testing and Materials, 2020). (Accessed on May 2024)

ASTM. Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM D2435–04. (ASTM, 2011). (Accessed on May 2024)

Aguilar, R. et al. The potential use of chitosan as a biopolymer additive for enhanced mechanical properties and water resistance of earthen construction. Constr. Build. Mater. 114, 625–637. https://doi.org/10.1016/j.conbuildmat.2016.03.218 (2016).

Chang, I., Im, J., Chung, M. K. & Cho, G. C. Bovine casein as a new soil strengthening binder from dairy wastes. Constr. Build. Mater. 160, 1–9. https://doi.org/10.1016/j.conbuildmat.2017.11.009 (2018).

Fatehi, H., Abtahi, S. M., Hashemolhosseini, H. & Hejazi, S. M. A novel study on using protein-based biopolymers in soil strengthening. Constr. Build. Mater. 167, 813–821. https://doi.org/10.1016/j.conbuildmat.2018.02.028 (2018).

Feng, R., Peng, B., Wu, L., Cai, X. & Shen, Y. Three-stage consolidation characteristics of highly organic peaty soil. Eng. Geol. 294, 106349. https://doi.org/10.1016/j.enggeo.2021.106349 (2021).

Latifi, N. et al. Improvement of problematic soils with biopolymer—An environmentally friendly soil stabilizer. J. Mater. Civ. Eng. 29(2), 04016204. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001706 (2017).

Hamza, M. et al. Strengthening potential of xanthan gum biopolymer in stabilizing weak subgrade soil. Clean Technol. Environ. Policy 24(9), 2719–2738. https://doi.org/10.1007/s10098-022-02347-5 (2022).

Oliveira, P. J. V. & Reis, M. J. Effect of the organic matter content on the mechanical properties of soils stabilized with xanthan gum. Appl. Sci. 13(8), 4787. https://doi.org/10.3390/app13084787 (2023).

Sykora, M., Diamantidis, D., Holicky, M. & Jung, K. Target reliability for existing structures considering economic and societal aspects. In Life-Cycle of Structural Systems Vol. 3 (eds Furuta, H. et al.) 181–194 (Routledge, 2016).

US Army Corps of Engineers. Engineering and design: Introduction to probability and reliability methods for use in geotechnical engineering, Eng circular 1110-2-547 (US Dept. of the Army, 1997).

European Committee for Standardisation (CEN) (2004). Eurocode 7: Geotechnical design, Part-1: General rules, EN 1997–1, CEN.

Naghibi, F. & Fenton, G. A. Target geotechnical reliability foundations systems. Can. Geotech. J. 54, 945–952. https://doi.org/10.1139/cgj-2016-0478 (2017).

Becker, D. E. Geotechnical risk management and reliability based design-Lessons learned. In Geo Risk 2017, vol. 282, 98–121 (Geotechnical Special Publication, 2017)

Theng, B. K. G. Clay-polymer interactions—Summary and perspectives. Clays Clay Miner. 30(1), 1–10. https://doi.org/10.1346/ccmn.1982.0300101 (1982).

Roberts, K., Kowalewska, J. & Friberg, S. The influence of interactions between hydrolyzed aluminum ions and polyacrylamides on the sedimentation of kaolin suspensions. J. Colloid Interface Sci. 48(3), 361–367. https://doi.org/10.1016/0021-9797(74)90178-7 (1974).

Acknowledgements

This research is funded by the Researchers Supporting Project Number (RSP2024R279), King Saud University, Riyadh, Saudi Arabia. The authors extend their appreciation to the Researchers Supporting Project Number (RSP2024R279), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

R.M.R., A.A.B.M., B.M.B.: Conceptualization, Writing—original draft. R.M.R., A.A.B.M., B.M.B., A.A.: Writing—review and editing. R.M.R.: Formal analysis. R.M.R., A.A.B.M., B.M.B.: Methodology. R.M.R.: Investigation. R.M.R., A.A.B.M.: Software. A.A.B.M.: Supervision. A.A.B.M..: Visualization. R.M.R., A.A.B.M.: Validation. R.M.R.: Data curation. A.A.: Funding.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix

Appendix

Primary compression index (Cc) of untreated and biopolymer modified organic clay

Equation (4) presents the multivariate regression model for predicting Primary Compression index (Cc) of untreated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Equation (5) presents the multivariate regression model for predicting Primary Compression index (Cc) of chitosan-treated soil (Dch) with R2 = 0.99 and \(R_{adj}^{2}\) = 0.98.

Equation (6) presents the multivariate regression model for predicting Primary Compression index (Cc) of casein-treated soil (Dca) with R2 = 0.99 and \(R_{adj}^{2}\) = 0.96.

Secondary compression index (Cα) of untreated and biopolymer modified organic clay

Equation (7) presents the multivariate regression model for predicting Secondary Compression index (Cα) of untreated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Equation (8) presents the multivariate regression model for predicting Secondary Compression index (Cα) of chitosan-treated soil (Dch) with R2 = 0.89 and \(R_{adj}^{2}\) = 0.72.

Equation (9) presents the multivariate regression model for predicting Secondary Compression index (Cα) of casein-treated soil (Dca) with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Coefficient of consolidation (Cv) of untreated and biopolymer modified organic clay

Equation (10) presents the multivariate regression model for predicting Coefficient of Consolidation (Cv) of untreated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Equation (11) presents the multivariate regression model for predicting Coefficient of Consolidation (Cv) of chitosan-treated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Equation (12) presents the multivariate regression model for predicting Coefficient of Consolidation (Cv) of casein-treated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Hydraulic conductivity (K) of untreated and biopolymer modified organic clay

Equation (13) presents the multivariate regression model for predicting Hydraulic conductivity (K) of untreated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Equation (14) presents the multivariate regression model for predicting Hydraulic conductivity (K) of chitosan-treated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Equation (15) presents the multivariate regression model for predicting Hydraulic conductivity (K) of casein-treated soil with R2 = 0.99 and \(R_{adj}^{2}\) = 0.99.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rasheed, R.M., Moghal, A.A.B., Basha, B.M. et al. Target reliability-based design optimization studies on cohesive soil amended with chitosan and casein for liner applications. Sci Rep 14, 14202 (2024). https://doi.org/10.1038/s41598-024-64408-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-64408-7

This article is cited by

-

Enhancing durability and erosion resistance of soils with varying plasticity using crosslinked biopolymers

Scientific Reports (2025)

-

Reliability-Based Design Analysis of Cohesive Soil as an Embankment Material Amended Using Hydrophobic Biopolymers

Arabian Journal for Science and Engineering (2024)

-

Biobased-Sustainable Choices to Improve Seismic Resilience of Soils

Journal of the Indian Institute of Science (2024)