Abstract

To investigate the dispersion process of the underground toxic gas carbon monoxide (CO) into the refuge chamber during a mine disaster and enhance the survival rate of trapped miners, a simplified model of an underground refuge chamber and the main roadway was constructed. The impact of temperature and pressurized air volume on CO dispersion into the refuge chamber has been examined through both analog experiments and numerical simulations, and the reliability of the simulation results was verified. The results indicate that CO dispersion into the refuge chamber through the top of the protective isolation door occurs when the temperature in the refuge chamber is lower than that of the toxic gas. When the temperature of the toxic gas is higher, it tends to enter the refuge chamber through the bottom of the protective isolation door. The evolution of CO concentration in the transition chamber can be divided toxic survival chamber can be categorized into a sudden decline stage and a stable stage. And a flexible isolation door designed to control the entry of toxic gases into the refuge chamber was implemented, and its impact on CO dispersion has been compared and analyzed. When the temperature of the main roadway is 50 °C and the temperature of the refuge chamber is 20 °C, the required pressurized air volume to maintain the CO concentration within the safe threshold (24 ppm) is reduced to 69.6% of that needed without the isolation door, thereby significantly reducing the infiltration of harmful gases from the main roadway into the refuge chamber.

Similar content being viewed by others

Introduction

China, recognized as the world’s foremost coal producer, has numerous coal mines and a high frequency of mining activities1. At present, about 95% coal in Chian is mainly mined underground1,2, and various disasters and accidents may occur in the mining process, among which gas explosion and mine fire accidents are the most serious3,4,5,6,7. After gas explosion and mine fire accidents, the initial blast and high temperatures result in a limited number of casualties. However, about 75% of the deaths are attributed to prolonged inhalation of the harmful gases, with carbon monoxide (CO) being the predominant hazard8. The refuge chamber, a critical component of a coal mine’s six major safety systems9, is designed to offer miners a secure haven during disasters and accidents. Fresh air is continuously supplied to the chamber through a borehole connected to the ground10, ensuring miner survival in the event of a disaster. During the critical period of a mine disaster, the dispersion of toxic gases has been a subject of intense scrutiny. Li et al.11,12,13 studied the expression of the wind network of exogenous gas emission in the mine 3D ventilation network, introducing the concept of an active wind network and crafting a corresponding mathematical model. Liu et al.14 examined the progression of harmful gases following a gas explosion, delineating the process into three temporal phases and formulating models for toxic gas diffusion in still roadways and propagation within the ventilation network. Zhang et al.15 investigated the dynamic propagation characteristics of CO in the wind network subsequent to an explosion at the mining face, and concluded that the initial spread of CO beyond the confines of the mining roadway was significantly influenced by the interplay between shock wave flame and wind flow during the explosion’s onset. Subsequently, as the explosion progressed, the dominant factor shaping CO dispersion became the wind flow. Lei et al.16 developed a model for the unsteady transport of disaster gases within the mine’s ventilation network. By integrating gas concentration data from various monitoring points, they were able to pinpoint the origin and the precise timing of the gas explosions. Li et al.17 analyzed the change characteristics of migration velocity and size of harmful gas cloud following a gas explosion, and the research showed the velocity of air currents during the mining accident period had a positive correlation with the peak levels of CO, while there was a less pronounced link to the extent of the toxic air mass. Currently, research on the post-explosion dispersion of harmful gases, such as CO, is primarily centered on specific mine roadways or the ventilation systems as a whole. However, a comprehensive understanding of dispersion of these toxic gases into refuge chambers during mine disasters, remains a ___domain that is not fully explored.

Research on the environment inside the refuge chamber during a mining disaster, Zhang et al.18 conducted a test to monitor changes in the environment of the chamber over 8.5 h after the entry of 50 adult men into the chamber. They concluded that the average metabolic rates of O2 consumption, CO2 production, and heat generation during the refuge period were 0.34–0.37 L min −1, 0.34 L·min−1, and 117–128 W, respectively. Additionally, they determined that the permissible CO concentration in the refuge chamber over a 96-h period should not exceed 50 ppm. Ji et al.19 proposed a refuge chamber windproof system composed of a positively pressurized air supply chamber in front of the refuge chamber and a section of roadway with exhaust functionality. Through small-scale model tests and numerical simulation, it was verified that the back-blown air current formed by the front chamber can effectively prevent smoke from invading the refuge chamber. Du et al.10 determined that the maximum tolerable limits for human occupancy as 35 ℃for temperature and 80% relative humidity (RH) within the refuge chamber. Aiming to optimize environmental control efficiency, they developed an innovative air conditioning system that achieves a 35% reduction in the energy consumption of the air conditioning unit and a 15% decreases the necessary ice storage capacity.

Currently, research within refuge chamber predominantly concentrates on the life support and environmental control system, as well as the modifications of ventilation methods. However, it is difficult to achieve for the built mine. Therefore, there is an urgent need for strategies that can effectively prevent the infiltration of toxic gas into the refuge chamber without changing the existing building structure of the refuge chamber.

Therefore, in this work, based on the existing isolation door of the refuge chamber, a flexible isolation door is designed to prevent a large amount of toxic gas from entering the refuge chamber during the escape process. Simulation experiments on the intrusion of toxic gases into the refuge chamber during mining disasters were conducted, and a numerical simulation model for toxic gas intrusion was established. These studies investigated the diffusion patterns of toxic gases under various temperature and pressurized air volume conditions. Additionally, the effectiveness of the flexible isolation door in preventing toxic gases was examined. The goal was to effectively control the spread of toxic gases in the refuge chamber and improve the survival rate of miners in mining disasters.

Methods and materials

Experimental device

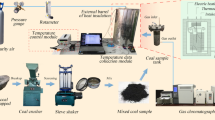

To confirm the diffusion patterns of toxic gases through the protective isolation door into the refuge chamber from the main roadway under different temperature conditions during mining disasters. Furthermore, to verify the viability of controlling toxic gas concentrations within the refuge chamber by increasing the volume of pressurized air from the ground borehole, this study establishes a foundation for simulation and offers corroboration with the outcomes of such simulations. A set of experimental equipment for harmful gas intrusion into the refuge chamber was established, as shown in Fig. 1. The device consists of a transition chamber, a protective airtight door, and a main lane. It is constructed with two glass plates sealed by a silicone strip and mounted on a stainless steel test rack. The left side simulates the refuge chamber’s transition chamber, featuring a pressure outlet that represents the ground borehole for fresh air intake. The right side replicates the main underground roadway, equipped with four exhaust ports and one smoke outlet for dispersing white smoke symbolizing toxic gases. Additionally, a heating film is integrated to warm the toxic gases.

Theoretical analysis

The flow of fluids follows the laws of fluid conservation, such as the law of conservation of energy, the law of conservation of mass, and the law of conservation of momentum. If the fluid is composed of different components, it also obeys the law of conservation of components. Furthermore, if the fluid is in turbulent flow, it additionally obeys the turbulent transport equation.

The conservation laws are mathematically described by the governing equations.

Mass conservation is shown in Eq. (1):20

where \(\rho\) is the fluid density, kg·(m3)−1; t is the time, s; µ is the dynamic viscosity, m·s−1; ui is the velocity component in the i direction, m·s−1.

Momentum conservation is shown in Eq. (2):

where grad ui is the velocity gradient in the i direction, m·s-1; p is the pressure, Pa; Si is the additional momentum loss source term in the i direction.

Energy conservation is shown in Eq. (3):

where T is the thermodynamic temperature, K; k is the heat conductivity of the fluid, W·(m k)−1; Cp is the specific heat capacity, J·(kg k)−1; ST is the viscous dissipation term, J·kg−1.

Species mass conservation is shown in Eq. (4):

where Cs is the volume concentration of the components, %; Ds is the diffusion coefficient of the component, m·s−1; Ss is the mass of component s produced by chemical reactions per unit volume per unit time, kg·(m3 s)−1.

Simulation parameter setting

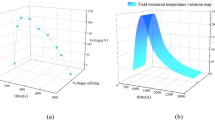

Figure 2. illustrates the refuge chamber model and its grid division. The model consists of a main lane, transition chamber, and survival chamber. The main lane is gridded into 150,200 grids, the transition chamber into 43,950 grids, and the survival chamber into 263,712 grids. Table 1. displays the basic parameters.

In this model, the ground borehole is set as the inlet (inlet1), and the gas within the refuge chamber is directed to flow in the negative direction along the Y-axis. The toxic gases in the main roadway flow along the Z-axis. The Blue Cross-section indicates the inlet (inlet2), and the Red Cross-section shows the outflow. The airtight door connecting the transition chamber and the survival chamber is set as an interior surface. It is formed by combining the section of the refuge chamber with the rectangular facade by using the subtract real face function, with the rectangular facade being retained. The protective isolation door connecting the refuge chamber and the main lane is set as the interface (interior), and the remaining surface is the wall. Applying the RNG k-ε model21, Gambit defaults the entire 3D model to the fluid region. The average grid size (interval size) is set to 0.1 m. With a square ground borehole, structured grids can be applied to divide each part of the refuge chamber. This approach to grid structuring improves the stability of the simulation.

The main roadway gas composition is set with a concentration of O2 at 22% and CO at 0.789%, equivalent to a volume fraction of 0.8%, with N2 making up the remainder. The gas flow rate is set at 3.5 m·s−1. The concentration of O2 in the borehole gas is set at 22%, and the rest of the gas is composed of N2. In the simulation, fresh air is introduced through the ground borehole into the top of the survival chamber within the refuge chamber and is then conveyed to the main alley.

Analysis of experimental results

Low and high temperature CO intrusion regulars

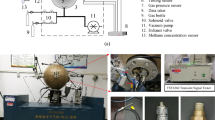

The heating device was adjusted to achieve the intrusion of high and low temperature CO into the refuge chamber, as shown in Fig. 3. With an increase in temperature, the average speed of gas molecules increases and the intermolecular forces weaken, causing a reduction in the number of molecules per unit volume. Consequently, the density of toxic gases becomes less than that of air, allowing white smoke, indicative of toxic gases, to infiltrate the refuge chamber from above the airtight door. At low temperatures, where toxic gases are denser than air, they enter the refuge chamber from below the airtight door.

Influence of pressurized air volume on high-temperature CO intrusion

To determine if elevating the ground borehole’s pressurized air volume can efficiently prevent the invasion of toxic gases into the refuge chamber, illustrative experiments on the intrusion of toxic gases under varying pressurized air volumes have been executed. The process of CO intrusion into the refuge chamber is obtained by altering the volume of pressurized air under high-temperature conditions, as shown in Table 2.

Analysis of the white smoke’s shape and light transmittance has revealed the process by which pressurized air through the ventilation inlet expels CO from the refuge chamber. Furthermore, an increase in the pressurized air volume is accompanied by a corresponding increase in the distance between the white smoke and the lower edge of the device. This correlation suggests that increasing the pressurized air volume from the ground borehole could prevent high-temperature toxic gases in the main roadway from infiltrating the refuge chamber.

Design of flexible isolation door for toxic gas in refuge chamber

To accommodate the need for rapid passage of miners, to simultaneously eliminate toxic gases carried by miners entering the chamber, and to effectively reduce the intrusion of toxic gases into the chamber, a flexible isolation door for toxic gases in the mine refuge chamber with positive pressure ventilation has been designed. The installation of a flexible isolation door reduces the area available for CO diffusion into the refuge chamber when the door is open, and the amount of CO diffusing into the refuge chamber is also significantly reduced.

The flexible isolation door is positioned behind of the protective isolation door. Featuring a central slit that opens and closes freely. miners are able to pass through the narrow opening provided without fully opening the door to enter the refuge chamber. As the pressure within the chamber exceeds that of the main roadway, air from the chamber is rapidly directed towards the main roadway through this seam when miners enter the chamber. This results in an airflow that is counter to the movement of the individuals, effectively removing toxic gases carried by refuge miners. The configuration and the ___location of the flexible isolation door are shown in Fig. 4.

Simulation results of anti-virus protection in refuge chamber

The results of CO intrusion into the refuge chamber under different pressurized air volumes

The main roadway is set at 50 ℃, while the transition chamber and survival chamber within the refuge chamber are maintained at 20 ℃.The local effects diagram of the numerical simulation results for the refuge chamber model is shown in Fig. 5. The effect diagram of the simulation results qualitatively shows whether a large amount of CO from the main roadway has entered the refuge chamber. Additionally, the numerical simulation results provide specific values for CO concentration distribution, which can be quantitatively analyzed to assess the extent of CO diffusion into the refuge chamber.

The simulation results indicate that under conditions where the temperature in the main roadway is higher than that inside the refuge chamber, toxic gases (CO) infiltrate the refuge chamber from above the protective isolation door, consistent with the experimental findings.

Figure 6 illustrates the variation in the maximum and average concentrations of CO within the transition room, obtained by altering the pressurized air volume through the ground borehole. The CO concentration in the transition chamber, analyzed for its decreasing trend, shows that changes with the variation in pressurized air volume occur in three distinct stages. As the pressurized air volume increases from 47.9 to 95.9 m3 min−1, the maximum CO concentration in the transition chamber experiences a sharp decrease from 3327 to 954 ppm. This decrease marks the first stage of CO concentration change in the transition chamber, known as the sudden drop stage. When the pressurized air volume increased from 95.9 to 192.4 m3 min−1, the maximum CO concentration in the transition chamber decreased from 954 to 490 ppm. This decrease corresponds to the second stage of CO concentration change, referred to as the slow decline stage. The pressurized air volume rose from 192.4 to 336.3 m3 min−1, yet the maximum CO concentration in the transition chamber remained above 472.2 ppm. Initially increasing and then decreasing, the concentration exhibited an inverted ‘U’ pattern relative to the air volume change in the third stage, which is characterized as an unstable stage. As depicted in Fig. 6b, the average CO concentration in the transition chamber follows the three-stage trend observed in maximum CO concentration. Figure 6 indicates that increasing the ground borehole pressurized air volume effectively decreases the CO concentration within the refuge chamber before reaching the critical volume, confirming the experimental findings on the intrusion of toxic gases into the refuge chamber.

During mining accidents, a large amount of CO is present in the main roadway. As shown in Fig. 6, increasing the ground borehole’s pressurized air volume can reduce but not completely eliminate the CO concentration in the transition chamber. When the ground borehole’s pressurized air volume increases to the unstable stage, the maximum and average CO concentrations in the transition chamber no longer decrease with the increase in pressurized air volume Therefore, the method of eliminating CO in the transition chamber by continuing to increase the ground borehole’s pressurized air volume is not feasible.

The average CO concentration in the transition chamber has decreased to a safe level of 24 ppm during the first stage. Data interpolation indicates that when the pressurized air volume is 51.7 m3 min−1, the average CO concentration is 24 ppm. Under these conditions, the critical pressurized air volume through the ground borehole is determined to be 51.7 m3 min−1.

The maximum and average CO concentrations in the survival chamber vary with changes in the ground borehole’s pressurized air volume, as shown in Fig. 7. The decrease in CO concentration in the survival chamber can be categorized into two stages based on the trend analysis, corresponding to the variations in pressurized air volume. As the pressurized air volume increases from 48.12 to 96.39 m3 min−1, the maximum CO concentration in the survival chamber sharply drops from 9.45 to 0.25 ppm. This stage is identified as the rapid decline stage of CO concentration change. When the pressurized air volume rose from 96.39 to 287.78 m3 min−1, the average CO concentration within the survival chamber decreased from 0.25 to 0.05 ppm. The rate of change during this period was only 0.005% of that observed in the rapid decline stage. This stage is characterized as the stable stage of CO concentration change in the survival chamber. Figure 7b illustrates that the trend of average CO concentration in the transition chamber conforms to the two-stage trend of CO concentration change observed in the survival chamber.

The results of CO intrusion with and without the activation of anti-toxic facilities are compared

The protective isolation door, following the installation of a flexible isolation door, were modeled with equivalent dimensions of 1.6 m by 0.35 m for the numerical simulation of toxic gas intrusion into the refuge chamber, as shown in Fig. 3. The simulations yielded localized effect diagrams of CO intrusion into the refuge chamber with the door both open and closed. Table 3 shows the closure of the protective isolation door reduces the area through which toxic gases can flow from the main roadway to the transition chamber. This reduction prevents a large amount of CO from entering the refuge chamber, ensuring the safety of the miners within.

The variation in the average concentration of CO in the transition chamber, both with and without the installation of a flexible isolation door, in response to changes in the pressurized air volume from the ground borehole, is shown in Fig. 8. Data interpolation after the installation of a flexible isolation door shows that at a pressurized air volume of 15.70 m3 min-1, the average CO concentration in the transition chamber is reduced to 24 ppm. As a result, under the preset conditions, the critical pressurized air volume through the ground borehole after the installation of the flexible isolation door is established at 15.70 m3 min−1.

Compared to the situation without the flexible isolation door, the installation has led to a 69.6% reduction in the critical pressurized air volume needed to achieve an average CO concentration of 24 ppm within the transition chamber.

Conclusions

In this paper, the influence of temperature and pressurized air volume on CO intrusion into the refuge chamber during the mining disaster is studied through the experiment of toxic gas diffusion and numerical simulation. A flexible isolation door has been designed, and the situation of CO intrusion into the refuge chamber following its installation has been simulated. The main conclusions are drawn:

-

(1)

Experiments and simulations have mutually verified that toxic gases invade the refuge chamber from above the protective isolation door under high temperature conditions, and from below the protective isolation door under low temperature conditions.

-

(2)

Increasing the pressurized air volume can reduce the concentration of CO in the refuge chamber, and the change of CO concentration in the intrusion transition chamber can be divided into a rapid decrease stage, a slow decrease stage and an unstable stage. The change of CO concentration in the survival chamber can be divided into sudden decline stage and stable stage.

-

(3)

When the temperature of the main roadway is 50 ℃ and the temperature of the refuge chamber is 20 ℃, the CO concentration required to reach the critical pressurized air volume can be reduced to 69.6% of that without the installation of the isolation door.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Zhu, Y. et al. A statistical analysis of coalmine fires and explosions in China. J. Process Saf. Environ. Protect. 121, 357–366 (2019).

Zheng, Y. et al. Study on the evolution characteristics of coal spontaneous combustion and gas coupling disaster region in goaf. J. Fuel 349, 128505 (2023).

Zhang, Y. et al. Analysis 320 coal mine accidents using structural equation modeling with unsafe conditions of the rules and regulations as exogenous variables. J. Accid. Anal. Prevent. 92, 189–201 (2016).

Jia, Q., Fu, G., Xie, X. & Hu, S. Method construction and evaluation: A more comprehensive and reliable classification of coal mine gas explosion causes. J. Energies 15(22), 8443 (2022).

Tan, B. et al. Research on size effect of gas explosion in the roadway. J. Tunnel. Undergr. Sp. Technol. 112, 103921 (2021).

Zhang, X. et al. Experimental and simulation study on hydroxyl group promoting low-temperature oxidation of active groups in coal. J. Fuel 340, 127501 (2023).

Zhang, X. et al. Correlation and stage change of key groups and thermal effects of spontaneous coal combustion due to long-term ultraviolet illumination. J. Energy 293, 130775 (2024).

Da, M., Ma, Y. & Ding, Y. Research and design of mine refuge chamber. J. Saf. Sci. Technol. 5(3), 194–198 (2009).

Sun, J. Key technologies of emergency avoidance in underground coal mine. J. China Coal Soc. 36(11), 1890–1894 (2011).

Du, Y. et al. Thermal comfort model analysis and optimization performance evaluation of a multifunctional ice storage air conditioning system in a confined mine refuge chamber. J. Energy 141, 964–974 (2017).

Li, Z. Active wind grid model and its application calculation. J. China Coal Soc. 35(S1), 118–122 (2010).

Li, Z. et al. Simulation study on disaster evolution of ventilation system in coal and gas outburst mine. J. China Coal Soc. 42(4), 929–934 (2017).

Li, Z., Wang, T. & Jia, J. Simulation study on the process of external gas migration and dispersion in mine roadway. J. China Coal Soc. 42(5), 731–735 (2013).

Liu, Y. & Chen, H. Propagation law of toxic gas in mine gas explosion. J. China Coal Soc. 34(6), 788–791 (2009).

Zhang, M. et al. Numerical simulation of CO diffusion in gas explosion in driving face. J. Coal Technol. 34(1), 239–242 (2015).

Lei, B. et al. A study on source identification of gas explosion in coal mines based on gas concentration. J. Fuel 290, 120053 (2021).

Li, Y. et al. Transport characteristics of toxic gas cloud after shock wave disturbance of gas explosion. J. China Univ. Min. Technol. 50(4), 667–675 (2021).

Zhang, Z. et al. Experimental investigation on environmental control of a 50-person mine refuge chamber. J. Build. Environ. 210, 108667 (2022).

Ji, J., Wang, Z. & Fan, Y. Experimental and numerical simulation of smoke control structure system in underground refuge chamber. J. Mining Saf. Eng. 46(11), 66–69 (2015).

Li, L., Si, J. & Li, Z. Characteristics of the spatial and temporal evolution of the environmental parameters for belt fire in underground coal mine roadway. J. Case Stud. Therm. Eng. 49, 103346 (2023).

Li, Z. et al. 3D goaf gas floating storage based on RNG k-ε turbulence model. J. China Coal Soc. 39(5), 880–885 (2014).

Acknowledgements

This study was financially supported by National Natural Science Foundation of China (52074122, 51774170) and Natural Science Foundation of Hebei Province in China (E2021508010).

Author information

Authors and Affiliations

Contributions

After revising the article according to the review comments of the reviewers, the degree of contribution of theauthors to the article has changed., HUANG not only completed the main body of the article, language editing, correction, etc., but also revised the article after being reviewed, and her workload was the largest. Z.L. and J.S. corrected the article and proposed many modifications, L.L. assisted HUANG in the experiment, and J.W. analyzed some experimental data. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Z., Huang, S., Li, L. et al. Study on CO dispersion characteristics and isolation door control technology of refuge chamber in coal mine. Sci Rep 14, 21553 (2024). https://doi.org/10.1038/s41598-024-72188-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-72188-3

Keywords

This article is cited by

-

Similar pipeline experiment and disaster control emergency plan of updraft airflow fire in mine

Scientific Reports (2024)