Abstract

To address the issues of uncertain pressure relief effectiveness and poor control of surrounding rock caused by the composite nature of the roof strata in the gob-side entry retained (GER), as well as significant changes in strata’s thickness and stability differences, this study focuses on the airway of the panel 3113 N in Longtan Coal Mine. Through field detection, theoretical analysis, and on-site applications, a stable mechanical model of the hard roof strata is established, elucidating the factors influencing fracture and instability in composite roof strata. The results indicate that roof stability of the GER depends on the position and ultimate load-bearing capacity of the hard roof strata, which in turn affects roof pressure relief effectiveness. Based on this, a roof classification method centered on “hard rock strata position and bearing capacity” is proposed. The retained roadway roof is categorized into four levels: Grade I (stable), Grade II (moderately stable), Grade III (unstable), and Grade IV (extremely unstable). Specific pressure relief methods, key parameters, roof control measures, and slope reinforcement methods are provided for each level of roof, forming a graded and zoned pressure relief technology for GER with composite roof. This approach emphasizes strong support and roof control, reinforced roadway sides, and precise roof cracking as core strategies. Field application results demonstrate that this graded and zoned pressure relief technology performs well, effectively maintaining stability of the surrounding rock in retained roadways.

Similar content being viewed by others

Introduction

GER (gob-side entry retained) is a widely used mining method that eliminates coal pillars, thereby enhancing coal recovery rates, reducing roadway construction frequency, and mitigating strained relationships between mining and extraction processes1,2,3. However, the roofs of retained roadways often consist of composite structures with diverse rock masses, creating complex and varied stratigraphic conditions within the roadway. These roof conditions are characterized by their complexity and diversity, and the strata of a single roadway can undergo significant changes over time. This variability poses challenges in ensuring effective pressure relief and controlling the surrounding rock, which are pressing issues that need to be addressed4,5,6,7.

Numerous scholars have conducted extensive research on classification methods for the stability of composite roofs, achieving rich research results. Liu et al.8,9 used the positional changes of stable rock strata as indicators for classifying the level of roof fall hazards, dividing them into four types: stable, moderately stable, unstable, and extremely unstable. Zhang et al.10 classified such roadways based on the thickness and distribution of composite mudstone in the roof, resulting in three different types of composite mudstone roofs. Jia et al.11 used the area of the interlayer damage hazard zone as a benchmark and the thickness of top coal as a classification indicator, dividing the roof of the 16 − 3 coal seam mining roadway into three levels. Zhao et al.12 used Barton’s rock mass quality classification and rock mass geomechanical classification methods to grade the stability of the mining area in Xincheng Gold Mine and conducted a comparative analysis of the results of the two classification methods. They concluded that the stability levels of the rock masses in the hanging wall, ore body, and footwall of the mining area in Xincheng Gold Mine were grades II and III, and the overall stability of the mining area was generally average or poor. Wang et al.13 studied the stress field and fracture field of the overlying strata in ascending mining, dividing the overlying strata into five failure zones and the fractures into four zones. Wang et al.14,15,16,17,18,19 studied the influence of cracks on rock strength, providing a scientific basis for roof stability analysis.

Meanwhile, extensive research has been conducted on the roof cutting and pressure relief technology for composite roof strata. Gao et al.20 described the pressure relief mechanism of deep hole blasting for forced roof cutting, specifically employing deep hole blasting to relieve roof pressure and improve the support effect of the roadway left alongside the coal seam. Tang et al.21 addressed the technical challenges of thick soft rock roof strata by proposing a technology for filling the roadway with fractured roof strata, creating a coordinated control method for surrounding rock using “fractured roof pressure relief + roadway side collapse filling.” Zhang et al.22,23 proposed shallow hole blasting, high-water materials for constructing the roadway side filling body, and control techniques for the hard roof strata to address dynamic disasters such as large-area roof pressure in the roadway left alongside the coal seam. Wang et al.24 based on the expansion characteristics of rock masses, proposed using directional roof cutting technology to optimize the stress environment of the left roadway, reduce the rotation and subsidence of the upper roof strata, and suggested a support method focusing on “constant resistance large deformation anchor cables + roof cutting support frames” for the roadway roof, while for the gravel sidewalls, they proposed a control concept of “lateral dynamic-static combination and longitudinal telescopic pressure relief.” Wang et al.25,26 and Gao et al.27,28,29 studied the deformation characteristics of fragmented rock under the pressure relief of self-formed roadway rock, explored the mining height effects of gob impact during the roof cutting process, and proposed a multi-level control strategy focusing on dynamic pressure prevention, pressure relief yielding, and constant pressure stabilization.

In order to address the aforementioned challenges, this paper aims to establish a stability mechanical model for the composite and hard roof strata in GER based on the detection of the roof stratigraphic structure. It presents pressure relief methods, key parameters for pressure relief, countermeasures for roof control, and reinforcement countermeasures for the rib area for different grades of roof strata. While ensuring the effectiveness of pressure relief in the composite roof of GER, this approach can improve construction efficiency and provide valuable insights for other similar mines.

Project background

Overview of roadway engineering

The Longtan Coal Mine is currently focused on extracting coal from the K1 coal seam. The coal seam averages 2.08 m in thickness at the working face, with a stable dip angle averaging 3°. The specific mining face, 3113 N, extends along a strike length of 1625.7 m and a dip length of approximately 243.2 m, situated at a burial depth of around 400 m. Within the roof of the coal seam, there is a layer of hard rock comprising fine sandstone and micrite limestone, ranging in thickness from 4.6 to 6.5 m, as depicted in Fig. 1. Above this hard rock strata lies a weak interlayer consisting of soft mudstone and sandy mudstone, averaging 4.5 m in thickness, which exhibits relatively low strength characteristics. These weak interlayers are susceptible to expansion and damage under the influence of intensive mining activities, posing potential risks to the stability of the roadway roof. In managing the return airway for the panel 3113 N, the primary method adopted for GER involves borehole blasting for roof cutting. The roof is subjected to significant stress induced by mining operations, resulting in frequent instances of sudden large deformations. These deformations contribute to challenges in maintaining the stability of the surrounding rock within the retained roadway.

Exploration of roadway roof strata structure

Coal measures strata are primarily layered rock formations formed through sedimentation, influenced by varying sedimentary environments, lithology, and petrographic characteristics. These factors lead to diverse combinations and mechanical properties of roof strata, both vertically and laterally30. Vertical variations include cyclic changes in lithology and petrography, often accompanied by weak planes or soft interlayers. Lateral variations can result in thickness changes, thinning, or even disappearance, causing significant spatial differences in the composite structure and mechanical strength of roof strata.

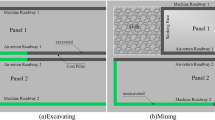

To gain a detailed understanding of the roof strata structure, five strategically positioned boreholes (labeled 1#, 2#, 3#, 4#, and 5#) were drilled at intervals along the strike direction of the return airway in the panel 3113 N. These locations were chosen at distances of 10 m, 200 m, 400 m, 600 m, and 800 m. The borehole inspection results were used to create a comparative diagram illustrating the roof strata variations along the strike direction, depicted in Fig. 2.

From the comparative analysis of roof strata along the strike direction, it is evident that the mining roadway roof primarily comprises layers of limestone, sandstone, sandy mudstone, and mudstone, displaying complex composite characteristics. Within depths ranging from 1 m to 7 m from the roof at different positions along the roadway, varying thicknesses of hard rock strata are present. This hard rock strata consists of fine sandstone and compact muddy limestone. The excavation of the roadway has led to damage and separation in the shallow areas of the roof, particularly affecting the mudstone and sandy mudstone layers. Therefore, the ___location, thickness, and strength of this hard rock strata are critical factors determining the stability of the gob-side entry retention roof.

Stability analysis of composite roof

Mechanical model for stability of composite roof

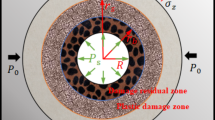

Based on the theoretical principles of materials mechanics, a stable mechanical model for the roof strata is developed. The model is based on the observation of fracture morphology in the roof, particularly when the hard roof above the gob area is exposed and begins to fracture, leading to initial and periodic collapses. As the roof undergoes subsidence and bending deformation, it may first come into contact with the floor within the gob area, while the end near the solid coal side may not necessarily fracture, thus resembling a cantilever beam configuration for analysis31.

The hard rock strata experience tension-dominated fractures primarily due to differences in force sources such as self-gravity and overlying rock load of the hard rock strata and supporting force32. These fractures significantly influence the overall stability of the hard rock strata, which can be conceptualized as a finite plate model with damaged cracks (Fig. 3). By analyzing the stress characteristics at the tip of a finite plate with a single-edge crack, the stress intensity factor at the crack tip can be computed.

Stability analysis of hard rock strata

According to the formulas for the finite plate model, the load on the hard rock strata is a complex composite load. The stress intensity factor for a finite plate with a single-edge crack can be decomposed into three simple basic loads: horizontal force, bending moment, and shear force. Corresponding formulas for calculating the stress intensity factor under these loads can be derived33.

Stress intensity factor induced by horizontal force

The mechanical model under horizontal force33 is shown in Fig. 4.

where F is the horizontal force acting on the ends of the undamaged hard rock strata (MPa); h is the thickness of the undamaged hard rock strata (m); a is the crack length (m); \({F_1}\left( {\frac{a}{h}} \right)\)is non dimensional parameters caused by horizontal force.

The horizontal compressive force T acting on the undamaged hard coal strata can be simplified as a uniform stress σ (\(\sigma = - {T \mathord{\left/ {\vphantom {T h}} \right. \kern-0pt} h}\)) applied to the ends of the undamaged hard coal strata. Before failure, the undamaged hard rock strata can be assumed as completely elastic. By rearranging Eq. (1), the horizontal compressive force can be determined as follows:

Stress intensity factor induced by bending moment

The mechanical model under bending moment33 is shown in Fig. 5.

where B is the width of the undamaged hard rock strata, and is taken as 1 m.

The bending moment generated at the ends of the undamaged hard rock strata, owing to the ultimate uniform load q that the undamaged hard rock strata can withstand, is denoted by M \((M=q{L^2}/12).\) Hence, the following relationship is obtained:

where q is the ultimate uniform load that the undamaged hard rock strata can withstand (kN/m); M is the bending moment generated at the ends of the undamaged hard rock strata (kN·m); T is the horizontal compressive force (kN); L is the width of the roadway (m); \({F_2}\left( {\frac{a}{h}} \right)\)is non dimensional parameters caused by bending moment.

Stress intensity factor induced by shear force

The mechanical model under shear force33 is shown in Fig. 6.

P can be regarded as the concentrated load formed by the gravity of the hard rock strata and the load on the overburden, and its support resistance can be equivalent to a pair of concentrated shear forces P \(\left( {P = qL - Q_{z} } \right).\) Hence, the following relationship is obtained:

where Qz is the support force exerted on the hard rock strata (kN); \({F_3}\left( {\frac{a}{h}} \right)\)is non dimensional parameters caused by shear force.

Based on extensive experiments and field studies34, the criterion for rock and concrete material failure can be expressed as follows:

where λ is the shear-compression ratio coefficient, and KC is the fracture toughness of the rock. By substituting Eqs. (2), (4), and (6) into Eq. (7), the following relationship is obtained:

As indicated by Eq. (8), the stability of the roadway roof is directly influenced by the ultimate load that the hard rock strata can bear. This ultimate load capacity of the hard rock strata is determined by parameters such as fracture toughness, thickness, crack length, horizontal compressive force, and roadway width. These parameters collectively affect the ability of the hard rock strata to withstand ultimate loads under intense mining-induced stress, thereby determining the stability of the roadway roof. Therefore, clarifying the key factors influencing the ultimate load capacity of the hard rock strata can provide a scientific theoretical basis for classifying the stability of composite roofs in GER.

Classification of composite roof stability

The coal seam roof at Longtan Coal Mine includes varying thicknesses of hard sandstone strata, which are critical targets for roof cutting and pressure relief in GER operations. Due to these substantial variations in hard rock strata, the stability of the roof varies across different areas of the mining face. The position of the hard rock strata within the roof (its distance from the roadway surface) and its bearing capacity are pivotal factors influencing the stability of the retained roadway roof in GER.

-

1.

Position of hard rock strata in the roof: The anchoring effect of bolts (such as cable bolts) typically requires embedding them within the hard rock strata. Therefore, the presence of a hard rock strata within the anchoring segment of the bolt is crucial for ensuring stability. The ___location of this anchoring layer relative to the roof’s hard rock strata serves as an indicator for judging roof stability.

-

2.

Bearing capacity of hard rock strata in the roof: This parameter is closely tied to various characteristics of the hard rock strata. Factors such as fracture toughness, roadway width, and horizontal compressive strength are considered constant parameters. Even a small crack length can significantly impact the overall stability of the hard rock strata. Typically, a crack length of 0.03 m is initially assumed when minor fractures occur, in order to reflect the actual condition of the hard rock layer as accurately as possible. Changes in the thickness of the hard rock strata directly influence roof stability, affecting the ultimate load-bearing capacity of these strata. Hence, the bearing capacity of the hard rock strata is another critical factor in evaluating roof stability.

Given these considerations, a roof classification method is proposed that centers on “the position and bearing capacity of the hard rock strata in the roof.” This approach integrates these factors comprehensively to assess and classify the stability of the roof in GER operations. By systematically evaluating these parameters, mining operations can better manage and predict the stability of the roof in different geological contexts (Table 1).

Pressure relief technology by classification and zoning for GER with composite roof

Pressure relief methods by classification and zoning for GER with composite roof

In the process of pressure relief for GER, the thickness of the hard rock strata in the roof is a key factor that affects the ease of fracturing. Generally, Thicker hard rock strata generally require more effort to fracture. However, when the hard rock strata are relatively thin, effective rock fracturing can be achieved by arranging roof cutting boreholes at a certain density35. To manage hard rock strata of varying thicknesses, measures such as dense boreholes, directional blasting, strong support on the goaf-side roof, and reinforced strengthening of the roadway sides must be flexibly adopted. These measures should be based on the position and thickness of the roof strata to ensure effective fracture structure formation on the goaf side, thereby enhancing pressure relief efficiency.

Based on the stability analysis of the composite roof in GER, the hard rock strata in the roof are classified into four levels: Grade I roof (position below 2.0 m, thickness above 7.0 m), Grade II roof (position 2.0 ~ 4.0 m, thickness 3.5 ~ 7.0 m), Grade III roof (position 4.0 ~ 6.0 m, thickness 1.0 ~ 3.5 m), and Grade IV roof (position above 6.0 m, thickness below 1.0 m). Furthermore, a graded and zoned pressure relief technology for GER with composite roof is proposed, with core strategies including strong support for roof control, reinforced strengthening of roadway sides, and precise roof fracturing.

The core strategies of this system cover three key aspects: firstly, using strong support technology to control the stability of the roof under mining-induced stress with high-strength support; secondly, significantly enhancing the overall bearing capacity of the roadway through reinforced strengthening of its sides; and thirdly, implementing precise roof fracturing measures to effectively eliminate the potential threat of hard rock strata to the roadway’s stability.

Determination of key parameters for classified roof cutting and pressure relief in composite roof

-

(1)

Depth and angle of roof cutting boreholes.

In the process of classified roof cutting and pressure relief for composite roofs, determining key parameters for effective pressure relief is crucial. These parameters are determined based on the actual position and thickness of the hard rock strata in the roof to ensure boreholes can penetrate the hard rock. Taking the 311 mining area of the Longtan Coal Mine as an example, the depth of roof cutting boreholes is set at 5 ~ 9 m, with an inclination angle towards the goaf side ranging from 5° to 15°. This configuration facilitates convenient construction while ensuring the fractured roof collapses effectively.

-

(2)

Spacing of roof cutting boreholes.

Using FLAC3D numerical simulation software, a numerical model was established based on themechanical parameters of coal and rock at the panel 3113 N of Longtan Coal Mine (Table 2) and the coal seam occurrence conditions. The model has dimensions of length × height = 303 m × 40 m. The rectangular roadway has dimensions of width × height = 4.3 m × 2.6 m, the length of coal face is 243 m., and the diameter of the pressure relief boreholes is 50 mm. The vertical boundaries of the numerical model are hinged supports, with velocities and displacements in the X and Y directions constrained. The upper surface of the model is a free surface with an overlying rock stress of 10.0 MPa applied, and the lower surface of the model is a fixed constraint. The simulation calculations adopt the Mohr-Coulomb criterion.

Considering the effects of roof cutting and blasting as well as the actual construction conditions, the roof-cutting drilling angle is determined to be 85°. Under the simulated movement of the overburden rock in the gob area, the characteristics of fracture induction in hard rock strata under different thicknesses of hard rock strata and different roof-cutting drilling densities were investigated. The thickness of the hard rock strata above the K1 coal seam ranges from 2 to 5 m, and numerical models for two typical thicknesses of 2 m and 5 m were established. The numerical models and simulation schemes are shown in Fig. 7.

Specifically, under the condition of a 5 m thick hard rock stratum, the model width (in the strike direction of the working face) is 4.8 m, and five scenarios with roof-cutting drilling spacings of 0.4 m, 0.8 m, 1.2 m, 1.6 m, and 2.0 m were simulated to obtain the influence of roof-cutting drilling density on the fracture induction in the hard rock stratum. Under the condition of a 2 m thick hard rock stratum, the model width (in the strike direction of the working face) is 2.4 m, and the fracture characteristics of the hard rock stratum were simulated under five scenarios with roof-cutting drilling spacings of 0.4 m, 0.5 m, 0.6 m, 0.7 m, and 0.8 m, aiming to determine the roof-cutting drilling density that can induce fractures in the hard rock stratum under such conditions.

When the thickness of the hard rock strata is 5 m, the development of the failure zone around the drill holes gradually increases as the spacing between the cut-top drill holes changes from 2.0 m to 0.4 m. When the drill hole spacing is 2.0 m, shallow areas around the drill holes exhibit damage, with a range of approximately 0.65 m, primarily due to plastic deformation caused by tunnel excavation itself. No damage zone appears in the middle area, while deeper drill hole regions show damage of about 2.5 m, as shown in Fig. 8a. During the interval from 1.6 m to 0.8 m drill hole spacing, the area and extent of damage in the hard rock strata around the drill holes gradually increase from 2.8 m at 1.6 m spacing to 3.0 m at 0.8 m spacing. When the drill hole spacing is 400 mm, the damaged area in the hard rock strata around the drill holes reaches approximately 4.1 m.

When the hard rock strata is 2 m thick, under the influence of overburden movement in the goaf, the density of cut-top drill holes similarly significantly affects the distribution of the drill hole section damage area in the hard rock strata, as shown in Fig. 8b. The spacing between the cut-top drill holes decreases gradually from 0.8 m to 0.4 m. The proportion of the damaged area around the drill holes in the hard rock strata gradually increases, reaching 89% when the spacing is 0.5 m and 96% when the spacing is 0.4 m.

In summary, under certain conditions of hard rock strata thickness, the density of roof cutting drill holes is positively correlated with the extent of the drill hole section damage area. The difficulty of fracturing the overlying hard rock strata, which dominates the stress relief in the retained roadway, directly depends on its thickness. Grading control of the roof strata can be based on the thickness of the hard rock strata to determine the method of fracturing. For thinner hard rock strata, effective fracturing of the roof strata can be achieved using a certain density of roof cutting drill holes. When the hard rock strata reaches a certain thickness, advance fracturing of the roof using directional blasting is necessary.

Considering self-gravity and overlying rock load of the hard rock strata and supporting force, the spacing and fracturing method of roof cutting boreholes should effectively fracture and displace hard rock strata. When the hard rock strata are relatively thin, high-density roof cutting boreholes spaced at 300 mm ~ 400 mm apart can effectively fracture the roof strata. In practical engineering applications, a spacing of 300 mm is suitable for pressure relief boreholes in Grade III roof, while a 400 mm spacing is appropriate for Grade IV roof.

For thicker hard rock strata such as Grade I roof or Grade II roof, a directional shaped charge blasting method is recommended. The stress-induced damage cracks generated after blasting in adjacent blast holes should effectively interconnect. According to the C-J theory of condensed explosives, and considering the site’s uncoupled charging structure and the directional energy concentration effect of the shaped charge tube36,37, the criterion for connecting the damage cracks of two holes is that the cumulative depth of damage from the two shaped charge blast holes should exceed the spacing between them. At this point, the criteria for the peak pressure of the shock wave on the blasthole wall and the spacing d between the blast holes are as follows:

Where \({P_{\text{b}}}\) is the peak pressure of the shock wave on the blast hole wall (MPa); d is the blast hole spacing (mm); \({\rho _j}\) is the explosive density, and is taken as 1200 kg/m3; \({D_j}\) is the explosive detonation velocity, and is taken as 2000 ~ 4000 m/s; γ is a constant related to the properties of the explosive and charge density, and is taken as 2 ~ 3; \(~{r_{\text{e}}}\) is the radius of the cartridge (mm); \({r_{\text{b}}}\) is the radius of the blast hole ( mm); \({l_{\text{e}}}\) is the total length of the cartridge (mm); \({l_{\text{b}}}\) is the charge length (mm); n is the increased coefficient of the explosion product action, and is taken as 8 ~ 11; µ is the dynamic poisson’s ratio of the roof rock; η is the lateral pressure coefficient (\(\eta = \mu /\left( {1 - \mu } \right)\)); D is the initial damage coefficient of the rock mass, and is taken as 0.45; P is the in-situ stress (MPa); \({\sigma _t}\) is the tensile strength of the rock mass (MPa); τ is the blasting stress attenuation coefficient (\(\tau =2 - \lambda\)).

Based on the actual geological conditions of Longtan Coal Mine, the relevant parameters were substituted into Eq. (9) to obtain the specific parameters of directional energy accumulation blasting for the roof of Longtan Coal Mine, as shown in Table 3.

To ensure that the hard rock strata can fracture and shear off under the combined effects of self-gravity and overlying rock load of the hard rock strata and supporting force, forming a force source difference, so that the cracks between two blasting holes can be fully interconnected. Considering that the roof of the roadway in the working face is composed of a hard rock strata with high strength and significant thickness, the selected directional blasting hole spacings for Grade I roof and Grade II roof are 500 mm and 600 mm, respectively.

During the start and conclusion of the mining period at the working face, the span of the hanging roof structure in the goaf area increases correspondingly. Additionally, a certain degree of triangular hanging roof with corner arcs may form, thereby complicating pressure relief efforts. Hence, pressure relief for the roof during the initial and final mining periods of the coal mining face is categorized as Grade I roof management.

Roof control methods and techniques on the gob side of GER

In the GER area, another critical aspect of ensuring effective roof fracturing involves reinforcing the roof on the gob side to maintain a state similar to fixed support during the movement of overlying strata in the gob. This enhanced support not only helps prevent the overall displacement of hard rock strata but also promotes their cracking and fracturing, thereby ensuring the long-term stability of the retained roadway roof.

Considering the current method of long roof cutting cable bolts (LRCCB), there are issues with the stirring effectiveness of the anchoring agent and problems with reflux, which compromise the anchoring quality of the cable bolts. To address this issue, an enhanced anchoring and efficiency-increasing structure for cable bolts has been developed (Fig. 9). This structure consists primarily of two key components: a blocking-guide-centered device and a stirring-centered device. The stirring-centered device can break the outer bag of the anchoring agent and mix it uniformly, while using shrapnel to ensure that the cable bolt remains centered in the anchoring hole. The blocking-guide-centered device, through its unique left-handed thread protrusion and shrapnel structure, effectively achieves sealing, secondary lifting, and centering of the anchor cable. Through efficient stirring, high-quality sealing, and effective centering of this device, the effectiveness of the anchoring agent is maximized, the anchoring quality of the cable bolt is improved, and the supporting force of the roof cutting cable bolts is fully utilized.

For Grade I roof and Grade II roof, characterized by thick hard rock strata, the gob-side roof experiences intense disturbance during roof cutting. Therefore, to ensure structural stability, in addition to arranging double rows of LRCCB, supplementary block masonry support alongside the roadway is necessary to enhance the overall structural support capacity.

However, Grade III roof and Grade IV roof, which can collapse under their own weight and the load from overlying strata, require only a single row of LRCCB. This setup not only meets the necessary support strength for roof cutting but also reduces construction costs.

Reinforcement methods and techniques for GER’s sides

-

(1)

Block masonry support alongside the gob-side roadway.

As the retained roadway reaches a certain length, the combined effect of overlying strata and block masonry alongside the roadway causes the main roof on the gob side or higher-level strata to collapse along the edge of the filling body, allowing fallen coal and gangue to completely fill the gob. To prevent issues such as excessive pressure on the gob-side roof due to incomplete collapse and filling in the upper and lower triangles, and to ensure the retained roadway maintains a sufficient section size for reuse in adjacent working faces, block masonry support alongside the roadway is essential38. For Grade I roof, characterized by thick hard rock strata and limited spontaneous collapse, blocks are necessary to bolster support strength.

-

(2)

Bolt support on the solid coal side.

Bolt support is a proactive method that significantly enhances the peak and residual strength of the anchored body, thereby boosting the load-bearing capacity of the surrounding rock. Therefore, bolts must possess ample extensibility to sustain high support forces while accommodating potential large deformations in roadway sides. During GER, employing bolt support on the solid coal side effectively transfers the resistance of roadside support and collaborates with block masonry alongside the roadway to sever the roof at a specified height on the gob side, reducing support force requirements for advanced roof splitting.

To optimize support efficacy, bolt materials must offer sufficient extensibility and robust shear resistance. A high-extension combined bolt (HCB) has been developed, illustrated in Fig. 10. Key components include a stirring device, high-strength shear-resistant sleeve, continuous tightening lock, and the bolt body. The HPB235 bolt body, known for its exceptional ductility, maintains integrity even under engineering extension rates up to 20%, preventing breakage during significant surrounding rock deformations.

To enhance anchoring effectiveness, the bolt end features a toothed stirring device for thorough mixing of the anchoring agent. The top 600 mm of the bolt body incorporates left-handed crescent ribs to aid anchoring agent entry and increase contact area, preventing anchor detachment. A rubber fixing ring prevents anchoring agent backflow, stabilizes the high-strength shear-resistant sleeve, and mitigates potential slippage. A high-strength shear-resistant sleeve at the bolt body tail protects against shear risks from shallow surrounding rock plastic failure.The continuous tightening device ensures secure anchoring even after bolt tensile deformation, significantly improving bolt reusability and overall performance.

For Grade I roof with thick hard rock strata and low spontaneous collapse potential, reinforcing roadway sides with HCB bolts and super-strong anchoring enhancement devices is crucial. This ensures stable, high-support resistance to the roof, enabling timely collapse under self-gravity and overlying rock load of the hard rock strata and supporting force, thereby improving stress conditions in the retained roadway’s surrounding rock.

Graded and zoned pressure relief technology for GER with composite roof

The pressure relief technology for GER through roof cutting involves arranging blasting holes or dense boreholes for roof cutting on the inner side of the roadway reserved ahead of the working face, complemented by robust support for the surrounding rocks of the roadway. This approach creates a differential force environment involving the weight of the hard rock strata, the load from overlying strata, the expansion and extrusion effects within interlayers’ plastic zones, and the support they receive. This differential promotes fracturing of the suspended roof section of hard rock strata in the retained roadway along the weak plane formed by roof cutting, thereby enhancing the stress conditions of the surrounding rocks in the retained roadway.

The characteristics of the hard rock strata in the composite roof for GER in the 311 mining area of the Longtan Coal Mine have undergone significant changes, presenting considerable challenges to traditional pressure relief design concepts. Based on comprehensive analysis, a roof grading method centered on the position-bearing capacity of the hard rock strata of the roof is proposed. This method forms the basis for constructing a graded and zoned pressure relief technology for GER with composite roof, incorporating core strategies such as strong roof support and control, reinforced roadway side support, and precise roof fracturing (Table 4).

Engineering application

Roof cutting and pressure relief scheme for GER

In the 3113 N return airway of Longtan Coal Mine, the graded and zoned pressure relief technology for GER with composite roof is implemented. The working face spans 1625.7 m along its strike and approximately 243.2 m in dip length. Through roof strata structure detection along the roadway and considering the current area’s hard rock strata thickness and position, the roof is classified as Grade II. The specific pressure relief scheme is designed based on the graded and zoned pressure relief technology system for GER detailed in Table 4.

-

(1)

Advanced layout of LRCB.

The 3113 N return airway, located 50 m ahead of the working face, employs roof reinforcement using cable bolts with “W” steel strips. These cable bolts are positioned 500 mm from the west side of the roadway, measuring 9.2 m in length and 17.8 mm in diameter. Three CK2370 resin anchoring agents secure the cable bolts, supplemented by a super anchoring and reinforcement structure providing a 2.1 m anchoring length. The cable bolts are arranged in a single row with a spacing of 1.6 m.

-

(2)

Reinforced roadway side support.

-

①

Solid coal side bolt support.

Due to the unreliable resin anchoring of the side bolts, φ16 × 1800 mm metal expandable shell recoverable bolts are used, with a spacing of 800 × 1000 mm.

-

②

Gob-side roadway block support.

Initially, the gob side is sealed with sprayed concrete, incorporating columns, metal meshes, steel meshes, and collapsed rocks to form a stable wall. To address excessive roof pressure and inadequate corner collapse filling, 0.5 m×0.15 m×0.2 m blocks are employed to construct the wall, adjusted in height according to roof conditions for a tight seal. In areas where direct wall construction is impractical, wooden pegs are used for filling to ensure close contact with the roof and enhance roadway stability.

-

①

-

(3)

Roof cutting and pressure relief through blasting.

-

①

Location of pre-splitting blast holes for roof cutting and pressure relief.

Pre-splitting blast holes are strategically placed in the roof of the 3113 N return airway, 200 mm from the west side. The spacing and alignment of these blast holes adhere to specifications detailed in Table 4, with a depth ranging from 5 to 9 m and a horizontal angle of 5° during construction.

-

②

Detailed parameters for pre-splitting blast design for roof cutting and pressure relief in GER are outlined in Table 5.

-

①

Monitoring of field implementation effects

After implementing graded and zoned pressure relief technology on the roof of the panel 3113 N, deep displacement monitoring was conducted. A dual-basepoint deep displacement monitor was utilized with basepoint depths of 2 m and 8 m. A deep displacement monitoring station for the roadway roof, designated as Station #1, is arranged at a distance of 900 m from the roadway entrance. Subsequently, Station #2 and Station #3 are arranged at intervals of 30 m towards the roadway entrance (Fig. 11). Figure 12 illustrates the monitoring results of the roof’s deep displacement in the GER section of the panel 3113 N.

From Fig. 12, it is evident that during the monitoring period, the overall subsidence of the roof ranged between 50 and 63 mm. Initially, the rate of roof deformation was relatively high within the first 0 to 30 d after the roadway was formed. This was primarily attributed to plastic failure and surrounding rock deformation occurring in the shallow area of the roof within 0 to 2 m depth. Subsequently, between 30 and 40 d after roadway formation, the rate of roof deformation gradually decreased, and overall deformation tended to stabilize. This phase highlighted the effective support provided by the graded and zoned pressure relief technology for the composite roof, demonstrating successful application.

Meanwhile, the efficiency of GER has been significantly enhanced. Under Grade II roof conditions, the entry retaining efficiency can be increased by 45%, and the advancement of the coal mining face is basically no longer constrained by the speed of entry retaining.

Conclusions

The following conclusions were drawn from this study:

-

(1)

The roof of the mining roadway in the 311 mining area of Longtan Coal Mine exhibits significant composite characteristics, and the rock stratum combination varies greatly. There exist hard rock layers of varying thicknesses at depths of 1 to 7 m within the roof, and the fracture and instability state of these hard rock layers determine the stability of the GER.

-

(2)

A stable mechanical model for the cantilever-like hard strata in the composite roof of the GER section was established based on materials mechanics theory. It was determined that the stability of the roadway roof is contingent upon the ultimate load-bearing capacity of the hard strata.

-

(3)

Considering the thickness and load-bearing capacity of the hard strata in the GER section roof, a grading method centered on “position and bearing capacity of the hard strata” was devised. This classification categorizes the GER section roof into four grades: Grade I (stable), Grade II (moderately stable), Grade III (unstable), and Grade IV (extremely unstable).

-

(4)

Based on the classification of roof stability levels, pressure relief methods, key parameters for pressure relief, roof control strategies, and reinforcement support methods for the sides were provided. Forming a graded and zoned pressure relief technology for GER with composite roof, with the core strategies of strong support for roof control, reinforced sidewall strengthening, and precise roof fracturing. The field application of this technology showed good results.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Qian, M. G. & Shi, P. W. Mine Pressure and Ground Control 60–65 (China University of Mining & Technology Press, 2003).

Xu, L. et al. Parameters and surrounding rock control of gob-side driving under double key stratum after roof cutting. Sci. Rep. 14, 5106. https://doi.org/10.1038/s41598-024-55679-1 (2024).

Zhang, L. X. et al. Evolutionary law and regulatory technology of roof migration on gob-side entry retaining. Sci. Rep. 14, 5581. https://doi.org/10.1038/s41598-024-56108-z (2024).

Zhao, M. Y. et al. Research on “short masonry hinge” structure and support resistance of gob side entry roof without pillar cutting. J. China Coal Soc. 46(S1), 84–93. https://doi.org/10.13225/j.cnki.jccs.2020.0776 (2021).

Wang, K. et al. Study on deformation and failure characteristics and control of gob side entry retaining in soft thick coal seam. Geotechnical Mech. 43(7), 1913–1924. https://doi.org/10.16285/j.rsm.2021.1743 (2022).

Yu, G. Y. et al. Large deformation mechanism and comprehensive control technology of floor heave in gob side entry retained with block filling. J. Min. Safety Eng. 39(2), 335–346. https://doi.org/10.13545/j.cnki.jmse.2021.0147 (2022).

Wang, M. & Wan, W. A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int. J. Rock Mech. Min. Sci. 123, 104094. https://doi.org/10.1016/j.ijrmms.2019.104094 (2019).

Liu, H. T. & Ma, N. J. Coal mine roadway roof caving high risk areas recognition technology. J. China Coal Soc. 36(12), 2043–2047. https://doi.org/10.13225/j.cnki.jccs.2011.12.018 (2011).

Liu H.T., Ma N.J., Wang J.M., et al., Analysis on roof falling hidden danger grading of mining gateway.Coal Sci Technol, 40 (3) 6–9, 104. https://doi.org/10.13199/j.cst.2012.03.11.liuht.009 (2012).

Zhang, L. et al. Study on the classification of coal roadway with compound roof and controlling technology. Coal Eng. 46(4), 80–82. https://doi.org/10.11799/ce201404028 (2014).

Jia, H. S. et al. Failure law and classification control of extremely soft roof in mining roadway of unstable thickness coal seam. Chin. J. Rock Mech. Eng. 41(S2), 3306–3316. https://doi.org/10.13722/j.cnki.jrme.2021.1137 (2022).

Zhao, X. D. et al. Rock mass structural plane digital recognition and stope stability classification based on the photographic surveying method. J. Min. Safety Eng. 31(1), 127–133. https://doi.org/10.13545/j.issn1673-3363.2014.01.021 (2014).

Wang, C. et al. Control principles for roadway roof stabilization in different zones during ascending mining. J China Univ. Min. Technol. 41(4), 543–550. (2012).

Wang, M. et al. A calibration framework for the microparameters of the DEM model using the improved PSO algorithm. Adv. Powder. Technol. 32, 358–369. https://doi.org/10.1016/j.apt.2020.12.015 (2021).

Wang, M., Wan, W. & Zhao, Y. L. Prediction of uniaxial compressive strength of rocks from simple index tests using random forest predictive model. Comptes Rendus Mecanique 348(1), 3–32. https://doi.org/10.5802/crmeca.3 (2020).

Wang, M., Wan, W. & Zhao, Y. L. Experimental study on crack propagation and coalescence of rock-like materials with two pre-existing fissures under biaxial compression. Bull. Eng. Geol. Env. 79(6), 3121–3144. https://doi.org/10.1007/s10064-020-01759-1 (2020).

Wang, M. et al. Experimental and numerical study on peak strength, coalescence and failure of rock-like materials with two folded preexisting fissures. Theoret. Appl. Fract. Mech. 125, 103830 (2023).

Wang, M. et al. Peak strength, coalescence and failure processes of rock-like materials containing preexisting joints and circular holes under uniaxial compression: Experimental and numerical study. Theoret. Appl. Fract. Mech. 125, 103898. https://doi.org/10.1016/j.tafmec.2023.103898 (2023).

Wang, M. et al. Calibrating microparameters of DEM models by using CEM, DE, EFO, MFO, SSO algorithms and the optimal hyperparameters. Comp. Part. Mech. 11, 839–852. https://doi.org/10.1007/s40571-023-00656-0 (2024).

Gao, K. et al. Application of deep borehole blasting to gob-side entry retaining forced roof caving in hard and compound roof deep well. Chin. J. Rock Mech. Eng. 32(8), 1588–1594. https://doi.org/10.3969/j.issn.1000-6915.2013.08.010 (2013).

Tang, F. R. et al. Study on key parameters of filling gob-side roadway in the thick layer soft rock fault top. J. Min. Safety Eng. 36(6), 1128–1136. https://doi.org/10.13545/j.cnki.jmse.2019.06.008 (2019).

Zhang, Z. Z. et al. Shallow-hole blasting mechanism and its application for gob-side entry retaining with thick and hard roof. Chin. J. Rock Mech. Eng. 35(S1), 3008–3017. https://doi.org/10.13722/j.cnki.jrme.2014.1442 (2016).

Chen, Y. et al. Study on the application of short-hole blasting with guide hole to roof cutting pressure relief of gob-side entry retaining. J. Min. Safety Eng. 32(2), 253–259. https://doi.org/10.13545/j.cnki.jmse.2015.02.013 (2015).

Zhu, Z. et al. An innovative non-pillar mining method for gate road formation automatically and its application in Ningtiaota coal mine. J. China Univ. Min. Technol. 48(1), 49–56. https://doi.org/10.13247/j.cnki.jcumt.000965 (2019).

Wang, Q. et al. The influence of gravel particle size on the bearing deformation characteristics of the top-cut roadway. J. China Univ. Min. Technol. 51(01), 100–106. https://doi.org/10.13247/j.cnki.jcumt.001362 (2022).

Guo, Z. B. et al. Broken expand properties and lateral pressure analysis of mud rock of gangue rib in god-side entry retaining formed by roof-cutting and pressure-releasing. J. China Univ. Min. Technol. 47(05), 987–994. https://doi.org/10.13247/j.cnki.jcumt.000924 (2018).

Wang, M. Discussion on “Study on mechanical and fracture characteristics of rock-like specimens with rough non-persistent joints by YADE DEM simulation”. Comput. Geotech. 167, 105966. https://doi.org/10.1016/j.compgeo.2023.105966 (2024).

Wang, M. et al. Numerical study on the strength and fracture of rock materials with multiple rough preexisting fissures under uniaxial compression using particle flow code. Comput. Part. Mech. https://doi.org/10.1007/s40571-024-00811-1 (2024).

Wang, M. et al. A calibration framework for DEM models based on the stress-strain curve of uniaxial compressive tests by using the AEO algorithm and several calibration suggestions. Comp. Part. Mech. https://doi.org/10.1007/s40571-024-00820-0 (2024).

Jiang, L. S. et al. Deformation and failure characteristics and roof caving hidden danger classification of roadways compound roof. J. China Coal Soc. 39(7), 1205–1211. https://doi.org/10.13225/j.cnki.jccs.2013.1219 (2014).

Sun, X. M. et al. Key parameters of gob-side entry retaining formed by roof cut and pressure releasing in thin coal seams. Chin. J. Rock Mech. Eng. 33(7), 1449–1456. https://doi.org/10.13722/j.cnki.jrme.2014.07.017 (2014).

Jia, H. S. et al. Roof fall mechanism and control method of roof with weak interlayer in mining roadway. J. Min. Safety Eng. 51(1), 67–76. https://doi.org/10.13247/j.cnki.jcumt.001367 (2022).

Chinese Aeronautics Research Institute. Hand-Book of Stress Intensity Factors (revised edition) 323–324 (Science Press, 1993).

Yu, X. Z., Qiao, C. X. & Zhou, Q. L. Fracture Mechanics of Rock and Concrete 443–463 (Central South University of Technology Press, 1991).

Jia, H. S. et al. Mechanism and application of classification “roof control-pressure relief” of gob-side entry retained with weakly caking compound roof. J. China Univ. Min. Technol. 52(06), 1191–1202. https://doi.org/10.13247/j.cnki.jcumt.20230196 (2023).

He, M. C. et al. An energy-gathered roof cutting technique in no-pillar mining and its impact on stress variation in surrounding rocks. Chin. J. Rock Mech. Eng. 36(6), 1314–1325. https://doi.org/10.13722/j.cnki.jrme.2016.1180 (2017).

Wang, E. Y. et al. Mechanism and application of roof cutting by directional energy-cumulative blasting along gob-side entry. Sustainability 20, 13381–13381. https://doi.org/10.3390/SU142013381 (2022).

Zhang, Z. Z. et al. Review and development of surrounding rock control technology for gob-side entry retaining in China. J. China Coal Soc. 48(11), 3979–4000. https://doi.org/10.13225/j.cnki.jccs.2023.0382 (2023).

Acknowledgements

This work was supported by the “Science and Technology Innovation Fund” of Coal Mining Research Institute Co Ltd. of CCTEG (KCYJY-2023-MS-07).

Author information

Authors and Affiliations

Contributions

The authors confirm contribution to the paper as follows: Writing – original draft, Software, Formal analysis, Data curation: K.P. . Writing – review & editing, Methodology, Conceptualization: W. J. Data curation, Validation: B. H. Resources, Project administration, Methodology: H. J. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Pan, K., Ju, Wj., Hou, B. et al. An exploration of improving stability of gob-side entry retained with graded and zoned pressure relief technology: a case study. Sci Rep 14, 29440 (2024). https://doi.org/10.1038/s41598-024-79844-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-79844-8