Abstract

Ceiling beams at the top of tunnels are more common in actual projects. Under the influence of thermal buoyancy, the ceiling structure significantly affects the diffusion characteristics of fire smoke within the tunnel. This study performed several sets of model experiments and numerical simulations to investigate the impact of the height and spacing of ceiling beams on the diffusion of smoke in tunnel fires, which results show that the maximum temperature rise and temperature decay patterns of fire smoke follow exponential changes. The increased height of the ceiling beams and the reduced spacing correspond to higher maximum temperatures on the ceiling. Furthermore, as the height of the ceiling beams increases and the spacing decreases, the longitudinal attenuation of ceiling temperature accelerates within the tunnel. A predictive model for ceiling temperature rise and a dimensionless temperature attenuation model were developed to characterize this phenomenon. The relative error between the predicted results and experimental findings falls within ± 15%. This study broadens the application scope of fire smoke diffusion models, which can provide technical support for smoke prevention and exhaust design of tunnels with similar structures.

Similar content being viewed by others

Introduction

With the rapid pace of urbanization, structures such as traffic tunnels, subway transfer channels, urban underground pipe corridors, and building corridors are becoming more widespread in practical projects1,2,3,4. These spaces are characterized by a long, narrow structure that is open at both ends, posing a significant fire hazard5,6.

Numerous scholars have investigated the characteristics of smoke diffusion in such spaces, which has primarily focused on the maximum ceiling temperature7, temperature decay8, critical velocity9 and smoke layer thickness10. And these studies have predominantly centered on the influence of tunnel structures on fire dynamics, considerations in these studies have incorporated factors such as tunnel cross-sectional geometry11,12, slope13,14,15, and tunnel curvature16,17, among other relevant factors.

It is worth noting that various structures exist in long and narrow confined space buildings, considering the needs of structural stress or building functions. Beams and similar structures are commonly installed in architectural corridors, highway tunnels, or subway transfer passages. For instance, support beams or frame beams are implemented based on the load-bearing structure of the edifice. Smoke-proof vertical walls are provided on the ceiling to divide smoke-proof zones, and there are signs or billboards on the ceiling, etc. The thermal buoyancy-driven ceiling jet resulting from fire smoke causes it to spread longitudinally along the tunnel ceiling18, It is evident that the presence of these structural features exerts a substantial influence on the diffusion of fire smoke.

Maximum ceiling temperature and ceiling temperature profile are crucial parameters for tunnel fire safety. Alpert19, Kurioka et al.20, and Li et al.21 successively established theoretical and empirical models for the maximum ceiling smoke temperature. Ji et al.22 considered the impact of fires at different lateral positions on the maximum smoke temperature and introduced improvements to Alpert’s model. Oka et al.23,24 studied the effect of the ceiling inclination angle on the temperature profile. Pan et al.25 investigated the effect of curved sidewalls on flame shape and maximum temperature under the centerline of the ceiling. Zhang et al.26 explored the temperature distribution of heat flow under a sloped ceiling induced by the fire plume of an attached wall. Qiu et al.27 studied the influence of the distance between two transverse fire sources and the power of the fire source on the maximum temperature of the ceiling. The predicted values from the improved dimensionless temperature rise model were in good agreement with the results of the experimental model. Liu et al.28 conducted full-scale experiments to study the temperature profile of fire-induced smoke in the node area of naturally ventilated mine tunnels and developed a correlation model to predict the dimensionless ceiling temperature rise and longitudinal temperature changes.

In the study of the ceiling temperature decay, Delichatsios29 was the first to discover the law that the ceiling jet temperature decays exponentially with longitudinal distance. He et al.30 conducted a series of model experiments to study the rules governing the attenuation of ceiling smoke temperature from two-fire sources of different sizes and distances in a naturally ventilated tunnel. Huang et al.31 used numerical simulation studies to consider the effects of fire ___location, fire source power, tunnel aspect ratio, and tunnel length on ceiling gas temperature. He proposed an empirical equation to predict the changing trend of the maximum ceiling gas temperature under the influence of longitudinal fire ___location.

As a result of the obstructive influence exerted by the ceiling beams within the tunnel, the airflow pattern tends to become disrupted when subjected to ventilation measures, thereby leading to an unstable temperature distribution within the tunnel during a fire event. Many scholars have conducted a series of studies considering various tunnel blocking conditions. Hu et al.32 demonstrated that downstream blockage has less influence on the maximum ceiling temperature. When the blockage is located upstream, the maximum temperature and blockage are related to the distance from the fire source. Meng et al.33 studied flame tilt behavior under different ventilation speeds and blocking rates based on numerical simulations. They developed a dimensionless model to predict the maximum smoke temperature under the tunnel ceiling. Chen et al.34 investigated the impact of obstacles on ceiling temperature distribution, vertical temperature distribution, and air flow field structure in a subway station fire scenario. Their findings showed that the presence of obstacles causes the ceiling temperature to decrease proportionally. Han et al.35 focused on the effect of ceiling extraction on smoke diffusion characteristics and temperature distribution in a tunnel closed at one end. He developed an empirical formula to predict the ceiling temperature attenuation in such tunnels. Chen et al.36 analyzed the impact of strong fire plume on the maximum temperature rise of the tunnel ceiling under different sealing conditions. The results showed that the ceiling gas temperature rise under the sealing effect would be lower than that without sealing.

The studies mentioned earlier only focus on fire scenarios where blockages occur on the tunnel floor (i.e., vehicle or people blockage) and do not address scenarios where blockages occur in the upper part of the tunnel, such as the presence of ceiling beams. To compare with previous research, a series of model experiments and numerical simulations of tunnel fires were carried out, mainly investigating the influence of the structural characteristics (beam height, beam spacing) of multiple beams in the tunnel ceiling on tunnel fire smoke temperature. Additionally, models were developed for predicting the maximum ceiling temperature and the dimensionless temperature decay of fire smoke within a ceiling featuring multiple beams. The research results can provide a reference for the fire safety of tunnels with similar structures.

Experimental and numerical simulation design

In order to study the impact of structural attributes of tunnel ceilings on the diffusion of smoke during tunnel fires, a model experiment was conducted, supplemented by numerical simulations. To facilitate a comparative analysis with prior research endeavors, the research initially encompassed smoke diffusion experiments and numerical simulations within unobstructed-ceiling tunnels, followed by analogous investigations in tunnels featuring multi-beam ceilings, which account for distinctive ceiling structural attributes. The model experiments served the purpose of validating the veracity of the numerical simulations, while the numerical simulations complemented and expanded upon the observations derived from the experimental trials.

Model experiment

Experimental model design

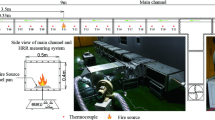

The tunnel model, featuring a ceiling with multiple beams, is depicted in Fig. 1. The internal dimensions of the model encompass a length of 12 m, a height of 30 cm, and a width of 30 cm. The tunnel’s construction comprises a multi-layered board structure for enhanced thermal insulation properties. The tunnel’s structural composition, progressing from the interior to the exterior, comprises a single layer of 5 mm iron plate, two strata of 9.5 mm gypsum board, and one layer of 2 mm galvanized iron plate, resulting in a cumulative thickness of 2.6 cm. The base of the tunnel is furnished with a 5 mm iron plate, and its impact on the thermal properties of flue gas is deemed negligible.

For the purpose of facilitating experimental observation and measurement, observation windows, measuring 0.5 m in length and 0.3 m in width, are strategically positioned along the model’s side walls at 2 m intervals. A variable frequency axial flow fan, located at one terminus of the tunnel, facilitates longitudinal ventilation during model experiments. The fan’s adjustable rotational speed enables a variable average velocity range within the tunnel section, ranging from 0 to 5 m/s. The tunnel model’s ceiling incorporates multiple beams, each adjustable in terms of height and spacing. These beams, constructed from 1 cm thick acrylic plates, possess dimensions of 30 cm in length and 20 cm in width. The height of the beams is variably adjustable within a range of 0 to 15 cm, while the beam spacing is available in three distinct specifications: 30 cm, 90 cm, and 150 cm.

The structural integrity of the tunnel is upheld by a support frame measuring 1 m in height, which is fabricated from 4 cm × 6 cm square steel. At a height of 60 cm above the ground, an operational platform is positioned, featuring a surfacing of 2 mm galvanized iron plate. This operating platform primarily serves as a workstation for the placement of experimental equipment and related apparatus.

Measurement layout

The model experiment primarily entailed the measurement of flue gas temperature and airflow velocity within the tunnel. Ceiling temperature was gauged using K-type armored thermocouples characterized by a 1 mm diameter, 0.1 °C accuracy, and a one second response time. These thermocouples were positioned 1 cm below the tunnel ceiling, maintaining a horizontal spacing of 30 cm between them. In addition, temperatures were recorded both upwind and downwind at the lower boundary of the ceiling beam to assess the potential smoke dispersion towards the ceiling beam. Airflow velocity measurements were taken at a distance of 45 cm from the fan, employing three multi-channel anemometers evenly distributed along the longitudinal center section with a 10 cm interval. The resultant airflow velocity was calculated as the average of the three measurements. The ambient conditions at the site encompassed temperatures ranging from 0 to 5℃ and humidity levels between 30% and 50%.

Experimental cases

The model experiment uses three different specifications of square fuel disks, with side lengths of 5 cm, 8 cm, and 10 cm respectively. See Table 1 for details. Methanol is used as fuel, and the initial thickness of the fuel is 3 cm.

The main variables in the model experiment are divided into 3 types of oil pan specifications, 5 types of beam heights, and 3 types of beam spacings. There are 3 groups of tunnel model experiments without obstacles on the ceiling (ME-1 ~ ME-3), and 19 groups of multi-beams tunnel model experiments on the ceiling (ME-4 ~ ME-21). After certain combinations, a total of 21 groups of working conditions are formed. The specific working conditions are shown in Table 2. The experiments were all conducted under natural ventilation conditions.

Numerical simulation

Simulation model design

In order to improve and expand the model experimental research, a 20:1 numerical calculation model was established using the similarity theory for the tunnel model in section “Experimental model design”. The size of the calculation model are 240 m × 6 m × 6 m and 240 m × 6 m × 4 m, as shown in Fig. 2. The numerical model was constructed using Fire Dynamics Simulator (FDS) version 6.3.2, developed by NIST. This computational fluid dynamics (CFD) tool facilitates the numerical assessment of heat and mass transfer processes during the propagation of smoke. Numerous prior investigations have substantiated the trustworthiness of simulation outcomes40.

Mesh sensitivity verification and boundary conditions

The grid size is one of the key parameters that determines the accuracy of the simulation results37. Selecting an appropriate grid size can not only ensure the accuracy of the simulation calculation results, but also improve the calculation efficiency as much as possible. The FDS User Guide38 provides a dimensionless parameter “D*/δx” to determine the grid size. This parameter represents the number of calculation units with a grid size “δx “within the fire source characteristic diameter “D*”. The expression for “D*” is as follows:

The recommended value of the calculation grid “δx” is in the range of 1/16 to 1/4 of the fire source characteristic diameter “D*”39. Because this work is an expansion of previous research work, the grid setting and selection and other boundary condition settings can refer to previous research40. Therefore, the grid size of 0.25 m is still used in this research.

Simulation cases

There are a total of 20 groups of numerical simulations for tunnel without obstacles, listed in Table 3. The main variables are the heat release rate of the fire source and the height of the tunnel. The working cases NS-18 ~ NS-20 are numerical models established using similar theories and correspond one to one to the working cases ME-1 ~ ME-3 in the model experiment.

There are a total of 103 groups of numerical simulations for tunnel with multi-beam on the ceiling. The specific working cases are shown in Table 4. The main variables are heat release rate, tunnel height, beam height and beam spacing. The 19 working conditions, numbered NS-21 to NS-39, represent numerical models established using similar theories and correspond one-to-one with the working conditions ME-4 to ME-21 in the multi-beam tunnel model experiment. Working condition numbers NS-40 to NS-123 involve numerical simulation under different settings of heat release rate, beam height, and beam spacing.

Results and discussion

Maximum ceiling temperature for tunnel

Maximum ceiling temperature for tunnels without ceiling beam

Experiments were conducted within a tunnel setting, void of ceiling beams, to explore the behavior of methanol pool fires of varying dimensions. The fuel pans used in these experiments were labeled as S-1, S-2, and S-3, with side lengths of 5 cm, 8 cm, and 10 cm, respectively. It is noteworthy that the combustion of the S-1 fuel pan did not result in any contact between its flame and the tunnel ceiling. Conversely, the flames emanating from the S-2 and S-3 fuel pans exhibited intermittent interactions with the tunnel ceiling, thus establishing the presence of an intermittent flame zone near the fire source.

In parallel, numerical simulations were undertaken to evaluate heat release rates emanating from various fire sources within differing ceiling height configurations. An investigation conducted by Ji et al.41, which indicated that the tunnel width had only a small influence on the maximum ceiling temperature. Consequently, in the context of the simulations, the tunnel width was held constant. Furthermore, Li et al.21 elucidated that, under conditions of natural ventilation, the maximum ceiling temperature was primarily concentrated along the central axis directly above the fire source. As such, the determination of the maximum ceiling temperature was executed through the utilization of a thermocouple directly positioned above the fire source.

Previous research efforts have furnished expressions governing the maximum ceiling temperature, heat release rate, and the vertical distance from the oil pool to the ceiling, as articulated in Eq. (2)40,41 However, the specific formulations of these expressions remain undisclosed within the provided text. To facilitate a more comprehensive discussion, it is imperative to present the relevant equations and additional details pertaining to the aforementioned parameters.

The determination of the constant parameter “A” involves fitting experimental and simulated data. However, variations in the values of “A” emerge in the works of different scholars, potentially attributable to discrepancies in experimental conditions or other calculation factors. Notably, Alpert 19 assigns a value of 16.9 to “A”, Li et al.21 opts for a value of 17.5, Ji et al.22 selects 17.9, Ji et al.41 reports a value of 18.03, and Yao et al.42 employs a value of 22.7.

In this section, a comparison is drawn between the experimental values and simulated values using the above model, as shown in Fig. 3. The analysis reveals a significant agreement between the experimental data and the simulated values, predominantly aligning with Li’s model. Consequently, for conditions featuring a ceiling without beams, the value of “A” is stipulated as 17.5 in this section.

In a tunnel without obstacles on the ceiling, the maximum ceiling temperature rise under natural ventilation conditions can be expressed as Eq. (3):

Maximum ceiling temperature for tunnel with ceiling beams

In tunnel scenarios featuring ceiling beams, the parameters of beam height and beam spacing exert a significant influence on the maximum ceiling temperature. Taking an example, for a fire of 0.5 MW, Figs. 4 and 5 respectively show the dimensionless maximum ceiling temperature rise under different beam heights and different beam spacing conditions. It can be seen that a higher beam height leads to higher maximum ceiling temperature, and beam spacing values are associated with reduced maximal ceiling temperatures. Furthermore, these changes obey an exponential distribution pattern.

This phenomenon is attributed to the effects of longitudinal smoke diffusion within the fire scenario. Specifically, the presence of ceiling beams serves as an obstruction, causing a portion of the smoke to circumvent these obstacles and diffusing further, and the other part of the smoke will accumulate inside the beams. In comparison to tunnels where the beam heights are relatively lower, those with elevated ceiling beam heights result in increased smoke accumulation, consequently culminating in higher ceiling temperatures. However, as the distance between the beams ceiling increases, ceiling temperature will decay more during the longitudinal diffusion process. This observation is graphically elucidated in Fig. 6.

After fitting, it was found that the relationship between the maximum ceiling temperature and the beam height conforms to the following formula:

The relationship between the maximum ceiling temperature and the beam spacing conforms to the following formula:

When considering Figs. 4 and 5 in conjunction with consistent boundary conditions, it becomes evident that only changed the beam height or beam spacing, the maximum ceiling temperature rise of the tunnel with ceiling beams is an exponential function with respect to the beam height and beam spacing. Furthermore, his increase exhibits a positive correlation with the dimensionless maximum ceiling temperature rise. Furthermore, increasing beam height is positively correlated with the dimensionless maximum ceiling temperature rise. Increasing beam spacing is inversely related to the dimensionless maximum ceiling temperature rise.

After considering the influence of ceiling beam height and beam spacing on the maximum ceiling temperature respectively, a unified expression needs to be established to express the influence. Based on the trends observed in Figs. 4 and 5, it is reasonable to assume that the dimensionless rise expression for the maximum ceiling temperature in a tunnel with ceiling beams can be expressed as Eq. (6):

Combining Eq. (3), the maximum ceiling temperature rise of a tunnel with ceiling beams can be expressed as Eq. (7):

The establishment of a maximum ceiling temperature model for tunnel featuring ceiling beams necessitates a foundational reference to tunnel without such structural elements. According to Eq. (4), the value of the constant “A” is determined to be 17.5. It is worth noting that Fig. 5 illustrates that the value of “n1” is below 0, while Fig. 6 illustrates that the value of “n2" exceeds 0. In the case where there are no ceiling beams in the tunnel, that is, when the beam height “hB = 0” and beam spacing “dB = ∞”, Eq. (7) can be simplified to Eq. (3), which is consistent with the research of the aforementioned scholars.

The data from model experiments and numerical simulations were fitted based on Eq. (7), and the fitting results were “A = 17.5, B = 3.5, n1 = 0.2, n2 = 1.6”. Therefore, the maximum ceiling temperature model of a tunnel with ceiling beams under natural ventilation conditions is as follows Eq. (8):

Figure 7 presents a comprehensive comparison among experimental values, simulated values, and predicted values obtained from Eq. (8). It is evident that Eq. (8) provides a more accurate prediction of the maximum ceiling temperature for tunnel with ceiling beams under natural ventilation conditions, with the relative error of this prediction model within ± 15%.

Ceiling temperature decay for tunnel

Ceiling temperature decay for tunnel without ceiling beam

Scholars have conducted extensive studies on the tunnel ceiling temperature decay model through theoretical derivation, model experiments, full-scale experiments and other methods. Commonly employed models in this ___domain are summarized in Table 5. Building upon the existing temperature decay model applied to tunnel ceilings without beams, considering the structural characteristics of ceiling beams and established a temperature decay model for tunnels with ceiling beams.

Ceiling temperature decay for tunnel with ceiling beams

In the 2 MW tunnel fire scenario, Fig. 8 illustrates the longitudinal temperature decay rules of the tunnel ceiling under different beam height conditions while maintaining a consistent beam spacing. As shown in Fig. 9, it is evident that as the beam height increases, the longitudinal temperature decay occurs at a more accelerated rate. This phenomenon can be attributed to the heightened beam height, resulting in an increased obstructive effect on smoke dispersion. During the longitudinal propagation of fire smoke, the beams act as barriers, leading to the continuous accumulation of smoke. When the thickness of the smoke layer exceeds the height of the beam, the smoke bypasses the beams and extends longitudinally. Consequently, with greater beam heights, a larger volume of smoke accumulates in regions closer to the fire source, causing the temperature to rise at a slower pace in areas distanced from the fire source.

Similarly, Fig. 9 illustrates the longitudinal decay law of the tunnel ceiling temperature under different beam spacing conditions while keeping the beam height constant. It can be observed from Fig. 9 that a decrease in the spacing between the ceiling beams is associated with a faster longitudinal temperature decay. Reduced beam spacing promotes the accumulation of fire smoke in areas closer to the fire source. As the smoke accumulates and bypasses the ceiling beams, a greater amount of heat is lost, resulting in an accelerated temperature decay.

To quantitatively describe the influence of beam height and spacing on ceiling temperature decay, it is essential to establish a predictive model. Following the fitting of ceiling temperature data acquired from model experiments and simulations, it is evident that the model structure, in concordance with the works of Ingason and Li46, Gong et al.47, and Liu et al.28, which can be shown as Eq. (9):

According to the boundary conditions, it can be seen that:

By fitting a large number of experimental and simulated data, it can be determined that parameter “A1” remains within a relatively stable range. Consequently, by computing the average of the fitting values for each working condition, we have determined that “A1 = 0.46”, while “A2 = 0.54”. Also, “t1” floats up and down at a certain value, take the average of the fitting values of each working condition, “t1 = 0.34”. Furthermore, it is notable that the parameter t2 shows obvious regularity as the height of the beam increases and the spacing between the beams increases. Figure 10 shows how t2 changes with the height of the dimensionless beam when the spacing between the top beams is constant. There is a good linear relationship between “t2” and the height of the dimensionless beam. Figure 11 shows how “t2” changes with the distance between dimensionless beams when the height of the top beam is constant. There is an obvious exponential function relationship between “t2” and the distance between dimensionless beams.

Combining the fitting results in Figs. 10 and 11, it can be assumed that the relationship between “t2”, the dimensionless beam height and the dimensionless beam spacing is Eq. (11):

After fitting the experimental data and simulated data, the expression of “t2” can be obtained as Eq. (12):

Figure 12 presents a comparative analysis between the “t2” values predicted by Eq. (12) and those obtained through data fitting. The comparison shows that Eq. (12) can better predict the “t2” value under different ceiling beam heights and ceiling beam spacing conditions.

Combining Eq. (9) and Eq. (12), the ceiling temperature longitudinal decay model of tunnel fire with ceiling beams can be obtained as Eq. (13):

Figure 13 shows the comparison of the dimensionless temperatures predicted by Eq. (13) at different longitudinal distances from the ceiling under different working conditions with experimental and simulated data. It can be seen that Eq. (13) can better predict the longitudinal temperature distribution in the case of fire in tunnel containing with ceiling beams.

Conclusions

In order to investigate the impact of tunnel ceiling structure on smoke diffusion, a series of reduced-scale model tunnel experiments and numerical simulations were carried out to study the effects of the height and spacing of tunnel ceiling beams on the smoke temperature distribution characteristics. The main conclusions are as follows:

-

(1)

The presence of ceiling beams has a significant impact on the diffusion of smoke in tunnel. The higher the beam height, the higher the maximum ceiling temperature. Conversely, wider beam spacing leads to lower maximum ceiling temperatures, and these variations follow an exponential distribution.

-

(2)

A predictive model Eq. (8) for the maximum ceiling temperature in tunnels with ceiling beams has been developed, and there is a high degree of agreement between experimental and numerical simulation results and the model predictions.

-

(3)

Considering the two parameters of ceiling beam height and beam spacing, an exponential model Eq. (13) is developed to predict non-dimensional ceiling smoke temperature attenuation along the tunnel axis. The results indicate that the higher the ceiling beam height and the smaller the beam spacing, the faster the ceiling temperature decreases along the longitudinal direction of the tunnel.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Change history

11 June 2025

A Correction to this paper has been published: https://doi.org/10.1038/s41598-025-04536-w

Abbreviations

- ρ 0 :

-

Air density, kg/m3

- T0 :

-

Ambient temperature, K

- cp :

-

Specific heat capacity at constant pressure, J/g K

- g :

-

Gravitational acceleration, m/s2

- Q :

-

Heat release rate, kW

- D* :

-

Fire source characteristic diameter

- δ x :

-

Grid size

- hB :

-

Beam height, m

- dB :

-

Beam spacing, m

- Δ Tmax :

-

Maximum excess temperature, K

- Hef :

-

Effective height of tunnel ceiling, m

- H :

-

Height of tunnel, m

- x :

-

Longitudinal distance from the fire source, m

- Δ Tx :

-

Ceiling temperature rise at x m distance from fire source, K

- Δ T :

-

Average temperature of fire site gases, K

- w :

-

Width of tunnel, m

- St :

-

Stanton number

- Q* :

-

Dimensionless heat release rate

- Q c :

-

Convective heat release rate, kW

- Tf :

-

Average temperature of fire site gases, K

- Ac :

-

Cross-sectional area of tunnel, m2

- A, B, ξ, η, K1, K2, A1, A2, n1, n2, t1, t2, a1, a2, b1, b2 :

-

Coefficients or parameters

References

Tian, X., Liu, C. & Zhong, M. in Heat Transfer Summer Conference. V001T006A002 (American Society of Mechanical Engineers).

Zhu, H., Ji, J. & Nie, J. Early fire evolution and alarm characteristics of cable fires in long and narrow spaces. Fire Saf. J. 131, 103627 (2022).

Lee, Y. T. et al. Effects of control zone, exhaust rate and station extent on smoke dispersal during emergency concourse fires in underground stations. Int. J. Therm. Sci. 191, 108363 (2023).

Wu, K. et al. Flame behavior and fire-induced flow field characteristic in building corridor fire with longitudinal partition. J. Building Eng. 76, 107358 (2023).

Hu, L. et al. Modeling fire-induced smoke spread and carbon monoxide transportation in a long channel: Fire dynamics simulator comparisons with measured data. J. Hazard. Mater. 140, 293–298 (2007).

Su, Z. et al. A study of the critical velocity and the confinement velocity of fire accident in a longitudinally ventilated underground train with different door opening scenarios. Tunn. Undergr. Space Technol. 131, 104776 (2023).

Li, T. et al. Experimental study of air curtain thermal insulation efficiency and maximum temperature rise beneath the ceiling under longitudinal ventilation in bifurcated tunnels. Tunn. Undergr. Space Technol. 137, 105112 (2023).

Huang, Y., Li, Y., Dong, B., Li, J. & Liang, Q. Numerical investigation on the maximum ceiling temperature and longitudinal decay in a sealing tunnel fire. Tunn. Undergr. Space Technol. 72, 120–130 (2018).

Chen, C. et al. Experimental investigation on the influence of longitudinal fire ___location on critical velocity in a T-shaped tunnel fire. Tunn. Undergr. Space Technol. 134, 104983 (2023).

Tanno, A., Oka, H., Kamiya, K. & Oka, Y. Determination of smoke layer thickness using vertical temperature distribution in tunnel fires under natural ventilation. Tunn. Undergr. Space Technol. 119, 104257 (2022).

Li, Y. Z. & Ingason, H. Effect of cross section on critical velocity in longitudinally ventilated tunnel fires. Fire Saf. J. 91, 303–311 (2017).

Li, Y. Z., Fan, C. G., Ingason, H., Lönnermark, A. & Ji, J. Effect of cross section and ventilation on heat release rates in tunnel fires. Tunn. Undergr. Space Technol. 51, 414–423 (2016).

Jiang, L. & Xiao, M. Effect of tunnel slope on the critical velocity of densimetric plumes and fire plumes in ventilated tunnels. Tunn. Undergr. Space Technol. 123, 104394 (2022).

Lei, P. et al. Study on heat allocation and temperature profile in a T-shaped branched tunnel fire with different branch slopes under natural ventilation. Tunn. Undergr. Space Technol. 126, 104508 (2022).

Li, J. et al. Experimental analysis of the effect of the ramp slopes on the maximum exceedance temperature in a branched tunnel fire. Tunn. Undergr. Space Technol. 131, 104829 (2023).

Xu, Z., Zhou, D., Tao, H., Zhang, X. & Hu, W. Investigation of critical velocity in curved tunnel under the effects of different fire locations and turning radiuses. Tunn. Undergr. Space Technol. 126, 104553 (2022).

Jafari, S., Farhanieh, B. & Afshin, H. Numerical investigation of critical velocity in curved tunnels: Parametric study and establishment of new model. Tunn. Undergr. Space Technol. 135, 105021 (2023).

Alpert, R. L. Ceiling jet flows. SFPE Handb. Fire Prot. Eng. 429–454 (2016).

Alpert, R. L. Turbulent ceiling-jet induced by large-scale fires. Combust. Sci. Technol. 11, 197–213 (1975).

Kurioka, H., Oka, Y., Satoh, H. & Sugawa, O. Fire properties in near field of square fire source with longitudinal ventilation in tunnels. Fire Saf. J. 38, 319–340 (2003).

Li, Y. Z., Lei, B. & Ingason, H. The maximum temperature of buoyancy-driven smoke flow beneath the ceiling in tunnel fires. Fire Saf. J. 46, 204–210 (2011).

Ji, J., Fan, C., Zhong, W., Shen, X. & Sun, J. Experimental investigation on influence of different transverse fire locations on maximum smoke temperature under the tunnel ceiling. Int. J. Heat. Mass. Transf. 55, 4817–4826 (2012).

Oka, Y., Imazeki, O. & Sugawa, O. Temperature profile of ceiling jet flow along an inclined unconfined ceiling. Fire Saf. J. 45, 221–227 (2010).

Oka, Y. & Imazeki, O. Temperature and velocity distributions of a ceiling jet along an inclined ceiling–part 1: Approximation with exponential function. Fire Saf. J. 65, 41–52 (2014).

Pan, R. et al. Experimental study on the fire shape and maximum temperature beneath ceiling centerline in utility tunnel under the effect of curved sidewall. Tunn. Undergr. Space Technol. 99, 103304 (2020).

Zhang, X., Hu, L. & Sun, X. Temperature profile of thermal flow underneath an inclined ceiling induced by a wall-attached fire. Int. J. Therm. Sci. 141, 133–140 (2019).

Qiu, D., Yang, J., Liu, C., Zheng, Y. & Zheng, J. Experimental study on temperature distribution beneath tunnel ceiling under the condition of transverse double fire sources. Tunn. Undergr. Space Technol. 132, 104889 (2023).

Liu, C., Zhong, M., Shi, C., Zhang, P. & Tian, X. Temperature profile of fire-induced smoke in node area of a full-scale mine shaft tunnel under natural ventilation. Appl. Therm. Eng. 110, 382–389 (2017).

Delichatsios, M. A. The flow of fire gases under a beamed ceiling. Combust. Flame. 43, 1–10 (1981).

He, K. et al. Experimental study on temperature attenuation of smoke flow driven by dual fire sources in a tunnel. Tunn. Undergr. Space Technol. 134, 105004 (2023).

Huang, P. et al. Study on the maximum and longitudinal distribution of ceiling gas temperature in a naturally ventilated tunnel: The effect of longitudinal fire ___location. Int. J. Therm. Sci. 185, 108037 (2023).

Hu, L., Tang, W., Chen, L. & Yi, L. A non-dimensional global correlation of maximum gas temperature beneath ceiling with different blockage–fire distance in a longitudinal ventilated tunnel. Appl. Therm. Eng. 56, 77–82 (2013).

Meng, N. et al. Effect of blockage-induced near wake flow on fire properties in a longitudinally ventilated tunnel. Int. J. Therm. Sci. 134, 1–12 (2018).

Chen, J. F. et al. Study on the effect of obstacles on smoke diffusion and airflow structure in subway stations. Build. Environ. 242, 16. https://doi.org/10.1016/j.buildenv.2023.110553 (2023).

Han, J. et al. Effect of ceiling extraction on the smoke spreading characteristics and temperature profiles in a tunnel with one closed end. Tunn. Undergr. Space Technol. 119, 104236 (2022).

Chen, L. et al. Research on ceiling gas temperature rise and floor heat flux driven by strong fire plume in a sealing tunnel. Int. J. Therm. Sci. 193, 108534 (2023).

McGrattan, K. B., Floyd, J. E., Forney, G. P., Baum, H. R. & Hostikka, S. A. Improved radiation and combustion routines for a large eddy simulation fire model (2005).

Kevin, M. Fire Dynamics Simulator (Version 4): User’s Guide. – 1019 (National Institute of Standards and Technology, 2004).

McDermott, R., McGrattan, K. & Hostikka, S. Fire dynamics simulator (version 5) technical reference guide. NIST Spec. Publ. 1018, 3–4 (2008).

Tian, X., Liu, C. & Zhong, M. Numerical and experimental study on the effects of a ceiling beam on the critical velocity of a tunnel fire based on virtual fire source. Int. J. Therm. Sci. 159, 106635 (2021).

Ji, J., Bi, Y., Venkatasubbaiah, K. & Li, K. Influence of aspect ratio of tunnel on smoke temperature distribution under ceiling in near field of fire source. Appl. Therm. Eng. 106, 1094–1102 (2016).

Yao, Y. et al. Maximum smoke temperature beneath the ceiling in an enclosed channel with different fire locations. Appl. Therm. Eng. 111, 30–38 (2017).

Evers, E. & Waterhouse, A. A Computer Model for Analysing Smoke Movement in Buildings (Building Research Establishment, 1978).

Bailey, J., Forney, G. P., Tatem, P. & Jones, W. W. Development and validation of corridor flow submodel for CFAST. J. Fire. Prot. Eng. 12, 139–161 (2002).

Hu, L., Huo, R., Chow, W. K., Wang, H. & Yang, R. Decay of buoyant smoke layer temperature along the longitudinal direction in tunnel fires. J. Appl. fire Sci. 13, 53–77 (2004).

Ingason, H. & Li, Y. Z. Model scale tunnel fire tests with longitudinal ventilation. Fire Saf. J. 45, 371–384 (2010).

Gong, L. et al. Theoretical and experimental study on longitudinal smoke temperature distribution in tunnel fires. Int. J. Therm. Sci. 102, 319–328 (2016).

Tian, X., Zhong, M., Shi, C., Zhang, P. & Liu, C. Full-scale tunnel fire experimental study of fire-induced smoke temperature profiles with methanol-gasoline blends. Appl. Therm. Eng. 116, 233–243 (2017).

Acknowledgements

This work was supported by the National Key R&D Program of China (2023YFC3009100), Central Fundamental Research Funds of CASST (2023JBKY15) and National Natural Science Foundation of China (52104198).

Author information

Authors and Affiliations

Contributions

X.T.: Conceptualization, Methodology, Validation, Funding acquisition, Formal analysis, Writing-review & editing. X.D.: Data analysis, Writing-original draft. L.X.: Conceptualization, Data curation.C.L.: Funding acquisition, Supervision. S.F.: Funding acquisition, Supervision, Resources. M.Zh.: Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The original version of this Article contained an error in the name of the author Xiangliang Tian, which was incorrectly given as Xiangling Tian.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Tian, X., Ding, X., Xiang, L. et al. Numerical and experimental study on smoke diffusion characteristics of tunnel with ceiling beams. Sci Rep 14, 30373 (2024). https://doi.org/10.1038/s41598-024-82368-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-82368-w