Abstract

During maritime operations, extreme events such as explosions, grounding, and seal failures can cause water ingress into lubricant compartments, forming oil-water emulsions that significantly affect the lubrication performance of ship stern bearings. Existing studies mainly focus on low water content, with limited exploration of the impact of high water content on lubrication performance. To address this gap, viscosity measurements of oil-water mixtures were conducted, and an emulsification viscosity equation applicable to varying water contents was derived. A thermal elastohydrodynamic lubrication model for stern bearings, incorporating rough surface contact and emulsification viscosity, was developed. Numerical results reveal two flow regimes of oil-water mixtures—water-in-oil (W/O) and oil-in-water (O/W)—each exhibiting distinct lubrication behaviors. In the high-viscosity W/O regime, water contamination increases lubricant viscosity, raises minimum oil film thickness, and lifts the journal, but significantly increases the friction coefficient and power consumption. The high specific heat capacity of water mitigates the temperature rise caused by increased viscosity. In the low-viscosity O/W regime, the mixture shows lower temperature rise and friction power under high-speed light-load conditions. However, under low-speed heavy-load conditions, the lubrication transitions to the boundary regime, leading to sharp increases in friction and temperature detrimental to bearing performance. This study highlights the critical influence of water content in oil-water emulsions on stern bearing lubrication, providing valuable insights for improving bearing design and operational reliability.

Similar content being viewed by others

Introduction

Bearings are critical components in mechanical systems, and their performance is directly tied to the overall operational quality and efficiency of the equipment. At present, extensive research on bearings conducted by scholars worldwide has achieved significant progress,with the related theories and technologies reaching a high level of maturity1,2,3. Lubrication performance is a key aspect of bearing functionality, directly impacting friction, wear,and operational stability. Extensive research in lubrication has further highlighted its critical role in engineering and industrial applications4,5,6,7,8.

The stern bearing is a crucial component of a ship’s shaft system, primarily responsible for supporting the shaft and controlling its circumferential movement. The quality of the lubricant significantly impacts the performance of the stern bearing. However, lubricants in ship stern bearings are prone to contamination by seawater9. When seawater infiltrates the lubrication system and mixes with the lubricant, it forms an emulsion, which adversely affects the lubrication performance. Excessive seawater contamination can lead to electrochemical corrosion of the bearings10, increased wear, reduced lifespan, and severe damage11,12. Various factors can lead to seawater contamination, including damage to lubricating oil tanks and increased shaft seal gaps caused by external hazards such as explosions, collisions, and groundings during service13,14.

Several researchers have studied the emulsification of lubricants with water. Schatzberg et al.15 found that water contamination induces “hydrogen embrittlement” in bearings, impairing their performance. Eachus et al.16 summarized the effects of water contamination on bearing lubrication, noting that it decreases lubrication capacity by reducing effective viscosity. Al-Sharif et al.17 formulated the Reynolds equation for oil-water two-phase fluids based on mixture theory and applied it to bearings under mixed lubrication, demonstrating that the pressure in oil-film bearings increases with water content up to a certain point, beyond which it decreases. Wilson et al.18 compared various mixture elastohydrodynamic lubrication models with Dow’s experimental values, revealing that conventional models using effective viscosity to correct for continuous phase viscosity underestimated oil film thickness, whereas the concentration-based calculations closely matched experimental values. Harika et al.19 experimentally demonstrated that water presence minimally affects liquid film thickness and frictional torque when the water content is below a certain threshold, but it significantly influences film temperature and viscosity compared to pure oil.

These studies indicate that water contamination alters the physical properties of lubricating oils, such as viscosity, density, and specific heat. Thus, determining the relationship between these properties and the emulsified viscosity of marine lubricating oils is crucial for understanding and predicting the mixed lubrication state of stern bearings. Scholars have conducted extensive research on mixed fluid viscosity models and proposed various solutions. Chen et al.20 proposed a viscosity model for water-in-oil mixtures, while Chen et al.21 developed a model for oil-in-water mixtures. Yan et al.22 derived an equivalent viscosity model based on mixture theory, suitable for different liquid film areas and types of mixtures (oil-in-water or water-in-oil). Hu et al.23 used 46# hydraulic wear-resistant oil and tap water as lubricating media in experiments to simulate oil-water two-phase flow and proposed a new model to calculate the viscosity of oil-water mixtures by measuring pressure drop, indicating higher accuracy in viscosity calculations for emulsions.

Current research on ship stern bearing lubrication primarily addresses low levels of water contamination, with limited studies on high-moisture oil-water mixtures. Additionally, there are fewer investigations into the mixed lubrication of stern bearings when the minimum film thickness of oil-water emulsions is comparable to the surface roughness of the bearings and journals. Extreme events in maritime operations, such as grounding or explosions, can cause significant seawater ingress, leading to high-moisture oil-water mixtures and severely affecting stern bearing performance. To better understand the lubrication characteristics of stern bearings contaminated by seawater under such extreme conditions, it is imperative to develop a widely applicable prediction model for the lubrication characteristics of emulsified lubricants in ship stern bearings.

In this paper, emulsification viscosity characterization tests of marine lubricants mixed with seawater were conducted. Viscosity equations were fitted for water contents ranging from 0 to 100% and temperatures from 35 to 60 °C. A thermal elastohydrodynamic lubrication model for stern bearings, incorporating the emulsification viscosity equation and rough contact, was developed. This model encompasses fluid and mixed lubrication as well as lubrication state transitions. The lubricating media considered include water, oil, and emulsions with water content ranging from 0 to 100%. The lubrication characteristics of the bearing under different water contents were calculated using the finite difference method, and the effects of varying levels of seawater contamination on bearing lubrication were analyzed in terms of friction coefficient, oil film thickness, temperature and pressure. Furthermore, it facilitates the prediction of stern bearing performance under extreme conditions such as grounding or seal failures, addressing critical needs for the maritime industry.

Emulsification characterization of lubricating oil in water

Experimental equipment

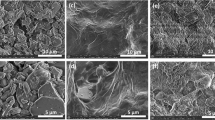

To measure the viscosity of oil-water emulsions with different water contents, a viscosity measurement experimental device for oil-water emulsions was designed, as shown in Fig. 1(a). The device includes a viscometer, as depicted in Fig. 1(b), which can measure multiple physical parameters such as viscosity, torque, and shear force with a measurement accuracy of ± 1%. The measurement principle is based on calculating the kinematic viscosity of the lubricant from the viscous resistance experienced by the rotor at a specific speed24.The viscometer allows for adjustments to the measurement range through its touchscreen interface. Lower rotor speeds increase the measurable viscosity range of the liquid, while higher rotor speeds reduce it. The measurement range of the viscometer is 0.2 mPa·s to 6000 mPa·s.The experimental samples consist of VG68 lubricant oil and standard seawater25, as shown in Fig. 1(c). A magneto stirrer, illustrated in Fig. 1(d), is used to ensure thorough mixing of the oil-water mixture to achieve full emulsification. Additionally, an electronic balance is employed, as depicted in Fig. 1(e).

Experimental procedure

The test temperature range was set between 35 °C and 60 °C, with increments of 5 °C. Under ambient conditions at 27 °C, 11 sets of samples with water contents ranging from 0 to 100% were prepared using an ultra-micro balance, with a step size of 10%. The samples were stirred at room temperature for 5 min, allowed to stand for 1 min, and then 3 mL of each sample was placed into the viscometer for viscosity testing. Before starting the experiment, the viscometer was checked to ensure it was functioning properly, and sample cups were handled carefully to avoid damage. The constant-temperature water bath was turned on, and the target temperature was set and stabilized before testing began. The selected rotor was installed, and its height was adjusted so that the tip was appropriately distanced from the bottom of the sample cup. After adjustments, the indicator light was turned off. Using a pipette, an appropriate amount of the sample was drawn and transferred into the sample cup. The rotation speed and testing time were set, and the viscosity test was initiated while data was recorded. If the torque value exceeded the set range, the rotation speed was adjusted, and the test was repeated. Upon completing the experiment, the viscosity values and testing conditions (such as temperature and water content) were recorded. Finally, the rotor and sample cups were cleaned, air-dried, and stored properly for future use.

Experimental results

The experimentally measured data are presented in Fig. 2, where the horizontal axis represents the water mass fraction in the lubricant, and the vertical axis represents the lubricant’s dynamic viscosity. The experiments demonstrated that both temperature and water content significantly impact the lubricant’s viscosity. As the temperature increases, the viscosity of the emulsion decreases, with higher temperatures causing a slower rate of viscosity reduction. For instance, when the water mass fraction was 0%, the dynamic viscosity of the emulsion decreased from 85.42 mPa·s to 32.11 mPa·s as the temperature increased from 35 °C to 60 °C, a decrease of 62.41%. At a water mass fraction of 50%, the viscosity decreased by 65.1%, from 290.10 mPa·s to 101.66 mPa·s over the same temperature range. When the water content was between 0% and 50%, the viscosity of the sample increased with the water content, with higher temperatures resulting in smaller increases in viscosity. For example, at 35 °C, the viscosity increased from 85.42 mPa·s to 290.10 mPa·s, an increase of 239.71%, as the water content increased from 0 to 50%. At 60 °C, the viscosity increased from 32.11 mPa·s to 101.66 mPa·s, an increase of 216.66%. However, as the water content increased from 50 to 60%, the viscosity decreased significantly compared to the viscosity at 50% water content. When the water content was between 60% and 100%, the viscosity of the emulsion decreased with increasing water content, with the rate of decrease diminishing as the water content and temperature increased.

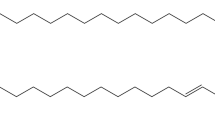

This phenomenon occurs because, after mixing pure oil and water, the physical properties of the two-phase liquid differ from those of a single fluid (oil or water), and the viscosity of the mixed liquid is usually related to its manifold26. At low water contents, oil is the continuous phase27,28, and water is the dispersed phase. In this water-in-oil (W/O) manifold stage29, the intervals between the dispersed water phases are large, and the interaction between the water droplets has a minimal effect on the lubricant’s viscosity. As the water content increases, the proportion of the dispersed phase (water) increases dramatically, leading to the aggregation of water droplets. This aggregation increases the interaction force and contact area, resulting in slip and collision in the liquid phase and an increase in the lubricant’s viscosity due to the surface energy effect. When the water content continues to increase beyond a certain limit, the lubricant cannot completely encapsulate the water, leading to a sudden change in the emulsion’s internal structure. The droplets change the manifold, causing a phase transition in the oil-water mixture, manifested by a reduction in viscosity. At this stage, oil becomes the dispersed phase, and water becomes the continuous phase, forming an oil-in-water (O/W) manifold30,31,32. The trans-phase process of oil-water mixed liquids is illustrated in Fig. 3.

The theoretical understanding of the transition point from the water-in-oil (W/O) manifold to the oil-in-water (O/W) manifold is still immature33,34. Although some scholars have measured the transition point experimentally, the values obtained vary slightly due to the influence of the test environment and human factors. To determine the transition point from the water-in-oil (W/O) to the oil-in-water (O/W) manifold, emulsion solutions were prepared in 1% increments, and the transition point was experimentally measured under different water contents. At room temperature (27 °C), repeated tests determined the transition point to be at a water content of 54%. However, as temperature significantly affects the stability of the interfacial film and the viscosity values of emulsions, we further analyzed the role of temperature. The experimental results indicate that as temperature increases, the structural stability of the emulsion system gradually weakens, and the viscosity measurements at the transition point become unstable. Stable viscosity values could only be obtained at 35 °C, which was therefore set as the key temperature for measuring the transition point in our experiments.

It is noteworthy that when the moisture content ranged from 60 to 90%, the samples showed significant stratification after standing, which did not occur when the moisture content was between 0% and 50%. The viscosity of emulsified oil decreased from 135.4 mPa·s to 87.43 mPa·s at 35 °C. Consequently, oil-in-water (O/W) manifold mixtures are structurally unstable, and their viscosity cannot be accurately measured with existing equipment.

Thermal elastohydrodynamic lubrication model

Viscosity Equation

The viscosity µ of an oil-water emulsion, as determined by experiments measuring water mass fraction τ and temperature T, is expressed as µ(τ, T). Specifically, µ(1, T) and µ(0, T) represent the viscosity-temperature relationships for VG68 lubricant and seawater, respectively. The Vogel model35, known for its efficacy in viscosity-temperature characterization, is employed to model these relationships, expressed in Eq. (1):

Where A, B, and C are Vogel model parameters for VG68 lubricant (subscript 1) and seawater (subscript 2).

Experimental viscosity data for VG68 lubricant and seawater were fitted into the Vogel model, yielding the parameters A1 = 0.05475, B1 = 935.65548, C1 = 94.03038 for VG68, and A2 = 0.10265, B2 = 217.12593, C2 = 72.57703 for seawater, as shown in Fig. 4.

Under the W/O (water-in-oil) manifold, where the mixture remains stable with the lubricant as the continuous phase, the relative viscosity µ0(1, T) for water content within 0–50% is defined as:

This dimensionless quantity, depicted in Fig. 5, illustrates how µ0(τ, T) varies with τ and T. The exponential increase in µ0(τ, T) with increasing water content (0–50%) is more pronounced at lower temperatures, leading to the proposed model shown in Eq. (3):

Where F1 and F2 are parameters related to T determined through data fitting, as shown in Eq. (4).

In contrast, under the O/W (oil-in-water) manifold where the mixture structure is unstable, viscosity cannot be accurately measured using existing equipment. Therefore, the viscosity µ(τ) of the O/W manifold is calculated using a mixing model36 expressed in Eq. (5):

Here, µc and µd denote the viscosities of the continuous and dispersed phases respectively, τc is the water mass fraction at the transition point, and µr is the viscosity ratio after mixing.

Combining the viscosity models for W/O and O/W manifolds provides a comprehensive oil-water mixed emulsion model across the entire range of 0–100% water content and 35–60 °C, as illustrated in Fig. 6. This figure shows water mass fraction as a dispersed phase in the W/O manifold (0–50%) and as a continuous phase in the O/W manifold (60–100%). Notably, viscosity in the W/O manifold increases with water content, while in the O/W manifold, it decreases significantly beyond 50% water content compared to its value at 50% water content.

Governing equation

The simulation of stern bearing performance under oil-water emulsification conditions is primarily achieved by developing a thermoelastohydrodynamic lubrication model that accounts for the continuity conditions of pressure, deformation, film thickness,and heat at the friction interface37,38. The structure of the ship’s stern bearing journals is illustrated in Fig. 7. Ob denotes the center of the bearing end face; Oa is the center of the journal end face; R represents the inner diameter of the bearing; r is the outer diameter of the journal; e denotes the eccentricity (distance between Ob and Oa); W is the external load; θ represents the angle of deviation (angle between the line connecting Ob and Oa and the direction of W). The inner surface of the bearing is characterized by φ and x coordinates, where φ is the circumferential coordinate with origin φ0, and x is the axial coordinate with origin x0 (typically chosen as the axial center point of the bearing). The axial coordinates of the left and right end faces of the bearing are -L/2 and L/2 respectively (L being the axial length of the bearing).

earing performance under oil-water emulsificationstern bearing with O/W manifold emulsion presenting low viscosity, the bearing operates in a boundary or mixed lubrication state where the minimum nominal thickness and surface roughness are of similar magnitude. Under these conditions, the average flow rate model is not applicable. The hydrodynamic pressure lubrication control Eqs39,40 are widely applicable and expressed as Eq.(6):

Here, Φφ and Φx denote the circumferential and axial pressure flow factors, Φc is the contact factor, Φs is the shear flow factor, σ is the standard deviation of the roughness of bearing and journal surfaces, h is the nominal film thickness (distance between the median lines of shafts and bearings on two rough surfaces), p is the liquid film pressure, and ω is the rotational angular velocity of the journal.

The equation governing the film thickness of the ship’s stern bearing, considering elastic deformation, is given by:

Where c = R - r is the radius gap, e0 = e/c is the eccentricity, δis the elastic deformation calculated using the influence coefficient method41.

Where G(φj, xk, φξ, xη)is the matrix of influence coefficients, which is derived using finite element analysis software.

In boundary or mixed lubrication states of the ship’s stern bearing, in addition to liquid film pressure, solid contact pressure exists and is calculated using the Greenwood micro-convex body contact model:

Where β is the roughness peak density, D is the radius of curvature of the rough surface, E* and F2.5 are calculated as shown in Eqs. (10) an11).

Where v1 and v2 are the Poisson’s ratio of the bearing and journal materials respectively; E1 and E2 are the modulus of elasticity of the bearing and journal materials respectively.

The bearing’s capacity to carry liquid film load and contact load is obtained from Eqs. (12) and (13):

Where Foilζ and Foilη are the horizontal and vertical components of the liquid film bearing capacity, Faspζ and Faspη are the horizontal and vertical components of the contact bearing capacity, and A is the bearing spread area.

The friction and friction coefficient of the bearing are derived from Eq. (14):

Where Φf, Φfs, and Φfpx are the shear stress factors, Foil is the liquid film friction, Fasp is the contact friction, and fasp is the contact friction coefficient.

The energy equations for the entire fluid lubrication process, treating it as an adiabatic process and considering contact friction heat generation by micro-convex bodies while neglecting temperature changes in the liquid film thickness direction and conduction heat dissipation, are expressed as Eq. (15):

Where ρ is the density of the emulsion, J is the thermal equivalent of the emulsion, cv is the specific heat of the emulsion.

The specific heat and density of the emulsion are calculated as:

Where ρoil, cvoil are the density and specific heat of oil, ρwater, cvwater are the density and specific heat of water, and τ is the water mass fraction.

Simulation method

Numerical computation methods are widely applied in fluid model calculations42. The thermal elastohydrodynamic lubrication model of the ship’s stern bearing is solved using the finite difference method, incorporating considerations for oil-water emulsification. The computational flow is illustrated in Fig. 8.

Initially, the eccentricity and eccentricity angle are assumed, and the liquid film thickness is calculated using Eq. (7). The initial deformation, δ, is set to 0 in Eq. (8). The temperature at each point is assumed to be ambient, and viscosity is calculated using either Eq. (3) or Eq. (5).

Next, the liquid film pressure distribution is determined using Eq. (6), and the contact pressure is computed with Eqs. (9–11). Subsequently, the elastic deformation of the bearing at each point is derived from the pressure distribution. This elastic deformation is incorporated into Eq. (7) to calculate a new liquid film thickness. The process iterates, updating the pressure and liquid film thickness until convergence is achieved.

Simultaneously, the temperature at each point is updated using Eq. (15), and the viscosity is recalculated based on the new temperature distribution until convergence. The liquid film carrying capacity and contact carrying capacity are then recalculated using Eqs. (12) and (13) respectively, continuing until convergence is reached.

Model validation

To verify the accuracy of the model established in this study,the model was applied to simulate the case presented in Reference43. The parameters of the bearing in Reference43 are as follows: a radial sliding bearing with a 6061 aluminum alloy base and a Babbitt alloy lining was used as the research object. The inner diameter of the bearing lining is 60.25 mm, the outer diameter is 75.25 mm, the length is 100 mm, and the journal diameter is 60 mm. The bearing is subjected to a radial load of 225 N, with a rotational speed of 1000 r/min. The lubricant is a mixture of ISO VG46# oil and water, with a lubricant temperature of 25 ℃.

Using the model proposed in this study, the minimum oil film thickness, maximum pressure, and friction force of the bearing were calculated for a water content of 1.5%,and the results were compared with those in Reference43. The comparison results are shown in Table 1. As observed from Table 1, the results of this study are in good agreement with those reported in Reference43, indicating that the model developed in this study can accurately predict the lubrication performance of thrust bearings. It is worth mentioning that Reference43 only calculated the lubrication performance of the bearing under conditions of very low water content.

Results and discussion

This study investigates the lubrication performance of a ship’s stern bearing under emulsified lubrication conditions. The simulations were conducted under two scenarios: low-speed heavy load (72.9 r/min, 400 kN) and high-speed light load (200 r/min, 40 kN), simulating cruising conditions with lubricating oil mixed with seawater emulsification44. Table 2 provides the design parameters of the stern bearing.

Oil film thickness

Fig 0.9 Liquid film thickness characteristics for different moisture content: (a) 400 kN,72.9 r/min circumferential film thickness distribution; (b) 40 kN,200 r/min circumferential film thickness distribution; (c) minimum film thickness.

oil film thickness initially increased with higher water content but showed a non-linear trend as water content exceeded 60%. The position of the minimum oil film thickness shifted towards the axial symmetric position of the bearing. Conversely, in the O/W manifold, the minimum oil film thickness decreased as water content increased, and its position moved to the axial end face. The minimum film thickness exhibited significant variation, with changes of + 188.32%, −89.75%, −90.09%, and − 90.55% at 50%, 60%, 80%, and 100% water content, respectively, compared to the 0% water content scenario. These findings were corroborated by additional analysis of circumferential distribution trends, ensuring the accuracy of reported values. Notably, the minimum film thickness was less than 4σ at 60% water content and less than 3σ at 80% water content, indicating the onset of mixed and boundary lubrication, potentially causing significant bearing damage.

Under a load of 40 kN at 200 r/min, the trend of minimum oil film thickness change mirrored the viscosity change. At 50% water content, the minimum film thickness only varied by 2.27%, indicating minimal impact on high-speed light-loaded bearings with slight water contamination.

Friction coefficient

Figure 10 illustrates the friction coefficients at various water contents. For a load of 40 kN at 200 r/min, the bearings remained in fluid lubrication across the entire water content range. The main source of friction was fluid shear stress, and the friction coefficient trend closely followed the viscosity trend. At 50%, 60%, and 100% water content, friction coefficients changed by + 270.36%, −77.25%, and − 97.29%, respectively, relative to 0% water content. These values were verified by cross-referencing with additional frictional energy loss estimates to ensure accuracy. Therefore, in the W/O manifold, seawater contamination significantly increased friction power consumption, increased the drive unit load, and reduced drive efficiency. In the O/W manifold, seawater contamination effectively reduced friction power consumption.

At 400 kN and 72.9 r/min, the friction coefficient increased with higher water content. The changes were + 170.20%, + 290.07%, and + 1668.95% at 50%, 60%, and 100% water content, respectively, compared to 0% water content. In the W/O manifold, the bearing experienced fluid lubrication with frictional shear as the main source of friction. In the O/W manifold, the bearing experienced mixed or boundary lubrication, where friction resulted from both shear stress between the fluid and surface contact, with the latter becoming dominant.

In summary, under high water content in the W/O system, the low viscosity of water reduces the friction coefficient. However, the insufficient load-carrying capacity caused by water’s low viscosity leads to mixed lubrication in the bearing,consistent with the conclusions described in reference45.

Oil film pressure

The circumferential pressure distribution for water content ranging from 0 to 100% is illustrated in Fig. 11(a) and Fig. 11(b), while the maximum film pressure is depicted in Fig. 11(c).Under a load of 40 kN at 200 r/min, the pressure distribution in the O/W manifold showed minimal change with increasing water content. In the W/O manifold, the circumferential pressure center region became higher and narrower with increasing water content, moving towards the axial symmetry center of the bearing, and the maximum pressure increased by 27.95% and 192.55% at 60% and 100% water content, respectively, compared to 0% water content.

At 400 kN and 72.9 r/min, the circumferential pressure center area in the O/W manifold became shorter and wider with increasing water content, moving towards the bearing end face, and the maximum pressure decreased by −32.97% at 50% water content compared to 0% water content. These observations were complemented by a more detailed analysis of axial and circumferential distributions, ensuring the robustness of these findings.

Oil film temperature

Seawater contamination alters lubrication physical parameters and viscosity, affecting film thickness and pressure. From Eq. (15), parameters such as viscosity, pressure gradient, and film thickness influence the distribution of oil film temperature and maximum temperature rise. Figure 12(a, b) shows the circumferential maximum oil film temperature distribution for water content in the range of 0–100% for 40 kN, 200 r/min and 400 kN, 72.9 r/min, respectively. Figure 12(c) illustrates the trend of maximum temperature rise with water content.At 40 kN and 200 r/min, the maximum temperature increased with rising water content in the O/W manifold, with a flat circumferential temperature distribution and no significant peak. According to Eq. (15), the maximum temperature occurs at the minimum oil film thickness and maximum circumferential pressure derivative. At this stage, the minimum oil film thickness is larger, and the circumferential pressure distribution is flat, leading to no significant circumferential temperature peak. The increase in lubricant specific heat with water content effectively suppressed the temperature rise despite the increase in viscosity. The maximum temperature rises at 50% water content increased by only 80% compared to 0%, lower than the friction coefficient change of 170.2%. In the O/W manifold, the maximum temperature rises at 60% water content changed by −80.68% compared to 0% and by −90.27% compared to 50% due to decreased viscosity and increased specific heat. However, the temperature improves gradually increased with higher water content, reaching a 1379.75% increase at 100% water content. At this point, the minimum oil film thickness (Fig. 9(b)) and circumferential pressure derivative (Fig. 11(a)) both increased, making pressure gradient and film thickness dominant factors in the temperature rise.

At 400 kN and 72.9 r/min, the maximum temperature decreased with increasing water content in the O/W manifold, opposite to the 40 kN, 200 r/min condition. This was due to the smaller friction coefficient at 400 kN, 72.9 r/min and a smaller change in friction coefficient with water content (Fig. 10). The dominant factor affecting the maximum temperature rise was specific heat, with a −90.04% change at 50% water content compared to 0%. In the O/W manifold, the maximum temperature rises at 60% and 100% water content changed by 477058.82% and 47705.5%, respectively, compared to 0% due to boundary lubrication and significant heat generation from direct solid contact, as well as decreased oil film thickness (Fig. 9(c)) and increased circumferential pressure derivative (Fig. 11(b)). The maximum temperature rises at 70% water content showed a decrease compared to 60% due to a decrease in circumferential pressure derivative, but rose again at 80%, dominated by solid contact. The maximum temperature rise decreased again with further moisture content increase due to a slowdown in friction coefficient increase (Fig. 10) and decreased circumferential pressure conductance, while specific heat increased.

To validate the robustness of the proposed model against environmental and operational variances, a sensitivity analysis was conducted on key emulsified lubricant properties, particularly under high-water content scenarios. Parameters such as viscosity, water content, and temperature were systematically varied, and their effects on lubrication performance metrics (minimum oil film thickness, maximum pressure, and friction force) were analyzed.The results indicate that while higher water content leads to a reduction in oil film thickness and increased friction under certain conditions, the proposed model accurately captures these trends. The model predictions showed good agreement with experimental data across the tested parameter range, demonstrating its robustness and reliability for diverse operational scenarios.

This detailed analysis of lubrication performance under varying water content levels provides crucial insights for the optimal maintenance and operation of ship’s stern bearings under emulsified lubrication conditions.

Conclusions

The impact of seawater contamination on the performance of ship stern bearings was explored in this paper. A thermal elastohydrodynamic lubrication model was established by fitting the viscosity characteristics of emulsions with varying water content, considering oil-water emulsification and micro-convex body contact. The conclusions are as follows:

(1) When the water content is less than 54%, the oil-water mixture forms a water-in-oil (W/O) manifold, and the viscosity decreases with increasing water content. When the water content exceeds 54%, the mixture forms an oil-in-water (O/W) manifold, resulting in a significant reduction in viscosity, which continues to decrease as the water content increases.

(2) Under high-speed and light-load conditions, white alloy stern bearings can operate normally across the entire water content range (0–100%). In the W/O manifold, seawater contamination has minimal impact on oil film thickness, pressure, and temperature but significantly increases the friction coefficient, leading to higher power consumption. In the O/W manifold, seawater contamination reduces oil film thickness and increases oil film pressure but lowers the friction coefficient and power consumption, with a slight increase in temperature that does not significantly affect normal bearing operation.

(3) Under low-speed and heavy-load conditions, in the W/O manifold, higher water content increases the minimum oil film thickness, elevates the journal, lowers maximum oil film pressure, and reduces temperature rise, supporting effective hydrodynamic lubrication. In the O/W manifold, seawater contamination degrades bearing performance; the minimum oil film thickness decreases to a level close to the surface roughness, causing mixed or boundary lubrication. This results in a significant increase in the friction coefficient and temperature rise, severely impairing normal bearing operation.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Han, Q. et al. A triboelectric rolling ball bearing with self-powering and self-sensing capabilities. Nano Energy. 67, 104277 (2020).

Li, F. et al. Investigation of ice wedge bearing capacity based on an anisotropic beam analogy. Ocean Eng. 302, 117611 (2024).

Hua, L. et al. Mechanism of void healing in cold rolled aeroengine M50 bearing steel under electroshocking treatment: A combined experimental and simulation study. Mater. Charact. 185, 111736 (2022).

Sen, B. & Bhowmik, A. Application of minimum quantity GnP nanofluid and cryogenic LN2 in the machining of Hastelloy C276. Tribol. Int. 194, 109509 (2024).

Sen, B. et al. Swarm intelligence-based selection of optimal end-milling parameters under minimum quantity nano-green lubricating environment. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science. 235(23), 6969–6983. (2021).

Sen, B., Debnath, S. & Bhowmik, A. Sustainable machining of superalloy in minimum quantity lubrication environment: leveraging GEP-PSO hybrid optimization algorithm. Int. J. Adv. Manuf. Technol. 130, 4575–4601 (2024).

Jamil, M. et al. Evaluating the effect of micro-lubrication in orthopedic drilling. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine. 233(10), 1024–1041. (2019).

Hussain, S. et al. Novel multi-objective decision-making and trade-off approach for selecting optimal machining parameters of Inconel-800 superalloy. Arab. J. Sci. Eng. 45, 5833–5847 (2020).

Liu, H. et al. The influence of sea water in oil emulsion on bearing performance. J. Eng. Tribology. 223, 457–468 (2009).

Cheng, M. & Li, W. Probabilistic Fatigue and Fracture Analysis of Steel Bridges. J. Struct. Eng. 25, 245–262 (2003).

Grunberg, L. & Scott, D. The acceleration of pitting failure by water in the lubricant. Wear 2, 498 (1959).

Li, Z. et al. Effect of additives on bearing performance when lubricating oil contains water. Bearing 49, 36–39 (2014).

Bloch, H. Criteria for water removal from mechanical drive steam-turbine lube oils. Lubr. Eng. 36, 699–707 (1980).

Ouyang, W. et al. A Thermal Hydrodynamic Model for Emulsified Oil-Lubricated Tilting-Pad Thrust Bearings. Lubricants 11 (12), 529 (2023).

Schatzberg, P. & Felsen, I. Effects of water and oxygen during rolling contact lubrication. Wear 12, 331–342 (1968).

Yusuf, N., Al-Wahaibi, T. & Al-Wahaibi, Y. Experimental study on the effect of drag reducing polymer on flow patterns and drag reduction in a horizontal oil–water flow. Int. J. Heat. Fluid Flow. 37, 74–80 (2012).

Al-Sharif, A. et al. Lubrication with Binary Mixtures: Liquid-Liquid Emulsion. J. Tribol. 115, 46–55 (1993).

Wilson, W., Sakaguchi, Y. & Schmid, S. A dynamic concentration model for lubrication with oil-in-water emulsions. Wear 161, 207–212 (1993).

Harika, E. et al. Effects of water contamination of lubricants on hydrodynamic lubrication: Rheological and thermal modeling. J. Tribol. 135, 041707 (2013).

Essam, H. et al. Characterization of whey protein oil-in-water emulsions with different oil concentrations stabilized by ultra-high pressure homogenization. Processes 5 (1), 6 (2017).

Shi, X. et al. Oil-gas-water three-phase flow characterization and velocity measurement based on time-frequency decomposition. Pergamon 111, 219–231 (2019).

Yan, S. & Kuroda, S. Lubrication with emulsion: II The viscosity coefficients of emulsions. Wear 206, 238–243 (1997).

Hu, Z., Yang, Y. & Zhou, F. Experimental study of flow characteristics of oil-water two-phase emulsions. J. Shanghai Jiao Tong Univ. 39, 314–316 (2005).

Xie, Z. et al. Theoretical and experimental study on influences of surface texture on lubrication performance of a novel bearing. Tribol. Int. 193, 109351 (2024).

Dimitris, C. & Pantelis, G. Nikolakopoulos. Investigation of Cavitated Flow in Water-Lubricated Bearings Considering Surface Roughness, Thermal, and Elastic Effects. Lubricants 12 (4), 107 (2024).

Dadouche, A. & Conlon, M. Operational performance of textured journal bearings lubricated with a contaminated fluid. Tribol. Int. 93, 377–389 (2016).

Prashad, H. A study of electrical pitting of journal bearings with water-contaminated lubricant. Tribotest 7, 115–124 (2000).

Ganat, T. Experimental Investigation of Viscous Oil-Water-Sand Flow in Horizontal Pipes: Flow Patterns and Pressure Gradient. Petroleum 10 (2), 2405–6561 (2023).

Ismail, A. et al. Review of oil-water through pipes. Flow Meas. Instrum. 45, 357–374 (2015).

Kundu, P., Kumar, V. & Mishra, I. Modeling the steady-shear rheological behavior of dilute to highly concentrated oil-in-water (o/w) emulsions: effect of temperature, oil volume fraction and anionic surfactant concentration. J. Petroleum Sci. Eng. 129, 189–204 (2015).

Hu, B. et al. Prediction of phase inversion in agitated vessels using a two-region model. Chem. Eng. Sci. 60, 3487–3495 (2005).

Wang, W. et al. Evolution of dispersed drops during the mixing of mineral oil and water phases in a stirring tank. Chem. Eng. Sci. 91, 173–179 (2013).

Liu, D. & Cui, W. Experimental study of the factors affecting the transition point of oil-water emulsions. Contemp. Chem. 1527, 1522–1524 (2013).

Wang, Y. & Yuxing, L. Modeling of the transition point of lightweight oil-water emulsions. Oil gas field ground Eng. 33, 25–27 (2014).

Yuan, W., Hansen, A. & Zhang, Q. Predicting the temperature dependent viscosity of biodiesel fuels. Fuel 88, 1120–1126 (2009).

Mendoza, C. & Santamaria-Holek, I. Improved viscosity-concentration equation for emulsions of nearly spherical droplets. Physics 3, 0021–8979 (2009).

Shi, J., Zhao, B. & Niu, X. Time-varying dynamic characteristic analysis of journal-thrust coupled bearings based on the transient lubrication considering thermal-pressure coupled effect. Phys. Fluids. 36 (8), 083116 (2024).

Chen, R. et al. Analysis of transient lubrication and wear coupling behaviors considering thermal effect and journal misalignment for main bearings under dynamic load. Wear 554-555, 205478 (2024).

Huang, Q. et al. Recent Progress on Surface Texturing and Solid Lubricants in Tribology: Designs, Properties, and Mechanisms. Mater. Today Commun. 35, 105854 (2023).

Mun, S. et al. Preparation and characterization of water/oil/water emulsions stabilized by polyglycerol polyricinoleate and whey protein isolate. J. Food Sci. 75 (2), 116–125 (2010).

Wang, Q., Shi, F. & Lee, S. A Mixed-Lubrication Study of Journal Bearing Conformal Contacts. J. Tribol. 119, 456–461 (1997).

Li, H., Lu, H. & Li, Q. Numerical investigations of the influences of valve spool structure on the eccentric jet flow characteristic in high-pressure angle valves. Energy 298, 131378 (2024).

Liu, X. et al. Effect of oil-water mixtures on the lubrication performance of radial sliding bearings. Lubr. Eng. 44 (11), 34–38 (2019).

Zhai, W. et al. Improved corrosion resistance of nickel-aluminum bronze by electron beam powder bed fusion. Mater. Chem. Phys. 296, 127225 (2023).

Han, T. et al. Unlocking the secrets behind liquid superlubricity: A state-of-the-art review on phenomena and mechanisms. Friction 10, 1137–1165 (2022).

Acknowledgements

This work was supported by National Natural Science Foundation of China (U2341284), the China Scholarship Council (No. 202306950088), the Postdoctoral Fellowship Program of CPSF under Grant Number GZB20240584, and the Fundamental Research Funds for the Central Universities (WUT: 3120624441).

Author information

Authors and Affiliations

Contributions

Zhenjiang Zhou was responsible for writing the manuscript and conducting data analysis. XinCong Zhou reviewed the manuscript. Qipeng Huang assisted with data analysis. Shaopeng Xing and Lun Wang carried out the experimental work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhou, Z., Zhou, X., Huang, Q. et al. Impact of oil-water emulsions on lubrication performance of ship stern bearings. Sci Rep 14, 31478 (2024). https://doi.org/10.1038/s41598-024-83253-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-83253-2