Abstract

In-situ stress plays a pivotal role in influencing the desorption, adsorption, and transportation of coalbed methane. The reservoir gas content represents a pivotal physical parameter, encapsulating both the coalbed methane enrichment capacity and the underlying enrichment law of the reservoir. This investigation collates, computes, and consolidates data concerning pore pressure, breakdown pressure, closure pressure, triaxial principal stress, gas content, lateral pressure coefficient, and other pertinent variables from coal reservoirs within several coal-bearing synclines in the Liupanshui coalfield, China. This study elucidates the characteristics of longitudinal stress development in the study area, the gas content of the longitudinal reservoirs and their interrelationships. The study area is situated within the middle-high stress zone, exhibiting discernible evolution patterns from reverse fault mechanism to strike-slip fault mechanism to normal fault mechanism, progressing from shallow to deep. In the deeper stratigraphy, a strike-slip-normal fault mechanism emerges. The relationship between burial depth and triaxial principal stress is subjected to linear regression, resulting in the proposal of a simplified model for vertical in-situ stress. The hyperbolic regression algorithm was employed in order to derive both the envelope and median formulas for lateral pressure coefficient (k values). The k value displays discrete behavior along the vertical axis in shallow depths, gradually converging in deeper strata and ultimately stabilising at approximately 0.65 with increasing depth. A comprehensive examination of the k value substantiates the efficacy of the simplified in-situ stress model along the vertical axis, offering profound insights into the vertical interrelationships and evolving patterns of the triaxial principal stresses. The mean gas content in the study area was found to be 11.89 m³/t, exhibiting a general increase in depth, followed by a subsequent decrease. The pore pressure (Pp) displays a discernible positive correlation with gas content. This study comprehensively elucidates the developmental patterns of the stress field, the simplified model of vertical in-situ stress, the attributes of the stress ratio (KH, kh, lateral pressure coefficient k), the characteristics of reservoir gas content, and the corresponding and transformative relationships between coupled geostress field parameters and gas content. The lateral pressure coefficient conversion depth, in-situ stress conversion depth, and gas inversion depth are delineated, accompanied by a detailed exposition of their definition process, physical significance, and interrelations. Within the study area, the lateral pressure coefficient conversion depth is estimated to range between 450 and 500 m, while the critical depth for in-situ stress conversion is approximately 670 m. Moreover, the critical depth for gas content conversion falls within the range of 700–800 m. It is noteworthy that the critical depth for deep coalbed methane within the Liupanshui coalfield has been identified as approximately 800 m. Subsequently, a vertical “in-situ stress-gas content mode” relationship model for coalbed methane development was formulated, thereby providing a structured framework for understanding the dynamic interactions between vertical in-situ stress and gas content.

Similar content being viewed by others

Introduction

Coalbed methane (CBM), colloquially referred to as gas, poses significant challenges to coal mine safety. Nonetheless, CBM represents a high-quality, environmentally friendly, and economically viable non-conventional energy resource that is easily transportable. According to the International Energy Agency (IEA), China ranks third globally in CBM resources, trailing behind the USA and Canada, with its reserves accounting for 12% of the world’s total CBM reservoirs. Guizhou Province, situated in southern China, stands as a pivotal region endowed with abundant coal and CBM resources1,2,3,4,5. The latest assessment of CBM resources in Guizhou Province reveals that the Upper Permian geological formations harbor considerable CBM resources, exceeding 4 m3/t of recoverable coal beds, totaling 3.06 × 1012 m3. This volume constitutes approximately 22% of China’s overall CBM resources, with the majority concentrated in the Liupanshui coalfield. Within the Liupanshui coalfield, CBM resources are predominantly concentrated in 15 syncline structure, including Panguan, Qingshan, and Tucheng, boasting an average resource density of approximately 2.6 × 1010 m3/km2, significantly surpassing the national average CBM reserves in coalfields across China. Moreover, CBM reserves accessible at depths shallower than 1500 m, viable for extraction using current mining technologies, amount to 2.56 × 1012 m3, constituting 83.7% of the total reserves within the province6,7,8,9.

In-situ stress is a significant index for optimization of dessert segments for CBM development. In-situ stress gradients induce changes in the physical characteristics of the reservoir, including mechanical attributes, permeability, sensitivity to stress, porosity, and fracturing behavior of coal seams. These changes constitute key determinants influencing the productivity of CBM wells. Furthermore, gas content represents a crucial physical property parameter, reflecting both the enrichment capacity and enrichment patterns of CBM within the reservoir. A comprehensive examination of gas content characteristic parameters facilitates a deeper comprehension of the quality and developmental potential of CBM resources within the Liupanshui coalfield.

Every geological formation within the Earth’s crust experiences forces exerted by neighboring media. In-situ stress denotes the internal stress inherent in the lithosphere10. This natural stress evolves over extended geological timescales, devoid of any engineering interventions, arising from diverse geological processes, and can be categorized into paleostress and present-day stress based on temporal considerations. In-situ stress represents a dynamic “field” continually evolving over time, primarily comprising three components: static rock pressure, tectonic stress, and thermal stress11. Coal formations, characterized by a lower Young’s modulus and a higher Poisson’s ratio, are prone to fractures12. Factor influencing the in-situ stress state within CBM reservoirs encompass burial depth, tectonic forces, and coal composition13. The magnitude, orientation, and spatial distribution of geostress constitute primary areas of inquiry during CBM exploration endeavors. It is imperative to conduct localized, unit-specific, well-level, planar, and cross-sectional investigations into the in-situ stress state, as macro and regional analyses alone prove insufficient. Such comprehensive research endeavors encompass the mechanical properties of strata, the mechanics underlying the geostress field, the spatial distribution patterns of geostress, and numerical simulations14.

As burial depth increases, the geostress regime typically undergoes a transformation, resulting in variations in reservoir physical properties at varying depths. These variations include changes in desorption, porosity, gas content, mechanical characteristics, stress sensitivity, permeability, and fracturing performance15,16,17. The prevailing stress state in the subsurface exerts control over the stress concentration around a wellbore, the well stimulation, the fluid flow dynamics within fractured reservoirs, and the production of coal fines18. Nevertheless, despite these transformations, the economic and efficient exploitation of deep CBM remains unrealised due to the inherent challenges posed by reservoir characteristics19,20,21,22. Integrated geomechanical modelling necessitates the analysis of pore pressure and geostress, in addition to data regarding rock strength, modulus of elasticity, and uniaxial compressive strength12,23.

In the petroleum and gas industry, advanced sonic logs provide invaluable insights into various aspects, including the velocity of the acoustic waves within the formation, facilitating seismic-to-well ties, supporting geomechanical modeling, and offering crucial data for engineering applications24,25. Combining oil and gas exploration logging technology and geophysical seismic data, and assisting appropriate advanced algorithms, static data in the plane or longitudinal direction, on a single stratigraphic layer or on a single profile can be converted into dynamic data that changes over time, expanding the role of analyzing the data and the scope of use. In the later engineering applications, not only can the research geological body be grasped as a whole, but also the scale of development of the ground stress field and whether the tectonic cracks are in the critical stress state can be scientifically speculated. Give an example, pore pressure and in-situ stress are indirectly estimated from well logging, seismic data, rock chip characterization and drilling parameters12. Pore pressure estimation based on seismic and logging data will use seismic wave velocity, acoustic waves, resistivity, density and neutron logging26. In a related study in the Raniganj Basin, India, Banerjee and Chatterjee combined inversion-generated seismic attributes with pore pressures estimated by the Bower’s and Eaton’s methods, using sonic logging to estimate loading curves and normal compaction trend lines of pore pressures, as well as to determine the direction of maximum horizontal stresses from resistivity-imaging logs12. The study conducted by Khademian et al.27 used a hybrid methodology based on localized stress measurements to determine in-situ stresses and validate the results of hydraulic fracturing measurements. In addition, resistivity logging imaging records provide accurate azimuthal determinations of tensile fractures and well-wall avalanches. Tensile fracture and well-wall avalanche azimuths are strongly correlated indicators of the direction of in-situ stress. Information can be obtained on fault mechanics, transformations, and the likelihood that faults will become reactivated under stress conditions in response to changes in pore pressure28.

In recent years, numerous scholars have concentrated on the peculiarities of deep CBM accumulation processes and have introduced the concept of “deep effect” of CBM, considering it as a fundamental premise for deepening the understanding of the deep-seated aggregation laws of coal-series gas2,29,30,31,32,33,34,35,36,87. Qin and Shen suggest that the distinctive geological conditions of deep coal reservoirs arise from elevated geostatic stress and formation temperatures34. They are influenced by the transition in geostatic stress states, the adsorption capability of coal, the adverse effects of the geothermal field, and the specific physical attributes of coal rock under different temperature and pressure conditions. Parameters such as gas content within coal reservoirs, elasticity modulus of coal rock, permeability, and other chemical, mechanical, and pore properties of coal rock exhibit a “critical depth.” Beyond this threshold, these parameters undergo an “inflection point”35.

Discourses regarding the heterogeneity of coal reservoirs within the Liupanshui coalfield in the Qianxi region of China are prevalent. However, investigations into the conversion dynamics of the deep in-situ stress field, nexus between gas content and in-situ stress, and the characteristics of deep CBM reservoirs are scant. Equally rare are discussions concerning the critical depth for deep CBM within the study area. The Liupanshui coalfield, situated in western Guizhou and the focal point of this study, has emerged as a pivotal new hub for comprehensive energy and coal-power integration in China. Consequently, a comprehensive examination of the gas content and in-situ stress field features within the Liupanshui coalfield across various depths, alongside their vertical evolution, is imperative. This entails probing the transition interfaces engendered by the distinct reservoir physical properties and their corresponding depth values. Ultimately, establishing a cohesive relationship model encapsulating the “in-situ stress-gas content pattern” for CBM development is paramount. In Liupanshui coal field and Zhina coalfield in western Guizhou, some preliminary engineering work has been carried out and good in-situ reservoir data has been obtained, but the related research work is still in the development stage. This study is of great significance to further elucidate the mechanism of deep-seated CBM accumulation and reservoir formation, which will guide the subsequent geological evaluation and geological development.

Geologic background

The Upper Permian transitional zone emerges as the primary focal point for CBM development in Guizhou, predominantly extending in a north-eastern direction. This zone encompasses a series of land-sea transitional phase coal-bearing deposits characterized by intercalations of clastic, carbonate, and coal, with Longtan formation constituting the principal coal-bearing strata. The thickness of the Upper Permian coal-bearing stratum exhibits considerable variation, ranging from 76 to 543 m. The distribution of coal types is comprehensive, with Romax ranging from 0.67 to 3.13%. Coal seam spacing is minimal, spanning from 0.5 to 22 m, while individual seam thickness tends to be slender, typically ranging from 0.25 to 2.6 m. The number of obtainable seams and their accumulated thickness display significant disparities, varying from 0 to 26 seams and 0 to 29.8 m, respectively. Thin to medium-thickness coal seams are notably prevalent, often accompanied by multiple segments of organic-rich mudstone. Moreover, the presence of longitudinal multilayers of CBM reservoirs was a common occurrence37,38,39,40. Among these, region boasting the most favorable material base for CBM formation primarily spans the area between Panxian, Shuicheng, and Nayong, characterized by the typical development of coal seam groups. The Upper Permian coal-bearing stratum generally exhibit a weakly water-bearing propensity. Fault zones and fracture zones typically display poor hydraulic conductivity, making it challenging to establish hydraulic pathways between the coal-bearing strata and highly water-bearing strata or surface water bodies8,41,42,43,44.

The Late Permian coal-bearing stratum in Guizhou were deposited during the Longtan epoch, exhibiting a tectonic evolution characterized by “multi-stage development, large divergence, and late stereotyping,” resulting in a complex structural framework managed by folds and reverse thrust faults. During the Himalayan period, coal-bearing basins underwent compression and uplift, leading to extensive erosion of Upper Permian coal systems from the axial regions of anticlines, rendering large-scale anticlines or complex anticlines the primary structural controls on coal within the region45. Sedimentary development is typified by interactions between marine and terrestrial environments, planar differentiation, and frequent vertical changes, thereby establishing distinctive geological conditions conducive to CBM formation. In summary, the geological environment of CBM reservoirs within the Liupanshui area is characterized by the presence of multiple seams, thin individual seams, substantial accumulated thickness, multi-layer arrangement, relative seam concentration (small seam distance), significant variations in coal mass structure, low porosity and permeability, high geostress levels, abundant gas level et al.9,46. CBM represents an unconventional natural gas reservoir self-generated and self-stored within coal seams, with CBM enrichment exhibiting typical syncline-controlled gas characteristics, thus rendering these discrete coal-bearing synclines favorable units for CBM accumulation in Guizhou (Fig. 1). Owing to the unique tectonic evolutionary history of the Liupanshui area, multiple dispersed and fragmented coal accumulation basin structural units serve as primary preservation sites for Upper Permian coal-bearing rock system coal seams. Furthermore, these coal-bearing structural units exhibit significant similarities in sedimentary geological backgrounds, gas reservoir storage laws, and evolution, thereby facilitating systematic investigation of multi-layer overlapping independent gas content systems.

Location of Liupanshui area (coalfield) in China and histogram of coal-bearing strata14.

Theoretical background, methods and calculation formulas

In this investigation, a total of 156 in-situ stress assessments from 51 parameter wells were compiled within the western region of Guizhou Province, China, encompassing the current focal points of CBM exploration and development. These datasets were acquired through the injection/fall-off well testing method across seven major coal-bearing basins (Qingshan, Panguan, Gemudi, Tucheng et al.). Certain data are referenced from scholarly works of Xu et al.47. Notably, the in-situ stress data presented by Xu et al.47 do not include information from the Tucheng and Panguan synclines, whereas the primary focus of data collection in this manuscript is on these synclines. Consequently, the available data for this investigation essentially encompass the principal CBM development zones and mining wellfields within the Liupanshui area, all sourced from the latest development outcomes dating since 2014 (with data post-2016 comprising the majority), thereby offering a comprehensive and representative dataset.

Deep effects and critical depth for gas content conversion

According to the traditional Langmuir’s single-molecule adsorption theory, CBM adsorption satisfies the following Langmuir’s equation (Type I isotherm):

Where V is the adsorbed volume of CBM, \(\:{m}^{3}/t\); a and \(\:{V}_{L}\) are the Langmuir volume of coal, \(\:{m}^{3}/t\); b is the adsorption constant of coal, i.e., the inverse of the Langmuir pressure, \(\:MP{a}^{-1}\); p is stream pressure of the reservoir (pore pressure), \(\:MPa\); PL is Langmuir pressure, \(\:MPa\); and P is the equilibrium partial pressure of adsorbate in the gas phase, \(\:MPa\).

Many scholars assert that the influence of stratum pressure and temperature on the adsorptivity of coal seams exhibits two distinctly different effects. Under the condition of uniformity in other factors, an escalation in stratum pressure enhances the coal’s adsorption capacity for gas, thereby resulting in an elevation of the gas content within the coal seam-termed as the positive effect of pressure relative to adsorptivity (gas content). Conversely, as the stratum temperature rises, molecular thermal motion intensifies, bringing about a reduction in the coal matrix’s adsorption capacity for methane gas. Consequently, the isothermal adsorption curve of coal bed gas declines and shifts towards desorption, causing a decrease in the gas content of the coal bed-identified as negative effect of the relative adsorption (gas content) within the ground temperature field.

Qin et al. concluded that deeper CBM adsorption is affected by both temperature and pressure, and is also related to coal rank15, and their relationship is generally consistent with the Langmuir full-factor model:

Where V,a,\(\:{V}_{L}\),b,p,PL, P are the same definitions as the variables in Eq. (1). \(\:{T}_{1}\) is the adsorption experiment temperature, K; T is the coal bed temperature, K; \(\:{M}_{1}\) is the coefficient related to coal quality; n is the temperature influence coefficient related to pressure.

Under the effect of the ground temperature field, the depth of the coal bed is positively correlated with its temperature:

Where: \(\:{T}_{0}\) is the surface temperature, K; G is the ground temperature gradient, \(\:K/m\); \(\:{H}_{c}\) is the buried depth of coal seam, m; \(\:{H}_{cm}\) is the depth of thermostatic zone, m.

According to Langmuir’s law, the isothermal adsorption curves of coal exhibit a rapid ascent in the lower pressure range and a gradual increase to a plateau in the higher pressure range (Eq. 2). This implies that as depth increases, the influence of pressure on adsorption diminishes gradually until reaching a certain threshold. Conversely, the adverse effect of rising temperature on adsorption capacity with depth shows a linear correlation (Eqs. 2 and 3). From these relationships, it can be inferred that at a certain depth within the coal-bearing stratum, the combined influence of the ground temperature field and pressure field may surpass that of pressure alone. At greater depths, the negative effect induced by temperature begins to outweigh the positive effect of pressure. Simultaneously, within shallower depths, where the positive effect prevails, the nature of CBM is predominantly manifested as adsorptive gas. However, as depth increases, the negative effect gains ascendancy over the positive, resulting in a shift towards desorption equilibrium. This leads to the conversion of a significant portion of adsorbed gas into free gas, with the proportion of free gas increasing steadily with depth. This phenomenon constitutes one of the distinctive characteristics of the geological conditions of deep CBM, succinctly encapsulated as the “deep effect” of CBM by Qin et al. (Fig. 2).

In summary, under specific burial depth conditions, the adsorption quantity of CBM is similarly or equally influenced by the opposing forces of temperature and pressure, delineating an inflexion point in the connection between adsorbed gas content and depth of coal beds. This inflection point has been previously designated as the conversion critical depth of gas content2,4,15,32,34,35,36. Furthermore, it is posited that under constant conditions, the conversion critical depth becomes shallower with a rise in ground temperature gradient and deeper with a rise in pressure gradient.

(adapted from Qin et al.4). P- Pore pressure; V- Coalbed methane adsorption capacity; T- Temperature; H- Depth; HGI- Critical depth.

P-V-T-H correlation system CBM endowment state transformation model.

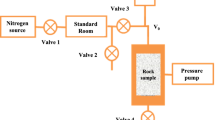

Engineering test methods for in-situ stress and triaxial in-situ stress calculation formulas

The technology utilized for testing CBM wells, known as CBM test well testing technology, represents an experimental measurement method. It serves as a crucial tool for delineating coal reservoirs, conducting reservoir evaluations, monitoring production dynamics, evaluating completion efficiency, and performing in-situ stress measurements within coal reservoirs. The injection/fall-off well test (IFOT) adheres to the fundamental principles of an unstable well test. By inducing an artificial alteration in pressure within the fluid of a reservoir operating under flow equilibrium, a disturbance occurs at the well’s base. The destabilization process resulting from this pressure disturbance is intricately linked to the formation and characteristics of the fluid.

In view of the fact that there have been many literatures and reports discussing the methodology of obtaining Pp(reservoir pressure or pore pressure), Pb(breakdown pressure), and Pc(closure pressure)through IFOT, which in turn provides engineering data for obtaining triaxial principal stress values48,49. In this study, we will not go into details, and the specific process can be referred to the previous research papers50 published by the researcher of this paper.

The magnitude of three components, namely horizontal maximum principal stress (δHmax), horizontal minimum principal stress (δhmin), and vertical principal stress (δv), along with the direction of δHmax, are commonly utilized to represent the in-situ stress state51,52,53,54,55,56. This system is continued in this study, and the methodology for calculating triaxial principal stresses from the in-situ stress data obtained by IFOT can be found in the published paper50 of the researchers of this paper.

Statistical results of the type and distribution of in-situ stress in each coal-bearing syncline

Statistical results of in-situ stress measurement parameters

In the Liupanshui area, the values of three principal stresses (δH, δh, δv) in the longitudinal coordinate system are able to be computed using triaxial geostress calculation formula respectively. Data from various coal-bearing synclines are generalized in Table 1. The range of δH spans from 5.42 to 28.77 MPa (average 17.11 MPa), with a corresponding gradient ranging from 1.21 to 4.74 MPa/hm (average 2.70 MPa/hm). δv varies from 3.92 to 32.60 MPa, averaging at 17.55 MPa, while the range of δh extends from 4.51 to 23.35 MPa (average 12.71 MPa), with a corresponding gradient ranging from 1.12 to 2.99 MPa/hm (average 1.98 MPa/hm). Following the established in-situ stress classification standard for Chinese coalfields (> 30 MPa indicating ultra-high stress zone; 18–30 MPa indicating high stress zone; 10–18 MPa indicating medium stress zone; 0–10 MPa indicating low stress zone)57, a significant portion of Liupanshui coal seams (53.6%) fall within the medium stress zone, while another portion falls under the high and ultra-high stress zones (41.4%). In comparison with other coal-bearing basins worldwide (e.g., Bowen Basin, Black Warrior Basin, Piceance Basin, and Sydney Basin), the geostresses in Chinese coal reservoirs are notably larger43,58,59,60,61. Regarding the comparison of the average δh gradient, it is 1.96 MPa/hm in the southern part of Qinshui Basin, approximately 1.9 MPa/hm in the eastern part of Ordos Basin, and about 1.6 MPa/hm in the southern part of Junggar Basin. The Liupanshui coalfield in the study area exhibits an average of 1.98 MPa/hm, placing it at a relatively high level among coal-bearing basins in China.

Distribution results of each coal-bearing syncline in-situ stress type

Among the 156 datasets, 89 entries, validated by precise well ___location information, were chosen to scrutinize the variations in vertical in-situ stress across diverse coal-bearing synclines. Following collation and consolidation, all datasets are encompassed within six prominent CBM development synclines in the Liupanshui area, namely Panguan, Qingshan, Yangmeishu, Dahabian, Tucheng, and Liuzhi. E.M. Anderson elucidated the fault formation mechanism based on stress conditions, positing that due to the absence of shear stress between the ground and the air, one of the stress axes in fault formation tends to align with the horizontal-vertical plane51. Building upon this premise, he delineated three stress states corresponding to subsequent evolution into normal faults, strike-slip faults, and reverse faults. Anderson’s rupture criterion has gained widespread acceptance among geologists, serving as a foundational framework for analyzing and interpreting surface or near-surface brittle fractures62,63. In this investigation, the distribution of three distinct in-situ stress mechanisms (states) in Liupanshui area was statistically assessed utilizing Anderson’s classification (refer to Table 2; Fig. 3, and 4).

Vertically, the three distinct fault mechanisms roughly adhere to a distribution pattern from shallow to deep (refer to Fig. 4). According to the characteristics of the box plot, the interquartile range encompasses 50% of the median data, with the average burial depth of the reverse fault mechanism recorded at 300.77 m, indicating the lowest distribution variance. The strike-slip fault mechanism primarily spans depths ranging from 506.82 to 689.83 m, with a median depth of 579.17 m. The distribution variability and variance of the strike-slip fault mechanism are the highest, with data exhibiting a right-skewed distribution, indicating a relatively minor concentration trend, with the median line slightly skewed towards shallower depths within the concentration area. The normal fault mechanism predominantly occupies depths ranging from 646.05 to 815.26 m, with a median depth of 713.67 m. Its distribution variance surpasses that of the reverse fault mechanism but remains inferior to that of the strike-slip fault mechanism.

Percentage of different in-situ stress states at different depths50.

Figure 4 corroborates the distribution pattern of various fault types and provides further elucidation from an alternative data analysis perspective. The reverse fault stress mechanism only appears at shallow depths (< 400 m). Strike-slip fault mechanism is well represented at depths of 400–600 m. The normal fault mechanism arises less frequently at shallow stratigraphic depths, and rises rapidly after 600 m, becoming the main stress mechanism, under which the vertical stress is the utmost and the stratigraphy is the most stable. Above 400 m, strike-slip fault mechanism is rigorously negatively correlated with the normal fault mechanism. In the deeper stratum, the in-situ stress state tends to favor strike-slip-normal fault mechanism due to δH ≈ δv>δh. Kang et al.64 believes that the heightened incidence of strike-slip fault mechanism in deeper strata stems from intense geotectonic movements in the horizontal plane.

In essence, the prevalence of reverse fault mechanism is minimal, with δH and δv exerting roughly equal influence. Hence, attention within the study area should be directed towards the strike-slip and normal fault mechanism, as well as their interconversion relationship. Vertically, there is a discernible progression from the development of reverse fault mechanism→ strike-slip fault mechanism→normal fault mechanism, with depth. Horizontally, the three stress development modes in different coal-bearing inclinations exhibit distinct characteristics, with varying depths of stress transition zones and regions of complex stress changes. Nevertheless, the developmental patterns of in-situ stress states across syncline are broadly similar.

Establishment of simplified vertical model for in-situ stress

Relation between different stresses and burial depth and correlation between stresses

During the pressure cycling test conducted in the well testing process of CBM parameter wells in the Liupanshui coalfield, data pertaining to Pp, Pc, and Pb were also acquired (Table 1). The collected data in this study were organized to demonstrate that the Pp ranged from 2.29 to 14.95 MPa (average: 6.63 MPa), while the Gp varied from 0.63 to 1.50 MPa/hm (average: 1.02 MPa/hm), indicating normal pore pressure reservoir. The Pb ranged from 5.55 to 26.8 MPa (average: 14.2 MPa), and the corresponding Gb ranged between 1.37 and 3.57 MPa/hm (average: 2.22 MPa/hm).

Pore pressure refers to scalar hydraulic potential energy present within the interconnected deep pore space, denoting the pressure exerted by the pore fluid within the formation65. Typically, deep Pp values are associated with hydrostatic pressure. When the deep pore pressure equals the hydrostatic pore pressure, it signifies that the pore-fracture network is continuous from the surface to the measured depth. However, in deep confined stratums, reservoir pressures may surpass hydrostatic pressure levels, resulting in overpressurization, or they may fall below hydrostatic pressure values, leading to underpressurization. The superior limit of Pp is determined by the overlying stratum pressure δv, while consistently remaining below δ3 (the smallest among triaxial principal stresses)50.

Pore pressure, breakdown pressure, and closure pressure exhibit a linear increase with depth across various depths and coal-bearing synclines in the Liupanshui area, as illustrated in Fig. 5. The correlation coefficients exceed 0.67, indicating a robust correlation. This trend mirrors that observed in Qinshui Basin of China66. Notably, the relevance between Pb and Pc is notably strong, with correlation coefficients surpassing 0.9. In the absence of direct measurements, the Pc (Numerical value equal to δh) in the Liupanshui area could be approximated utilizing this relationship. The close positive correlation between Pc and Pb underscores the critical effect of structural stress field on coal reservoir pressure. It suggests that a significant portion of the fluid power within the coal seam stems from the transfer of geostress, rather than solely from the groundwater dynamic field.

Simplified modeling of vertical in-situ stress

Upon further examination, the findings of this study reveal that the computed outcomes from the in-situ stress test wells encapsulate significant essential relationships among reservoir physical parameters, particularly emphasizing the association between triaxial principal stress and depth. Broadly, a linear positive correlation is observed between δH and burial depth (refer to Figs. 6 − 1) as well as between δh and burial depth (refer to Figs. 6 − 2). However, the correlation coefficients R2 are relatively modest, with the correlation coefficient for δH and burial depth standing at a mere 0.45, and the slightly higher correlation coefficient for δh and burial depth at 0.68. This outcome contrasts with findings from other coal-bearing basins in China36,67. On one hand, this disparity may suggest the variability inherent in the in-situ stress field within the research area. On the other hand, it raises the possibility that defining horizontal stress and depth solely through a linear relationship may be overly simplistic.

In their examination of the stress field within southern reaches of Qinshui basin, Shen et al.68 expounded upon the connection between horizontal principal stress and depth, delineating it as a logarithmic function with a positive correlation. Specifically, they observed that as depth increases, the progression of horizontal stress decelerates gradually. This recognition prompted further investigation, particularly in Figs. 6 − 1 and 6 − 2, where it became apparent that data points at greater depths exhibit greater deviation from the fitted line. Moreover, the slope of the fitted line for deeper data diminishes, as evidenced by the delineation with a dashed line, thus necessitating a segmented discussion. Data points representing horizontal stresses exceeding 600 m in depth are segregated, and a linear fit is performed, as depicted in Figs. 6 − 3 and 6 − 4. The resultant correlation coefficients, R2, surpass those observed in Figs. 6 − 1 and 6 − 2, And the slopes of the fitted lines all decrease. Consequently, attributing a linear positive correlation between horizontal stress and depth is untenable due to substantial statistical variance. Similarly, characterizing the relationship between horizontal stress and depth as logarithmic, as in Qinshui Basin, proves unreasonable given the significant increase in horizontal stress values at greater depths, which contradicts established knowledge. In summation, this article argues that relationship between horizontal stress and depth in the study area ought to be delineated by both the solid and dotted lines in Figs. 6 − 1 and 6 − 2, signifying a positive correlation. Moreover, the derivative value of the stress-depth curve decreases with increasing depth, a key insight derived from this article.

Figures 7 − 1 and 7 − 2 depict the interplay between depth and horizontal principal stress gradient. A discernible observation emerges as the distribution of data points appears notably scattered. This dispersion underscores the discrete nature of relationship between horizontal principal stress and depth, suggesting either a lack of correlation or the necessity for further elucidation regarding their interdependence.

The pertinent data regarding δH, δh and δv in the Liupanshui area are consolidated within Fig. 8. Within this visual representation, the yellow straight lines signify hydrostatic pressure. Notably, the minimum principal stresses of CBM reservoirs at various depths within distinct regions surpass the corresponding hydrostatic pressure at those depths, mitigating the risk of potential hydraulic fracturing of the reservoirs. This finding aligns with the conclusions drawn by Zoback et al. following their investigations into the North Sea oilfields, the Cordillera, and the Gulf of Mexico oilfields65,69,70. In Fig. 8, the gray straight line represents the δv, while the orange broken line depicts the linearly fitted trend line for the δh, and the dark blue broken line portrays the linearly fitted trend line for the δH. By definition, the gray straight line passes through the coordinate origin, while the orange broken line and the dark blue broken line intersect the positive semi-axis of the X-axis at shallower depths. Figures 7 − 3 and Figs. 8 − 1 collectively reveal a notable correlation between δH and δh. This correlation is further substantiated by the minimal disparity observed between the slopes of the orange and dark blue broken lines following segmentation, both in shallow and deep segments. This consistency underscores a high degree of concordance between the minimum and maximum principal stresses with increasing depth.

Horizontal principal stress gradient vs. depth and relationship between horizontal principal stresses. PGEW, The eastern wing of the Panguan syncline; PGWW, The western wing of the Panguan syncline; QS, Qingshan syncline; YMS, Yangmeishu syncline; DHB, Dahebian syncline; TC, Tucheng syncline; ZN, Zhina coalfield.

Based on the aforementioned understanding, this study has redrawn a simplified model map illustrating the connection between triaxial principal stresses and depth in Liupanshui area, as depicted in Figs. 8 − 2. Within this region, δH demonstrates a robust correlation and synchronous variation with δh, while the gradient of δv variation surpasses that of the horizontal principal stresses. Consequently, the vertical in-situ stress mechanism exhibits distinct zonal variations, as illustrated in Figs. 8 − 1. In shallower stratigraphic layers, specifically from shallow to H1, in-situ stresses predominantly manifest a reverse fault mechanism. Within the transitional zone between H1 and H2, triaxial in-situ stress values converge, resulting in a complex array of stress types, indicative of a crucial transition zone. This observation resonates with earlier statistical analyses of in-situ stress patterns (refer to Table 2; Fig. 4). In deeper strata beyond H2, the overall in-situ stress pattern adopts a normal fault mechanism. Notably, the proportional increase of δH and δh with depth ceases, resembling the curvature akin to a logarithmic function, as observed in the findings of Shen et al.68. Furthermore, the similar slopes of δH and δh in deeper segments suggest their proximity, simplifying the in-situ stress pattern as δv ≈ δH>δh. The gray dashed line signifies the average horizontal stress, computed as \(\:{(\delta\:}_{H}+{\delta\:}_{h})/2\). It can be inferred that within strata shallower than H3, horizontal stress surpasses vertical stress, whereas in strata deeper than H3, the inverse holds true, with vertical stress surpassing horizontal stress. The delineation of H3 facilitates subsequent investigations into lateral pressure coefficients.

Zhao et al.71 investigated the variation pattern of the ratio between average horizontal stress and vertical stress in Chinese sedimentary rocks with depth, suggesting that beyond a depth of 700 m, this ratio fluctuates around 1.0, with the observed data exhibiting minimal dispersion. The characteristic δv ≈ δH>δh exhibited in the model of this study at depth not only closely matches the discrete data of actual deep-seated stress (Table 2; Fig. 4), but also shares similarity with the structural findings of studies conducted in other basins36,61. This feature of the in-situ stress will be repeatedly discussed in subsequent sections of this research.

Distribution law of stress ratio and establishment of hyperbolic regression relationship

Definition of lateral pressure coefficient k

In the investigation of the variation pattern within the in-situ stress field, the lateral pressure coefficient, denoted as k, serves as a common descriptor for delineating the state of in-situ stress at specific locations72. The k value constitutes a pivotal parameter for depicting the distribution of in-situ stress. Through global data synthesis, the typical range for k spans from 0.5 to 5, with the majority falling within the interval of 0.8 to 1.573. The definition of k is as follows:

Similarly, there are stress ratios kH and kh, which may be named and symbolized differently by different scholars, but their physical significance is exactly the same, and this study draws on the naming system of Wang et al.74. While kH denotes the ratio of the horizontal maximum principal stress δH to the vertical principal stress δv, while kh denotes the ratio of the horizontal minimum principal stress δh to the vertical principal stress δv.

Brown and Hoek75, in their study of global geostress data, concluded that the stress ratios are related to the depth of burial by a special hyperbolic function in the inverse proportional function. The author also came to a similar conclusion through mathematical fitting in his past study that all three ground stress ratios in the Liupanshui coalfield have a linear relationship with the inverse of the burial depth50, and the equation can be described as:

The procedure for linear regression of the raw data to derive k using the triaxial ground stress formula can be found in the author’s pre-published paper50.

Establishment of hyperbolic regression relationship based on lateral pressure coefficient k

Brown and Hoek75 encapsulated in-situ stress data from global sources and discerned that the stress ratio, denoted as k, typically falls within the delineated spectrum as follows:

The average of k in Eq. (6) is:

In a similar vein, adhering to the Brown-Hoek methodology, certain Chinese academics have consolidated the spectrum of lateral pressure coefficient variability in China’s in-situ stress, along with the depth-dependent variation pattern71,76,88, whose envelope equation curves conform to a hyperbolic structure. The lateral pressure coefficients characterizing shallow crust in mainland China typically adhere to the ensuing intervals:

Meanwhile, the average value of k for sedimentary rocks in China is:

The raw data for the geostress hyperbolic regression analysis performed in this chapter are mainly from IFOT of wells with different parameters in the Liupanshui area, totaling 95 sets of triaxial in-situ stress data. The k values pertaining to the Liupanshui area in-situ stress dataset exhibit a span from 0.39 to 1.95, with a mean value of 0.94. By means of linear regression analysis (refer to Fig. 8) conducted on the in-situ stress measurements within the Liupanshui coalfield50, the median curve delineating the k values of lateral pressure coefficients within the study ___domain can be deduced as follows:

In Fig. 9, the median curve of the Liupanshui in-situ stress is depicted by the yellow dashed line. It is evident that the in-situ stress data from the parameter wells exhibit a relatively uniform distribution on either side of the median curve, thereby affirming the rationality and viability of employing the lateral pressure coefficient k method for investigating in-situ stress within the Liupanshui locale. Drawing upon the methodologies delineated by Brown-Hoek and other scholarly contributions61,72,74,76,77, and leveraging the extant dataset, the lateral pressure coefficient k range characterizing in-situ stress within the study ___domain was ascertained in this investigation as follows:

The k value serves as an indicator of the magnitude of horizontal stress in relation to vertical stress. Within the shallow strata of the study ___domain, the k value indicates a wide-ranging and intricate variability, with this variability gradually diminishing as depth increases. Concurrently, the rate at which the k value diminishes also reductions with depth, thereby evincing a trend characterized by “shallow discreteness” transitioning into “deep convergence”50. The Brown-Hoek envelope, the envelope specific to shallow crust in mainland China, and the k value envelope derived in the Liupanshui study are all depicted in Fig. 9. Notably, the Brown-Hoek inner envelope coincides with the inner envelope of shallow crust in mainland China, sharing identical equations. Evidently, the k value envelopes for shallow crust in mainland China all lie within the confines of the Brown-Hoek envelope, with both sets of curves exhibiting relatively comparable trends. Moreover, the relationship between k and depth observed in the Liupanshui strata mirrors that documented in southern Qinshui Basin78, eastern Ordos Basin79, and Liulin area within the eastern Ordos Basin80 in China, albeit with notable quantitative disparities. This alignment reinforces the hyperbolic nature of k variation with depth.

All in-situ stress data within the Liupanshui fall within the ambit of the Brown-Hoek envelope, yet they notably skew towards the lower end of the spectrum. Specifically, 97.6% of the data points are smaller than the median curve for shallow crust in mainland China, with the exception of two outlier sets of in-situ stresses. This article posits several potential explanations for these anomalies: firstly, Brown and Hoek’s findings are predicated on stress data encompassing not only sedimentary rocks but also magmatic and metamorphic formations at depths of 2806 m, where anomalously high values exceeding 3 are predominantly situated within granites and gneisses75; secondly, the k values attributed to sedimentary rocks cited by Brown and Hoek (e.g., mudstone, siltstone, sandstone, and shale) range between 0.85 and 2.56, contrasting with the stratigraphic statistics delineated in this study50; and lastly, coal rock in-situ stresses inherently differ, sometimes markedly, from in-situ stresses within coal-system stratigraphy in the intact state36. The conspicuous irregularities in the data underscore the distinctive characteristics of coal formation in-situ stress, warranting further investigation.

The presence of inner and outer hyperbolic envelopes enables speculation regarding potential variations in in-situ stress parameters with depth. In conjunction with the aforementioned envelope equations and Fig. 9, it is observed that the k value diminishes with increasing depth, ultimately stabilizing and converging. The ratio of average horizontal stress to vertical stress diminishes towards a fixed value, approaching k → 0.65. Additionally, the range of k values at a specific depth in the subsurface may be delineated using the envelope50. Give an example, the predicted k value at a depth of 2.5 km spans from 0.416 to 0.85, with an average value of 0.70. Considering the gravitational influence of the overlying strata, the vertical stress approximates 67.5 MPa. Hence, it may be deduced that the average horizontal principal stress at a depth of 2.5 km ranges from 28.08 to 57.38 MPa, with an average of 47.25 MPa. This furnishes a solid foundation for subsequent ultra-deep CBM extraction and reservoir enhancement operations. Such findings offer a theoretical framework for forthcoming endeavors in ultra-deep coalbed gasification and reservoir reformation initiatives.

In this investigation, statistically, within the coal-bearing basins of the Liupanshui area, k values less than 0.86 denote predominantly normal fault mechanisms in the geostress regime; values ranging from 0.86 to 1.2 signify a tendency towards strike-slip fault mechanisms; and k values exceeding 1.2 indicate a proclivity towards reverse fault mechanisms. Within the depth range covered by available data, the minimum k value is observed within the 600–900 m interval, approximately ranging from 0.4 to 0.6. Nonetheless, within this depth range, numerous recording points still exhibit higher k values, indicating that the overlying stress surpasses tectonic stress in certain coal-bearing stratum within this range, and the residual tectonic stress is relatively feeble81. Based on empirical observations, significant abrupt changes in overlying stress along the longitudinal axis are not anticipated. Such phenomena likely arise from localized drops in structural pressure, attributable to the distinct multi-seam accumulation and multi-level closed reservoir pressure system characteristic of the study area82,83. These abrupt reductions in tectonic pressure trigger rapid declines in reservoir permeability and induce complex alterations in the magnitude and direction of in-situ stress field, introducing numerous uncertain control factors for coal seam modification and fracturing operations.

Within the depth interval of 800–1100 meters, k values exhibit a gradual increasing trend, suggesting that the average horizontal stress remains lower than the vertical stress, albeit approaching convergence. The transition from a predominantly normal fault mechanisms of in-situ stress towards a strike-slip fault mechanisms is evidenced, corroborating the theoretical consistency of the model, as illustrated in Fig. 8. With deeper elucidation of well ___location data and burial depths, coupled with stratigraphic ___location data collected through IFOT, it is relatively close to the core of coal-bearing strata syncline. The tectonic framework of the Liupanshui shows that the area is mainly characterized by alternating distribution of synclines and anticlines, with synclines tightly closed. Strata situated near the core of synclines experience a stress environment characterized by rapidly escalating lateral compressive stress, consequently leading to an anomalous increase in k value at depths of 800 m. This abnormal depth corresponds to the minimum value of the average horizontal stress relative to the vertical stress near a depth of 800 m in Fig. 8. The intersection of the median curve with the straight line defined by ‘k = 1’ in Fig. 9 corresponds to depth H3 in Fig. 8. ‘k’ values tend to be predominantly less than 1 for formations with depths exceeding 700 m, with k values exceeding 1.2 only evident in formations with depths less than 400 m. The mean k value of 0.94 aligns closely with calculations by Chen et al.61, further corroborating the predominance of strike-slip and normal fault mechanisms in transition zone and deeper regions, with reverse fault mechanisms constituting a minor proportion50. The applicability of the model depicted in Fig. 8 is further underscored through the analysis of k values distribution patterns within this context.

In-situ stress conversion depth (ICD)

The depth at which the dominant stress changes from horizontal to vertical has been defined as the “in-situ stress transition depth”74,76,84, i.e., the depth at which the in-situ stress mechanism in this paper changes from strike-slip fault mechanism to normal fault mechanism. Considering the complexity of the in-situ stress, the “conversion depth” is usually expressed as a depth band50. It is worth noting that the “transition depth” under this concept is different from the transition depth defined by Qin et al. According to Yang, the transition depth in mainland China is 465 m84. Wang et al. believe that the modern in-situ stress transition depth in mainland China is around 800 m88. The critical depth for k = 1 in Brown-Hoek ‘s method is 143–3000 m (average about 1330 m)75. In his research of the Fanzhuang block of Qinshui basin, Shen et al.68 argued that the connection between stress ratio and hydraulic fracturing can be deduced from the fact that horizontal fractures occur in the area at shallower below 650 m, but induction is required at depths deeper than 650 m. In this study, the average values of the conversion depths statistically derived from Table 2 are in the range around 625.2 m. The mean values of the conversion depths in this study are in the range around 625.2 m. When k = 1, corresponding to the depth of H3 in Fig. 8, the average horizontal principal stress magnitude is equal to the vertical principal stress, which is defined as the lateral pressure coefficient conversion depth (LCD) in this paper. Obviously, the LCD is not the conversion depth of the in-situ stress, and the corresponding in-situ stress mode is dominated by the strike-slip fault mechanism, so defining the conversion depth of lateral pressure coefficient corresponding to k = 1 as the in-situ stress conversion depth (ICD) is a typical misunderstanding formed by many researchers. After a lot of statistics and deduction, when k = 0.84, the conversion depth derived from the formula of the median curve of the Liupanshui in-situ stress is 667.9 m, and at this time, a large number of in-situ stress modes are converted to the normal fault mechanism. Summarizing the above conclusions, the ICD of Liupanshui area in Qianxi should be about 670 m, which roughly coincides with the depth of H2 in Fig. 8. This depth is basically consistent with the vertical transformation depth of 600–700 m defined by Ju et al. in the neighboring area36.

Gas content patterns and gas content conversion depths

As a necessary step for well test analysis and an important parameter for reservoir evaluation, it is quite an important work to carry out on-site desorption of the target reservoir and calculate the gas content of each layer. Generally speaking, the field desorption work for CBM content determination in China follows the national standard GB/T 28,753 − 2012. The CBM content is calculated by the formula:

Where, GC, CBM content, cm3/g; VL, volume of lost gas, cm3; VD, volume of desorbed gas, cm3; VR, volume of residual gas, cm3; mT, total mass of the sample, g; mR, mass of the sample for the determination of residual gas, g.

The total number of gas content data collected from different exploratory boreholes in each coal-bearing synclines in the study area is more than 400, and after removing the data with obvious deviation, the total number of data is 395, and the data are more evenly distributed in different coal seams in different inclines, including several layers of unnamed coal seams and non-dominant coal seams. The minimum value of the obtained data comes from the 5# coal seam with a depth of 897.2 m in Songhe block of Tucheng syncline, which is 1.803 m3/t. The maximum value of the obtained data comes from the unnamed coal seam with a depth of 740.15 m in Mayi block of Qingshan syncline, which is 40.03 m3/t. The average gas content in the coal seams of the Liupanshui coalfield is 11.89 m3/t. Figures 10 − 1,10 − 2 and 10 − 3 show data from Panguan, Tucheng and Yangmeishu syncline, respectively, and the red curves are the fitted average gas content values. Vertically, gas content first fluctuates and rises, and then monotonically decreases after reaching a certain depth. In other words, the gas content in different synclines undergoes an inflection point at a certain depth, and the depth of the inflection point is roughly around 700 m. Projection of all gas content data in the research area onto the cross-axis of the depth, Figs. 10 − 4, shows an obvious trend of increasing and then decreasing, and the trend reaches its maximum value in the range of 650–800 m, which is the conversion depth of the gas content.

Meanwhile, it is also found that the reservoir pressure Pp also shows some positive correlation with gas content in the data of several parameter wells. Generally speaking, Pp has a primary function relationship with depth, and the value of pore pressure gradient in the shallow crust averages 0.98 MPa/hm. Langmuir isothermal adsorption equation: \(\:V=\frac{{V}_{L}P}{P+{P}_{L}}\) can partially explain the principle of synchronous change of reservoir pressure and gas content for us. In hydrogeology, the overpressure reservoir formation is well closed, the reservoir water communication is poor, and the desorbed gas is difficult to be transported with the fluid, and a localized gas-rich zone will appear85.

Focusing on the relationship between the in-situ stress and gas content, it’s generally accepted that there is no direct relationship between the two. According to the previous discussion, vertically, the envelope of k value of lateral pressure coefficient shows a hyperbolic law, and the envelope of gas content shows a law of increasing and then decreasing, which is a more significant change in the law indicating the intrinsic connection between the two. Generally speaking, the gas content is affected by the combined changes of various factors, and the in-situ stress generally affects the changes of gas content through the Pp and effective stress. Figure 11 presents the correlation between the value of lateral pressure coefficient k and gas content. With the increase of lateral pressure coefficient, the gas content envelope has a tendency of increasing and then decreasing. The shaded portion of the figure presents the region of maximum gas content, which corresponds to a range of k values roughly 0.9 < k < 1, i.e., the horizontal stress is slightly less than the vertical stress. The k value in this region corresponds to the shallow part of the normal fault mechanism in Fig. 8, just near the depth of H2. That is, the maximum value of gas content corresponds to the depth of transition from strike-slip fault mechanism to normal fault mechanism, which is about 700–800 m in Fig. 8, and the maximum value of gas content corresponds to the depth of 650–800 m in Figs. 10 − 4, which is roughly coincident with the two depths, and this confirms the applicability of the theoretical model in the research area to a certain extent.

Of all the gas content data, 81 data that can be distinguished from fault mechanisms were selected to map the distribution relationship box plot of gas content under different fault mechanisms (Fig. 12). Among them, there are 9 reverse fault mechanisms, 34 strike-slip fault mechanisms, and 38 normal fault mechanisms. The author finds, the medians of the three fault mechanisms correspond to different gas contents, with the lowest gas contents under the reverse fault mechanism, and the strike-slip and normal fault mechanism correspond to similar gas contents sizes. The reverse fault mechanism has the longest data box, the largest variance, and the data are significantly right-skewed. The reason is that the reverse fault mechanism occurs only in shallow strata and the data are highly discrete. The median value of gas content under the strike-slip fault mechanism is 12.32 m3/t, and the data show a left bias, indicating that a large amount of data exists in the upper half of the box above the median, i.e., the range of 12.32-15.00 m3/t. The data distribution variability and variance under the normal fault mechanism are the smallest, and the trend of data concentration is the largest, indicating that in the deep part of the stratum of the research area, the fluctuation and change of the gas content is small, and the multi-layer stacked reservoir system has a more excellent CBM preservation environment and a gradual change of the reservoir pressure system.

Discussion

The coal-bearing stratum of the Upper Permian within the study area exhibits the typical attributes associated with seam group development, including a multitude of coal seams (ranging from 8 to 111 seams) and slender individual seam thicknesses (ranging from 0.1 to 8.2 mm). Additionally, the coal seams exhibit narrow spacing (ranging from 0.5 to 22 m), substantial cumulative thickness (ranging from 7.5 to 54.6 m), and a comprehensive distribution of coal species (Romax ranging from 0.67 to 3.13%). The resource endowment and conditions of coal seams vary significantly across different regions37,38,39,40. Extensive research conducted by the Guizhou Coalfield Geological Bureau has delineated specific characteristics of the research area as follows: the Longtan formation of coal-bearing stratum exhibits a propensity towards weak water content; the tectonic configuration and the abundance of coal seams exert considerable influence on CBM endowment; coal seam gas content, reservoir pressure, The resource abundance and in-situ stress levels are comparatively higher, and the total CBM resource volume, coal grade variation magnitude, coal seam permeability disparities, and vertical geological condition alterations are more pronounced41,42,86. The Liupanshui area’s distinctive tectonic evolution history has resulted in the formation of numerous scattered and fragmented tectonic units within coal gathering basins, which serve as primary preservation sites for Upper Permian coal seams. These coal seams display gas content and in-situ stress characteristics comparable to those observed in other coal-bearing basins in China, while also exhibiting distinctive relative attributes. This underscores the importance of the present article.

Gas content is affected by coal quality, maximum reflectance Romax of specular group, coal thickness, deposition, tectonics, magmatic activity, etc50. In-situ stress is affected by rock mechanical properties, reservoir pore pressure, formation temperature, and formation denudation, etc50. Depth of burial has an important, if not the most important, influence on the gas content and the geostress field of coal beds, and has a more important influence on the reservoir modification and gas production capacity. The practice of Qinshui basin shows that: 500–800 m is the ideal depth for CBM development, and it is more difficult to exploit more than 1000 m. Various geological factors of the reservoir will affect the development of CBM. Various reservoir geologic factors will affect the ease or difficulty of mining at different depths, and geostress plays a vital role in this. The transformation of stress field is important to the gas content of the reservoir and the gas production of CBM wells. In-situ stress affects the gas content through the pore pressure and other factors, and affects the gas production performance through the reservoir modification. According to the previous research, there is a strong coupling relationship between the lateral pressure coefficient k and the transition of in-situ stress modes. The gas content of the Liupanshui coalfield rises gradually at shallow depths and undergoes an inflection point at a certain depth. Qin et al. believe that the “deep effect” of CBM will lead to the emergence of a “critical depth” for in-situ stress and gas content, beyond which the gas content will gradually decrease, and the in-situ stress pattern will be significantly different above and below the critical depth. It is also believed that the critical depth is controlled by the transformation depth of the in-situ stress state (k value) (Fig. 2)2,4,35. In this study, the above essential factors are summarized and drew on the same vertical depth map. Integrated triaxial principal stress (in-situ stress mechanism), vertical in-situ stress simplified model, lateral pressure coefficient k, gas content and other parameter relationships, coupled in-situ stress field parameters and gas content correspondence and conversion relationship. The relationship model of vertical " in-situ stress-gas content mode” for CBM development is displayed in Fig. 13.

The vertical simplification mode of the Liupanshui in-situ stress shows the typical feature of segmentation by depth, from shallow to deep, in the order of reverse fault mechanism → strike-slip fault mechanism → normal fault mechanism. In the stratum corresponding to the reverse fault mechanism, the lateral pressure coefficient k is larger, the horizontal stress dominates, and the gas content of the reservoir is smaller at this time. The depth H1 of the boundary between the reverse fault mechanism and the strike-slip fault mechanism is roughly 250 m. Beyond 250 m, the in-situ stress is changed to be dominated by the strike-slip fault mechanism, and the gas content is generally increased in the middle of the oscillation. There is an important interface within this mechanism, i.e., the depth at which the average horizontal principal stress is equal to the vertical principal stress with a continuously decreasing lateral pressure coefficient (k = 1), called lateral pressure coefficient conversion depth (LCD), which corresponds to a depth range of roughly 450–500 m. The LCD represents some unique reservoir physical characteristics, where the triaxial in-situ stress values are all relatively close, and the reservoir’s parafacial and vertical fissures reach large fissure opening widths under the influence of the Griffith rupture criterion50. When the depth reaches H2 (600–700 m), the value of δH is equal to δv, and the vertical principal stress begins to take absolute dominance, corresponding to the conversion of the in-situ stress pattern to a normal fault mechanism, and the corresponding depth is called in-situ stress conversion depth (ICD). It is worth noting that, from LCD to ICD, k is close to 1. The rock stress causes the porosity of the reservoir to increase, and the corresponding permeability is relatively high regardless of the direction from which it is calculated. In actual CBM development work, this depth (450–650 m) possesses several main coal seams for reservoir modification operations, and is the key segment for CBM exploitation. After exceeding the ICD, there is a small depth range corresponding to the average horizontal stress is much smaller than the vertical stress, the nature of the normal fault is obvious, and the gas content of the reservoir at this depth reaches the maximum value, which is called gas inversion depth (GID). After exceeding the GID, the average horizontal principal stress gradient increases, resulting in the average horizontal principal stress value being closer to the vertical principal stress value, and the state of the ground stress can be described as δv ≈ δH>δh. The value of gas content (adsorbed gas) decreases rapidly, and the deep reservoir corresponds to higher in-situ stress, formation temperature and formation fluid pressure, which makes desorption difficult, and the ratio of critical desorption pressure to pore pressure is extremely low, so the economy of CBM development decreases and the difficulty of development increases greatly. Therefore, the depth of deep CBM in study area starts from GID, i.e., GID can be taken as the critical depth of deep CBM in Liupanshui coalfield.

In deriving the definition of deep CBM, Qin et al. used the lateral pressure coefficient k = 1 and/or gas content inversion to characterize the “critical depth”, and concluded that there are three types of boundaries in the “deep”: (1) k = 1 corresponds to a depth < GID; (2) k = 1 corresponds to a depth > GID; (3) k = 1 corresponds to a depth equal to GID34. According to the study, this definition does not seem to be applicable to the study area. As mentioned before, k = 1 corresponds to depth H3 (LCD), which is shallower than the true in-situ stress transition depth H2 (ICD), and the two do not coincide, and the depth at k = 0.84 corresponds to the actual ICD. The ICD in the study area is also different from the GID, and the ICD will be slightly shallower than the GID, with a 50–100 m transition zone between the two, which is named “Transitional CBM” by Qin and Shen34. This transition zone is limited by the ICD and GID, and the lower depth limit is about 800 m, which is the critical depth of deep CBM in Liupanshui coalfield. The emergence of Transitional CBM indicates that the reversal of gas content will have a certain lag compared to conversion of in-situ stress, and the critical depth of gas content conversion controlled by temperature-pressure conditions will be deeper than the critical depth of in-situ stress conversion, and the reasons for this need to be further discussed and investigated.

In comparison with conventional free natural gas, deep CBM is adsorbed and requires desorption during the mining process. Additionally, the adsorption and desorption characteristics of CBM are more evidently influenced by formation pressure and formation temperature34. The transformation of the in-situ stress state with burial depth, and its coupling relationship with gas content, permeability and formation temperature, determine the difference in engineering mechanical properties between deep and shallow coal reservoirs. This, in turn, affects the modification mode and modification effect of deep coal reservoirs.

Conclusion

The correlation between stratum pressure and stratum temperature delineates the critical depth range for the conversion of gas content in deep CBM. Concurrently, the interaction between the three principal axes of stress determines the stress field environment and establishes the critical conversion depth range of in-situ stress at coal-rock locations, thereby influencing the distribution of effective stress and reservoir pressure. Subsequently, this dynamic exerts an influence on the pathways through which gas is transported, the levels of saturation attained by the gas, and the configuration and orientation of well trajectories. The interplay between pore pressure and gas content determines the dynamic equilibrium of the adsorption-desorption physical state within coal reservoirs, which in turn affects the seepage capacity and gas production potential of coal reservoirs during coalbed gas production operations.

This paper presents the findings of an investigation into the coupling relation between the distribution pattern of the in-situ stress field and the gas content of CBM reservoirs in the Liupanshui area. Additionally, it examines the unit division of the multi-dimensional pattern of “in-situ stress-gas content,” which is controlled by various factors. The conclusions of this investigation are displayed herein.

(1) At a specific burial depth in Liupanshui coalfield, the adsorption of CBM experiences similar influence from both positive and negative effects of temperature and pressure fields, leading to the formation of an inflexion point in the relation between adsorbed gas content and coal bed depth, known as the critical depth of gas content conversion. Vertically, the dominance of the strike-slip fault mechanism is notable within the 300–600 m range (primarily situated between depths of 506.82–689.83 m, with a median depth of 579.17 m), whereas the normal fault mechanism prevails beyond the 600 m mark (mostly located within the depth range of 646.05–815.26 m, with a median depth of 713.67 m). Progressing from shallower to deeper strata, a clear developmental sequence is discernible: reverse fault mechanism → strike-slip fault mechanism→normal fault mechanism. Horizontally, distinct stress development patterns characterize different coal-bearing synclines within the study area, with variations in the depths of stress transition zones and stress complexity zones. However, the developmental trends of in-situ stress states within each synclines exhibit comparable patterns. In deeper strata, the prevailing stress state inclines to align with a strike-slip-normal fault mechanism. Horizontal differential stresses are very little related to depth, and the ratio of horizontal stresses is linearly negatively correlated with depth.

(2) By conducting linear fitting of triaxial principal stress against burial depth and scrutinizing the relationship between correlation coefficient and gradient via multiple comparisons of fitted trend line equations, a simplified model plot depicting triaxial principal stress against depth in the Liupanshui coalfield is reconstructed. It is observed that δH exhibits a strong correlation and synchronicity with δh, while the gradient (slope) of δv variation surpasses that of horizontal principal stress. The vertical upward in-situ stress mechanism within study area manifests conspicuous zonal alterations, particularly between regions denoted as H1 and H2, where triaxial in-situ stress values converge closely and stress types become intricate, signifying a pivotal transition zone of in-situ stress. In deeper strata beneath H2, the overall in-situ stress predominantly adopts a normal fault mechanism, with the gradients of δH and δh exhibiting similar changes, no longer proportionally increasing with depth and resembling a logarithmic function curve. Within the deep stratum, δH and δh values approximate each other, thereby simplifying the pattern of in-situ stress to δv ≈ δH>δh. This simplified model diagram of triaxial principal stress - depth will provide an important theoretical reference for later energy development.

(3) Using the Brown-Hoek method to acquire a series of stress ratios (kH, kh, lateral pressure coefficient k) to discuss the variation pattern of the stress field. Through application of the hyperbolic regression algorithm, both the median formula and envelope formula of k are derived. In the longitudinal direction, the k value exhibits a discrete nature in shallow regions and converges as depth increases, gradually approaching 0.65. From a statistical perspective, k values less than 0.86 denote a predominantly normal fault mechanism of in-situ stress, while values ranging from 0.86 to 1.2 indicate a tendency towards a strike-slip fault mechanism, and k values exceeding 1.2 signify a reverse fault mechanism. The average k value is calculated at 0.94. The envelope formula for k facilitates the computation of the ___domain of in-situ stress values at various depths within the research area. Analysis of the regularity in k values further corroborates the applicability of the simplified model diagram of triaxial principal stress - depth.

(4) The medians of the three fault mechanisms correspond to different gas contents, with the lowest gas contents under the reverse fault mechanism, and similar gas contents under the strike-slip fault mechanism and the normal fault mechanism. The minimum value of gas content in the research area is 1.803 m3/t, the maximum value is 40.03 m3/t, averaging at 11.89 m3/t. The value of gas content fluctuates upward and then monotonically decreases after reaching the inflection point. The inflection point is defined as the critical depth for gas content conversion, which is roughly around 700 m. The gas content values of the gas content are in the range of 1000 to 2000 m. The pore pressure Pp is also positively correlated with the gas content. The maximum value of gas content corresponds to the depth zone of transition from advective to normal fault mechanism (also known as GID), which is approximately 700–800 m. The lateral pressure coefficient conversion depth (LCD) and the in-situ stress conversion depth (ICD) are defined. The lateral pressure coefficient conversion depth roughly corresponds to the depth range of 450–500 m, and the critical depth of the in-situ stress transformation should be 670 m. It is considered that the definition of the LCD corresponding to k = 1 as the ICD is a typical misunderstanding developed by many researchers, and is not applicable to the present study area. The critical depth of gas content conversion controlled by temperature and pressure conditions will be deeper than the critical depth of in-situ stress conversion, with a 50–100 m transition zone called “Transitional CBM” between the two. The depth below 800 m in the Liupanshui coalfield is considered as the critical depth for deep CBM, which is approximately 800 m.

(5) The stress field transition represents a significant role in both the gas content of reservoirs and the gas production of CBM wells. In-situ stress, influenced by elements such as reservoir pressure, directly affects gas content, while reservoir modification impacts gas production performance. In this research, we synthesize the relation between triaxial principal stress (in-situ stress mechanism), engineering stress, simplified model of vertical in-situ stress, k, gas content, and other parameters, and the correspondence and conversion relation between the coupled in-situ stress field parameters and gas content. The relationship model of vertical " in-situ stress-gas content mode” for CBM development is derived from the study.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- CBM:

-

Coalbed methane

- ICD:

-

In-situ stress conversion depth

- IFOT:

-

Injection/fall-off well test

- LCD:

-

Lateral pressure conversion depth

- GID:

-

Gas inversion depth

- R2 :

-

Pearson correlation coefficient

- δHmax(δH):

-

Horizontal maximum principal stress

- δHmin(δh):

-

Horizontal minimum principal stress

- δv :

-

Vertical stress

- k:

-

Lateral pressure coefficient

- kH and kh :

-

Stress ratios

- Pb :

-

Breakdown pressure

- Pc :

-

Closure pressure

- Pp :

-

Reservoir(pore) pressure

- Romax :

-

Vitrinite reflectance

References

Zou, C. et al. Resource types, formation distribution and development prospects of coal-based natural gas. Pet. Explor. Dev. 46, 433–442 (2019).

Qin, Y. Coal system gas aggregation system and development of geologic research strategy. J. Coal. 46, 2387–2399 (2021).

Xu, F. et al. Current situation and development strategy of China’s coalbed methane industry. Pet. Explor. Dev. 50, 669–682 (2023).

Qin, Y., Shen, J. & Shi, R. Strategic value and strategic choice of China’s coal gas industry. J. Coal. 47, 371–387 (2022).

Zheng, S. & Sang, S. Progress and development trend of coalbed methane exploration and development. Petroleum Explor. 61, 951–962 (2022).

Yi, T. Characteristics of coalbed methane in Guizhou Province. Guizhou Geol. 4, 346–348 (1997).

Yang, Z., Qin, Y., Li, Y., Sun, H. & Yi, T. Geological Evaluation Techniques for Coalbed Methane Multi-Layer Coalbed Methane Development. Xuzhou: China University of Mining and Technology Press. (2020).

Gao, W., Han, Z., Lv, F., Bai, L. & Jin, J. Geological characteristics and causes of gas content of coal seams in Liupanshui area. Coal Sci. Technol. 50, 122–130 (2022).

Jin, J. et al. Progress, potential and prospect of coalbed methane development in Guizhou Province. J. Coal. 47, 4113–4126 (2022).

Bell, J. S. In-situ stress and coal bed methane potential in Western Canada. Bull. Can. Pet. Geol. 54, 197–220 (2006).

Enever, J., Casey, D. & Bocking, M. The role of in-situ stress in coalbed methane exploration. Coalbed Methane: Sci. Environ. Economic Evaluation 297–303 (1999).

Banerjee, A. & Chatterjee, R. Pore pressure modeling and in situ stress determination in Raniganj basin, India. Bull. Eng. Geol. Environ. 81, 1–18 (2022).

Liu, D., Zhou, S., Cai, Y. & Yao, Y. Research on the effect of geostress on coal reservoir permeability and its control mechanism. Coal Sci. Technol. 45, 1–8 (2017).

Lv, F. Structural and geostress characteristics of coal bodies in Liupanshui Coalfield and their application to the selection of favorable sections for coalbed methane development. Guizhou University. (2023).

Qin, Y. & Gao, D. Prediction and evaluation of coalbed methane resource potential in Guizhou Province. Xuzhou: China University of Mining and Technology Press. (2012).