Abstract

The diameter and quantity of internal pores in concrete significantly influence its mechanical properties. While existing studies predominantly focus on the influence of pore quantity, this study utilizes pre-fabricated pores made from polystyrene particles (EPS) to investigate the effects of different pore diameter and porosity on the fracture mechanical properties of concrete. The results indicate that the incorporation of EPS degrades the fracture mechanical properties of concrete. The initiation load, peak load, initiation fracture toughness, instability fracture toughness, and fracture energy of concrete all decrease with increasing porosity. At constant porosity, the initiation load and initiation fracture toughness of concrete with a hole diameter of 0.3 to 0.6 mm decreased the most, with maximum reductions of 48.98% and 49.30%, respectively. The peak load, instability fracture toughness and fracture energy of concrete with a hole diameter of 3 to 5 mm decreased the most, with maximum reductions of 26.88%,38.46%,24.02%, respectively. In comparison to porosity, pore size has a more significant impact on the initiation fracture toughness of concrete. The influence of porosity on the instability fracture toughness and fracture energy of concrete is greater than that of pore size.

Similar content being viewed by others

Introduction

Concrete, being the most widely used construction material1 it is mechanical properties such as durability2 and strength3 has been a focal point of scholarly research4. Porosity is one of the primary factors influencing the durability and strength of concrete, during the setting and hardening process, as well as under the influence of external environmental conditions, concrete inevitably develops pores, resulting in a complex and disordered connectivity and morphology of its pore structure5 the quantity and size of these internal pores significantly influence the physical and mechanical properties of concrete.

Fracture performance, as a critical characteristic of concrete’s mechanical properties, serves as a valid criterion for assessing crack stability and is heavily influenced by the porosity and pores distribution within the material6,7,8,9. Some researchers have initially conducted studies on the testing and analysis of the initial pore structure within concrete. Currently, the primary methods employed include computed tomography (CT) scanning technology10 mercury intrusion porosimetry11 and capillary water absorption tests to obtain the internal porosity of concrete. The advancement of these techniques has further deepened the investigation into the impact of porosity on the mechanical properties of concrete12. Several scholars have established theoretical models to further account for the influence of concrete porosity on its internal stress distribution13. Building upon the existing research on pore structure, the researchers are conducting a study on the impact of porosity on the physical and mechanical properties of concrete. Long et al.14 employed multiscale modeling techniques to investigate the influence of varying aggregate volume fractions (AVF) on the mechanical behavior and failure mechanisms of concrete, the study found that higher AVF reduces concrete porosity, thereby reducing the risk of localized failure modes. Zhang et al.15 utilized expanded polystyrene (EPS) particles to simulate the pores within concrete. Experimental results indicate that porosity significantly affects the elastic modulus of concrete; specifically, the elastic modulus decreases with an increase in the porosity of the interfacial transition zone. Furthermore, when the total porosity remains constant, the porosity of the interfacial transition zone has a more pronounced impact on the elastic modulus of concrete compared to the porosity of the mortar. Wang et al.16 employed the mercury intrusion method to determine the porosity of concrete samples and found that the incorporation of both fly ash and silica fume significantly reduced the porosity of the concrete, thereby enhancing its mechanical properties. Wang et al.17 conducted a study on the correlation between porosity and mechanical properties of concrete under early freezing conditions. They found that as the porosity of the early-frozen concrete specimens increased, both the compressive strength and elastic modulus exhibited a trend of initially increasing followed by a subsequent decrease. Zhang et al.18 conducted experimental research on the influence of pore structure characteristics on the strength of wind-blown sand concrete. They concluded that there is an inverse relationship between the porosity and strength development in concrete. 3D concrete printing (3DCP) is progressively embraced by the civil engineering sector due to its many distinct advantages19,20. However, the weak interlayer strength of 3D concrete printing remains a critical issue. Recent studies addressing this problem have revealed a correlation between interfacial porosity and interlayer bond strength21. However, the research conducted by the aforementioned scholars is limited to investigating the influence of porosity on the mechanical properties of concrete. There is insufficient comprehensive study on the effects of concrete pore structure on its mechanical properties, lacking systematic research.

Apart from the aforementioned research on the relationship between porosity and the mechanical properties of concrete, some scholars have conducted experimental studies on the impact of pore diameter on the mechanical properties of concrete. Some research results indicate that the size and distribution of internal pores in concrete have a significant impact on its compressive strength and thermal conductivity22,23. The smaller the distance between large pores, the higher the stress around the pores, leading to a greater likelihood of microcracks and damage24. Upon incorporating recycled sand (RS) into high-ductility cement-based composites (ECC) as modified by Bai et al.25 it was observed that with an increase in the substitution rate of RS, the critical pores radius of ECC shifted towards a larger equivalent pore size. Through research, Ni et al.26 found that when the equivalent pore size is between 1.5 mm and 2 mm, the compressive strength of the specimens is higher. Another study indicated27 that there is a parabolic relationship between compressive strength and pore size, reaching the maximum value when the pore size is greater than 3.35 mm for composite materials. Compressive strength is most sensitive to the content of small pores (0 mm2 to 1.5 mm2). Zhang et al.28 found that with the increase of carbonization age, pores in the range of 0–40 μm have a negative impact on the splitting tensile strength. This is because the increase in carbonization products leads to an increase in expansion stress in small pores, damaging them, and further damaging the concrete structure under external forces. Pores in the range of 40–2000 μm have a positive impact on the splitting tensile strength. This is because large pores can accommodate expansion products, reduce the generation of expansion stress, and thus help improve the splitting tensile strength of concrete. The above research results indicate that the pore size has a significant impact on the strength of concrete. However, the studies only examined the influence of the pore size on the mechanical properties of concrete, lacking a systematic study on the influence of concrete pore structure on its mechanical properties.

The diameter of pore size and porosity exert a combined influence on the mechanical properties of concrete. Several researchers have conducted studies examining the effects of various pore sizes and porosities on the mechanical performance of concrete, integrating both theoretical analysis and experimental approaches. Zhang et al.29 investigated the effects of porosity and pore size on the mechanical properties of foam concrete using millimeter-scale superabsorbent polymers (SAP). Their findings revealed that as porosity and pore size increased, the compressive strength and splitting tensile strength of foam concrete exhibited a declining trend. However, when the pore size exceeded 9.5 mm and the porosity was below 10%, the influence of pore size on the mechanical properties of the concrete became negligible. Yang et al.30 proposed a novel numerical modeling approach for concrete and conducted uniaxial tensile simulations on mesoscopic models of concrete with identical aggregate structures but differing pore structures. They discovered that for specimens with the same total porosity, the elastic modulus increased with the rise in the content of larger pores. Furthermore, for pores with radii ranging from 0.15 to 0.8 mm, smaller pore diameters had a more significant impact on the elastic modulus and tensile strength, while their effect on peak strain was comparatively minimal. Bian et al.31 proposed the parameter known as the “Pores Comprehensive Impact Factor,” which quantifies the combined effects of pore size distribution and porosity on the compressive strength of concrete. Zhang et al.32 conducted studies using the MTS electro-hydraulic servo rock mechanics test system and split Hopkinson pressure bar system (SHPB) investigate the effects of various porosities and pore sizes on the mechanical properties and energy dissipation of porous concrete. Their findings revealed that under static conditions, the elastic modulus of concrete increases with larger pore sizes. Additionally, the energy absorption values and energy utilization rates of porous concrete with different pore sizes are significantly influenced by porosity, demonstrating a pronounced pore size effect. The findings of the aforementioned study indicate that the physical and mechanical properties of concrete are influenced by a combination of porosity and pore diameter, with the impact of pore diameter also being significant.

Currently, researchers are primarily focused on the impact of pores on indicators such as the strength and elastic modulus of concrete. There is a scarcity of studies assessing the influence of pores on the fracture properties of concrete. The fracture performance of concrete directly affects the safety and durability of structures, serving as a critical criterion for evaluating the stability of concrete cracks. In the study of the fracture performance of concrete, With the advancements in artificial intelligence (AI) technology and computational resources, scholars have increasingly leveraged machine learning (ML) and deep learning (DL)33 to address challenges in solid mechanics. Hu et al.34 applied the Physics-Informed Neural Networks (PINNs) approach to identify, assess, and predict fracture-related issues in materials and structures. Xu et al.35 proposed a more straightforward and practical dual-K fracture model after thoroughly considering the advantages and disadvantages of existing fracture models. They introduced the concepts of initiation and instability fracture toughness to describe the entire process of material fracture. Jiang et al.36 conducted a study utilizing XCT technology and a discrete grid fracture model to investigate the impact of the pore structure (including porosity, pore diameter, and spacing distribution) of foam concrete on its mechanical properties. The findings indicate that the presence of the pore structure contributes to an increase in the brittleness of foam concrete, thereby reducing its fracture toughness. Rehder et al.37 discovered that the fracture toughness of permeable concrete is primarily influenced by porosity; for similar porosity levels, an increase in pore diameter results in a decrease in fracture toughness. Despite the extensive research conducted by the aforementioned scholars, the impact of pores on the fracture performance of concrete has not been thoroughly investigated, warranting further exploration.

In summary, research on the impact of pores on the mechanical properties of concrete has primarily focused on strength, with limited studies addressing its fracture mechanics. Furthermore, investigations into pores have largely concentrated on single pore sizes or porosity levels, lacking a comprehensive approach that considers the simultaneous effects of pore size and porosity on the fracture mechanics of concrete. This has resulted in a lack of systematic understanding regarding the influence of porosity and pore size on the fracture mechanical properties of concrete. The internal structure of EPS particles exhibits a closed-cell configuration, characterized by lightweight properties, low strength, and hydrophobicity, making them commonly utilized for simulating the pores within concrete38,39,40 moreover, compared to traditional concrete, EPS lightweight aggregate concrete is stable and lightweight, with low water absorption, excellent energy absorption capacity, ductility, and compressive strain capacity. Therefore, this study pre-fabricated four types of porosity and five sizes of pore diameters in concrete by controlling the diameter and dosage of EPS particles. Since concrete inherently contains some pores prior to the introduction of the target pores, the experiment disregarded the inherent pores of the concrete. The specimens without EPS particles were considered as the control group with a porosity of 0% and a pore diameter of 0 mm, representing the initial concrete specimens. Based on this, a study was conducted using the wedge splitting method to investigate the fracture mechanical properties of concrete with varying prefabricated pore diameters and porosities. This research establishes a connection between the fracture parameters of concrete and the characteristics of its pore structure, providing a foundation for assessing the fracture safety of concrete containing millimeter-scale pores.

Materials and methods

Experimental materials and concrete mix design

The composite Portland Cement (P•C) 42.5 composite silicate cement used in the experiment has an initial setting time of 221 min, a final setting time of 285 min, and a standard consistency of 26.4%. The fine aggregate is composed of manufactured sand, while the coarse aggregate consists of secondary graded limestone gravel with sizes of 5–20 mm and 20–40 mm, mixed in a ratio of 1:1. The physical and mechanical properties of both aggregates are detailed in Table 1.

As shown in Fig. 1, the selected sizes of EPS particles range from 0.3 to 0.6 mm, 1–2 mm, 3–5 mm, 6–8 mm, and 8–10 mm, with their apparent densities detailed in Table 1. Due to the presence of inherent pores in concrete before the prefabricated target pores, the experiment overlooked the inherent pores in concrete. The specimens without added EPS particles were considered as having a void content of 0% and served as the standard control group with a void diameter of 0 mm. According to the “Code for Design of Concrete Mix Proportion for Hydraulic Engineering” (DL/T 5330 − 2015), The concrete used in this experiment had a strength grade of C35, a commonly used concrete grade in construction engineering, the water-cement ratio for this test is 0.57, and the concrete mix proportion is as shown in Table 2.

Experimental design and equipment

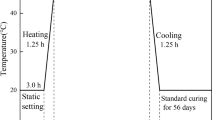

The experiment was conducted based on the “Test Regulations for Fracture of Hydraulic Concrete” (DL/T 5332 − 2005). The size of the wedge splitting test specimen was 330 mm × 300 mm × 120 mm, with a reserved notch size of 50 mm × 30 mm × 120 mm, and an initial crack height ratio of 0.4. A total of 6 sets of concrete specimens were prepared for the experiment, including 5 sets of test groups with pore diameters of 0.3–0.6, 1–2, 3–5, 6–8, 8–10 mm, and 1 control group. Each test group was further divided into specimens with pore rates of 1%, 4%, 7%, and 10%, each with 3 pieces. The specimen preparation process is shown in Fig. 2.

As shown in Fig. 3, the universal electronic bending test machine and loading device used in this experiment are depicted. By utilizing load sensors, clip-on extensometers, resistance strain gauges, and a stress-strain tester, the initiation load and peak load of the specimen can be measured.

Experimental results and analysis

Calculation of concrete fracture characteristic parameters

Based on the theory and fundamental assumptions of linear elastic fracture mechanics, while considering the effect of cohesive strength in the fracture process zone, this study employs the dual K fracture model41 criterion to calculate the initiation fracture toughness \(\:{K}_{IC}^{ini}\) and instability fracture toughness \(\:{K}_{IC}^{un}\) to determine the initiation of cracks and unstable state, with the corresponding fracture criteria detailed in Table 3.

Calculation of initiation fracture toughness

Before calculating the initiation fracture toughness, it is essential to determine the initiation load. The initiation load is identified as the nonlinear inflection point on the load-displacement curve at the crack. According to the “Test Method for Fracture of Hydraulic Concrete” (DL/T 5332—2005), the formula for calculating the initiation fracture toughness is as follows:

Where, \(\:{P}_{Q}\) is Vertical initiation load, kN; \(\:m\) is Wedge loading rack mass, kg;\(\:g\) is Gravitational acceleration, g = 9.81 m/s2;\(\:\:{P}_{HQ}\) is Horizontal initiation load, kN;\(\:{K}_{IC}^{ini}\) is initiation fracture toughness,\(\:\:\text{M}\text{P}\text{a}\bullet\:{\text{m}}^{1/2}\); t is Specimen thickness, mm; W is The effective height of the specimen, mm;\(\:{a}_{0}\) is Initial crack length, mm;\(\:\:\alpha\:\) isInitial seam height ratio, Dimensionless.

Calculation of instability fracture toughness

This article measures the peak load and critical crack opening displacement through experiments, calculates the elastic modulus E, and ultimately determines the instability fracture toughness \(\:{K}_{IC}^{un}\). The calculation formula is based on the “Test Code for Fracture of Hydraulic Concrete” (DL/T 5332—2005) as follows:

Where, \(\:{P}_{V\text{m}\text{a}\text{x}}\) is Vertical peak load, kN; \(\:{P}_{H\text{m}\text{a}\text{x}}\) is Lateral peak load, kN; \(\:{K}_{IC}^{un}\) is instability fracture toughness,\(\:\:\text{M}\text{P}\text{a}\bullet\:{\text{m}}^{1/2}\); \(\:{a}_{c}\) is Critical effective crack length, mm; \(\:{h}_{0}\) is The thickness of the stainless steel thin blade of the clip-on extensometer installation, mm; \(\:{CMOD}_{c}\) is Critical crack opening displacement, mm; E is Elastic modulus, GPa; \(\:{c}_{i}\) is Initial rising segment CMOD/F value of test specimen,\(\:{\upmu\:}\text{m}/\text{k}\text{N}\)。

Calculation of fracture energy

Fracture energy GF is the average energy required for the expansion of cracks per unit area of concrete, indicating the concrete’s ability to resist crack propagation. The formula for calculating fracture energy is as follows:

Where, \(\:{G}_{F}\) is Fracture energy of concrete, N/m; Q is Work of fracture, J; \(\:{A}_{li\text{g}}\) is Area of ligament rupture,\(\:{\text{m}\text{m}}^{2}\); \(\:{CMOD}_{0}\) is Maximum opening displacement of the crack mouth,\(\:\text{m}\text{m}\); \(\:{P}_{H}\) is Horizontal loads; kN。

Research on the fracture failure and deformation characteristics of concrete under different pores

Based on the dual K fracture model, the pre-cracking stage, stable crack extension stage, and unstable stage of concrete specimens can be described using the PH-CMOD curve graph. Figure 4 shows the complete curve of horizontal load-crack mouth opening displacement for concrete wedge splitting specimens with different pore size and porosity rates.

From Fig. 4, it can be observed that during the initial loading phase of the specimen, there is a linear relationship between the transverse load PH and the crack mouth opening displacement CMOD, indicating that the concrete specimen is undergoing elastic deformation. As the load continues to increase, pre-existing cracks at the tip of the specimen begin to propagate, leading to the initiation of cracking in the specimen. At this point, the relationship between the PH-CMOD curve is no longer linear, and the slope of the curve decreases to a horizontal, reaching the peak load. Once the load reaches its peak value and begins to unload, the specimen will experience failure and will no longer bear the load. During the unloading process, the presence of the load causes an increase in the displacement of the crack opening. The crack propagates around the coarse aggregate from the pre-existing crack tip, continuing to develop between the aggregate and the mortar, resulting in the formation of a primary crack that extends downward. The displacement of the crack opening in the specimen continues to increase until the conclusion of the test. The fracture process of concrete with porosities of 1%, 4%, 7%, and 10% under different Pore sizes exhibits fundamentally similar PH-CMOD curves. Under the condition of constant pore diameter, as the porosity increases, the peak load of the PH-CMOD curve decreases. For instance, when the pore diameter is between 1 and 2 mm and the porosity is 1%, the peak load of the concrete specimen is 8.82 kN. In contrast, at the same pore diameter with a porosity of 10%, the peak load of the concrete specimen drops to 7.13 kN, and the descending segment becomes more gradual.

The double K fracture toughness of concrete under varying pores conditions

The impact of pore structure on initiation load and peak load

As illustrated in Fig. 5, the vertical load- strain curves for different porosities at an Pore size of 6 to 8 mm show that during the initial loading phase of the experiment, the strain values at the tip of the pre-existing crack gradually increase with the rising load. Once the load reaches a certain threshold, the strain peaks and then begins to decrease, indicating the initiation of crack propagation at the pre-existing crack tip. The load corresponding to this inflection point, denoted as PQ, represents the crack initiation load. After reaching the initiation load, the strain continues to decrease while the load increases until it reaches the maximum peak load, PVmax. Similar patterns are observed in the vertical load-strain curves for different porosities at other Pore sizes.

Figure 8 shows the relationship between porosity and lateral initiation load and peak load. It can be observed from Fig. 8(a) and (b) that when the specimen is subjected to load, the presence of pores on the fracture surface reduces the load-bearing capacity of the cross-section. This leads to concrete cracking prematurely under lower loads due to the increasing number of pores. Therefore, under the same pore size, both lateral initiation load and peak load of concrete decrease significantly with the increase in porosity, the observed variation trend is generally consistent with that reported in the literature [8]. For instance, when the pore diameter is 3–5 mm, the lateral initiation load and peak load with porosity rates of 1%, 4%, 7%, 10% compared to a porosity of 0% respectively are 78.23%, 72.96%, 68.88%, 64.46%, and 83.87%, 80.18%, 75.7%, 73.12%.

Based on Fig. 8(a), it can be observed that when the porosity is the same, the decrease rate of the transverse initiation load is the fastest for pore sizes of 0.3–0.6 mm, while the decrease is minimal for pore sizes of 8–10 mm. This indicates that smaller pore sizes significantly reduce the initiation load of concrete, this phenomenon can be attributed to the fact that, at the same porosity level, although the size of smaller pores is reduced, their quantity increases substantially. This leads to a greater total surface area of defects per unit volume, resulting in a decrease in the effective area of the concrete, an increase in the average stress, and a higher likelihood of stress concentration. Consequently, this facilitates the onset of damage, thereby reducing the crack initiation load. According to Fig. 8(b), the transverse peak load value of specimens with pore diameters greater than 6 mm is generally higher than that of specimens with pore diameters less than 5 mm. For pore sizes between 3 ~ 5 mm, the transverse peak load of specimens with various porosities is lower than that of the transverse peak load of other test groups.

Figure 9 illustrates the relationship between pore size and load. From Fig. 9(a), it is evident that the initiation load of concrete is particularly sensitive to pore diameters in the range of 0.3 to 0.6 mm, this is also due to the fact that, at the same porosity level, although the diameter of the small pores is reduced, their quantity significantly increases. This leads to a greater likelihood of stress concentration occurring in the transition zones near the pores and the aggregate interfaces, resulting in the initiation of microcracks at these weak points, thereby reducing the crack initiation load. As the pore diameter increases from 0.3 to 0.6 mm to a range of 1 to 2 mm, the transverse initiation load of the concrete specimens increases. However, as the pore diameter gradually expands to 10 mm, the transverse initiation load approaches a plateau, for instance, when the porosity is at 4%, the lateral initiation load fluctuates between 4.29 and 4.76 kN.

It can be observed from Fig. 9(b) that the peak load of the concrete exhibits a greater sensitivity to pore diameters in the range of 3 to 5 mm, this is because, under the experimental conditions, when porosity remains constant, although the number of 0.3–0.6 mm and 1–2 mm pores exceeds that of 3–5 mm pores, the latter are more prone to act as initiation points for major cracks, triggering rapid macroscopic fracture. In contrast, 0.3–0.6 mm and 1–2 mm pores require crack propagation and interconnection among multiple pores, consuming more energy and thereby delaying the fracture process. However, for pores with diameters of 6–8 mm and 8–10 mm, their larger size results in a reduced number of pores and a more dispersed distribution. This disperses localized stress or forces cracks to propagate along more tortuous paths (requiring greater energy expenditure), thereby mitigating their adverse effect on peak load. When the porosity are 1%, 4%, 7%, and 10%, the lateral peak load fluctuates between 7.49 and 8.87 kN, 7.16 to 8.44 kN, 6.76 to 7.73 kN, and 6.53 to 7.49 kN, respectively, as the pore diameter increases. The presence of pores in the specimen renders it more susceptible to failure, while the distribution of EPS particles within the specimen is random. Upon loading, the concrete specimen splits along the pre-existing cracks, resulting in an increase pore size. Concurrently, the number of pores on the fracture surface may fluctuate, leading to variations in the initiation load and peak load.

Variation in double K fracture toughness of concrete under different pore conditions

By conducting fracture tests to determine the initiation load, we obtain the vertical initiation load (PQ). Subsequently, we input the data into Eq. (1) to (3) for calculations, which indirectly yield the corresponding initiation fracture toughness (\(\:{K}_{IC}^{ini}\)). Similarly, we first determine the vertical peak load (PVmax) and then calculate the instability fracture toughness (\(\:{K}_{IC}^{un}\)) using Eq. (4) to (9).

(1)The variation in initiation fracture toughness of concrete under different porosity conditions.

The impact of varying porosity on the initiation fracture toughness of concrete specimens is illustrated in Fig. 8, while the changes in initiation fracture toughness under different pore diameters are depicted in Fig. 9.

As can be seen from Fig. 8, when the pore size is the same and the porosity increases, the initiation fracture toughness of concrete specimens will be significantly reduced. For example, when the pore diameter is 1–2 mm and the porosity is 1%, 4%, 7%, and 10%, the initiation fracture toughness is reduced by 9.86%, 19.72%, 28.17%, and 32.39%, respectively, compared with when the porosity is 0%. This phenomenon is attributed to the increase in porosity, which results in a reduction of the distance between pores. When subjected to loading, stress concentrations develop at the upper and lower ends of the pores, leading to the formation of cracks in the regions of concentrated stress surrounding the pores. Once cracks initiate, they propagate and penetrate due to the matrix’s tensile strength being lower than the horizontal splitting force. Consequently, as porosity increases, the macroscopic manifestation is a decrease in the initiation fracture toughness of the specimen.

As shown in Fig. 9, the initiation fracture toughness of concrete is more significantly sensitive to pores in the range of 0.3–0.6 mm in diameter. When the pore diameter increases from 0.3 to 0.6 mm to 1–2 mm, the initiation fracture toughness of concrete specimens all increases. When the pore diameter gradually increases to 10 mm, the initiation fracture toughness approaches a horizontal. Due to the randomness of the distribution of EPS particles, the number of pores on the splitting surface is different. Under the same porosity, the difference in initiation fracture toughness of different pore diameters fluctuates between 0.15 and 0.18 MPa·m1/2.

(2)Variation law of instability fracture toughness of concrete under different pores.

As shown in Fig. 10, the influence of porosity on the instability fracture toughness of concrete specimens. As shown in Fig. 11, the change of instability fracture toughness under different pore diameters.

It can be observed from Fig. 10 that the presence of pores reduces the instability fracture toughness of concrete. The instability fracture toughness of concrete specimens with varying pore diameters gradually decreases as the porosity increases, the observed variation trend is generally consistent with that reported in the literature [36]. For example, when the pore diameter is between 1 and 2 mm and the porosity levels are 1%, 4%, 7%, and 10%, the fracture toughness decreases by 21.79%, 25%, 30.13%, and 31.41%, respectively, compared to a porosity of 0%. This is primarily due to the presence of pores, which causes the concrete to crack prematurely and enter the crack propagation phase. As the number of pores increases, it further facilitates the expansion of the cracks, leading to the crack length reaching a critical value and resulting in premature instability.

As shown in Fig. 11, the reduction in instability fracture toughness of concrete is most significant within the pore size range of 3 to 5 mm, while the decrease is minimal for pore sizes between 8 and 10 mm. The variability in the number of pores on the instability fracture surface, caused by the randomness of EPS particle distribution, results in fluctuations in the fracture toughness of concrete with different pore sizes, ranging from 0.2 to 0.31 MPa·m1/2 at the same porosity.

The variation of fracture energy in concrete under different porosities

The fracture energy GF of concrete, which represents the energy consumed per unit area of concrete when a crack propagates, is one of the critical fracture performance parameters in the design of concrete structures. It is typically used to analyze and determine the fracture performance and toughness of concrete specimens. Table 4; Fig. 12 illustrate the trends of change in fracture energy of concrete under varying pore diameters and porosities.

It can be observed from Table 6; Fig. 12 that the pores significantly reduces the fracture energy of concrete. Under various pore sizes, the fracture energy of concrete specimens consistently decreases with the increase in porosity. For example, when the pore diameter ranges from 0.3 to 0.6 mm and the porosity is set at 1%, 4%, 7%, and 10%, the fracture energy of the concrete decreases by 6%, 12.81%, 16.73%, and 21.61% respectively compared to the control group. Furthermore, it is observed that as the porosity increases, the reduction in fracture energy becomes more pronounced. When the porosity remains constant, the increase in pore diameter does not significantly affect the fracture energy; however, compared to the control group, all experimental groups in this study resulted in a reduction of the fracture energy of concrete. When the prefabricated pore diameter ranges from 3 to 5 mm, the reduction in concrete fracture energy is most pronounced, this is due to the fact that under the experimental conditions, when the porosity is constant, an increase in the number of pores measuring 0.3–0.6 mm and 1–2 mm facilitates the propagation of cracks through the connection of small defects. This reduces the quantity of matrix strength (including the paste, aggregate, and interface) that must be overcome along the propagation path, resulting in a decrease in the fracture energy of specimens with varying porosities compared to the control group. However, the tortuous nature of the crack propagation path leads to micro-crack bridging and interfacial friction, which slightly increases energy consumption. Pores measuring 3–5 mm are more likely to serve as the initiation points for primary cracks, rapidly triggering macroscopic fracture and significantly shortening the effective fracture path, thereby reducing micro-crack bridging and aggregate interlocking, which results in a substantial decrease in fracture energy. When the pore diameters are 6–8 mm and 8–10 mm, the larger pore sizes correspond to a reduction in the number of pores and a sparser distribution, which increases the amount of matrix strength (paste, aggregate, and interface) that must be overcome for crack propagation. This may necessitate frequent detours or penetration through the aggregate, leading to a long and tortuous fracture process zone that consumes a significant amount of energy. Therefore, when the prefabricated pore diameter is 3–5 mm, the reduction in concrete fracture energy is most pronounced. For instance, with a porosity of 1%, the fracture energy of concrete, compared to the control group, decreases by 6% for pore diameters of 0.3 to 0.6 mm, 5.9% for 1 to 2 mm, 12.39% for 3 to 5 mm, 4.76% for 6 to 8 mm, and 4.35% for 8 to 10 mm.

In summary, through a systematic investigation of the effects of different pore characteristics on the double-K fracture toughness and fracture energy of concrete, it was found that an increase in porosity leads to a deterioration in the fracture performance of concrete. Notably, pores with diameters ranging from 0.3 to 0.6 mm have the most significant impact on the initiation fracture toughness of concrete, while pores with diameters of 3 to 5 mm predominantly influence the unstable fracture toughness and fracture energy. Therefore, for concrete applications that require maintaining a certain level of porosity, such as in porous concrete, it is essential to minimize the presence of macro-pores in the 3 to 5 mm range to reduce the loss of crack resistance. Additionally, incorporating appropriate fiber materials can effectively disperse the directional stresses within the concrete, thereby enhancing its crack resistance and toughness.

Analysis of the fracture characteristics of concrete

By studying the fracture characteristics of concrete, we can gain a better understanding of the crack propagation patterns during the failure process of concrete materials. Scholars have categorized the fracture characteristics of concrete into the following three types42as illustrated in Fig. 13: (1) fracture of the binder between aggregates, (2) interfacial fracture at the aggregate-binder interface, and (3) fracture of the aggregates themselves. Figure 14 shows the different forms of concrete fractures in this experiment.

This study investigates the fracture characteristics of concrete with millimeter-scale porosity by photographing and observing the fracture cross-sections of specimens, as illustrated in Fig. 14. The discussion does not address the fracture of the binder, as it is present in all forms of fracture. Figure 14 indicates that the specimens incorporating EPS particles exhibit a significantly higher number of aggregate fractures (including both EPS and aggregate) compared to those without EPS particles, resulting in a reduction in fracture surface roughness and an increase in the extent of flat regions. The primary reason for this outcome is the inherent inability of EPS particles to bear loads, coupled with the lack of cohesion between the EPS particles and the binder, which facilitates easier fracture of the concrete. Additionally, Fig. 14 reveals that the increase in porosity leads to a decrease in the density of the cement paste, thereby hindering the compact accumulation of hydration products and resulting in a loose, porous microstructure of the fracture surface.

The combined effect of pore diameter and porosity on the fracture performance of concrete

Two-factor analysis of variance can describe the extent to which two independent variables affect a dependent variable, while also considering the interaction effects produced by the combination of the two factors on the dependent variable. To investigate the influence of pore diameter and porosity on the fracture performance of concrete, this section employs a two-factor analysis of variance method. Based on the calculated results of initiation fracture toughness, instability fracture toughness, and fracture energy, a significance test of their effects is conducted. Assuming that different porosities are factor A and different pore sizes are factor B, with no interaction effects between the two factors, the mathematical model for the two-factor analysis of variance is presented in Eq. (11).

In the equation: \(\:{y}_{ij}\) represents the two-factor interaction effect (i = 1,2,…,a; j = 1,2,…,b); \(\:\mu\:\) denotes the overall mean; \(\:{\alpha\:}_{i}\) indicates the effect of factor A at level \(\:{A}_{i}\); \(\:{\beta\:}_{j}\) signifies the effect of factor B at level \(\:{B}_{j}\);\(\:{\epsilon\:}_{ij}\) represents the random error term; a refers to the number of levels for factor A; b refers to the number of levels for factor B.

Analyzing the differences between factors A and B to determine whether they have a significant impact on the experimental results, thereby testing the validity of the following hypothesis:

In the formula: i and j represent the total number of levels for factors A and B, respectively. When testing the hypothesis, if the between-group difference \(\:{F}_{A}\) of factor A is greater than the between-group difference \(\:{F}_{{\uplambda\:}}\) at the significance level λ, then the null hypothesis \(\:{H}_{01}\) is rejected, meaning that the effect of factor A is statistically significant, and vice versa, the same applies to factor B.

Table 5 presents the analysis results of fracture toughness and fracture energy variance for concrete containing preformed pores. Among them, the F value represents the difference between groups, with the significant coefficient P indicating the reliability of the computed results. A larger F value and a smaller P value indicate more accurate results. Taking the significance level λ = 0.05, critical significant coefficient [P] = 0.01, and total degrees of freedom of 12 are used to determine the accuracy of the computed results.

From Table 5, it can be observed that the significant coefficients P for the initiation fracture toughness, unstable fracture toughness, and fracture energy of the concrete are all less than the critical significant coefficient [P], indicating a high reliability of the calculated results. For factor A, the F values of all fracture indicators exceed F0.05(3,12) = 3.49; for factor B, the F values of all fracture indicators surpass F0.05(4,12) = 3.26. According to statistical criteria, it is evident that pore diameter and porosity have a significant impact on the fracture toughness and fracture energy of concrete. Moreover, in comparison to porosity, the size of the pore diameter has an even more pronounced effect on the initiation fracture toughness of concrete. This is due to the absence of solid material within the concrete caused by the pore size, which results in a decrease in the specimen’s flexural and tensile strength, leading to premature cracking under relatively small loads and moments. The impact of porosity on the instability fracture toughness and fracture energy of concrete is greater than that of pore diameter.

Conclusion

This paper employs EPS particle simulation the pores within concrete. It conducts fracture performance tests on concrete with varying pore structures using the wedge splitting method, thereby systematically investigating the comprehensive effects of porosity and pore size on its fracture performance. The experiment measured the initiation load, peak load, and crack opening displacement under different pore structures. Based on the experimental data, the fracture parameters of concrete were calculated and analyzed. The specific conclusions are as follows:

-

(1)

Concrete with a pores structure undergoes an uncracked phase, a stable crack propagation phase, and an instability phase during fracture testing. As the porosity increases, the peak load of the PH-CMOD curve decreases, for example, when the pore size ranges from 1 to 2 mm and the porosity increases from 1 to 10%, the peak load decreases by 19.86%, and the descending branch of the curve also becomes more gradual.

-

(2)

The presence of pores leads to premature cracking and instability in concrete. When the pore diameter is constant, the initiation load, peak load, initiation fracture toughness, instability fracture toughness, and fracture energy of the concrete all gradually decrease with an increase in porosity. Under the same porosity, the variability in the number of pores on the fracture surface, caused by the randomness of EPS particle distribution, results in a decrease in the number of pores as the pore diameter increases. This leads to fluctuations in the mechanical parameters of concrete fracture. However, compared to the control group, the presence of pores consistently reduces the mechanical parameters of concrete fracture. The crack initiation load and the reduction in fracture toughness are most significant for concrete with pore diameters ranging from 0.3 to 0.6 mm. Specifically, when the porosity is 10%, the crack initiation load and fracture toughness decrease by 48.98% and 49.30%, respectively, compared to the control group. For concrete with pore diameters between 3 and 5 mm, the peak load, unstable fracture toughness, and fracture energy exhibit the greatest reductions, with decreases of 26.88%, 38.46%, and 24.02%, respectively, when the porosity is also 10% in comparison to the control group.

-

(3)

Due to the inherent inability of EPS particles to bear loads, coupled with the lack of cohesion between the EPS particles and the binder, the number of aggregate fractures (including both EPS and conventional aggregates) in specimens incorporating EPS particles is significantly higher than in those without EPS particles. The porosity and pore size of EPS particles can deteriorate the fracture performance of concrete. Compared to porosity, pore size has a more significant impact on the initiation fracture toughness of concrete. The influence of porosity on the instability fracture toughness and fracture energy of concrete is greater than that of pore size. Under the same porosity, as the pore diameter increases, the number of pores decreases. Therefore, when evaluating the fracture performance of concrete with pore defects, it is essential to comprehensively consider the effects of both porosity and pore size on its fracture characteristics.

Data availability

The datasets generated during the current study are available upon reasonable request from the corresponding author, Guohui Zhang (zgh_[email protected]).

References

Sharma, R., Jang, J. G. & Hu, J. W. Phase-Change materials in concrete: opportunities and challenges for sustainable. Constr. Building Mater. J. 15 (1). https://doi.org/10.3390/ma15010335 (2022).

Zhang, W. et al. Experimental and numerical studies on flexural performance of composite beams under cyclic loading. journal. 70. (2024). https://doi.org/10.1016/j.istruc.2024.107728

Zhang, W. et al. Experimental and numerical study on the torsional behavior of rectangular Hollow reinforced concrete columns strengthened by CFRP. Journal. 70. (2024). https://doi.org/10.1016/j.istruc.2024.107690

Naderi, S. & Zhang, M. Meso-scale modelling of static and dynamic tensile fracture of concrete accounting for real-shape aggregates. journal. 116. (2021). https://doi.org/10.1016/j.cemconcomp.2020.103889

Tan, H. et al. Utilization of lithium slag by wet-grinding process to improve the early strength of sulphoaluminate cement paste. Journal 205, 536–551. https://doi.org/10.1016/j.jclepro.2018.09.027 (2018).

Zeng, Y. et al. Investigation of Axial Tensile Fracture Performance of Recycled Brick Coarse Aggregate Concrete Using a Cohesion Model. journal. 17(15). (2024). https://doi.org/10.3390/ma17153630

Cao, X. et al. Molecular dynamics study on microporous direction effect on C-S-H fracture performance. Journal. 39. (2024). https://doi.org/10.1016/j.mtcomm.2024.109168

Han, X. et al. Determining the fracture properties of pervious concrete specimens with various micro-structures and geometries. journal. 117. (2022). https://doi.org/10.1016/j.tafmec.2021.103151

Vicente, M. A. et al. Influence of the pore morphology of high strength concrete on its fatigue life. journal. 112 106–116. (2018). https://doi.org/10.1016/j.ijfatigue.2018.03.006

Koenig, A. Analysis of air voids in cementitious materials using micro X-ray computed tomography (µXCT). Journal 244 https://doi.org/10.1016/j.conbuildmat.2020.118313 (2020).

Basu, P. et al. Strength, permeation, freeze-thaw resistance, and microstructural properties of self-compacting concrete containing sandstone waste. journal. 305. (2021). https://doi.org/10.1016/j.jclepro.2021.127090

Tian, G., Deng, H. & Xiao, Y. Correlation analysis between microscopic pore parameters and macroscopic mechanical properties of Rock-like materials from the perspective of Water-Cement ratio and Sand-Cement ratio. Journal 15 (7). https://doi.org/10.3390/ma15072632 (2022).

Wang, Z. et al. Crack imaging of underwater concrete components using interfacial waves and transducer array. journal. 224. (2025). https://doi.org/10.1016/j.ymssp.2024.111998

Long, X. et al. Numerical predictions of progressive collapse in reinforced concrete beam-column sub-assemblages: A focus on 3D multiscale modeling. Journal 315 https://doi.org/10.1016/j.engstruct.2024.118485 (2024).

Zhang, G. et al. Experimental and theoretical prediction model research on concrete elastic Modulus influenced by aggregate gradation and porosity. Journal 13 (4). https://doi.org/10.3390/su13041811 (2021).

Wang, L. et al. Pore structural and fractal analysis of the influence of fly Ash and silica fume on the mechanical property and abrasion resistance of concrete. Journal 29 (2). https://doi.org/10.1142/s0218348x2140003x (2021).

Wang, C. H. et al. Influence of Early Freezing on the Pore Structure Characteristics of Concrete and Its Correlation with Mechanical Properties. journal. 14(1). (2024). https://doi.org/10.3390/buildings14010047

Zhang, H. et al. Influence of pore structure characteristics on the strength of aeolian sand concrete. Journal 76 (1), 35–45. https://doi.org/10.14256/jce.3602.2022 (2024).

Yang, L. et al. Three-dimensional concrete printing technology from a rheology perspective: a review. Journal 36 (12), 567–586. https://doi.org/10.1680/jadcr.23.00205 (2024).

Zhao, H. et al. Review on solid wastes incorporated cementitious material using 3D concrete printing technology. journal. 21. (2024). https://doi.org/10.1016/j.cscm.2024.e03676

He, L. et al. Development of novel concave and convex trowels for higher interlayer strength of 3D printed cement paste. Journal 21 https://doi.org/10.1016/j.cscm.2024.e03745 (2024).

Su, Y., Li, Y. & Sheng, J. Relationship between compressive strength and pore structure of hybrid Fiber-Reinforced concrete subjected to carbonation. Journal. 35(11). (2023). https://doi.org/10.1061/jmcee7.Mteng-15954

Feng, S. et al. Influence of fibers and bubble structure on thermal conductivity and mechanical performances of foam concrete. journal. 445. (2024). https://doi.org/10.1016/j.conbuildmat.2024.137956

Shan, J., He, J. & Li, F. Numerical Simulation of Pervious Concrete Based on Random Pore Model. journal. (2020). https://doi.org/10.1155/2020/8831506 (2020).

Bai, M. et al. Pore structure characteristics and mechanical property of engineered cementitious composites (ECC) incorporating recycled sand. journal. 408. (2023). https://doi.org/10.1016/j.conbuildmat.2023.133721

Ni, T. et al. Interface reinforcement and a new characterization method for pore structure of pervious concrete. journal. 267. (2021). https://doi.org/10.1016/j.conbuildmat.2020.121052

Yu, F. et al. Influence of aggregate size on compressive strength of pervious concrete. journal. 209 463–475. (2019). https://doi.org/10.1016/j.conbuildmat.2019.03.140

Zhang, Z. et al. Understanding of the deterioration characteristic of concrete exposed to external sulfate attack: insight into mesoscopic pore structures. Journal 260 https://doi.org/10.1016/j.conbuildmat.2020.119932 (2020).

Zhang, S. et al. Influence of the porosity and pore size on the compressive and splitting strengths of cellular concrete with millimeter-size pores. journal. 235. (2020). https://doi.org/10.1016/j.conbuildmat.2019.117508

Yang, H., Zhu, E. & Liu, L. Analysis of the Effect of Pore Structure on the Mechanical Properties of Concrete Based on the Meso Numerical Model. journal. 12(11). (2022). https://doi.org/10.3390/app12115428

Bian, P. et al. Prediction model of compressive strength of foamed concrete considering pore size distribution. journal. 409. (2023). https://doi.org/10.1016/j.conbuildmat.2023.133705

Zhang, J. et al. Influence of the porosity and pore size on the mechanical properties and energy dissipation of cellular concrete utilizing millimeter-size SAP. Journal 417 https://doi.org/10.1016/j.conbuildmat.2024.135298 (2024).

Niu, Y. et al. Plastic damage prediction of concrete under compression based on deep learning. Journal 235 (1), 255–266. https://doi.org/10.1007/s00707-023-03743-8 (2023).

Hu, H., Qi, L. & Chao, X. Physics-informed Neural Networks (PINN) for computational solid mechanics: Numerical frameworks and applications. journal. 205. (2024). https://doi.org/10.1016/j.tws.2024.112495

Xu, S. L. & Reinhardt, H. W. A simplified method for determining double-K fracture parameters for three-point bending tests. Journal 104 (2), 181–209. https://doi.org/10.1023/a:1007676716549 (2000).

Jiang, N. et al. Experimentally validated meso-scale fracture modelling of foamed concrete. journal. 122. (2022). https://doi.org/10.1016/j.tafmec.2022.103631

Rehder, B., Banh, K. & Neithalath, N. Fracture behavior of pervious concretes: The effects of pore structure and fibers. journal. 118 1–16. (2014). https://doi.org/10.1016/j.engfracmech.2014.01.015

Amianti, M. & Botaro, V. R. Recycling of EPS: A new methodology for production of concrete impregnated with polystyrene (CIP). Journal. 30(1) 23–28. (2008). https://doi.org/10.1016/j.cemconcomp.2007.05.014

Miled, K., Sab, K. & Le Roy, R. Particle size effect on EPS lightweight concrete compressive strength: experimental investigation and modelling. Journal 39 (3), 222–240. https://doi.org/10.1016/j.mechmat.2006.05.008 (2007).

Miled, K., Sab, K. & Le Roy, R. Effective elastic properties of porous materials: homogenization schemes vs experimental data. Journal 38 (2), 131–135. https://doi.org/10.1016/j.mechrescom.2011.01.009 (2011).

Yin, X. et al. The double-K fracture model: A state-of-the-art review. journal. 277. (2023). https://doi.org/10.1016/j.engfracmech.2022.108988

Park, S. B. et al. An experimental study on the hazard assessment and mechanical properties of porous concrete utilizing coal bottom Ash coarse aggregate in Korea. Journal 166 (1), 348–355. https://doi.org/10.1016/j.jhazmat.2008.11.054 (2009).

Acknowledgements

This work was supported by National Natural Science Foundation of China project (grant number 52469021),The Yunnan Fundamental Research Projects [grant number 202401AT070338].

Author information

Authors and Affiliations

Contributions

G. Z.: Writing - review & editing, Writing - original draft, Visualization, Validation, Formal analysis, Data curation, Conceptualization. D. G.: Visualization, Validation, Software, Investigation, Data curation. Y. G.: Visualization, Validation, Supervision, Software. M. Z.: Supervision, Methodology, Investigation. B. Z.: Visualization, Validation. M.W.:Supervision, Software.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, G., Gu, D., Gu, Y. et al. Concrete double-K fracture toughness and fracture energy influenced by porosity and pore size. Sci Rep 15, 22528 (2025). https://doi.org/10.1038/s41598-025-05841-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-05841-0