Abstract

To minimize waste and maximize the utilization of wild Rosa roxburghii Tratt fruits, the quality characteristics of soluble dietary fiber (SDF) extracted from wild Rosa roxburghii Tratt fruits sourced from ten regions were assessed in this study through an in-depth analysis. This analysis included the evaluation of chemical composition, physicochemical properties, structural elucidation, antioxidant capacity, and functional properties in yogurt applications. Communally, these SDFs are acidic heteropolysaccharides mainly composed of glucose, galacturonic acid, galactose, arabinose, and rhamnose, and all of them showed the infrared spectrum and high molecular weight (Mw) characteristics of polysaccharides. Meanwhile, the results indicated significant regional variations in the quality of SDF. Specifically, the SDF sourced from region LP possessed the highest arabinose glucose ratio (75.63%), Mw (312.488 kDa) and diffraction intensity. While the SDF sourced from region AZ indicated the lowest sugar content (41.57%) and diffraction intensity, but highest the swelling capacity (1.02 mL/g) and emulsion stability (41.90%). Furthermore, the SDF sourced from region ZS revealed the lowest Mw (149.476 kDa), total protein ratio (8.61%) and oil-holding capacity (1.63 g/g), but highest the total sugar ratio (58.63%). Additionally, the foaming capacity and DPPH free radical scavenging ability of SDF sourced from region TR were significantly superior to those of other regions (p < 0.05), and SDF sourced from region BD was also similar in terms of ABTS free radical scavenging rate and total protein proportion. Meanwhile, these SDFs’ differences in surface morphological features and application properties in yogurt were also observed. These findings provide essential data for the further exploration of wild Rosa roxburghii Tratt and the enhancement of the quality of its soluble dietary fiber.

Similar content being viewed by others

Introduction

Rosa roxburghii Tratt (R. roxburghii), a member of the Rosaceae family, is commonly found in mountainous regions at altitudes ranging from 500 to 2500 m in southwestern China, including provinces such as Guizhou, Sichuan, Yunnan, and Guangxi1. Known as the “king of vitamin C”, R. roxburghii has a vitamin C content nine times higher than that of kiwi fruit. This fruit has high nutritional and medicinal value, making it a natural wild fruit with dual purposes for both food and medicine2,3. Reports have confirmed that R. roxburghii exhibits antioxidative, anti-aging, anti-mutagenic, anticancer, antitumor, heavy metal toxicity-reducing, blood pressure-lowering, blood sugar-lowering, and blood lipid-lowering effects. It also regulates immune function and prevents atherosclerosis. These benefits are attributed to its rich content of dietary fiber, polyphenols, flavonoids, ellagic acid, amino acids, organic acids, triterpenes, and vitamins, making it a high-quality raw material for functional food processing. Among these, dietary fiber is the main functional component4,5,6.

Dietary fiber (DF) is considered the seventh essential nutrient in living organisms. Based on solubility, it can be divided into soluble dietary fiber (SDF) and insoluble dietary fiber (IDF). Compared to IDF, SDF is preferred for its good solubility, oil/water holding capacity, interfacial and surface properties, and its potential to bind various molecules7,8. SDF possesses higher physiological activity and health-promoting effects, making it a key factor in influencing physiological functions. Studies have shown that SDF can alleviate constipation, lower cholesterol and blood sugar levels, be decomposed by intestinal microorganisms, regulate intestinal flora, and produce various short-chain fatty acids. It has a certain effect in preventing and treating colon cancer9,10,11. According to modern nutritional perspectives, daily intake of SDF can effectively regulate blood sugar and lipid levels, inhibit tumor growth, and promote intestinal digestion and absorption. Furthermore, SDF easily forms a colloidal structure, which plays an important role in food emulsification and gel formation. When used in food processing, it not only improves the texture and mouthfeel of the food but also does not affect its original taste, making it highly valuable for developing functional foods12.

Guizhou Province has abundant wild R. roxburghii resources13. Its characteristics of having many seeds, little juice, and abundant fiber make it a high-quality dietary fiber material. Approximately 1200 tons of fresh wild R. roxburghii fruits are produced annually14. However, the fruit is not being utilized reasonably, leading to significant resource waste. Factors such as altitude, climate, humidity, and light exposure cause noticeable differences in the quality and nutritional composition of wild R. roxburghii fruits from different growing regions15. However, there have been no reports on the differences in the quality of soluble dietary fiber in wild R. roxburghii among various cities and counties in Guizhou through analysis and comparison. This knowledge gap poses a challenge for the development, utilization, and quality control of SDF from wild R. roxburghii. To address this issue, the current study collected wild R. roxburghii fruits from ten different regions in Guizhou to analyze the quality characteristics of their SDF. The objective is to provide a theoretical foundation for the precise processing of wild R. roxburghii fruit, promote value-added processing, develop the R. roxburghii dietary fiber industry, and explore new applications.

Materials and methods

Materials and chemicals

All reagents used in this experiment were of analytical grade. The full spectrum microplate reader (Multiskan SkyHigh) was manufactured by Thermo Scientific, a company based in the United States. The centrifuge (H1650) was produced by Xiangyi Centrifuge Instrument Co., Ltd., located in the Changsha High-tech Industrial Development Zone. The freeze dryer (16–0362) was supplied by Yonghao Vacuum Equipment Co., Ltd. The ultrasonic cleaning machine (YM-020 S) was manufactured by Shenzhen Fangao Microelectronics Co., Ltd., in Linhai City, China. The high-performance liquid chromatography system (UltiMate 3000) was provided by Thermo Scientific. The differential refractometer (OPTILAB T-rex) was produced by Wyatt. The ion chromatography system (ICS 5000+) was supplied by Thermo Scientific. The nitrogen gas purge system (Reacti-Therm) was also provided by Thermo Scientific.

In this study, about 3 kg wild R. roxburghii fruits with consistent size and maturity from ten different regions of Guizhou Province were selected as experimental raw materials, as detailed in Fig. 1. The fruits collected above are wild and unidentified varieties.

Different environmental conditions in various regions. This map was created by ArcGIS10.8 software, which was obtained from the Geographic Information System platform developed by the Environmental Systems Research Institute company in the United States (https://gme.youqun1.cn/soft/106402.html?bd_vid=7186879175202514624#).

SDF extraction from wild R. roxburghii fruits

Following the literature with slight modifications16,17, 2.0 g of crushed wild R. roxburghii powder was weighed and added to a citric acid and sodium hydroxide solution at a ratio of 1:15 (powder to liquid) to adjust the pH to 7–8. Subsequently, 0.2% cellulase was added, and ultrasonic assistance was used for enzymatic hydrolysis for 21 min at 40 °C. The enzymatic hydrolysis continued for 41 min, followed by enzyme inactivation at 90 °C for 10 min. The suspension was then centrifuged to separate the supernatant from the precipitate. The precipitation was washed by hot-water (90 °C) three times, freeze-dried (48 h), then the water-insoluble dietary fiber (IDF) was obtained. The concentrated supernatant and washing liquor were mixed with a 95% ethanol solution at a ratio of 4:1 (v/v) and incubated at 4 °C for 24 h. The mixture was then centrifuged at 4500 r/min for 15 min, and the precipitate was collected and washed twice with 95% ethanol before being redissolved in a small amount of water. The Sevage reagent (n-butanol: chloroform = 1: 4) was used for mixing and shaking at 4000 r/min, followed by centrifugation for 10 min. After centrifugation, the Sevage reagent was removed using a rotary evaporator. A certain amount of distilled water was then added, and the mixture was placed in the refrigerator for 24 h. Finally, SDF was obtained through vacuum freeze-drying.

Structural characterization analysis

UV spectrum scanning analysis

The ultraviolet spectrum of SDF solutions (1 mg/mL) were scanned across the full-band range of 200–800 nm using a microplate reader (Multiskan GO, Thermo Fisher Scientific, Waltham, MA, USA). This procedure was carried out in accordance with methods described in previous literature18.

Fourier Transform infrared spectroscopy (FTIR) analysis

The structure and functional groups of SDF samples were analyzed by FT-IR, based on the method of19. Briefly, SDF samples were mixed with 200 mg KBr and pressed into 1 mm sheets. An FT-IR spectrometer (Nicolet iZ-10, Thermo Fisher Scientific, Waltham, MA, USA) was used for analysis in the scanning range of 4000-1–400 cm-1 with 32 scans.

Monosaccharide composition analysis

The monosaccharide composition of SDFs were determined by ion chromatography20. Briefly, SDF samples were hydrolyzed with 1 mL of 2 M triffuoroacetic acid (TFA) in a chromatographic bottle at 121°C for 2 h. The samples were dried with nitrogen, washed with 99.99% methanol and dried again under nitrogen (three times), and then dissolved in sterile water for testing. The Dionex™ CarboPac™ PA20 (150 × 3.0 mm, 10 μm) liquid chromatography column was used in the ion chromatography system (ICS5000, Thermo Fisher Scientiffc, Waltham, MA, USA). The sample size was 5 µL, and the mobile phases were A (H2O), B (0.1 M NaOH) and C (0.1 M NaOH, 0.2 M NaAc) at a flow rate of 0.5 mL/min. The column temperature was 30◦C and the elution gradient was 0–60 min.

Molecular mass analysis

The SDF samples were dissolved in 0.1 M NaNO₃aqueous solution containing 0.02% NaN₃at a concentration of 1 mg/mL and filtered through a 0.45 μm pore size filter. They were also dissolved in DMSO solution containing lithium bromide (0.5% w/w) (DMSO/LiBr) at a concentration of 1 mg/mL and filtered through a 0.45 μm pore size nylon filter membrane. The homogeneity and molecular weight of various fractions were measured using SEC-MALLS-RI. The weight-average Mw, number-average molecular weight (Mn), and polydispersity index (Mw/Mn) of various fractions in 0.1 M NaNO₃aqueous solution containing 0.02% NaN₃were measured on a DAWN HELEOS-II laser photometer (Wyatt Technology Co., USA) equipped with two tandem columns (300 × 8 mm, Shodex OH-pak SB-805 and 803; Showa Denko K.K., Tokyo, Japan) held at 45 °C using a model column heater by Sanshu Biotech Co., LTD (Shanghai, China). The flow rate was 0.6 mL/min. A differential refractive index detector (Optilab T-rEX, Wyatt Technology Co., USA) was simultaneously connected to determine the concentration of fractions and the dn/dc value. The dn/dc value of the fractions in 0.1 M NaNO₃aqueous solution containing 0.02% NaN₃was determined to be 0.141 mL/g. The homogeneity and molecular weight of various fractions in DMSO solution containing 0.5% LiBr were also measured using SEC-MALLS-RI. The weight-average Mw, Mn, and Mw/Mn of these fractions were measured on a DAWN HELEOS-II laser photometer (Wyatt Technology Co., USA) equipped with three tandem columns (300 × 8 mm, Shodex OH-pak SB-805, 804, and 803; Showa Denko K.K., Tokyo, Japan) held at 60 °C using a model column heater by Sanshu Biotech Co., LTD (Shanghai, China). The flow rate was 0.3 mL/min. A differential refractive index detector (Optilab T-rEX, Wyatt Technology Co., USA) was simultaneously connected to determine the concentration of fractions and the dn/dc value. The dn/dc value of the fractions in DMSO solution was determined to be 0.07 mL/g. Data were acquired and processed using ASTRA 6.1 (Wyatt Technology), and quantified data were output into Excel format21.

Scanning electron microscopy (SEM) analysis

The molecular morphologies of SDF samples were observed using a scanning electron microscope (Zeiss Merlin Compact, Germany). The samples, coated with a thin gold layer, were placed on the substrate. Images were then captured at magnifications of 500×, 5000×, and 10,000× under high vacuum by Sanshu Biotech Co., LTD (Shanghai, China)22.

X-ray diffraction (XRD) analysis

The XRD spectra of the SDF samples were obtained using a diffractometer (D8, Bruker, Saarbrucken, Germany) within the scanning range of 5–80° (40 kV, 40 mA)23.

Physicochemical properties

Oil holding capacity

This procedure was adapted from a previously established method with slight modifications10. Accurately weigh 0.100 g of wild R. roxburghii fruit SDF, add 5 mL of vegetable oil, and mix thoroughly. Allow the mixture to stand at 4 °C in a refrigerator for 24 h. Centrifuge at 4500 rpm for 15 min to remove the supernatant, then use blotting paper to absorb any remaining residue. Finally, measure the wet weight of the sample.

Swelling capacity

Following the method with slight modifications10. Weigh 0.300 g of wild R. roxburghii fruit SDF into a graduated test tube and record the initial volume. Add 8 mL of distilled water to the test tube, allow it to stand at room temperature for 12 h, and then measure the free swelling volume of the sample.

Foaming properties and foam stability

Referring to the previously established method with slight modifications24. After high-speed stirring of a 0.01 g/mL SDF solution of wild R. roxburghii fruit in a homogenizer for 3 min, quickly transfer the solution and foam into a 100 mL measuring cylinder. Immediately record the volume occupied by the foam and, after 30 min, record the retained foam volume. Use egg white as a control sample.

Chemical composition

Total sugar content

Following the previously established method with slight modifications25. Accurately weigh 1.000 g of glucose standard into a 100 mL volumetric flask, dissolve, and dilute to the mark to obtain a concentration of 10 mg/mL. Prepare glucose standard solutions by transferring 0.0, 0.1, 0.2, 0.3, 0.4, and 0.5 mL into separate 10 mL volumetric flasks. Add 1 mL of 5% phenol to each flask, mix well, then add concentrated sulfuric acid. Heat the mixtures in a boiling water bath for 20 min and rapidly cool to room temperature. Measure the absorbance at 490 nm. Plot a standard curve with the glucose concentration (mg/mL) on the x-axis and absorbance (A) on the y-axis. Prepare a 20 µg/mL solution of wild R. roxburghii fruit SDF and follow the same procedure to calculate the glucose concentration. Determine the total sugar content in the sample using the standard curve.

Protein content

Following the method with slight modifications26. Accurately measure 1.000 g of the sample into a 100 mL volumetric flask to achieve a concentration of 10 mg/mL. Prepare a 0.1 g/L protein standard solution and transfer 0.03, 0.06, 0.12, 0.24, 0.48, 0.72, 0.84, and 0.96 mL of the protein standard solution into separate 10 mL volumetric flasks, adjusting the volume with distilled water. Add 5 mL of Coomassie Brilliant Blue G-250 solution to each flask, mix gently, and let stand for 5 min. Measure the absorbance at 595 nm using a spectrophotometer and plot the standard curve. Prepare a 10 mg/mL SDF solution and follow the same procedure to calculate the protein content in the wild R. roxburghii fruit SDF.

Antioxidant activity

The methods for determining the scavenging abilities of ABTS and DPPH free radicals were referenced and slightly modified27.

ABTS free radical scavenging capacity

Weigh a specific amount of ABTS and potassium persulfate into a 10 mL volumetric flask, then mix the two solutions. After allowing the mixture to stand in the dark for 12 h, obtain the ABTS working solution. Before use, dilute this solution with ethanol to achieve an absorbance of approximately 0.7 at 734 nm. In a 96-well plate, mix 50 µL of wild R. roxburghii fruit SDF extract at various concentrations (20, 40, 60, 80, 100 µg/mL) with 150 µL of ABTS working solution. Use 50 µL of ethanolic extract as the control group, along with 150 µL of ABTS working solution. Incubate in the dark for 30 min, then measure the absorbance at 734 nm.

DPPH free radical scavenging capacity

Accurately measure 4 mg of DPPH, dissolve in 95% methanol, and dilute to 100 mL. In a 96-well plate, mix 50 µL of wild R. roxburghii fruit SDF extract at various concentrations (40, 80, 120, 160, 200 µg/mL) with 150 µL of DPPH solution. After thorough mixing, allow the mixture to stand at room temperature for 20 min, then measure the absorbance at 517 nm, using a 95% methanol solution as the blank. As a negative control, measure the absorbance of a mixture of 50 µL of 95% methanol solution and 150 µL of DPPH methanol solution.

The application properties of R. Roxburghii fruit SDF in yogurt

Following a slightly modified method28, preheat the raw milk to 55 ~ 60 ℃ and maintain this temperature for 10 min. Add 8% white sugar and 0.5% wild R. roxburghii fruit SDF, stirring thoroughly. Process the mixture at 90 ~ 95 ℃ for 8 ~ 10 min, then rapidly cool to 40 ℃ ~ 42 ℃. Incorporate lactobacillus powder, seal the mixture, and ferment for 6 h. After fermentation, cool the yogurt and allow it to mature at 4 °C for 24 h before consumption. A blank experiment without wild R. roxburghii fruit SDF serves as the control group.

Titration of acidity

Combine 10 g of yogurt with 20 mL of distilled water in a 150 mL conical flask. Add 0.5 mL of 0.5% phenolphthalein solution as an indicator. Titrate with 0.1 mol/L NaOH standard solution until a faint pink color persists for 30 s. Record the volume of NaOH used.

pH

Store the yogurt for 1 ~ 3 days. Stir the sample for 30 s to ensure uniformity, then measure the pH value using a pH meter.

Water solubility

Weigh 8 g of yogurt sample and place it into a 50 mL centrifuge tube. Centrifuge the sample at 3500 rpm for 20 min. Remove and weigh the supernatant.

Texture and structure

Set the device to measure in the mode for old yogurt. Configure the test program with the following parameters: descent speed at 1.0 mm/s, testing speed at 1.0 mm/s, return speed after testing at 1.0 mm/s, trigger force at 5 g, shape variable at 50%, and dwell time between compressions at 10 s. Analyze and output the test data using computer software.

Results and discussion

Structural characterization analysis

Spectral analysis of SDF

As shown in Fig. 2a, the wild R. roxburghii fruit SDF samples sourced from various regions exhibited a distinct absorption peak at 280 nm. This peak suggested the presence of minor impurities, such as nucleic acids or proteins, in the wild R. roxburghii fruit SDF.

The Fourier-transform infrared (FT-IR) spectra in Fig. 2b revealed that the infrared absorption profiles of R. roxburghii fruits from different regions are relatively similar, although some differences in wavelength are evident. The absorption peak near 2935.07 cm⁻¹ corresponds to the stretching vibration of methyl or methylene C-H groups, indicating the presence of O-H and C-H groups in the SDF structure29. Absorption peaks around 1588.81 cm⁻¹ suggested the presence of carboxyl and carbonyl groups, indicating the existence of aldonic acids. Peaks in the range of 1000–1200 cm⁻¹ are attributed to the stretching vibration of the C-O-H pendant group, the C-O-C glycosidic bond vibration of the pyranose ring, and the stretching vibration of the asymmetric ring30. Analysis of these functional groups indicated that SDFs sourced from different regions all contain polysaccharide-specific functional groups, confirming that they possess typical polysaccharide structures with subtle compositional variations.

Monosaccharide composition of the SDF

The composition of monosaccharides was a significant factor influencing the structural characteristics of dietary fiber, as well as being intricately linked to its biological activity. The monosaccharide profile of the SDFs derived from wild R. roxburghii fruits were meticulously outlined in Table 1. The SDF primarily consisted of glucose (41.57-75.63%), followed in abundance by galacturonic acid (10.90-22.01%), galactose (7.68-17.48%), arabinose (6.66-11.87%), and rhamnose (2.37-7.13%). In the SDF extracted from region LP, the glucose concentration peaked at 75.63%. This elevated glucose level indicates that glucan likely constitutes the principal framework of the SDF from wild R. roxburghii fruit, with other monosaccharides serving as side chain branches. Conversely, in the AZ region, the glucose content was recorded at its lowest level of 41.57%. This variation may be attributed to the differences in active ingredients present31. The SDFs sourced from various regions exhibited distinct concentrations of galacturonic acid, thus confirming its classification as an acidic polysaccharide, which aligns with the findings from the infrared spectroscopy analysis. Furthermore, the SDFs extracted from these regions showed varying levels of rhamnose, arabinose, and galactose, indicating these SDFs are acidic heteropolysaccharides with a minor presence of pectin. The presence of pectin and large amounts of glucose may confer a prebiotic effect on SDF from wild R. roxburghii fruit, which lowers blood sugar levels and enhances fermentation by intestinal microbiota16.

Molecular mass analysis

According to Table 2, there were considerable differences in molecular weight among the various samples. The SDF sourced from the LP region exhibited higher number average molecular weight, weight average molecular weight, and peak molecular weight in comparison with other regions. The results indicated that the SDF sourced from the LP region may contain more monomer units, and the macromolecules occupy the dominant position in the molecular weight distribution of the polysaccharide, and a relatively concentrated high molecular weight distribution region may be formed1. The z-average molecular weight of the SDF sourced from the QP region was higher than that of other regions. In contrast, the SDF sourced from ZR region possessed the lowest number-average molecular weight and peak molecular weight, suggesting greater molecular dispersion32. Considered that relatively high molecular weight could improve the apparent viscosity of SDF, which is beneficial for its biological activity. However, relatively lower molecular weight can improve the water solubility of polysaccharides and make them more bioactive. Therefore, this may be due to differences in biological activity18.

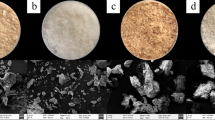

Surface morphology

Scanning electron microscopy (SEM) were employed to examine the microstructure of SDFs. Figure 3 revealed notable variations in the SDF structures from different regions. At 500× magnification, SDFs sourced from TR, BD, QP, ZR, LP, LZ, and QK region displayed irregular, fragmented, flake-like structures. In contrast, the SDF sourced from QX region exhibited a smooth and uniform texture. The SDF sourced from AZ region showed pronounced wrinkles and a slightly fluffy texture. At higher magnifications of 5000× and 10000×, further distinctions emerge. The SDF sourced from TR region featured wrinkles and curls reminiscent of wood ear fungi, while the SDF sourced from QP region appeared as spherical particles. The SDF sourced from LP is relatively smooth with minor wrinkles, presenting a dense, silk-like flat structure. The SDF from LZ region exhibited numerous small holes, resembling a honeycomb. These structure properties may increase the surface area of the polysaccharide, which facilitate water absorption in the intestinal tract, increase the satiety, and improve the adsorption apacity of wild R. roxburghii fruit SDF. However, the SDF sourced from QX region formed cubic, sugar-like blocks. These structural differences in SDFs may be related to variations in monosaccharide composition and strong intermolecular interactions33. Additionally, factors such as altitude, temperature, and regional climate could influence the structural characteristics of wild R. roxburghii fruit SDFs.

X-ray diffraction (XRD) analysis

The crystalline structure of SDF directly governed its tensile strength, flexibility, solubility, expansibility, and other physical properties. XRD was capable of characterizing the phase of the sample and precisely determining the crystal structure and crystallinity of the sample. The form of the diffraction peak could mirror the material structure. The sharp and narrow peak was corresponding to the crystal structure, while the wide peak was corresponding to the amorphous structure34. Figure 4 illustrated that the XRD patterns of wild R. roxburghii fruit SDFs sourced from various regions were similar, with broad and smooth diffraction peaks around 19° to 21°. These broad peaks suggested that the SDF is predominantly amorphous, akin to the crystalline structure of cellulose, and may also reflect contributions from the amorphous portion of the material35. There are variations in diffraction intensities among the samples, with the SDF sourced from LP region showed the highest diffraction intensity and the SDF from AZ the lowest. Overall, wild R. roxburghii fruit SDF from different regions exhibited a lower degree of crystalline structure and demonstrates an amorphous arrangement. These differences may be attributed to geographical ___location, environmental conditions, and other regional factors, which contribute to the variability observed in the XRD patterns of SDF from different topographic areas.

Physicochemical properties of SDF

The oil-holding capacity was a crucial property for food applications, reflecting a material’s ability to retain oil and thus reduce oil loss. Swelling capacity measures the hydration ability of dietary fibers36, while foaming properties were essential for the quality of various food products, including milk, ice cream, whipped cream, cakes, and bread37. Foam stability refereed to the foam’s ability to remain intact after formation, and was influenced by numerous challenging factors38. As shown in Table 3, the SDF sourced from QP region demonstrated a significantly higher oil-holding capacity (8.81 g/g) compared to other regions (p < 0.05), A high OHC of dietary fiber can guarantee the stabilization of high-fat food and dairy products39. Conversely, the SDF sourced from ZR and ZS regions exhibited the poorest oil-holding capacity, with values of 1.67 g/g and 1.63 g/g, respectively. The swelling and stability of SDF sourced from AZ region were notably higher than those from other regions (p < 0.05), although the SDF sourced from QP had the lowest swelling ability (0.12 mL/g) among the regions studied. The SDF sourced from TR region showed significantly better foaming properties compared to other regions (p < 0.05), while other regions, including QK region, exhibited relatively poor foaming ability, with QK region showing the lowest foam stability. These physicochemical properties of wild R. roxburghii fruit SDF sourced from different regions indicate their future application prospects in the food industry .

Chemical composition analysis

As illustrated in Fig. 5a, the total sugar content of SDF in wild R. roxburghii fruit varies significantly across the 10 different regions tested. Specifically, the SDFs sourced from QP, LZ, and QK regions exhibited relatively low total sugar content, with the SDF sourced from LZ region being the lowest at an average of approximately 12.91%. Conversely, the SDF sourced from ZS region showed a markedly higher total sugar content, averaging 58.63%, which was significantly greater than that of other regions (p < 0.05). Figure 5b further demonstrated that the protein content of wild R. roxburghii fruit SDF also varied in different regions. The SDF sourced from BD region stood out with significantly higher SDF protein content compared to other regions, while the SDF sourced from ZS region possessed the lowest protein content. However, all values fell within the range of 8.61–11.69%. These findings were consistent with those depicted in Fig. 2a. It is worth noting, these nutrients suggested that wild R. roxburghii fruit SDF may be useful as a high-protein and low-calorie ingredient for healthy diets. This result was the same as that reported in reference40, which showed that the protein content of SDF obtained by cellulase extraction was significantly higher than that obtained by hot water extraction. In addition, the literature showed that compared with hot water extraction, cellulase extraction exhibited higher crystallinity, higher thermal stability and more porous structure. In addition, cellulase extraction showed higher water retention, oil retention, water solubility, nitrite ion absorption capacity, antioxidant activity and α-glucosidase inhibitory activity. These findings suggested that high-protein SDF may be a potential functional food as well as a promising natural source of dietary fiber.

Analysis of antioxidant activity results

The IC50 values presented in Table 4 revealed that the scavenging ability becomes stronger as the required concentration decreases. Within a specific concentration range, the scavenging activity of SDF against ABTS and DPPH free radicals increased with higher SDF concentrations40. Notably, the SDF sourced from BD region exhibited a significantly greater scavenging effect on ABTS free radicals (p < 0.05), while the SDF sourced from TR region demonstrated a markedly higher ability to scavenge DPPH free radicals compared to other SDFs (p < 0.05). It was evident from Tables 2 and 3 that the value of Mw/Mn, the content of protein and foamability in SDF sourced from BD and TR regions were more prominent. And these findings suggested that the antioxidant activity of wild R. roxburghii fruit SDFs were influenced by a combination of factors, including structural characteristics, monosaccharide composition, molecular weight, and physicochemical properties41,42. Meanwhile, variations in altitude, regional conditions, and environmental factors may all contribute to differences in antioxidant activity among SDF samples from different regions.

Applicational properties of SDF analysis in yogurt

The applicational properties of SDFs significantly influenced the characteristics of the yogurt supplements they were incorporated into. As demonstrated in Fig. 6a and b, the values titration acidity (TA) of the yogurt in all regions where SDFs were added were notably higher than that of the control group (p < 0.05). Notably, the acidity in the yogurt added the SDF sourced from QP region was the highest, accompanied by a lower pH. This increase in acidity and decrease in pH were attributed to the growth and lactic acid production of lactic acid bacteria, suggesting that the addition of SDFs enhanced the acid-producing capacity of these bacteria. The rate of acid production was also crucial for yogurt gel formation, as a slower rate led to delayed gelation, larger casein particles, and a looser yogurt structure.

Moreover, the titratable acidity and pH were key indicators of yogurt quality. Excessively high titratable acidity or low pH could result in increased syneresis and undesirable flavors, ultimately compromising the yogurt’s taste and sensory scores43. The pH values of the SDF-containing yogurts ranged from 4.19 to 4.67. These changes might be related to the bacterial metabolism during yogurt fermentation and storage, which breaks down dietary fiber in SDFs to produce lactic acid and other organic acids44.

In addition to acidity and pH, the water-holding capacity (WHC) of yogurt, which impacts its texture and structure, was also influenced by the SDFs. Generally, the compact structure of SDFs was disrupted by fermentation into a porous structure with smaller particle sizes, exposing more hydrophilic and lipophilic groups. This structural transformation facilitated the easy penetration and absorption of water and oil molecules10. As shown in Fig. 6c, the addition of wild R. roxburghii SDF significantly improved the water retention effect compared to the control group (p < 0.05). This enhancement was likely due to the hydrophilic groups in SDFs, which improved water binding and immobilization in yogurt, reducing water separation and slightly enhancing the WHC. Notably, the water retention capacity of wild R. roxburghii fruit SDF from ten different regions was particularly effective.

In summary, the functional properties of SDFs, including their ability to enhance acid production, influence pH and titratable acidity, and improve water-holding capacity, significantly affected the quality and sensory characteristics of the yogurt supplements.

As indicated by the results from the texture analyzer presented in Table 5, the firmness and adhesiveness of the yogurt containing SDFs sourced from different regions were notably higher than those of the control group (p < 0.05). This enhancement in firmness and adhesiveness could be attributed to the polysaccharides in SDFs, which had the ability to bind with water. This binding action enhanced the stability of the fermented milk and strengthens the internal molecular interactions within the yogurt matrix. As a result, there was a promotion of aggregation among larger molecules, leading to an increase in both the firmness and thickness of the yogurt45.

Notably, the yogurt samples containing SDF sourced from LP region exhibited the highest firmness and consistency. This observation may be linked to the higher molecular weight of the polysaccharides present in these SDFs, which could contribute to a more robust and cohesive yogurt structure. Therefore, the applicational properties of the SDFs, particularly their polysaccharide composition and molecular weight, play a crucial role in determining the textural quality of the yogurt supplements.

Conclusions

The quality characteristics of wild R. roxburghii fruit SDFs sourced from different regions exhibited significant variability. Notably, the total sugar content of SDF sourced from ZS region was markedly higher than that of other regions (p < 0.05), while the SDF sourced from QP region demonstrated remarkable oil holding capacity (8.8071 g/g). Conversely, the SDF sourced from AZ region exhibited outstanding swellability (1.0889 mL/g) and stability (41.90%), with higher contents of arabinose, rhamnose, and galactose compared to other regions (p < 0.05). The SDF sourced from TR region stood out with significantly higher foaming properties (726.68% foaming capacity) than other regions (p < 0.05).

In terms of structural characterization, the SDF isolated from wild R. roxburghii fruits across different regions displayed wide peaks at approximately 19° to 21°, indicating a low crystal structure. The infrared absorption spectra of these SDF samples are similar, with comparable absorption peaks, albeit with slight variations in wavelength. All samples possessed the typical structure of polysaccharide compounds, comprising glucose, galacturonic acid, galactose, arabinose, and rhamnose. However, the surface morphology differs among regions. Notably, SDFs sourced from BD and TR regions exhibited excellent antioxidant activity, warranting further research to explore its potential therapeutic applications and health benefits.

Regarding the application of these SDFs, the titratable acidity, water holding capacity, solidity, and consistency of SDF-yogurt prepared from various regions were significantly higher than those of the control group. These findings provided a scientific basis for the development of R. roxburghii-based products for food and nutrition. Moreover, they offered valuable insights for the exploitation and utilization of wild R. roxburghii fruit resources, as well as for the production, processing, and in-depth industrial development of this plant.

In conclusion, the degree of variability among regions in the important parameters evaluated, such as physicochemical properties, functional properties, and structural characteristics, has significant implications for the efficient industrial use of this dietary fiber source. Further research is necessary to fully understand and harness the potential of R. roxburghii’s SDF for various applications in the food and nutrition industry.

Data availability

Data are contained within the article.

References

Huang, Y. et al. Influence of three modification methods on the structure, physicochemical, and functional properties of insoluble dietary fiber from R. Roxburghii Pomace. Molecules 29, 2111 (2024).

Oktay, B., Yolaçaner, E. & Aytaç S.Ultrasound-assisted extraction of betalain-rich bioactive compounds of prickly pear fruit: an optimization study. Food Biosci. 61104734–61104734. (2024).

Yin, F. et al. Genome-wide identification of Rosa roxburghii CML family genes identifies an RrCML13-RrGGP2 interaction involved in calcium-mediated regulation of ascorbate biosynthesis. Plant Physiol. Biochem.. 214108874–214108874. (2024).

Jain, A., Sarsaiya, S., Gong, Q., Wu, Q. & Shi, J. Chemical diversity, traditional uses, and bioactivities of rosa roxburghii tratt: A comprehensive review. Pharmacol. Ther. 259. (2024).

Yin, C. et al. Exploring rosa roxburghii tratt polysaccharides: from extraction to application potential in functional products - an in-depth review. Int. J. Biol. Macromol. 280. (2024).

Yang, Z. & Chen, G. Inhibition of proliferation and induction of apoptosis in Prostatic Carcinoma DU145 cells by polysaccharides from Yunnan Rosa roxburghii Tratt. Molecules 29, 1575 (2024).

Song, Y. et al. Optimization of composite enzymatic extraction, structural characterization and biological activity of soluble dietary fiber from Akebia Trifoliata peel. Molecules 29, 2085 (2024).

Kang, Z. et al. Dynamic high pressure microfluidization modified oat dietary fiber: Texture modulation and its mechanistic in whole grain oat milk. Food Hydrocoll. 157110418–157110418. (2024).

Zhang, S., Xu, X., Cao, X. & Liu, T. The structural characteristics of dietary fibers from Tremella fuciformis and their hypolipidemic effects in mice. Food Sci. Hum. Wellness. 12, 503–511 (2023).

Wang, X. et al. Characterization of physicochemical and functional properties of soluble dietary fiber from separate and co-fermented okara by lactic acid bacteria and Kluyveromyces Marxianus C21. LWT. 205116476–205116476. (2024).

Li, M. & Ma, S. A review of healthy role of dietary fiber in modulating chronic diseases. Food Res. Int. 191114682–191114682. (2024).

Zhang, S. S., Duan, J. Y., Zhang, T. T., Lv, M. & Gao, X. G. Effect of compound dietary fiber of soybean hulls on the gel properties of myofibrillar protein and its mechanism in recombinant meat products. Front. Nutr. 10, 1129514 (2023).

Wang, L. et al. Recent advances on main active ingredients, pharmacological activities of Rosa roxbughii and its development and utilization. Foods 12, 1051. (2023).

Niu, Y. et al. Characterization of volatile compounds of R. Roxburghii by gas chromatography olfactometry, quantitative measurements, odor activity value, and aroma intensity. Molecules 26, 6202 (2021).

Yu, L., Zhao, Z., Zhang, W. & Ren, T. Comparative comprehensive quality analysis of Rosa roxburghii fruit from different regions in Guizhou province. Mod. Food Sci. Technol. 37 (9), 169–178 (2021).

Yu, P. et al. Ultrasound-assisted enzymatic extraction of soluble dietary Fiber from Hericium erinaceus and its in vitro lipid-lowering effect. Food Chemistry: X, 23101657-101657. (2024).

Li, M. et al. A polysaccharide PRCP from Rosa Cymosa Tratt fruit: Structural characteristics and immunomodulatory effects via MAPK pathway modulation in vitro. Int. J. Biol. Macromol. 276, 133025–133025 (2024).

Tan, X. et al. Characterization and function analysis of soluble dietary fiber obtained from radish pomace by different extraction methods. Molecules 29, 0500 (2024).

Vandanjon, L. et al. The use of FTIR spectroscopy as a tool for the seasonal variation analysis and for the quality control of polysaccharides from seaweeds. Mar. Drugs. 21, 482 (2023).

Zhu, M. et al. Structural characterization and immunological activity of pectin polysaccharide from kiwano (Cucumis metuliferus) peels. Carbohydr. Polym. 254, 117371 (2021).

Shen, S. et al. Structures, physicochemical and bioactive properties of polysaccharides extracted from Panax notoginseng using ultrasonic/microwave-assisted extraction. LWT 154, 112446 (2022).

Wu, J. et al. Structural differences of polysaccharides from Astragalus before and after honey processing and their effects on colitis mice. Int. J. Biol. Macromol. 182, 815–824 (2021).

Chen, P. et al. Application of X-ray diffraction and energy dispersive spectroscopy in the isolation of sulfated polysaccharide from Porphyra haitanensis and its antioxidant capacity under in vitro digestion. J. Sci. Food. Agric. 101, 6452–6462 (2021).

Zhao, X. et al. Modifying the physicochemical properties, solubility and foaming capacity of milk proteins by ultrasound-assisted alkaline pH-shifting treatment. Ultrason. Sonochem. 88, 106089 (2022).

Isamu, O., Miyuki, S., Rie, T., Hiroyuki, M. & Tomohiko, M. Optimization of microplate-based phenol-sulfuric acid method and application to the multi-sample measurements of cellulose nanofibers. Anal. Biochem. 681115329–681115329. (2023).

Lv, D., Chen, J. & Yang, C. The physicochemical properties and antioxidant activities of the hawthorn pectin extracted using ultra-high pressure assisted acid extraction (UPAAE). Foods 13, 983 (2024).

Yu, Q. et al. Preparation, characterization, and antioxidant activities of extracts from Amygdalus persica L. Flowers. Molecules 29, 633 (2024).

Dong, R. et al. Enrichment of yogurt with carrot soluble dietary fiber prepared by three physical modified treatments: microstructure, rheology and storage stability. Innovative Food Sci. Emerg. Technol. 10290. (2021).

Jun, L. et al. Physicochemical characterization and antimicrobial analysis of vegetal chitosan extracted from distinct forest fungi species. Polymers 15, 2328 (2023).

Cheng, Z., Zheng, Q., Duan, Y., Cai, M. & Zhang, H. Effect of subcritical water temperature on the structure, antioxidant activity and immune activity of polysaccharides from Glycyrrhiza Inflata Batalin. Int. J. Biol. Macromol. 261, 129591 (2024).

Abaidullah, M. et al. Polysaccharide from smilax glabra roxb mitigates intestinal mucosal damage by therapeutically restoring the interactions between gut microbiota and innate immune functions. Nutrients 15, 4102 (2023).

Cheng, L. et al. Characterisation of physicochemical and functional properties of soluble dietary fibre from potato pulp obtained by enzyme-assisted extraction. Int. J. Biol. Macromol. 1011004–1011011. (2017).

Shen, Y. et al. The isolation, structural characterization and anti-inflammatory potentials of Neutral polysaccharides from the roots of Isatis Indigotica Fort. Molecules 29, 2683 (2024).

Chao, C. et al. Isolation, purification, structure characterization and antibacterial activity of polysaccharides from proso millet bran. Sci. Technol. Food Ind. 45, 1–7 (2024).

Mojo-Quisani, A. et al. Characterization of nano- and microstructures of native potato starch as affected by physical, chemical, and biological treatments. Foods 13, 2001 (2024).

Fan, R. et al. Characterization of the structure and physicochemical properties of soluble dietary fiber from Peanut shells prepared by pulsed electric fields with three-phase partitioning. Molecules 29, 1603 (2024).

Deng, M. et al. Physicochemical and functional properties of dietary fiber from pummelo (Citrus grandis L. Osbeck) and grapefruit (Citrus Paradisi Mcfad) cultivars. Food Biosci. 40, 100890 (2021).

Ye, M. et al. Effects of drying methods on the physicochemical and functional properties of Cinnamomum camphora seed kernel protein isolate. Foods. 13 968. (2024).

Li, W., Yang, H., Coldea, T. E. & Zhao, H. Modification of structural and functional characteristics of brewer’s spent grain protein by ultrasound assisted extraction. LWT-Food Sci. Technol. 139, 110582 (2021).

Li, P., Li, C., Fu, X., Huang, Q. & Chen, Q. Physicochemical, functional and biological properties of soluble dietary fibers obtained from Rosa roxburghii Tratt pomace using different extraction methods. Process Biochem. 128, 40–48 (2023).

Hua, M. et al. Functional soluble dietary fiber from ginseng residue: Polysaccharide characterization, structure, antioxidant, and enzyme inhibitory activity. J. Food Biochem. 44, e13524–e13524 (2020).

Khan, A. A. et al. Comparative analysis of physicochemical properties and biological activities of crude polysaccharides isolated from selected Auricularia cornea strains. Food Biosci. 60104486. (2024).

Peng, F. et al. Physicochemical property, and functional activity of dietary fiber obtained from pear fruit pomace (Pyrus ussuriensis Maxim) via different extraction methods. Foods. 11 2161. (2022).

Qin, X. et al. Fortified yogurt with high-quality dietary fiber prepared from the by-products of grapefruit by superfine grinding combined with fermentation treatment. LWT, 188. (2023).

Tian, Y., Sheng, Y., Wu, T. & Wang, C. Effect of modified okara insoluble dietary fibre on the quality of yoghurt. Food Chemistry: X, 21101064. (2024).

Radzki, W., Skrzypczak, K., Sołowiej, B., Jabło ´nska-Ry´s, E. & Gustaw, W. Properties of yogurts enriched with crude polysaccharides extracted from Pleurotus Ostreatus cultivated mushroom. Foods 12, 4033 (2023).

Funding

This research was funded by the Natural Science Foundation of Guizhou Province (ZK[2023]451); Engineering Research Center Program of Guizhou Provincial Education Department (KY[2020]022); Zunyi Technology and Big Data Bureau, Moutai Institute Joint Science and Technology Research and Development Project (ZSKHHZ[2021] No. 308); Research Foundation for Scientiffc Scholars of Moutai Institute (mygccrc[2022]091); Guizhou Provincial Innovation and Entrepreneurship Training Program for College Students (S202214625027X).

Author information

Authors and Affiliations

Contributions

Conceptualization, methodology, writing—review and editing, Y.S.; supervision, Y.S., H.Z. and S.Y.; Investigation, Q.L., Y.L. C.L., X.B. and Y.M.; methodology, Y.L., Z.Y. and N.N.; writing—original draft, funding acquisition, S.Y. and H.Z. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Song, Y., Li, Q., Liu, Y. et al. Discrepancy on the quality characteristics of soluble dietary fiber in wild Rosa roxburghii Tratt fruits from different regions. Sci Rep 15, 8289 (2025). https://doi.org/10.1038/s41598-025-86002-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-86002-1