Abstract

The study is based on applying Artificial Neural Network (ANN) based machine learning and Response Surface Methodology (RSM) as simultaneous bivariate approaches in developing controlled-release rivaroxaban (RVX) osmotic tablets. The influence of different types of polyethylene oxide, osmotic agents, coating membrane thickness, and orifice diameter on RVX release profiles was investigated. After obtaining the trial formulation data sets from Central Composite Design (CCD), an ANN-based model was trained to get the optimized formulations. The Physiological-based Pharmacokinetic (PBPK) modeling of the predicted formulation was performed by GastroPlus™ to simulate in vivo plasma profiles under fasting and fed conditions. In vitro release tests showed zero-order RVX release for up to 12 h. Using graphical and numerical methods, the predicted formulation generated by the prediction profiler was cross-validated by the CCD-based optimized formulation. Analysis of Variance (ANOVA) findings revealed no significant difference between the predicted and optimized formulations and these formulations have a shelf life of 22.47 and 17.87 months, respectively. The PBPK modeling of RVX push-pull osmotic pump (PPOP) tablets suggested enhanced bioavailability in the fasted (up to 82%) and fed (up to 98.5%) state compared to immediate-release tablets. The results indicated that ANN can be effectively used for osmotic systems due to their complex nature and nonlinear interactions between dependent and independent variables.

Similar content being viewed by others

Introduction

Thromboembolic diseases are a leading source of morbidity and mortality associated with some of the most severe health conditions, such as pulmonary embolism (PE), deep vein thrombosis (DVT), stroke, and myocardial infarction (MI). Warfarin is the most widely used oral anticoagulant, with annual prescriptions typically equal to 0.5–1.5% of the population1,2. Direct oral anticoagulants targeting the single coagulation factor (Xa or thrombin) have been developed in recent years to circumvent the limitations of traditional anticoagulants3. Rivaroxaban (RVX) is an oral, direct Factor Xa inhibitor that has been licensed in over 100 countries for the prevention and treatment of venous thromboembolism (VTE) after elective hip or knee replacement surgery, as well as stroke prevention in individuals with nonvalvular atrial fibrillation4. Several dosage strengths of rivaroxaban immediate-release tablets 2.5, 5, 10, and 20 mg have shown dose-dependent food effects. The highest dose strength tablet (20 mg) should be taken with food to achieve the favorable food effect for oral absorption and systemic availability, while the lower dose (10 mg or less) can be taken with or without food5. One approach to address the food effects on drug bioavailability is developing osmotically controlled drug delivery systems (ODDSs).

Osmotically controlled-release dosage formulations represent a significant advancement in drug delivery systems, offering distinct advantages over matrices and reservoir-based oral controlled-release systems. The osmotic pressure generated within the tablet’s core serves as a driving force to control the drug release at a constant rate, independent of GI motility, pH, or food. Push-pull osmotic pump (PPOP) tablet systems consist of bilayer tablets, which are preferred over elementary osmotic pump (EOP) systems for achieving consistent and predictable drug release rates6,7. One layer holds the drug and an osmotic agent, while the other contains an osmopolymer or a hydrophilic expansion polymer. The swelling of the push layer in an aqueous environment aids in the drug release at a zero-order rate and produces a driving force against the drug layer. The drug suspension produced in the drug layer then comes out through the orifice8. Numerous benefits are associated with these dosage forms, like constant drug levels at the site of action, no peak fluctuations, lesser dosing frequency, fewer side effects, and better patient compliance6.

Pharmaceutical companies are investing billions of dollars in fostering the development of high-quality products and drug discoveries. As the FDA assesses the application’s process design’s execution and efficacy and risk management for a successful technology transfer from the lab to the production level, Quality by Design (QbD) has become crucial for product approval9. QbD aims to improve understanding of pharmaceutical products and manufacturing processes. Developing pharmaceutical products based on the QbD-based methodology entails complete compliance with a well-defined roadmap10. On the other hand, artificial neural networks (ANNs) are an efficient muti-variate pharmaceutical formulation optimization tool that can be applied as an efficient alternative methodology for product development. The ANN computational model is a non-linear predictor regression model due to better predictive capacity11. Multi-layer perception (MLP) models are among the most successful types of ANNs, with a fully connected network consisting of one or more layers built from datasets. Still, many ANN models are mostly built with one hidden layer and minimum numbers of input variables to avoid confounding12. Software like CAD/Chem, INForm, JMP-Pro, MATLAB, etc., are used to build ANN models for developing pharmaceutical products.

Physiologically based pharmacokinetic (PBPK) modeling is a predictive tool and used for analyzing and assessing pharmacokinetic data. Depending on the intended use and the degree of knowledge regarding the drug’s properties, PBPK models can include different levels of physiological complexity and drug disposition and elimination processes13. The clinical pharmacokinetic studies of RVX show significant inter-individual variability, most likely due to its numerous elimination routes14, variable mechanism of metabolism (breakdown by CYP3A4), and P-glycoprotein (Pgp)-dependent efflux15. CYP superfamily is the most abundant and critical enzyme family, responsible for over 75% of drug metabolism in humans16. The complex pharmacokinetics of RVX can be predicted by PBPK modeling without intensive in vivo studies, and only physicochemical, physiological, and formulation factors are considered when building a PBPK model. PBPK models provide a rational basis for data integration and can predict both the extent and rate of uptake17. Softwares such Kinetica, Phoenix, Symcyp, GastroPlus, etc., are the most reported for predicting pharmacokinetic profiles from in vitro dissolution data by integrating various physiological and drug-related parameters and simulating different demographic groups18,19.

The present work describes the simultaneous application of Artificial Neural Network (ANN) and Central Composite Design (CCD)-based Response Surface Methodology (RSM) techniques as multivariate systematic approaches for developing a robust and reproducible methodology for designing and optimizing push-pull osmotic tablets of RVX, a poorly soluble BCS class II drug with moderate inter-personal pharmacokinetic variability20. The input variables, like type and concentration of polyethylene oxides (PEOs), osmogen amount (sodium chloride), drug loading capacity, coating weight gain, and orifice size, were initially screened and optimized by numerical and graphical techniques. Finally, the developed ANN model was used to generate a prediction profiler. The application of ACAT (Advanced Compartmental and Transit) based developed and optimized PBPK model using GastroPlus™ was also demonstrated as a predictive tool for obtaining the in vivo pharmacokinetic profile of the optimized formulation (Fpred). The current work aimed to develop an interpretable bivariate approach using ANNs and QbD in any data-rich production step i.e. from the formulation design to the quality assurance of the final dosage form in line with Gastroplus™ as a well-established PBPK modeling tool.

Materials and methodology

Materials and chemicals

Rivaroxaban was gifted from Searle Pharmaceuticals (Karachi, Pakistan). Opadry® CA and PEOs (WSR N-10 NF, WSR N-750 NF, WSR N-80 NF, WSR-301 NF, WSR-303 LEO, and WSR Coagulant) were kindly provided by Colorcon Limited (Kent, United Kingdom). Avicel™ PH-101, Aerosil™ 200, and Magnesium Stearate were purchased from FMC Corporation (United States). Sodium Hydroxide, Potassium dihydrogen Phosphate, sodium chloride, Acetonitrile, Methanol, and hydrochloric acid [37–38% w/w] were purchased from Merck (Germany). All other chemicals utilized during the study were of analytical grade.

Screening of formulation parameters to develop Rivaroxaban PPOP tablets

The initial screening of formulation variables like the concentration and grade of Polyethylene oxide (PEO), sodium chloride (NaCl) amount, coating weight gain percent, and orifice diameter, was performed in both the layers (push and pull) to identify their suitability for developing PPOP tablets. The effect of drug amount (5, 15, and 30 mg) was also assessed to study the impact of varying levels of the formulation factors on drug release percent. The input factors were tested at three levels (see Table 1).

Compression of core tablets

For the pull layer, calculated amounts of RVX, PEO, NaCl, Avicel, and magnesium stearate were sieved separately through Mesh # 60. All the powders except magnesium stearate were mixed with the tumbling action for 5–6 min. Magnesium stearate was later added and further blended for 3 min. A similar method was applied to push layer ingredients, which contained iron oxide as a colorant for identification. The powder blend was compressed into bilayer tablets by double compression method: the initial pre-compression of the drug layer under 0.5 ± 0.15 kN was followed by the final compression of the push layer under 6.0 ± 0.55 kN with a target compression weight of 450 mg using biconcave punches using a benchtop tablet press-Natoli NP-RD10A (Natoli Engineering Inc. MO, USA)21.

Coating and drilling of tablets

A commercially available Opadry® CA coating system was applied following a 24-hour resting period to provide elastic stress relaxation to create a semi-permeable membrane on the tablets. Acetone and water in a ratio of 9:1 by weight were used to make the coating solution, which contained 7% w/w amount of Opadry® CA22. The compressed tablets were then coated using a traditional tablet coating pan that was rotated 3–6 rotations per minute. The inlet and outlet air temperatures were kept at approximately 45 °C and 28 °C, respectively23,24. The coating solution was then sprayed at a rate of 4–5 ml/min, the automation pressure was adjusted to 1 kg/cm2, and the coating pan speed was increased to 18–24 rpm25. The coated tablets were kept for drying overnight in a hot air oven at 50 °C for 16 h after the required coating weight gain was reached. The drug-containing side of the tablet was drilled through in the center using a micro-drilling bit measuring between 0.3 and 0.9 mm.

In-vitro drug release studies and statistical analysis

In-vitro drug release studies of all the trial batches were conducted using the USP Type-II apparatus (Erweka DT600, GmbH, Huesenstamm, Germany). The tablets were tested in a 900 ml dissolution medium of acetate buffer pH 4.5 + 0.5% SLS26 at the agitation speed of 75 rpm, and the medium temperature was maintained at 37 ± 0.5 °C. A sample of 10 ml was drawn at pre-determined time intervals (0.5, 1, 2, 3, 4, 6, 8, 10, and 12 h) and filtered through a 0.45 μm filter to make the working strength equivalent to 0.01 mg/ml. The cumulative percentage of drug release was determined using a UV-spectrophotometer (UV-1800, Shimadzu Corporation, Kyoto, Japan) at 248 nm27. Equal volumes of fresh medium were replaced after every sampling. The dissolution profiles were compared using the similarity factor (f2) test (ref) according to the given equation:

Where Ri and Ti are, respectively, the release from reference and test samples at time intervals, and t and n are the number of samples analyzed. The effect of input factors on percentage drug release was considered significant if the two profiles exhibited the f2 value below 5028.

Experimental design for rivaroxaban PPOP tablets

Central Composite Design (CCD), a meticulously chosen tool in the formulation optimization process, was employed to statistically analyze critical factors at a minimum of three levels. The Design of Experiment (DoE) was obtained by Design Expert ® version 13 (Stat Ease, Inc, Minneapolis MN 55413, USA), keeping the amount of PEO in the push layer (40–80 mg), NaCl amount in the drug layer (20–50 mg), and coating weight gain (4–12%) as the independent variables (X1−X3). Twenty trial runs i.e. 8 factorial points, 6 central points, and 6 axial points (F1−F20) were observed for the critical output variables, i.e., % drug release at 2, 6 and 12 h (Y1−Y3) and zero-order rate constant (Y4; RSQ_Zero). The data sets of the 20 trial formulations obtained from CCD were utilized to train the ANN model and get the predicted quantities of the input variables (X1−X3) to obtain the targeted critical responses (Y1−Y4).

Pre-compression assessment of API and blends

To examine the flow characteristics of the trial powder blends, the pre-formulation assessment of trial batches, including bulk and tapped densities, Carr’s index or compressibility index, Hausner’s ratio, and angle of repose was carried out per pharmacopeial specifications29,30. After adding the known quantity of powder blends to a 10-ml measuring cylinder, bulk density was calculated. After mechanically tapping the graduated vessel until the volume decrement was constant, the tapped density was measured. The parameters were calculated using the following equations:

Where ρbulk the bulk density, and bulk volume is the initial powder blend volume in the cylinder.

Powder material was passed through a funnel that measured 9.5 cm in height and had an internal orifice diameter of 1.8 cm and an upper spout diameter of 7.2 cm to calculate the angle of repose. The funnel was set up on the workbench, mounted roughly at 20 cm height from the Petri dish’s base. After the material was put into the funnel with the spout plugged, it was allowed to pass through the opening and gathered in a petri dish. A sliding vernier caliper measured the cone’s height (h) and diameter (d) three times31. The angle of repose was computed using the mean values of “d” and “h.” according to the formula:

Compression and coating of the designed formulations

All the designed batches (F1−F20) were directly compressed into bilayer tablets using the double compression method, as explained in the previous section. The coating procedure and conditions were identical, as described in earlier sections. The formulations were then drilled by a micro-drill machine (Proxxon MF 70, Germany) to create the optimum orifice of 0.6 mm.

Compatibility studies by FTIR and DSC analysis

The drug-excipient interaction was evaluated by Fourier transform infrared (FTIR) spectroscopy (Nicolet-6700; Thermo Scientific, United States). The spectra of the pure drug and powder excipients individually were generated in the 4000–400 cm–1 range. Similarly, the center point formulation tablet was crushed in a mortar and pestle and analyzed to identify any post-compression interaction. The samples were then examined at an accelerating voltage of 20 kV. Finally, the IR spectra of the pure drug and samples were compared32.

Differential scanning calorimetric (DSC 250, TA Instruments, DE, USA) analysis was carried out for pure rivaroxaban, individual excipients (microcrystalline cellulose, PEO, NaCl, and magnesium stearate), and a drug-excipient mixture from crushed tablets (center point formulation). The 2–8 mg samples were hermetically sealed and kept at the temperature range of 40–400 °C at the heating rate of 10 °C min–1. Standard Indium was used to calibrate the instrument at the Nitrogen purging rate of 50–100 ml/min. The data acquisition and subsequent calculations were performed using TRIOS software (TA Instruments, New Castle, DE, USA). The overlay thermograms were constructed using MS PowerPoint 365 (Microsoft Corp. USA) and were observed for any interaction33.

Pharmaceutical quality evaluation of tablets

All the coated and core tablets of the trial batches were subjected to various pharmacopeial and non-pharmacopeial assessments (n = 20), i.e., weight, thickness, and diameter variation tests using electronic weighing balance (Sartorius 224 S, Germany) and digital vernier caliper (Seiko brand, China). The mechanical strength of the core tablets was assessed by friability and hardness tests using Roche-type friabilitor (Erweka D2800, Huesenstamm, Germany) and Dr. Schleuniger Pharmatron M50 MultiTest 50 (Pharmatron, Switzerland)34.

Content uniformity test

The content uniformity test of all the trial formulations was performed using the HPLC method described by Effat Souri et al.35. The standard stock solution of rivaroxaban was prepared by dissolving 10 mg of the drug in a mixture (10 ml) of acetonitrile and methanol (85:15 v/v). The calibration curve was constructed for 50, 25, 15, 10, 5, 3, and µg/ml–1 solutions, prepared in the mobile phase containing a mixture of KH2PO4 50 mM (pH 3.0) and acetonitrile (60:40, v/v). The mobile phase was filtered through a 0.45 μm membrane filter and degassed by ultrasonication before use. Chromatographic separation was performed through a C18 column (3.9 × 300 mm, Bondapak RP) at 25 °C using HPLC (LC-10 AT VP Shimadzu Japan). The rivaroxaban response was recorded at 249 nm using a UV detector (LC 10a VP, Shimadzu, Japan). The test solutions of each tablet (n = 10) equivalent to 50 µg/ml–1 were prepared, and the percentage drug content was calculated36.

In vitro drug release studies and release kinetics studies

The in-vitro drug release was performed on all the designed formulations per the procedure explained in the previous section of dissolution testing. The drug release mechanism was examined using the dissolution profiles of each trial batch. Weibull, Higuchi, Korsmeyer Peppas, Hixon Crowell, and first-order kinetic models were among the models used to use DD Solver to analyze the kinetic mechanism of in-vitro drug release37. The cumulative percent drug release at 2, 6, and 12 h (Y1−Y3) was assessed to evaluate the effect of independent variables. The zero-order release constant (Y4; RSQ_Zero) was also determined to evaluate the RVX release kinetics38.

ANN-assisted development of rivaroxaban PPOP tablets

The current study used the Multilayer perceptrons (MLPs) based feed-forward back propagation method to train and test the ANN model to develop RVX-PPOP tablets using JMP® Pro 16 software (SAS Institute Inc. North Carolina, USA). The developed model was later cross-validated using the most established numerical and graphical optimization techniques. The CCD-generated data (Y1–Y4) of the trial formulations was prepared in replicates of ten and was applied for the supervised training of the ANN model by the Holdback input randomization method. The data set was divided into a ratio of 70:30 for the training and testing model39. Since the ANN model efficiency depends on the number of neural nodes in the hidden layer, the optimal number of the neural nodes was tested in the range of 3–7 by the activation function TanH (Tangent Hyperbolic). The neural node showing the value of r2 closer to unity with the minimum sum of square errors (SSE) against each critical response (Y1–Y4) was considered optimum and selected to generate the prediction profiler (predicted formulation variables)40. The prediction and contour profilers were generated at the neural node exhibiting the maximum value of the coefficient of regression (node 5; r2 = 1). The predicted formulation, Fpred was prepared, and all the critical response variables were determined.

Optimization based on the QbD approach

The Numerical and graphical optimization procedure using “Design Expert” software version 10 (Stat-Ease, Minneapolis, United States) was used to ascertain the formulation performance (Fpred) obtained by the developed ANN model. The technique was adopted to get the optimum amounts of X1−X3 variables to achieve the desirable response factors (Y1−Y4) within the targeted constraints. The targeted constraints were : <20% DR at 2 h, 40–60% DR at 6 h, > 85% DR at 12 h, and 0.95−1 as RSQ− zero for the corresponding response factors Y1-Y4 respectively. The individual and interactive effects of PEO, NaCl, and percentage weight gain after perturbation plots graphically and mathematically presented coating, 3D response surface curves, and polynomial model equations. For the individual responses, model fitness was evaluated by the ANOVA (analysis of variance), and “p < 0.05” was considered significant. The model equations (polynomial) generated for each critical response variable were later used to get the optimized formulation Fopt based on the desirability function closer to unity. The ramp and overlay plots were constructed to present the optimum X1–X3 for the targeted constraints (Y1–Y4) and the generated design space40.

Comparison of the optimized and predicted formulations by ANOVA

The trained ANN model was cross-validated by comparing the predicted formulation (Fpred) and the CCD-generated formulation (Fopt) obtained by numerical and graphical optimization approaches. The formulations were prepared in triplicates, and the drug release percentage (Y1–Y3) was determined in dissolution medium pH 4.5 (acetate buffer; 0.5% sodium lauryl sulfate). The drug release data of the formulations were compared by ANOVA (analysis of variance), “F” was calculated, and a significant difference was considered at a 95% confidence interval (p < 0.05). The RSQ_Zero (Y4) and the rest of the pharmaceutical attributes (weight thickness, diameter. Hardness variation, percentage friability, and content assay) were also determined40.

Scanning electron microscopy analysis

The optimized formulation (Fpred) surface morphology was analyzed using the SEM study before and after the complete drug release. After mounting the SEM samples on aluminum studs, they were covered in 250°A of gold coating. The coated tablets were carefully placed in a petri dish and dried at 50 °C for 12 h in a hot air oven following the completion of the 24-hour dissolution process, and then the scanning electron micrographs were obtained (JSM-6380 A, JEOL, Japan)41.

Accelerated stability studies

The optimized formulations were stored in airtight amber glass bottles. According to ICH guidelines, they were kept in the stability chamber (NuAire, Plymouth, MN, United States) at 40 ± 2 °C and 75 ± 5% relative humidity for 0, 1, 3, and 6 months under accelerated stability conditions. Using Minitab® 20 (Minitab, LLC, Pennsylvania, USA), shelf life was calculated after determining the percentage drug assay and all the critical parameters (Y1–Y4)42.

PBPK modeling and simulation

Model building

The systemic disposition of rivaroxaban from the optimized formulation (Fpred) was predicted using the ‘Advanced Compartmental Absorption and Transit’ (ACAT ®) model embedded in GastroPlus™ software version 9.9 (Simulations Plus Inc., Lancaster, CA, USA). Different formulation and physiological parameters (logP, blood: plasma ratio, pKa, unbound plasma fraction, effective permeability) obtained from the literature and ADMET™ predictor (Simulations Plus Inc., Lancaster, CA, USA) module were incorporated and depicted in Table 25,43,44. Due to the non-availability of intravenous plasma data in the literature, an oral 10 mg solution plasma profile was used to deduct the drug disposition parameters like systemic clearance (Clsys), half-life (T1/2), volume of distribution (Vd), and distribution constants between central and peripheral compartments. These pharmacokinetic parameters were obtained using an empirical model fitting in the PKPlus® module of GastroPlus® by employing 1, 2 and 3 compartments separately. The best-fitted compartmental model was selected based on the Akaike information criterion (AIC) and Schwarz criterion (SC), whereas the Hooke & Jeeves pattern search method was used, and the weighing was equal to 1/Yhat2. The obtained parameters were fixed and employed for further simulations5.

Model validation

The robustness and predictive power were initially evaluated by comparing the simulated plasma profile of 10 mg oral solution with the in vivo data obtained from the literature, followed by the verification of the developed model by simulating the in vivo profiles of the oral tablet (10 mg)45. The model was then validated (based on r2 values), and the calibration was performed based on the relative accuracy between predicted and observed PK parameters, which were compared by determining the percent predictive error and fold error according to the formulae46:

Simulation of RVX PPOP tablets

Different inputs were added in the prediction process like the dissolution testing result of the optimized formulation in USP-defined biorelevant media for fasting and fed conditions and CR Gastric as the dosage form47. The built model was used to simulate the PK profile of the optimized controlled-release formulation (30 mg) in both the fed and fasted states to assess the impact of food on the degree and extent of intrinsic absorption of RVX from the gut wall48.

Results

Screening of formulation parameters on the drug layer of RVX-PPOP tablets

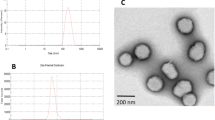

Three different types of PEOs were used in the same concentration (200 mg) with different molecular weights, 100k (N-10), 200k (N-80), and 300k (N-750) in formulations F1–F3 and drug release profiles were obtained as shown in Fig. 1a. On comparison, the f2 values for N-10 and N-80 were 50.58, but no similarity was observed for N-80 and N-750 (f2; 40.12) and N-750 and N-10 (f2; 30.58); however, the lag time of 3 h and 1 h was observed with N-750 and N-80 that might be attributed to their high molecular weights, i.e., 200 K and 300 K respectively. The suitable amount of PEO N-80 was later evaluated for the concentrations of 200 mg, 250 mg, and 300 mg (F4-F6). The results are illustrated in Fig. 1b, and the f2 values obtained were 63.96 (200 mg vs. 250 mg), 67.51 (250 mg vs. 300 mg), and 58.26 (300 mg vs. 200 mg).

Figure 1c presents the influence of different NaCl concentrations (20 mg, 35 mg, and 50 mg) on drug release of F7-F9. The drug release rate was observed to increase significantly with the increasing amounts of NaCl. At the test levels, the f2 values were found to be < 50, i.e., for formulations 20–35 mg (F7 vs. F8), 35–50 mg (F8 vs. F9), and 20–50 mg (F7 vs. F9), the values were 46.05, 47.41, and 34.91, respectively. The influence of drug loading was identified by changing the API content of the tablets (F10–F12). Figure 1d showed the release profiles of varying drug amounts of 30, 15, and 5 mg, and the f2 of each formulation pair was 80.49 (30–15 mg), 76.98 (30–5 mg), and 86.33 (15–5 mg), respectively.

Screening of formulation parameters on the push layer of RVX-PPOP tablets

Three different grades of PEO were tested, i.e., WSR 303 (7000 KDa), WSR Coagulant (5000 KDa), and WSR 301 (4000 KDa) to investigate the influence of PEO molecular weight in the push layer on drug release profiles, f2 values were calculated to be 62.01 (WSR 301 vs. WSR Coagulant), 51.83 (WSR 301 vs. WSR 303), and 59.07 (WSR 303 vs. WSR Coagulant), respectively indicating that the release profiles of the three formulations (F13–F15) were similar (Fig. 1e). To explore the effect of different amounts of WSR Coagulant (5000 KDa) on the release profile, PEO in the push layer was tested at three levels, i.e., 40 mg, 60 mg, and 80 mg (F16–F18). As shown by Fig. 1f, the drug release rate increased remarkably as the amount of PEO in the push layer increased with the f2 values smaller than 50 (f2: 40–60 mg: 49.72; 60–80 mg: 43.87; 40– 80 mg: 34.11). The influence of NaCl amount (F19:20 mg, F20:35 mg, and F21:50 mg) in the push layer on drug release is illustrated by Fig. 1g, and the f2 values obtained were 49.06 (20 mg vs. 35 mg), 81.32 (35 mg vs. 50 mg), and 45.33 (50 mg vs. 20 mg).

Screening of coating weight gain and orifice diameter on drug release

To investigate their influence on drug release profile, both were tested at three levels, i.e., 4%, 8%, and 12% (F22–F24) and 0.3 mm, 0.6 mm, and 0.9 mm (F25–27), respectively. Figure 1h illustrates that the f2 values were 4% vs. 8%: 48.64, 8% vs. 12%: 42.31, and 4% vs. 12%: 30.55, respectively. For PPOP, an orifice is created at the drug layer side for the release of drug solution/suspension. Various orifice diameters were generated 0.3 mm, 0.6 mm, and 0.9 mm and evaluated for the change in drug release (F25–F27). As illustrated in Fig. 1i, no significant change was observed as the pore size was changed (f2: 0.30 vs. 0.60 mm: 58.32, 0.60 vs. 0.90 mm: 79.58, 0.30 vs. 0.90 mm: 53.40).

Experimental design and micromeritic assessment

Based on the screening data, 20 experimental runs (F1–F20) were obtained from CCD (see Table 3). Before compressing the push and pull layers, the micromeritic properties of all the formulations (F1–F20) powder blends were evaluated and were found to be good to excellent, i.e., angle of repose 22.03°–26.29°, Hausner’s ratio 1.09–1.14 and Carr’s index 11.34–16.42%, indicating the free-flowing nature of powder blends with good compressibility29.

Compatibility studies by FTIR and DSC analysis

The FTIR spectrum of the pure rivaroxaban (Fig. 2) showed characteristic absorption bands located at 3358 cm–1 for tertiary amine C-N (stretching), 3067 cm−1 for C-H aryl (stretching), 2914 cm−1 for C-H bond, 2867 cm−1 for symmetric –CH2 (stretching), 1739 cm−1 for C=O ester, 1647 cm−1 for secondary amine N–H (bending), 1324 cm−1 for aromatic tertiary amine C-N (bending), 1300–1150 cm−1 for C-O-C (stretching) for both ethers and esters, 1145 cm−1 for secondary amine C–N (stretching), 1100–1000 cm−1 for C–O (stretching), and 769 cm−1 for C-Cl (stretching).

Differential scanning calorimetry (DSC) was performed to assess the exothermic or endothermic phase transformations. The thermal behavior of pure rivaroxaban and excipients were determined and compared, and the overlay DSC scans are illustrated in Fig. 3. A sharp endothermic peak at 235 °C is indicative of rivaroxaban’s melting point, and a little exothermic peak at 334 °C presents a carbonization initiation reaction after melting49. In contrast, the Avicel PH-102 sample showed a broad endothermic reaction beginning at 43 °C with a peak at ~ 85 °C. The pure Polyox presented sharp peaks at 72 °C and 68 °C for WSR-Coagulant and WSR-N-80, respectively.

Physical and chemical evaluation of RVX-PPOP tablets

The mean tablet weight of the trial runs (F1–F20) was 446.12 ± 3.13 mg to 452.43 ± 2.01 mg, hardness was 7.45 ± 0.71 kg/cm2 to 10.02 ± 0.59 kg/cm2, and the maximum percentage friability was 0.61 ± 0.11%. The mean diameter and thickness of the tablets were in the range of 10.00 ± 0.02 mm to 10.03 ± 0.03 mm and 5.50 ± 0.07 mm to 5.53 ± 0.09 mm, respectively (see Table 4). The results of the content uniformity test of each formulation blend (n = 10) were 99 ± 3.45% to 105 ± 5.34%, as illustrated in Table 4, and the chromatogram of the pure API and the optimized formulations are expressed in Fig. S1. The dissolution profiles of all the trial formulations (F1-F20) are given in Fig. 4, and the results demonstrated that formulations having higher coating weight gain control the drug release comparatively better than the formulations with low coating weight gain (< 85% in 8 h). Meanwhile, the increased osmogen and/or polymer concentrations lead to faster drug release (≥ 85% in 8 h) and more deviation from the zero-order release kinetics. The evaluation of release kinetics by empirical (zero order, first order, and Higuchi) and non-empirical (Korsmeyer-Peppas and Hixon Crowell) models is illustrated in Table 5.

ANN-assisted prediction of rivaroxaban PPOP tablets

Twenty sets of experimental data (Y1–Y4), each with a sample size of 10 runs, were fed into the ANN network for training and testing (70:30) by Random Holdback at Model launch TanH 3–7. The results of activation nodes and generalized coefficient of correlation are illustrated in Fig. 5; Table 6. The prediction profiler obtained on the selected node is represented in Fig. 6.

Numerical and graphical optimization for rivaroxaban PPOP tablets

The polynomial equations express the mathematical relationship among the independent and dependent variables are given in Table 7, and Fig. 7 represents the 3D response surface curves and perturbation plots. The effect of individual input variables on the critical responses is expressed in Table 8. Figure 8 presents the design space, and based on the desirability function, Fopt was manufactured and evaluated for critical response factors.

Comparison of the optimized and predicted formulations by ANOVA

The ANOVA (one-way) findings revealed no significant difference between Fpred and Fopt, as the p-value was 0.9705 (p ≤ 0.05). The value of F = 0.0014 was also in the acceptance region, which is less than the F critical value (4.3512) (see Table 9). This indicates a high level of similarity between the release profiles of optimized and predicted formulations and the difference in the mean dissolution rate of both the formulations was statistically insignificant.

Scanning electron microscopy (SEM) and stability studies

The scanning electron micrograph results of Fpred are presented in Fig. S2. The shelf life was also found to be 22.47 months and 17.87 months for Fpred and Fopt, respectively (Table S1).

In Silico PBPK modeling and simulation of RVX PPOP tablets

The reported pharmacokinetics study of an oral solution of 10 mg RVX was applied for model building; the two-compartmental model was selected with the help of the PKPlus® module5. Using the ‘Human Physiology-Fasted’ state, the simulation of the oral solution of 10 mg RVX showed an underestimation of the physiological events of the oral absorption, resulting in poor curve-fitting of the concentration-time profile (See Fig. 9). The PBPK (physiology-based pharmacokinetic) model was developed and verified by predicting the parameters of the RVX 10 mg immediate-release tablets, and the fold error (FE) was found within the acceptable limits, i.e., 1.04–1.20 (Table 10). The in vivo pharmacokinetic profiles of the ANN predicted formulation (Fpred) under fed and fasted states were simulated by the developed and tested PBPK model. There was observed a rise in Cmax under the fed state than in fasting conditions (235.05 vs. 168.1), whereas the Tmax was reduced (6.66 vs. 8.1). When compared, the AUC0 − inf and AUC0 –t under the fed condition were greater than the fasted state, i.e., 3990 vs. 3280.5 and 3648.1 vs. 2980.6, respectively (See Table 10).

Discussion

Screening of formulation parameters on drug layer of RVX-PPOP tablets

The grade and concentrations of polyethylene oxide (PEO), sodium chloride, and RVX were screened for the percentage of drug release by comparing the in vitro drug release profiles obtained up to 12 h. Different grades and concentrations of PEO influence the drug release due to its variable swelling characteristics. The right strength of the osmotic agent (sodium chloride) used will lead to the formation of the suspension in situ due to water imbibition associated with the generation of osmotic pressure. The volumetric expansion of the push layer aids the efflux of this drug suspension out of the delivery orifice present over the drug layer. For developing PPOP, different strengths of RVX were also tested to ascertain that the cumulative percentage drug release from PPOP is independent of drug dose50.

PEO (N-80) was found to be a suitable swelling agent in the drug layer because of complete drug release without burst effect; this may be attributed to excessive swelling of the polymer in the later stages. Meanwhile, N-10 exhibited relatively quicker and incomplete release, and N-750 showed comparatively greater lag time. PEOs with low MW(100–600 kDa) are usually utilized in the drug layers to acquire the zero-order release profiles50, as they are hydrated fast in the initial 3–4 h, forming a flowable suspension51,52. However, the percentage of drug release was found to be complete with 200 mg N-80 as compared to 250 mg and 300 mg, which may be associated with the increases in viscosity of drug suspension53.

This variation of osmotic agent demonstrated that NaCl in the drug layer was an essential factor, as it could influence the drug release significantly; therefore, in the present work, NaCl was further tested by CCD in the range of 20–50 mg in the drug layer54. The change in API amount in the drug layer indicated that the percentage of drug release is independent of the drug amount tested. Based on the current observation, it can be stipulated that the drug is delivered from the orifice as a comparatively high viscous hydrogel suspension; however, the robustness in PPOP formulations was observed for the drugs less than or equal to 30%55.

Screening of formulation parameters on the push layer of RVX-PPOP tablets

The primary contributor to the drug release in PPOP tablets is the polymer present in the push layer and its water uptake properties. As previously reported, the swelling ratio of polyethylene oxide is directly related to the molecular weight and number of units of the polymer52. Therefore, as the molecular weight of the PEO was increased, the percentage drug release was observed to be increased due to greater volume expansion after more water uptake, resulting in the complete pushing of drug suspension through the orifice. In the current work, WSR Coagulant (5000 KDa) was selected for further studies due to complete drug release, whereas WSR 303 and WSR 301 showed greater lag time and incomplete release, respectively. Coagulant (5000 KDa), by its high molecular weight in the push layer, acts as a promising swelling agent and controls the release of the active moiety either by the mechanism of swelling or by swelling/erosion51. It was also observed that when the amount of PEO in the push layer was increased (e.g., 80 mg), the PEO suspension in the drug layer remained undischarged from the orifice in due time, and the coating membrane was also deformed, resulting in an erratic release pattern at the later phase of drug release. Based on the above observation, the amount of Coagulant (5000 KDa) tested by CCD for the optimization process was 40–80 mg56.

An increase in the amount of NaCl causes an increase in the release rate of Rivaroxaban. The quick hydration and swelling of the push layer lead to the greater pushing force generated in the coating membrane and, consequently, rapid drug release. Lin S.Y. et al. also reported that an increase in the osmotic agent amount enhances the dissolution rate and faster drug release from the core tablet57. In the current study, no difference was observed in the release profiles of F20 and F21, so the minimum amount of NaCl required to achieve the appropriate osmotic pressure was selected as 35 mg for further studies.

Screening of coating weight gain and orifice diameter on drug release

The tablet coating weight gain and orifice diameter significantly affect the drug release rate, which depends on the fashion of the water imbibition through the coating membrane. The results indicated that an increase in the coating thickness caused an inadequate driving force for water uptake, resulting in a poor drug release rate; contrarily, a thinner coating membrane produced less resistance to water influx. However, too thin a coating membrane results in a very fragile mechanical barrier, which could be cracked if the internal pressure exceeds the tensile strength of the layer, leading to abrupt and erratic drug release58. Therefore, in the current work, coating weight gain in the range of 4–12% was further investigated by CCD at five levels.

No significant changes in drug release were observed as the pore size was altered but in the case of 0.3 mm, there was observed tablets deformation because of the mechanical pressure generated due to the expansion of polymers inside. For further studies, 0.6 mm was selected as a moderate orifice size to reduce the contribution to the rate of drug diffusion through the orifice and to minimize the osmotic pressure generated inside59,60.

Experimental design

The application of CCD produced 20 experimental formulations (F1–F20), including six central points. Keeping PEO Coagulant (X1; 40–80 mg), NaCl amount in the drug layer (X2; 20–50 mg) and percentage coating weight gain (X3; 8–12%), as independent variables, their impact on percentage drug release (Y1; %DR at 2 h, Y2; %DR at 6 h and Y3; %DR at 12 h) and zero-order coefficient of regression (Y4; RSQ_Zero) was critically evaluated. Xin Tang (2013) designed and evaluated gliclazide push-pull osmotic tablets and used PEO-N-80 and PEO WSR-303 in the drug and push layers, respectively61. Similarly, Xiaohong Liu also developed Nimodipine PPOP tablets (2014) using solid dispersion techniques and different molecular weight PEO to control the drug release62. Another study by Yuenan Li in 2019 suggests that the amount and type of PEO are critical for developing actarit double-layered osmotic pump tablets63.

Compatibility studies by FTIR and DSC analysis

The characteristic fingerprints of the pure rivaroxaban, polymers (Polyox Coagulant and Polyox N-80), Avicel PH-102, and sodium chloride spectra remained unaffected in the formulation blend, indicating the absence of any interaction among them64. The absence of any extra peak in the DSC spectrum shows that the drug is homogenously distributed in the amorphous state65,66.

Physical and chemical evaluation of RVX-PPOP tablets

The mechanical strength (percentage friability and hardness) of the tablets of all the trial batches was found satisfactory in terms of withstanding the mechanical shock during the coating process. Uniformity of thickness and diameter is essential to create a smooth coating layer on the tablet surface, which is a prerequisite to cause consistent water imbibition. All the batches met the official requirements of weight variation and chemical assay29,34. The coefficient of correlation (r2) was estimated using DD Solver, and zero-order (r2: 0.943–0.995) and Hixon Crowell (r2: 0.991–0.999) models were found to be the best-fitted release kinetic models. Our results demonstrated that most of the formulations followed a constant pattern of drug release as a zero-order profile due to the optimum balance between the osmotic agent and the swelling polymer67,68. Similarly, higher values of the coefficient of correlation for the Hixon Crowell model are indicative of the decrease in the total volume of tablets’ surfaces due to the continuous removal of core material from the inside. Based on the dissolution results, three dissolution points, i.e., %DR at 2, 6, and 12 h (Y1–Y3) and zero-order release coefficient, i.e., RSQ_Zero (Y4), were set as output variables for further prediction and optimization using ANN and QbD tools.

ANN-assisted prediction of Rivaroxaban PPOP tablets

An ANN-based multivariate approach was applied after the supervised training of the model for the prediction of in vitro release from Rivaroxaban PPOP. The best activation node obtained was 5, showing the maximum value of the generalized coefficient of correlation for training and testing (r2 = 1) with the least value of SSE (sum of square errors) for all the variables (training; Y1 = 84.904, Y2 = 24.49, Y3 = 19.21 and Y4 = 0.011) (testing; Y1 = 98.12, Y2 = 4.38, Y3 = 6.89 and Y4 = 0.007). For the subsequent higher nodes over training were observed, showing a fall in the values of coefficient of correlation (neural node 6; training r2 = 0.9881, testing r2 = 0.991) (neural node 7; training r2 = 0.9997, testing r2 = 0.9997) and comparatively higher SSE. Patel et al. incorporated ANN in developing controlled porosity osmotic tablets for the pH-dependent soluble drug Isradipine and optimized neural node five based on the highest r2 and lowest root mean square values69. The data training was stopped further to avoid overfitting, and a prediction profiler was generated at node 5 to get the optimum levels of PEO, sodium chloride, and percentage weight gain after coating (Fpred). Ibrić et al. utilized GRNN contour plots to observe the effect of Eudragit percentage and tablet hardness on the cumulative drug release of extended-release aspirin tablets70. Similarly, Simões et al. explained the importance of a prediction profiler in simultaneously observing the effects of input variables on the pharmaceutical tablet manufacturing of a class IV drug71.

Numerical and graphical optimization for Rivaroxaban PPOP tablets

In the current work of numerical and graphical optimization, a well-defined technique was applied to get the finest levels of independent variables (X1–X3) to achieve the targeted critical responses (Y1–Y4). These quantities of PEO (X1), sodium chloride (X2), and coating weight (X3) were also computed by the polynomial equations of each response factor to get the targeted constraints. According to the fit summary (ANOVA), the best model fitted to Y1 (%DR @1 hr.), Y2 (%DR @ 6 h.), and Y4 (RSQ_Zero) responses was a quadratic model, whereas drug release at 12 h (Y3) followed a linear model (p < 0.05). The effect of PEO (X1) was insignificant on drug release at 2 h (Y1), but the drug release was observed to be significantly increased with the increasing concentration of PEO. It was observed that sodium chloride (X2) significantly increased the drug release at 2, 6, and 12 h (Y1-Y3), but RSQ_Zero decreased considerably with the increasing concentration of osmogen. Coating weight gain (X3) reduced the drug release at initial hours (2 and 6 h) considerably but did not affect cumulative drug release at 12 h; however, RSQ_Zero improved with the rise in coating weight gain. Shah HP and Prajapati ST also applied numerical and graphical optimization to develop gastroretentive floating osmotic capsules of clopidogrel bisulfate72.

Comparison of the optimized and predicted formulations by ANOVA

To cross-validate the prediction of the developed ANN model, analysis of variance was applied, and the critical response variables (Y1–Y4) were compared obtained from the predicted formulation (Fpred) by the developed ANN model and the optimized formulations (Fopt) by numerical and graphical optimization. Yuksel et al.73 discussed ANOVA-based methods’ applicability and usefulness in comparing in vitro dissolution profiles of film-coated naproxen tablets.

Scanning electron microscopy (SEM) and stability studies

The Fpred scanning electron micrographs of the coated tablets before dissolution revealed the existence of an even and uncomplicated layer of Opadry® CA coating devoid of any surface pores or cracks. As reported in the literature by Verma et al., the increasing concentration (0–55%) of pore former (polyvinyl pyrrolidone) increases the percentage porosity due to dissolution medium imbibition, leading to the expected effect on the percentage drug release. In contrast, the development of numerous micropores was observed on the surface of the tablets after dissolution (and overnight drying)74. Following the ICH guidelines (International Council for Harmonization, 2003) for the accelerated conditions, Fpred and Fopt formulations were placed at 40 ± 5 °C and 75 ± 5% RH. Various quality tests, including assay, dissolution, and disintegration tests, were performed during the study period of 0, 3, and 6 months. Both formulations expressed good quality characteristics and were found stable. Many reported studies have also demonstrated that osmotic drug delivery systems, when subjected to stability evaluation, retained their physicochemical characteristics and remained stable for an extended period with suitable shelf lives65,75,76.

In Silico PBPK modeling and simulation of RVX PPOP tablets

The prediction of the pharmacokinetic profile and parameters of Fpred was carried out using the ACAT® model. During the model development stage, the simulation of the oral solution of 10 mg RVX showed a decrease in plasma concentration. The underprediction may be due to the regional pH variation, influx transporters, efflux proteins, and differences in surface-to-volume ratio throughout the gastrointestinal tract. In the current work, the underpredicted absorption phase of the concentration-time profile was adjusted by scaling the regional effective permeability (Peff) using the ASF (absorption scaling factor) multiplier model Opt logD Model SA/V 6.1. It is evident from Fig. 9 that the bioavailability curves of Fpred under fed and fasted states are dissimilar, which may be because of faster dissolution and subsequent absorption of RVX under fed conditions. It has been previously reported that the presence of bile salts that are released after a meal is supportive of increasing the RVX solubility and its subsequent absorption from the duodenum and proximal segment of jejunum, resulting in a significant rise in oral bioavailability up to 27–35%77. The current predictive results suggest that the fed state bioavailability was improved (up to 82%) with the administration of RVX PPOP vis-â-vis the IR tablet due to the temporal release of the drug from the system, which may allow continuous absorption from the gut wall and avoid immediate saturation of the lumen. Alam N et al. also reported the enhanced bioavailability of trimetazidine osmotic tablets compared to the marketed formulation due to enhanced gastro retention and absorption78.

Conclusion

In the current study, a neural computing framework based on an ANN model was effectively used to speculate the critical response variables for a bilayer push-pull osmotic tablet formulation of a sparely soluble drug, rivaroxaban. The formulation parameters were initially screened to assess the critical factors influencing the drug release. The predicted formulation of the ANN tool following model training was examined and cross-validated using the proven multivariate CCD technique. The optimal osmotic pump tablet delivered the drug in a zero-order pattern for up to 12 h, demonstrating their usefulness for developing controlled-release tablet formulations. The PBPK modeling of the predicted formulation showed improved oral bioavailability in the fasting state compared to the available immediate-release marketed formulation. Thus, based on the in-silico pharmacokinetic model, it is possible to formulate controlled-release osmotic tablets for drugs with distinctive inter-personal pharmacokinetic variability. The proposed approach considers information on the formulation of an ODDS and the ability to evaluate compositional quality and key parameters to guide formulation research. This is a bivariate model of ANNs and QbD that can be applied in the future to many areas of other dosage forms and pharmaceutical research. Implementation of these predictive models could effectively reduce the timeline and material use of drug development and proactively promote the development of robust drug products.

Data availability

The results from the present investigation are available from the corresponding author upon reasonable request.

Abbreviations

- ANN:

-

Artificial neural network

- RSM:

-

Response surface methodology

- RVX:

-

Rivaroxaban

- CCD:

-

Central composite design

- ANOVA:

-

Analysis of variance

- PBPK:

-

Physiologically based pharmacokinetic

- PPOP:

-

Push-pull osmotic pump

- PE:

-

Pulmonary embolism

- DVT:

-

Deep vein thrombosis

- MI:

-

Myocardial infarction

- VTE:

-

Venous thromboembolism

- ODDSs:

-

Osmotic drug delivery systems

- EOP:

-

Elementary osmotic pump

- FDA:

-

Food and drug administration

- QbD:

-

Quality by design

- MLP:

-

Multi-layer perceptron

- CYP:

-

Cytochrome-P

- Pgp:

-

P-glycoprotein

- PEO:

-

polyethylene oxide

- ACAT:

-

Advanced compartment and transit

- USP:

-

United States pharmacopoeia

- SLS:

-

Sodium lauryl sulphate

- DoE:

-

Design of experiment

- FTIR:

-

Fourier transform infrared

- DSC:

-

Differential scanning calorimetry

- SEM:

-

Scanning electron microscope

- AIC:

-

Akaike information criterion

- SC:

-

Schwarz criterion

- API:

-

Active pharmaceutical ingredient

- ICH:

-

International Council for Harmonization

References

Li, H. et al. The effects of warfarin on the pharmacokinetics of Senkyunolide I in a rat model of biliary drainage after administration of Chuanxiong. Front. Pharmacol. 9, 1456. https://doi.org/10.3389/fphar.2018.01461 (2018).

Li, H. et al. The effects of ferulic acid on the pharmacokinetics of warfarin in rats after biliary drainage. Drug. Des. Devel. Ther. 10, 2173–2180. https://doi.org/10.2147/DDDT.S107917 (2016).

Mueck, W., Stampfuss, J., Kubitza, D. & Becka, M. Clinical pharmacokinetic and pharmacodynamic profile of rivaroxaban. Clin. Pharmacokinet. 53, 1–16. https://doi.org/10.1007/s40262-013-0100-7 (2014).

Kreutz, R. Pharmacodynamic and pharmacokinetic basics of rivaroxaban. Fundam. Clin. Pharmacol. 26, 27–32. https://doi.org/10.1111/j.1472-8206.2011.00981.x (2012).

Kushwah, V. et al. On absorption modeling and food effect prediction of Rivaroxaban, a BCS II drug orally administered as an Immediate-Release tablet. 13, 283 (2021).

Keraliya, R. A. et al. Osmotic drug delivery system as a part of modified release dosage form. Int. Schol. Res. Notices 2012, 528079. https://doi.org/10.5402/2012/528079 (2012).

Li, X. P. D. & Jasti, B. R. Design of Controlled Release Drug Delivery Systems (McGraw-Hill, 2006).

Santus, G. & Baker, R. W. Osmotic drug delivery: a review of the patent literature. J. Controlled Release. 35, 1–21. https://doi.org/10.1016/0168-3659(95)00013-X (1995).

Joshi, M., Gokhale, C., Kenjale, P. & Pokharkar, V. J. B. J. o. P. S. Optimization of Diltiazem hydrochloride osmotic formulation using QBD approach. Braz. J. Pharmaceut. Sci. 58, e19779 (2022).

Sangshetti, J. N., Deshpande, M., Zaheer, Z., Shinde, D. B. & Arote, R. Quality by design approach: regulatory need. Arab. J. Chem. 10, S3412–S3425. https://doi.org/10.1016/j.arabjc.2014.01.025 (2017).

Agatonovic-Kustrin, S. & Beresford, R. Basic concepts of artificial neural network (ANN) modeling and its application in pharmaceutical research. J. Pharm. Biomed. Anal. 22, 717–727. https://doi.org/10.1016/S0731-7085(99)00272-1 (2000).

Mandal, U. et al. Optimization of Metformin HCl 500 mg sustained release matrix tablets using artificial neural network (ANN) based on multilayer perceptrons (MLP) model. Chem. Pharm. Bull. 56, 150–155. https://doi.org/10.1248/cpb.56.150 (2008).

Isoherranen, N. Physiologically based pharmacokinetic modeling of small molecules: how much progress have we made? Drug Metab. Dispos. 53, 100013. https://doi.org/10.1124/dmd.123.000960 (2025).

Xu, R., Ge, W. & Jiang, Q. Application of physiologically based Pharmacokinetic modeling to the prediction of drug-drug and drug-disease interactions for Rivaroxaban. Eur. J. Clin. Pharmacol. 74, 755–765. https://doi.org/10.1007/s00228-018-2430-8 (2018).

Trujillo, T. & Dobesh, P. P. Clinical use of rivaroxaban: pharmacokinetic and pharmacodynamic rationale for dosing regimens in different indications. Drugs 74, 1587–1603. https://doi.org/10.1007/s40265-014-0278-5 (2014).

Lou, Y. et al. Effects of the CYP3A inhibitors, voriconazole, Itraconazole, and fluconazole on the pharmacokinetics of osimertinib in rats. PeerJ 11, e15844 (2023).

Parrott, N. & Lavé, T. Prediction of intestinal absorption: comparative assessment of Gastroplus™ and Idea™. Eur. J. Pharm. Sci. 17, 51–61. https://doi.org/10.1016/S0928-0987(02)00132-X (2002).

Wang, K. et al. Physiologically based pharmacokinetic models are effective support for pediatric drug development. AAPS PharmSciTech 22, 208. https://doi.org/10.1208/s12249-021-02076-w (2021).

Zhu, J. et al. Physiologically based pharmacokinetic/pharmacodynamic modeling to evaluate the absorption of midazolam rectal gel. Eur. J. Pharm. Sci. 167, 106006. https://doi.org/10.1016/j.ejps.2021.106006 (2021).

Bratsos, S. Pharmacokinetic properties of rivaroxaban in healthy human subjects. Cureus 11, e5484. https://doi.org/10.7759/cureus.5484 (2019).

Maqbool, T. et al. Cellulose ether and carbopol 971 based gastroretentive controlled release formulation design, optimization and physiologically based Pharmacokinetic modeling of Ondansetron hydrochloride minitablets. Int. J. Biol. Macromol. 276, 133841. https://doi.org/10.1016/j.ijbiomac.2024.133841 (2024).

Ahmed, K. et al. Use of Opadry® CA—A cellulose acetate/polyethylene glycol system for rate-controlled osmotic drug delivery of highly soluble antispastic agent eperisone HCl. Adv. Polym. Technol. 37, 2730–2742. https://doi.org/10.1002/adv.21946 (2018).

Okimoto, K. et al. Applicability of (SBE)7m-β-CD in controlled-porosity osmotic pump tablets (OPTs). Int. J. Pharm. 286, 81–88. https://doi.org/10.1016/j.ijpharm.2004.08.002 (2004).

Seo, K. S., Bajracharya, R., Lee, S. H. & Han, H. K. Pharmaceutical application of tablet film coating. Pharmaceutics 12, 853 (2020).

Lin, W. et al. Preparation and evaluation of bilayer-core osmotic pump tablets contained topiramate. PLOS ONE. 17, e0264457. https://doi.org/10.1371/journal.pone.0264457 (2022).

Reddy, M. S. & Himavarsha, M. J. I. J. O. P. & sciences, B. Formulation development and evaluation O. immediate release anti-coagulant drug Rivaroxaban film coated tablets. J. Pharma Bio Sci. 8, 369–378 (2018).

Çelebier, M., Kaynak, M., Altınöz, S. & Şahin, S. J. D. T. UV spectrophotometric method for determination of the dissolution profile of rivaroxaban. Dissolution Technol. 2014, 21 (2014).

Shah, V. P., Tsong, Y., Sathe, P. & Liu, J. P. In vitro dissolution profile Comparison—Statistics and analysis of the similarity factor, f2. Pharm. Res. 15, 889–896. https://doi.org/10.1023/A:1011976615750 (1998).

Convention, U. S. P. U.S. Pharmacopeia National Formulary 2017: USP 40 NF 35 United States Pharmacopeial Convention (2016).

Suñé Neģre, J. M. et al. Formulation Tools for Pharmaceutical Development 109–135 (eds. Aguilar, J. E.) (Woodhead Publishing, 2013).

Saleem, M. T. et al. SeDeM tool-driven full factorial design for osmotic drug delivery of Tramadol HCl: formulation development, physicochemical evaluation, and in-silico PBPK modeling for predictive pharmacokinetic evaluation using GastroPlus™. Front. Pharmacol. 13, 974715. https://doi.org/10.3389/fphar.2022.974715 (2022).

Husain, T. et al. Halloysite nanotubes-cellulose ether based biocomposite matrix, a potential sustained release system for BCS class I drug verapamil hydrochloride: compression characterization, in-vitro release kinetics, and in-vivo mechanistic physiologically based pharmacokinetic modeling studies. Int. J. Biol. Macromol. 251, 126409. https://doi.org/10.1016/j.ijbiomac.2023.126409 (2023).

Sikandar, M. et al. Nanoclay-Based composite films for transdermal drug delivery: development, characterization, and in Silico modeling and simulation. Int. J. Nanomed. 17, 3463–3481. https://doi.org/10.2147/ijn.S367540 (2022).

USP 38–NF 33 the United States Pharmacopeia and National Formulary 2015: Main Edition Plus Supplements 1 and 2. (Deutscher Apotheker (2014).

Souri, E., Mottaghi, S., Zargarpoor, M., Ahmadkhaniha, R. & Jalalizadeh, H. Development of a stability-indicating HPLC method and a dissolution test for Rivaroxaban dosage forms. J. Acta Chromatogr. Acta Chromatogr. 28, 347–361. https://doi.org/10.1556/1326.2016.28.3.05 (2016).

Convention, U. S. P. Usp35-Nf30 United States Pharmacopeia (2011).

Costa, P. & Sousa Lobo, J. M. Modeling and comparison of dissolution profiles. Eur. J. Pharm. Sci. 13, 123–133. https://doi.org/10.1016/S0928-0987(01)00095-1 (2001).

Laracuente, M. L., Yu, M. H. & McHugh, K. J. Zero-order drug delivery: state of the Art and future prospects. J. Controlled Release. 327, 834–856. https://doi.org/10.1016/j.jconrel.2020.09.020 (2020).

Bashiri, M. & Farshbaf Geranmayeh, A. Tuning the parameters of an artificial neural network using central composite design and genetic algorithm. Sci. Iran. 18, 1600–1608. https://doi.org/10.1016/j.scient.2011.08.031 (2011).

Khan, M. Z. et al. A hybrid framework of artificial intelligence-based neural network model (ANN) and central composite design (CCD) in quality by design formulation development of orodispersible Moxifloxacin tablets: physicochemical evaluation, compaction analysis, and its in-silico PBPK modeling. J. Drug Deliv. Sci. Technol. 82, 104323. https://doi.org/10.1016/j.jddst.2023.104323 (2023).

Bathool, A. et al. Development and evaluation of microporous osmotic tablets of diltiazem hydrochloride. J. Adv. Pharmaceut. Technol. Res. 3, 124–129. https://doi.org/10.4103/2231-4040.97292 (2012).

Sengupta, P., Chatterjee, B. & Tekade, R. K. Current regulatory requirements and practical approaches for stability analysis of pharmaceutical products: a comprehensive review. Int. J. Pharm. 543, 328–344. https://doi.org/10.1016/j.ijpharm.2018.04.007 (2018).

Takács-Novák, K. et al. Biorelevant solubility of poorly soluble drugs: rivaroxaban, furosemide, papaverine and niflumic acid. J. Pharm. Biomed. Anal. 83, 279–285. https://doi.org/10.1016/j.jpba.2013.05.011 (2013).

Willmann, S. et al. Development of a paediatric population-Based model of the pharmacokinetics of rivaroxaban. Clin. Pharmacokinet. 53, 89–102. https://doi.org/10.1007/s40262-013-0090-5 (2014).

Kubitza, D., Becka, M., Voith, B., Zuehlsdorf, M. & Wensing, G. Safety, pharmacodynamics, and pharmacokinetics of single doses of BAY 59-7939, an oral, direct factor Xa inhibitor. Clin. Pharmacol. Therapeut. 78, 412–421. https://doi.org/10.1016/j.clpt.2005.06.011 (2005).

Cvijic, S., Ibric, S., Parojcic, J. & Djuris, J. An in vitro—in Silico approach for the formulation and characterization of ranitidine gastroretentive delivery systems. J. Drug Deliv. Sci. Technol. 45, 1–10. https://doi.org/10.1016/j.jddst.2018.02.013 (2018).

Klein, S. The use of biorelevant dissolution media to forecast the in vivo performance of a drug. AAPS J. 12, 397–406. https://doi.org/10.1208/s12248-010-9203-3 (2010).

Li, M., Zhao, P., Pan, Y. & Wagner, C. Predictive performance of physiologically based pharmacokinetic models for the effect of food on oral drug absorption: current status. CPT: Pharmacometr. Syst. Pharmacol. 7, 82–89. https://doi.org/10.1002/psp4.12260 (2018).

Sherje, A. P. & Jadhav, M. β-Cyclodextrin-based inclusion complexes and nanocomposites of Rivaroxaban for solubility enhancement. J. Mater. Sci.: Mater. Med. 29, 186. https://doi.org/10.1007/s10856-018-6194-6 (2018).

Malaterre, V., Ogorka, J., Loggia, N. & Gurny, R. Evaluation of the tablet core factors influencing the release kinetics and the loadability of Push–Pull osmotic systems. Drug Dev. Ind. Pharm. 35, 433–439. https://doi.org/10.1080/03639040802425230 (2009).

Xu, H. et al. A novel bi-layer ascending release osmotic pump tablet: in vitro investigation and in vivo investigation in pharmacokinetic study and IVIVC evaluation. Int. J. Pharm. 458, 181–187. https://doi.org/10.1016/j.ijpharm.2013.09.031 (2013).

Rowe, R. C., Sheskey, P. & Quinn, M. Handbook of Pharmaceutical Excipients (Libros Digitales-Pharmaceutical, 2009).

Nie, S., Li, W., Luan, L., Pan, W. & Wang, X. Studies on Bi-Layer osmotic pump tablets of water-Insoluble allopurinol with large dose: in vitro and in vivo. Drug Dev. Ind. Pharm. 33, 1024–1029. https://doi.org/10.1080/03639040601179897 (2007).

Patel, V., Chudasama, A., Nivsarkar, M., Vasu, K. & Shishoo, C. Push-pull osmotic pump for zero order delivery of lithium carbonate: development and in vitro characterization. Pharm. Dev. Technol. 17, 375–382. https://doi.org/10.3109/10837450.2010.542577 (2012).

Malaterre, V., Ogorka, J., Loggia, N. & Gurny, R. Approach to design push–pull osmotic pumps. Int. J. Pharm. 376, 56–62. https://doi.org/10.1016/j.ijpharm.2009.04.015 (2009).

Monton, C. & Kulvanich, P. Push-Pull osmotic pumps using crosslinked hard gelatin capsule as a structural assembly for delivery of drugs with different water solubilities. J. Pharm. Innov. 17, 791–805. https://doi.org/10.1007/s12247-021-09562-5 (2022).

Lin, S. Y., Lin, K. H. & Li, M. J. Influence of excipients, drugs, and osmotic agent in the inner core on the time-controlled disintegration of compression‐coated ethylcellulose tablets. J. Pharm. Sci. 91, 2040–2046. https://doi.org/10.1002/jps.10197 (2002).

Dredán, J., Antal, I. & Rácz, I. Evaluation of mathematical models describing drug release from lipophilic matrices. Int. J. Pharm. 145, 61–64. https://doi.org/10.1016/S0378-5173(96)04725-4 (1996).

Liu, X., Chen, D. & Zhang, R. Evaluation of monolithic osmotic tablet system for Nifedipine delivery in vitro and in vivo. Drug Dev. Ind. Pharm. 29, 813–819. https://doi.org/10.1081/DDC-120021781 (2003).

Theeuwes, F. Elementary osmotic pump. J. Pharm. Sci. 64, 1987–1991. https://doi.org/10.1002/jps.2600641218 (1975).

Tang, X. et al. In vitro and in vivo evaluation of Gliclazide push-pull osmotic pump coated with aqueous colloidal polymer dispersions. Drug Dev. Ind. Pharm. 39, 67–76. https://doi.org/10.3109/03639045.2012.657646 (2013).

Liu, X. et al. A two-step strategy to design high bioavailable controlled-release nimodipine tablets: the push-pull osmotic pump in combination with the micronization/solid dispersion techniques. Int. J. Pharm. 461, 529–539. https://doi.org/10.1016/j.ijpharm.2013.12.023 (2014).

Li, Y. et al. Double-layered osmotic pump controlled release tablets of Actarit: in vitro and in vivo evaluation. Asian J. Pharm. Sci. 14, 340–348. https://doi.org/10.1016/j.ajps.2018.05.009 (2019).

Metre, S., Mukesh, S., Samal, S. K., Chand, M. & Sangamwar, A. T. Enhanced biopharmaceutical performance of rivaroxaban through polymeric amorphous solid dispersion. Mol. Pharm. 15, 652–668. https://doi.org/10.1021/acs.molpharmaceut.7b01027 (2018).

Gundu, R., Pekamwar, S., Shelke, S., Shep, S. & Kulkarni, D. Sustained release formulation of Ondansetron HCl using osmotic drug delivery approach. Drug Dev. Ind. Pharm. 46, 343–355. https://doi.org/10.1080/03639045.2020.1716372 (2020).

Vodáčková, P. et al. Evaluation and comparison of three types of spray dried coprocessed excipient avicel® for direct compression. BioMed Res. Int. 2018, 2739428. https://doi.org/10.1155/2018/2739428 (2018).

Ketjinda, W., Sinchaipanid, N., Limsuwan, P., Leuenberger, H. & Mitrevej, A. Development of Push–Pull osmotic tablets using Chitosan–Poly(Acrylic Acid) interpolymer complex as an osmopolymer. AAPS PharmSciTech 12, 132–140. https://doi.org/10.1208/s12249-010-9572-z (2011).

Wu, C. et al. Preparation of a push–pull osmotic pump of felodipine solubilized by mesoporous silica nanoparticles with a core–shell structure. Int. J. Pharm. 475, 298–305. https://doi.org/10.1016/j.ijpharm.2014.08.033 (2014).

Patel, A., Mehta, T., Patel, M., Patel, K. & Patel, N. Design porosity osmotic tablet for delivering low and pH-Dependent soluble drug using an artificial neural network. Curr. Drug Deliv. 9, 459–467. https://doi.org/10.2174/156720112802650662 (2012).

Ibrić, S. et al. Artificial neural networks in the modeling and optimization of aspirin extended release tablets with Eudragit L 100 as matrix substance. AAPS PharmSciTech 4, 9. https://doi.org/10.1208/pt040109 (2003).

Simões, M. F. et al. Artificial neural networks applied to quality-by-design: from formulation development to clinical outcome. Eur. J. Pharm. Biopharm. 152, 282–295. https://doi.org/10.1016/j.ejpb.2020.05.012 (2020).

Shah, H. P. & Prajapati, S. T. Quality by design based development and optimization of novel gastroretentive floating osmotic capsules of clopidogrel bisulfate. J. Pharm. Invest. 49, 295–311. https://doi.org/10.1007/s40005-018-0405-5 (2019).

Yuksel, N., Kanık, A. E. & Baykara, T. Comparison of in vitro dissolution profiles by ANOVA-based, model-dependent and -independent methods. Int. J. Pharm. 209, 57–67. https://doi.org/10.1016/S0378-5173(00)00554-8 (2000).

Verma, R. K., Kaushal, A. M. & Garg, S. Development and evaluation of extended release formulations of isosorbide mononitrate based on osmotic technology. Int. J. Pharm. 263, 9–24. https://doi.org/10.1016/S0378-5173(03)00360-0 (2003).

Farooqi, S. et al. Quality by design (QbD)-Based numerical and graphical optimization technique for the development of osmotic pump Controlled-Release Metoclopramide HCl tablets. Drug Des. Dev. Ther. 14, 5217–5234. https://doi.org/10.2147/dddt.S278918 (2020).

Shireen, F. & Ajitha, M. J. Nateglinide modified release dosage form using elementary osmotic pump and push pull osmotic pump methods: formulation and in-vivo evaluation. J. O P N R 13, 1521–1530 (2022).

Stampfuss, J., Kubitza, D., Becka, M. & Mueck, W. The effect of food on the absorption and pharmacokinetics of Rivaroxaban. Int. J. Clin. Pharmacol. Ther. 51, 549–561. https://doi.org/10.5414/cp201812 (2013).

Alam, N. et al. Mucoadhesive elementary osmotic pump tablets of trimetazidine for controlled drug delivery and reduced variability in oral bioavailability. Drug Dev. Ind. Pharm. 41, 692–702. https://doi.org/10.3109/03639045.2014.900076 (2015).

Acknowledgements

The authors are thankful to the Department of Pharmaceutics, Faculty of Pharmacy and Pharmaceutical Sciences, University of Karachi for providing laboratory facilities for conducting this research work.

Funding

No external funding from any local governmental or private organization.

Author information

Authors and Affiliations

Contributions

M.T.S has done major investigation, analysis, software, writing draft preparation. M.H.S involves in conceptualization, methodology, supervision, software, writing- reviewing and editing, R.I.Y helped in methodology, software, validation, writing- reviewing and editing, F.S has done some analysis and method validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent for publication

It is hereby confirmed that all authors are aware of the contents of this manuscript and provide consent for its publication.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Saleem, M.T., Shoaib, M.H., Yousuf, R.I. et al. RSM and AI based machine learning for quality by design development of rivaroxaban push-pull osmotic tablets and its PBPK modeling. Sci Rep 15, 7922 (2025). https://doi.org/10.1038/s41598-025-91601-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-91601-z