Abstract

Thread milling plays a critical role in the machining of aviation components. However, for parts with complex shapes and high precision requirements, traditional three-axis milling often results in significant errors, making it difficult to meet the stringent machining specifications. In this paper, an error control method based on a crossed axes strategy for five-axis thread milling is proposed. Firstly, the thread profile is constructed using both the axial cross-section and the normal section. The geometry of the thread mill is derived from the nominal profile on the axial cross-section. Then, the tool path is defined, where a new locus is introduced to control milling errors. Building upon this, the envelope theory is employed to establish an error model for the milling process, and the errors under different milling strategies are compared. Finally, the impact of the fixed angle on machining errors is analyzed, and experiments are conducted to compare the thread milling performance of three-axis and five-axis. The results demonstrate that as the fixed angle changes from 0 to 0.0282 radians, the angle error shifts from −0.796 to 0.808 degrees, and by selecting an optimal fixed angle in 5-axis milling, the error can be minimized, validating the superior machining accuracy and effectiveness of the proposed approach.

Similar content being viewed by others

Introduction

Threads are a fundamental form of mechanical connection and have become an essential structural element in modern machinery due to their simple design, reliable performance, and ease of disassembly. This is especially true in the aviation industry. For instance, critical components such as the fuselage, wings, and tail of an aircraft are connected using bolts and nuts to ensure the stability and safety of each part under the high-stress conditions of flight. Additionally, many parts of the aircraft landing gear system, including the main strut, steering gear, and support rods, are threaded to withstand the substantial impact and load during takeoff and landing. As a result, the design and machining of threads in aviation applications must meet stringent standards, with thread accuracy being critical to ensuring flight safety.

Thread machining methods mainly include turning, milling, tapping, sleeve wire, grinding, and cyclone cutting. Among these, turning, tapping, and milling are the most widely used. Thread turning is primarily suited for single-piece and small batch production, while tapping is typically used for small diameter internal threads. However, for large diameter internal threads, especially in aircraft components, the machining becomes more challenging. Traditional turning and tapping methods face difficulties due to workpiece structure and thread type. These methods often struggle with clamping, low efficiency, and high processing costs, which significantly limit the production and application of large diameter internal threads. When tapping is used for large diameter internal threads, efficiency is severely constrained by the low cutting speed of the tap and the need to reverse the tool after each pass. On the other hand, turning large diameter internal threads is challenging due to the requirement for the workpiece to rotate. Additionally, when machining deep internal threads with large diameters, long chips can easily wind around the tool, especially if chip evacuation is poor, which severely affects processing efficiency1.

With the continuous improvement in the precision and rigidity of CNC machine tools and the unprecedented advancements in tooling technology, thread milling has increasingly demonstrated its advantages in the machining field. Thread milling is an advanced and efficient processing technology, where the tool’s rotational motion is combined with the spiral interpolation motion of the machine tool2. During the thread milling process, the tool geometry traces the thread’s profile, and the desired thread is machined into the workpiece. Compared to other thread machining methods, thread milling offers several advantages, especially for large diameter and large pitch threads3,4,5,6. First, thread milling generates lower cutting forces, as the cutting force can be optimized by adjusting the tool radius compensation value, allowing for better control over the forces the tool can withstand. Additionally, since the diameter of the thread milling cutter is smaller than the internal thread’s small diameter, there is sufficient chip clearance, which reduces the likelihood of chip clogging. This effectively prevents chip damage to the machined surface and improves thread quality. Moreover, when milling large, non-rotating internal threads, the workpiece can remain stationary, and machining is carried out by the movement of the thread milling cutter. This eliminates the need for complex clamping setups and minimizes the challenges associated with ensuring the dynamic balance of rotating workpieces.

In the study of thread milling, Lee et al.7 developed a mechanical cutting force model based on the geometry of the milling cutter, incorporating tool runout errors to predict the unbalanced force distribution across the cutter’s teeth. Araujo et al.8 investigated the influence of thread geometry, cutting conditions, and tool angles on cutting force and torque, validating their findings through experiments. Hu et al.9 proposed a thread milling force model that considers instantaneous thickness, simplifying the cylindrical thread milling process to a straight milling operation. Wan et al.10 explored the dynamics of the thread milling process, presenting a periodic dynamic force model that predicts the effects of spindle speed, axial depth of cut, tool path, and geometric shape on the milling process’s stability. Based on cutting tests, Sharma et al.11 analyzed the impact of thread milling cutter geometry and cutting modes on cutting forces during spiral milling of threaded holes. They also proposed a method for evaluating the cutting performance of thread milling cutters with different numbers of teeth. Furthermore, through cutting force analysis, an optimization method for milling cutter geometry was suggested, with cutting test results showing that smaller variations in cutting force to reduced tool chatter. Malkov et al.12 developed an algorithm and program for the theoretical calculation of the components of the cutting force during thread milling with single-disk cutters using the parameters of the section of the cut layer. The above studies mainly focus on the cutting force during thread milling, but do not study the error of thread milling.

In thread milling, machining errors significantly limit the improvement of thread machining precision, making it crucial to conduct in-depth research in this area. Regarding the analysis of machining errors, Fromentin et al.13 developed a model to calculate interference errors when milling cylindrical internal threads with symmetrical teeth. Building on this interference error model, they analyzed the influence of the thread milling cutter’s tooth profile on the machining accuracy of threads. Later, Benjamin et al.14 established a model for calculating machining interference errors during the milling of asymmetric cylindrical internal threads. Their study revealed that the radial interference error of internal thread milling increases with a higher ratio of pitch to thread diameter, a larger cutter diameter relative to the thread diameter, and a greater thread side angle. Sharma et al.15 proposed a model to calculate machining interference errors in the cut section of internal screw milling. They compared the interference degree of different cutting methods, including direct radial cut, half screw cut, and quarter screw cut. J.H. Ahn et al.16 developed a theoretical model for the tool tip path during the milling process, based on matrix transformation, and conducted simulations to study the effects of process parameters on the tool tip path. They analyzed the impact of workpiece surface roughness, chip thickness, and cutting force on actual cutting errors, with the simulation results validated through extensive experiments. Dogrusadik et al.17 used an analytical method to model the thread contour during thread milling, finding that the thread contour was not a straight line but a curve, with the thread slope being smaller than the slope of the tool. Fan et al.18 explored the causes of thread milling errors, established a machining error model for the entire manufacturing process based on geometric analysis, and transformed the error calculation problem into determining the positional relationship between the intersection point of the tool contour and the thread contour on the cross section. Ghogha et al.19 investigated the impact of various infeed strategies-radial, modified flank, and incremental-on flank wear during thread milling, taking into account different cutting speeds. The above research primarily focuses on modeling machining errors in thread milling for three-axis machining, with little attention given to the study of machining errors in thread milling using five-axis machining.

In the field of machining error control for thread milling, Lee et al.20 proposed a novel optimization method for the tooth profile of thread milling cutters. This method utilized CNC cutting simulation to analyze machining interference errors between the standard thread profile and the machined thread profile, and adaptively corrected the thread milling cutter’s tooth profile based on the interference error. This approach helps optimize the machining process by minimizing interference errors. Chaves-Jacob et al.21 introduced a technique to reduce interference errors in non-developable straight surface milling. By optimizing the tool geometry, this method effectively reduced interference errors during the milling process. Guilaume et al.13 analyzed overcut and residue in thread machining by comparing the thread contour generated by the thread milling cutter envelope with the precise cylindrical thread contour. They then corrected the tooth profile of the thread milling cutter based on the error value between the two contours, ensuring that the machining envelope generated by the cutter, through both rotation and revolution, would align as closely as possible with the standard thread surface. This correction improved both the profile integrity and the accuracy of the machined threads. Amir MK et al.22 investigated the impact of cutting fluid pressure, feed speed, and spindle speed as input parameters and used the minimum milling interference value as the optimization target, applying an artificial neural network algorithm. Their study concluded that increasing cutting speed, feed speed, and cutting pressure improved the surface quality of the top thread. Omirou et al.23 introduced a new canned cycle for CNC milling machines, detailing its design, implementation, and experimental validation, which allows for the precise and efficient cutting of threads with both fixed and variable pitch and radius. From the above error control studies, it is evident that the design of the milling cutter mainly relies on the axial cross-section of the thread, which inevitably impacts machining accuracy. Few studies have focused on designing the milling cutter profile based on a specific axial cross-section to control errors, and even fewer have explored reducing machining errors through a five-axis milling strategy.

In summary, the above analysis reveals that research on thread milling has primarily focused on cutting force modeling, while studies on machining error modeling and control are limited, with only a few articles addressing this topic. Additionally, such research predominantly concentrates on three-axis thread milling. However, for aviation parts, which have complex structures and stringent precision requirements, especially when threads need to be machined on inclined surfaces, curved surfaces, or in hard-to-reach areas, three-axis machining fails to provide sufficient flexibility and accuracy. Therefore, this paper proposes a five-axis thread milling strategy to effectively reduce machining errors. The primary contributions of this research are centered around the following objectives:

-

(1)

To propose a method for defining the profile of a thread milling cutter using both normal and axial sections, enabling the analysis and identification of machining errors.

-

(2)

To introduce a novel locus in the tool path definition to control milling errors, thereby enhancing precision.

-

(3)

To develop an error model for the milling process based on envelope theory, facilitating a comparison of errors across different milling strategies.

The structure of the study is outlined in (Fig. 1). And the remaining paper is organized as follows. Section 2 develops a geometric model of the thread mills based on both the axial cross-section and the normal section, laying the foundation for subsequent modeling and analysis. Section 3 presents a machining error model using envelope theory, which is further demonstrated through a practical example. Section 4 provides an experimental comparison between three-axis and five-axis thread milling, showcasing the accuracy and feasibility of the proposed method.

Structure of thread mills

The profile of a thread mill is derived from a specific section of the corresponding thread, with this section forming the rotational surface of the mill’s profile. Therefore, accurately obtaining this section from the thread profile is crucial for the design process. Traditionally, the axial cross-section has been used for thread mill design. In contrast, this paper introduces a novel approach where the nominal profile is derived directly from the axial cross-section, which is key to the proposed method for constructing thread mills more efficiently and accurately.

Axial cross section

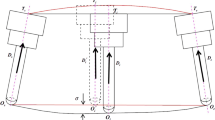

The axial cross section of an internal thread profile can be defined by parameters exhibited in (Fig. 2).

Two threads are illustrated in (Fig. 2). In this figure, there are 8 points from P1 to P8. P is the pitch of thread. D is the nominal diameter. D1 is the internal diameter. D2 is the intermediate diameter. R is the root radius. \(\:\theta\:\) is the thread form angle. \(\:{\theta\:}_{1}\) is the left thread flank angle. \(\:{\theta\:}_{2}\) is the right thread flank angle of the right thread. H is the initial height of triangle. H1 is the top depth of truncation. H2 is the bottom depth of truncation.

It should be noting that these parameters with different values represents different type of thread. For instance, when this is the international metric thread, these values are:

For American standard thread, the profile of a thread is the same as that of the international metric thread except that the curve \(\:\widehat{\mathbf{P}4\mathbf{P}5}\:\)changes into a line. For buttress threads, curve \(\:\widehat{\mathbf{P}4\mathbf{P}5}\:\)is a line and the parameters are changed into:

A coordinate system {O, xyz} is set on the axis of the internal thread, z-axis is parallel to the thread axis, x-axis points to radius direction and contains point P1. O is on the plane embracing point P1. The thread profile is in the zOx plane. According to this definition, the thread profile can be expressed by a mathematical model. Supposed that P(\(\:\mu\:\)) is a point on the thread profile, this point can be evaluated by:

In this equation, \(\:\mu\:\in\:\left[\text{0,4}\right]\). \(\:{\alpha\:}_{1}\) and \(\:{\alpha\:}_{2}\) are performed using the following equation:

\(\:{\mathbf{P}}_{\varvec{o}}\) is the center of the circle and can be computed using:

The points from P1 to P5 can be expressed as:

If \(\:\widehat{\mathbf{P}4\mathbf{P}5}\) is a line, \(\:\mathbf{P}\left(x,z\right)\) in \(\:\left(\left.\mathbf{P}4,\mathbf{P}5\right]\right.\) can be expressed by:

At this time \(\:\mathbf{P}4\) and \(\:\mathbf{P}5\) can be expressed by another form:

Then, a point \(\:\mathbf{S}\left(\mu\:,{\upvartheta\:}\right)\) on the surface of a thread can be calculated using the following equation:

For left-hand thread, i = 1 and for the right-hand thread i = 2. \(\:{\upvartheta\:}\) is the rotational angle.

Normal section

The normal section of a thread at any position are the same. Therefore, to simplify the calculation process, the plane embracing the normal section and the origin point of the coordinate system {O, xyz} is set up as seen in (Fig. 3).

In Fig. 3, the zone A (simplified) which is the axial cross section of an internal thread profile is illustrated, and the normal section which can be seen in direction \(\:\mathbf{n}\left(\beta\:\right)\) denoting the normal vector can be obtained in the normal plane. For this normal plane, the normal vector \(\:\mathbf{n}\left(\beta\:\right)\) can be expressed as:

\(\:\beta\:\) is the lead angle. Then, because the normal plane contains the point [0, 0, 0]T, an arbitrary point on this plane as well as on the thread surface which is evaluated by Eq. (9) can be expressed by using the formula:

Let \(\:\mathbf{P}\left(\mu\:\right)\) in Eq. (3) can be expressed by element-form using \(\:\mathbf{P}\left(\mu\:\right)={\left[\begin{array}{ccc}x\left(u\right)&\:0&\:z\left(u\right)\end{array}\right]}^{T}\) in the coordinate system {O, xyz}, Eq. (11) can be expanded as:

Using this equation, \(\:{\upvartheta\:}\) can be calculated when parameter \(\:u\) is given. Then substituting \(\:\left(\mu\:,{\upvartheta\:}\right)\) into formula (9), the normal section of threads can be obtained. Actually, when we need to use numerical methods to solve Eq. (12) from 0 to \(\:{360}^{^\circ\:}\) for \(\:{\upvartheta\:}\), there are two same normal sections. The first one is in the zone of [\(\:{0}^{^\circ\:}\), \(\:{180}^{^\circ\:}\)] and the other one is located in the range of [\(\:{180}^{^\circ\:}\), \(\:{360}^{^\circ\:}\)] and the phase difference between two normal sections is 180°. Therefore, Newton iteration or golden section way can be used to deal with Eq. (12). Here, we take internal thread M27 × 2 as an example. For this thread, D = 27 mm, P = 2 mm, \(\:H=P/\left(tan\left({\theta\:}_{1}\right)+tan\left({\theta\:}_{2}\right)\right)\), D2=D-3H/8, D1=D-2H, H1=H/4 and H2=H/8.

In Fig. 4, P1m, P2m, P3m, P4m and P5m are the points on the normal sections corresponding to the P1, P2, P3, P4 and P5. ‘Along thread profile’ means that the length from a point on the thread profile to P1 along the thread profile, for example, horizontal coordinates of 2− in the third row stands for the length of curve P1P2 in the second row. Subscript + and – represent right and left neighborhood. From the deviation images, it can be found that the profile corresponding to the line of the axial cross section is not line again. For examples, the deviation from 1 to 2− is not a line, the P1P2 is line in the first row in (Fig. 4). Therefore, in the second row the curve between P1 and P2 is not a line anymore. Furthermore, the largest value of the deviation 0.4 \(\:\mu\:\)m for \(\:{\theta\:}_{1}={\theta\:}_{2}={30}^{^\circ\:}\) and 0.7 \(\:\mu\:\)m for \(\:\:{\theta\:}_{1}={30}^{^\circ\:},\:{\:\theta\:}_{2}={3}^{^\circ\:}\). Therefore, the normal section can represent the axial cross section in some cases that with low requirement of accuracy.

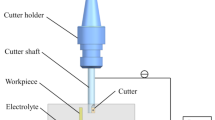

Geometry of the thread mill

In the thread milling process, thread mill is a key tool to determine the machined surface. Owing to absence of helix angle, the thread mill is a rotational surface. In this section, we take two ways to build a mill, the first one is using the normal section to create the thread mill. The other one making the thread milling is taking the axial cross section. For both of these situations, the mill coordinate system {Om, xmymzm} is set up. zm-axis is parallel to the mill axis, xm-axis points to radius direction and contains point P1. Original point Om is on the mill axis.

For the first situation, the cutter’s profile can be illustrated in (Fig. 5). d is the nominal diameter. d1 is the internal diameter. d2 is the intermediate diameter. Due to the profile is not composed of a series of lines. Thus, for each curve such as \(\:\widehat{\mathbf{P}1\mathbf{P}2}\) in (Fig. 5), cubic B-spline curve can be used to interpolate points obtained in the above subsection. Here, for each curve-segment in (Fig. 5).

(\(\:\widehat{\mathbf{P}1\mathbf{P}2},\widehat{\:\mathbf{P}2\mathbf{P}3},\widehat{\:\mathbf{P}3\mathbf{P}4}\:\text{o}\text{r}\:\widehat{\mathbf{P}4\mathbf{P}5}\)), a point \(\:{\mathbf{P}}_{\varvec{n}}\left(u\right)\) on the cubic B-spline curve can be expressed as:

\(\:{u}_{1}\in\:\left[\text{0,1}\right]\). \(\:{\mathbf{P}}_{j}\) is the control points which can be obtained using interpolating method with points on the normal section of the thread. Then, these curves rotate about zm axis and a point \(\:{\mathbf{P}}_{\varvec{s}}\left({u}_{1},\theta\:\:\right)\) on this rotating surface can be evaluated as:

\(\:\theta\:\in\:\left[\text{0,2}{\uppi\:}\right]\). For the second way using the axial cross section, many works have made great efforts on this topic7,9. Therefore, this paper uses the theory in7,9 to build the thread mill and does not discuss it here.

To illustrate the thread mill using two methods, we use the axial cross section and the normal section in Fig. 3 to set up the surfaces of the thread mill. The results are showed in (Fig. 6). Here, let d = 10 mm.

Using the mills obtained in this subsection, the machining error can be obtained and analyzed. Therefore, in the next section, errors induced by mills made from normal section and axial cross section.

Error control method using five-axis milling strategy

To reduce the milling error, this paper introduces the five-axis machining strategy. In this section, the envelope theory is used to set up the error model. Therefore, the structure of this section is divided into three subsections. The first part involves determining the tool paths for both three-axis and five-axis machining, while the second part focuses on setting up the error model and providing several examples in the final subsection.

Tool path definition

To build errors, the tool path must be defined firstly. As we know, main code segment in tool path file can be defined by the following format in the coordinate system {O, xyz}:

\(\:\mathbf{Q}\left(t\right)\) is the mill ___location point and its components along three directions are \(\:x\left(t\right)\), \(\:y\left(t\right)\), and \(\:z\left(t\right)\). \(\:\mathbf{a}\left(t\right)\) is corresponding mill axis vector and \(\:a\left(t\right)\), \(\:b\left(t\right)\) and \(\:c\left(t\right)\) are components of \(\:\mathbf{a}\left(t\right)\), t is time. For two types of mills: mill I-obtained from normal section, and mill II-obtained from axial cross section, two types of tool paths are defined. The first one is the existed trace nowadays defined by:

\(\:\omega\:\) is the angular velocity about thread axis and r is the revolution radius of the mill. Traditionally, r can be optimized to gain higher accuracy and lower error.

The second one is the new locus presented by this paper to be used to control milling error. In this method, the mill axis is no longer [0 0 1]T. At the same time, the included angle between mill and thread axes is β and trajectory can be expressed by:

Then, using the information obtained above, the error can be constructed.

Error construction

Just like Fig. 7, the error of the milling process can be defined by the deviation between the envelope surface and the desired thread surface.

Supposed that point Pe is on the envelope surface, through this point, a line vertical to the desired surface can be made and the foot-point is Pm. Then, the error \(\:\epsilon\:\) can be constructed by the following Eq.

If point Pe locates on the positive side of the desired surface, let \(\:ii=0\), else let \(\:ii=1\). Then, the key step is to calculate the envelope surface and foot point.

\(\:{\varvec{P}}_{\varvec{m}}\) on the machined surface

This paper introduces the relative theory briefly, the details are illustrated in work24. When a point of the mill surface locates on the envelope surface, this point must meet the condition that in the {Om, xmymzm}:

\(\:{\mathbf{n}}_{\mathbf{v}}\) and \(\:{\mathbf{v}}_{\mathbf{v}}\) are the normal and velocity vectors of point \(\:\mathbf{S}\left({u}_{1},\theta\:\right)\), respectively. The velocity vector can be calculated using:

Taking Eq. (20) into Eq. (19), we can get the following formula:

with

Then, the first equation in (21) can be calculated by:

Substituting the above equation into formula (14), the point on the envelope surface can be obtained and can be transformed into the {O, xyz} using:

\(\:{\varvec{P}}_{\varvec{m}}\) on the desired surface

For a thread surface, the following condition must be met.

The meaning of the first equation is that \(\:{\left[\begin{array}{ccc}{\left.\frac{\partial\:\mathbf{S}\left(\mu\:,{\upvartheta\:}\right)}{\partial\:{\upvartheta\:}}\right|}_{x}&\:{\left.\frac{\partial\:\mathbf{S}\left(\mu\:,{\upvartheta\:}\right)}{\partial\:{\upvartheta\:}}\right|}_{y}&\:0\end{array}\right]}^{T}\) is also a tangential vector at point \(\:\mathbf{S}\left(\mu\:,{\upvartheta\:}\right)\) on the thread surface. The second and third formulas represent that the normal vector of a point on the axial cross section can also vertical to the vector \(\:{\left[\begin{array}{ccc}{\left.\frac{\partial\:\mathbf{S}\left(\mu\:,{\upvartheta\:}\right)}{\partial\:{\upvartheta\:}}\right|}_{x}&\:{\left.\frac{\partial\:\mathbf{S}\left(\mu\:,{\upvartheta\:}\right)}{\partial\:{\upvartheta\:}}\right|}_{y}&\:0\end{array}\right]}^{T}\).

Therefore, to find a line, containing \(\:{\mathbf{P}}_{\mathbf{m}}\) of point \(\:{\mathbf{P}}_{\mathbf{e}}\), perpendicular to the thread surface, the first step is reverse rotating point \(\:{\mathbf{P}}_{\mathbf{m}}\) from current position to the point \(\:{\mathbf{P}}_{\varvec{e}1}\) in the axial cross plane xOz.

Function \(\:floor\left(\right)\) means ‘round up’ towards mins-direction \(\:(e.g.\:floor\left(3.2\right)=3)\). Then, a line, through point \(\:{\mathbf{P}}_{\varvec{e}1}\), vertical to the axial cross section can be built, the foot point \(\:{\mathbf{P}}_{\varvec{m}1}\)can be found and evaluated by:

Finally, \(\:{\mathbf{P}}_{\varvec{m}}\) can be computed using the following equation:

Error examples

Based on the above content, the error can be obtained. To exhibit the error with different strategy, some combinations listed in Table 1 are taken as examples.

The nominal diameter of the mill is 10 mm, r = 8.5 mm, and \(\:\omega\:=50\:\)rounds per second. And the results are shown in (Fig. 8). In this figure, the first raw is for the three-axis milling process and the second raw adopts the five-axis machining strategy. The largest error for path (a) is more than 3.5 µm (absolute value). However, for path (b), the largest error is less than 0.9 µm. The error reduces greatly, in the other words, the accuracy increases about 289%. Therefore, five axis machining strategy is superior to three axis milling process with the same cutting parameters. Furthermore, the content of the first column in Fig. 8 is the error induced by the mill from the normal section and the other one is the error induced by the cutter obtained by the axial cross section. For two mills and the same tool path, the errors are almost identical (3.6 µm for Mill I and 3.5 µm for Mill II in the three-axis machining process, and 0.65 µm for Mill I and 0.9 µm for Mill II). However, in the five-axis machining process, the error for Mill I ((-0.1 µm, 0. 62 µm)) is better than that for Mill II (-0.6 µm, 0.9 µm). Thus, the mill made from the normal section is the best tool removing the material to from the desired thread. Finally, it can be found that the biggest errors for four situations are at the left neighborhood of point P4. The lowest error is always on the curves that is approximately parallel to the z-axis of the thread such as curves between P2 P3 and P4 P5.

Milling error induced by different parameters in (Table 1).

Figure 9 shows the example of (I, (b)). In this example, the machined surface is milled by Mill I from the normal section and this mill is also shown. This can prove that the strategy presented in this paper can be used to mill the thread.

Experimental verification and discussion

From the above section, we can get the truth that the five-axis milling strategy is better than the three-axis machining method. Simultaneously, Mill I can obtain higher accuracy than Mill II. Due to the fact that Mill I cannot be bought. Therefore, in this section, we adopt Mill I made from the normal section as target to study the effect of the included angle (the fix angle) between the mill axis and the thread axis on the error in the first subsection. Then, some experiments using Mill II are carried out in the next subsection.

Fix angle’s effect

The fix angle may affect the machining error, including. Therefore, this subsection analyzes its effect on the machining error.

In theory, the included angle between the mill axis and the thread axis named as the fix angle is equal to the lead angle \(\:\beta\:\). In this section, \(\:\beta\:\) is equal to 0.0248 rad. In order to analyze the effect of the fix angle on the machining error, the range of the fix angle is chosen as [\(\:\beta\:-0.0148,\:\beta\:+0.0148\)]. From this image, we can also get that the fix angle definitely affects the machining error. The surface of the error is illustrated in (Fig. 10a). With the increase of the fix angle, the error for the cutter edge between P3P4 and P5P6 raises first and then declines. That means with the change of the fix angle, there is one maximum value of overcut and the error changes from undercut to overcut and then to undercut. And when the fix angle is \(\:\beta\:\), the error curve is not optimal. For example, when the fix angle is \(\:\beta\:\), the error is shown in (Fig. 8I, (b)). It can be observed from this figure that the error range spans from −0. to 0.6 μm. Specifically, when the fixed angle is set to 0.0198 rad (β − 0.005), as shown in (Fig. 10b), the error range is reduced to −0.1 to 0.35 μm. On the other hand, when the fixed angle is increased to 0.0298 rad (β + 0.005), as depicted in (Fig. 10c), the error range expands to –0.1 to 0.58 μm. This highlights the effect of the fixed angle variation on the error range, demonstrating how slight changes in the angle influence the resulting machining accuracy.

Experiments

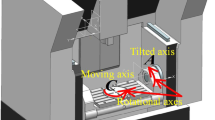

In this subsection, some experiments are conducted to prove the effectiveness of the proposed theory. The experiments are conducted on the five-axis machining center DMG DMU 60 monoBLOCK, as shown in (Fig. 11).

The material in this paper is AL7075. The parameters of the cutter are listed in (Table 2). In this table, L1 is the empty length, L2 is the total length, Dm1 is the diameter of cutting edge, Dm2 is the total length, N is the amount of the cutter edges, the material of the mill is cemented carbide. The image of the thread cutter is also illustrated in (Table 2). The parameters of the thread are: the diameter of the thread is 14 mm. The thread form angle is 60 degrees. The left thread flank angle equals to the right thread flank angle, they are 30 degrees. The depth of the pre-machined hole is 18 mm.

Just as the above section, two strategies are used here. The first one is using traditional way which is the three-axis machining method. The other one using the five-axis machining strategy. In the five-axis machining process, the including angle between cutter axis and the thread axis equals to 0.0282 rad. Additionally, during the machining process, other parameters are selected based on the recommendations25. Specifically, the spindle speed is set to 1500 rpm and the feed to 30 mm/min. To ensure the accuracy of the experimental machining, the cutting depth is divided into three stages: the first two cuts are 0.9 mm each, while the final cut is 0.4 mm. Coolant is applied continuously throughout the cutting process.

After the thread are milled, the thread is measured by the three-coordinate measuring machine ZEISS PRISMO just as in (Fig. 12). The maximum detecting length along three directions are 900, 1200 and 600 mm. The positioning accuracy of this machine is 0.1 µm.

Here, the axial cross section of the thread is measured to compare the machining accuracy between two machining strategies that are the three-axis and the five-axis machining methods.

When the data are measured. Though two group of data are in the same coordinates systems, they are not in the same plane. At the same time, they are not at the same height along the axis of the thread. Therefore, the data are processed before they are compared using the following steps.

-

(1)

The data are expressed in the same axial cross section. In this paper, all the data are rotated into the XOZ plane.

-

(2)

One groove of the thread for both machining strategy are chosen to be compared. When they are rotated into the same plane, they are translated to the same height to be compared.

Figure 13 shows the measured results of one groove using the 3-axis and 5-axis machining technology. From this figure, it can be seen that, using different milling strategy, the profile is different. This prove that the 5-axis machining technology definitely affect the profile of the thread.

This part is also detected using the Zygo New View 5000, a non-contact white light interferometer, the results are showed in (Fig. 14). In this figure, (a) and (b) show the profiles of the grooves milling by two strategies, (c) shows the parallel lines of the two side lines belonging to two grooves. The similar principle as Fig. 13 can be found in this figure, the two profiles are different from each other. Furthermore, the angle between the side line and x-direction are calculated. For the 3-axis machining process, this angle is 29.204 degrees. For the 5-axis milling process, this angle equals to 30.8079 degrees. All of them deviate from the nominal value which is 30 degrees (half of the thread form angle). This proves that the five-axis machining technology can change the profile of the groove. Then, when the including angle between cutter axis and the thread axis changes from 0 to 0.0282 rad., the error of the angle changes from −0.796 to 0.808 degrees. That means the error changes from minus to zero and then to plus value. Therefore, there may be a opt-value.

Conclusions

Thread is a typical connecting structure between two parts. And this structure is widely used in the aviation. For some extremely important parts, the machining accuracy of threads is vital for the strength of the connection, serving life of the connecting parts, and so on. For these threads, traditional three-axis milling method cannot meet the requirements. Therefore, five axis milling strategy is proposed and some researches are done in this paper for the first time. Some important conclusions are got.

-

(1)

In order to study the thread milling process using the five-axis machining method, the structure of threads is analyzed and the mathematical model are developed. Based on this, the structure of the thread mill is deduced.

-

(2)

Five-axis milling technology is used to machine the thread. The tool path used to milling threads are designed. Then, the machining error is defined. An Example is performed to prove the viewpoint that five-axis milling strategy can reduce the machining error compared to the three-axis milling technology.

-

(3)

The Influence of fix angle on the milling error in the five-axis milling process are analyzed. It can be found that fix-angle definitely affect the machining error. Fix angle can be obtained through changing direction of the tool. This can be realized by five-axis centers.

-

(4)

Experiments are done to prove the validity of the proposed theory. In the experiments, three-axis and five-axis machining strategies are used to mill threads. The axial cross section of the thread is measured to compare the machining accuracy. The results show that the theory in this paper can reduce the machining error significantly.

-

(5)

The five-axis thread milling proposed in this paper offers high machining accuracy but requires careful consideration of the following aspects:

Complexity

The design and manufacturing of five-axis equipment and thread milling cutters are demanding, and the operation and maintenance require a high technical skill level, making implementation more challenging.

Cost

The substantial investment in five-axis equipment and high-precision milling cutters may increase overall production costs.

Scope of application

While effective for high-precision machining, this method may be less cost-effective for low-accuracy requirements, so its applicability should be evaluated on a case-by-case basis.

Data availability

The data that support the findings of this study are available on request from the corresponding author upon reasonable request.

References

Siqueira, B. S., Freitas, S. A., Robson, B. D. P., Carlos, H. L. & Lincoln C. B. Influence of chip breaker and helix angle on cutting efforts in the internal threading process. Int. J. Adv. Manuf. Technol. 102, 5–8. https://doi.org/10.1007/s00170-024-13970-5 (2019).

Kosarev, V. A., Grechishnikov, V. A. & Kosarev, D. V. Milling internal thread with planetary tool motion. Russ. Eng. Res. 29, 1177–1179. https://doi.org/10.3103/S1068798X09110227 (2009).

Smid, P. CNC Programming Handbook: a Comprehensive Guide To Practical CNC Programming (Industrial Press Inc, 2008).

Fromentin, G. & Poulachon, G. Geometrical analysis of thread milling-part 1: evaluation of tool angles. Int. J. Adv. Manuf. Technol. 49, 73–80. https://doi.org/10.1007/s00170-009-2402-3 (2010).

Fromentin, G. & Poulachon, G. Geometrical analysis of thread milling-part 2: calculation of uncut chip thickness. Int. J. Adv. Manuf. Technol. 49, 81–87. https://doi.org/10.1007/s00170-009-2401-4 (2010).

Guo, Q. et al. Development, challenges and future trends on the fabrication of micro-textured surfaces using milling technology. J. Manuf. Process. 126, 285–331. https://doi.org/10.1016/j.jmapro.2024.07.112 (2024).

Lee, S. W., Kasten, A. & Nestler, A. Analytic mechanistic cutting force model for thread milling operations. Proc. Cirp. 8, 546–551. https://doi.org/10.1016/j.procir.2013.06.148 (2013).

Araujo, A. C., Fromentin, G. & Poulachon, G. Analytical and experimental investigations on thread milling forces in titanium alloy. Int. J. Mach. Tools Manuf. 67, 28–34. https://doi.org/10.1016/j.ijmachtools.2012.12.005 (2013).

Hu, Z. et al. An effective thread milling force prediction model considering instantaneous cutting thickness based on the cylindrical thread milling simplified to side milling process. Int. J. Adv. Manuf. Technol. 110, 1275–1283. https://doi.org/10.1007/s00170-020-05919-1 (2020).

Wan, M. & Altintas, Y. Mechanics and dynamics of thread milling process. Int. J. Mach. Tools Manuf. 87, 16–26. https://doi.org/10.1016/j.ijmachtools.2014.07.006 (2014).

Sharma, V. S. et al. Investigation of tool geometry effect and penetration strategies on cutting forces during thread milling. Int. J. Adv. Manuf. Technol. 74, 963–971. https://doi.org/10.1007/s00170-014-6040-z (2014).

Malkov, O. V. & Karelsky, A. S. Force modeling of thread milling. AIP Conf. Proc. 2549, 170004. https://doi.org/10.1063/5.0108272 (2023).

Fromentin, G. & Poulachon, G. Modeling of interferences during thread milling operation. Int. J. Adv. Manuf. Technol. 49, 41–51. https://doi.org/10.1007/s00170-009-2372-5 (2010).

Fromentin, G., Bbeler, D. & Lung, B. Computerized simulation of interference in thread milling of non-symmetric thread profiles. Proc. CIRP 31, 496–501. https://doi.org/10.1016/j.procir.2015.03.018 (2015).

Sharma, V. S. et al. Effect of thread milling penetration strategies on the dimensional accuracy. J. Manuf. Sci. Eng. Trans. ASME 133 (4), 1–13. https://doi.org/10.1115/1.4004318 (2011).

Ahn, J. H., Kang, D. B. & Lee, M. H. Investigation of cutting characteristics in side-milling a multi-thread worm shaft on automatic lathe. CIRP Ann. Manuf. Technol. 55 (1), 63–66. https://doi.org/10.1016/S0007-8506(07)60367-9 (2006).

Dogrusadik, A. Analytical derivation of thread profile in internal thread milling process. Proc. Inst. Mech. Eng. E J. Process. Mech. Eng. 236 (3), 1047–1055. https://doi.org/10.1177/09544089211056033 (2022).

Fan, Y. et al. Machining error model for full machining process of thread milling. Int. J. Adv. Manuf. Technol. 123, 511–526. https://doi.org/10.1007/s00170-022-10200-8 (2022).

Ghogha, H., Farahnakian, M. & Elhami, S. Experimental and numerical studies on the flank wear during the thread milling; effect of infeed strategies in different cutting speeds. Tribol. Int. 198, 109899. https://doi.org/10.1016/j.triboint.2024.109899 (2024).

Lee, S. W. & Nestler, A. Simulation-aided design of thread milling cutter. Proc. Cirp 1 (1), 120–125. https://doi.org/10.1016/j.procir.2012.04.019 (2012).

Chaves-Jacob, J., Poulachon, G. & Duc, E. New approach to 5-axis flank milling of free-form surfaces: computation of adapted tool shape. Comput. Aided Des. 41, 918–929. https://doi.org/10.1016/j.cad.2009.06.009 (2009).

Amir, M. K. et al. Investigation on the effect of cutting fluid pressure on surface quality measurement in high speed thread milling of brass alloy (C3600) and aluminum alloy (5083). Measurement 82 (10), 55–63. https://doi.org/10.1016/j.measurement.2015.12.016 (2016).

Omirou, S., Charalambides, M. & Chasos, C. Advanced CNC thread milling: a comprehensive canned cycle for efficient cutting of threads with fixed or variable pitch and radius. Int. J. Adv. Manuf. Technol. 133, 2219–2233. https://doi.org/10.1007/s00170-024-13970-5 (2024).

Sun, Y. & Guo, Q. Analytical modeling and simulation of the envelope surface in five-axis flank milling with cutter runout. J. Manuf. Sci. Eng. 134, 021010. https://doi.org/10.1115/1.4005802 (2012).

Dogrusadik, A. Effect of cutting conditions and thread mill diameter on cutting temperature in internal thread milling of Al7075-T6. Sādhanā 47 (157). https://doi.org/10.1007/s12046-022-01935-x (2022).

Acknowledgements

The Fundamental Research Funds for the Universities of Henan Province (No. NSFRF240307) and the research group of efficient and precision manufacturing technology and equipment (No. 2023ZK01).

Author information

Authors and Affiliations

Contributions

Theoretical derivation:Jinjie Jia, Wenyuan Song, Mingcong Huang; Content writing: Ye Zhang, Xinman Yuan, Xicheng Zhang; Experiment and analysis: Dan Tang, Tingyu Zhang, Zhao Xue; Master plan: Yan Jiang.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jia, J., Song, W., Huang, M. et al. Error control method using crossed axes strategy in the five-axis thread milling process. Sci Rep 15, 11165 (2025). https://doi.org/10.1038/s41598-025-95159-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-95159-8