Abstract

The interlayer connection of circuits within stretchable electronic devices is crucial for enhancing their performance. Conventional methods for interlayer circuit connections are fragile and prone to mechanical deformation, prompting the need for new approaches. Although various methods have been proposed for creating interconnections in stretchable circuits, a universally efficient method for junctions remains to be fully developed. In this study, we propose a method to connect the interlayers of stretchable circuits using electro-driven silver nanowires. By comparing the conventional junction method with our proposed method, we verify the efficiency of the new approach. The results reveal that applying a high electric field during the solidification of the circuit interlayer aligns the isotropic state of the silver nanowires parallel to the field, thereby increasing the conductivity of the interlayer junction. Additionally, the study demonstrates that using silver nanowires for the junction provides better mechanical stability to the junction compared to that of the bulk material, as verified through mechanical stretch experiments. An in-depth analysis with mathematical modeling is presented at the end of the study. The proposed method is a promising approach for creating junctions in stretchable devices and is expected to pave the way for increasing their efficiency.

Similar content being viewed by others

Introduction

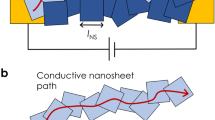

Stretchable electronics are devices that can be stretched or bent, offering the advantage of conforming to various 3D surfaces. Due to their versatility, stretchable devices are used in various applications, such as wearable devices1,2, flexible displays3, smart sensing arrays4,5, and smart robots6,7. To enhance the performance of stretchable electronics, efficient deposition of the stretchable circuit is essential8,9,10,11, and finding effective ways to connect circuits across different layers in a stretchable device is crucial. Conventional methods for interlayer circuit connections are fragile and susceptible to mechanical deformation12,13,14,15, necessitating new approaches for connecting stretchable circuits, as shown in Fig. 1(a). Various methods have been proposed for creating interconnections in stretchable circuits, such as using conductive polymers16,17, filling with liquid metal18,19,20, and the stamping-pillar method21. Although these methods have demonstrated promising interconnecting performance in stretchable circuits, their methods are primarily confined in research purpose, and an efficient solution for junctions in stretchable circuits has yet to be fully realized.

In this study, we propose an efficient method for creating vertical junctions among stretchable circuits. We established the connections between the circuits by infiltrating electro-driven silver nanowires (AgNWs) into a polydimethylsiloxane (PDMS) layer during polymerization. The performance of the interlayer connections was studied by measuring the electric conductivity of the junction under mechanical deformation. The experimental analysis focused on nanowire penetration depth, electrical resistance, and stretchability, which are crucial parameters that determine reliability and efficiency of flexible electronic devices. Additionally, micromechanical model was introduced to analyze the homogenized electrical conductivity of AgNW–PDMS nanocomposites, considering electron hopping and the conductive network. The influences of fiber orientation on the homogenized electrical conductivity were investigated and validated experimentally.

Materials and methods

Sample fabrication and characterization

A mold created using a 3D printer (Sindoh A1) was used for sample fabrication, as shown in Fig. 1(b). Initially, copper tape was placed on a plastic substrate, and a 3D-printed mold was positioned over it. The mold was secured with Pi tape for insulation. A solution of PDMS (Sylgard 184, Dow Corning) mixed at a ratio of 10:1 (base to curing agent) was prepared. The mixture was degassed in a vacuum chamber at − 0.08 MPa for 1 h to remove any air bubbles. Subsequently, the PDMS solution was poured into the mold. A droplet of silver nanowires (NovaWire-Ag-A70) was applied onto the PDMS layer. Two electrodes were placed on the top and bottom of the sample (Fig. 1(c)). A 60 V electric field was applied between the electrodes while the sample was polymerizing in a vacuum oven at 60 °C for 1 h. Scanning electron microscopy (SEM) imaging was performed on selected samples to analyze the distribution and structural integrity of the silver nanowires within the PDMS matrix.

Stretch experiment

Samples were mounted on a customized jig with a motorized actuator (TAMM60 - 15 CR, Optosigma), as shown in Fig. 2. The samples were prepared on a PDMS substrate measuring 4 cm in width and 2.5 cm in length. The steady-state electrical resistance of the samples was measured under mechanical deformation, applying two types of deformation: (1) cyclic stretch, and (2) long-range stretch. For cyclic stretching, the samples were subjected to repeated stretching and contracting for 200 cycles. Three different samples were used for each condition (0 V, 30 V, 60 V) in cyclic stretch stretch experiment. The resistance of the samples was measured simultaneously using a multimeter (A34461, Keysight), as shown in Fig. 2. For long-range stretching, the resistance of the samples was measured at various strain levels, ranging from 0 to 30%. Three samples were used to assess the resistance changes. Similarly, samples fabricated using silver paste instead of AgNW were prepared and tested under the same conditions for performance comparison.

Mathematical modeling

Micromechanical models were employed to predict the homogenized electrical conductivity of PDMS nanocomposites incorporating long AgNWs22. The focus of the modeling was on investigating the influence of fiber orientation on the homogenized electrical conductivity of the PDMS nanocomposites, considering electronic hopping and conductive network mechanisms. The diameter and length of AgNWs are defined in Table 1.

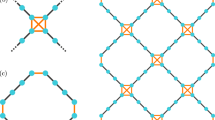

In this study, we assumed that the formation of the conductive networks is initiated when the AgNW volume fraction reaches the percolation threshold (\(\:{f}_{p}\))23. The overall electrical conductivity of the composites can be determined through a combined approach using the general micromechanics formulation provided in representattive volume element (RVE) Eqs24,25,26, as follows:

where θ and φ denote the Euler angles that define the orientation of the effective particles (Fig. 3); ρ(θ,φ) represents the orientation distribution; \(\:{f}_{eff}\) represents effective volume fraction of the solid particles; \(\:\stackrel{\sim}{\sigma\:}\) and \(\:{\stackrel{\sim}{\sigma\:}}_{m}\) denote the electrical conductivity tensors of the effective particles and matrix, respectively; \(\:\stackrel{\sim}{A}\)denotes the electric field concentration tensor gotten by Mori-Tanaka’s method26. Specific derivation of the \(\:\stackrel{\sim}{\sigma\:}\), \(\:{f}_{eff}\), \(\:\stackrel{\sim}{A}\) is provided in supplementary.

Assumming net conductivity of the AgNW Network is influenced by both electron hopping and conductive network of AgNW, generallized electrical conductivity of AgNW network can be described by the extension of the Eq. (1) as follows:

where \(\:{\stackrel{\sim}{\sigma\:}}_{EH}\) and \(\:{\stackrel{\sim}{\sigma\:}}_{CN}\) denote the electron hopping conductivity tensor and conductive network conductivity tensor, respectively; AEH and ACN denote the electron hopping concentration tensor and conductive network concentration tensor, respectively. \(\:\xi\:\) represents the proportion of percolated AgNW defined in Eq. (3) as follows:

The proposed mixed micromechanics model, considering both electron hopping and conductive networks, was utilized to predict the effective electrical conductivity of AgNW–PDMS nanocomposites. Conductivity calculation under various volume fractions and alignment angles are illustrated in supplementary1 file.

In order to predict change of electrical conductivity of AgNW–PDMS nanocomposites under mechanical stretch, soft elasticity of nematic elastomer theory27 has been introduced to identify align change of AgNW network. Assuming align of AgNW is compatible with nematic director of the elastomer, formulation of director change of the AgNW network under mechanical stretch is provided in Eq. (4) as follows:

where, \(\:{\stackrel{\sim}{{l}}}_{0}\) and \(\:\stackrel{\sim}{S}\) represent align director before and after stretch for each, and \(\:\stackrel{\sim}{\lambda\:}\) represents deformation gradient of the stretch. Assuming uniaxial stretch, \(\:\stackrel{\sim}{\lambda\:}\) can be expressed as diagonal matrix with single parameter λ. As \(\:\stackrel{\sim}{S}\) is diagonal matrix modified director can be defined as \(\:r/{\lambda\:}^{2}\), and modified rotation angle (Θ) can be defined as Eq. (5):

By Connecting Eq. (5) with Eq. (2), the conductivity change of AgNW-PDMS system under mechanical stretch has been simulated. In the case of silver paste modeling, r was set to 1, assuming that the silver particles were spherical and non-directional. In order to derive electrical resistance from conductivity, AgNW junction has been assumed as cylindrical shape with both radius and hight is set as 200 μm as shown in Fig. 3-b). Resistance of the AgNW junction has been derived by using conductivity-resistance relationship, shown in Eq. (6)

Here, \(\:R\) and \(\:\rho\:\) represents electric resistance and conductivity of AgNW junction respectively. \(\:l\) and \(\:r\) represents height and radius of the AgNW junction, regarded as cylindrical shape.

Data results

Experimental result

Image processing was performed on the SEM image of the AgNW–PDMS junction. As AgNW in SEM image is represented as multiple line segments, Hough algorithm in MATLAB R2024a software was applied to extract AgNW alignment vectors, as shown in Fig. 4(a). By performing inner product between the alignment vectors and major alignment vector, align angle distribution of AgNW junction has been extracted, as shown in Fig. 4(b), 4(c), and 4(d). The angle distribution (Fig. 4(b), 4(c), and 4(d)) reveals that the AgNW–PDMS junction with an applied electric field is better aligned than the sample without it.

Figure 5(a) displays the experimental results of the resistance change of the sample under 200 cycles of stretching and contraction. The resistance change during the cycles demonstrates that the AgNW–PDMS junction maintains stable electric conductance under cyclic loading. Samples subjected to voltage during the AgNW application process exhibited consistently lower resistance values throughout 200 cycles of stretching and contracting. This indicates that voltage application enhances the integration and alignment of AgNWs within the PDMS matrix, contributing to improved electrical conductivity.

Figure 5(b) illustrates the change in resistance under long-range stretch, with the silver paste-PDMS sample included for comparison. Samples using silver paste demonstrated significantly higher resistance compared to those using AgNW when the stretch ratio reached 25% of the original length.

Analysis results

We analyzed the electrical conductivity of AgNW–PDMS nanocomposites, comparing our findings with experimental data using the model information from Table 1. The results indicate that the effective electrical conductivity varies significantly with the orientation of AgNW particles. The electrical conductivity changes with the orientation of AgNW (Fig. 6). Specifically, when AgNW particles are aligned through the application of voltage, the electrical conductivity is approximately 2.74 times higher. This trend is consistent with the experimental data shown in Fig. 6, where voltage-driven AgNW nanocomposites exhibit three times lower resistance than randomly oriented AgNW nanocomposites.

Discussion

Effect of voltage

Alignment of the AgNW in the SEM image suggests that inducing voltage re-aligns AgNW parallel to the electric field and pushes them in the reverse direction (Fig. 1(c)). The alignment of AgNWs in SEM images suggests that voltage application facilitates realignment parallel to the electric field while also generating a driving force for infiltration into the PDMS solution. This phenomenon is attributed to dielectrophoresis, wherein AgNWs, possessing high dielectric anisotropy, respond to the applied electric field similar to liquid crystals28. Due to the high viscosity of PDMS before polymerization, a higher voltage (30–60 V) is necessary to achieve effective alignment and infiltration. In addition, decreasing deviation of the resistance in Fig. 5(a) implies that realignment of the AgNW due to the voltage makes consistent quality of junction between interlayer of the stretchable circuits.

Alignment-Conductivity relationship

According to the mathematical modeling, the major parameters influencing the conductivity of the AgNW–PDMS system are the alignment and density of the AgNW in PDMS. A two-phase nanocomposite model, which considers the AgNW network and their alignment, predicted that increasing the alignment angle (θ) enhances the effective conductivity of the AgNW–PDMS junction, closely matching experimental results.

Stretch-Conductivity relationship

Both mathematical modeling and experimental results in Fig. 7 indicate that applying in-plane stretch reduces the average alignment angle (θ) of the AgNW network within the PDMS matrix, which, in turn, lowers the conductivity at the junction between interlayers of the circuit. However, due to the nonlinear relationship between alignment angle and conductivity (as shown in Fig. 6), the rate of conductivity decrease varies significantly with the initial alignment angle of the AgNW network. Notably, mechanical stretching has a diminished effect on conductivity when the AgNW network is in a highly aligned state, suggesting that inducing voltage can effectively stabilize interlayer junctions in stretchable circuits.

Comparison with other junction methods

The proposed electro-driven AgNW method offers better mechanical stability than liquid metal-based interconnects18,19, which are susceptible to leakage and oxidation. In addition, it offers higher flexibility than rigid metal interconnects16while maintaining conductivity under strain. Its simpler and more scalable fabrication process, requiring only electric voltage and heat, makes it easier to integrate into stretchable devices compared to multilayer and reconfigurable designs17,20. Additionally, the aligned AgNW network enhances electrical conductivity over bulk conductive materials. However, However, limitations include lower mechanical stiffness compared to traditional metal interconnects16, potential material compatibility concerns, and sensitivity to electric field variations during fabrication.

Conclusion

In this study, we proposed a method for interconnecting circuits in different layers of stretchable devices. By applying high voltage to AgNW during the polymerization of the layer, AgNW infiltrated the layer and aligned well, resulting in good conductivity and durability of the junction under mechanical stretch. Since this method only requires electric voltage and heat to create junctions, it is easy to incorporate with other fabrication methods used in stretchable devices. We believe the method proposed in this study is a promising approach for creating junctions in stretchable devices and will pave the way for increasing their efficiency.

Data availability

Overall data is provided within the manuscript. Mathematical derivation and calculated conductivity examples are shown in Supplementary1 file. Specific raw data for the experiments are shown in supplementary 2 file.

References

Bao, Z., Chen, X., Flexible & Devices, S. Adv. Mater. 28 4177–4179. https://doi.org/10.1002/adma.201601422. (2016).

Gillan, L., Hiltunen, J., Behfar, M. H. & Rönkä, K. Advances in design and manufacture of stretchable electronics. Japanese J. Appl. Phys. 61, SE0804 (2022). https://cris.vtt.fi/en/publications/advances-in-design-and-manufacture-of-stretchable-electronics

Lee, S., Yang, J. C. & Park, S. Geometrical engineering for implementing stretchable electronics. J. Flex. Print. Electron. 1, 125–136. https://doi.org/10.56767/jfpe.2022.1.2.125 (2022).

Kim, J. H., Lee, S. E. & Kim, B. H. Applications of flexible and stretchable three-dimensional structures for soft electronics. Soft Sci. 3, 16. https://doi.org/10.20517/ss.2023.07 (2023).

Yang, T., Xie, D., Li, Z. & Zhu, H. Recent advances in wearable tactile sensors: materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R Reports: Rev. J. 115, 1–37. https://doi.org/10.1016/j.mser.2017.02.001 (2017).

Kim, K. K., Suh, Y. & Ko, S. H. Smart stretchable electronics for advanced Human–Machine interface. Adv. Intell. Syst. Adv. Intel Syst. 3 (2). https://doi.org/10.1002/aisy.202000157 (2021).

Heng, W., Solomon, S. & Gao, W. Flexible electronics and devices as Human–Machine interfaces for medical robotics. Adv. Mater. 34, 2. https://doi.org/10.1002/adma.202107902 (2022).

Ji, S. & Chen, X. Enhancing the interfacial binding strength between modular stretchable electronic components. Nat. Sci. Rev. 10, nwac172. https://doi.org/10.1093/nsr/nwac172 (2023).

Wang, B. et al. High–k gate dielectrics for emerging flexible and stretchable electronics. Chem. Rev. 118, 5690–5754. https://doi.org/10.1021/acs.chemrev.8b00045 (2018).

Baruah, R. K., Yoo, H. & Lee, E. K. Interconnection technologies for flexible electronics: materials, fabrications, and applications. Micromachines 14, 1131. https://doi.org/10.3390/mi14061131 (2023).

Fernandes, D. F., Majidi, C. & Tavakoli, M. Digitally printed stretchable electronics: a review. J. Mater. Chem. C. 7, 14035–14068. https://doi.org/10.1039/C9TC04246F (2019).

Root, S. E., Savagatrup, S., Printz, A. D., Rodriquez, D. & Lipomi, D. J. Mechanical properties of organic semiconductors for stretchable, highly flexible, and mechanically robust electronics. Chem. Rev. 117, 6467–6499. https://doi.org/10.1021/acs.chemrev.7b00003 (2017).

Nagels, S. & Deferme, W. Fabrication approaches to interconnect based devices for stretchable electronics. Rev. Mater. 11, 375. https://doi.org/10.3390/ma11030375 (2018).

Biswas, S. et al. Integrated multilayer stretchable printed circuit boards paving the way for deformable active matrix. Nat. Commun. 10, 4909–4908. https://doi.org/10.1038/s41467-019-12870-7 (2019).

Di Vito, D., Mosallaei, M., Khorramdel, B., Kanerva, M. & Mäntysalo, M. Mechanically driven strategies to improve electromechanical behaviour of printed stretchable electronic systems. Sci. Rep. 10, 12037 (2020).

Gonzalez, M. et al. Design of metal interconnects for stretchable electronic circuits. Microelectron. Reliab. 48, 825–832. https://doi.org/10.1016/j.microrel.2008.03.025 (2008).

Jung, D. et al. Multilayer stretchable electronics with designs enabling a compact lateral form. Npj Flex. Electron. 8, 13–19. https://doi.org/10.1038/s41528-024-00299-y (2024).

Yim, D. R. & Park, C. W. Hybrid-type stretchable interconnects with double-layered liquid metal-on-polyimide serpentine structure. ETRI J. 44, 147–154. https://doi.org/10.4218/etrij.2021-0188 (2022).

Wang, B. et al. Liquid Metal-Based High‐Density interconnect technology for stretchable printed circuits. Adv. Funct. Mater. 34, 2309707. https://doi.org/10.1002/adfm.202309707 (2023).

Zhu, J. et al. Recent progress in multifunctional, reconfigurable, integrated liquid metal-based stretchable sensors and standalone systems. Prog Mater. Sci. 142, 101228. https://doi.org/10.1016/j.pmatsci.2023.101228 (2024).

Lee, B. & Khang, D. Non-deterministic transfer-printing of LED chips with controllable pitch using stretchable elastomeric stamps. Extreme Mech. Lett. 45, 101287. https://doi.org/10.1016/j.eml.2021.101287 (2021).

Feng, C. & Jiang, L. Micromechanics modeling of the electrical conductivity of carbon nanotube (CNT)–polymer nanocomposites. Compos. Part. A. 47, 143–149. https://doi.org/10.1016/j.compositesa.2012.12.008 (2013).

Deng, F. & Zheng, Q. S. An analytical model of effective electrical conductivity of carbon nanotube composites. Appl. Phys. Lett. 92, 071902. https://doi.org/10.1063/1.2857468 (2008).

Mohammadpour-Haratbar, A., Zare, Y. & Rhee, K. Y. Simulation of electrical conductivity for polymer silver nanowires systems. Sci. Rep. 13, 5. https://doi.org/10.1038/s41598-022-25548-w (2023).

Taya, M. Electronic composites. (2005). https://doi.org/10.1017/CBO9780511550508

Mori, T. & Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 21, 571–574. https://doi.org/10.1016/0001-6160(73)90064-3 (1973).

Warner, M. & Terentjev, E. M. Liquid crystal elastomers. Clarendon press Oxford, ISBN 0-19-852767-5 142–173. (2006).

Park, S., Heo, S. & Han, W. S. Dielectrophoresis-based multi-step nanowire assembly on a flexible superstrate. Nanotechnology 29, 025301. https://doi.org/10.1088/1361-6528/aa9a22 (2017).

Acknowledgements

Jung-Hoon Yun and Hyunseong Shin are co-corresponding authors and contributed equally to this research. This work was supported by the research grant of Kongju National University in 2023. This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. RS- 2024 - 00405333). MATLAB software version R2024a has been used for model computation and image process. (https://www.mathworks.com/products/matlab.html)

Author information

Authors and Affiliations

Contributions

G. Park wrote main manuscript text and performed experiments. W. Lee computed simulation results. H. Shin administrated simulation results, and J. Yun administrated experimental results. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Park, G., Lee, W., Shin, H. et al. Proof of principle demonstration of electro driven silver nanowire for stretchable circuit junctions. Sci Rep 15, 12762 (2025). https://doi.org/10.1038/s41598-025-97533-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-97533-y