Abstract

The ever-increasing generation of sewage sludge in megacities places a substantial burden on waste treatment systems. The complex and resilient structure of sludge renders conventional pretreatment and biological reclamation methods time-consuming, energy-inefficient and environmentally burdensome. Here we present an integrated mechano-electro-bioprocess that valorizes sludge with minimal environmental impact. We achieve nearly complete recovery of organics with ~91.4% total organic carbon (TOC), which are effectively converted into single-cell protein (>63% TOC) in a tandem process. Heavy metals are efficiently concentrated and stabilized, while simultaneously producing green hydrogen at an impressive efficiency and rate (~10% solar-to-hydrogen energy efficiency, rate >13 l per hour). A comprehensive life-cycle and techno-economic analysis confirms the substantial environmental and economic benefits of this approach. Notably, it results in a 99.5% reduction in CO2 emissions and a 99.3% decrease in energy depletion compared with conventional anaerobic digestion. As renewable electricity deployment expands globally, this mechano-electro-bioprocess offers a promising path towards sustainable development.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

118,99 € per year

only 9,92 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All study data are included in the article and its Supplementary Information.

References

LeBlanc, R. J., Matthews, P. & Richard, R. P. Global Atlas of Excreta, Wastewater Sludge, and Biosolids Management: Moving Forward the Sustainable and Welcome Uses of a Global Resource (UN-Habitat, 2009).

Zhen, G., Lu, X., Kato, H., Zhao, Y. & Li, Y.-Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: current advances, full-scale application and future perspectives. Renew. Sustain. Energy Rev. 69, 559–577 (2017).

Shanmugam, K., Gadhamshetty, V., Tysklind, M., Bhattacharyya, D. & Upadhyayula, V. K. K. A sustainable performance assessment framework for circular management of municipal wastewater treatment plants. J. Cleaner Prod. https://doi.org/10.1016/j.jclepro.2022.130657 (2022).

Hii, K., Baroutian, S., Parthasarathy, R., Gapes, D. J. & Eshtiaghi, N. A review of wet air oxidation and thermal hydrolysis technologies in sludge treatment. Bioresour. Technol. 155, 289–299 (2014).

Low, E. W., Chase, H. A., Milner, M. G. & Curtis, T. P. Uncoupling of metabolism to reduce biomass production in the activated sludge process. Water Res. 34, 3204–3212 (2000).

Gonzalez, A., Hendriks, A., van Lier, J. B. & de Kreuk, M. Pre-treatments to enhance the biodegradability of waste activated sludge: elucidating the rate limiting step. Biotechnol. Adv. 36, 1434–1469 (2018).

Wang, Q. et al. Technologies for reducing sludge production in wastewater treatment plants: state of the art. Sci. Total Environ. 587-588, 510–521 (2017).

Appels, L., Baeyens, J., Degrève, J. & Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 34, 755–781 (2008).

Toutian, V., Barjenbruch, M., Unger, T., Loderer, C. & Remy, C. Effect of temperature on biogas yield increase and formation of refractory COD during thermal hydrolysis of waste activated sludge. Water Res. 171, 115383 (2020).

Neumann, P., Pesante, S., Venegas, M. & Vidal, G. Developments in pre-treatment methods to improve anaerobic digestion of sewage sludge. Rev. Environ. Sci. Biotechnol. 15, 173–211 (2016).

Fan, Y., Hornung, U. & Dahmen, N. Hydrothermal liquefaction of sewage sludge for biofuel application: a review on fundamentals, current challenges and strategies. Biomass Bioenerg. https://doi.org/10.1016/j.biombioe.2022.106570 (2022).

Tyagi, V. K., Khan, A. A., Jern, N. W., Khursheed, A. & Kazmi, A. A. Post Treatments of Anaerobically Treated Effluents (IWA Publishing, 2019).

Van Wijk, A., van der Roest, E. & Boere, J. Solar Power to the People (IOS Press, 2018).

Zhang, S. et al. Atomically dispersed bimetallic Fe–Co electrocatalysts for green production of ammonia. Nat. Sustain. https://doi.org/10.1038/s41893-022-00993-7 (2022).

Yang, X. et al. Achievements, challenges, and perspectives on nitrogen electrochemistry for carbon-neutral energy technologies. Angew. Chem. https://doi.org/10.1002/anie.202215938 (2022).

Verbeeck, K. et al. Upgrading the value of anaerobic digestion via chemical production from grid injected biomethane. Energy Environ. Sci. 11, 1788–1802 (2018).

Xiao, K. & Zhou, Y. Protein recovery from sludge: a review. J. Cleaner Prod. https://doi.org/10.1016/j.jclepro.2019.119373 (2020).

Bruni, C. et al. Targeted bio-based volatile fatty acid production from waste streams through anaerobic fermentation: link between process parameters and operating scale. ACS Sustain. Chem. Eng. 9, 9970–9987 (2021).

Chen, Y. et al. Enhanced volatile fatty acids (VFAs) production in a thermophilic fermenter with stepwise pH increase—investigation on dissolved organic matter transformation and microbial community shift. Water Res. 112, 261–268 (2017).

Yuan, Y. et al. Advances in enhanced volatile fatty acid production from anaerobic fermentation of waste activated sludge. Sci. Total Environ. 694, 133741 (2019).

Barrios, J. A., Cano, A., Rivera, F. F., Cisneros, M. E. & Duran, U. Efficiency of integrated electrooxidation and anaerobic digestion of waste activated sludge. Biotechnol. Biofuels 14, 81 (2021).

Huang, H., Zeng, Q., Heynderickx, P. M., Chen, G. H. & Wu, D. Electrochemical pretreatment (EPT) of waste activated sludge: extracellular polymeric substances matrix destruction, sludge solubilisation and overall digestibility. Bioresour. Technol. 330, 125000 (2021).

Zeng, Q. et al. Electrochemical pretreatment for stabilization of waste activated sludge: simultaneously enhancing dewaterability, inactivating pathogens and mitigating hydrogen sulfide. Water Res. 166, 115035 (2019).

Chen, Y., Chen, H., Li, J. & Xiao, L. Rapid and efficient activated sludge treatment by electro-Fenton oxidation. Water Res. 152, 181–190 (2019).

Olvera-Vargas, H., Zheng, X., Garcia-Rodriguez, O. & Lefebvre, O. Sequential ‘electrochemical peroxidation–electro-fenton’ process for anaerobic sludge treatment. Water Res. 154, 277–286 (2019).

Anglada, A., Urtiaga, A. & Ortiz, I. Pilot scale performance of the electro-oxidation of landfill leachate at boron-doped diamond anodes. Environ. Sci. Technol. 43, 2035–2040 (2009).

Jafari, M. & Botte, G. G. Electrochemical valorization of waste activated sludge for short-chain fatty acids production. Front. Chem. 10, 974223 (2022).

Geng, S.-K. et al. Nickel ferrocyanide as a high-performance urea oxidation electrocatalyst. Nat. Energy 6, 904–912 (2021).

Li, Y., Wei, X., Chen, L. & Shi, J. Electrocatalytic hydrogen production trilogy. Angew. Chem. https://doi.org/10.1002/anie.202009854 (2020).

Kaufman Rechulski, M. D., Käldström, M., Richter, U., Schüth, F. & Rinaldi, R. Mechanocatalytic depolymerization of lignocellulose performed on hectogram and kilogram scales. Ind. Eng. Chem. Res. 54, 4581–4592 (2015).

Yao, S. G. et al. Mechanochemical treatment facilitates two-step oxidative depolymerization of kraft lignin. ACS Sustain. Chem. Eng. 6, 5990–5998 (2018).

Sun, J., Zhang, L. & Loh, K.-C. Review and perspectives of enhanced volatile fatty acids production from acidogenic fermentation of lignocellulosic biomass wastes. Bioresour. Bioprocess. https://doi.org/10.1186/s40643-021-00420-3 (2021).

Pikaar, I. et al. Resource Recovery from Water: Principles and Application (IWA Publishing, 2022).

Honda, R., Fukushi, K. & Yamamoto, K. Optimization of wastewater feeding for single-cell protein production in an anaerobic wastewater treatment process utilizing purple non-sulfur bacteria in mixed culture condition. J. Biotechnol. 125, 565–573 (2006).

Hülsen, T., Hsieh, K., Lu, Y., Tait, S. & Batstone, D. J. Simultaneous treatment and single cell protein production from agri-industrial wastewaters using purple phototrophic bacteria or microalgae—a comparison. Bioresour. Technol. 254, 214–223 (2018).

Wu, D., Zhang, L., Le, C., Wang, L. & Zhou, Y. Pathways and mechanisms of single-cell protein production: carbon and nutrient transformation. ACS ES&T Water 1, 1313–1320 (2021).

Hulsen, T., Stegman, S., Batstone, D. J. & Capson-Tojo, G. Naturally illuminated photobioreactors for resource recovery from piggery and chicken-processing wastewaters utilising purple phototrophic bacteria. Water Res. 214, 118194 (2022).

Mukherjee, A. et al. Effective power management system in stacked microbial fuel cells for onsite applications. J. Power Sources https://doi.org/10.1016/j.jpowsour.2021.230684 (2022).

Wilberforce, T., Sayed, E. T., Abdelkareem, M. A., Elsaid, K. & Olabi, A. G. Value added products from wastewater using bioelectrochemical systems: current trends and perspectives. J. Water Process Eng. https://doi.org/10.1016/j.jwpe.2020.101737 (2021).

Zheng, T. et al. Upcycling CO2 into energy-rich long-chain compounds via electrochemical and metabolic engineering. Nat. Catal. 5, 388–396 (2022).

Vincent, I., Kruger, A. & Bessarabov, D. Development of efficient membrane electrode assembly for low cost hydrogen production by anion exchange membrane electrolysis. Int. J. Hydrogen Energy 42, 10752–10761 (2017).

Spiller, M. et al. Environmental impact of microbial protein from potato wastewater as feed ingredient: comparative consequential life cycle assessment of three production systems and soybean meal. Water Res. 171, 115406 (2020).

Sakarika, M. et al. Purple non-sulphur bacteria and plant production: benefits for fertilization, stress resistance and the environment. Microb. Biotechnol. 13, 1336–1365 (2020).

Zarezadeh, S. et al. Microalgae and phototrophic purple bacteria for nutrient recovery from agri-industrial effluents: influences on plant growth, rhizosphere bacteria, and putative carbon- and nitrogen-cycling genes. Front. Plant Sci. 10, 1193 (2019).

Zhao, H. et al. Raw biomass electroreforming coupled to green hydrogen generation. Nat. Commun. 12, 2008 (2021).

Chen, X., Yang, H., Zhong, Z. & Yan, N. Base-catalysed, one-step mechanochemical conversion of chitin and shrimp shells into low molecular weight chitosan. Green Chem. 19, 2783–2792 (2017).

Lu, D. et al. Liquid and solids separation for target resource recovery from thermal hydrolyzed sludge. Water Res. 171, 115476 (2020).

Chen, Y. et al. Phosphorus release and realignment in anaerobic digestion of thermal hydrolysis pretreatment sludge–masking effects from high ammonium. Water Res. 255, 121488 (2024).

He, C., Wang, K., Yang, Y., Amaniampong, P. N. & Wang, J. Y. Effective nitrogen removal and recovery from dewatered sewage sludge using a novel integrated system of accelerated hydrothermal deamination and air stripping. Environ. Sci. Technol. 49, 6872–6880 (2015).

Taitt, B. J., Nam, D.-H. & Choi, K.-S. A comparative study of nickel, cobalt, and iron oxyhydroxide anodes for the electrochemical oxidation of 5-Hydroxymethylfurfural to 2,5-furandicarboxylic acid. ACS Catal. 9, 660–670 (2018).

Huang, X., Guo, Y., Zou, Y. & Jiang, J. Electrochemical oxidation of glycerol to hydroxypyruvic acid on cobalt (oxy)hydroxide by high-valent cobalt redox centers. Appl. Catal. B https://doi.org/10.1016/j.apcatb.2022.121247 (2022).

Qi, Y. et al. Insights into the activity of nickel boride/nickel heterostructures for efficient methanol electrooxidation. Nat. Commun. 13, 4602 (2022).

Yu, X. et al. Hydrogen evolution reaction in alkaline media: alpha- or beta-nickel hydroxide on the surface of platinum? ACS Energy Lett. 3, 237–244 (2018).

Fan, L. et al. High entropy alloy electrocatalytic electrode toward alkaline glycerol valorization coupling with acidic hydrogen production. J. Am. Chem. Soc. 144, 7224–7235 (2022).

Song, F. et al. Interfacing nickel nitride and nickel boosts both electrocatalytic hydrogen evolution and oxidation reactions. Nat. Commun. https://doi.org/10.1038/s41467-018-06728-7 (2018).

You, B., Jiang, N., Sheng, M., Bhushan, M. W. & Sun, Y. Hierarchically porous urchin-like Ni2P superstructures supported on nickel foam as efficient bifunctional electrocatalysts for overall water splitting. ACS Catal. 6, 714–721 (2016).

Chen, Q. et al. Synergistic effect in ultrafine PtNiP nanowires for highly efficient electrochemical hydrogen evolution in alkaline electrolyte. Appl. Catal. B https://doi.org/10.1016/j.apcatb.2021.120754 (2022).

Zhou, K. L. et al. Platinum single-atom catalyst coupled with transition metal/metal oxide heterostructure for accelerating alkaline hydrogen evolution reaction. Nat. Commun. 12, 3783 (2021).

Nørskov, J. K. et al. Trends in the exchange current for hydrogen evolution. J. Electrochem. Soc. 152, J23 (2005).

Wang, Y. et al. Enhanced nitrate-to-ammonia activity on copper–nickel alloys via tuning of intermediate adsorption. J. Am. Chem. Soc. 142, 5702–5708 (2020).

Meng, N., Huang, Y., Liu, Y., Yu, Y. & Zhang, B. Electrosynthesis of urea from nitrite and CO2 over oxygen vacancy-rich ZnO porous nanosheets. Cell Rep. Phys. Sci. https://doi.org/10.1016/j.xcrp.2021.100378 (2021).

Du, W. & Parker, W. Characterization of sulfur in raw and anaerobically digested municipal wastewater treatment sludges. Water Environ. Res. 85, 124–132 (2013).

Du, N. et al. Anion-exchange membrane water electrolyzers. Chem. Rev. 122, 11830–11895 (2022).

Immerz, C. et al. Effect of the MEA design on the performance of PEMWE single cells with different sizes. J. Appl. Electrochem. 48, 701–711 (2018).

Robinson, R. K. Encyclopedia of Food Microbiology (Academic Press, 2014).

Tian, B. & Hua, Y. Carotenoid biosynthesis in extremophilic Deinococcus–Thermus bacteria. Trends Microbiol. 18, 512–520 (2010).

Spanoghe, J. et al. Storage, fertilization and cost properties highlight the potential of dried microbial biomass as organic fertilizer. Microb. Biotechnol. 13, 1377–1389 (2020).

Hulsen, T. et al. Outdoor demonstration-scale flat plate photobioreactor for resource recovery with purple phototrophic bacteria. Water Res. 216, 118327 (2022).

NEMS Prices (Energy Market Company, 2021); https://www.nems.emcsg.com/nems-prices

LaTurner, Z. W., Bennett, G. N., San, K.-Y. & Stadler, L. B. Single cell protein production from food waste using purple non-sulfur bacteria shows economically viable protein products have higher environmental impacts. J. Cleaner Prod. 276, 123114 (2020).

Hülsen, T., Barnes, A. C., Batstone, D. J. & Capson-Tojo, G. Creating value from purple phototrophic bacteria via single-cell protein production. Curr. Opin. Biotechnol. 76, 102726 (2022).

Renewable Energy Market Update–May 2022 (IEA, 2022).

Federation, W. E. & Association, A. Standard Methods for the Examination of Water and Wastewater (APHA, 2005).

Environmental Management–Life Cycle Assessment–Requirements and Guidelines (ISO, 2006).

ISO Technical Committee in Environmental Management—Life Cycle Assessment—Principles and Framework 235–248 (ISO, 2006).

Vince, F., Aoustin, E., Bréant, P. & Marechal, F. LCA tool for the environmental evaluation of potable water production. Desalination 220, 37–56 (2008).

Renou, S., Thomas, J. S., Aoustin, E. & Pons, M. N. Influence of impact assessment methods in wastewater treatment LCA. J. Cleaner Prod. 16, 1098–1105 (2008).

CML-IA Characterisation Factors (Universiteit Leiden, 2016).

Nicholson, S. R., Rorrer, N. A., Carpenter, A. C. & Beckham, G. T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 5, 673–686 (2021).

Co-digestion of food waste and used water sludge enhances biogas production for greater energy generation. National Environment Agency https://www.nea.gov.sg/media/news/news/index/co-digestion-of-food-waste-and-used-water-sludge-enhances-biogas-production-for-greater-energy-generation (2019).

Solid waste management infrastructure. National Environment Agency https://www.nea.gov.sg/our-services/waste-management/waste-management-infrastructure/solid-waste-management-infrastructure (2024)

Acknowledgements

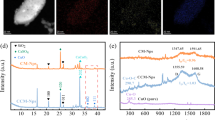

This work was supported by A*STAR Science and Engineering Research Council AME IRG funding (A1983c0029, H.L.) and the National Research Foundation, Prime Ministers Office, Singapore under its Campus for Research Excellence and Technological Enterprise (CREATE) programme (award number NRF2022-ITC004-0001, H.L.). We acknowledge the Facility for Analysis, Characterization, Testing and Simulation (FACTS), Nanyang Technological University Singapore for use of electron microscopy and X-ray facilities and L.M. Shan and A.K.J. On from NEWRI Analytics Cluster, Nanyang Technological University, Singapore, for their guidance on product analysis.

Author information

Authors and Affiliations

Contributions

H.Z. and H.L. designed the experiments. H.Z. performed electrode fabrication and electrochemical characterizations. D.W. carried out the biosynthesis experiments. C.L., H.Z. and L.Q.L. conducted the product identification and quantification. H.Z. performed material characterizations. Y. Lv helped with the GPC and high-performance liquid chromatograph analysis. X.C. helped with the schematic diagram drawing. Z.S. took the LCA and TEA analysis. H.Z. wrote the paper. H.Z., D.L., Z.S., Y. Li, O.L.D., W.T., Z.Z., J.Z., Y.Z. and H.L. discussed the results and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

H.Z., L.Q.L. and H.L. are inventors on a PCT application related to this work, filed by International Bureau at the WIPO (application number PCT/SG2022/050112). The other authors declare no competing interests.

Peer review

Peer review information

Nature Water thanks Rong He, Damien Voiry and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Methods, Notes 1–7, Figs. 1–63 and Tables 1–6.

Supplementary Video 1

Solar-driven MEA reactor for scalable hybrid sludge reforming and hydrogen generation demonstration.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, H., Sun, Z., Li, C. et al. Solar-driven sewage sludge electroreforming coupled with biological funnelling to cogenerate green food and hydrogen. Nat Water 2, 1102–1115 (2024). https://doi.org/10.1038/s44221-024-00329-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44221-024-00329-z

This article is cited by

-

Food production from sludge

Nature Water (2024)