Abstract

The increasing demand for lightweight, high-strength, and multifunctional materials is driving the rapid development of complex metal lattice metamaterials through additive manufacturing (AM). However, fabrication challenges often hinder their full design potential. This study presents an easy-to-apply finite element (FE)-based design framework, governed by six fundamental equations, offering a holistic lattice design approach that meets the manufacturability requirements of laser powder bed fusion AM. By integrating global and natural coordinate systems with shape functions, the method enables precise lattice node positioning and accurate strut inclination angle calculations, essential for determining inclined strut diameter using an established model. Demonstrated with complex, bespoke Ti–6Al–4V lattices, the framework achieves high design-fabrication consistency, yielding robust structures with desirable mechanical properties. This versatile framework efficiently designs complex lattices with arbitrary boundary conditions, advancing design, fabrication, and performance in a synchronized manner.

Similar content being viewed by others

Additive manufacturing (AM) continues to push the boundaries of material innovation, particularly in the development of metal lattice metamaterials1,2. As a new class of multifunctional cellular materials, these metamaterials are being increasingly applied across a wide range of industries, including lightweight engineering3, medical devices4,5, oil–gas separation6, catalytic reactions7, heat exchangers8, fuel cells9, thermal protection systems10, and other industrial sectors11. Driven by emerging industry needs and the integration of artificial intelligence (AI)-assisted design12,13, the design of more complex, high-performance metal metamaterials is advancing rapidly. These materials are characterized by unit cells with varying sizes, orientations, topologies, and irregular boundaries, presenting significant challenges in their design and fabrication, making them far more complex than conventional lattice structures.

The design of complex metal lattice structures requires careful consideration of several critical factors to ensure both functionality and robust manufacturability. A key aspect is the precise determination of the inclination angle for each strut, especially within large and often irregular design spaces. This factor is crucial as it directly impacts the manufacturability of the structure using laser-based powder bed fusion of metals (PBF-LB/M). Unlike regular lattice metamaterials, the manufacturability of complex lattices is less predictable and presents greater challenges, as outlined in the following steps. Another important consideration is determining manufacturable strut diameters that align with the inclination angle and the lattice’s relative density. This requirement ensures that the lightweight design remains within the capabilities of AM processes, particularly in terms of resolution and structural integrity14,15,16.

To maintain conformity to desired geometric and dimensional specifications, smooth transitions of unit cells to irregular boundaries are essential. These transitions are critical for achieving optimal surface quality and minimizing stress concentrations that could compromise the lattice’s mechanical properties17,18. Furthermore, efficient geometric model generation must prioritize powder occlusion avoidance. This aspect is vital for preventing defects during manufacturing and ensuring the consistency of the final printed part19.

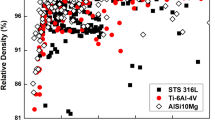

The above complexity of lattice design becomes particularly pronounced when scaling up to hundreds of thousands of struts. For instance, a relatively modest design space of 200 × 200 × 200 mm³ can encompass more than 500,000 struts, each inclined at unique angles4,20. Some of these challenges are further intertwined with strut materials. For example, the volume of Ti–6Al–4V shrinks less than 10% from the melt pool temperature (2500 °C) to room temperature21, while the volume of AlSi10Mg shrinks more than 33% over the same temperature range based on its density changes21,22,23. This impacts the design and manufactured strut diameters which are often 0.5–1.0 mm thick. Furthermore, the solidus temperature can be distinctly different among various metal materials (e.g. 1605 °C for Ti–6Al–4V24 vs. 557 °C for AlSi10Mg25), which affects powder sintering and, therefore, powder occlusion.

The successful design and manufacture of high-performance complex metal lattice structures depend on addressing the challenges discussed above. To overcome these challenges, an integrated design and manufacturability approach is required—one that is currently not readily available for PBF-LB/M. This work aims to bridge this gap by developing a user-friendly, versatile design approach for complex metal lattice materials. Detailed experimental evaluations confirm the high applicability of our method.

Results

Finite element (FE)-based design methodology for complex lattices

This section outlines our lattice design methodology, organized into five interconnected steps. It includes the selection of lattice relative density, material choice, detailed design algorithms, and the creation of STL files for PBF-LB/M.

Determining lattice relative density and strut material

Metal lattice materials are suitable for both structural and functional applications. The choice of lattice relative density and strut material serves as a starting point for design, guided by the target application. Figure 1 summarizes key design considerations for both types of applications, using two examples: an airplane bracket (structural) and a heat exchanger (functional). In this study, we focus on metal lattice materials for structural applications, which require low density, high strength, and high stiffness (Fig. 1, left). For these applications, the lattice relative density (\({\rho }_{\text{RD}}\)) and the mechanical properties of the lattice strut material are key variables that determine the lattice yield strength (\({\sigma }^{* }\)) and elastic modulus (\({E}^{* }\)), as shown in the extended Gibson–Ashby model below26:

where \({E}_{{\rm{s}}}\) and \({\sigma }_{{\rm{s}}}\) are the elastic modulus and yield strength of the lattice strut material, respectively.

Equations (1) and (2) are supported by experimental data from various types of cellular materials, including non-metallic ones26. They were formulated by considering concurrent deformation of bending, stretching, and shear based on the Timoshenko beam theory1. Thus, they complement the classic Gibson–Ashby model27, which is limited to one deformation mechanism (bending or stretching) and is only applicable to low-density lattices with strut length-to-diameter ratios greater than five1.

To demonstrate our method, we design a Ti–6Al–4V toroidal lattice (Fig. 2). The objective is to create a lightweight, lattice-based alternative to the solid toroidal component shown in Fig. 2a while maintaining identical geometry and dimensions. Ti–6Al–4V is selected for its desirable properties and low density. The application requires a minimum yield strength of σ* = 100 MPa and a minimum elastic modulus of E* = 10 GPa. PBF-LB/M-fabricated Ti–6Al–4V has a typical yield strength of σs = 1000 MPa and an elastic modulus of Es = 120 GPa28. Using Eqs. (1) and (2), we calculate the required lattice relative density (\({\rho }_{\text{RD}}\)) of Ti–6Al–4V to be 60%. We select the diamond lattice topology (Fig. 2a), which presents a challenging scenario for optimizing strut inclination angles in irregular design spaces.

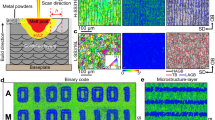

a Steps 1: the input geometry is meshed with hexahedral elements and described in the global (x, y, z) and natural \(\left(\xi ,\eta ,\zeta \right)\) coordinate systems. Then a lattice unit cell is inserted into each hexahedral element. b Step 2: the line-based complex lattice topology is generated using the algorithm described. c Step 3: Calculating and assigning inclination angle-dependent strut diameters to complete the design. STL Standard triangle language, INP Input file (ABAQUS). The software and CAD model involved in each step are designated in square brackets and angle brackets.

The remaining design focuses on generating a manufacturable geometric model for the Ti–6Al–4V toroidal diamond lattice with \({\rho }_{\text{RD}}\) = 60% and exporting it as an STL file for PBF-LB/M.

Method selection for lattice geometry model generation

A variety of lattice geometry model generation methods have been proposed to date. These include the Bezier surface approach29, Boolean operation30, voxelization-based approach31, wireframe modeling (curve division)32, non-uniform rational B-Spline (NURBS) free-form deformation (FFD)33 and layered depth-normal images (LDNI) methods34, Voronoi tessellation35, shape morphing36 and FE-based approach37. Our recent review38 evaluated each of these methods using six key criteria: (i) accessibility via commercial software such as HyperWorks, ABAQUS, ANSYS, and Rhinoceros 3D; (ii) integrity of lattice cell topology at irregular boundaries; (iii) ability to accurately and quickly define strut inclination angles; (iv) compatibility with lattice cell types; (v) applicability to complex, irregular design spaces; and (vi) ease of coding. We concluded that the FE-based approach offers several clear advantages over other methods:

-

Easily accessible through common software tools;

-

Easily adaptable to all geometries;

-

Ability to determine the angle of inclination of each strut in any irregular design space with ease; and

-

Capability to implement topologically complete lattice cells at boundaries, regardless of boundary complexity.

Notably, the FE-based approach was not introduced for conformal lattice generation until 2001 by Rosen et al.37. The moving iso-surface threshold (MIST) method39, a novel topology approach that eliminates the need for explicit sensitivity analysis, has further facilitated the adoption of the FE-based approach. The MIST method simplifies the FE process by enabling seamless interfacing with in-house or commercial FE analysis programs39,40,41,42. As a result, the FE-based approach has been successfully employed in the design of various complex lattices42,43,44. However, a significant challenge remains in applying FE-based methods to the design of complex lattices. Specifically, no existing FE-based method has accounted for the influence of strut inclination on manufacturability using PBF-LB/M, even though this is a critical factor in lattice strut manufacturability14,15,16,45. In this study, we address this issue by incorporating a recently developed lattice strut inclination angle model20 into our FE-based approach.

As outlined in Fig. 2, our proposed FE-based method consists of three main steps: (1) discretizing the input geometry into hexahedral elements (meshes, Fig. 2a) and nesting a diamond lattice unit cell within each hexahedral element; (2) determining the global coordinates of each lattice cell node in the design space and connecting them to form a line-based lattice structure (Fig. 2b); and (3) calculating the inclination angle of each line strut, determining its manufacturable diameter, and checking the resulting lattice relative density and minimum lattice cell size (to avoid powder occlusion) to complete the design (Fig. 2c). The most critical step is to efficiently obtain the precise global coordinates of all lattice cell nodes in the design space, which corresponds to Step 2. Our solution for this step is described below.

Determining lattice cell node positions within the design space

Using our selected FE-based approach, we discretize the input geometry into hexahedral element objects and embed a diamond lattice cell within each element (Fig. 2a). However, a key challenge arises: each diamond lattice cell has 14 nodes, whereas each hexahedral element has only eight nodes (I–VIII), resulting in a node mismatch. Furthermore, the hexahedral elements often deviate from perfect hexahedra, adopting twisted shapes to conform to complex design spaces or geometries. Consequently, determining the coordinates of lattice cell nodes in the design space becomes decoupled from the hexahedral element node coordinates, even when node counts coincide. This node coordination issue poses significant computational challenges and requires substantial computational resources. For example, lattice cell nodes 2 and 10 in Fig. 2a have precise coordinates of (3.36148643, 12.3864889, 17.1428566)Node 2 and (2.6891892, 9.90919113, 21.4285717)Node 10, obtained through a complex process. In contrast, hexahedral element node coordinates can be readily determined using established methods38, such as the Delaunay-based method and the quadtree–octree method. These coordinates are readily available in the generated INP file. The challenge, therefore, becomes how to determine the lattice cell node coordinates from the hexahedral element nodes.

Our solution consists of two steps: introducing a natural coordinate system \(\left(\xi ,\eta ,\zeta \right)\) into each hexahedral element to precisely determine the position of each lattice cell node, and then introducing a shape function \(N\left(\xi ,\eta ,\zeta \right)\) by which the natural coordinates \(\left(\xi ,\eta ,\zeta \right)\) of each lattice node can be easily converted into the global coordinates (x, y, z) using the natural and global coordinates of the hexahedral element nodes in the design space. The first step is straightforward. For example, lattice cell nodes 1–3 in Fig. 2a have natural coordinates of (−1, −1, −1)Node 1, (−0.5, −0.5, −0.5)Node 2 and (−1, 0, 0)Node 3. Table 1 lists the natural coordinates of each diamond lattice cell node and each hexahedral element node, where the eight hexahedral element nodes are denoted as \(({\xi }_{i},{\eta }_{i},{\zeta }_{i})\) (\({\boldsymbol{i}}\) = I–VIII), while the 14 diamond lattice cell nodes are expressed as \(({\xi }_{j},{\eta }_{j},{\zeta }_{j})\) (j = 1–14).

The shape function \({N}_{i}({\xi }_{j},{\eta }_{j},{\zeta }_{j})\) is constructed as follows:

For a four-node tetrahedral element, the denominator 8 in Eq. (3) should become 4. Using Eq. (3), the global coordinates \(({x}_{j},{y}_{j},{z}_{j})\) of each lattice cell node are defined as

where \(({x}_{j},{y}_{j},{z}_{\text{j}})\) (j = 1, 2, 3, … 14, Table 1) are the global coordinates of each lattice cell node in the hexahedral element, and \(\left({x}_{\text{i}},{y}_{\text{i}},{z}_{\text{i}}\right)\) (\(i\) = I, II, III, …, VIII) on the right-hand side are the global coordinates of each hexahedral element node (Table 1).

To illustrate the use of Eqs. (3) and (4), we take lattice node 9, i.e. \(({\xi }_{9},{\eta }_{9},{\zeta }_{9})\) in Table 1 as an example, where \(({\xi }_{9},{\eta }_{9},{\zeta }_{9})=(-\mathrm{0.5,0.5,0.5})\) (Table 1). Using the coordinate information of \(({\xi }_{i},{\eta }_{i},{\zeta }_{i})\) (\(i\) = I, II, III, …, VIII) in Table 1, it is easy to obtain from Eq. (3) (for brevity, only the expressions for NI, NII, and NVIII are listed):

As mentioned earlier, the global coordinates of each hexahedral element node (Fig. 2a) can be easily determined as \(({x}_{\text{I}},{y}_{\text{I}},{z}_{\text{I}})\), \(({x}_{\text{II}},{y}_{\text{II}},{z}_{\text{II}})\), \(({x}_{\text{III}},{y}_{\text{III}},{z}_{\text{III}})\), …, \(({x}_{\text{VIII}},{y}_{\text{VIII}},{z}_{\text{VIII}})\). Using Eq. (4), the global coordinates of lattice cell node 9 (Table 1) is now determined as

The introduction of a dual coordinate system and shape functions (Eqs. (3) and (4) enable the rapid and accurate determination of global coordinates for any lattice cell node within the design space (hexahedral elements).

Alternative interpolation techniques to shape functions, such as moving least squares (MLS) and isogeometric analysis (IGA), also exist. The MLS method constructs interpolation functions without requiring a predefined mesh46, offering flexibility for handling complex geometries. However, its high computational cost, sensitivity to parameter choices, and incompatibility with finite element frameworks limit its practical application47. Similarly, IGA employs high-order functions like non-uniform rational B-splines (NURBS) for precise CAD geometry integration. Despite its accuracy, IGA is complex to implement, heavily reliant on CAD tools, and less adaptable to unconventional geometries, which hinders its widespread adoption48.

In contrast, shape functions integrate seamlessly with the dual coordinate system, enhancing tracking and localization within complex systems. This integration significantly improves efficiency and accuracy in lattice design, making shape functions a practical and reliable choice. They outperform alternative methods in terms of computational efficiency and adaptability.

Determining the lattice strut inclination angle and manufacturable strut diameter

Following node coordinate definition, custom code in the INP file merges and renumbers shared nodes between adjacent lattice cells. This technical procedure involves calculating inter-node distances (where zero distance indicates a shared node). Merging overlapping nodes reduces data size, facilitates strut connections, and automatically links thousands of neighboring lines. This operation yields a line-based lattice topology (Fig. 2b) within the design space, enabling efficient representation and analysis of the complex lattice structure.

Next, the inclination angle (θ) of each valid line strut can be calculated using Eq. (7):

where \(\left({x}_{{\rm {s}}},{y}_{{\rm {s}}},{z}_{\rm {{s}}}\right)\) and \(\left({x}_{\rm {{b}}},{y}_{{\rm {b}}},{z}_{{\rm {b}}}\right)\) are the coordinates of the strut vector and build direction vector, respectively, as illustrated in Fig. 2c.

To fully unlock the design potential, it is crucial to ensure uniformity in the cross-section of each strut along its cylindrical axis, thereby preventing issues such as necking. Detailed theoretical analyses, supported by experimental observations, indicate that this cross-sectional uniformity is primarily influenced by the strut inclination angle (θ)20. Additionally, factors such as the layer thickness (h0) used in PBF-LB/M, powder bed density (ρPBD), and the targeted strut diameter (d) also play significant roles in influencing uniformity. These comprehensive analyses have ultimately led to the development of Eq. (8)20:

In Eq. (8), φ is a strut additive continuity indicator (0 < φ ≤ 1), and ρTD is the theoretical density of the powder material. The closer the value of \({{\varphi }}\) to 1.0, the more uniform the cross section of the inclined strut along its axis is. A minimum of \({{\varphi }}\) = 0.9 is recommended, but for high-fidelity PBF, φ ≥ 0.96 is preferred20. For PBF of Ti–6Al–4V, ρPBD/ρTD can be taken as 0.6 for most PBF systems20. Alternatively, the exact value of ρPBD can be determined using a PBF capsule approach49. Equation (8) defines the strut diameter as a function of the inclination angle and other factors for complex lattice design20. It inherently accounts for the effect of surface roughness induced by PBF-LB/M, which is influenced by various factors such as strut orientation and heat accumulation50.

Using Eqs. (7) and (8), all line struts in the line-based lattice structure can now be assigned a manufacturable diameter. The assignment of strut diameters can be performed using the beam elements in ABAQUS (through assigning the beam elements in the INP file). At this stage, it is important to check the resulting lattice ρRD, which can be adjusted through selecting the value of φ in Eq. (8) from 0.9 to 0.96. At the same time, the minimum lattice cell size should be reviewed for the selected PBF-LB/M process to avoid powder occlusion.

STL File Creation for PBF-LB/M

After assigning inclination angle-dependent strut diameters, the lattice model is exported from ABAQUS as an OBJ file and processed using SOLIDWORKS or Rhinoceros 3D, or Autodesk Inventor to generate the final STL file for PBF-LB/M.

In summary, Eqs. (1)–(8) provide a comprehensive foundation for designing complex lattices with irregular boundaries:

-

Equations (1) and (2): Estimate lattice relative density as the design starting point.

-

Equations (7) and (8): Convert line-based lattice to manufacturable lattice with required relative density.

Design of complex lattices

This section demonstrates the efficacy of our design method using three customized Ti–6Al–4V lattice examples with irregular boundaries. As mentioned previously, PBF-LB/M Ti–6Al–4V has a yield strength (σs) of ≥1000 MPa51. Its theoretical density (ρs) is 4.43 g/cm3. We consider a specific application that requires a yield strength of 65 MPa, comparable to as-cast Mg–9Al–1Zn43. Using Eq. (2), we calculate the required relative density as ρRD = 41%.

Figure 3 illustrates the design process for a gyroid lattice unit cell with ρRD ≈ 41%. The input geometry (Fig. 3a) is first meshed using 2D quadrilateral elements (Fig. 3b), then a 2D line-based lattice cell is nested within each element (inset, Fig. 3c). Equations (7) and (8) are applied to determine the inclination angle and calculate the corresponding diameter for each line strut, using φ = 0.96, h0 = 30 μm, and ρRD/ρTD = 0.6. The calculated diameters are assigned to each strut, confirming the resulting lattice relative density (41%). The final design (Fig. 3c) features a minimum void size of 0.8 mm, 20 times the powder size Dv(90)19, making it manufacturable by PBF-LB/M without powder occlusion52. The “shape loss” from Fig. 3a to c is attributed to the figure’s positioning angle and the use of a relatively large mesh size (this setup is intended for demonstration purposes only).

Figure 3d–g illustrates the 3D distribution of each inclined strut in the final lattice model. For clarity, we have categorized the struts into four groups based on their inclination angles: θ = 0° (red); 0° < θ < 30° (purple); 30° ≤ θ < 30° (green) and 60° ≤ θ < 90° (blue). Each group is associated with a specific strut diameter, as indicated in Fig. 3 (i.e., d0°, d15°, d45° and d75°).

Our second design example, shown in Fig. 4, is a strut inclination-sensitive (SIS) complex octet-truss lattice. As with the previous design, Ti–6Al–4V is chosen as the lattice strut material, but here we use a cubic lattice unit cell. This SIS lattice design requires a relative density of 19%. Following the same procedure as outlined above, we meshed the input geometry (Fig. 4a and b) and completed the design for PBF-LB/M (Fig. 4c).

a Input geometry (30 × 30 × 30 mm3). b Geometric modeling via FE meshing using hexahedral elements. c Cubic unit cells are embedded in each hexahedral element and interconnected to form a complex lattice. d–h 3D distribution of each group of struts in the CAD model: d θ = 0°; e 0° < θ < 30°; f 30° ≤ θ < 60°; g 60° ≤ θ < 90°; and h θ = 90°. This lattice contains 2101 struts.

This SIS lattice has 2101 struts inclined at different angles:

-

(i)

30 struts at θ = 90°;

-

(ii)

417 struts at 0° < θ < 30°;

-

(iii)

1272 struts at 30° ≤ θ < 60°;

-

(iv)

110 struts at 60° ≤ θ < 90°; and

-

(v)

272 struts at θ = 0°.

To simplify the design process, we used θ = 15° for all struts inclined at 0° < θ < 30°; θ = 45° for 30° ≤ θ < 60°; and θ = 75° for 60° ≤ θ < 90° to calculate the strut diameter (φ = 0.96, h0 = 30 μm; ρPBD/ρTD = 0.6). As a result, Eq. (8) results in d = 1250.00 μm for θ = 0°; d = 1207.50 μm for θ = 15° (0° < θ < 30°); d = 883.80 μm for θ = 45° (30° ≤ θ < 60°); and d = 323.80 μm for θ = 75° (60° ≤ θ < 90°). For θ = 90°, we choose d = 200 μm, which is close to the manufacturability limit for typical PBF-LB/M of Ti–6Al–4V20.

Figure 4d–h shows the 3D distribution of each group of struts in the final lattice design (Fig. 4c). The minimum lattice cavity size is 1.5 mm, which is sufficient to prevent powder occlusion52,53,54. The resulting lattice relative density is ~19.9%, close to the target value of 19.2%. This design will be experimentally evaluated in the next section.

Quantitative assessment of complex lattice manufacturability

To ensure the manufacturability of complex lattice structures, a quantitative assessment is crucial for evaluating the viability of our holistic design approach under the constraints of the chosen PBF-LB/M process. This involves a detailed analysis of factors such as strut diameters versus inclination angles, strut connectivity, defects, and mechanical performance of lattice structures. By quantitatively assessing these parameters, a reliable, high-performance lattice can be designed for AM, ensuring both structural robustness and manufacturability.

The complex lattice design shown in Fig. 4c was fabricated in Ti–6Al–4V using PBF-LB/M. Figure 5a shows a photograph of the printed complex lattice SIS lattice, while Fig. 5b is a reconstruction based on its μ-CT images. The lattice struts exhibited a high relative density of 99.96%, consistent with the well-established PBF-LB/M process for Ti–6Al–4V. Only a small amount of internal defects were detected, as shown in Fig. 5c.

To investigate the internal structural details of the Ti–6Al–4V SIS lattice, three cross-sections were extracted from its μ-CT reconstruction (Fig. 5b) and are shown in Fig. 6a–c. These cross-sections include lattice struts inclined at angles ranging from 0° to 90°. As observed, all lattice struts exhibit a uniform cross-section. The smallest unit cell of the lattice is shown in Fig. 6d, with a cell cavity size of 1.2 mm. No powder occlusion was detected. The strut diameters for this smallest unit cell were designed to be 1207.50 μm for an inclination angle of 5° and 883.80 μm for 45°. The manufactured strut diameters were 1200 μm for 5° and 900 μm for 45° (Fig. 6d).

Figure 6e–g provides further details about the strut diameters and strut inclination angles. The comparisons are as follows: for θ = 90° (Fig. 6e), the manufactured strut diameter is 0.22 mm versus the designed value of 0.2 mm; for θ = 60° (Fig. 6f), 0.38 mm (manufactured) versus 0.362 mm (designed); for θ = 50° (Fig. 6g), 0.65 mm (manufactured) versus 0.839 mm (designed); for θ = 45° (Fig. 6f, g), 0.71/0.74 mm (manufactured) versus 0.839 mm (designed); and for θ = 0° (Fig. 7e), 1.2 mm (manufactured) versus 1.25 mm (designed).

a A reconstructed μ-CT digital model. b A μ-CT cross-sectional view corresponding to the highlighted section in (a). c–h Unit cells extracted from the μ-CT digital model to demonstrate strut manufacturability. The position of each extracted unit cell c–h is displayed in (b) (see the six colored unit cells).

Figure 7a shows a μ-CT image of the PBF-LB/M-fabricated Ti–6Al–4V SIS lattice from a different angle, while Fig. 7b presents a cross-section extracted from the red rectangle indicated in Fig. 7a. Together, they provide additional structural details of the lattice. As observed previously, all lattice struts exhibit a uniform profile across the full range of inclination angles (0°–90°). Furthermore, six lattice unit cells oriented at different angles (0°, 10°, 16°, 70°, 85°, and 90°) were extracted from the reconstructed lattice (Fig. 7a). These are shown in Fig. 7c–h, where a uniform profile is evident for each strut along its axis, demonstrating the high applicability of our approach.

Table 2 presents a comparison of the simulated or designed and manufactured strut diameters in SIS Ti–6Al–4V lattices, categorized by inclination angle. Representative SEM images for each group of struts are displayed in the left-hand column of Fig. 8, demonstrating the high cross-sectional uniformity achieved for each strut through the application of Eq. (8). The right-hand column of Fig. 8 displays the measured strut diameters, corresponding to the data listed in Table 2, revealing good consistency between designed and fabricated struts across all inclination angles. Importantly, the analyzed struts were selected from various irregular lattice cells of different sizes and orientations. This consistency thereby validates our holistic design approach.

The 2101 struts are divided into five groups according to their inclination angle: 90°, 60° ≤ θ < 90°, 30° ≤ θ < 60°, 0° < θ < 30°, 0°. a, c, e, g, i Representative SEM images of each group of struts in this SIS lattice. b, d, f, h, j Comparison of designed and measured strut diameters for each group of struts.

The observed deviations can be attributed to several factors. Firstly, using a narrower range of inclination angles (e.g., 5°) or applying the precise inclination angle for each strut is expected to reduce these deviations. Secondly, powder bed density (\({{\rm{\rho }}}_{{\rm{PBD}}}\)) plays a crucial role in build quality, as described in Eq. (8). \({{\rm{\rho }}}_{{\rm{PBD}}}\) is influenced by powder characteristics and the recoating mechanism55. Increasing \({{\rm{\rho }}}_{{\rm{PBD}}}\) can enhance consistency and minimize deviations. Lastly, the ~10% volume shrinkage of the Ti–6Al–4V alloy during cooling from the PBF-LB/M processing temperature to room temperature20,56 is an often-overlooked factor. This shrinkage should be incorporated into the FE-based design model to improve accuracy, as it was not considered in the current design.

To counter-validate our holistic design approach, we designed and fabricated a strut inclination-insensitive (SII) complex octet-truss lattice, assigning a uniform strut diameter of 200 µm, regardless of inclination angle. This diameter, suitable for a 90° inclination, is significantly smaller than required for other angles (e.g., 1250 µm at 0°). The printed sample (Fig. 9b) exhibits poor strut connectivity, with localized disconnections and excessively large diameters in certain areas. In contrast, the SIS lattice design (Figs. 5–8) demonstrated high additive manufacturability. This comparison validates our design approach, based on Eqs. (3)–(8), ensuring high-quality PBF-LB/M fabrication.

a Cubic unit cells are embedded within each hexahedral element and interconnected to form the lattice. The mesh model is identical to that shown in Fig. 5b; however, all struts maintain a uniform diameter of 200 μm, irrespective of their inclination. b The PBF-LB/M-fabricated SII lattice exhibits poor strut connectivity, with localized disconnections (red arrows) and excessively large strut diameters in certain areas (yellow arrows).

Mechanical performance testing is the ultimate step in evaluating the effectiveness of a lattice design and its manufacturability under real-world conditions. To further evaluate our design approach, compression tests were conducted on SIS and SII Ti–6Al–4V lattice samples, with the results shown in Fig. 10a, b. Since these lattice samples have different densities (ρ = 0.88 g/cm³ for SIS lattices while ρ = 0.23 g/cm³ for SII lattices), to isolate the effect of lattice design, specific strength (σ*/ρ) and specific elastic modulus (E*/ρ) were compared, as shown in Fig. 10c, d, rather than absolute values.

The specific yield strength of the SIS lattices is nearly 5.5 times that of the SII lattices (8.1 vs. 1.5 MPa cm³/g) (Fig. 10c), while the specific elastic modulus of the SIS lattices is more than six times that for the SII lattices (401.4 vs. 59.1 MPa cm³/g) (Fig. 10d). These significant improvements in mechanical performance are attributed to the high-quality fabrication enabled by our design approach. This comparison validates the effectiveness of our holistic design methodology for complex metal metamaterials, emphasizing the critical interplay between design, fabrication quality, and mechanical performance.

Scalability challenges of the proposed design approach

The scalability challenges of the proposed design approach for large, complex lattices are primarily expected to stem from practical considerations. From a design perspective, once the relative position of each mesh within the entire model is determined using shape functions, the analysis can then focus on individual meshes. As a result, the scalability of this design approach is not constrained by the overall model size.

However, a significant practical challenge lies in generating high-quality hexahedral element meshes for these models. Currently, commercial software such as HyperWorks is used to perform this task, which becomes increasingly time-intensive as model complexity grows. Overcoming this challenge largely depends on the capabilities of commercial FE meshing algorithms, as alternative solutions remain limited. Additionally, the irregularity of boundary cells poses another challenge, as extensive and non-uniform boundaries may require additional design time. Nevertheless, the demonstrated approach remains technically applicable without requiring further modifications.

From a manufacturing perspective, particularly in PBF-LB/M fabrication, the production of large and complex lattices must address challenges related to unit cell cavity sizes and powder occlusion, which are closely linked to the properties of the strut base alloy. For instance, aluminum alloys exhibit significant volume shrinkage (~33 vol%) during cooling from the high PBF-LB/M melt pool temperature to room temperature, which can significantly impact the cross-sectional uniformity of thin strut diameters (0.5–1.0 mm). Furthermore, as previously discussed, their low liquidus temperature (557 °C for AlSi10Mg compared to 1605 °C for Ti–6Al–4V) increases the tendency for powder occlusion due to easy powder sintering and adhesion to strut surfaces. Addressing these material-specific challenges is crucial to ensuring the manufacturability and structural integrity of large and complex lattice structures produced via PBF-LB/M.

Another significant practical factor to consider is the computational cost. The expense of conducting high-fidelity simulations of PBF-LB/M fabrication for large-scale lattice designs remains prohibitively high. As a result, prototype exploratory experiments are essential to obtain first-hand experimental data to refine and optimize the design approach. We recently compared the FE-based lattice design approach with 10 other contemporary lattice design methods across six fundamental criteria38. Our findings indicate that the FE-based approach offers distinct advantages over alternative methods. As a result, the generic FE-based methodology developed in this study is anticipated to be highly competitive in terms of both cost-effectiveness and time efficiency compared to existing design approaches.

As a future direction, integrating AI into our design methodology is anticipated to provide a cost-effective and scalable solution to these challenges. AI-driven approaches, such as machine learning and deep learning algorithms, can facilitate adaptive learning from both successful and unsuccessful fabrication attempts, leading to continuous improvement in design and manufacturing strategies. This integration has the potential to address key scalability concerns while ensuring robust manufacturability at an industrial scale.

Discussion

By developing and validating a practical, design-manufacturability interlocked model (Eqs. (3)–(8)), we address three key challenges that have traditionally limited the design potential of complex metal lattice metamaterials: rapid determination of strut inclination angles within irregular design spaces, identification of manufacturable strut diameters relative to inclination angle and lattice relative density, and geometric formation of lattice structures with topologically complete unit cells on irregular boundaries for additive manufacturing. Our holistic approach integrates a dual coordinate system with shape functions, enabling the rapid and accurate determination of lattice node locations while ensuring precise definitions of strut inclination angles.

Experimental validation of bespoke, complex Ti–6Al–4V lattice designs fabricated via PBF-LB/M demonstrates a high degree of consistency between design and manufacturing, with all structural details successfully realized without powder occlusion. The manufactured Ti–6Al–4V structures exhibit the desired mechanical properties, confirming the effectiveness of our approach. This research contributes to the growing demand for lightweight, high-strength, and multifunctional materials, unlocking the potential of complex metal lattice metamaterials for a wide range of applications.

While the scalability of the proposed design approach is not constrained by the overall model size, several practical challenges must be addressed. These include the efficient generation of high-quality hexahedral element meshes for large models; material-specific limitations in PBF-LB/M AM; and the high computational cost of conducting high-fidelity simulations for large-scale lattice designs. Integrating artificial AI into our design methodology is expected to provide a more cost-effective and scalable solution to these widely encountered challenges.

Materials and methods

Argon gas-atomized spherical Ti–6Al–4V powder (size range: 15–45 μm, Dv(90) = 40 μm) was used for PBF-LB/M in this work. The selection of Ti–6Al–4V is due to the extensive data available for PBF-LB/M of conventional Ti–6Al–4V lattices, its small volumetric shrinkage in PBF-LB/M and high solidus temperature just described above. Additionally, lattice materials made in Ti–6Al–4V can inherit its high strength, medium density, excellent corrosion resistance, biocompatibility, low thermal expansion, paramagnetic properties, compatibility with composite materials, and good heat resistance (up to 350 °C), making them attractive for a variety of applications.

A Trump TruPrint 1000 PBF-LB/M system was employed to print all Ti–6Al–4V complex lattice designs. The PBF-LB/M settings are laser power = 95 W, laser beam size = 80 μm (zero offsets), layer thickness = 30 μm, laser scan speed = 1200 mm/s, hatch spacing = 80 μm and a threshold of 0.1 μm for hatch vector filter. The oxygen content in the build chamber was maintained at less than 100 ppm via a high-purity argon gas flow at 30 l/min (once the oxygen level reaches 100 ppm, the gas flow will stop).

A microfocus computed tomography (μ-CT) system (ZEISS Xradia 520 Versa) was used to characterize all manufactured lattice samples. The μ-CT was operated at 100 kV and 9 W. A voxel size of 44.9 μm was used for the complex lattices. The Dragonfly software tool developed by object research systems (ORS) was employed to reconstruct the CT data.

Scanning electron microscopy (SEM, TESCAN LYRA3) was used to further quantify the uniformity of as-printed lattice struts. Secondary electron imaging was applied at 20 kV with a spot size of 5.7 nm. Measurements were taken at the two ends and in the middle of each lattice strut of interest using ImageJ software. The process consisted of three steps:

-

1.

Image capture: The lattice sample was positioned at different angles within the SEM to capture a comprehensive set of images;

-

2.

Strut selection: SEM images were taken for at least 10 struts at the same inclination angle; and

-

3.

Detailed measurements: For each group, individual struts were measured at both ends and the middle from the SEM images using ImageJ software.

The measured diameters were then compared with their respective computer-aided design (CAD) diameters.

Mechanical evaluation of the manufactured lattices was conducted using uniaxial compression tests. These tests were performed on a SANS electromechanical universal testing machine at a displacement rate of 0.5 mm/min according to the International Standard ISO 13314:2011(E)57. The resulting stress–strain curves were used to assess the mechanical performance of each lattice design, in compliance with the same standard57.

Several software tools were used to facilitate the generation of complex lattice design models for PBF-LB/M using our finite element (FE)-based algorithm. The finite elements were generated using Hypermesh (Version: 13.0, Altair Engineering Inc.). The beam element of ABAQUS (Version: 2021, Dassault Systèmes Simulia Corp.) was adopted to assign lattice strut diameters, which led to the creation of an Object (OBJ) file. Finally, SOLIDWORKS (Dassault Systèmes SOLIDWORKS Corp.) or Rhinoceros 3D (Robert McNeel & Associates) was used to convert the OBJ file into an STL file for PBF-LB/M.

Data availability

Data is provided within the manuscript.

References

Zhong, H. Z. et al. The Gibson–Ashby model for additively manufactured metal lattice materials: its theoretical basis, limitations and new insights from remedies. Curr. Opin. Solid State Mater. Sci. 27, 101081 (2023).

Kadic, M., Milton, G. W., van Hecke, M. & Wegener, M. 3D metamaterials. Nat. Rev. Phys. 1, 198–210 (2019).

du Plessis, A. et al. Properties and applications of additively manufactured metallic cellular materials: a review. Prog. Mater. Sci. 125, 100918 (2022).

Zhang, X., Leary, M., Tang, H., Song, T. & Qian, M. Selective electron beam manufactured Ti–6Al–4V lattice structures for orthopedic implant applications: current status and outstanding challenges. Curr. Opin. Solid State Mater. Sci. 22, 75–99 (2018).

Wang, X. et al. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review. Biomaterials 83, 127–141 (2016).

Tang, H. et al. A honeycomb-structured Ti–6Al–4V oil–gas separation rotor additively manufactured by selective electron beam melting for aero-engine applications. JOM 68, 799–805 (2016).

Kovacev, N. et al. The synergy between substrate architecture of 3D-printed catalytic converters and hydrogen for low-temperature aftertreatment systems. Chem. Eng. Sci. 269, 118490 (2023).

Thole, K. A., Lynch, S. P. & Wildgoose, A. J. Review of advances in convective heat transfer developed through additive manufacturing. Adv. Heat Transf. 53, 249–325 (2021).

Baroutaji, A., Arjunan, A., Robinson, J., Abdelkareem, M. A. & Olabi, A.-G. Additive manufacturing for proton exchange membrane (PEM) hydrogen technologies: merits, challenges, and prospects. Int. J. Hydrogen Energy 52, 561–584 (2023).

Noronha, J. D. J., Rogers, J., Leary, M., Brandt, M. & Qian, M. Titanium multi-topology metamaterials with exceptional strength. Adv. Mater. 36, 2308715 (2024).

Zhu, C. et al. Toward digitally controlled catalyst architectures: hierarchical nanoporous gold via 3D printing. Sci. Adv. 4, eaas9459 (2018).

Jiao, P. & Alavi, A. H. Artificial intelligence-enabled smart mechanical metamaterials: advent and future trends. Int. Mater. Rev. 66, 365–393 (2021).

Cerniauskas, G., Sadia, H. & Alam, P. Machine intelligence in metamaterials design: a review. Oxf. Open Mater. Sci. 4, itae001 (2024).

Jam, A. et al. Manufacturability of lattice structures fabricated by laser powder bed fusion: a novel biomedical application of the beta Ti–21S alloy. Addit. Manuf. 50, 102556 (2022).

Noronha, J. et al. Additive manufacturing of Ti–6Al–4V horizontal hollow struts with submillimetre wall thickness by laser powder bed fusion. Thin-Walled Struct. 179, 109620 (2022).

Zhang, X. Z. et al. Toward manufacturing quality Ti–6Al–4V lattice struts by selective electron beam melting (SEBM) for lattice design. JOM 70, 1870–1876 (2018).

Yang, L. et al. Fatigue properties of Ti–6Al–4V Gyroid graded lattice structures fabricated by laser powder bed fusion with lateral loading. Addit. Manuf. 46, 102214 (2021).

Yu, G., Li, X., Dai, L., Xiao, L. & Song, W. Compressive properties of imperfect Ti–6Al–4V lattice structure fabricated by electron beam powder bed fusion under static and dynamic loadings. Addit. Manuf. 49, 102497 (2022).

Tanlak, N., De Lange, D. F. & Van Paepegem, W. Numerical prediction of the printable density range of lattice structures for additive manufacturing. Mater. Des. 133, 549–558 (2017).

Zhang, X. Z. et al. Additive manufacturing of intricate lattice materials: ensuring robust strut additive continuity to realize the design potential. Additive Manuf. 58, 103022 (2022).

Song, T. et al. Strong and ductile titanium–oxygen–iron alloys by additive manufacturing. Nature 618, 63–68 (2023).

Mohr, M., Wunderlich, R., Novakovic, R., Ricci, E. & Fecht, H.-J. Precise measurements of thermophysical properties of liquid Ti–6Al–4V (Ti64) alloy on board the international space station. Adv. Eng. Mater. 22, 2000169 (2020).

Wang, H., Yang, S. & Wei, B. Density and structure of undercooled liquid titanium. Chin. Sci. Bull. 57, 719–723 (2012).

Qian, M., Xu, W., Brandt, M. & Tang, H. Additive manufacturing and postprocessing of Ti–6Al–4V for superior mechanical properties. MRS Bull. 41, 775–784 (2016).

Wei, P., Wei, Z., Chen, Z., He, Y. & Du, J. Thermal behavior in single track during selective laser melting of AlSi10Mg powder. Appl. Phys. A 123, 1–13 (2017).

Zhong, H. Z., Das, R., Gu, J. & Qian, M. Low-density, high-strength metal mechanical metamaterials beyond the Gibson–Ashby model. Mater. Today 68, 96–107 (2023).

Ashby, M. & Gibson, L. Cellular Solids: Structure and Properties (Press Syndicate of the University of Cambridge, Cambridge, UK, 1997).

Maconachie, T. et al. SLM lattice structures: properties, performance, applications and challenges. Mater. Design 183, 108–137 (2019).

Peri, D. Conformal free form deformation for the optimisation of complex geometries. Ship Technol. Res. 59, 36–41 (2012).

Langton, C., Whitehead, M., Langton, D. & Langley, G. Development of a cancellous bone structural model by stereolithography for ultrasound characterisation of the calcaneus. Med. Eng. Phys. 19, 599–604 (1997).

Stanton, E., Crain, L. & Neu, T. A parametric cubic modelling system for general solids of composite material. Int. J. Numer. Methods Eng. 11, 653–670 (1977).

Rizzi, C. et al. Design Tools and Methods in Industrial Engineering, Conference Proc. ADM 107, Chaari, F. et al. (eds), (Springer, 2019).

Dal Fabbro, P. et al. Analysis of a preliminary design approach for conformal lattice structures. Appl. Sci. 11, 11449 (2021).

Chen, Y. & Wang, C. C. L. Regulating complex geometries using layered depth‐normal images for rapid prototyping and manufacturing. Rapid Prototyp. J. 19, 253–268 (2013).

Brennan-Craddock, J. The Investigation of a Method to Generate Conformal Lattice Structures for Additive Manufacturing. Thesis (Loughborough University, 2011).

Jiang, C., Rist, F., Wang, H., Wallner, J. & Pottmann, H. Shape-morphing mechanical metamaterials. Comput.-Aided Design 143, 103146 (2022).

Dutta, D., Prinz, F. B., Rosen, D. & Weiss, L. Layered manufacturing: current status and future trends. J. Comput. Inf. Sci. Eng. 1, 60–71 (2001).

Zhong, H. et al. Design of conformal lattice metamaterials for additive manufacturing. Curr. Opin. Solid State Mater. Sci. 30, 101162 (2024).

Vasista, S. & Tong, L. Topology optimisation via the moving iso-surface threshold method: implementation and application. Aeronaut. J. 118, 315–342 (2014).

Vasista, S. & Tong, L. Design and testing of pressurized cellular planar morphing structures. AIAA J. 50, 1328–1338 (2012).

Tong, L. & Lin, J. Structural topology optimization with implicit design variable—optimality and algorithm. Finite Elem. Anal. Des. 47, 922–932 (2011).

Chen, W., Zheng, X. & Liu, S. Finite-element-mesh based method for modeling and optimization of lattice structures for additive manufacturing. Materials 11, 2073 (2018).

Viswanath, A., Dieringa, H., Ajith Kumar, K.K., Pillai, U.T.S. & Pai, B.C. Investigation on mechanical properties and creep behavior of stir cast AZ91-SiCp composites. J. Magnes. Alloys 3, 16–22 (2015).

You, J.-H. & Park, K. Design and additive manufacturing of thermal metamaterial with high thermal resistance and cooling capability. Additive Manuf. 41, 101947 (2021).

Zhong, H. et al. Characterization of the structural features of Ti–6Al–4V hollow-strut lattices fabricated by laser powder bed fusion. Mater. Charact. 217, 114364 (2024).

Tey, W. Y., Che Sidik, N. A., Asako, Y., Muhieldeen, M. W. & Afshar, O. Moving least squares method and its improvement: a concise review. J. Appl. Comput. Mech. 7, 883–889 (2021).

Breitkopf, P., Rassineux, A. & Villon, P. An introduction to moving least squares meshfree methods. Rev. Européenne Élém. Finis 11, 825–867 (2002).

Nguyen, V. P., Anitescu, C., Bordas, S. P. & Rabczuk, T. Isogeometric analysis: an overview and computer implementation aspects. Math. Comput. Simul. 117, 89–116 (2015).

Jacob, G., Donmez, A., Slotwinski, J. & Moylan, S. Measurement of powder bed density in powder bed fusion additive manufacturing processes. Meas. Sci. Technol. 27, 115601 (2016).

Elambasseril, J. et al. Laser powder bed fusion additive manufacturing (LPBF-AM): the influence of design features and LPBF variables on surface topography and effect on fatigue properties. Crit. Rev. Solid State Mater. Sci. 48, 132–168 (2023).

Nguyen, H. D. et al. A critical review on additive manufacturing of Ti–6Al–4V alloy: microstructure and mechanical properties. J. Mater. Res. Technol. 18, 4641–4661 (2022).

Amin Yavari, S. et al. Relationship between unit cell type and porosity and the fatigue behavior of selective laser melted meta-biomaterials. J. Mech. Behav. Biomed. Mater. 43, 91–100 (2015).

Wang, S. et al. Pore functionally graded Ti6Al4V scaffolds for bone tissue engineering application. Mater. Des. 168, 107643 (2019).

Kadkhodapour, J. et al. Failure mechanisms of additively manufactured porous biomaterials: effects of porosity and type of unit cell. J. Mech. Behav. Biomed. Mater. 50, 180–191 (2015).

Elambasseril, J. et al. Effect of powder characteristics on layer density, defects, and tensile properties of Ti‑6Al‑4V via laser powder bed fusion: establishing benchmark parameters for quality. Prog. Additive Manuf. https://doi.org/10.1007/s40964-025-01046-z (2025).

Noronha, J., Leary, M., Brandt, M. & Qian, M. AlSi10Mg hollow-strut lattice metamaterials by laser powder bed fusion. Mater. Adv. 5, 3751–3770 (2024).

ISO 13314. Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals (International Organization for Standardization, 2011).

Acknowledgements

Funding from the National Natural Science Foundation of China (NFSC) through 52305270, China postdoctoral Science Foundation through 2023M742258 and the Australian Research Council (ARC) through DP200102666 is acknowledged.

Author information

Authors and Affiliations

Contributions

Conceptualization: H.Z. Zhong, M. Qian. Methodology: H.Z. Zhong, M. Qian, H.X. Mo, Y. Liang, C.W. Li, R. Das, Yuanji Hong. Investigation: H.Z. Zhong (numerical and experimental; critical analysis), M. Qian (critical analysis), J.F. Gu (discussion). Funding acquisition: H.Z. Zhong, J.F. Gu, M. Qian. Project administration: H.Z. Zhong, J.F. Gu, M. Qian. Supervision: M. Qian, J.F. Gu. Writing: H.Z. Zhong, M. Qian. Writing—review: C.W. Li, H.X. Mo, G. Shen, Y. Liang, J.F. Gu.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhong, H.Z., Mo, H.X., Shen, G. et al. Laser powder bed fusion of complex metal lattice metamaterials: a structurally robust holistic design approach. npj Adv. Manuf. 2, 9 (2025). https://doi.org/10.1038/s44334-025-00019-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44334-025-00019-y