Abstract

The direct nitridation of binder jet additively manufactured silicon to produce porous silicon nitride was explored. The Taguchi Design of Experiments method was used to systematically study the effect of time, temperature, and nitrogen flow rate on the direct nitriding of binder jet additively manufactured silicon to produce porous reaction-bonded silicon nitride (RBSN). Highly porous (61%) samples with high conversion (99%) to silicon nitride were achieved using a thermal profile that utilized two isothermal holds. Further, it was shown that these samples exhibited thermal shock resistance and a low coefficient of thermal expansion. These results indicate that RBSN is readily achievable through additive manufacturing.

Similar content being viewed by others

Introduction

Silicon nitride (Si3N4) has material properties desirable for a variety of applications such as heat exchangers, integrated circuity, osteointegration scaffolds, thermal and environmental barrier coatings, and radio communication1. Silicon nitride is often difficult to process due to its high sintering temperature (1750–1900 °C)2,3. However, these temperatures can be lowered using various oxide-based sintering aid combinations4,5,6,7,8,9,10,11,12 where these compounds form a ternary eutectic with the silicon dioxide (SiO2) surface-oxide layer of silicon nitride. Studies have shown that high relative density (>97%) can be achieved, even with pressureless methods. However, sintering aids also have drawbacks. For example, magnesia13,14, alumina, and yttria14 all decrease the oxidation resistance of Si3N4 through the formation of glassy silicate phases in both dry and humid air, thus limiting application above 1200 °C. This has led researchers to develop other processing strategies for monolithic silicon nitride. One such method is reaction bonding (RB), where metallic silicon is heated in a nitrogen-rich environment to create silicon nitride through nitrogen diffusion into the silicon. The nitrided preform is then often sintered to full density, producing a material referred to as sintered reaction-bonded silicon nitride (SRBSN). Compared with sintered silicon nitride powders, SRBSN lowers processing temperatures by 350–500 °C2,15, reducing energy costs, and the starting materials are readily available and inexpensive. The nitriding of silicon powder compacts has been studied by Zhu et al. 2 and Guo et al. 15, where studies showed high extent of nitriding (>97%) at 1400 °C. However, both studies utilized sintering aids to assist with densification. Zhu et al.2 achieved high relative density (>99%) by sintering at 1800 °C, while Guo et al. 15 achieved moderate relative density (<74%) during a single nitriding step. Despite the low relative density, nitriding of silicon powder compacts is an effective strategy for creating silicon nitride structures since it represents a lower temperature processing strategy. However, it should be noted that high density is not required for all applications.

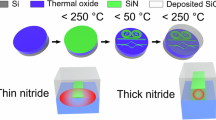

Porous silicon nitride-based ceramics have been shown to have interesting properties, specifically moderate strength and thermal shock resistance to 800 °C16,17,18 and lowered dielectric constant19,20,21. These porous materials have been made using traditional techniques such as gel or slip casting1. While these methods have shown success for two-dimensional and axisymmetric three-dimensional components, there is a need for parts with three-dimensional complexity, such as internal features for lightweighting or unique strength, heat exchange, and electromagnetic properties. Additive manufacturing (AM) is a promising method by which ceramic components can be made1,22. Of the AM technologies, binder jet AM (BJAM) is an interesting technology due to its simplicity23. A disadvantage of this method is that the printed preforms are highly porous. However, this porosity could be readily utilized if a porous ceramic is the goal.

Synthesizing the findings of prior studies leads to the conclusion that silicon nitride structures can readily be fabricated through BJAM and nitriding. Therefore, the objective of this work is to demonstrate a novel processing methodology by which reaction-bonded silicon nitride (RBSN) is produced through direct nitridation of AM silicon without the use of sintering aids or the need for further densification. The demonstrated approach utilizes BJAM to print silicon preforms, which were subjected to nitriding in a high purity nitrogen-based gas. It is known that small particles are more readily converted to silicon nitride from silicon2,24,25. However, BJAM requires particles in the 10–40 microns range for printability23. Initial flowability tests showed that 10 µm silicon powder did not flow well, so 20 and 40 µm powders were chosen. A Taguchi Design of Experiments (TDoE) was used to determine the appropriate nitriding conditions using the Taguchi L9 array, which was utilized to reduce the total number of experiments while maximizing the amount of information obtained from each experiment. High but incomplete conversion to Si3N4 has been previously reported2 at 1400 °C so the experimental design started with temperatures close to this value. The TDoE investigated the effect of time, temperature, nitrogen flow rate, the number of isothermal holds, and particle size on conversion to silicon nitride. As a means for understanding the mechanical and thermomechanical behavior the flexural strength, thermal shock strength, and coefficient of thermal expansion were measured.

Results

Nitriding

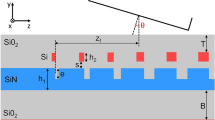

Tables 1–4 detail the experimental structure and EN of TDoE #1, TDoE#2, TDoE#3, and TDoE#4, respectively. The level mean, which is the average of the response (e.g., EN) to the control factor (i.e., time, temperature, flow rate, etc.) level and is detailed in Table 5 for each level and each TDoE. As an example, for the low temperature condition the average EN is computed regardless of the level for time and flow rate. This was repeated eight times to produce the nine unique data points shown in each section of Table 5. The 36 data points in Table 5 were used to construct Fig. 1 where there are 9 data points per panel which correspond to the specific TDoE. In each panel of Fig. 1, the x-axis shows the level for the time, temperature, and flow rate. While the physical units for each of these are different, assigning the value of 1, 2, or 3 allowed them to be displayed on the same figure for ease of comparison to determine the optimal processing parameters. In each panel, the y-axis shows the mean EN from Table 5 The first design of experiments (TDoE #1) with N2, showed that increased time and temperature lead to increased EN and increased flow, which counterintuitively led to decreased EN. When the processing gas was switched to N2-4%H2 (TDoE #2), the same behavior, as compared to TDoE #1, was observed for time and temperature and accompanied by a large increase in the EN. However, with flow rate a large increase in the EN is seen from 100 to 250 sccm and then a smaller increase from 250 to 400 sccm. A second isotherm was introduced for the third design of experiments (TDoE #3). First, the samples were held at 1390 °C for 8 h before increasing the temperature and the hold time at that high temperature. Samples processed at 1400 °C and 1410 °C, during TDoE #2, exhibited signs of silicon melting. Indicating that the temperature exceeded 1414 °C due to the response time of the microcontroller. Melting was not observed in samples processed at 1390 °C and moderate nitriding was observed, therefore, 1390 °C was selected as the temperature for the first isothermal hold to be used in TDoE #3 and TDoE #4. The intent of introducing a second isothermal hold was to allow nitriding to begin at a lower temperature and finish at a higher temperature, where diffusion kinetics would be increased. It can be seen again that increased time and temperature increase the EN. However, it appears that there are diminishing returns with increased flow rate in TDoE #3. A large initial EN increase is observed between 400 and 500 sccm and then a decrease from 500 to 600 sccm. The same trends are observed in the final design of experiments (TDoE #4) with 20 µm silicon powder. Since the conditions for the highest conversion to silicon nitride were achieved in TDoE #4, the optimal conditions from this TDoE were used to fabricate samples for XRD and mechanical testing. These conditions are: 8-hour isothermal hold at 1390 °C followed by a 12-hour isothermal hold at 1450 all with N2 + 4% H2 flowing at 500 sccm.

Shown in Fig. 2 are the samples following the experiments outlined by TDoE #4. In can be visually observed that high conversion to silicon nitride is achieved by the white appearance of the specimen.

X-ray diffraction

The XRD pattern obtained from a sample processed at the optimal conditions from TDoE #4 is presented in Fig. 3. The sample shows the presence of α- and β-Si3N4 phases along with a smaller presence of Si. The Rietveld refinements revealed the phase fractions as follows: α-Si3N4: 52.4 wt.%, β-Si3N4: 47.0 wt.% and Si: 0.7 wt.%.

Flexural strength, thermal shock, and specimen geometry

The results of flexural strength before and after thermal shock are shown in Fig. 4. Relevant geometry and statistics are shown in Table 6. Geometry data are provided for reference to the ASTM C1525 Type B bar, which has a geometry of 45 mm x 3 mm x 4 mm. Fig. 4 shows that the RBSN of this study can withstand a 600 °C thermal shock before strength is reduced below 30% of the room temperature value. For each test, 15 samples were tested. Table 6 lists the average and standard deviation for the length, width, and thickness of the specimen, density, extent of nitriding, and strength as well as the Weibull scale factor and shape parameter. The unshocked specimen exhibits a high shape parameter, indicating high reliability of the unshocked strength. The shape parameter decreases with after the 200 °C thermal shock followed by an increase between the 400, 600, and 800 °C thermal shocks. It should be stated clearly that the minimum number of samples were not tested to meet the requirements for a true Weibull analysis. The data presented here are for qualitative assessment only.

Coefficient of thermal expansion (CTE)

Shown in Fig. 5 are the results of the CTE measurements vs temperature at 100 °C increments starting at 100 °C ending at 1000 °C. These data show that CTE increases with temperature, with the magnitude of the increase decreasing as temperature increases. At 100 °C the CTE is measured to be 1.25 × 10−6/°C.

Discussion

An important consideration when interpreting these results is that the EN is a mass-based measurement that is more sensitive to overestimation of the starting mass than it is to the underestimation of the final mass. Overestimation of the starting mass can be as simple as measuring the mass of a sample that has absorbed atmospheric moisture, which is typically the case in humid environments. This overestimated starting mass is used to compute the theoretical mass if full conversion to silicon nitride is achieved. Since the mass of silicon is lower than the apparent sample mass, the estimated EN will also be lower. It is worth discussing that the reactivity of the metal is inherently linked to the temperature. As temperature increases, reaction kinetics also increase. Further, the reaction to silicon nitride is based on the availability of nitrogen to complete the reaction. In the experiments using N2 as the reactive gas (TDoE #1), a naïve interpretation of the data presented in Fig. 1 would be that the EN decreased with increasing flow rate. It is worth mentioning that while the Taguchi method is designed to de-convolute the effect of each factor on the response during experimentation, this can be challenging based on the specific response. In the present case, the EN is a mass-based calculation which indicates the mass change during experimentation (i.e., the amount of nitrogen absorbed during heating). Small changes in the mass can lead to large changes in the computed EN. Melting of the silicon was observed in samples processed at 1400 and 1410 °C. As such, spherical nodules were present on the surface of the samples during post-experimental observations. While recording the post-experimental mass, it was difficult to account for all the spherical nodules and thus, the recorded mass was lower. Since the flow rate was simultaneously changed when the temperature was changed for each experiment, this indicated that higher flow rates of N2 lead to decreased EN. Further, it must be noted that for the data presented in Fig. 1, the average EN for the 400 sccm flow rate was low, in part, because silicon was melted during the experiments at 1410 °C. Nevertheless, the conversion to silicon nitride was low because of the presence of the native-oxide layer on the exterior of the silicon particles that naturally occurs when the silicon particles are introduced to air during printing. Therefore, the process gas was switched to N2-4%H2.

In the second set of experiments (TDoE #2), it was observed that after the processing gas was switched to N2-4%H2, a glassy layer was found on the inner diameter of the furnace tube on the outlet side of the furnace. This glassy layer was presumed to be silicon monoxide (SiO). This is supported by studies indicating that SiO2, in the presence of hydrogen, reacts to form SiO and H2O gases26,27. Though the reaction between SiO and N2 to Si3N4 is thermodynamically favorable, the presence of the glassy layer indicates that the high flow rate carried SiO gas downstream quickly enough that reaction did not occur. It is shown in Fig. 1 that the presence of hydrogen is highly beneficial for silicon nitride conversion from silicon. This has previously been reported in the literature2,24,25. Despite this benefit, the EN was still low. Post-experimental observations showed that samples processed at 1400°C and 1410 °C exhibited melting of the silicon, in-spite of higher EN as compared to samples processed at 1390 °C. Though the melting temperature was not exceeded by the temperatures selected for experimentation, the melting temperature was exceeded due to the response time of the furnace microcontroller. Here it was postulated that two isothermal holds could lead to increased EN. The first isothermal hold was to start nitriding of the silicon, and the second isothermal hold to increase reaction kinetics and finish nitriding. Similarly, less melting was observed for samples processed for 8 h when compared to samples processed for 12 h, again, in-spite of the higher EN observed in the 12-hour samples. As mentioned, the reaction to silicon nitride is based on the availability of nitrogen to complete the reaction. This also applies to the availability of hydrogen to complete the reduction reaction and thus enable nitriding. In TDoE #2 an EN increase is observed with increasing flow rate, in-spite of the issues with melting and final mass measurement described previously.

The third set of experiments (TDoE #3) consisted of an 8-hour hold at 1390 °C and then heating to higher temperatures, holding for different amounts of time, and increasing the flow rate based on the findings of TDoE #2. The set of experiments showed that utilization of a second isothermal hold was highly beneficial to increasing the EN (Fig. 1). These results differ from previous studies where a single isothermal hold was used2,24,25. It must be noted that these previous studies used smaller silicon powders (1–10 micron) and the latter two studies used various metal catalysts to improve nitriding. From the currently presented findings, it seems that larger silicon particles melt, before significant nitriding is experienced. Therefore, time at the lower temperature is needed to create a nitride layer strong enough to resist penetration of the molten silicon within the particle once the melting temperature of silicon is exceeded. Further, an observed decrease in EN with increased flow rate is observed. Likely, due to increased availability of hydrogen for the reduction reaction leading to melting, thus furthering the reaction since reaction products are being pulled away in the form of SiO gas.

As mentioned previously, smaller particles are more easily nitrided2,24,25. Fig. 1 shows that temperature and flow rate affect nitriding of the 20 µm particles (TDoE #4) at approximately equivalent rates as the 40 µm particles (TDoE #3). However, the EN increased at a much faster rate with time that previously shown for the 40 µm particles. This final TDoE showed that the best conditions for nitriding of this silicon are to first hold the samples at 1380 °C for 8 h, then heat to 1450 °C and hold for 12 h, all with 500 sccm of flowing N2 + 4%H2. These conditions were chosen because they provided the highest EN. However, this is not immediately clear from Fig. 1. There was a 1% EN difference between the level mean for level 2 and level 3 temperature in TDoE#4 (Table 5). Though 1% may not be a significant increase between level 2 and level 3, it must be kept in mind that the optimal conditions are chosen to be the conditions that produce the highest EN regardless of level. These conditions resulted in a sample that showed a mass-based EN of 88%, which is a significant increase when compared to both level 2 and level 3 temperature EN. Analyzing samples processed at these conditions indicated that >99% conversion to silicon nitride was achieved by Rietveld analysis of the XRD data in Fig. 3. This discrepancy between the XRD and the EN measured clearly indicates inaccuracies of the mass-based EN, as discussed previously. Regardless, EN is useful for quickly measuring experimental success in the lab and is valid enough for making experimental decisions. However, this may not be applicable to all materials systems (i.e., other nitrides or carbides). Using the optimal conditions of TDoE #4, samples were made for mechanical testing.

The mechanics of materials are heavily dictated by porosity28, with some material properties (e.g., elastic modulus) showing a quadratic decrease with increasing porosity. Shan et al.29 created porous silicon nitride samples using carbothermal reduction and nitridation of silica. These researchers used three different particle sizes of SiO2 and report flexural strengths between 24–176 MPa with porosity levels between 36 – 71%. In a recent review paper30, the strengths of porous silicon nitride made from different manufacturing methods are tabulated. The strength is between 60–150 MPa (30–50% porosity) for extrusion molding, 10–30 MPa (70–90% porosity) for direct foaming, 6–65 MPa (60–90% porosity) for freeze drying, 100–250 MPa (40–60% porosity) for gelcasting, <100 MPa (45–75% porosity) for carbothermal reduction and nitridation, 50–300 MPa (40–60% porosity) for reaction sintering, and 100–400 MPa (35–60% porosity) for phase change sintering starting with α-Si3N4 powders. This study reports a flexural strength of 19.40 MPa for samples with ~62% porosity. The currently presented findings (Table 6) are within the range of literature data, albeit the low end. Furthermore, the data presented here indicate that a significant reduction in strength is not experienced even after a 600 °C thermal shock. Similar behavior has been observed for 42% porous gel-cast silicon nitride with sintering aids31, 47% porous silicon nitride fabricated using self-propagating synthesis18, and 57% porous pressureless sintered silicon nitride32. It is worth noting that these previous studies all utilized small particle sizes, on the range of 0.37–1 µm diameter17,31,33. The material performance exhibited in these studies can be, at least partially, attributed to the porosity level and particle size. Smaller particles directly translate to smaller pores and, therefore, more interfaces to inhibit crack propagation during quenching. Previous studies have shown that control of the pore size and orientation have a direct effect on thermal shock resistance34. Though careful control of the pore size is not achievable in binder jet, since the powder particles are randomly packed, the results presented here are promising for AM of thermal shock resistant silicon nitride.

The presented CTE data (Fig. 5) show an increase from 1.25 × 10−6/°C to 3.75 × 10−6/°C between 100 °C and 1000 °C. The CTE of fully dense silicon nitride is reported to be between 3.1 – 3.58 × 10−6/°C35,36. Comparing the presented results with those previously published indicates a negative correlation between CTE and porosity. It is acknowledged that comparing the CTE of a porous material and a dense material is not a one-to-one comparison, but this comparison will have to suffice since it has been challenging to find porous silicon nitride CTE data in the literature. However, the same negative correlation between CTE and porosity has been shown in porous silicon carbide37, alumina38, and cordierite-mullite-alumina composites39. Independent of a fair literature comparison, the presented data indicate low CTE, which provides insightful information for future engineering applications, such as integration with metals for industrial heat exchangers or low thermal expansion materials used as insulation.

Binder jet additively manufactured silicon was subjected to direct nitridation with high conversion efficiency. Highly porous samples (62%) exhibited thermal shock resistance to 600 °C thermal shock without strength degradation. It is known that porosity control has direct implications for a material's performance. Synthesizing results from previous studies, it can be concluded that a random pore distribution from the stacking of spherical or semi-spherical particles does not affect the thermal shock resistance behavior of highly porous silicon nitride. It can be further concluded that the methodology described in this study is suitable for creating highly porous silicon nitride through a combination of AM of silicon followed by direct nitridation. These findings have implications for the fabrication of complex-shaped, highly-porous silicon nitride heat exchangers, osteointegration scaffolds, and radomes.

Methods

Silicon powders (99.9% purity, <0.001% Fe, Cu, Ni, Ca, and Mn, <0.002% Mg and Al, <0.005% B, and <0.008% P) were purchased from US Research Nanomaterials (product number US5008) in two particle sizes, 40 and 20 µm, and printed, separately, on an ExOne Innovent with ExOne AquaFuse Binder. Relevant printing parameters are provided in Table 7. Samples used in TDoE #1 – TDoE #4 were printed in batches of 20 and were nominally 25 mm in diameter and 6 mm thick. Specimens for flexural strength, thermal shock, and CTE measurement were all printed in the same additive build. The as-printed densities and geometric variations for the samples used in each experimental design, are provided in Table 8.

Before nitriding, all preforms were subject to a thermal debind cycle with Ar-4%H2 flowing at 200 sccm in a 5-inch inner diameter and 36-inch furnace tube. During the debind, preforms were heated to 450 °C at 4.1 °C/min, held for 30 min, and then heated to 630 °C at 4.1 °C/min and held for 2-hours to decompose the polymeric binder. The Taguchi method is a flexible method for a systematic experimental investigation that maximizes useful information from a fewer number of samples, as compared to Full-Factorial or Fractional-Factorial design of experiments methods. As such, per the Taguchi Method, one sample was run for each experiment. Within the TDoE the control factors were time, temperature, and flow rate of a nitrogen-based gas (N2 or N2-4%H2) were varied to determine their effect on nitriding. As experimental progress was made, a second isothermal hold was investigated to determine if elevated temperature enhanced diffusion kinetics such that a significant increase in nitriding could be observed. Four different TDoE were performed and are shown in Tables 1–4. The first set of experiments (TDoE #1) used N2 as the nitrogen source while the second set of experiments (TDoE #2) used N2-4%H2. Based on findings from TDoE #1 and #2 an isothermal hold at 1390 °C for 8 h was used, and then the temperature was increased to complete nitriding in TDoE#3 and TDoE #4. TDoE #3 used N2-4%H2, and the TDoE #4 was a duplication of the third but used samples printed with a 20 µm powder. The N2 and N2-4%H2 used in this study were high purity (99.99%, AirGas). In each experimental set the control factors were varied between a low, medium, and high level where were assigned the values of 1, 2 and 3, respectively. This was done solely for plotting purposes, which is explained in the Results section.

During the nitriding experiments all samples were heated in a CM 1600 Series Rapid Temp Lab Furnace with three heated zones, each controlled with a Eurotherm 3508 microcontroller and a 3-inch inner diameter 48-inch furnace tube. During experimentation, a 4.1 °C/min heating rate was used from room temperature to 900 °C, 10 °C/min was used from 900 °C to the final temperature, and the furnace was cooled at 4.1 °C/min. The slower heating rate was used to prevent thermal shock of the furnace tube. The conversion to Si3N4 was estimated by computing the Extent of Nitriding (EN) using Eq. 140.

Where \({{\rm{m}}}_{{\rm{observed}}}\) is the mass of the sample after nitriding, \({{\rm{m}}}_{{\rm{initial}}}\) is the mass of the silicon sample before nitriding, and \({{\rm{m}}}_{{\rm{theoretical}}}\) is the theoretical mass of the sample if the stoichiometric reaction to silicon nitride occurs. The mechanical performance of the silicon nitride was assessed using four-point bending per ASTM C116141 and thermal shock per ASTM C152542, both using Type B bars. Samples were shocked to produce a temperature difference of 200, 400, 600, and 800 °C. 15 samples were tested for flexural strength and thermal shock resistance in the as-printed condition after nitriding. Dilatometry was performed using a dual-pushrod dilatometer following ASTM E228 (Netzsch DIL 402HT Supreme-Expedis) to obtain the CTE. The manufacturer stated uncertainty for CTE is ±5.3% of measurement. The standard specimens were 25.0 mm long and 2.0–4.0 mm in diameter. Heating rates of 3 °C/min were used. The measurements were performed in an Ar-purge gas with 20–80 ml/min flow rate. A NIST sapphire standard was used to calibrate the thermal expansion of the pushrods and sample holder. The CTE was measured on five samples. A continuous θ-2θ scan was performed on the Panalytical X’pert diffractometer from nominally 10 to 90° 2θ using CuKα radiation (λ = 1.540598 Å). ¼° fixed slits, ½° anti-scatter slit, 0.04 soller slits coupled with a 10 mm mask (beam length) were used. For the phase identification procedure, a search match was conducted using the Jade software43 and the ICDD database44. Rietveld refinement was performed using the GSAS II software45. XRD data were collected from a polished cross-section of an as-produced sample. A sample processed at the optimal nitriding conditions from TDoE #4 was sliced through the thickness of the sample.

Data availability

All data are provided within the manuscript.

References

Aguirre, T. G., Cramer, C. L. & Mitchell, D. J. Review of additive manufacturing and densification techniques for the net- and near net-shaping of geometrically complex silicon nitride components. J. Eur. Ceram. Soc. 42, 735–743 (2022).

Zhu, X., Zhou, Y., Hirao, K. & Lenčéš, Z. Processing and thermal conductivity of sintered reaction-bonded silicon nitride. I: Effect of Si powder characteristics. J. Am. Ceram. Soc. 89, 3331–3339 (2006).

Guedes-Silva, C. C., De Souza Carvalho, F. M. H. & Bressiani, J. C. Effect of rare-earth oxides on properties of silicon nitride obtained by normal sintering and sinter-HIP. J. Rare Earths. 30, 1177–1183 (2012).

Lu, T. et al. Fabrication of high thermal conductivity silicon nitride ceramics by pressureless sintering with MgO and Y2O3 as sintering additives. Ceram. Int. 46, 27175–27183 (2020).

Oh, H. M. & Lee, H. K. Controlling the width of particle size distribution of Si powder and properties of sintered reaction-bonded silicon nitride (SRBSN) ceramics with high thermal conductivity. Ceram. Int. 46, 12517–12524 (2020).

Li, Y. et al. Microstructure and thermal conductivity of gas-pressure-sintered Si3N4 ceramic: the effects of Y2O3 additive content. J. Eur. Ceram. Soc. 41, 274–283 (2021).

Lukianova, O. A., Khmara, A. N., Perevislov, S. N., Kolesnikov, D. A. & Krasilnikov, V. V. Electrical resistivity of silicon nitride produced by various methods. Ceram. Int. 45, 9497–9501 (2019).

Lukianova, O. A. & Ivanov, O. N. The effect of Al2O3-MgO additives on the microstructure of spark plasma sintered silicon nitride. Ceram. Int. 44, 390–393 (2018).

Lenz, J., Enneti, R. K., Park, S. J. & Atre, S. V. Powder injection molding process design for UAV engine components using nanoscale silicon nitride powders. Ceram. Int. 40, 893–900 (2014).

Gal, C. W. et al. Fabrication of pressureless sintered Si3N4 ceramic balls by powder injection molding. Ceram. Int. 45, 6418–6424 (2019).

Sainz, M. A., Serena, S., Belmonte, M., Miranzo, P. & Osendi, M. I. Protein adsorption and in vitro behavior of additively manufactured 3D-silicon nitride scaffolds intended for bone tissue engineering. Mater. Sci. Eng. C. 115, 110734 (2020).

Wyzga, P., Mashimo, T., Yoshiasa, A., Jaworska, L. & Klimczyk, P. The effect of high-energy methods of forming on the sintering behaviour and properties of Si3N4-based materials. Int. J. Refract. Met. Hard Mater. 80, 277–285 (2019).

Chen, Y. et al. Effect of Si powder-supported catalyst on the microstructure and properties of Si3N4-MgO-C refractories. Constr. Build. Mater. 240 (2020).

Blugan, G., Wittig, D. & Kuebler, J. Oxidation and corrosion of silicon nitride ceramics with different sintering additives at 1200 and 1500 °C in air, water vapour, SO2 and HCl environments - A comparative study. Corros. Sci. 51, 547–555 (2009).

Guo, W. M., Wu, L. X., Ma, T., You, Y. & Lin, H. T. Rapid fabrication of Si3N4 ceramics by reaction-bonding and pressureless sintering. J. Eur. Ceram. Soc. 36, 3919–3924 (2016).

Barta, J., Manela, M., Fischer, R. Si3N4 and Si2N20 for High Performance Radomes, 1985.

Wang, C., Wang, H., Qiao, R., Zhang, C. & Chen, L. Fabrication and thermal shock resistance of β-Si3N4-based environmental barrier coating on porous Si3N4 ceramic. Ceram. Int. 42, 14222–14227 (2016).

Zhang, Y. et al. Fabrication and mechanical properties of porous Si3N4 ceramics prepared via SHS. Ceram. Int. 45, 14867–14872 (2019).

Yin, S. et al. Effects of sintering temperature and sintering additive on microstructure, mechanical and dielectric properties of porous Si3N4 ceramics by gelcasting. J. Alloy. Compd. 979, 173560 (2024).

Cao, S. et al. Synthesis of self-toughness porous Si3N4 ceramics with three-dimensional cage structures. Mater. Lett. 270, 127651 (2020).

Yin, S., Jiang, Y., Fang, X., Wang, Y. & Yang, J. High-strength and low-dielectric porous Si3N4 ceramics prepared by gelcasting using DMAA. J. Alloy. Compd. 896, 162945 (2022).

Aguirre, T. G., Lamm, B. W., Cramer, C. L., Mitchell, D. Zirconium-diboride silicon-carbide composites: A review. Ceram. Int. (2021).

Mostafaei, A. et al. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 119, https://doi.org/10.1016/j.pmatsci.2020.100707 (2021).

Pavarajarn, V. & Kimura, S. Catalytic effects of metals on direct nitridation of silicon. J. Am. Ceram. Soc. 84, 1669–1674 (2001).

Cofer, C. G. & Lewis, J. A. Chromium catalysed silicon nitridation. J. Mater. Sci. 29, 5880–5886 (1994).

Gardner, R. A. The kinetics of silica reduction in hydrogen. J. Solid State Chem. 9, 336–344 (1974).

Han, G. & Sohn, H. Y. Kinetics of the hydrogen reduction of silica incorporating the effect of gas-volume change upon reaction. J. Am. Ceram. Soc. 88, 882–888 (2005).

Gibson, L. J., Ashby, M. F., Harley, B. A. Cellular Materials in Nature and Medicine, Cambridge University Press, 2010.

Shan, S. Y., Jia, Q. M., Jiang, L. H., Wang, Y. M. & Yang, J. F. Microstructure control and mechanical properties of porous silicon nitride ceramics. Ceram. Int. 35, 3371–3374 (2009).

Zha, H. et al. Progress in preparation and properties of porous silicon nitride ceramics. Silicon 15, 6631–6653 (2023).

Lu, X. et al. Porosity and oxide layer dependence of thermal shock behavior of porous silicon nitride ceramics. J. Mater. Sci. Technol. 30, 1217–1222 (2014).

Chen, M., Wang, H., Jin, H., Pan, X. & Jin, Z. Transient thermal shock behavior simulation of porous silicon nitride ceramics. Ceram. Int. 42, 3130–3137 (2016).

Lin, X. et al. Preparation and Properties of Pressureless-Sintered Porous Si3N4 Ceramics, in: Adv. Funct. Mater., Springer Singapore, Singapore, 2018: pp. 93–100.

Ohji, T. Microstructural design and mechanical properties of porous silicon nitride ceramics. Mater. Sci. Eng. A. 498, 5–11 (2008).

Strobl, S. et al. Fracture toughness of silicon nitride balls via thermal shock. J. Eur. Ceram. Soc. 38, 1278–1287 (2018).

Wang, L. et al. A novel thermally matched conductive phase of silicon nitride ceramics. J. Phys. Chem. Solids 179, 111379 (2023).

Zhu, S., Ding, S., Xi, H. & Wang, R. Low-temperature fabrication of porous SiC ceramics by preceramic polymer reaction bonding. Mater. Lett. 59, 595–597 (2005).

Kuscer, D., Bantan, I., Hrovat, M. & Malič, B. The microstructure, coefficient of thermal expansion and flexural strength of cordierite ceramics prepared from alumina with different particle sizes. J. Eur. Ceram. Soc. 37, 739–746 (2017).

Zhang, L., Olhero, S. & Ferreira, J. M. F. Thermo-mechanical and high-temperature dielectric properties of cordierite-mullite-alumina ceramics. Ceram. Int. 42, 16897–16905 (2016).

Kato, T. & Sugawara, K. Low-temperature synthesis of aluminum nitride by addition of ammonium chloride. ACS Omega 4, 14714–14720 (2019).

American Society for Testing and Materials, Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature, Order A J. Theory Ordered Sets Its Appl. 94 (1996).

American Society for Testing and Materials, Standard Test Method for Determination of Thermal Shock Resistance for Advanced, Test. (2003).

Jade, (2010). https://www.icdd.com/mdi-jade/.

ICDD, PDF-4+, (2022). https://www.icdd.com/pdf-4-minerals/.

Toby, B. H. & Von Dreele, R. B. GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J. Appl. Crystallogr. 46, 544–549 (2013).

Acknowledgements

The authors thank Dr. Amy M. Elliott for the technical review at ORNL.

Author information

Authors and Affiliations

Contributions

T.G.A. conducted the experiments, wrote the main manuscript text, and prepared figures. M.C.M. conducted mechanical testing, and M.D.R. printed samples. J.L.M. conducted thermal shock experiments. E.C. conducted XRD and Rietveld Analysis. H.W. measured the coefficient of thermal expansion. C.L.C. T.R.M., V.K., and J.W.K. provided guidance and discussion for the experiments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript has been authored by UT-Battelle, LLC, under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Aguirre, T.G., Cramer, C.L., Martinez, M.C. et al. Strength and thermal shock resistance of porous reaction-bonded silicon nitride by direct nitriding of binder jet additively manufactured silicon. npj Adv. Manuf. 2, 13 (2025). https://doi.org/10.1038/s44334-025-00026-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44334-025-00026-z