Abstract

Six iron sword samples dated to the Western Han to Xinmang period (206 BC–24 AD) of the Han Dynasty excavated from Tuchengpo Cemetery in Wushan, Chongqing, were characterized by Raman spectroscopy combined with SEM-EDS technology. The results showed that corrosion products on the iron swords were mainly divided into two corrosion layers. In the external layer, mineralized wood residue of scabbard was observed, and calcite, goethite, lepidocrocite, hematite, and carbon were detected. Different dense products were distinguished by color, including goethite (orange), lepidocrocite (reddish-brown), akaganeite (yellowish-brown), magnetite (black), and hematite (red), which formed rust sublayers in the internal layer. Chloride was mainly distributed in the internal layer, which had almost the same structure as the rust sublayers. This study provided the basic insights into the corrosion products of iron artifacts excavated from the Three Gorges region of Chongqing, as well as the comprehensive scientific information for protection of iron artifacts.

Similar content being viewed by others

Introduction

The investigation of corrosion products on the archeological iron objects is considerably essential for a comprehensive understanding of the condition, the corrosion mechanism and buried environment of the iron artifacts, the physicochemical events that artifacts experienced in the past, and possible conservation concepts and restoration strategies of the iron artifacts. The chemical and structural analysis of the corrosion products on the archeological iron objects has been the subject of study during the last decades. Previous research has demonstrated that rust layers covering archeological ferrous objects are complex systems; the components of rust represent a large set of mineral phases1,2,3,4,5. A range of investigative methods have been used to study the corrosion features of unearthed iron objects and to establish the corrosion systems for archeological iron artifacts6,7,8,9,10.

In China, the earliest artificially smelted iron objects were iron swords, which were unearthed in the cemetery of Guo State in Sanmenxia, Henan Province, during the late Western Zhou Dynasty11. With the development of the ancient iron industry, the iron casting technology of the Han Dynasty had reached a significant degree of maturity12. During this period, the production of iron Jian was extremely declined and gradually replaced by the ring-pommel iron Dao. The manufacturing process of iron Jian was different from that of iron Dao. The iron Jian was beautifully crafted to be used as a symbolic accessory to show the status of owners. The hilt and blade of the Jian were connected by a guard, and the forged double-edged blade was usually decorated by the pattern-welding technique13. On the other hand, the ring-pommel iron Dao was easy to mass-produce as a more practical weapon. The hilt and blade of the Dao were directly attached and the single-edged blade was only used for the fold-forging technique without any decoration14.

The Tuchengpo Cemetery, located in Wuxia town of Wushan country in Chongqing, was a well-preserved public burial ground near the confluence of the Yangtze River and the Daning River. It used to be a high terrace with mountains and rivers, and this area is also the beginning of the Wu Gorge (Fig. 1). Several excavations had been carried out at the Tuchengpo Cemetery by the Wuhan Municipal Institute of Cultural Relics and Archaeology and the Wushan Relics Administrative Office15,16,17. Material remains show that this cemetery, occupied from the Warring States period to the Ming and Qing Dynasties (475 BC–1911 AD), had been a public burial ground for generations. Numbers of iron artifacts, especially iron weapons of the Han Dynasty, were unearthed in this cemetery. It provided a wealth of materials for the research of the technology of iron metallurgy and the corrosion system of iron artifacts in this area. The Three Gorges region is one of the few areas in China where comprehensive archeological excavations have been carried out and numerous archeological iron objects have been rescued18. In recent years, research on the archeological iron artifacts unearthed from the Three Gorges region mainly focused on their utility, metallography, and typological analysis19,20. Only a few scholars have used XRD and industrial CT technology to determine the composition of corrosion products on iron tools and swords excavated from the region of Three Gorges prior to the restoration process21,22. In fact, there are no approaches established to investigate rust layers of iron artifacts in this region. Hence, more research on this topic is needed to be done in the future.

The corrosion of iron artifacts was heavily influenced by the soil burial environment during the long-term corrosion process. There was the risk of complete destruction of iron artifacts in well-drained, well-aerated, and high-chloride-content soils23. The Daning Valley, where the Tuchengpo cemetery was located, suffered soil erosion due to frequent river floods and mountain torrent disasters after the Han Dynasty24. Previous soil analysis of the Tuchengpo site showed low levels of phosphate ions in the soil, as compared to the Lijaba site in the Three Gorges region25.

Currently, a variety of analysis techniques have been used to investigate the structures and compositions of the corrosion products. Raman spectroscopy, as a widely applicable technique, is ideal for the study of artifacts and their degradation products because it is extremely reliable, sensitive, and compound-specific. In addition, Raman spectroscopy is characterized by in situ analysis to directly reveal the distribution of corrosion products in samples. Hence, it has been used frequently in the analysis of corrosion products on iron artifacts4,26. Six iron swords from the Tuchengpo Cemetery of the Han Dynasty were analyzed by various scientific methods. Raman spectroscopy, microscopy, and SEM-EDS technology were combined to comprehensively study the structure of rust layers and deeply explore the corrosion mechanism and preservation environment of iron cultural relics, so as to provide valuable information for the protection of iron artifacts excavated in the Three Gorges region.

Methods

Materials

Six incomplete iron swords with fragments dated from the Western Han to Xinmang period (206 BC–24 AD) of the Han Dynasty were chosen for analysis. Corrosion product samples were selected from scraps that dropped from the surface of iron swords. The size of each sample was less than 5 × 5 mm. The information about these samples was shown in Table 1. There was a series of damage, such as cracks, broken pieces, and the thickening of corrosion products on all swords, and the surfaces of some swords were covered with the mixture of iron rust and mineralized wood residue of scabbard (Fig. 2). These iron swords were all unearthed from different tombs in the same site, and the date of these iron swords was determined by the date of the tombs. Based on their general characteristics, they can be categorized into short, medium, and long swords27. Most of the sites in the Three Gorges region were along the Yangtze River, and the excavated artifacts in these tombs were badly corroded where the human bodies were also largely decomposed28. In addition, this cemetery was special because it was located at the confluence of the Yangtze River and the Daning River. Soil erosion and deposit of silt caused torrential floods happened frequently in the archeological layers since the Han Dynasty29. The iron artifacts in this cemetery had been severely corroded in the special environment filled with water, oxygen, and soluble salts. Therefore, the study of corrosion products on the iron swords excavated in this cemetery was representative and significant for the knowledge of other iron objects unearthed from the Three Gorges region in similar burial environments.

Sample preparation

The samples were embedded in epoxy resin (the ratio of epoxy slow resin and hardener was 3:1) at room temperature, then polished sequentially with silicon carbide sandpaper from P240 to P2000 and polished with diamond suspension (1 µm) sprayed on the polishing cloths.

Microscopy analysis

A three-dimensional stereo digital microscope (VHX-5000, Keyence Ltd., Japan) equipped with a super-depth field zoom lens (VH-Z100W) from 100 to 1000× was used to observe the rust layers and topical corrosion products on the cross-section of samples in dark field mode.

SEM-EDS analysis

A desktop scanning electron microscope (TM4000PlusII, Hitachi Ltd., Japan) coupled with an energy dispersive spectrometer (AZtecOne, Oxford Ltd., UK) was used to show the morphology in detail and perform elemental analysis. Samples were analyzed at ~10 mm working distance under the certain condition. The accelerating voltage was 20 kV in Mode 2, the vacuum level was standard (M), and the detector was BSE. Map and point scanning were both used to measure the distribution and chemical composition of elements in phases with acquisition times of 30 s. For the accuracy of the experimental results, light elements such as carbon and oxygen were removed from the analysis. Both qualitative and quantitative compositions of the element results were provided by AZtecOne software.

Raman spectroscopy analysis

A Renishaw inVia Raman spectrometer coupled with a microscope was used to record the Raman spectrum of samples. The detection temperature is 25 °C with the humidity lower than 50%. The Raman spectral shift was routinely calibrated against the value of a silicon wafer (520.7 cm−1) to ensure the accuracy of the data being tested that followed. The spectra were recorded from 2000–100 cm−1 in extended mode with a laser wavelength of 532 nm and 50 L× objective leans. Laser power was chosen for emission at 1% power, ~0.5 mW. The exposure time was 10 s, and the number of accumulations was from 1 to 5, depending on the sample. Repeated measurements were made on different areas of the samples to ensure that high-quality spectra were recorded.

Results

Identification of corrosion products

Corrosion products were mainly detected in two corrosion layers, which were the internal layer and the external layer. According to the previous research, the internal layer was named the “dense product layer” (DPL), while the external layer was called the “transformed medium” (TM)7,8,30,31. Corrosion products in DPL are generally well crystallized and more compact compared with those in TM. TM is a transition zone between the DPL and the soil outside. Both iron corrosion products and markers from the soil can be detected in the TM. The original surface of the object was the interface between DPL and TM, and the corrosion products in this area were examined as magnetite (Fe3O4) and goethite (α-FeOOH)32. It was shown in Fig. 3 that the mineralized wood trace (blue box) can be obviously distinguished from the boundary of DPL. The corrosion sublayer marked by the red box in DPL was connected to TM marked by the blue box. Corrosion products distributed at the interface between DPL and TM were identified as goethite (α-FeOOH) (blue box) and lepidocrocite (γ-FeOOH) (red box) by Raman spectroscopy. Moreover, calcite (CaCO3), lepidocrocite (γ-FeOOH), and goethite (α-FeOOH) were identified in TM, while lepidocrocite (γ-FeOOH), goethite (α-FeOOH), and magnetite (Fe3O4) were detected in DPL. It is evident that the burial environment of this iron artifact was aerated based on the corrosion products detected in the DPL and TM26.

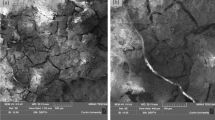

Ancient Chinese scabbards were usually made of wood or bamboo as wrappings for the blades of iron swords. The hardwood characteristics about vessels (pores) and fiber tracheids of mineralized wood can be observed in TM of C2 (Fig. 4a, b). The wooden structure was permeated by the iron corrosion products because the wooden scabbard was in prolonged contact with the corroded iron sword. The negative imprint of the cellular structure was obtained, and the mineralized wood residue was preserved. However, organic components of the wood were completely replaced by iron corrosion products, so that the species of the wood was difficult to determine33,34. The mineralized wood structure of the vessel and fiber tracheid marked in yellow boxes were characterized by SEM (Fig. 4c, d). Two points in the vessel (green and blue crosses) and one point in the fiber tracheid (red cross) were identified as different phases by Raman spectroscopy (Fig. 4e).

a, b Yellow boxes indicate observation areas; c, d BSE images by SEM; e raman spectra of test points; green, blue and red spectra were acquired from the points marked by the green, blue and red crosses in (c, d) (green spectrum: calcite; blue spectrum: goethite, hematite, and carbon; red spectrum: goethite and lepidocrocite).

The strongest and most conspicuous band at 1087 cm−1 and well-resolved bands at 156, 284, and 711 cm−1 (green spectrum in Fig. 4e) are assigned to calcite (CaCO3)1,30. The Raman peaks (red spectrum in Fig. 4e) at 214, 248, and 1296 cm−1 are ascribable to lepidocrocite (γ-FeOOH), whereas peaks at 298, 396, 539, and 658 cm−1 indicate the existence of goethite (α-FeOOH)35. The strongest band at 392 cm−1 of the blue spectrum in Fig. 4e is the characteristic of goethite (α-FeOOH), and the well-defined Raman bands at 1317 cm−1 and 1591 cm−1 are ascribable to hematite (α-Fe2O3) and carbon (C), respectively36,37. The mineralized vessel was identified as calcite, goethite, hematite, and carbon, while the mineralized fiber tracheid was detected as goethite and lepidocrocite. Corrosion products of calcite (CaCO3) formed in the mineralized vessel should be the result of the hydroxide anions from the iron corrosion reaction with dissolved ions of soil, such as calcium ions and bicarbonate. The chemical reaction could be processed as follows: Ca2+ + HCO3− + OH−→CaCO3 ↓ + H2O38. The carbon may be from the lacquer coated on the wooden scabbard39.

TM and DPL were found together in C2 and C4. DPL was detected in C1, C3, C5, and C6 without the presence of TM. Microscopic observations of the DPL reveal that rust sublayers form different distribution features in cross-sections with cracks, and colors of rust sublayers appear as black, brown, orange, yellow, red, gray, and white. The characteristics of rust sublayers of four samples are shown in Fig. 5. These rust sublayers were sequentially numbered in natural numbers starting with 1 from the outer to the inner. It can probably be divided into 3–6 rust sublayers in the DPL of every sample. The rust sublayers of C1 are alternately distributed inside the DPL in the form of thin “ropes” shaped (Fig. 5a). These rust sublayers are distributed parallel to the cross-section, with a gradual change in color from light red to reddish-brown from the inside to the edge. Multiple connected rust sublayers of ‘horseshoes’ shape can be observed in C2 (Fig. 5b). These rust sublayers stacked on top of each other vary from 43 μm to 358 μm. The colors are reddish-brown, black, yellow, red, orange, and brown from outside to inside. The appearance feature of rust sublayers in C3 is clearly marked “strips” by identified color (Fig. 5c). The colors of the rust sublayers are yellowish-brown, black, and gray from the center to the surrounding area, and the thickness is 80–168 μm, 20–25 μm, and 254–297 μm, respectively. Broad rust sublayers have formed as “bandages” in C6, and the thickness of the yellowish-brown rust sublayer is from 260 μm to 482 μm from inside to outside (Fig. 5d).

Iron oxides and oxyhydroxides were detected in the DPL. The phases identified by Raman spectroscopy in different rust sublayers of DPL are listed in Table 2. The Raman spectrum of the black corrosion product (in sublayer 2 of C2) is shown in Fig. 6D. The presence of magnetite (Fe3O4) can be inferred by a conspicuous strong band at 667 cm−1 and a weak band at 307 cm−1 40,41. Magnetite (Fe3O4) is an electrically conducting corrosion product accumulated around the DPL, which formed at the beginning of the corrosion due to the high aeration of the buried soil. An orange strip area (in sublayer 6 of C3) with a strong Raman peak at 386 cm−1 and medium peaks at 301, 551, 687, and 999 cm−1 (Fig. 6A) indicates the presence of goethite (α-FeOOH)7,41,42. Because of its good stability in thermodynamics and electrochemistry, goethite (α-FeOOH) is the final steady product of iron corrosion. The well-defined Raman bands of the reddish-brown area (in sublayer 1 of C4) present at 216, 251, 378, 527, and 1299 cm−1 (Fig. 6B) are characteristic of lepidocrocite (γ-FeOOH)43,44. The Raman spectrum of the yellowish-brown area (in sublayer 2 of C1) has a strong band at 722 cm−1 and three weak bands at 303, 405, and 537 cm−1 (Fig. 6C), and these well-resolved bands indicate the existence of akaganeite (β-FeOOH)45. The accumulation of akaganeite (β-FeOOH) is one of the main factors for the accelerating corrosion of the iron artifacts. As shown in Fig. 6E, the Raman spectrum reveals that a “horseshoes” shaped strip with mixed colors of red and orange area (in sublayer 4 of C2) represents two different phases. The presence of hematite (α-Fe2O3) can be deduced by bands at 226, 288, 403, and 1317 cm−1 26,46, and the existence of goethite (α-FeOOH) can be confirmed by bands at 303, 387, and 681 cm−1.

Akaganeite was found to be prevalent in the DPL as a catalyst for accelerating iron corrosion. The aggregation of this corrosion product is blamed for the damage to the iron artifacts. Generated akaganeite is peeled off the corrosion layer because the akaganeite crystal is produced vertically to the surface of iron artifacts. The formation of akaganeite is related to the concentration of Cl− ions. If the concentration of chloride ions reaches a certain level, akaganeite will be formed. Cl− ions absorbed on the surface of the crystal are the main cause of accelerated corrosion of excavated iron artifacts, whereas Cl− ions in the tunnel are more stable and difficult to release47. However, if akaganeite is converted to other phases, Cl− ions in the tunnel are also released to accelerate the corrosion process.

Element distribution and content

The SEM-EDS results of samples (Fig. 7, Table 3) show that the main elements that exist in the corrosion products are iron, chlorine, calcium, sulfur, silicon, and sodium. Point scanning was used to reflect the element content in different corrosion layers, while images of map scanning can provide visual elemental distribution of samples. In the TM of C2 (Fig. 7b, Table 3), the element silicon was distributed in small particles with a high concentration of 92.0% at spot-2. The presence of element silicon was related to quartz from the burial environment of soil. Compounds of the element calcium were embedded in the corrosion products of the element iron, which corresponded to the results with calcium carbonate, goethite, and hematite identified in the mineralized wood by Raman spectroscopy. In the DPL of C2 (Fig. 7a, Table 3), a sulfur strip (4.7% at spot-2) was detected between the interface of the DPL and TM. There were many explanations for the formation of this layer, and one possibility could be the consequence of a biological activity26,48. Also, bacteria was determined as the primary degraders in the waterlogged soil environment where oxygen was limited49. Organic matter, such as wood covered on iron swords, served as a carbon source for reducing bacterial reactions. The element chlorine with a concentration of 6.0% at spot-3 was detected in the corrosion area where akaganeite was identified by Raman spectroscopy. In the DPL of C1 and C6 (Fig. 7c, d, Table 3), the element chlorine with amounts of 7.1% (at spot-1 in C1-DPL) and 6.1% (at spot-1 in C6-DPL) was also found in the area that was identified as akaganeite and magnetite by Raman spectroscopy. Element chlorine was found in all brightly colored areas observed by the microscope. The presence and quantities of Cl– ions within the iron artifacts were important after excavation due to considerable changes in the environment to which the artifacts were exposed50. In addition, element calcium-formed strips were distributed in the cracks of DPL.

spots of point scanning in Table 3 and elemental distribution images of map scanning by SEM-EDS. a DPL of C2 (M48:6), b TM of C2 (M48:6), c DPL of C1 (M19:15), d DPL of C6 (M2:17).

The element distribution of chlorine was consistent with the rust sublayers of the DPL in C1, C2, and C6. It demonstrated that the rust sublayers of DPL in these samples were corrosion areas with element chlorine. A wide variety of corrosion products, such as goethite, lepidocrocite, hematite, akaganeite, and magnetite, were found in thin “ropes” shaped areas of element chlorine (Fig. 7a, Table 2), whereas goethite, hematite, and akaganeite were detected in the “horseshoes” distribution of element chlorine (Fig. 7c, Table 2). Only akaganeite was detected in the “bandages” element chlorine areas (Fig. 7d, Table 2). Goethite, lepidocrocite, and akaganeite can be obtained in high, intermediate, and low solutions with Fe2+ ions and Cl– ions, respectively45. The presence of Cl– ions greatly contributed to the corrosion of iron artifacts because Cl– ions were constantly consumed and regenerated during the reaction. This process was considered to be an acid regeneration cycle51,52. The distribution of chloride ions corresponded to the presence of akaganeite, since chloride ions were present on the crystal surface and in the tunnels of akaganeite. When the akaganeite was transformed from the iron corrosion products containing chloride, the process was mainly influenced by the changes in the burial environment. Once iron objects buried in a moist soil environment for a long-term steady period were exposed to air when they were excavated, akaganeite was abundantly generated. If the iron artifact was dried rapidly, ferrous chloride may crystallize as the salt column on the surface. If the artifact was dried slowly, akaganeite would form in cracks and pores32. Moreover, if the burial environment was changed from dry to humid, the crystalline ferrous chloride would convert to akaganeite through hydrolysis53. While the environmental factors were the major cause of iron corrosion, the manufacturing process of the swords may also be a worth-considered factor in the formation of layered rust. The forging technique significantly improved qualities such as strength and ductility of iron swords and may have played an important role in the production of iron artifacts of the Han Dynasty54. However, iron swords would form the layered structure after repeated heating, folding, and hammering steps55. Gaps between the layers happened to provide a channel for the water, oxygen, and soluble salts from the burial environment, and these factors prepared the conditions for the ‘autocatalytic effect’ in the occluded cell. The autocatalytic process accelerated the deep growth of the holes and crevices and gave rise to the inside pH fall and enrichment of anions like Cl– ions56. Small atomic size and high mobility of Cl– ions led to the remarkable enrichment of Cl– ions in layered or laminated structures57. In addition, it was obvious that the ‘horseshoes’ shaped rust sublayers were more curved in structure than other rust sublayers by comparing the distribution of element chlorine in different samples. The “horseshoes” shaped rust sublayers correspond to iron Jian, while other rust sublayers were observed in iron Dao. It is hypothesized that the formation of “horseshoes” shaped rust sublayers was related to the metallurgical process because the Jian was forged in a more complex and delicate craft than Dao. Calcium carbonate were both significantly enriched in the mineralized wood area of TM and the cracks of DPL. So it seemed probable that the calcium carbonate in the corrosion products was from the burial environment. The mean calcium carbonate content from the riverine sediment cores near the Tuchengpo Cemetery (the intersection of the Yangtze and Daning Rivers) was about 10%58. The other possibility was the decomposition of the human bodies. In fact, iron swords C1 and C6 were all buried next to the buried individuals. The excavation records indicated that the human bodies had been decomposed when tombs were excavated. Thus, it is also possible that the presence of calcite was formed by the long-term interaction of the buried individuals with the waterlogged buried environment.

Discussion

The composition and characterization of corrosion products on Han Dynasty iron swords unearthed from Tuchengpo Cemetery in southwest China have been comprehensively studied by Raman spectroscopy, microscopy, and SEM-EDS technology.

Based on the different morphology of corrosion products, the rust layer of iron swords can be divided into two layers. The internal layer (DPL) was mainly composed of different iron corrosion products that formed sublayers such as goethite (orange), lepidocrocite (reddish-brown), akaganeite (yellowish-brown), magnetite (black), and hematite (red). The mineralized wood residue and porous cell structure that were related to wood scabbards were detected in the external layer (TM). The mineralized vessels were identified as calcite, goethite, hematite and carbon, while the mineralized fiber tracheid was detected as goethite and lepidocrocite. Chloride were mainly found in the DPL. It is indicated that the iron artifacts were still suffering active corrosion after excavation.

The occurrence of the calcite in the external layer may reflect an essential relationship between iron swords and the burial environment. The abundance of calcium carbonate in the natural environment or decomposition by the human body may provide diverse ways for calcite enrichment. Sulfur detected in the samples also showed that the iron corrosion mechanism was also affected by the biological activity. Limited oxygen and waterlogged soils may provide favorable conditions for bacterial decomposition. In summary, this study highlights the significance of recreating the microenvironment in which the iron artifacts were buried in the past.

The formation of rust sublayers with different features in the internal layer was directly related to the forging and decoration process required in the manufacturing stage of iron swords. More curved ‘horseshoes’ shaped rust sublayers were only found in the Jian, while the morphology of rust sublayers of the Dao was more straight. It was likely that a more sophisticated forging and decoration technique was used in the Jian. Furthermore, the layered structure of iron swords created conditions for the enrichment of the chloride, which made the distribution of the element chlorine consistent with the rust sublayers in the internal layer.

Finally, advanced techniques and cross-section analysis have been employed to scientifically investigate the corrosion products of iron artifacts unearthed from the Three Gorges region in southwest China for the first time. It is important to note that the amount of data available for conclusions to be drawn from this study is still small. In order to gain a comprehensive understanding of the corrosion products of iron artifacts excavated from this region, the collection of additional samples in the future is necessary. The knowledge gained from the study is useful to develop strategies for the long-term conservation of iron swords.

Data availability

Data is provided within the manuscript or supplementary information files. The data used during the study are available from the corresponding author on reasonable request.

Abbreviations

- SEM:

-

Scanning electron microscope

- EDS:

-

Energy dispersive spectrometer

- BSE:

-

Back scattered electron

- CT:

-

Computed tomography

- XRD:

-

X-ray diffraction

- DPL:

-

Dense product layer

- TM:

-

Transformed medium.

References

Azoulay, I., Conforto, E., Refait, P. & Rémazeilles, C. Study of ferrous corrosion products on iron archaeological objects by electron backscattered diffraction (EBSD). Appl. Phys. A110, 379–388 (2013).

Wang, Q. An investigation of deterioration of archaeological iron. Stud. Conserv. 52, 125–134 (2007).

Saheb, M., Neff, D., Dillmann, P., Matthiesen, H. & Foy, E. Long-term corrosion behaviour of low-carbon steel in anoxic environment: characterisation of archaeological artefacts. J. Nucl. Mater. 379, 118–123 (2008).

Das, S. & Hendry, M. J. Application of Raman spectroscopy to identify iron minerals commonly found in mine wastes. Chem. Geol. 290, 101–108 (2011).

Zhao, F. et al. Revealing the manufacturing and corrosion characteristics of Chinese archaeological metal arrows by non-destructive neutron techniques. Archaeol. Anthropol. Sci. 16, 50 (2024).

Selwyn, L. S., Sirois, P. I. & Argyropoulos, V. The corrosion of excavated archaeological iron with details on weeping and akaganéite. Stud. Conserv. 44, 217–232 (1999).

Neff, D., Reguer, S., Bellot-Gurlet, L., Dillmann, P. & Bertholon, R. Structural characterization of corrosion products on archaeological iron: an integrated analytical approach to establish corrosion forms. J. Raman Spectrosc. 35, 739–745 (2004).

Neff, D., Dillmann, P., Bellot-Gurlet, L. & Béranger, G. Corrosion of iron archaeological artefacts in soil: characterisation of the corrosion system. Corros. Sci. 47, 515–535 (2005).

Grousset, S. et al. In situ monitoring of corrosion processes by coupled micro-XRF/micro-XRD mapping to understand the degradation mechanisms of reinforcing bars in hydraulic binders from historic monuments. J. Anal. Spectrom. 30, 721–729 (2015).

Sif Einarsdóttir, S. Mass-conservation of Archaeological Iron Artefacts a Case Study at the National Museum of Iceland 25–33 (University of Gothenburg, 2012).

Han, R. A metallographic study on early iron objects of China. Cult Relics. 02, 87–96 (1998).

The Chinese Archaeo-Metallurgy Study Group The iron an steel making techniques of the Han Dynasty in Honan. Acta Archaeol. Sin. 02, 1–24 (1978).

Gilmour, B. The metallurgy, development, and purpose of pattern welding. Hist. Metall. 51, 57–70 (2017).

Chao, H., Jaquet, D. & Kim, L. Martial Culture and Historical Martial Arts in Europe and Asia: a Multi-perspective View on Sword Culture 201–238 (Springer Nature Singapore, 2022).

Wuhan Municipal Institute of Cultural Relics and Archaeology. et al. A preliminary report of 2004 excavation at the Tuchengpuo Burials in Wushan, Chongqing. Jianghan. Archaeol.02, 24–55 (2009).

Wei, H. et al. A preliminary report of 2006 excavation at the Tuchengpuo Burials in Wushan, Chongqing. Sichuan. Cult. Relics. 03, 3–20 (2008).

Chen, Y., Guo, C., Pei, J., Xu, Z. & Wang, H. Preliminary report of the excavation at the tuchengpuo cemetery in Wushan. Jianghan. Archaeol. 01, 37–59 (2008).

Zou, H. & Bai, J. Archaeological discoveries of iron products from the Eastern Zhou to the Six Dynasties in the Three Gorges Region and related issues. Jianghan. Archaeol. 03, 55–66 (2008).

Zou, H. et al. The earliest loaded iron bomb excavated from the Baidicheng fort site, Chongqing, China. Archaeol. Res. Asia. 36, 100485 (2023).

Wei, G., Qin, Y., Gong, M. & Sheng, D. Analysis of excavated artifacts excavated from the Daping Cemeteries in Wanzhou, Chongqing. Southeast. Cult. 03, 28–32 (2006).

Gu, L., Ye, L. & Liu, P. Conservation study of iron swords with gold and silver inlays of the Han Dynasty excavated from Fengdu, Chongqing. Yangtze. River Civiliz. 04, 89–96 (2023).

Gu, L., Ye, L. & Lv, G. Desalting protection of iron artifacts unearthed in the Three Gorges Area of Chongqing. Corros. Prot. 44, 76–82 (2023).

Gerwin, W. & Baumhauer, R. Effect of soil parameters on the corrosion of archaeological metal finds. Geoderma 96, 63–80 (2000).

Zhang, Y. & Zhu, C. Environmental archaeology of the Dachang region in the Daning Valley, the Three Gorges reservoir region of the Yangtze River, China. Chin. Sci. Bull. 53, 140–152 (2008).

Fan, X. & Freestone, I. C. Occurrence of phosphatic corrosion products on bronze swords of the Warring States period buried at Lijiaba site in Chongqing, China. Herit. Sci. 5, 48 (2017).

Bellot-Gurlet, L. et al. Raman studies of corrosion layers formed on archaeological irons in various media. J. Nano Res. 8, 147–156 (2009).

Zhao, F., Sun, M., Li, X., Guo, F. & Li, M. The manufacturing technology of iron swords from the capital of the Han Empire in China. SN Appl. Sci. 2, 1–11 (2020).

Fan, X. Characteristics of mimetite (Pb5 (AsO4) 3Cl)-pyromorphite (Pb5 (PO4) 3Cl) corrosion products on Han Dynasty bronzes from Chongqing, China. Microchem. J. 149, 104062 (2019).

Zhang, Y., Zhu, C. & Yu, S. Environmental evolution and human activity over 3000 years in Daning Valley, the Three Gorges of Changjiang River. Sci. Geogr. Sin. 21, 267–271 (2001).

Pingitore, G. et al. Structural characterization of corrosion product layers on archaeological iron artifacts from Vigna Nuova, Crotone (Italy). J. Cult. Herit. 16, 372–376 (2015).

Salem, Y., Oudbashi, O. & Eid, D. Characterization of the microstructural features and the rust layers of an archaeological iron sword in the Egyptian Museum in Cairo (380–500 A.D.). Herit. Sci. 7, 1–12 (2019).

Knight, B. A review of the corrosion of iron from terrestrial sites and the problem of post-excavation corrosion. Conserv 14, 37–43 (1990).

Tegel, W., Muigg, B. & Büntgen, U. The wood of Merovingian weaponry. J. Archaeol. Sci. 65, 148–153 (2016).

Haneca, K. & Deforce, K. Wood use in early medieval weapon production. Archaeol. Anthr. Sci. 12, 9 (2020).

De Faria, D. L., Venâncio Silva, S. & de Oliveira, M. T. Raman microspectroscopy of some iron oxides and oxyhydroxides. J. Raman Spectrosc. 28, 873–878 (1997).

Zhang, W. et al. An in-situ Raman study on the oxidation of mackinawite as a corrosion product layer formed on mild steel in marginally sour environments. Corros. Sci. 188, 109516 (2021).

Cuesta, A., Dhamelincourt, P., Laureyns, J., Martínez-Alonso, A. & Tascón, J. D. Raman microprobe studies on carbon materials. Carbon 32, 1523–1532 (1994).

Zhang, Y. & Zhang, R. Characterization of corrosion and scientific conservation of iron artifact clusters excavated from the western Han Dynasty Xiangshan tomb of Qingzhou, Shandong Province. Sci. Conserv. Archaeol. 26, 54–60 (2014).

Han, B., Fan, X., Chen, Y., Gao, J. & Sablier, M. The lacquer crafting of Ba state: insights from a Warring States lacquer scabbard excavated from Lijiaba site (Chongqing, southwest China). J. Archaeol. Sci. Rep. 42, 103416 (2022).

Rull, F., Martinez-Frias, J., Sansano, A., Medina, J. & Edwards, H. G. M. Comparative micro-Raman study of the Nakhla and Vaca Muerta meteorites. J. Raman Spectrosc. 35, 497–503 (2004).

Hanesch, M. Raman spectroscopy of iron oxides and (oxy) hydroxides at low laser power and possible applications in environmental magnetic studies. Geophys. J. Int 177, 941–948 (2009).

Legodi, M. A. & de Waal, D. The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste. Dyes Pigm 74, 161–168 (2007).

Antunes, R. A., Costa, I. & Faria, D. L. A. D. Characterization of corrosion products formed on steels in the first months of atmospheric exposure. Mat. Res. 6, 403–408 (2003).

Jia, M., Hu, P. & Hu, G. Corrosion layers on archaeological cast iron from Nanhai I. Materials 15, 4980 (2022).

Rémazeilles, C. & Refait, P. On the formation of β-FeOOH (akaganéite) in chloride-containing environments. Corros. Sci. 49, 844–857 (2007).

Oh, S. J., Cook, D. C. & Townsend, H. E. Characterization of iron oxides commonly formed as corrosion products on steel. Hyperfine Interact. 112, 59–66 (1998).

Zhang, R. Formation and hazards of corrosion product β-FeOOH on iron cultural relics. Corros. Prot. 42, 1–11 (2021). in Chinese.

Zhang, H., Shen, D., Zhang, Z. & Ma, Q. Characterization of degradation and iron deposits of the wood of Nanhai I shipwreck. Herit. Sci. 10, 202 (2022).

Björdal, C. G., Nilsson, T. & Daniel, G. Microbial decay of waterlogged archaeological wood found in Sweden applicable to archaeology and conservation. Int. Biodeterior. Biodegrad. 43, 63–73 (1999).

Näsänen, L. M., González-Pereyra, N. G., Cretté, S. A. & DeViviés, P. The applicability of subcritical fluids to the conservation of actively corroding iron artifacts of cultural significance. J. Supercrit. Fluids 79, 289–298 (2013).

Askey, A. et al. The corrosion of iron and zinc by atmospheric hydrogen chloride. Corros. Sci. 34, 233–247 (1993).

Wang, H. et al. Study of the corrosion mechanism and the protection methods of iron objects in Qin and Han Dynasties. Sci. Conserv. Archaeol. 15, 7–11 (2003).

Turgoose, S. Post-excavation changes in iron antiquities. Stud. Conserv. 27, 97–101 (1982).

Zhang, M. et al. Forging or casting: new evidence of iron production in the Chengdu Plain in the Han dynasty. Archaeol. Anthropol. Sci. 13, 111 (2021).

Zhao, F. et al. Metallographic structures and corrosion: cross-section investigation of archaeological iron objects from the Qin-Han Yueyang City site in Xi’an, China. Eur. Phys. J. 138, 64 (2023).

Wang, Z., Xu, C. & Dong, X. Localized corrosion and phase transformation of simulated archaeological iron. Chin. J. Chem. Eng. 16, 299–305 (2008).

Ståhl, K. et al. On the akaganéite crystal structure, phase transformations and possible role in post-excavational corrosion of iron artifacts. Corros. Sci. 45, 2563–2575 (2003).

Wu, X. et al. The impact of Three Gorges reservoir on sedimentation of Daning River: changes in carbonate and major element contents. Geol. Rev. 54, 419–426 (2008).

Acknowledgements

This research was supported by the Foundation of Chongqing Normal University for support (20xwB005). The authors would like to appreciate the Chongqing China Three Gorges Museum for providing the experimental instruments. We also greatly thank Wushan Museum for supplying the samples.

Author information

Authors and Affiliations

Contributions

Z.D.: methodology, formal analysis, investigation, data curation, visualization, writing—original draft. X.Z.: resources, supervision, writing—review, and editing. H.Z.: sample information, supervision, writing—review, and editing. W.S.: investigation, experimental assistance. X.F.: methodology, formal analysis, project administration, supervision, writing—review, and editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Di, Z., Zhao, X., Zhang, H. et al. Characterization of corrosion products on Han Dynasty iron swords excavated from Tuchengpo Cemetery in Wushan, Chongqing, China. npj Herit. Sci. 13, 114 (2025). https://doi.org/10.1038/s40494-025-01685-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s40494-025-01685-z