Abstract

Lignin-like materials share chemical similarities with wood and exhibit excellent mechanical properties along with resistance to aging and microbial degradation. This study focuses on eugenol as a target lignin-like monomer. Three eugenol nanoemulsions with concentrations of 10%, 20%, and 30% were prepared using surfactant Pesticide Emulsifier 1602 and co-surfactant diethylene glycol mono butyl ether (DEGBE). Laccase facilitated the in-situ polymerization of eugenol on the cell walls of waterlogged archeological wood (WAW) from the Nanhai No.1 shipwreck at temperatures of 35 °C °C, 45 °C, and 55 °C for dehydration and consolidation purposes. The 30 wt% eugenol emulsion at 45 °C showed the best consolidation effectiveness, with a minimal shrinkage rate of 3.62% and a 400–1000% increase in bending strength compared to controls. The polymer reinforced the decayed wood while preserving cellular lumens, offering an innovative, environmentally sustainable conservation method for WAW.

Similar content being viewed by others

Introduction

The primary goal in preserving waterlogged archeological wood (WAW) is to ensure its dimensional stability throughout the dehydration process. Since the 1980s, PEG stood out as the most widely utilized dehydration and consolidation agent, evidenced by its effective application in prominent cases such as the preservation of the Bremen Cog in Germany1, the Vasa warship in Swedish2, the Sinan shipwreck in South Korea3, and Penglai shipwrecks in China4. PEG boasts several advantages, including its strong affinity for WAW, non-toxic, cost-effectiveness, and simplicity of use, as it does not require any organic solvents1,5. Nevertheless, it also faces certain challenges, such as extended treatment times, moisture absorption6, and limited resistance to biological activity7. Moreover, there would be considerable weight gain8, and plasticizing effects when using high-concentration and high molecular weight PEGs. In long-term preservation, PEG is prone to oxidative and iron-catalyzed degradation9, and the acidic by-products formed during these processes constitute a risk of further chemical degradation of the wood10,11 that leads to a creep deformation8,12. Sucrose, lactitol, trehalose, and sucralose13,14 have been explored as alternatives to PEG. However, these sugars are highly susceptible to microbial degradation15, limiting their practical application. Additionally, studies have investigated the use of hydrolyzed proteins16, nanocellulose17, and esterified colophony18 for filling and stabilizing WAW, though these approaches remained confined to laboratory-scale research.

In-situ polymerization via monomer penetration emerges as a potential approach for achieving high penetration efficiency and reduced weight gain during the consolidation of WAW19. Since 1998, melamine resins have been successfully utilized for the consolidation of waterlogged wooden artifacts5. The melamine resin demonstrated excellent penetrability into the wood and underwent in-situ polymerization to solidify, thereby significantly enhancing the wood’s stability. In China, glyoxal has been widely employed as a consolidating agent for waterlogged wooden artifacts, particularly for the stabilization of lacquerware20. However, the toxicity associated with these materials remains a significant concern. In recent years, laboratory-scaled studies have been conducted to investigate the effectiveness of various monomers and oligomers for the dehydration and consolidation of WAW, including polysaccharides21, acrylate resins22, and organosilicon23,24. Among the newly proposed materials, plant-derived lignin-like compounds are anticipated to serve as effective green consolidants for next-generation WAW consolidation candidates. These materials closely resemble lignin, the primary component remaining in WAW that helps maintain the mechanical stability of wood cells25, thus demonstrating a high level of compatibility with the wood structure26,27,28. In comparison to cellulose and nanocellulose29, lignin possesses higher chemical and biological resistance properties30, which enables it to be stably preserved in wooden subjects and reduce the dimensional instability and hygroscopicity of wood31. However, due to its insolubility in water, lignin or lignin-like polymers struggle to evenly penetrate WAW, typically requiring to be prepared into nanoparticles for effective application32. As a solution, in-situ polymerization of lignin-like oligomers (dehydrogenated polymers, DHPs33) has been proposed to preserve such wood. McHale et al. 34,35. synthesized the lignin-like oligomers from isoeugenol using a water-soluble Cu(salen) catalyst and horseradish peroxidase at pH 10, all without the use of organic solvents. They proceeded to investigate the in-situ polymerization of these oligomers and successfully developed new lignin-like structures within the archeological wood. However, the efficacy of this method in terms of dehydration and consolidation still requires further evaluation36,37.

This study has chosen an environmentally friendly biocatalyst: fungal laccase. Fungal laccase is renowned for its broad substrate range, efficiently catalyzing reactions involving phenols38, aromatic amines39, carboxylic acids and their derivatives40, and certain non-phenolic compounds41. It has a small molecular size42 that can easily penetrate the wood cell lumen. Additionally, fungal laccase is particularly noteworthy for its robust enzymatic activity under acidic conditions43, which aligns well with the mildly acidic environment44 typically present in WAW. The enzymatic process can be conducted at easily achievable temperatures close to normal conditions, requiring only oxygen and producing water as the sole byproduct45. These characteristics eliminate the necessity for additional metal-complexes catalysts during the in-situ polymerization of lignin-like monomers catalyzed by laccase within WAW.

Among the various lignin-like monomers that can be catalyzed by laccase, eugenol has emerged as the preferred choice owing to its chemical structural similarity to phenylpropane structural units in softwood46. Its notable antimicrobial47,48, and insecticidal properties49 combined with its low price and availability on the market, further enhance its appeal. Since the 1940s, eugenol has primarily been produced industrially from abundant natural oil sources, with Eugenia caryophyllata being the principal source50,51,52. Additionally, Eugenol also be obtained through the depolymerization of lignin53. Due to its wide range of antimicrobial properties, pharmacological effects, and good biosafety profile54,55, eugenol is extensively utilized in cosmetics, food additives, pharmaceuticals, and pesticides. Research by Cheng et al. 56. revealed that eugenol exhibited strong antifungal activity against the white-rot fungus Lenzites betulina and brown-rot fungus Laetiporus sulphureus, effectively protecting wood from decay. Eugenol also holds potential as a plant-based polymerization material57. Huang et al. prepared modified bamboo that obtained long-term antimicrobial properties by in-situ polymerization of eugenol via laccase catalyzation58. Watanabe et al. 59. synthesized a series of urushiol analogs from eugenol, crafting environmentally sustainable and high-performance coatings. Various plant-based polymer materials such as polyurethanes, epoxy resins, and phenolic resins, can be produced through functionalization reactions of eugenol, paving the way for applications in the manufacture of modified wood or wood fiber boards57.

Existing research has preliminarily demonstrated the potential of laccase-catalyzed eugenol for in situ polymerization modification of wood. Building upon this foundation, this study aims to explore the effectiveness of this method for the dehydration and reinforcement of waterlogged archeological wood (WAW). In this study, eugenol was encapsulated in an oil-in-water (O/W) nanoemulsion to reduce the viscosity of the consolidants and facilitate better integration between the eugenol emulsion and the laccase solution. The fungal laccase from Aspergillus oryzae was used to catalyze the in-situ polymerization process that introduced eugenol to WAW for modification treatment. Through the evaluation of dimensional stability, mechanical properties, and hygroscopicity, this study preliminarily assessed the effectiveness of the proposed method for the stabilization of WAW. Based on the results, optimal eugenol concentration and reaction temperature were identified. Additionally, through microscopic analysis and infrared spectroscopy, the potential mechanism of eugenol’s action within WAW was preliminarily elucidated.

Methods

Samples

Waterlogged archeological wood (Pinus sp.) used in this research was taken from a plank of the Nanhai No. 1 shipwreck (an 800-year-old shipwreck, Guangdong, China). The plank has been stored in pure water for 5 years after excavation Its wood structure was severely deteriorated with the measured maximum water content (MWC) of 527% (the measuring method is described in section 2.5.1). The wood was cut into small sample cubes of ~1 cm × 1 cm × 1 cm (radial, tangential, longitudinal direction), with the volume of each sample being about 1 cm3.

Materials

Eugenol (99%, MERYER Co., Ltd., USA), diethylene glycol mono butyl ether (DEGBE,99%, Yatai Chemical Co., Ltd., Jiangsu.), triphenylethylene phenol polypropylene-polyoxyethylene ether (trade name Pesticide Emulsifier 1602, 99%, Haian Petrochemical Plant, Jiangsu), and laccase from Aspergillus oryzae with an optimal enzyme activity temperature at 50 °C (10 000 U, Enming Biological Engineering Technology Co., Ltd., Jiangsu). All materials were used without further purification.

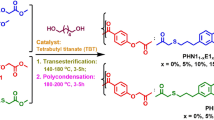

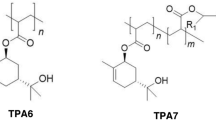

Preparation and characterization of eugenol emulsion

In this study, eugenol emulsions were prepared for the dehydration treatment of WAW. A schematic diagram depicting the eugenol emulsion synthesis process is presented in Fig. 1. Initially, eugenol was dispersed in diethylene glycol monobutyl ether (DEGBE) through dissolution and mixing. Subsequently, Pesticide Emulsifier 1602 and pure water were incorporated into the solution, resulting in a light-yellow transparent emulsion. The entire preparation process was carried out under 25 °C, with the solution temperature maintained at approximately 19.5°C. The stirring speed was set at 1000 rpm, and each step was stirred for more than 10 min until a homogeneous mixture was achieved. Three emulsion groups, numbered E1, E2, and E3, were generated with the eugenol weight percentage of 10%, 20%, and 30%, respectively, as outlined in Table 1.

The viscosity of the emulsion was determined using a digital viscometer (NDJ-5S, Yueping Scientific Instrument Co., Ltd., China) at a temperature of 25 °C, with the rotational speed set as 30 r/min. The particle size of the emulsion was analyzed using a laser particle size analyzer (MS3000, Malvern Instruments Co., Ltd., UK), which has a testing range of 0.01–3500 nm and a data acquisition speed of 10,000 Hz.

Consolidation of waterlogged archeological wood

A semi-immersion technique was employed to enhance the penetrating efficiency of eugenol emulsion (Fig. 2). The WAW was submerged in the eugenol emulsion with its cross-section (face A) oriented upwards for 1 day, allowing the emulsion to reach halfway up the wood. As the moisture within the wood gradually evaporated, capillary action facilitated the infiltration of the emulsion into the wood. Following this process, the orientation was switched so that face B was facing upwards, and the sample was immersed for an additional day.

Following a 2-day immersion in the eugenol emulsion, the WAW was transferred to a laccase solution. The catalysis for eugenol polymerization was performed in the water bath at temperatures of 35 °C, 45 °C, and 55 °C to create mild and controlled reaction conditions for laccase. The laccase catalysis procedure also employed a semi-immersion approach to facilitate oxygen supply for the reaction. After 24 h the laccase solution became turbid, which indicated that the reaction was completed. Then the laccase solution was changed, and the wood sample was reversed to have face B upwards for another 24 h of polymerization. This entire catalytic process lasted for 2 days.

Following the completion of the treatment, any residual substances on the wood surface were meticulously removed using cotton swabs dipped in pure water. The sample was then air-dried at 25 °C in a controlled environment where the relative humidity (RH) gradually decreased from 85% to 50%. This dehydration process continued until there was no discernible alteration in the size and weight of the sample. The untreated sample, designated as R1, underwent the same air-drying procedure.

Testing methods

Physical property testing

Photographs and dimensional measurements of the wood samples were conducted using the ultra-depth video microscope (VHX-6000, KEYENCE, Ōsaka, Japan). The basic density (BD) and maximum water content (MWC) of the wood were calculated according to Eq. (1) and Eq. (2), respectively. The mass of the waterlogged sample, ~1 cm3, was measured by an analytical balance (JA2003, SUNNY HENGPING Instrument, Shanghai, China) and recorded as \({M}_{1}\). After drying in an oven at 103 ± 2 °C, the mass of the sample was recorded as \({M}_{0}\). The drainage method was employed to determine the waterlogged volume \({V}_{1}\) and dry volume\(\,{V}_{0}\) under normal conditions (at 25 °C with a relative humidity of 34.5% ± 1.5%). During this process, the sample was fully immersed in pure water on the analytical balance, ensuring it did not touch the bottom or sides of the beaker. According to Archimedes’ principle, the volume of the wood sample (cm3) is equal to the increase in weight (g) of the displaced pure water.

The weight percent gain (WPG) was calculated using Eq. (3), where m1 represents the dry mass of the wood after treatment and after achieving equilibrium under normal conditions, while m0 denotes the theoretical dry mass of the wood sample (estimated based on \({M}_{1}\) and MWC). The volume shrink rate (Sv) was calculated using Eq. (4).

Microstructure analysis

Optical microscopy and scanning electron microscopy (SEM) were utilized for the microstructure analysis. Initially, an ultra-depth video microscope (VHX-6000, KEYENCE, Ōsaka, Japan) was used to examine the micro-morphology of wood cells. Subsequently, the SEM analysis was conducted at a high voltage range of 15 kV using an ultra-high-resolution field-emission scanning electron microscope (Regulus 8100, HITACHI, Tokyo, Japan). Before SEM analysis, all samples underwent a gold coating process.

Mechanical property testing by thermomechanical analyzer (TMA)

The thermomechanical analyzer (TMA) utilized in this study is HITACHI TMA7100 (HITACHI analyzer, Tokyo, Japan) to perform a three-point bending test, featuring a load range of 5.8 N, a load resolution of 9.8 μN, and a displacement resolution of 0.01 μm. The testing method was based on our previous work and can be referenced in ref. 60.

The sample preparation for the three-point bending test proceeded as follows: A manual rotary microtome (Leica 2010R Leica, Baden-Württemberg, Germany) was used to prepare waterlogged archeological wood slices of 10 mm × 10 mm × 0.3 mm (longitudinal × radial × tangential). After drying under normal conditions (at 25 °C with a relative humidity of 34.5% ± 1.5%), the wood slices were hand-cut into samples of 10 mm × 2 mm × 0.3 mm (longitudinal × radial × tangential). To ensure consistency in the comparative experiments, equal proportions of earlywood and latewood specimens were selected for each sample. Before testing, the samples were conditioned under the testing conditions (at 25 °C with a relative humidity of 60.5% ± 1.5%) for a duration exceeding 24 h.

In the bending test, a quartz probe and a supporting component with a span (L) of 5 mm were used. The test was performed under normal conditions with an initial load of 0.1 mN and a loading speed of 20 mN/min until the sample broke. The width b and the thickness d of the sample were measured using an ultra-depth video microscope (VHX-6000, KEYENCE, Ōsaka, Japan) with an accuracy of 0.01 mm. The bending strength \(\sigma\) and the fracture strain \(\varepsilon\) were calculated according to Eqs. (5) and (6).

Dynamic vapor sorption testing (DVS)

The maximal moisture content under various relative humidity (RH) conditions was assessed using a high-throughput dynamic vapor sorption tester (SPSx-1μ, ProUmid, Ulm, Germany) following the protocols outlined in refs. 61,62. This analysis included untreated samples dried under normal conditions and samples that underwent treatment with eugenol emulsions and were subsequently dried. The humidity range assessed was 0–95% RH, with a gradient of 10% RH, and the temperature was maintained at 25 °C. The default sampling frequency was set at 10 min, with a minimum measurement time of 50 min and a maximum measurement time of 300 min for each gradient. The default weight limit was established at 1000%, and the equilibrium condition was defined as dm/dt≤0.01. To ensure consistency in the comparative experiments, equal proportions of earlywood and latewood specimens were selected for each sample.

Fourier transform infrared spectroscopy (FT-IR) analysis

Fourier transform infrared spectroscopy (FT-IR) was performed to investigate the alterations in the chemical structures of the wood samples. The analysis utilized the Nicolet™ iSTM5 Fourier transform infrared spectrometer (Thermo Scientific, Waltham, MA, USA) and employed the potassium bromide pellet method, maintaining a sample-to-potassium bromide mass ratio of 1:100. The instrumental parameters were configured as follows: 32 scanning times, a resolution of 4.000 cm−1, a sampling gain of 1.0, a mirror velocity of 0.4747, and an aperture of 100.00.

Results

Characterization of the emulsion

In this study, eugenol emulsions were prepared at concentrations of 10 wt%, 20 wt%, and 30 wt%. As depicted in Fig. 3a, the resulting emulsions ranged from transparent to yellowish transparent, with the color deepening as the concentration increased. A green laser at a wavelength of 532 nm demonstrated a clear Tyndall effect when penetrating the emulsions. The emulsion exhibited stability under normal conditions, remaining free from delamination or oil bleaching for over 30 days.

As determined, the viscosity of the 10–30 wt% eugenol emulsions at 25 °C registered at 10, 17, and 24 mPa·s, respectively, signifying that they are low-viscosity fluids. This characteristic underscored its superior penetration capability when applied to archeological wood. Details regarding the particle size of the 30 wt% eugenol emulsion can be found in Table 2 and are illustrated in Fig. 3b, revealing a Gaussian distribution with a uniform particle size dispersion. Notably, the DV (90) value was measured at 0.164 μm, which classified it as nanoemulsion.

Physical properties

Three groups of archeological wood, numbered E1, E2, and E3, were dehydrated using eugenol emulsions at concentrations of 10 wt%, 20 wt%, and 30 wt%, respectively. We tested the effect of in situ polymerization on the dimensional stabilization of WAW at three different catalytic temperatures: 35 °C, 45 °C, and 55 °C. The control samples, numbered R1, were untreated wood air-dried under normal conditions. Figure 4 illustrates the shape and color changes observed in the nine treated samples and untreated samples before and after dehydration. Overall, all the treated groups were acceptable in color after dehydration, showing a natural light pine color. However, it was noted that eugenol polymerized at 55 °C resulted in excessive polymer formation on the surface of the samples in both groups E2 and E3.

In terms of dimensional stability, severely decayed archeological wood tends to experience considerable shrinkage during the dehydration process if left untreated (as shown in Fig. 4j). The basic density (BD), volume shrinkage rate (Sv), and weight percent gain (WPG) of WAW samples after dehydration are listed in Table 3. The untreated waterlogged archeological wood exhibited a volume shrinkage rate of 63.02%, leading to severe distortion. Therefore, achieving a lower volume shrinkage rate after dehydration is crucial for assessing the effectiveness of the consolidants.

The samples in group E1 experienced cracking with the highest Sv among all groups ranging from 15.55% to 18.48%, regardless of the catalyzed temperature. In contrast, group E2 showcased less shrinkage. The 45 °C-catalyzed wood samples demonstrated only slight cracking and the lowest Sv of 5.15%, while the wood catalyzed at other temperatures in this group experienced volumetric shrinkage of around 13%. Meanwhile, group E3 benefited from both 45 °C and 55 °C catalyzing, achieving effective dimensional stabilization with Sv of 3.62% and 7.27%, respectively.

In addition, it should be noted that the differences in the proportions of earlywood and latewood in WAW samples also impacted the results of physical properties. Earlywood has thinner and weaker cell walls compared to latewood, making it more susceptible to deformation; thus, samples with a higher proportion of earlywood generally exhibited greater shrinkage in this study. Additionally, samples with wider annual rings were more prone to radial cracking, such as E1–45 °C and E2–35°C, which might be attributed to the structural differences between earlywood and latewood leading to uneven stress distribution.

Moreover, it was observed that the dry shrinkage rate of the wood samples decreased as the weight gain rate and basic density increased. The samples E2–45 °C, E3–45°C, and E3-55 °C exhibited the lowest dry shrinkage rates with WPG of 169.66%, 172.16%, and 197.81%, respectively, alongside a significant increase in wood density of over 260%. It was inferred that a higher weight gain indicated a greater production of polymeric products within the wood, leading to improved reinforcement of the structure. A higher concentration of eugenol emulsion provides sufficient reactive monomers within the wood. The reaction rate rose as the catalytic temperature increased, resulting in the generation of more free radicals. Consequently, samples subjected to treatments of high concentration and elevated temperature will experience lower dimensional changes and a higher weight gain. Overall, the WPG of all conserved samples did not exceed 200%, although the absorbed moisture due to incomplete drying may have resulted in overestimated data.

Moisture properties

High humidity levels typically challenge the preservation of wooden artifacts, as they facilitate rapid moisture absorption that is prone to cause dimensional instability, cracking, and disintegration during long-term preservation. As depicted in Fig. 5, the DVS testing curves for dried WAW samples, both before and after being treated with eugenol emulsion, offered insights into their moisture absorption behaviors. Group E1 and E2 only exhibited slightly reduced moisture absorption after eugenol emulsion treatment. In contrast, group E3 displayed a moisture absorption rate between 16.67% and 21.78% at 95% relative humidity, compared to 25.68% recorded for air-dried untreated samples. Furthermore, the hygroscopicity of the wood samples markedly decreased as the catalytic temperature increased. The increased temperature enhanced the reaction rate, resulting in a reduction of phenolic hydroxyl content and the formation of more oligomers that fill the pores, thereby decreasing the moisture absorption sites in the wood structure. These observations indicate reduced moisture absorption conferred by consolidation, thus favoring the long-term preservation of artifacts.

Bending strength

The effectiveness of eugenol emulsion in enhancing mechanical properties was evaluated across three distinct wood sample groups that exhibited acceptable dimensional stability effectiveness during dehydration: E2-45°C, E3-45°C, and E3-55°C, the bending strength results are shown in Fig. 6. After air-drying, the untreated wood displayed markedly low strength, measuring at 1.09 MPa. The application of eugenol emulsions resulted in substantial reinforcement of the wood, with an increase in bending strength correlated with escalating emulsion concentration and catalytic temperature. Specifically, the E3 emulsion achieved enhancements of 314% and 848% in wood strength when catalyzed at 45 °C and 55 °C, respectively. Furthermore, for the E2 and E3 samples when catalyzed at 45 °C, the stiffness of the wood was improved by 20% compared to untreated samples. However, the E3-55 °C samples experienced a 46.8% reduction in fracture strain.

These findings indicated that eugenol can effectively enhance the strength and rigidity of wood cell walls, reducing their susceptibility to fracture under bending stress. However, it is crucial to carefully regulate the polymerization process, as excessive impregnation of the cell walls under high concentration and high catalytic temperature can render the wood hard and brittle. Integrating these results with complementary assessments, a 30% concentration of eugenol emulsion at a catalytic temperature of 45 °C was identified as the optimal configuration for facilitating superior dehydration and consolidation of WAW.

Microstructures

Microscopic examinations of the dried samples were conducted using a high-depth-of-field microscope and SEM. For example, when analyzing the three groups catalyzed at 45 °C (Fig. 7), the micro-morphology of the E1 samples closely resembled that of the untreated samples. The wood cells still underwent noticeable deformation, although some reflective polymers were found in the cells. These wood samples were all fragile and it was not easy to make a smooth and flat cut without embedding. In contrast, the wood cells of the E2 and E3 samples showed significantly different morphologies. The cellular shape did not exhibit significant distortion, and the cross-section of the cell walls appeared relatively smooth, which indicated improvements in cell wall consolidation after being treated with 20–30wt% eugenol emulsions. This observation suggested that the treatment did not induce major structural alterations to the wood cells, but effectively reinforced their structure, thereby reducing shrinkage and deformation of the wood.

The SEM analysis was conducted to further investigate the reinforcing effects on wood cell walls, as depicted in Fig. 8. Untreated archeological wood exhibited significant cell collapse and deformation following drying, in apparently contrast to the less change in cell shape observed in the eugenol-treated samples. The eugenol-treated wood showed no apparent shrinkage or deformation after drying, with the wood cells retaining their original morphology.

Furthermore, the SEM images highlighted the influence of eugenol concentration and catalytic temperature on the effectiveness of in-situ polymerization. An increase in eugenol concentration allowed for the penetration of a greater quantity of active components into the wood cells, substantially enhancing the reparative effects on the cell wall. Measured on the SEM images, the thickness of the cell walls in the E2 and E3 groups generally ranged from 7.71 μm to 10.17 μm, which is significantly greater than that of the E1 group (around 6.03 μm), with the secondary walls (S2) exhibiting a strong adhesion to the intercellular layers. Furthermore, the pores caused by microbial degradation and the deformation of the cells were markedly reduced. Higher catalytic temperatures were found to be effective in improving the degree of polymerization of the resultant products. Notably, only in the E3-55 °C group, the wood cell walls became enveloped and coated by the formed polymer, which accounted for the notable increase in its bending strength.

From a microstructural perspective, eugenol functioned by reinforcing the cell walls rather than filling the cell lumen. The reinforced structure exhibited enhanced resistance to the internal stress generated during the dehydration process, thereby preventing deformation and collapse. This mechanism contributes to the advantage of a low weight gain rate and provides a certain degree of reprocessability. If future conservation requires the use of additional materials, these substances can still diffuse into the wood structure via the preserved cell lumens.

Spectroscopic analysis of archeological wood before and after consolidation

As depicted in Fig. 9, the peak observed at 1640 cm−1 signified the presence of C=C vibrations63 characteristic of alkenes within the aromatic nuclei. Additionally, the peak observed at 1461 cm−1 corresponds to the bending vibration of lignin CH2 and CH3 groups63, which show increased intensity following consolidation, suggesting a heightened lignin content in the treated samples.

Further analysis identified peaks at 1364 cm−1 and 1348 cm−1, which are associated with the vibration of the aromatic nucleus –OH groups63. The peak at 1235 cm−1 corresponds to C–O vibration, while the absorption peak related to C–O–C stretching vibration moved from 1140 cm−1 to 1096 cm−1–1125 cm−1, resulting from the condensation products of eugenol polymerization64,65. Additional peaks at 993 cm−1, 951 cm−1, 913 cm−1, and 819 cm−1 are linked to the vibration of the C–H group on the benzene ring, bending vibration of C=C, C–C, and C–H groups in lignin-like structures, respectively63. The appearance of these peaks may indicate the formation of eugenol-based oligomers within the treated wood sample.

In conjunction with infrared spectroscopy, our investigation elucidated the potential micro-scale mechanism underlying the consolidation treatment using eugenol emulsion (Fig. 10). Research on the natural formation of lignin in wood has demonstrated that DHPs are generated from phenylpropane units under the catalytic action of laccase, and then cross-link to form lignin macromolecules66. They can also interact with cellulose and hemicellulose to form lignin-carbohydrate complexes (LCCs)67. We hypothesize that eugenol-derived lignin-like oligomers may undergo a similar process in this study. The in-situ polymerization of eugenol catalyzed by laccase resulted in lignin oligomers known as DHP, which serve a crucial role in the reinforcement of degraded wood cells. Specifically, through the catalytic action of laccase, eugenol provided free radicals via its phenolic hydroxyl and allyl double bonds68, generating DHPs that cross-link the adhesion between decayed lignin and cellulose. This mechanism is reflected in the infrared spectroscopy results, which show an increase in the intensity of C-O-C and C-O bonds, indicative of enhanced characteristics of cross-linking structures in wood.

However, it is important to note that the conclusions drawn remain speculative because of the complex oxidation of eugenol catalyzed by laccase68. Laccase catalysis is known to initiate the polymerization of phenolic hydroxyl-containing monomers, as well as the copolymerization of these monomers with lignin and polysaccharide fragments69. The resulting structural units can form a variety of DHPs and LCCs through diverse linkage modes. The chemical structures of these products are highly similar to the native chemical structure of the wood itself. Further research would be required to elucidate the exact structural configurations and interactions involved.

Disscussion

This study revealed the capacity of eugenol in an O/W emulsion to penetrate the WAW samples effectively. Eugenol underwent in-situ polymerization catalyzed by laccase within the WAW matrix, resulting in the formation of lignin-like oligomers. The experiment evaluated three different concentrations of eugenol alongside three catalytic temperature conditions. For WAW samples with an MWC of 523%, a minimum eugenol concentration of 20 wt% was required to achieve acceptable dimensional stabilization. A 30 wt% concentration delivered the best performance, reducing shrinkage to just 3.62% post-dehydration and boosting bending strength more than fourfold compared to untreated samples. This study recommended a catalytic temperature of 45 °C, which is marginally lower than the optimal activity temperature of the laccase used. This temperature is only slightly above room temperature, making it easily attainable in practical applications, and is safe for wooden artifacts as well as restoration personnel. While higher catalytic temperature can substantially enhance the polymerization reaction rate and increase the bending strength of the wood, it may also lead to wood embrittlement or an excessive buildup of polymers on the surface.

Microscopic analysis indicated that the resulting lignin oligomers reinforced the cell walls without filling the cell lumens. The preservation of the original pore structure of the wood cell prevented significant weight gain, thereby avoiding excessive burden on the artifacts. Additionally, it ensured that future reprocessing materials could penetrate the wood. Therefore, this mechanism not only contributed to minimizing the shrinkage of the archeological wood but also facilitated smooth integration with subsequent conservation efforts.

In this study, the materials used are readily available, affordable, and nontoxic. This approach offers an innovative potential solution for the dehydration and consolidation of waterlogged wooden artifacts, while also embodying a sustainable and eco-friendly strategy for advancing conservation practices. However, this study remains an exploratory investigation into the use of laccase-catalyzed eugenol for the dehydration and consolidation of waterlogged wooden artifacts. There are still significant gaps in the in-depth research on the polymerization mechanisms and product structures, as well as in the control of the reaction processes. In future studies, the long-term stability of the treatment also needs to be investigated. Before practical application, the penetrability and dimensional stabilization effectiveness are necessary to be evaluated on wooden objects with larger scales and different degradation conditions.

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author upon reasonable request.

References

Hoffmann, P. To be and to continue being a Cog: the conservation of the Bremen Cog of 1380. Int. J. Naut. Archaeol. 30, 129–140 (2001).

Håfors B. Conservation of the Wood of the Swedish Warship Vasa of A.D. 1628. Evaluation of Polyethylene Glycol Conservation Programmes (Doctoral thesis). (University of Gothenburg, Acta Universitatis Gothoburgensis, 2010).

Christensen, M., Kutzke, H. & Hansen, F. K. New materials used for the consolidation of archaeological wood–past attempts, present struggles, and future requirements. J. Cult. Herit. 13, S183–S190 (2012).

Yuan, X. & Zhang, A. Analysis of conservation techniques for four shipwrecks discovered in Penglai, Shandong. China Cult. Herit. Sci. Res. 1, 81–84 (2013).

Hoffmann, P. & Wittköpper, M. Conservation of Archaeological Ships and Boats: Personal Experiences. 96–103 (Archetype Publications, 2013).

Ljungdahl, J. & Berglund, L. A. Transverse mechanical behaviour and moisture absorption of waterlogged archaeological wood from the Vasa ship. Holzforschung 61, 279–284 (2007).

Pan, L. & Gu, J. D. Characterization of aerobic bacteria involved in degrading polyethylene glycol (PEG)-3400 obtained by plating and enrichment culture techniques. J. Polym. Environ. 15, 57–65 (2007).

Hoffmann, P. On the long-term visco-elastic behaviour of polyethylene glycol (PEG) impregnated archaeological oak wood. Holzforschung 64, 725–728 (2010).

Hocker, E., Almkvist, G. & Sahlstedt, M. The Vasa experience with polyethylene glycol: a conservator’s perspective. J. Cult. Herit. 13, S175–S182 (2012).

Almkvist, G. & Persson, I. Degradation of polyethylene glycol and hemicellulose in the Vasa. Holzforschung 62, 64–70 (2008).

Almkvist, G., Norbakhsh, S., Bjurhager, I. & Varmuza, K. Prediction of tensile strength in iron-contaminated archaeological wood by FT-IR spectroscopy—a study of degradation in recent oak and Vasa oak. Holzforschung 70, 855–865 (2016).

Lechner, T., Bjurhager, I. & Kliger, R. I. Strategy for developing a future support system for the Vasa warship and evaluating its mechanical properties. Herit. Sci. 1, 1–11 (2013).

Leszek, B. Dimensional changes of waterlogged archaeological hardwoods pre-treated with aqueous mixtures of lactitol/trehalose and mannitol/trehalose before freeze-drying. J. Cult. Herit. 16, 876–882 (2015).

Tahira, A., Howard, W., Pennington, E. R. & Kennedy, A. Mechanical strength studies on degraded waterlogged wood treated with sugars. Stud. Conserv. 62, 223–228 (2017).

Kennedy, A. & Pennington, E. R. Conservation of chemically degraded waterlogged wood with sugars. Stud. Conserv. 59, 194–201 (2014).

Endo, R., Kamei, K., Iida, I. & Kawahara, Y. Dimensional stability of waterlogged wood treated with hydrolyzed feather keratin. J. Archaeol. Sci. 35, 1240–1246 (2008).

Hamed, S. A. A. K. M. & Hassan, M. L. A new mixture of hydroxypropyl cellulose and nanocellulose for wood consolidation. J. Cult. Herit. 35, 140–144 (2019).

Cavallaro, G., Lazzara, G., Milioto, S., Parisi, F. & Ruisi, F. Nanocomposites based on esterified colophony and halloysite clay nanotubes as consolidants for waterlogged archaeological woods. Cellulose 24, 3367–3376 (2017).

Zhou, Y., Wang, K. & Hu, D. An aqueous approach to functionalize waterlogged archaeological wood followed by improved surface-initiated ARGET ATRP for maintaining dimensional stability. Cellulose 28, 2433–2443 (2021).

Chen, Z., Cheng, L. & Li, L. Dehydration and reinforcement of formaldehyde to form the painted main coffins of Zeng Houyi’s tomb and Baoshan Chu’s tomb. Cult. relics Mus. 1, 81–83 (2009). (In Chinese).

Safa Abd Al Kader Mohamed, H. & Mohammad Lotfy, H. A new mixture of hydroxypropyl cellulose and nanocellulose for wood consolidation. J. Cult. Herit. 35, 140–144 (2019).

Chen, J. & Zheng, Y. Water-soluble acrylic resin used in consolidating and dewatering water-logged lacquer-ware. Sci. Conserv. Archaeol. 3, 28–34 (2005).

Zhou, Y., Chen, X. & Wang, K. Study on the mechanism of dimensional stabilization of waterlogged archaeological wood treated by γ-mercaptopropyltriethoxysilane. Sci. Conserv. Archaeol. 33, 1–11 (2021).

Broda, M. & Mazela, B. Application of methyltrimethoxysilane to increase dimensional stability of waterlogged wood. J. Cult. Herit. 25, 149–156 (2017).

Han, L., Tian, X., Keplinger, T., Zhou, H. & Guo, J. Even visually intact cell walls in waterlogged archaeological wood are chemically deteriorated and mechanically fragile: a case of a 170 year-old shipwreck. Molecules 25, 11–13 (2020).

Antonelli, F., Galotta, G., Sidoti, G., Zikeli, F. & Romagnoli, M. Cellulose and lignin nano-scale consolidants for waterlogged archaeological wood. Front. Chem. 8, 32 (2020).

Wakefield, J. et al. Aminoethyl substitution enhances the self-assembly properties of an aminocellulose as a potential archaeological wood consolidant. Eur. Biophys. J. 49. https://doi.org/10.1007/s00249-020-01451-y (2020).

Colombini, M. P. et al. A multi-analytical study of degradation of lignin in archaeological waterlogged wood. Talanta 80, 61–70 (2009).

Fornari, A. et al. Comparative studies on nanocellulose as a bio-based consolidating agent for ancient wood. Appl. Sci. 14, 7964 (2024).

Bjurhager, I. et al. State of degradation in archeological oak from the 17th Century Vasa Ship: substantial strength loss correlates with reduction in (holo)cellulose molecular weight. Biomacromolecules 13, 2521–2527 (2012).

Zhou, H., Li, J. & Ma, E. Multiscale modification of Populus cathayana by Alkali Lignin combined with heat treatment. Polymers 10, 1240 (2018).

Zhang, J. et al. Modified lignin nanoparticles as potential conservation materials for waterlogged archaeological wood. ACS Appl. Nano Mater. 6, 12351–12363 (2023).

Parijs, F. R. D. V., Morreel, K., Ralph, J., Boerjan, W. & Merks, R. M. Modeling lignin polymerization. I. Simulation model of dehydrogenation polymers. Plant Physiol. 153, 1332–1344 (2010).

McHale, E. et al. Synthesis and characterisation of lignin-like oligomers as a bio-inspired consolidant for waterlogged archaeological wood. Pure Appl. Chem. 88, 969–977 (2016).

Ohnishi, J., Watanabe, T. & Koshijima, T. Synthesis of dehydrogenation polymer—polyose complexes by peroxidase. Phytochemistry 31, 1185–1190 (1992).

Vanholme, R., Demedts, B., Morreel, K., Ralph, J. & Boerjan, W. Lignin biosynthesis and structure. Plant Physiol. 153, 895–905 (2010).

McHale, E., Steindal, C. C., Kutzke, H., Benneche, T. & Harding, S. E. In situ polymerisation of isoeugenol as a green consolidation method for waterlogged archaeological wood. Sci. Rep. 7, 46481 (2017).

Fåhraeus, G. & Ljunggren, H. Substrate specificity of a purified fungal laccase. Biochim. Biophys. Acta 46, 22–32 (1961).

Biswas, M., Taylor, K., Bewtra, J. & Biswas, N. Enzymatic treatment of sulfonated aromatic amines generated from reductive degradation of reactive azo dyes. Water Environ. Res. 79, 351–356 (2007).

Felici, M., Artemi, F., Luna, M. & Speranza, M. Determination of laccase activity with various aromatic substrates by high-performance liquid chromatography. J. Chromatogr. A 320, 435–439 (1985).

Bourbonnais, R. & Paice, M. G. Oxidation of non-phenolic substrates. An expanded role for laccase in lignin biodegradation. FEBS Lett. 267, 99–102 (1990).

Mehra, R., Muschiol, J., Meyer, A. S. & Kepp, K. P. A structural-chemical explanation of fungal laccase activity. Sci. Rep. 8, 17285 (2018).

Kumar, R., Kaur, J., Jain, S. & Kumar, A. Optimization of laccase production from Aspergillus flavus by design of experiment technique: partial purification and characterization. J. Genet. Eng. Biotechnol. 14. https://doi.org/10.1016/j.jgeb.2016.05.006 (2016).

Poggi, G. et al. Calcium hydroxide nanoparticles from solvothermal reaction for the deacidification of degraded waterlogged wood. J. Colloid Interface Sci. 473, 1–8 (2016).

Riva, S. Laccases: blue enzymes for green chemistry. Trends Biotechnol. 24, 219–226 (2006).

Xie, Y., Yasuda, S., Wu, H. & Liu, H. Analysis of the structure of lignin-carbohydrate complexes by the specific13C tracer method. J. Wood Sci. 46, 130–136 (2000).

Gou, J., Peng, Y. & Zhang, C. Inhibitory activity of forty kinds of Chinese herbal medicines against Phytophthora nicotiana. Chin. Tob. Sci. 38, 64–67 (2017).

Yen, T.-B. & Chang, S.-T. Synergistic effects of cinnamaldehyde in combination with eugenol against wood decay fungi. Bioresour. Technol. 99, 232–236 (2008).

Park, I.-K. & Shin, S.-C. Fumigant activity of plant essential oils and components from garlic (Allium sativum) and clove bud (Eugenia caryophyllata) oils against the Japanese termite (Reticulitermes speratus Kolbe). J. Agric. Food Chem. 53, 4388–4392 (2005).

Kamatou, G. P., Vermaak, I. & Viljoen, A. M. Eugenol—from the Remote Maluku Islands to the international market place: a review of a remarkable and versatile molecule. Molecules 17, 6953–6981 (2012).

Hartnoll, G., Moore, D. & Douek, D. Near fatal ingestion of oil of cloves. Arch. Dis. Child. 69, 392–393 (1993).

Bhuiyan, M. N. I. Constituents of the essential oil from leaves and buds of clove (Syzigium caryophyllatum (L.) Alston). Afr. J. Pharm. Pharmacol. 6, 1260–1263 (2012).

Brent, J. Medical toxicology of natural substances: foods, fungi, medicinal herbs, plants, and venomous animals. JAMA 302, 441–444 (2009).

Clark, G. C. Acute inhalation toxicity of eugenol in rats. Arch. Toxicol. 62, 381–386 (1988).

Evaluation of certain food additives and contaminants: eightieth report of the Joint FAO/WHO Expert Committee on Food Additives (2016).

Cheng, S.-S., Liu, J.-Y., Chang, E.-H. & Chang, S.-T. Antifungal activity of cinnamaldehyde and eugenol congeners against wood-rot fungi. Bioresour. Technol. 99, 5145–5149 (2008).

Morales-Cerrada, R., Molina-Gutierrez, S., Lacroix-Desmazes, P. & Caillol, S. Eugenol, a promising building block for biobased polymers with cutting-edge properties. Biomacromolecules 22, 3625–3648 (2021).

Huang, X. et al. Long-term mold resistance strategy of laccase-catalyzed eugenol-modified bamboo and its antimicrobial mechanism derived from lignin. Ind. Crops Prod. 222, 119479 (2024).

Watanabe, H., Takahashi, M., Kihara, H. & Yoshida, M. Biobased coatings based on eugenol derivatives. ACS Appl. Bio Mater. 1, 808–813 (2018).

Wu, M. et al. A quasi-nondestructive evaluation method for physical-mechanical properties of fragile archaeological wood with TMA: a case study of an 800-year-old shipwreck. Forests 13, 38 (2022).

Wu, M. et al. Anti-cracking TEOS-based hybrid materials as reinforcement agents for paper relics. Molecules 29, 1834 (2024).

Han, L. et al. Size effect on hygroscopicity of waterlogged archaeological wood by simultaneous dynamic vapour sorption. Forests 14, 519 (2023).

Chowdhry, B. Z., Ryall, J. P., Dines, T. J. & Mendham, A. P. Infrared and Raman spectroscopy of eugenol, isoeugenol, and methyl eugenol: conformational analysis and vibrational assignments from density functional theory calculations of the anharmonic fundamentals. J. Phys. Chem. A 119, 11280–11292 (2015).

Derkacheva, O. Y. & Sukhov, D. A. Investigation of lignins by FTIR spectroscopy. Macromol. Symp. 265, 61–68 (2008).

Faix, O. Classification of lignins from different botanical origins by FT-IR spectroscopy. Holzforschung 45, 21–28 (1991).

Ralph, J. et al. Lignins: natural polymers from oxidative coupling of 4-hydroxyphenyl- propanoids. Phytochem. Rev. 3, 29–60 (2004).

Xue-Fei, Z. Oxidation of lignin-carbohydrate complex by laccase/Co(salen) one-pot catalysis. Sains Malays. 51, 723–732 (2022).

Qi, Y. B. et al. Multicomponent kinetic analysis and theoretical studies on the phenolic intermediates in the oxidation of eugenol and isoeugenol catalyzed by laccase. Phys. Chem. Chem. Phys. 17, 29597–29607 (2015).

Wang, P., Xie, Y., Wu, C., Ye, Z. & Le, X. Dehydrogenation polymerization of isoeugenol and formation of lignin-carbohydrate complexes with presence of polysaccharide. Chem. Ind. For. Prod. 36, 45–50 (2016).

Acknowledgements

This research was funded by the National Key R&D Program of China, grant number 2020YFC1521803. The authors would like to thank Yafang Yin, Xiaomei Jiang, and Yonggang Zhang from the Research Institute of Wood Industry, Chinese Academy of Forestry for the wood identification support.

Author information

Authors and Affiliations

Contributions

M.W. and L.G. wrote the main manuscript text and prepared the schematic diagram. M.W. visualized the testing results. L.G. provided Figures 7 and 8. J.C. edited the manuscript text. X.H. and J.W. provided resources and analyzed the data. X.H. and H.G. supervised the research. X.H., Z.Z., and J.W. administrate the project. Z.Z. acquired the funding. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, M., Guo, L., Chen, J. et al. Dehydration and in situ consolidation of waterlogged archeological wood via laccase catalyzing eugenol nanoemulsion. npj Herit. Sci. 13, 164 (2025). https://doi.org/10.1038/s40494-025-01694-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s40494-025-01694-y