Abstract

Photoelectrochemical (PEC) cell is an ideal platform for organic transformation because of its green benefits and minimal energy consumption. As an emerging methodology, the reaction types of photoelectrocatalytic organic synthesis (PECOS) are limited to simple oxidation and C–H activation at current stage. Metal catalysis for the construction of C(sp2)–N bonds has not been touched yet in PECOS. We introduce here a PEC method that successfully engages Ni catalysis for the mild production of aniline derivatives. Experimental and computational investigations elucidate that the addition of photoanode-generated amine radical to Ni catalyst avoids the sluggish nucleophilic attack, enabling the reaction to proceed at an ultra-low potential (–0.4 V vs. Ag/AgNO3) and preventing the overoxidation of products in conventional electrochemical synthesis. This synergistic catalysis strategy exhibits good functional group tolerance and wide substrate scope on both aryl halides and amines, by which some important natural products and pharmaceutical chemicals have been successfully modified.

Similar content being viewed by others

Introduction

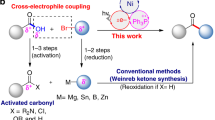

With distinctive physical and chemical properties, chemicals that contain aniline motif are widely used in agriculture, pharmaceutics, optoelectronics, and many other fields1,2,3,4,5. Such great demand urges the discovery and development of methods for efficiently producing aniline derivatives. In the past decades, metal catalysis has been proven a powerful strategy for construction of C(sp2)–N bonds6,7,8, in which Ni-based catalysts are recognized as promising candidates for the cross-coupling between amines and aromatic halides due to its relatively low cost and high reactivity9,10,11. The traditional Ni-catalyzed C–N cross-coupling has been usually operated under elevated temperature, strong alkoxide bases and elaborated ligands12,13, failing to meet the grandiose goal of sustainable production. To tackle these problems, attempts such as introducing electrical power14,15,16,17,18,19,20,21 (known as electrochemistry, EC) or light energy22,23,24,25,26 (known as photochemistry, PC) into Ni-catalysis have been made, but still suffering from high external bias or limited substrate scope (Fig. 1a).

a Comparison between traditional and PEC Ni-catalyzed C–N cross-coupling. b Reaction scheme. c Optimization of the reaction conditions. aStandard conditions: BiVO4 photoanode (1.2 cm × 2.5 cm), Ni foam cathode (1.0 cm × 3.0 cm), Ag/AgNO3 as reference electrode, 1 (0.4 mmol), 2 (0.2 mmol), LiBr (0.2 M), NiBr2·glyme (0.02 mmol), dtbbpy (0.03 mmol), DABCO (2 equiv), acetone (5.0 mL), E = –0.4 V vs Ag/AgNO3, blue LED, 12 h, N2. bYields are determined by 1H NMR analysis using benzhydrol as the internal standard. cNR = no reaction. d The proportion of reactant (2), by-products and product (3) and the corresponding selectivity of different methods (See Supplementary Table 1 for more details). Reaction conditions: PC: standard condition without electricity; EC: standard condition without light irradiation, and the bias is raised to +1.5 V vs. Ag/AgNO3; PEC: standard condition. The error bars are three standard deviations of measurement sets.

The versatility of photoelectrochemical organic synthesis (PECOS) is gaining increasing attention27,28,29,30,31,32. Benefitting from the integration of utilizing both electricity and light, PEC cells are expected to empower the organic synthesis to be conducted under mild conditions while retaining excellent efficiency and broad substrate scope33,34,35,36. Some reaction types including simple oxidation and C–H activation have been achieved by PEC cells37,38,39,40,41,42,43,44,45. However, metal catalysis with superiority in construction of C(sp2)–N bonds has not been explored yet in PECOS. Thus, it is imperative to introduce metal catalysis into PECOS for the diversification of reaction types.

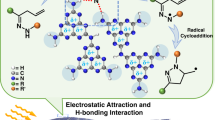

With this in mind, we initiated to bridge the gaps between PECOS and metal catalysis. In traditional electrochemical methods, nucleophilic attack of amine to Ni-based catalyst acts as the rate-determining step46,47,48. The sluggish kinetics of this process hinders the further improvement of the catalytic efficiency. Here, a PEC system is designed to bypass the sluggish nucleophilic attack step, where the photoanode together with a hydrogen atom transfer (HAT) catalyst activates amine substrates to amine radicals. Importantly, with the introduction of photoanode, the reaction can proceed under an ultra-low potential (–0.4 V vs. Ag/AgNO3), thus preventing the overoxidation of products.

Results

To optimize reaction conditions, the cross-coupling of N-methylaniline (1) and methyl 4-bromobenzonate (2) was picked as the model reaction. Catalytic tests with different conditions were carried out in an undivided PEC cell with a three-electrode configuration (Supplementary Figs. 1–3). The BiVO4 photoanode was successfully prepared (Supplementary Fig. 4) using the previously reported method36. Concurrently, a Ni foam electrode and a Ag/AgNO3 electrode were employed as the cathode and the reference electrode, respectively. In a typical test, the experiment was performed in N2 atmosphere under the irradiation of a 465 nm blue light emitting diode with a constant external bias of –0.4 V vs. Ag/AgNO3 (Fig. 1b).

Initially, the reaction was conducted using acetone as the solvent and LiBr as the electrolyte. NiBr2 glyme and the ligand 4,4′-Di-tert-butyl-2,2′-dipyridyl (dtbppy) were added to the reaction system simultaneously for the formation of Ni catalyst. 1,4-Diazabicyclo[2.2.2]octane (DABCO), a HAT mediator, was introduced to the PEC cell to facilitate the electron transfer between the photoanode and amine (Fig. 1c, entry 1). Such recipe led to a high yield of 82% towards the target product methyl 4-(methyl(phenyl)amino)benzoate (3). To investigate the solvent effect, acetone was in turn replaced by acetonitrile (MeCN), dimethylacetamide (DMA) and dichloroethane (DCE), but poor results were observed (Fig. 1c, entry 2–4). As for the influence of electrolyte, when LiBr was changed to nBu4NBr or nBu4NBF4, the yield dropped below 60% (Fig. 1c, entry 5–6). Reducing the amount of either HAT mediator or electrolyte had negative effects on the yield (Supplementary Fig. 5). Additionally, trace product was obtained when Pt plate was employed as the cathode (Fig. 1c, entry 7). Changing Ni precatalyst or reducing the ligand loading amount exhibited limited impact on the reaction, with yields consistently exceeding 70% (Fig. 1c, entry 8–9). However, replacing dtbppy with 2,2’-bipyridine (bpy) almost stopped the reaction from proceeding (Fig. 1c, entry 10). Recycling experiments were carried out to test the stability of the photoanode (Supplementary Fig. 6), and the catalytic performance of BiVO4 slightly decreased after five cycles of experiments.

The role of each component in the reaction was explored. As expected, no reaction happened when Ni precatalyst or ligand was omitted (Fig. 1c, entry 11). Similarly, only trace product was found in the absence of DABCO (Fig. 1c, entry 12) or electricity (Fig. 1d, left column). These results demonstrated that Ni catalyst, DABCO and electricity all played crucial roles in the catalysis. Electrocatalysis under dark condition was also carried out (Fig. 1d, middle column), and no product was detected until the potential was raised up to +1.5 V vs. Ag/AgNO3. Furthermore, due to the high overpotential of electrocatalysis, the yield and selectivity of product 3 were merely 16% and 62% at +1.5 V vs. Ag/AgNO3, respectively (Supplementary Table 1). Notably, introducing light to the electrocatalysis dramatically lowered the potential to –0.4 V vs. Ag/AgNO3, consequently improving the yield and selectivity of product 3 to 82% and 89% (Fig. 1d, right column).

Linear sweep voltammetry (LSV) and cyclic voltammetry (CV) were applied to investigate the EC and PEC properties of the reaction systems (See Supplementary Figs. 7–10 for more details). The onset potential on BiVO4 photoanode in PEC cell was much lower than that on glassy carbon (GC) anode in EC cell (Supplementary Fig. 7), suggesting the PEC approach significantly lowered the overpotential. As shown in Fig. 2a, the LSV diagram of BiVO4 anode showed significant onset potential decrease in the presence of light, which highlighted the superiority of PEC cell. Adding DABCO also contributed to the reduction of onset potential (Fig. 2a, pink curve vs. blue curve), indicating that DABCO served as a mediator to promote the charge transfer between the anode and the substrate. The function of DABCO was further revealed by CV curves (Fig. 2b). The considerably lower oxidation potential of DABCO (EOx,DABCO = +0.41 V vs. Ag/AgNO3) than that of the substrate N-methylaniline (EOx,N-methylaniline = +0.53 V vs. Ag/AgNO3) demonstrated that it was easier to be oxidized by the anode, which well accorded with LSV results. Moreover, in the presence of N-methylaniline (Fig. 2b, pink curve), the intensity of DABCO oxidation peak obviously exceeded the original one (Fig. 2b, orange curve), suggesting the interactions between oxidized DABCO and N-methylaniline. Furthermore, the EC properties of Ni catalyst were studied via CV tests. As illustrated in the right diagram of Fig. 2c, the CV curve of Ni catalyst displayed a reduction peak at Ered,1 = –1.73 V vs. Ag/AgNO3, which is attributed to the Ni(II/I) redox couple (orange curve). After the inclusion of aryl bromide, the intensity of reduction peak increased significantly (pink curve). The change in reduction signal reveals the oxidation addition of aryl bromide on Ni(I) catalyst. Meanwhile, the concurrent observation of enhanced Ni(I/0) redox signals (Ered,2 = –2.24 V vs. Ag/AgNO3) and the emergence of a new pair of reversible redox peaks at –2.0 V vs. Ag/AgNO3 fortified the existence of Ni(I)-participated oxidation addition15,47.

a LSV curves of BiVO4 photoanode under irradiation (pink), dark (black) and in the absence of DABCO (blue). b CV curves of blank electrolyte (black), in the presence of DABCO (orange), N-methylaniline (blue) and the mixture of DABCO and N-methylaniline (pink). c CV curves of blank electrolyte (black), methyl 4-bromobenzonate (denoted as Ar-Br, blue), NiBr2 glyme + dtbbpy (denoted as NiL, orange) and the mixture of Ar-Br and NiL (pink). Note that the CV curves are recorded on the glass carbon electrodes owing to its inert nature and wide electrochemical window compared with BiVO4.

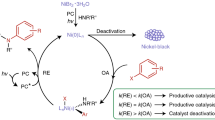

To dig deep into the reaction pathway, several control experiments and radical trapping experiment were designed and carried out. When the control experiment was conducted in a divided cell where all the reagents except for LiBr were placed in the cathode chamber (Fig. 3a, top), only trace 3 was obtained, displaying the importance of anode oxidation reaction. The addition of butylated hydroxytoluene (BHT), a radical-scavenging agent, greatly suppressed the generation of 3 (Fig. 3a, middle). Instead, BHT adduct 4 was detected by high-resolution mass spectrometry (HR-MS), demonstrating that the nitrogen-centered radical was an important intermediate in the PEC process. Control experiment in the absence of Ni catalyst led to 1,2-dimethyl-1,2-diphenylhydrazine (5) from coupling of 1 (Fig. 3a, bottom), offering another evidence about the existence of radical intermediate. This result indicated that the Ni catalyst played a critical role in the cross-coupling of 1 and 2. Further getting rid of DABCO from the reaction system resulted in the vanishment of 5, showing that DABCO took part in the generation of amine radical.

Based on the experimental results above, a plausible reaction mechanism of PEC C–N coupling was proposed (Fig. 3b). Under light irradiation, the electron in the valence band (VB) of BiVO4 photoanode was excited to the conduction band (CB) and left a hole behind. After migrating to the surface, the photogenerated hole oxidized DABCO (6) to DABCO cation radical (7) via a single-electron transfer reaction. The HAT between DABCO amine radical and the aniline substrate gave rise to the protonated DABCO (8) and the aniline radical (9). The deprotonation of the former accomplished the organocatalytic cycle and the latter participated in the Ni-catalytic cycle. Meanwhile, the Ni-catalytic cycle started from the reduction of NiII catalyst 10 at the Ni foam cathode. As-generated NiI intermediate 11, confirmed by high-resolution electrospray ionization mass spectrometry (ESI-HRMS) (Supplementary Fig. 11), involves the oxidative addition of aryl bromide to form NiIII intermediate 12 followed by receiving an electron from the cathode to generate NiII intermediate 13. Afterwards, the NiII intermediate was added by the aniline radical to produce NiIII intermediate 14. Finally, a reductive elimination occured and the coupling product was formed.

Density functional theory (DFT) simulations were performed (See Supplementary Information for details) to verify the rationality of the proposed reaction mechanism. The HAT from aniline to DABCO cation radical had a low activation energy of ∆G‡HAT-TS = +9.4 kcal mol–1 (Supplementary Fig. 12), indicating the fast kinetics of this process. As shown in Fig. 3c, the oxidative addition step of aryl bromide on 11 was proven to be a fast step (∆G‡11→TS1 = +9.4 kcal mol–1) with a Gibbs free energy change of ∆G11→12 = –4.4 kcal mol–1. The reduction step for the intermediate 12 was calculated to be endothermic (∆G12→13 = +22.9 kcal mol–1). Once NiII intermediate 13 was formed, it was possible to be attacked by N-methylaniline or its radical. Noteworthily, DFT simulation elucidated that compared with the traditional amine attacking pathway (13 → TS2’ → 15) in electrocatalysis, the radical attacking pathway (13 → TS2 → 14) had a much lower energy barrier (∆G‡13→TS2 = +5.0 kcal mol–1 vs. ∆G‡13→TS2’ = +9.9 kcal mol–1) and was more thermodynamically favorable (∆G13→14 = –9.2 kcal mol–1 vs. ∆G13→15 = –2.8 kcal mol–1), revealing the intrinsic advantage of PEC approach. Finally, the reductive elimination was a thermodynamically favorable step (∆G14→3 = –23.5 kcal mol–1) with an energy barrier of ∆G‡14→TS3 = +11.3 kcal mol–1.

Armed with mechanistic insights, we set out to explore the generality of our PEC C–N cross-coupling method. The scope of aryl bromide substrate was first investigated. As displayed in Fig. 4, the para-position exhibited excellent group tolerance under the standard condition. When the ester group was replaced by ketocarbonyl, phenyl and trifluoromethyl groups, good yields were obtained (16–18). Employing 1-bromo-4-chlorobenzene as substrate resulted in the selective production of 19, implying that the Ni-catalytic cycle had a high selectivity on activating halide groups. Thio- and cyano-containing substrates were also successfully coupled with N-methylaniline with slightly lower yields (20, 21). Even for bulky substituent such as tert-butyl or carbazole, the reaction took place with moderate yields (22, 23). Similar tolerance was observed for the meta- and multi-substituted substrates (24–31). Bromobenzene, bromonaphthalene and some more complicated bromated (hetero) aromatic compounds were further tested and fair to good yields were observed (32–38). In regard to the scope of amine substrate, aniline derivatives including para- and meta-substituted N-methylaniline, N-methyl-2-naphthylamine, cyclic amines, primary aryl amines and morpholine were tried (39–53). The catalytic performance varied greatly among different substrates, likely because the stability of amine radical was sensitive to the electronic effect and the steric hinderance.

aReaction condition: BiVO4 photoanode (1.2 cm × 2.5 cm), Ni foam cathode (1.0 cm ×3.0 cm), Ag/AgNO3 as reference electrode, amine (0.4 mmol), aryl bromide (0.2 mmol), LiBr (0.2 M), NiBr2·glyme (0.02 mmol), dtbbpy (0.03 mmol), DABCO (2 equiv), acetone (5.0 mL), E= –0.4 V vs Ag/AgNO3, 12 h, N2. bE = 0.2 V vs Ag/AgNO3. cE = 0.0 V vs Ag/AgNO3. Corresponding yields are shown.

Last but not least, we showcased the synthetic applicability of this synergistically catalytic approach with a few examples of late-stage functionalization. Impressively, the analog of phytol and L-menthol, two types of important natural product, were readily synthesized using this method (54, 55). Bromides derived from pharmaceutical chemicals (canagliflozin, bedaquiline and celecoxib precursor) also incorporated well into this protocol (56-58). Additionally, fenofibrate, indomethacin and etoricoxib, three famous drugs with aryl chloride moiety, were found to be compatible with this system, evincing that it is promising to apply the PEC mode to other halides (59-61).

Discussion

In summary, we presented here a brand-new methodology that engaged Ni catalysis in the PEC cross-coupling of aryl bromides with amines. With the aid of light, the PEC approach efficiently realized the C-N coupling in high yield at ultra-low potential. Mechanistic studies revealed that amine radicals participated in the Ni-catalytic cycle in a more rapid manner than the sluggish nucleophilic attack of amine in traditional EC catalysis. We envision that this new PEC strategy implemented under mild reaction condition will greatly unroll the synthetic potential of asymmetric catalysis, which provides stereoselective control and prevents problems such as substrate overoxidation or chiral catalyst inactivation.

Methods

Preparation of BiVO4 electrode

The BiVO4 electrode was prepared by an electrodeposition-calcination method. First, fluorine-doped tin oxide (FTO) substrates were sonicated with acetone, ethanol and water for 30 min each. Bi(NO3)3·5H2O (0.04 M) and KI (0.4 M) were dissolved in 60 mL distilled water to form a clear solution. Then, HNO3 was added to adjust pH value to 1.7. Next, 0.23 M p-benzoquinone ethanol solution (25 mL) was added to above mixed solution and stirred vigorously for 20 min. The electrodeposition was carried out in a three-electrode cell using a constant potential of –0.1 V vs Ag/AgCl for 600 s at room temperature, where FTO, Pt and Ag/AgCl were employed as working electrode, counter electrode and reference electrode, respectively. After the electrodeposition, a uniform red-brown film (BiOI) was formed on the FTO substrate. Then, 200 μL of a DMSO solution containing 0.2 M vanadyl acetylacetonate was dropped on the BiOI electrode, and the electrode was calcined at 450 °C for 1 h with a heating rate of 2 °C min–1. After being cooled down to room temperature, the electrode was soaked in 1.0 M NaOH solution to remove the excess V2O5. Finally, the BiVO4 electrode was rinsed with distilled water and dried with N2 gas.

General procedure for the photoelectrocatalysis

In a nitrogen-filled glove box, an oven-dried photoelectrochemical cell equipped with a stir bar was charged with NiBr2·glyme (0.02 mmol, 10 mol%), dtbbpy (0.03 mmol, 15 mol%), DABCO (0.4 mmol, 2 equiv), LiBr (0.2 M), methyl 4-bromobenzoate (0.2 mmol) and acetone (5 mL). The mixture was stirred at room temperature for 1 min. Then, N-methylaniline (0.4 mmol, 2 equiv) was added. The vial was sealed with the home-made cap, which was equipped with a BiVO4 photoanode (1.2 cm × 2.5 cm), a nickel foam cathode (1.0 cm × 3.0 cm) and an Ag/AgNO3 reference electrode, and then brought out of the glove box. After pre-stirring the resulting mixture for 1 min, photoelectrocatalysis was performed at a constant potential of –0.4 V vs. Ag/AgNO3 for 12 h. When the reaction was finished, the entire reaction mixture was then transferred to a silica gel column and purified with a mixture of hexane and ethyl acetate to give the corresponding products.

Data availability

The data supporting the findings of this study are provided within the article and in the Supplementary Information file. Additional data related to this work are available from the corresponding authors upon request. The Cartesian coordinates for all species involved are provided as a source data file. Source data are provided with this paper.

References

Fischer, C. & Koenig, B. Palladium- and copper-mediated N-aryl bond formation reactions for the synthesis of biological active compounds. Beilstein J. Org. Chem. 7, 59–74 (2011).

Beletskaya, I. P. & Cheprakov, A. V. The complementary competitors: palladium and copper in C-N cross-coupling reactions. Organometallics 31, 7753–7808 (2012).

Brown, D. G. & Bostrom, J. Analysis of past and present synthetic methodologies on medicinal chemistry: where have all the new reactions gone.J. Med. Chem. 59, 4443–4458 (2016).

Zhou, C. et al. Metal-free, redox-neutral, site-selective access to heteroarylamine via direct radical-radical cross-coupling powered by visible light photocatalysis. J. Am. Chem. Soc. 142, 16805–16813 (2020).

Sinha, S. K. et al. Toolbox for distal C-H bond functionalizations in organic molecules. Chem. Rev. 122, 5682–5841 (2022).

Ruiz-Castillo, P. & Buchwald, S. L. Applications of palladium-catalyzed C-N cross-coupling reactions. Chem. Rev. 116, 12564–12649 (2016).

Park, Y., Kim, Y. & Chang, S. Transition Metal-Catalyzed, C.-H. Amination: scope, mechanism, and applications. Chem. Rev. 117, 9247–9301 (2017).

Song, G. et al. Chiral arylated amines via C-N coupling of chiral amines with aryl bromides promoted by light. Angew. Chem. Int. Ed. 60, 21536–21542 (2021).

Corcoran, E. B. et al. Aryl amination using ligand-free Ni(II) salts and photoredox catalysis. Science 353, 279–283 (2016).

Ghosh, I. et al. General cross-coupling reactions with adaptive dynamic homogeneous catalysis. Nature 619, 87–93 (2023).

Lux, D. M., Aryal, V., Niroula, D. & Giri, R. Nickel-catalyzed regioselective intermolecular dialkylation of alkenylarenes: generation of two vicinal C(sp3-Csp3) bonds across alkenes. Angew. Chem. Int. Ed. 62, e202305522 (2023).

Barbor, J. P. et al. Development of a nickel-catalyzed N-N coupling for the synthesis of hydrazides. J. Am. Chem. Soc. 145, 15071–15077 (2023).

Yoo, C. et al. Nickel-catalyzed ester carbonylation promoted by imidazole-derived carbenes and salts. Science 382, 815–820 (2023).

Li, Z. et al. Electrochemically enabled, nickel-catalyzed dehydroxylative cross-coupling of alcohols with aryl halides. J. Am. Chem. Soc. 143, 3536–3543 (2021).

Ma, Y. et al. Aminomethylation of aryl bromides by nickel-catalyzed electrochemical redox neutral cross coupling. Org. Lett. 23, 9387–9392 (2021).

Sun, G.-Q. et al. Nickel-catalyzed electrochemical carboxylation of unactivated aryl and alkyl halides with CO2. Nat. Commun. 12, 7086 (2021).

Gao, Y., Zhang, B., He, J. & Baran, P. S. Ni-electrocatalytic enantioselective doubly decarboxylative C(sp3-Csp3) cross coupling. J. Am. Chem. Soc. 145, 11518–11523 (2023).

Hu, X., Cheng-Sanchez, I., Cuesta-Galisteo, S. & Nevado, C. Nickel-catalyzed enantioselective electrochemical reductive cross-coupling of aryl aziridines with alkenyl bromides. J. Am. Chem. Soc. 145, 6270–6279 (2023).

Luo, J. et al. Understanding formation and roles of Ni(II) Aryl Amido and Ni(III) Aryl Amido intermediates in Ni-catalyzed electrochemical aryl amination. React. J. Am. Chem. Soc. 145, 16130–16141 (2023).

Wang, Y.-Z. et al. Nickel/biimidazole-catalyzed electrochemical enantioselective reductive cross-coupling of aryl aziridines with aryl iodides. Nat. Commun. 14, 2322 (2023).

Li, P. et al. Nickel-electrocatalysed C(sp3)–C(sp3) cross-coupling of unactivated alkyl halides. Nat. Catal. 7, 412–421 (2024).

Lim, C. H., Kudisch, M., Liu, B. & Miyake, G. M. C-N cross-coupling via photoexcitation of nickel-amine complexes. J. Am. Chem. Soc. 140, 7667–7673 (2018).

Li, G. et al. Light-promoted C-N coupling of aryl halides with nitroarenes. Angew. Chem. Int. Ed. 60, 5230–5234 (2021).

Goldschmid, S. L. et al. Overcoming photochemical limitations in metallaphotoredox catalysis: red-light-driven C-N cross-coupling. J. Am. Chem. Soc. 144, 22409–22415 (2022).

Zhu, C., Yue, H. & Rueping, M. Nickel catalyzed multicomponent stereodivergent synthesis of olefins enabled by electrochemistry, photocatalysis and photo-electrochemistry. Nat. Commun. 13, 3240 (2022).

Lu, J., Yao, Y., Li, L. & Fu, N. Dual transition metal electrocatalysis: direct decarboxylative alkenylation of aliphatic carboxylic acids. J. Am. Chem. Soc. 145, 26774–26782 (2023).

Jiang, C., Moniz, S. J. A., Wang, A., Zhang, T. & Tang, J. Photoelectrochemical devices for solar water splitting - materials and challenges. Chem. Soc. Rev. 46, 4645–4660 (2017).

Wang, S., Liu, G. & Wang, L. Crystal facet engineering of photoelectrodes for photoelectrochemical water splitting. Chem. Rev. 119, 5192–5247 (2019).

Li, S. Y., Huang, K. F., Tang, Z. Y. & Wang, J. H. Photoelectrocatalytic organic synthesis: a versatile method for the green production of building-block chemicals. J. Mater. Chem. A 11, 3281–3296 (2023).

Wu, L. et al. Highly selective ammonia oxidation on BiVO4 photoanodes co-catalyzed by trace amounts of copper ions. Angew. Chem. Int. Ed. 63, e202316218 (2023).

Zhao, Y. et al. α-Fe2O3 as a versatile and efficient oxygen atom transfer catalyst in combination with H2O as the oxygen source. Nat. Catal. 4, 684–691 (2021).

Ko, M. et al. Direct propylene epoxidation with oxygen using a photo-electro-heterogeneous catalytic system. Nat. Catal. 5, 37–44 (2022).

Zhang, L. et al. Photoelectrocatalytic Arene C-H amination. Nat. Catal. 2, 266–373 (2019).

Lei, Y. J. C. T. et al. Tandem photoelectrochemical and photoredox catalysis for efficient and selective aryl halides functionalization by solar energy. Matter 4, 2354–2366 (2021).

Gong, M. et al. Harnessing visible-light energy for unbiased organic photoelectrocatalysis: synthesis of N-bearing fused rings. Green. Chem. 24, 837–845 (2022).

Wang, J. et al. Al2O3-coated BiVO4 photoanodes for photoelectrocatalytic regioselective C-H activation of aromatic amines. Angew. Chem. Int. Ed. 62, e202315478 (2023).

Cha, H. G. & Choi, K. S. Combined biomass valorization and hydrogen production in a photoelectrochemical cell. Nat. Chem. 7, 328–333 (2015).

Mesa, C. A. et al. Kinetics of photoelectrochemical oxidation of methanol on hematite photoanodes. J. Am. Chem. Soc. 139, 11537–11543 (2017).

Liu, D. et al. Selective photoelectrochemical oxidation of glycerol to high value-added dihydroxyacetone. Nat. Commun. 10, 1779 (2019).

Luo, L. et al. Selective photoelectrocatalytic glycerol oxidation to dihydroxyacetone via enhanced middle hydroxyl adsorption over a Bi2O3-incorporated catalyst. J. Am. Chem. Soc. 144, 7720–7730 (2022).

Li, T. et al. Photoelectrochemical oxidation of organic substrates in organic media. Nat. Commun. 8, 390 (2017).

Tateno, H., Iguchi, S., Miseki, Y. & Sayama, K. Photo-electrochemical C-H bond activation of cyclohexane using a WO3 photoanode and visible light. Angew. Chem. Int. Ed. 57, 11238–11241 (2018).

Wang, J. H. et al. Photoelectrochemical cell for P-H/C-H cross-coupling with hydrogen evolution. Chem. Commun. 55, 10376–10379 (2019).

Li, Z. et al. Photoelectrocatalytic C-H halogenation over an oxygen vacancy-rich TiO2 photoanode. Nat. Commun. 12, 6698 (2021).

Wang, X. D. et al. Surface passivated halide perovskite single-crystal for efficient photoelectrochemical synthesis of dimethoxydihydrofuran. Nat. Commun. 12, 1202 (2021).

Li, C. et al. Electrochemically enabled, nickel-catalyzed amination. Angew. Chem. Int. Ed. 56, 13088–13093 (2017).

Kawamata, Y. et al. Electrochemically driven, Ni-catalyzed aryl amination: scope, mechanism, and applications. J. Am. Chem. Soc. 141, 6392–6402 (2019).

Liu, D. et al. Nickel‐catalyzed N‐arylation of NH sulfoximines with aryl halides via paired electrolysis. Angew. Chem. Int. Ed. 133, 9530–9535 (2021).

Acknowledgements

This work was supported by National Key R&D Program of China (grant numbers: 2022YFA1205400 and 2021YFA1200302, Z.T.) Strategic Priority Research Program of Chinese Academy of Sciences (grant numbers: XDB36000000, Z.T.), and National Natural Science Foundation of China (grant numbers: 92356304 and 92056204, Z.T. 22301053, J.W.).

Author information

Authors and Affiliations

Contributions

J.W., L.W., and Z.T. conceived and designed the investigations. J.W., C.Y., H.G., and Z.G. performed and analyzed the experiments. J.W., H.G., L.Z, and P.Y. contributed to the scope and characterization. S.L., Y.J., and J.L. performed the density functional theory calculations. J.W., S.L., and Z.T. co-wrote the manuscript with contributions from all authors. J.L., L.W., and Z.T. co-guided the research and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, J., Li, S., Yang, C. et al. Photoelectrochemical Ni-catalyzed cross-coupling of aryl bromides with amine at ultra-low potential. Nat Commun 15, 6907 (2024). https://doi.org/10.1038/s41467-024-51333-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-51333-6

This article is cited by

-

Photoelectrocatalytic Cl-mediated C(sp3)–H aminomethylation of hydrocarbons by BiVO4 photoanodes

Nature Communications (2025)