Abstract

Due to the sulfur’s atoms’ propensity to form molecules and/or polymeric chains of various sizes and configuration, elemental sulfur possesses more allotropes and polymorphs than any other element at ambient conditions. This variability of the starting building blocks is partially responsible for its rich and fascinating phase diagram, with pressure and temperature changing the states of sulfur from insulating molecular rings and chains to semiconducting low- and high-density amorphous configurations to incommensurate superconducting metallic atomic phase. Here, using a fast compression technique, we demonstrate that the rapid pressurisation of liquid sulfur can effectively break the molecular ring structure, forming a glassy polymeric state of pure-chain molecules (Am-SP). This solid disordered chain state appears to be (meta)stable in the P-T region usually associated with phase I made up of S8. The elemental sulfur glass, made up from one of the simplest building blocks, offers a unique prospect to study the structure and property relationships of various other phases of sulfur and their interactions. More importantly, the fast compression technique performed at any temperature effectively like thermal quenching, opening up possibilities in high pressure synthesis by providing an effective and fast way of changing the fundamental thermodynamical parameter.

Similar content being viewed by others

Introduction

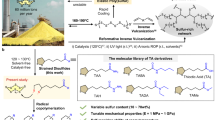

At ambient and near ambient conditions, elemental sulfur exhibits very rich molecular diversity, including many cyclic closed rings (Sn, n = 6–20), their mixtures, and different forms of open-ended spiral single chains1,2,3. This diversity is partially reflected in its phase diagram at low pressure and moderate temperatures (Fig. 1a). Within 11 GPa and 800 K, 5 solid phases (orthorhombic α-S8 (S-I), monoclinic β-S8, trigonal (S-II), tetragonal (S-III), rhombohedral S6 (S-IV) and 2 liquid states are known4,5,6,7,8. The α-S8, β-S8, and S6 are cyclic molecules, while the S-II and S-III phases exhibit polymer chain-like structures. The two known liquid states are the low-density (LDL) and high-density liquid (HDL), which consist of ring and chain molecules. Only the liquid located in a small region at the bottom of the LDL consists entirely of the 8-atom rings (Fig. 1a). The molecular liquid consisting of S8 rings is distinguished from the other region of LDL by the well-known λ-transition9. This transition is reversible and incomplete because above the λ-transition temperature, only some S8 rings open and polymerize into long chains. The LDL to HDL transformation is one of the very rare examples of an elemental liquid transforming into another via a first-order phase transition that ends at a P–T critical point8. These two liquids have different proportions of the constituent chains and rings.

a The low-density (LDL) and high-density liquid (HDL) sulfur are drawn in different shades of orange, and the dashed curve in the liquid LDL region denotes the transition between the liquid, made of pure rings, and LDL (lambda transition). The phase diagram shows five known solid phases (orthorhombic α-S8 (S-I), monoclinic β-S8, trigonal (S-II), tetragonal (S-III), rhombohedral S6 (Rh, S-IV). The melting curve and phase boundaries are from refs. 6,8. b The rapid compression of liquid sulfur to effectively break the ring structures and form an elemental sulfur glass of pure chain molecules (Am-SP). Liquid sulfur before the lambda transition and its supercooled product consists purely of S8 rings (Am-SR, indicated by the blue arrow). The solid orange arrows represent five pathways for preparing Am-SP by rapidly compressing the liquid (or supercooled liquid) sulfur at 300, 403, 423, 453, and 573 K. The red and blue double line arrows indicate isobaric variable-temperature experiments of Am-SP at 5 GPa, with temperatures ranging from 5 to 573 K. The orange double-line arrow represents the compression of Am-SP from 5 to 25.5 GPa at room temperature. Sulfur remains stable across all three pathways. The chains in Am-SP partially convert to rings when the pressure drops below 3 GPa, as indicated by the orange dashed line marking this transition pressure. The light red area indicates the (meta)stable region of Am-SP, which largely coincides with the P–T ___domain of the crystalline S-I phase. Δ denotes the experimental data points.

Chain sulfur in the melt is a truly intriguing subject in itself. Vitrification of single-element, monoatomic liquids is notoriously challenging10, but melting elemental sulfur has a different problem due to its allotropes’ diversity. Although a high-temperature melt can be rapidly quenched into a glass, the chain molecules will convert to rings below the λ-transition (Fig. 1b). This will result in an amorphous sulfur consisting of a mixture of chains and rings that gradually devitrifies into various crystalline allotropes made of ring molecules only. Consequently, pure chain sulfur glass has never been successfully synthesized. High pressure stabilizes sulfur chain molecules, and high P-T conditions could facilitate the synthesis of a pure amorphous chain state. However, it is quite difficult to achieve a high-temperature quenching rate under high pressure, and, therefore, one needs to explore an alternative path, e.g., very fast liquid-solid phase line crossing. In the generalized P–T quench11, glass could be formed by rapidly crossing the melting curve from the liquid to solid region with any combination of P–T paths.

Temperature quenching is the most common method to produce an amorphous (glassy) state. During the temperature quenching process, a liquid sample experiences a quick temperature drop across its freezing point, preventing nucleation formation and leading to vitrification. In principle, if the pressure increase across the liquid–solid boundary is sufficiently rapid, the melt could also be vitrified into a metastable amorphous glass, analogous to the temperature-quenched glass formation. However, rapid compression, characterized by a sharp increase in density, is more likely than rapid cooling to trigger changes in the molecular structure of materials. This, in turn, can influence the short- to medium-range order in amorphous materials. The liquid sulfur below Tλ is composed of S8 rings, thus, the amorphous sulfur quenched from LDL below Tλ comprises of an S8 ring (Fig. 1b, blue arrow). Now, a very interesting question arises: if rapid compression, instead of thermal quenching, is used to vitrify the S8 ring melt into the stable field of crystalline S-I (which is made of S8 rings), would the product be an S8 ring or chain glass?

High pressure provides a powerful additional dimension to explore the density-driven formation of crystalline phases and how sulfur’s molecules transform into three and fourfold chains or six-member rings4,5,6,7. It can shed some light on the exotic liquid-liquid transitions and the critical point in molten sulfur chains8. However, due to the specifics of the sulfur phase diagram, the pure chain sulfur disordered state has never been synthesized under any P–T conditions. Here, by adding time as another parameter to control the speed of compression, we have successfully synthesized a glassy polymeric state consisting of pure-chain sulfur molecules (Am-SP). We demonstrate that the rapid pressurization (10 GPa/s) of the S8 liquid at above 400 K effectively breaks the cyclic rings forming open-ended spiral polymeric chains. Our experiments also show that the rapid pressurization technique can act as an alternative and very effective way to create glassy materials at constant temperatures above ambient.

Results

For a detailed description of the experimental and calculational procedures, please refer to ref. 12, Methods and Supplementary Materials.

The formation of sulfur chains glass by fast compression of liquid sulfur

The liquid at 403 K was compressed from 0.05 to 4.1 GPa in 0.4 s, with an average compression rate of ~10 GPa/s. The time-resolved Raman and ruby fluorescent spectra throughout the pressurization process were collected with an exposure time of each spectrum of 0.04 s, with selected spectra shown in Fig. 2a, see also Supplementary Fig. 3. The typical Raman spectrum of α-S8 at ambient conditions can be divided into three regions: the region of lattice vibration modes (<120 cm−1), the region of the S–S–S bending modes of S rings (120–320 cm−1), and the region of the S–S stretching modes (400–500 cm−1)2,8,13. The polymer content Φ of sulfur can be obtained through the peak fitting in the region of the stretching modes13. The intensity of the two peaks in the bending vibration mode region is also an important indicator, as the intensity relationship between the bending and stretching modes in crystals under pressure is used to assess the stretching mode intensity of rings in amorphous crystals (see Methods and Supplementary Figs. 4 and 5). The Φ of the liquid sample at 403 K and at 0.05 GPa is 0, indicating that the liquid at these conditions is composed of S8 rings only. In the first 0.16 s, the liquid is compressed to ~0.95 GPa, and the broad peak located in the region of lattice vibration modes remained, indicating the formation of an amorphous sulfur. The increase in the stretching mode at 460 cm−1 (orange shaded peak) is attributed to polymerized chains and is accompanied by a reduction in the bending mode at 150 and 220 cm−1 (gray shaded peaks) and stretching mode at 471 cm−1 (blue shaded peak) of S8 rings. We estimate that about 50 percent of the content in the sample is in the form of polymeric chains. With further compression, the peaks in the bending modes region are strongly reduced in intensity, suggesting a large fraction of S8 rings in liquid sulfur transformed into polymeric chains. These randomly intertwined chains restrain the nucleation and growth of the crystalline sulfur and, thus, stabilize the amorphous state. The time-resolved ruby fluorescence spectra show the pressure was stabilized at 4.1 GPa after 0.4 s (Supplementary Figs. 3a and 6a). The two peaks in the bending mode region still show weak intensity at 0.4 s (red arrows in Fig. 2a). However, this intensity decreases, and the peaks disappear completely after 0.2 s, demonstrating that the rings have fully converted to chains. The main peak in the stretching mode region became unimodal at 0.6 s, indicating the formation of a purely chain-structured amorphous configuration. The time dependence of Φ is shown in Supplementary Fig. 6b, the Φ value continuously increased with increasing pressure and finally reached 1, indicating the formation of amorphous sulfur composed of purely polymeric chains (Am-SP).

a A ramp compression of liquid sulfur at pressures of 0.05–4.1 GPa in 0.4 s, with a rapid compression rate of ~10 GPa/s. Time-resolved Raman spectra of sulfur collected along the compression pathway. The exposure time is 0.04 s. b A ramp compression of liquid sulfur at pressures of 0.05–4.1 GPa in 8 s, with a much slower compression rate of ~0.05 GPa/s. Time-resolved Raman spectra of sulfur collected along the compression pathway. The exposure time is 0.1 s. SR and SP indicate the integrated area of the Raman signal for the sulfur ring and sulfur chain sections. The gray shaded areas indicate the bending modes of sulfur rings. The remaining bending modes indicated by the red arrows show that, for a brief period just after the pressure reached 4.1 GPa, there are residual S8 rings that have not been converted into polymeric chains. Note that the intensity of the Raman signal is significantly reduced in the amorphous state.

We conducted a control experiment pressurizing liquid sulfur at 403 K up to above 4 GPa with considerably lower compression rates. (see Fig. 2b and complete data in Supplementary Fig. S7). Upon slow compression to 0.34 GPa, the Φ of the liquid increased to 0.3, indicating an increasing number of rings transformed into polymeric chains under pressure. Then, the liquid crystallized into the S-I phase (see the comparison of Raman spectra with S-I under high pressure in Supplementary Fig. 8) the pressure drops to 0.2 GPa with the peaks in the stretching modes region becoming unimodal as the excitation corresponding to the chain stretching modes vanishes, indicating the absence of the polymeric chains in the crystalline state. After solidification is complete, the pressure rises continuously, increasing to 4.1 GPa in 8 s (Fig. 2b), see Supplementary Figs. 6(c) and 6(d) for the variations of pressure and Φ upon slow compression. In Supplementary Fig. 5, we provide a detailed comparison of the Raman spectra of crystalline sulfur and amorphous sulfur at various pressure points during the compression process, illustrating the gradual disappearance of the S8 rings in liquid sulfur under rapid compression. We interpret these two very different outcomes of two compression P–T–t paths as follows: at the slow or “normal” compression rate, the S8-rings liquid freezes into the thermodynamically stable S-I phase in which S8-ring molecules are preserved even though we observe some chain formation at the beginning of the compression in the liquid state (Fig. 2b, spectrum at 1 s). During fast compression the thermodynamic processes are different, yielding very different end results. At the beginning of the fast compression process, liquid sulfur has no time to solidify into the S-I phase, and the liquid is over-pressurized. The pressure acts as the driving force of the crystal growth but on the other hand, it induces their polymerization by breaking the sulfur rings, which effectively restricts the crystal growth. An amorphous product will be formed once the pressure increases above a critical value, where the fraction of polymeric chains is high enough to prevent crystallization. Furthermore, if the compression rate is high enough to let the pressure reach the critical value before the start of crystallization, amorphous sulfur will be produced. It appears that in order to initiate the synthesis of the glassy chain state by rapid compression at 403 K, the critical pressure and critical compression rate must reach above 0.7 GPa and 10 GPa/s, respectively.

To explore the chain glass’ stability range, we conducted several compression experiments at temperatures ranging from 300 to 573 K (see Supplementary Figs. 9 and 10). We note that at around 405 K, liquid sulfur consists of only pure S8 rings, whereas at higher temperatures in LDL/HDL states, liquid sulfur exists as a mixture of rings and chains. Therefore, it is easier to synthesize amorphous chain-like sulfur from the liquid where chains are already present and could serve as “seeds” during the synthesis process. Then, we conducted compression experiments on the supercooled liquid (which also consists of only pure S8 ring), at 300 and 373 K (see Supplementary Figs. 11 and 12). It appears that the supercooled liquid sulfur crystallized during slow compression at 373 K, Supplementary Fig. 11. However, Raman spectroscopy reveals that no ring-opening occurred throughout the compression process, in contrast to the 30% chain formation observed in the slow compression of liquid sulfur at 403 K before crystallization (Fig. 2b). This suggests that lower temperatures hinder ring opening, and requiring a fast compression rate to compensate at a lower temperature. Additionally, a small sulfur droplet supercooled to room temperature inside the pressure chamber was rapidly compressed, producing the Am-SP and achieving room-temperature synthesis of the chain glass (see Supplementary Fig. 12).

Randomly distributed S8 rings can easily undergo ring-opening reactions under pressure, whether they are in a liquid state, a supercooled, supercompressed liquid state, or an amorphous state. Preparing fully chain-structured sulfur glass starting from liquid sulfur requires maintaining the amorphous state and continuously applying pressure to open all rings fully. Therefore, the compression rate is the key factor in entering and maintaining the amorphous state, making it crucial for preparing Am-SP.

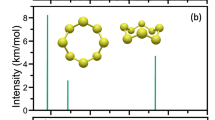

Diagnosis of molecular and crystalline-amorphous structure and the sulfur chain glass (meta)stability

We carried out synchrotron X-ray diffraction (XRD) measurements to study the microstructure of the sulfur glass made of pure-chain molecules. In the XRD experiments we followed identical P–T–t paths to those employed in the time-resolved Raman spectroscopy studies (see above and Fig. 3a) The diffraction pattern of the liquid sulfur ring at 403 K and 0.05 GPa is very distinct and consists of a main prominent peak located at ~1.7 Å−1 and a sideband at ~1.15 Å−1, respectively, Fig. 3a. There are also two considerably weaker peaks at around 3.4 and 4.1 Å−1, Fig. 3a. After rapid compression to above 4 GPa, the spectrum changes dramatically suggesting a structural evolution. The lowest energy peak indicative of a liquid state at ~1.15 Å−1 disappears, while the peak at ~4.1 Å−1 becomes the second most prominent feature, see Fig. 3a. After isobaric cooling to RT, the XRD pattern shows no apparent changes, indicating the non-crystalline nature of Am-SP. Figure 3b shows an XRD pattern collected on Am-SP sample at 4.1 GPa and 298 K, covering a Q range of up to ~9 Å−1. The structure factor S(Q) of Am-SP has three unimodal peaks located at ~2.05, ~4.06, and ~6.3 Å−1, and shows a striking difference to S(Q) of liquid sulfur rings below the λ-transition14 (Fig. 3c). We also note the similarity of S(Q) between Am-SP and reported liquid sulfur chains at 5.6 GPa and 900 K15, which points towards the chain structure of Am-SP (Fig. 3c). The black curve in Fig. 3d shows the pair distribution function (PDF) g(r) obtained by Fourier transformation of S(Q) at 4.1 GPa and RT. These first three peaks in the PDF are centered around ~2.04, ~3.33, and ~4.29 Å. Here, we first look at the PDF of two types of liquid sulfur reported in the literature8. The red curve in Fig. 4d is a pattern of an LDL sulfur below Tλ, which features an unimodal peak at 4.5 Å. The peak in the PDF spectrum at 4.5 Å (red vertical dashed line) is presumably a fingerprint of the S8 molecules previously reported14. The orange curve in Fig. 4d is a pattern of an LDL sulfur above Tλ. After the λ-transition, the original peak becomes bimodal; the peak at 4.5 Å is retained, and a new peak, indicative of the polymeric sulfur chains formation, appears at approximately 4 Å (marked by an orange vertical dashed line). The PDF of ω-S, which is crystalline chain sulfur obtained by quenching high-temperature amorphous sulfur and washing away the ring components with CS2 solvent, is shown by a blue curve in Fig. 4d. The third nearest neighbor is a single peak structure and does not overlap with the position of the fingerprint peak of S8 molecules (4.5 Å). This characteristic is consistent between Am-SP and ω-S, indicating that both have an all-chain structure. Similar to ω-S, Am-SP exhibits a broader peak in the 5–6 Å range, more pronounced than in liquid sulfur, which suggests that the sulfur chains in Am-SP are more ordered than those in the liquid state. We also compared the Raman spectra of Am-SP and ω-S in Supplementary Fig. 13, demonstrating that Am-SP has a similar helical long-chain structure to the ω-S.

a In-situ synchrotron XRD patterns illustrate the formation of Am-SP at 403 K. Sulfur was rapidly compressed at 403 K from 0.05 to 4.1 GPa forming Am-SP and then cooled down to 300 K. Asterisks (*) in a indicate the indices of orthorhombic α-S8 (S-I). b The XRD spectrum of Am-SP at 4.1 GPa and room temperature (RT). The orange curve is the raw integrated intensity, the gray curve is the background (BG) signal contributed by the diamond anvil cell (DAC) and the helium pressure transmitting medium (PTM), and the dark curve is the corrected XRD spectrum of Am-SP. c The comparison of the structure factor S(Q) between Am-SP, liquid sulfur chains, liquid sulfur rings, and a crystalline polymeric chain (ω-S). The scale bar represents a length of 100 μm. d The PDF g(r) comparison between Am-SP, liquid sulfur chains, liquid sulfur rings, and ω-S. The S(Q) and g(r) data of liquid sulfur are from refs. 8,14,15,33. Letters P and R indicate polymeric and ring chain configuration. The orange and red vertical dashed lines mark the two peaks in liquid sulfur at approximately 4 Å and 4.5 Å.

a, b The evolution of the XRD patterns and Raman spectra during the compression of Am-SP at room temperature. c The isobaric variable temperature Raman scatterings of Am-SP under the pressure of 5 GPa. The Am-SP is stable at a wide range of temperatures from 5 to 573 K. d The evolution of the Raman spectra and XRD patterns during the compression of Am-SP at 300 K.

We employed molecular dynamics to simulate the ring-opening mechanism of randomly distributed S8 rings under pressure and calculated the XRD patterns for pure rings, pure chains, and a mixture of rings and chains in amorphous sulfur. The calculated results closely matched the experimentally measured data (Supplementary Fig. 14).

We also studied the thermodynamic stability and photostability of Am-SP, Fig. 4. Upon compression to 25.5 GPa at RT, no structural changes were observed in the XRD patterns and Raman scattering of amorphous sulfur, except for the shift in peak positions and pressure-induced broadening of the Raman peaks, which caused the left shoulder to appear more pronounced (Fig. 4a, b). It is reported that the rings in crystalline α-S8 will open and transform into trigonal chains (S-II) under blue and green laser irradiation within 10 GPa2. In contrast, Am-SP exhibits remarkable photostability under high-intensity irradiation from a 532 nm laser (100 mW in our experiments) at pressures up to 25.5 GPa, suggesting that the Am-SP no longer contains S8 rings. Figure 4c shows the isobaric variable-temperature Raman scattering of Am-SP under the pressure of 5 GPa. The Am-SP remains stable across a wide temperature range, from 5 to 573 K. We also decompressed Am-SP at room and low temperatures and found that it remains (meta)stable down to approximately 3 GPa (see Raman and XRD data in Fig. 4d and Supplementary Fig. 15). The amorphous sulfur recovered at ambient pressure and room temperature contains 57% chains, whereas the sample released at 173 K contains 75%, indicating that lower temperatures favor the retention of chain sulfur. We summarize the experimental results and present them in the phase diagram shown in Fig. 2b. The light red area represents the (meta)stable region of Am-SP, overlapping with the main region typically associated with the S-I phase.

Discussion

The polymorphism that arises from transformations in molecular structures is observed in high-pressure liquids, crystalline solids, and amorphous materials16,17,18,19,20,21. Sulfur is one of the few elements that exhibit a vast panoply of states which often differs in its molecular structure changes. The transformation of molecular composition under different P–T conditions is considered the fundamental cause of sulfur’s phase transitions5,6,7,8. However, our experiments indicate that phase states of sulfur, specifically the stacking of S8 molecules, can also lead to alterations in molecular structure—a phenomenon not commonly observed under compression. During rapid compression, S8 rings in liquid and amorphous states undergo continuous ring-opening reactions at relatively low pressures (~0.3 GPa). In contrast, crystalline S8 rings require substantially higher P–T conditions for ring opening. For instance, the transition from S8 rings to triangular chains occurs at 3 GPa and 673 K (from S-I to S-II), and to squared chains above 36 GPa and at room temperature (from S-I to S-III). The disordered stacking state facilitates the dissociation and polymerization of S8 rings, while the resulting polymeric chains effectively inhibit crystallization and, thus, stabilize the amorphous state. This demonstrates that the molecular structure and phase structure relationship is complex and bidirectional, especially under high P–T conditions. Changes in the molecular structure can initiate phase transitions, but conversely, the occurrence of a phase transition can also drive alterations in molecular structure.

Cyclic ring sulfur (mostly S8) is a copious by-product of petroleum refining and is considered an environmental and storage burden. On the contrary, chain sulfur can potentially be linked by monomers and converted to a great variety of sulfur-based, high-performance plastics with superior optical, thermal, electrical, mechanical, and chemical properties for a vast range of possible applications from infrared imaging devices to alkali metal batteries. The “inverse vulcanization” process22 that opens the sulfur ring with chemical or photoinduced23 methods to form sulfur-based copolymer chains has recently attracted a great deal of attention among materials scientists24,25. Our study demonstrates that, in contrast to crystalline sulfur, a disordered stacking state promotes the dissociation of S8 rings at relatively low pressures. It is reasonable to expect that this will facilitate the subsequent copolymerization of elemental sulfur with unsaturated organic molecules. These findings could pave the way for innovative strategies in inverse vulcanization and other sulfur recycling methodologies.

Thermal quenching or rapid compression of sulfur melt are two effective ways to produce a disordered state. The former leads to the synthesis of the amorphous material but does not break the S8 molecules and the resulting glass reflects the molecular structure of the liquid above. Unlike temperature quenching, fast compression can open the rings and force the ring-to-chain transformation, which leads to the glassy state made up of the atomic chains. Interestingly, the chain glass synthesizes near the P–T area of S-II phase, made of the triangular chains6. This phase can be synthesized from S-I at above 600 K and, therefore, in some sense, represents the structural motif that sulfur adopts upon rapid compression and solidification. This pure-chain sulfur glass opens up opportunities to study the structure and property relationships of various other phases of sulfur and their interactions. The rapid compression method can introduce considerable density changes and drive subtle structure transformations in the melt, resulting in amorphous products with distinct properties. This ability to produce amorphous materials with modified molecular structures or short- to medium-range order underscores a key difference from the temperature quenching process, providing an effective way to synthesize potentially useful materials.

Methods

Experimental process

The starting sulfur powder was supplied by Shanghai Chem. Co. of China Medicine Group, with a purity of 99.9999%. Before all the measurements, the material was kept under a vacuum at a moderate temperature (353 K) for three days to reduce the moisture to a negligible level. In the compression experiments of liquid S, the sulfur sample was contained in a 200-µm-diameter hole in a T301 gasket, and no pressure-transmitting media was used. The gasket itself was pre-indented to ~60 µm thickness and clamped between two diamond anvils. The pressure was measured by the ruby-scale method26.

Raman spectroscopy

Raman experiments were carried out using a spectrometer (SpectraPro HRS-500, Princeton Instruments) coupled with an electron-multiplying charge-coupled device (ProEM 1024B, Princeton Instruments) with a 532 nm wavelength excitation. Raman spectra were collected in a backscattering geometry with an 1800 g/mm grating, and the slit width was 65 µm, corresponding to a resolution of ca. 1 cm−1. The sample image could also be collected through an achromatic lens, which was then focused onto a CCD detector to visually monitor the experiments (see Supplementary Fig. 1). (see ref. 12) We conducted six time-resolved Raman experiments utilizing the dynamic diamond anvil cell (d-DAC) capable of operating at elevated temperatures (see the DAC used for heating experiments in Supplementary Fig. 2). The Raman spectra collected as a function of time allow us to monitor the evolution of the sulfur’s state during the compression process. The laser power was kept below 1 mW (532 nm) to reduce the effect of photochemistry on the sample.

Polymer content (Φ) of sulfur

The polymer content of liquid S is defined by the relative weight fraction of polymeric chains to the total sulfur content. It can be calculated from the in-situ measurement of the Raman stretching spectra by the formula: Φ = SP/(SP + SR)13. The SP (orange-shaded area in Fig. 2) and SR (blue-shaded area in Fig. 2) denote the integrated intensity of the polymeric chains’ and S8 rings’ stretching modes, respectively. At zero pressure, the integrated area of the stretching mode at approximately 460 cm−1 and 471 cm−1 are assigned to the S–S stretching modes of the polymeric chains and S8 rings, respectively. These Raman modes shift as the pressure changes, and the peak positions used for the fit refer to the movement of crystallized sulfur under pressure. The peak fitting analyses are based on Gaussian–Lorentzian peak forms. The method for calculating the polymer content, along with the peaks fitting criteria of the SR and SP are introduced in detail in Supplementary Figs. 4 and 5.

X-ray diffraction

In-situ angle dispersive X-ray diffraction (XRD) measurements were performed at beamline 15U, the Shanghai Synchrotron Radiation Facility (SSRF, China), beamline 4W2, Beijing Synchrotron Radiation Facility (BSRF, China), and beamline 10XU, Super Photon ring-8 GeV (SPring-8, Japan). The collected 2-D images were integrated and subsequently performed with the software FIT2D to obtain plots of intensity versus 2θ27. We carried out two synchrotron XRD experiments at the BSRF and SSRF to monitor the formation of Am-SP at 403 K. We prepared Am-SP in a wide-opening angle DAC using liquid helium as the pressure-transmitting medium and collected the XRD data at SPring-8 under conditions of 4.1 GPa and room temperature. The DAC background was subtracted for the typical integrated XRD patterns. The structure factor, S(Q), was derived from the diffraction pattern of Am-SP, and the pair distribution function, g(r), was obtained by Fourier transforming S(Q) using the algorithm outlined in ref. 28.

Theoretical simulation

Simulations were carried out using molecular dynamics adopting the projector-augmented plane-wave (PAW) method with the Vienna ab initio simulation (VASP) code29,30,31. PAW potentials with a 350-eV energy cutoff were used with the local density approximation (LDA) exchange-correlation functional of Ceperley and Alder, as parameterized by Perdew and Zunger (CA-PZ) for molecular dynamics32. The NPT ensembles were carried out with simulation cells consisting of 256 sulfur atoms using Г-point sampling. The initial structure used was α-S8 with the space group of Fddd. At first, the system was heated to 1000 K for 10 ps to guarantee complete melting and then equilibrated at 403 K and atmospheric pressure for 20 ps. Then, the system was rapid-compressed to 1.9 and 5 GPa and equilibrated for 20 ps, respectively. Finally, the system was recovered to atmospheric pressure and 298 K for 20 ps to examine the stability at atmospheric conditions. See the optimized computational models and molecular dynamics trajectories provided as Supplementary Data 1–3.

Data availability

The data that support the findings of this study are available from the corresponding author upon request. Source data are provided in this paper.

Code availability

The codes that support the findings of this study are available from the corresponding author upon request.

References

Meyer, B. Elemental sulfur. Chem. Rev. 76, 367–388 (1976).

Steudel, R. & Eckert, B. Solid sulfur allotropes. Top. Curr. Chem. 230, 1–79 (2003).

Steudel, R. et al. A new allotrope of elemental sulfur: convenient preparation of cyclo-S14 from S8. Angew. Chem. Int. Ed. 37, 2377–2378 (1998).

Crichton, W. A., Vaughan, G. B. M. & Mezouar, M. In situ structure solution of helical sulfur at 3 GPa and 400 °C. Z. Kristallogr. 216, 417–419 (2001).

Crapanzano, L. et al. Alternating sequence of ring and chain structures in sulfur at high pressure and temperature. Nat. Mater. 4, 550–552 (2005).

Degtyareva, O. et al. Novel chain structures in group VI elements. Nat. Mater. 4, 152–155 (2005).

Fujihisa, H. et al. Spiral chain structure of high-pressure selenium−II′ and sulfur−II from powder X-ray diffraction. Phys. Rev. B 70, 134106 (2004).

Henry, L. et al. Liquid-liquid transition and critical point in sulfur. Nature 584, 382–386 (2020).

Sauer, G. E. & Borst, L. B. Lambda transition in liquid sulfur. Science 158, 1567–1569 (1967).

Zhong, L. et al. Formation of monatomic metallic glasses through ultrafast liquid quenching. Nature 512, 177–180 (2014).

Angell, C. A. Formation of glasses from liquids and biopolymers. Science 267, 1924–1935 (1995).

Su, L. et al. Static and dynamic diamond anvil cell (s-dDAC): a bidirectional remote-controlled device for static and dynamic compression/decompression. Matter Radiat. Extrem 7, 018401 (2022).

Kalampounias, A. G., Andrikopoulos, K. S. & Yannopoulos, S. N. Probing the sulfur polymerization transition in situ with Raman spectroscopy. J. Chem. Phys. 118, 8460–8467 (2003).

Vahvaselkä, K. S. & Mangs, J. M. X-ray diffraction study of liquid sulfur. Phys. Scr. 38, 737–741 (1988).

Liu, L. et al. Chain breakage in liquid sulfur at high pressures and high temperatures. Phys. Rev. B 89, 174201 (2014).

Katayama, Y. et al. A first-order liquid–liquid phase transition in phosphorus. Nature 403, 170–173 (2000).

Mao, H. K. et al. Solids, liquids, and gases under high pressure. Rev. Mod. Phys. 90, 015007 (2018).

Santoro, M. et al. New phase diagram of oxygen at high pressures and temperatures. Phys. Rev. Lett. 93, 265701 (2004).

Wilding, M. C. et al. Structural studies and polymorphism in amorphous solids and liquids at high pressure. Chem. Soc. Rev. 35, 964–986 (2006).

Yan, J. et al. Remarkable stability of γ-N2 and its prevalence in the nitrogen phase diagram. Sci. Rep. 14, 16394 (2024).

Pépin, C. M. et al. Metastable water at several compression rates and its freezing kinetics into ice VII. Nat. Commun. 15, 8239 (2024).

Chung, W. J. et al. The use of elemental sulfur as an alternative feedstock for polymeric materials. Nat. Chem. 5, 518–524 (2013).

Jia, J. H. et al. Photoinduced inverse vulcanization. Nat. Chem. 14, 1249–1257 (2022).

Lee, T. et al. Polymerizations with elemental sulfur: from petroleum refining to polymeric materials. J. Am. Chem. Soc. 144, 5–22 (2022).

Boyd, D. A. Sulfur and its role in modern materials science. Angew. Chem. Int. Ed. 55, 15486–15502 (2016).

Mao, H. K., Bell, P. M., Shaner, J. W. & Steinberg, D. J. Specific volume measurements of Cu, Mo, Pd, and Ag and calibration of the ruby R1 fluorescence pressure gauge from 0.06 to 1 Mbar. J. Appl. Phys. 49, 3276–3283 (1978).

Hammersley, A. P., Svensson, S. O., Hanfland, M., Fitch, A. N. & Hausermann, D. Two-dimensional detector software: From real detector to idealised image or two-theta scan. High. Press. Res. 14, 235–248 (1996).

Qiu, X., Thompson, J. W. & Billinge, S. J. L. PDFgetX2: a GUI-driven program to obtain the pair distribution function from X-ray powder diffraction data. J. Appl. Crystallogr. 37, 678 (2004).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Perdew, J. P. & Zunger, A. Self-interaction correction to density-functional approximations for many-electron systems. Phys. Rev. B 23, 5048–5079 (1981).

Stolz, M., Winter, R., Howells, W. S., McGreevy, R. L. & Egelstaff, P. A. The structural properties of liquid and quenched sulphur II. J. Phys. 6, 3619 (1994). May 16.

Acknowledgements

The authors acknowledge the support of beamline 15U1 in the Shanghai Synchrotron Radiation Facility (SSRF, China), beamline 4W2 in the Beijing Synchrotron Radiation Facility (BSRF, China), and beamline 10XU in the Super Photon ring-8 (SPring-8, Japan). This work is supported by the National Science Foundation of China (Nos. 21627802, 52325203, 21273206, 21803033, and 91963203), Science Challenge Project (No. TZ2016001). E.G., L.S., and H.K.M. acknowledge the financial support from Shanghai Key Laboratory of MFree, China (No. 22dz2260800) and Shanghai Science and Technology Committee, China (No. 22JC1410300).

Author information

Authors and Affiliations

Contributions

L.S., G.Y., E.G., and H.M. conceived the idea of this project; K.S., L.S., C.J., B. L., Z.Z., X.D., X-B.D., H.Y., P.Q., X.Z., and J.Z. performed the experiments; X.D. conducted the molecular dynamics simulations; Z.Z., L.S., K.S., G.Y., E.G. and H.M.contributed to the interpretation of the results. L.S., K.S., G.Y., Z.Z., E.G., and H.M. drafted the paper with contributions from all authors. K.S., X.D., and Z.Z. contributed equally to this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yoshio Kono and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shi, K., Dong, X., Zhao, Z. et al. Sulfur chains glass formed by fast compression. Nat Commun 16, 357 (2025). https://doi.org/10.1038/s41467-024-55028-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-55028-w