Abstract

Developing efficient and sustainable carbon sorbent for mercury vapor (Hg0) capture is significant to public health and ecosystem protection. Here we show a carbon material, namely graphdiyne with accessible sp-hybridized carbons (HsGDY), that can serve as an effective “trap” to anchor Hg atoms by strong electron-metal-support interaction, leading to the in-situ adsorption-coupled-oxidation of Hg. The adsorption process is benefited from the large hexagonal pore structure of HsGDY. The oxidation process is driven by the surface charge heterogeneity of HsGDY which can itself induce the adsorbed Hg atoms to lose electrons and present a partially oxidized state. Its good adaptability and excellent regeneration performance greatly broaden the applicability of HsGDY in diverse scenarios such as flue gas treatment and mercury-related personal protection. Our work demonstrates a sp-hybridized carbon material for mercury vapor capture which could contribute to sustainability of mercury pollution industries and provide guide for functional carbon material design.

Similar content being viewed by others

Introduction

The high-volatile and water-insoluble gaseous elemental mercury (Hg0) is difficult to curb and can migrate long distances by the atmosphere1,2,3,4,5, becoming a globally dangerous pollutant. High concentrations of mercury have been detected in fish, agricultural crops, animals over the world and even in the polar regions6,7. Deposited Hg0 can be biotically converted into methyl mercury (MeHg) with strong lipophilicity8,9,10, which is prone to bioaccumulate in the food chain and eventually brings serious harm to human health by causing nervous and cardiovascular diseases, cancer, and even sudden death. Industrial activities such as coal-fired power generation, non-ferrous metal smelting, cement production and measurement/electronic instruments manufacturing greatly contribute to the release of mercury into environments and have raised total atmospheric mercury concentrations by about 450% above natural levels11,12,13,14. Considering the serious harmful effects of mercury, developing efficient and sustainable mercury vapor removal technologies is mandatory and has attracted a great deal of interest recently.

Standing out from various mercury abatement methods15,16,17,18,19,20,21,22,23,24,25,26,27, adsorption holds great promise due to its low cost, simplicity and effectiveness. The porous structure and environmental friendliness of carbon material makes it a promising candidate for mercury vapor capture. Unfortunately, the weak interfacial bonding with mercury is still the choke point in efficient mercury capture by carbon material. Although introducing ligands with affinity towards mercury such as halogen, sulfur and selenium species can enhance mercury adsorption28,29,30,31, the possible leakage and loss of introduced species (e.g., toxic selenium) during sorbent application and regeneration would cause the performance decline as well as secondary pollution. The aforementioned problems necessitate the search for more efficient, sustainable and environmental-friendly carbon materials for mercury capture. As is known, metal ions (e.g., Hg2+ and Pb2+) can be immobilized on alkynyl groups via soft acid-soft base interactions32,33. Such complexation effect is also the foundation of catalytical hydrochlorination of C2H2 by HgCl2, which is widely applied in the synthesis of vinyl chloride monomer34. Inspired by this chemical nature of sp-hybridized carbon (C≡C), we hypothesized that acetylenic bond-rich carbon materials might have certain adsorption capacity for mercury vapor. However, different from directly adsorption of positively charged Hg2+ via electrostatic attraction and covalent bonding, the adsorption of electrically neutral Hg0 on carbon surface is more challenging. It requires an in-situ Hg0 adsorption-coupled-oxidation process, hardly achieved by traditional carbon materials such as sp2-hybridized (C=C) graphene, which has not been demonstrated over carbon-based sorbents.

To tackle the aforementioned challenges, a carbon material featured by hexagonal pore structure (16.3 Å) and extended π-conjugated carbon skeleton composed of aromatic rings and acetylene linkages, namely hydrogen substituted graphdiyne (HsGDY), was synthesized and utilized for mercury vapor capture. The rapid diffusion of Hg0 and effective interfacial electron transfer to form strongly-bonded Hg greatly boosts the immobilization of gas-phase Hg0 on HsGDY, which is benefited from the large hexagonal pore structure and uneven surface charge distribution of HsGDY. Such in-situ adsorption-coupled-oxidation over HsGDY enables efficient mercury vapor capture with adsorption capacity of 0.71 μg/m2, ~23.66 and 17.75 times as much as graphdiyne (GDY) and activated carbon (AC), respectively. Furthermore, HsGDY can achieve excellent regeneration performance via the adsorption-desorption process accompanied by reversible electron transfer between Hg and HsGDY. More encouraging is its adaptability to the complex industrial gas conditions such as high SO2 content and temperature fluctuation. We demonstrate that HsGDY has excellent Hg0 capture ability and the in-situ adsorption-coupled-oxidation over such sp-hybridized carbon material may offer more outstanding answers and provide guide for Hg0 capture as well as carbon material design, which attracts attention in future.

Results

The theoretically performance advantage of HsGDY

The traditional sp2-hybridized carbon (C=C) materials such as graphene (GE) show the common characteristics of uniform surface charge distribution, which might have weak charge transfer interaction with mercury atom. Especially, the newly emerged GDY is a two-dimensional planar periodic carbon allotropy formed by the direct connection of 1,3-diyne bonds (sp-hybridized carbon) and benzene rings (sp2-hybridized carbon), which has a triangular hole structure composed of 18-C atoms with the inscribed circle diameter of about 5.46 Å as shown in Supplementary Fig. 1a. GDY with non-uniform surface charge distribution has superior charge transfer properties35,36,37,38,39,40,41,42,43,44, possessing the potential for Hg0 adsorption. Nevertheless, the atomic diameter of the mercury atom (3.42 Å) is close to the pore size of GDY, which might impact the mercury mass transfer and accessibility of mercury binding sites. HsGDY is a carbon-rich polymer, with unit composed of 42-C hexagons by connecting six benzene rings through butadiyne linkages (−C≡C−C≡C−)45,46,47 as shown in Fig. 1a. Different from GE and GDY, HsGDY has lower atom density, larger pores (16.3 Å) and more sp-hybridized carbons in the pores, which might lead to higher Hg0 adsorption capacity. Density functional theory (DFT) calculations were employed to reveal the adsorption sites and evaluate the effectiveness of HsGDY for Hg0 capture. The atomic models and configurations of different typical carbon materials such as HsGDY, GDY, GE, and carbon nanotube (CNT) are displayed in Supplementary Fig. 2. The possible adsorption configurations and adsorption energies of the Hg atom on HsGDY, GDY, GE and CNT at different sites are displayed in Supplementary Tables 2–5. It can be seen that the calculated adsorption energies of Hg0 onto HsGDY, GDY, GE, and CNT for the optimal adsorption configuration are 0.005 eV, −0.082 eV, 0.102 eV, and −0.398 eV, respectively. The calculated Hg0 adsorption energy is somewhat related to but not perfectly consistent with the Hg0 adsorption performance. Adsorption is a complex process that involves many factors such as pore characteristics and surface chemical properties beyond just the calculated adsorption energy. For HsGDY, the Hg atom tends to be adsorbed at the side sites of acetylenic bond in plane with the adsorption energy of 0.005 eV. Overall, the adsorption energy of Hg0 onto HsGDY is not negative but close to 0, indicating the relative stability and potential for Hg0 adsorption over HsGDY with energy input.

a The molecular structure of HsGDY; b The 2D charge distribution of HsGDY (The value 0 to 1 implies the probability of electron localization); c HsGDY adsorbs multiple mercury atoms at the same quality (72 carbon atoms); d The atomic model and configuration of 2HsGDY; e The diffusion path of Hg atoms in 2HsGDY; f 2HsGDY adsorbs multiple mercury atoms (left figure for top view and right figure for side view); g HRETM image of fresh HsGDY (inset for the magnified image); h Raman spectra of fresh HsGDY; i C1s XPS spectra of fresh HsGDY.

The two-dimensional charge distribution of HsGDY and GDY based electron localization function (ELF) results are displayed in Fig. 1b and Supplementary Fig. 1b, respectively. It is implied that the charge distribution of HsGDY is more uneven compared to GDY. We quantitively compare the charge non-uniformity of GDY and HsGDY as shown in Supplementary Fig. 3. It can be seen that the charge non-uniformity (σ) of HsGDY is obviously higher than that of GDY. This uneven charge distribution of HsGDY might induce electron redistribution between the HsGDY and adsorbed Hg atom, leading to a strong interaction between them. The uneven charge distribution characteristics of HsGDY might be attributed to that the large pore structure leads to lower local atomic density and resultantly uneven distribution of sp-hybridized and sp2-hybridized carbons in the local space. Additionally, in a single pore, HsGDY with hexagonal pore structure has 12 sp-hybridized carbons which are double that of GDY with triangular hole structure. We calculated the adsorption of multiple Hg atoms by HsGDY and GDY composed of 72 carbon atoms (the same quality), respectively. As shown in Fig. 1c and Supplementary Fig. 1c, HsGDY with large hexagonal pore structure can ultimately adsorb 6 Hg atoms through the in-plane acetylene bond side mode in one single unit space, while GDY only adsorbs 2 Hg atoms. This implies that the unique architecture of HsGDY improves the accessibility of sp-hybridized carbons that serve as binding sites for mercury.

Furthermore, we simulated the adsorption of Hg atom over multi-layer HsGDY and GDY based on DFT calculation since the ideal single-layer material is normally scarce as a result of π-π interactions and Van der Waals forces. As shown in Fig. 1d and Supplementary Fig. 1d, HsGDY tends to exist stably in an “AB” stacking configuration with an interlayer distance of 0.420 nm (2HsGDY). While the GDY layers are stacked through Van der Waals forces and π-π interactions, forming the most stable “ABC” stacking structure with an interlayer distance of 0.365 nm (3GDY). For 2HsGDY, the Hg atom also tends to be adsorbed at the side sites of acetylenic bond in plane with the adsorption energy of −0.008 eV (Supplementary Table 6). It is relatively difficult for Hg atom to be adsorbed in the interlayer of 2HsGDY. This indicates that the rapid diffusion of Hg atoms can be achieved between layers of HsGDY (Fig. 1e). While for 3GDY, the Hg atom tends to be adsorbed at the center of triangular hole of GDY as well as the interlayer of 3GDY (Supplementary Table 7). The diffusion of Hg atoms between layers of 3GDY should overcome the effect of interlayer adsorption. In addition, the pore diameter of GDY (5.46 Å) is much smaller than HsGDY (16.3 Å). The staggered “ABC” stacking structure of 3GDY would result in a tortuous diffusion path of Hg atoms as shown in Supplementary Fig. 1e. Hence, the diffusion resistance of Hg atoms in 3GDY is larger compared to 2HsGDY, which is not conducive for the rapid diffusion of Hg atoms between carbon layers. The calculations of the adsorption of multiple Hg atoms by 2HsGDY and 3GDY indicate that 2HsGDY can adsorb 16 Hg atoms (Fig. 1f) while 3GDY only adsorbs 4 Hg atoms (Supplementary Fig. 1f) under the same quality conditions. The aforementioned analysis indicates that HsGDY theoretically has better Hg0 adsorption performance than other carbon materials.

The physico-chemical structure of as-prepared HsGDY was investigated. The SEM image results show that HsGDY is formed by the interconnection of nanospheres (Supplementary Fig. 4a). The interlayer distance of HsGDY is about 0.416 nm, which is the characteristic value for the multilayer HsGDY (Fig. 1g)45. The Raman spectra for HsGDY as shown in Fig. 1h exhibit four prominent peaks at 1358 cm−1, 1579 cm−1, 2021 cm−1, and 2193 cm−1 due to its rich aromatic rings and acetylenic bonds47. The C1s peaks of HsGDY (Fig. 1i) can be deconvoluted into four subpeaks of C-C (sp2) at 284.6 eV, C-C (sp) at 285.2 eV, C-O at 286.5 eV and C=O at 288.3 eV, respectively47. The ~1:1 area ratio of C-C (sp2) to C-C (sp) is consistent with the typical carbon skeleton of HsGDY. The pore structure of HsGDY was further studied by nitrogen adsorption-desorption experiments. It can be seen from Supplementary Fig. 4b that the adsorption quantity of N2 is sharply increased at very low P/P0 due to a mass of single-layer adsorption of N2 in the micropores. The specific surface area (SSA) calculated by Brunauer–Emmett–Teller (BET) method for the sample is 160.3 m2 g−1. The pore size distribution of HsGDY is centered at about 0.8 nm (Supplementary Fig. 4c), indicating a highly ordered porous structure in HsGDY. To summarize, the unique architecture, acetylenic bond structure, and uneven charge distribution characteristics of HsGDY might endow it with potential Hg0 capture performance.

The practical applicability of HsGDY

The applicability of HsGDY for gas-phase Hg0 capture was examined under N2 flow containing 340 μg m−3 Hg0 by a laboratory-scale fixed-bed reaction system (Supplementary Fig. 5 and Supplementary Table 1). The performances of GDY, CNT, GE, and AC were also explored for comparative analysis. As displayed in Fig. 2a, the Hg0 adsorption efficiency of HsGDY exceeds 90%, which is apparently superior to that of GDY, CNT, GE, and AC. The adsorption capacity during 90 min was determined as shown in Fig. 2b. HsGDY shows the highest adsorption capacity of 113.5 μg g−1 among the tested samples, which is ~17 times as much as GDY. The specific surface areas of GDY, CNT, GE, and AC were determined to be 210.7, 527.9, 38.8, and 1583.3 m2 g−1, respectively. The variation of Hg0 adsorption capacity with average pore volume and pore width is displayed in Supplementary Fig. 6. As shown in Fig. 2b, HsGDY also exhibits the highest value of Q/SSA (adsorption capacity divided by SSA), which is significantly higher than that of other samples. Above results imply that the pore structure of the material is not a decisive factor for Hg0 adsorption and the specific mechanism must be existed for the Hg0 capture over HsGDY.

a The Hg0 adsorption performances of different carbon sorbents (dash line indicates time point for gas flow passing through sorbent); b The adsorption capacities and Q/SSA of different carbon sorbents; c The experimental data analyzed by pseudo-second order model; d The Hg0 adsorption performance of HsGDY in the temperature range of 50–200 °C; e The effect of SO2 on Hg0 adsorption over HsGDY; f The performance of HsGDY during 8 adsorption-desorption cycles; g Comparison of HsGDY with other reported carbon sorbents (modification elements in the brackets) (see Supplementary Table 8 for the details).

The 50%-breakthrough curve of HsGDY for Hg0 capture is shown in Supplementary Fig. 7 and the corresponding adsorption capacity curve is displayed in Fig. 2c. In order to elucidate the interaction between Hg0 and HsGDY, the experimental data was analyzed by pseudo-first-order model (Supplementary Fig. 8a), pseudo-second-order model (Fig. 2c) and Weber-Morris model (Supplementary Fig. 8b), respectively. As can be seen, the correlation coefficient (R2) for the pseudo-second-order model describing the chemical adsorption nature is 0.99999, which is higher than that for the pseudo-first-order model (external mass transfer) and Weber-Morris model (intra-particle diffusion)48. This result implies that the adsorption of Hg0 onto HsGDY is mainly a chemisorption process. The formed mercury compounds on HsGDY surface were further examined by the temperature-programmed desorption of Hg (Hg-TPD) analysis. As shown in Supplementary Fig. 9a mercury desorption peak emerges at around 320 °C for HsGDY which can be ascribed to the decomposition/desorption of strongly bonded mercury species, e.g., oxidized mercury49. This result demonstrates an interaction between Hg0 and HsGDY with the occurrence of charge transfer. While for GDY, a mercury desorption peak at 160 °C is observed, which can be attributed to the weakly bonded mercury species. Moreover, the adsorption capacity of HsGDY at equilibrium is determined to be 1.27 mg g−1, which is superior to GDY and most of the other reported carbon sorbents such as the commercial Br-modified carbon sorbent DARCO® Hg-LH EXTRA (0.47 mg g−1)50 (Fig. 2g and Supplementary Table 8).

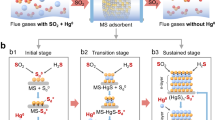

Furthermore, HsGDY might have broad applicability for Hg0 capture due to its excellent SO2 resistance and regeneration property. As shown in Fig. 2d, the Hg0 adsorption efficiency of HsGDY is stable over around 90% in the temperature range of 50–200 °C. The slight decrease of adsorption efficiency at 200 °C is attributed to that the Hg0 desorption will prevail over the adsorption at high temperature, which is verified by the Hg-TPD result as shown in Supplementary Fig. 9. Additionally, we adopted simple thermal treatment to regenerate the Hg-laden HsGDY. As shown in Fig. 2f, the Hg0 adsorption efficiency does not decline significantly in the 8 cycles of Hg0 capture and regeneration (thermal treatment at 400 °C under N2 stream), which facilitates its reusability and cost reduction. Considering that SO2, NO, and H2O are typical components in real flue gas and might influence Hg0 removal, we further examined the Hg0 adsorption performance of HsGDY in the gas stream containing different contents of SO2/NO/H2O. As shown in Supplementary Fig. 10, NO slightly promotes (at least not inhibitory) the Hg0 adsorption over HsGDY. H2O presence slightly decreases the Hg0 removal efficiency (from 97.4% to 87.7% under 3% vol. H2O) over HsGDY, which can be attributed to the competitive adsorption between Hg0 and H2O over the adsorption sites. As shown in Fig. 2e, the Hg0 removal efficiency of HsGDY maintains at around 97.5% under 600–2400 ppm SO2 conditions. As shown in Supplementary Fig. 11, the adsorption energies of the SO2 molecule at different adsorption sites over HsGDY are all nearly 3.5 eV, which is obviously higher than that of Hg atom (~0 eV). Above exciting results manifest that Hg0 is preferentially absorbed on HsGDY, leading to its excellent anti-SO2 ability.

From the viewpoint of real application, the Hg0 capture by HsGDY can be coupled to the dust removal system currently equipped in coal-fired power plants. Due to the excellent Hg0 capture performance of HsGDY, we proposed an improved bag filter system to efficiently capture Hg0 from flue gas. As shown in Supplementary Fig. 12a, HsGDY can be injected into the flue gas duct upstream the separate bag filter after dust removal. Hg0 in the gas stream will be immobilized on the HsGDY filter cake formed on the filter medium. The Hg-laden HsGDY can be recycled by dust cleaning such as mechanic vibration and then regenerated by thermal treatment. Specially, the aforementioned filter unit for Hg0 capture can be coupled into an integrated bag filter by partition design. As shown in Supplementary Fig. 12b, the filter medium can be modified by HsGDY and then immobilizes Hg0 from flue gas. The fly ash can be removed from the filter medium by reverse airflow (hot) cleaning. In the meantime, the desorption of mercury species will occur and the concentrated mercury is recovered by condensation which can be applied to industrial production. Such technical route requires the good high-temperature resistance performance of the filter medium.

We selected two typical commercial filter mediums i.e., glass-chemical compound fibers filter material (denoted as FMS) and polytetrafluoroethylene (PTFE), and examined their Hg0 adsorption performances without and with HsGDY modification. Briefly, HsGDY was first dispersed in deionized water by ultrasonic treatment to form a suspension. Then HsGDY was attached onto the filter medium via a vacuum filtration method. The macroscopic images and SEM images of the filter mediums are displayed in Fig. 3a and Fig. 3b, respectively. It can be seen from Fig. 3b that the HsGDY nano-particles with the layer thickness of ~ 115 nm are successfully coated on the surface of FMS fibers. The pictures of the different filter mediums placed in the quartz tubes are shown in Fig. 3c. The simulated flue gas containing 340 μg m−3, 600 ppm SO2, 600 ppm NO, 5% vol. O2, 3% vol. H2O and balanced N2 passed through the filter mediums and the outlet Hg0 concentration was detected. The Hg0 adsorption performances of different filter mediums are displayed in Fig. 3d. It can be seen that non-modified FMS and PTFE are not capable of Hg0 capture. However, HsGDY-FMS and HsGDY-PTFE show excellent Hg0 removal abilities. ~96% and ~91% of Hg0 can be respectively removed by HsGDY-FMS and HsGDY-PTFE. This result indicates that the Hg0 removal performance of filter medium can be greatly enhanced when HsGDY is attached to the filter medium, envisioning the possibility that the Hg0 capture by HsGDY can be coupled to the dust removal system currently available.

a The macroscopic images of HsGDY-FMS, HsGDY-PTFE, FMS, and PTFE; b The SEM images of HsGDY-FMS with different magnifications (the two sub-figures at top indicate the fiber structure of HsGDY-FMS; the sub-figure at the bottom left corner indicates the thickness of HsGDY coating layer labeled by 107.9 and 123.9 nm; the sub-figure at the bottom right corner indicates the particle structure of HsGDY over FMS fiber); c The pictures of the different filter mediums placed in the quartz tubes; d The Hg0 adsorption performances of different filter mediums; e The schematic diagram of mercury capture by HsGDY in the production workshop and mercury recycle.

Additionally, mercury is generally utilized in the manufacturing of scientific measurement instruments (such as barometers, thermometers, etc.) and electronic products. Extensive and long-term exposure to mercury in the production workshop will result in acute/chronic mercury poisoning and cause diseases of nerve, respiration, digestion, and urinary systems. There remains high concern for the populations with occupational exposure to mercury. Strengthening indoor ventilation and personal protection is of great significance to meet the occupational health requirements. Based on the above studies, HsGDY can be applied to the personal protective equipment (PPE) and ventilation system to prevent the workers from mercury exposure and remove the mercury vapor in the exhaust gas, as schematically illustrated in Fig. 3e. Superior to sulfur and selenium compounds with high mercury uptake capacity while high toxicity51, environmental-friendly pure carbon material, namely HsGDY, can be directly utilized in the filter layer of mask. HsGDY can be also attached to the filter medium in ventilation duct to remove mercury vapor from the gas stream. In addition, the mercury can be desorbed from the mercury-laden HsGDY by acid washing. The leached mercury in the solution can be effectively precipitated by Na2S and the formed HgS (small particles as shown in Supplementary Fig. 13) can be recovered and processed into raw materials for industrial production again. Hence, HsGDY is a sustainable carbon material with ultrahigh efficient mercury vapor capture and promising application prospects.

In-situ adsorption-coupled-oxidation mechanism

To better understand the ultrahigh efficient mercury vapor capture over HsGDY, the interaction mechanism between Hg0 and HsGDY is elucidated in detail. As displayed in Supplementary Fig. 14a, the Raman spectra of HsGDY after Hg0 adsorption (Hg/HsGDY) presents a shift in peak position and an increase in peak intensity compared to HsGDY, indicating the formation of coordination bonds between carbon atoms of conjugated diyne linkers (2021 cm−1 and 2193 cm−1)52,53,54 in HsGDY and Hg atoms. The increase in the intensity of the acetylene bond peak may be attributed to the Raman enhancement effect of Hg. The Hg 4f XPS analysis of Hg/HsGDY as shown in Supplementary Fig. 14b further reveals that gas-phase Hg atoms are successfully adsorbed on the HsGDY surface, mainly present in the form of partially oxidized state55. The morphology structure of Hg/HsGDY as shown in HRTEM image (Fig. 4a) and the corresponding energy dispersive X-ray spectroscopy (Supplementary Fig. 15 and Supplementary Fig. 16) indicate that the Hg atoms adsorbed onto HsGDY surface exist in a highly dispersed state. It can be further confirmed by the HAADF-STEM results that the isolated Hg atoms (bright) are clearly observed on the surface of spent HsGDY (relatively dark) as shown in Fig. 4b (Supplementary Fig. 17 for fresh HsGDY).

a The high-resolution transmission electron microscopy (HR-TEM) image of Hg/HsGDY; b The HAADF-STEM image of Hg/HsGDY (yellow circles for Hg atoms); c The HAADF-STEM image and corresponding element mapping images of C (red) and Hg (green); d The charge density difference of Hg/HsGDY (depletion and accumulation spaces are revealed in blue and yellow, respectively; the arrow represents the direction of electron transfer); e The two-dimensional projection of differential charge density contours of Hg/HsGDY; f The PDOS comparison for Hg 5d, Hg 6s, C 2p, and H 1s orbitals within Hg/HsGDY; g The charge density difference of Hg/GE (The arrow represents the direction of electron transfer); h The two-dimensional projection of differential charge density contours of Hg/GE; i The PDOS comparison for Hg 5d, Hg 6s, and C 2p orbitals within Hg/GE; j The molecular dynamic simulation results of Hg adsorption over HsGDY (inset figures for the adsorption configurations with time and the resultant electron transfer); k The molecular dynamic simulation results of Hg adsorption over GE (inset figures for the adsorption configurations with time and the resultant electron transfer).

DFT calculations were conducted to further reveal the Hg atom adsorption behavior and the binding mechanism over sp-hybridized carbon (HsGDY) compared to sp2-hybridized carbon (GE). The charge density difference in Fig. 4d indicates that significant electron redistribution occurs between sp-hybridized carbon and adsorbed Hg atom, in which electrons are accumulated on sp-hybridized carbon and depleted around the Hg atom. In detail, the Hg atom loses 0.27 e− which is transferred to sp-hybridized carbon, thus existing in a partially oxidized state. This is consistent well with the XPS results of Hg 4f. The two-dimensional projection of differential charge density contours of Hg/HsGDY results also clearly illustrate this electron transfer behavior between Hg atom and sp-hybridized carbon (Fig. 4e). Additionally, the calculated partial density of states (PDOS) exhibits an orbital overlap between H 1s, Hg 5d, Hg 6s, and C 2p below the Fermi energy level (~0 eV) for the adsorption configuration of Hg/HsGDY as shown in Fig. 4f. However, no obvious electron transfer and orbital overlap between Hg atom and sp2-hybridized carbon can be detected for the adsorption configuration of Hg/GE as shown in Fig. 4g, Fig. 4h and Fig. 4i, demonstrating the weak interfacial bonding between mercury and sp2-hybridized graphene. Moreover, the Ab initio molecular dynamics (AIMD) simulation results as displayed in Fig. 4j, Fig. 4k, and Supplementary Fig. 18 clearly show the adsorption process of Hg atom from free state to stable adsorption state, accompanied with significant electron transfer especially for HsGDY. Additionally, the adsorption of Hg atom onto HsGDY can reach a relatively stable state with smaller energy fluctuations as shown in Supplementary Fig. 19.

Above results manifest that HsGDY with accessible sp-hybridized carbons can serve as an effective “trap” to anchor Hg atoms by strong electron-metal-support interaction, leading to the in-situ adsorption-coupled-oxidation of Hg. The adsorption process benefits from the unique architecture of HsGDY as previously discussed: the large hexagonal pore structure and “AB” stacking structure of HsGDY can facilitate the rapid diffusion of Hg atoms across the sorbent and make the mercury binding sites highly accessible. The oxidation process is driven by the surface charge heterogeneity of HsGDY which can itself induce the adsorbed Hg atoms to lose electrons and present a partially oxidized state. The favorable environment with convenient mass transfer channels and surface charge heterogeneity promotes mercury diffusion and electron exchange, thus enhancing the mercury binding ability of HsGDY. The Hg0 adsorption onto traditional carbon material is primarily due to the physical adsorption determined by the porous structure of carbon material. The interfacial bonding of Hg0 with the carbon surface is generally weak. The electron transfer between adsorbed Hg0 and carbon material can enhance the Hg0 immobilization on the carbon surface, which is hardly achieved by traditional sp2-hybridized graphene with uniform surface charge distribution. Although GDY is also a sp-hybridized carbon material similar to HsGDY, it is defeated by HsGDY for mercury capture due to its constrained mass transfer and relatively lower surface charge heterogeneity. Moreover, different from toxic sulfur and selenium compounds, the environmental-friendly HsGDY can be applied to personal protective equipment, greatly broadening its application fields. Overall, an in-situ Hg0 adsorption-coupled-oxidation process can be achieved by HsGDY, which enables its efficient mercury vapor capture and thus effectively solves the bottleneck problem of the weak interfacial bonding between mercury and traditional carbon sorbents.

Acting as the reverse process of adsorption, it can be expected that there might be a “reduction-coupled-desorption” process for Hg desorption. We first calculated the Hg atom desorption barrier of HsGDY through theoretical calculations. As shown in Fig. 5a, the desorption of Hg atoms requires overcoming certain energy barriers due to the electronic interaction between Hg and HsGDY and HsGDY can be restored to the original state after Hg desorption. This is consistent well with the XPS Hg 4f and Raman results (Fig. 5b and Fig. 5c). The characteristic peak of 104 eV ascribed to partially oxidized Hg is not detected in the regenerated HsGDY sample. Additionally, the Raman spectroscopy results show that the characteristic peaks in the regenerated HsGDY attributed to aromatic rings and acetylenic bonds are still retained and basically restored to the state of fresh sample. Since the mercury analyzer can only detect the elemental mercury, we employed Ontario Hydro Method (OHM) to identify the desorbed mercury species during thermal regeneration. The results displayed in Supplementary Fig. 20 show that the desorbed mercury species are primarily present in the form of elemental mercury. Hence, the adsorbed Hg atoms that have lost electrons to HsGDY recapture the electrons and are released to the gas stream in the form of elemental mercury by heat treatment, which can be further verified by the molecular dynamic simulation results of Hg desorption over HsGDY at 300 °C as shown in Fig. 5d. Therefore, HsGDY can achieve excellent regeneration performance via the adsorption-desorption process accompanied by reversible electron transfer between Hg and HsGDY as shown in Fig. 5e. Moreover, as shown in Supplementary Fig. 21a and b, the regenerated HsGDY still exhibits a porous structure and its area ratio of C-C (sp2) to C-C (sp) is similar to that of fresh sample, indicating the structural stability of the carbon skeleton of HsGDY. The regeneration performance of sorbent is essential to its real application. Considering that the Hg0 adsorption efficiency of HsGDY does not decline significantly in the 8 cycles of Hg0 capture and regeneration, it is indicated that HsGDY has excellent regeneration property and application potential for mercury vapor capture.

a The Hg desorption barrier of HsGDY; b The XPS Hg 4f spectrum of Hg/HsGDY and HsGDY after regeneration; c The Raman spectra of HsGDY, Hg/HsGDY and HsGDY after regeneration; d The molecular dynamic simulation results of Hg desorption over HsGDY (inset figures for the adsorption configurations with time and the resultant electron transfer); e The schematic diagram of Hg0 adsorption-desorption process over sp-hybridized HsGDY (Hgδ+ denotes adsorbed Hg with partially oxidized state).

Discussion

Mercury poses serious hazards to the natural environment and public health due to its high toxicity, long atmospheric residence time, and bio-enrichment. Hence, developing efficient and sustainable mercury vapor removal technologies receives extensive attention. Carbon material sorbent exhibits high potential for mercury capture due to its porous structure and environmental friendliness. However, traditional carbon material cannot fulfill practical requirements for efficient elemental mercury capture due to its weak interfacial bonding with mercury. Owing to the large hexagonal pore structure, “AB” stacking structure and surface charge heterogeneity of HsGDY, HsGDY with accessible sp-hybridized carbons can realize an in-situ adsorption-coupled-oxidation of gas-phase elemental mercury, which enables its efficient mercury vapor capture and thus effectively solves the abovementioned bottleneck problem. The rapid diffusion of Hg0 and effective interfacial electron transfer to form adsorbed Hg with partially oxidized state greatly boosts the immobilization of gas-phase Hg0 on HsGDY, which has not previously been accessed in another carbon material. Furthermore, its adaptability to high SO2 content and excellent regeneration performance greatly broadens the applicability of HsGDY in diverse scenarios such as flue gas treatment and mercury-related personal protection. In summary, the findings of this work demonstrate a carbon material for protecting human beings from the hazards of mercury pollution and contributing to the sustainability of mercury pollution industries in the post-Minamata Convention era.

Methods

Synthesis of HsGDY. HsGDY powder was synthesized with a revised method through a classic in situ cross-coupling reaction of triethynylbenzene on copper foil as support in pyridine. In details, the cleaned copper foil was added to a three-necked flask along with 100 mL of pyridine. Subsequently, the 1,3,5-triethynylbenzene dissolved in 100 mL of pyridine was transferred to a constant-pressure dropping funnel and added dropwise to the three-necked flask at a rate that allowed the solution to be fully introduced within ~4 h. The reaction was then conducted at 100 °C under light shielding for 5 days. The obtained mixture was filtered under vacuum to obtain a yellow-brown powder. This powder was centrifuged with water, ethanol, and dimethyl sulfoxide (DMF) until the supernatant was colorless. After drying, the powder was refluxed in 2 M HCl at 80 °C for 6 h. The mixture was then washed with pure water until it reached a pH of 7. Subsequently, it was refluxed in 2 M sodium hydroxide solution at 80 °C for 6 h and washed with ultrapure water until it reached neutral again. The mixture was then centrifuged with water, ethanol, and DMF until the supernatant was colorless. The resultant product was dried under vacuum at 60 °C for 12 h. Under Ar atmosphere, the product was heated in a tubular furnace at a rate of 5 °C min−1 to 400 °C and calcined for 2 h to obtain a tawny powder, which is HsGDY. All the chemicals (analytical grade) were purchased from Sinopharm Chemical Reagent Co., Ltd and used without further purification. Ultrapure water was used in all the experiments.

Structure characterization. High-resolution transmission electron microscopy (HR-TEM) images of the typical samples were obtained on a Tecnai G2 F30 apparatus at an accelerating voltage of 200 kV. High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images were obtained on the aberration-corrected cubed FEI Titan Cubed Themis G2 60–300 operated at 300 kV with cold filed-emission gun and double hexapole Cs correctors (Thermo Fisher, USA). X-ray photoelectron spectroscopy (XPS) analysis was performed on a Thermo ESCALAB 250XI multifunctional imaging electron spectrometer, using monochromatic Al K radiation (1486.6 eV) operating at an accelerating power of 15 kW. The binding energy was calibrated using a C 1s peak at 284.8 eV as standard and quoted with an accuracy of ±0.1 eV. Raman spectroscopy were used to characterize molecular structure of the prepared materials. The Raman spectra were obtained by excitation at 532 nm using Raman Spectrometer (LabRAM HR JY-Evolution, 532 nm). Nitrogen adsorption/desorption measurements were recorded at 300 °C using a Micromeritics ASAP2020 gas-sorption system.

Computational details. All calculations using DFT in this work were carried out by Vienna ab initio simulation package (VASP 5.4.1)56. Exchange-correlation functions are taken as the generalized gradient approximation (GGA) in the form of Perdew–Burke–Ernzerhof (PBE)57. The projector augmented wave (PAW) method was used to replace the pseudopotential of inner core electrons and nucleus with the valence electrons58. The Kohn-Sham electron wave functions were expanded using the plane-wave functions with an energy cutoff of 400 eV. The optimization was considered convergence and each atom would be fully relaxed until the spring force between adjacent images was less than 0.05 eV Å−1. The total energy change upon two steps for the electronic self-consistent field iteration was less than 1E–4 eV.

Single-layer HsGDY and GDY was simulated by a repeated slab model with a 1 × 1 supercell. For the HsGDY (Supplementary Fig. 2a), the calculated lattice constants are a = b = 16.38 Å and c = 20.00 Å with α = β = 90 and γ = 120. For the GDY (Supplementary Fig. 2b), the calculated lattice constants are a = b = 9.46 Å and c = 20.00 Å with α = β = 90 and γ = 120. For the graphene (Supplementary Fig. 2c), the calculated lattice constants are a = b = 9.87 Å and c = 20.00 Å with α = β = 90 and γ = 120. For SWCNT (Supplementary Fig. 2d), the calculated lattice constants are a = b = 32.00 Å and c = 4.92 Å with α = β = 90 and γ = 120. The diameter of the SWCNT is 1.49 nm (consistent with experiments) and the spiral direction is along the c-axis. The replicas of layers were separated by a vacuum layer of 15 Å along the z-direction, which led to negligible interactions between the research system and their mirror images. Meanwhile, the 3 × 3 × 1 k-point meshes in Brillouin zone was sampled for structure optimization and electronic property according to the Monk Horst−Pack scheme59. As for the adsorption case of atoms and bulk, the binding energy (Ef) was defined as

where EHsGDY, EHg, and EHsGDY−Hg are the total energies of the bulk HsGDY substrates before formation and isolated free Hg atoms in its bulk form, and the total energy of Hg atoms inserted in HsGDY monolayer, respectively. All three types of energies were derived from the self-consistent field calculations using the same calculated setting parameters. With this definition, a negative value indicates an exothermic adsorption. The more negative this value is, the more stable configuration has been proved.

Charge transfers were calculated using the Bader charge analysis method. In addition, the climbing images nudged elastic band (CL-NEB)59 and dimer method60 were used to carry out the transition state (TS), which is further verified by means of frequency calculations. The number of inserting image was chosen by the formula “dist/0.8” derived from the difference-comparing scripts called dist.pl embedded in the transition state tools (VTST) software package compiled in VASP.

The Ab initio molecular dynamics (AIMD) simulations were performed under NVT canonical ensemble with a target temperature by the Nose-Hooverthermostat. The Verlet algorithm were used for integration and the time-step was 2 fs. The simulation time for each MD trajectories was 7 ps and the thermodynamic quantities of the system were statistically averaged in the last 2 ps.

The relative Gibbs energy of Hg as well as HsGDY with regard to the reaction of H+ + e− → 1/2 H2 was calculated to compare their abilities to lose electrons (Supplementary Fig. 22). The Gibbs free energy (∆GH*) is defined as follows: ∆GH* = ∆EH* + ∆EZPE − T∆S61, where ∆EH*, ∆EZPE, ∆S are the adsorption energy of hydrogen atom on surface, the zero point energy and the entropy change after the adsorption of hydrogen atom, respectively. ∆EH* is calculated by ∆EH* = EH/slab − Eslab − 1/2EH2, where EH/slab, Eslab are the energies of hydrogen atom adsorbed model, bare model, and EH2 is the energy of hydrogen molecule isolated in vacuum. The zero-point energy change ∆EZPE is obtained from vibrational frequency calculation. The entropy (S0) of the molecular hydrogen is used in the gas phase at standard conditions (1 bar of H2, pH = 0, and temperature T = 300 K). The entropy of the adsorbed hydrogen atom is negligible because the hydrogen atom is bound to the surface. Hence, the ∆S can be estimated by −1/2 × S0, and T∆S is about −0.2 eV at T = 300 K according to the reported literature62.

Comparing the charge non-uniformity of GDY and HsGDY. According to the electron localization function (ELF) results as shown in Fig. 1b and Supplementary Fig. 1b, we quantitively compared the charge non-uniformity of GDY and HsGDY by borrowing the concept of dispersion degree and also considering the mercury binding sites (the center of triangular hole for GDY and the side sites of acetylenic bond in plane for HsGDY). A high ELF value (0–1) implies a high probability of electron localization. The sampling points are uniformly located at the circle with radius of r and centered in the mercury binding site as shown in Supplementary Fig. 3. The calculation method is as follows:

where \({\sigma }_{r}\) indicates the charge non-uniformity; \({X}_{i,{r}}\) represents the ELF value of sampling point; \({X}_{r}\) represents the average ELF value of sampling points; r denotes the distance from the mercury binding site to the sampling point; n denotes the number of sampling points.

Adsorption performance evaluation. The adsorption performances of gas-phase Hg0 over different carbon materials were examined by a laboratory-scale fixed-bed reaction system as shown in Supplementary Fig. 5. A constant Hg0 vapor (340 μg m−3) was produced from a mercury permeation device. The generated Hg0 vapor was mixed with other gas components and then introduced into a quartz tube reactor where 100 mg sample was placed. The tube reactor was wrapped in a tubular furnace to maintain a desired reaction temperature. With N2 carrying, O2 (5% vol.), SO2 (600/1200/1800/2400 ppm), NO (600/1000 ppm), and H2O (1/3% vol.) were added into the gas stream when needed. All gas flows were controlled by flowmeters, with a total flow rate of flue gas maintained at 400 ml min−1. The gas hourly space velocity (GHSV) of the experiment was ~53000 h−1. An online mercury analyzer (QM201H, Suzhou Qing’an Instrument Co., Ltd) was used to detect the inlet and outlet Hg0 concentrations. Gases containing SO2/NO and water vapor were purified by Na2O2 and silica gel before entering the mercury analyzer. For each test, the gas stream was first switched to bypass and the inlet gas was sampled to acquire stable Hg0 concentrations. Thereafter, the Hg0 containing gas flow was passed through the reactor for Hg0 adsorption tests. At the end of test, the gas stream was switched to bypass again to verify the stability of feed Hg0 concentration. Hg0 and acid gases in tail gas were removed by solutions of acidic potassium permanganate and sodium hydroxide. The following equations were employed to evaluate the Hg0 removal efficiency \(\left({E}_{{Hg}}\right)\) and the Hg0 adsorption capacity \(\left({q}_{t}\right)\), respectively.

where \({E}_{{Hg}}\) indicates the Hg0 removal efficiency; \({{{Hg}}^{0}}_{{in}}\) and \({{{Hg}}^{0}}_{{out}}\) represent the instantaneous concentrations of Hg0 at the inlet and outlet of the reactor, respectively, μg m−3; m denotes the weight of sorbent, g; F represents the gas flow rate, m3 min−1; t denotes the adsorption time, min; \({q}_{t}\) is the Hg0 adsorption capacity, mg g−1.

Hg-TPD analysis. To identify the formed mercury species on HsGDY, the temperature programmed desorption of Hg (Hg-TPD) from the spent HsGDY was carried out. The Hg-laden HsGDY in the quartz tube reactor was firstly purged by N2 (400 ml min−1) at room temperature for 20 min. Then the sample was heated from 20 °C to 400 °C at a ramping rate of 2 °C min−1 in N2 atmosphere. During this process, the desorbed mercury concentration was measured by a mercury analysis device (QM201H, Suzhou Qing’an Instrument Co., Ltd).

Identification of the desorbed mercury species by OHM. The OHM was employed to examine the mercury speciation distribution during thermal regeneration. KCl solution (1 M) and 3% (w/v) KMnO4 in 10% (v/v) H2SO4 solution were used to capture the oxidized mercury and elemental mercury in gas stream, respectively. The resulting Hg concentration was measured by using Cold-Atomic Fluorescence Spectroscopy (AFS-930, Beijing Titan Instruments Co., Ltd).

Mercury desorption by acid washing. Before the acid-washing experiment, the mercury-laden HsGDY was purged by N2 for 30 min. Then the mercury-laden HsGDY was desorbed using 15 ml HNO3 solutions under continuously stirring for 24 h. Thereafter, the HsGDY was separated by filtration, and the mercury concentration in the filtrate was measured by ICP-OES (Prodigy 7, USA). Additionally, the pH of the obtained solution is adjusted to 7–8 by NaOH. Afterwards, Na2S dilute solution is dropwisely added into the aforementioned solution under continuously stirring at room temperature.

Kinetic simulation. The kinetic simulation can help to understand the Hg0 adsorption mechanism. The kinetic equations of the pseudo-first-order model, pseudo-second-order model, and Weber–Morris model are illustrated as follows:

where \({q}_{t}\) and \({q}_{e}\) are defined as the Hg0 adsorption capacities at time t and at equilibrium, respectively, mg g−1; \({k}_{1}\) is the adsorption rate constant for the pseudo-first-order model, min−1; \({k}_{2}\) represents the rate constant for the pseudo-second-order model, g mg−1 min−1; \({k}_{{id}}\) represents the intra-particle diffusion coefficient or the adsorption rate constant for the model, mg g−1 min−1/2); constant C is associated with the thickness of the boundary layer, mg g−1; t represents the adsorption time, min. By nonlinear fitting the adsorption breakthrough curve data to the models, the values of \({k}_{1}\), \({k}_{2}\),\(\,{k}_{{id}}\) and \({q}_{e}\) can be obtained.

Demonstrating the oxidation of Hg over HsGDY by electrochemical experiments. A standard three-electrode system was employed to conduct the electrochemical experiments at a CHI660E electrochemical workstation. The clean glassy carbon electrode as cathode (Pt as anode) was immersed in 1.5 × 10−3 M Hg(NO3)2 and 0.1 M KCl solutions. Then Hg will be deposited on the glassy carbon electrode to form an as-prepared Hg electrode by electrolysis. The HsGDY/Hg electrode (Hg deposited on HsGDY) was prepared from HsGDY electrode as a cathode by the same electrolysis method. The HsGDY electrode, Hg electrode, and HsGDY/Hg electrode were employed as the working electrodes, respectively. The Pt and saturated calomel electrodes were used as auxiliary electrodes and reference electrodes, respectively. The electrolyte was 0.5 M Na2SO4 solution. The electrochemical cyclic voltammetry (CV) testing was performed within the range of −1.5 to 1.5 V. Meanwhile, the CV characteristic curve was obtained and the results are displayed in Supplementary Fig. 23.

Data availability

The data supporting the findings of the study are included in the main text and supplementary information files. Raw data are available from the corresponding author upon request.

References

Wilcox, J. et al. Mercury adsorption and oxidation in coal combustion and gasification processes. Int. J. Coal Geol. 90, 4–20 (2012).

Scala, F. & Clack, H. Mercury emissions from coal combustion: Modeling and comparison of Hg capture in a fabric filter versus an electrostatic precipitator. J. Hazard. Mater. 152, 616–623 (2008).

Hao, R. et al. Removal and recovery of gaseous elemental mercury using a Cl-doped protonated polypyrrole@MWCNTs composite membrane. Environ. Sci. Technol. 56, 3689–3698 (2022).

Zhang, L. et al. In-situ synthesis of monodispersed CuxO heterostructure on porous carbon monolith for exceptional removal of gaseous Hg0. Appl. Catal. B Environ. 265, 118556 (2020).

Li, J., Song, X., Guo, Y., Yang, Q. & Feng, K. The determinants of China’s national and regional energy-related mercury emission changes. J. Environ. Manage. 246, 505–513 (2019).

Mon, M. et al. Selective and efficient removal of mercury from aqueous media with the highly flexible arms of a BioMOF. Angew. Chem. Int. Ed. 128, 11333–11338 (2016).

Huang, S. et al. Modeling the mercury cycle in the sea ice environment: a buffer between the polar atmosphere and ocean. Environ. Sci. Technol. 57, 14589–14601 (2023).

Li, Y. et al. Looping mercury cycle in global environmental–economic system modeling. Environ. Sci. Technol. 56, 2861–2879 (2022).

Beckers, F. & Rinklebe, J. Cycling of mercury in the environment: sources, fate, and human health implications: a review. Crit. Rev. Environ. Sci. Technol. 47, 693–794 (2017).

Mercury and health. Accessed 1 July 2023. https://www.who.int/news-room/fact-sheets/detail/mercury-and-health.

Liu, T. et al. Review on adsorbents in elemental mercury removal in coal combustion flue gas, smelting flue gas and natural gas. Chem. Eng. J. 45, 140095 (2023).

Ji, Z. et al. Recent progress on the clean and sustainable technologies for removing mercury from typical industrial flue gases: a review. Process Saf. Environ. Prot. 150, 578–593 (2021).

United Nations Environment Programme (UNEP). Global Mercury Assessment (2018).

The Minamata Convention on Mercury. Accessed 1 July 2023. https://www.mercuryconvention.org/en.

Liu, H. et al. Advances in mercury removal from coal-fired flue gas by mineral adsorbents. Chem. Eng. J. 379, 122263 (2020).

Xu, W., Hussain, A. & Liu, Y. A review on modification methods of adsorbents for elemental mercury from flue gas. Chem. Eng. J. 346, 692–711 (2018).

Kokkinos, E. et al. Study of elemental mercury removal from flue gases using Tetravalent manganese Feroxyhyte. Chem. Eng. J. 315, 152–158 (2017).

Nick, R. K., Hutson, D. & Srivastava, R. K. Simultaneous removal of SO2, NOx, and Hg from coal flue gas using a NaClO2-enhanced wet scrubber. Ind. Eng. Chem. Res. 47, 5825–5831 (2008).

Liu, Y. & Wang, Y. Elemental mercury removal from flue gas using heat and Co2+/Fe2+ coactivated oxone oxidation system. Chem. Eng. J. 348, 464–475 (2018).

Li, H., Wang, Y., Wang, S., Wang, X. & Hu, J. Promotional effect of Mo addition on CoOX/Ti-Ce catalyst for oxidation removal of elemental mercury in flue gas. Fuel 224, 424–433 (2018).

Yang, W. et al. Theoretical prediction of graphene-based single-atom iron as a novel catalyst for catalytic oxidation of Hg0 by O2. Appl. Surf. Sci. 508, 145035 (2020).

Zhang, H. et al. Satisfactory anti-interference and high performance of the 1Co–1Ce/Mn@ ZSM-5 catalyst for simultaneous removal of NO and Hg0 in abominable flue gas. Environ. Sci. Technol. 56, 3596–3603 (2022).

Granite, E. J. & Pennline, H. W. Photochemical removal of mercury from flue gas. Ind. Eng. Chem. Res. 41, 5470–5476 (2002).

Zhang, A. et al. Photocatalytic oxidation removal of Hg0 by ternary Ag@ AgCl/Ag2CO3 hybrid under fluorescent light. Fuel Process. Technol. 159, 222–231 (2017).

Wu, J. et al. Photocatalytic oxidation of gas-phase Hg0 by CuO/TiO2. Appl. Catal. B Environ. 176, 559–569 (2015).

Yang, J. et al. Electrochemical removal of gaseous elemental mercury in liquid phase with a novel foam titanium-based DSA anode. Sep. Purif. Technol. 250, 117162 (2020).

Li, H. et al. In situ acid etching boosts mercury accommodation capacities of transition metal sulfides. Nat. Commun. 14, 1395 (2023).

Li, J. et al. Engineering unsaturated sulfur site in three-dimension MoS2@rGO nanohybrids with expanded interlayer spacing and disordered structure for gaseous elemental mercury trap. Chem. Eng. J. 453, 139767 (2023).

Wang, F. et al. Spherical-shaped CuS modified carbon nitride nanosheet for efficient capture of elemental mercury from flue gas at low temperature. J. Hazard. Mater. 415, 125692 (2021).

Du, X. et al. Highly efficient simultaneous removal of HCHO and elemental mercury over Mn-Co oxides promoted Zr-AC samples. J. Hazard. Mater. 408, 124830 (2021).

Ralston, N. Nano-selenium captures mercury. Nat. Nanotechnol. 3, 527–528 (2008).

Li, Y. et al. Alkynyl carbon materials as novel and efficient sorbents for the adsorption of mercury (II) from wastewater. J. Environ. Sci. 68, 169–176 (2018).

Xie, S. et al. Ultra-high-efficiency capture of lead ions over acetylenic bond-rich graphdiyne adsorbent in aqueous solution. Proc. Natl. Acad. Sci. USA 120, e2221002120 (2023).

Xu, X. et al. Spongy acetylenic carbon material prepared by ball milling CaC2 and chlorinated rubber—Its mercury adsorption and electrochemical property. Chin. J. Chem. Eng. 27, 1988–1995 (2019).

Pan, C. et al. Neighboring sp-hybridized carbon participated molecular oxygen activation on the interface of sub-nanocluster CuO/graphdiyne. J. Am. Chem. Soc. 144, 4942–4951 (2022).

Pan, C. et al. Graphdiyne: an emerging two-dimensional (2D) carbon material for environmental remediation. Environ. Sci. Nano. 8, 1863–1885 (2021).

Pan, C. et al. Fabrication and excellent antibacterial activity of well-defined CuO/graphdiyne nanostructure. Chem. Res. Chin. Univ. 37, 1341–1347 (2021).

Gao, X., Liu, H., Wang, D. & Zhang, J. Graphdiyne: synthesis, properties, and applications. Chem. Soc. Rev. 48, 908–936 (2019).

Hui, L. et al. Highly efficient and selective generation of ammonia and hydrogen on a graphdiyne-based catalyst. J. Am. Chem. Soc. 141, 10677–10683 (2019).

Huang, C. et al. Progress in research into 2D graphdiyne-based materials. Chem. Rev. 118, 7744–7803 (2018).

Xue, Y. et al. Anchoring zero valence single atoms of nickel and iron on graphdiyne for hydrogen evolution. Nat. Commun. 9, 1460 (2018).

Fang, Y., Liu, Y., Qi, L., Xue, Y. & Li, Y. 2D graphdiyne: an emerging carbon material. Chem. Soc. Rev. 51, 2681–2709 (2022).

Yu, H. et al. Graphdiyne-based metal atomic catalysts for synthesizing ammonia. Natl. Sci. Rev. 8, 0–9 (2021).

Zheng, X. et al. Two-dimensional carbon graphdiyne: advances in fundamental and application research. ACS Nano. 17, 14309–14346 (2023).

Zheng, X. et al. Hydrogen-substituted graphdiyne-assisted ultrafast sparking synthesis of metastable nanomaterials. Nat. Nanotechnol. 18, 153–159 (2023).

Man, Z. et al. Hierarchical 3D porous hydrogen-substituted graphdiyne for high-performance electrochemical lithium-ion storage. ACS Appl. Mater. Interfaces 15, 26910–26917 (2023).

Ren, X. et al. Tailoring acetylenic bonds in graphdiyne for advanced lithium storage. ACS Sustain. Chem. Eng. 8, 2614–2621 (2020).

Wang, Z. et al. AMn2O4 (A=Cu, Ni and Zn) sorbents coupling high adsorption and regeneration performance for elemental mercury removal from syngas. J. Hazard. Mater. 388, 121738 (2020).

Liu, R., Xu, W., Tong, L. & Zhu, T. Role of NO in Hg0 oxidation over a commercial selective catalytic reduction catalyst V2O5–WO3/TiO2. J. Environ. Sci. 38, 126–132 (2015).

Xu, Y. et al. Adsorption and catalytic oxidation of elemental mercury over regenerable magnetic Fe-Ce mixed oxides modified by non-thermal plasma treatment. Chem. Eng. J. 358, 1454–1463 (2019).

Zheng, W. et al. Advances in flue gas mercury abatement by mineral chalcogenides. Chem. Eng. J. 411, 128608 (2021).

Li, J. et al. Atomic Pd on graphdiyne/graphene heterostructure as efficient catalyst for aromatic nitroreduction. Adv. Funct. Mater. 29, 1–9 (2019).

Yu, H. et al. Ultrathin nanosheet of graphdiyne-supported palladium atom catalyst for efficient hydrogen production. IScience 11, 31–41 (2019).

Yin, X. P. et al. Engineering the coordination environment of single-atom platinum anchored on graphdiyne for optimizing electrocatalytic hydrogen evolution. Angew. Chem. Int. Ed. 57, 9382–9386 (2018).

Liu, C., Xiang, K., Li, J., Liu, H. & Shen, F. Controllable disordered copper sulfide with a sulfur-rich interface for high-performance gaseous elemental mercury capture. Environ. Sci. Technol. 56, 13664–13674 (2022).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B. 50, 17953–17979 (1994).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Heyden, A., Bell, A. T. & Keil, F. J. Efficient methods for finding transition states in chemical reactions: comparison of improved dimer method and partitioned rational function optimization method. J. Chem. Phys. 123, 224101 (2005).

Nørskov, J. K. et al. Trends in the exchange current for hydrogen evolution. J. Electrochem. Soc. 152, 23–26 (2005).

Song, F. et al. Interfacing nickel nitride and nickel boosts both electrocatalytic hydrogen evolution and oxidation reactions. Nat. Commun. 9, 4531 (2018).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (22076060—Y.G., 51702112—Y.G., 52100134—H.L.), the Open Foundation of the Project of the State Key Laboratory of Advanced Technology for Materials Synthesis and Processing, Wuhan University of Technology, China (2020-KF−17—Y.G.), the Recruitment Program of Global Young Experts Start-up Funds of China, the Program of Introducing Talents of Discipline to Universities of China (B17019—Y.G.), Knowledge Innovation Program of Wuhan Shuguang Project (2022010801020289—Y.G.), the China Postdoctoral Science Foundation (2022M721284—H.L.) and the Project of the Hubei International Scientific and Technological Cooperation Base of Pesticide and Green Synthesis (Y.G.).

Author information

Authors and Affiliations

Contributions

H.L., C.P., and Y.G. designed the experiments, analyzed the data, and wrote the manuscript. X.P. evaluated the adsorption performance and analyzed the data. B.Z. carried out the DFT calculations and AIMD simulations. S.S., Z.X., and X.Q. synthesized the sorbent. X.Q. and C.P. carried out the material characterization experiments. Y.L. and J.W. conducted the electrochemical experiments and analyzed the results. Y.G. supervised the work. All the authors contributed to the overall scientific interpretation and edited the manuscript. H.L. and C.P. contributed equally.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Maohuai Wang, Huawei Zhang, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, H., Pan, C., Peng, X. et al. In-situ adsorption-coupled-oxidation enabled mercury vapor capture over sp-hybridized graphdiyne. Nat Commun 16, 2439 (2025). https://doi.org/10.1038/s41467-025-57197-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-57197-8