Abstract

Icing forecast provides advanced notification, enabling preemptive anti-icing treatments to prevent facility damage and minimize economic losses from unexpected icing events. However, in real-world environments and practical applications, current technologies struggle to accurately predict ice formation on solid surfaces. This difficulty arises from the random and unpredictable nature of ice nucleation, influenced by variable weather conditions, diverse ice-nucleating agents, complex surface properties, and uncertain material defects or contamination. Herein, inspired by the role of ice-nucleating proteins (INPs) in cellular responses to low-temperature stress, we develop an innovative icing forecast hydrogel (IFH) device that encapsulates INPs. By simply regulating the INP content, the advance forecast time for icing can be precisely controlled over a wide temperature range from −6 to −28 oC. To enhance forecasting accuracy, a color-coded grading system is implemented. The anti-icing application of this IFH device on wind turbines has proven its effectiveness, as it activated the de-icing system 70 min prior to real ice accretion on wind turbine blade, resulting in an additional 1898 kWh of electricity generated over two h. Our study presents a strategy for icing forecast, demonstrating its practical utility in wind power field and its potential for various anti-icing applications.

Similar content being viewed by others

Introduction

Undesired ice formation on external surfaces significantly impacts wind power generation1, electric grid facilities2, and transportation systems. This leads to substantial energy losses, economic disruptions, safety issues, and environmental hazards3. Existing strategies to prevent ice-related disasters primarily focus on the development of de-icing equipment and technologies, as well as the fabrication of anti-icing materials4. However, the study of icing forecast mechanisms and the development of icing forecast devices are often overlooked, despite their critical importance for effective de-icing5.

Taking thermal de-icing methods as an example, if a thick ice layer forms on a solid surface before the heating systems are activated, a substantial amount of thermal energy is required for the de-icing process. The formation of a melted water layer between the heated surface and the overlying ice can significantly reduce the heat transfer efficiency, prolonging the de-icing process6. More seriously, when large ice blocks that have melted at the bottom fall from rooftops, suspension bridges, power lines, and wind turbines, they pose severe safety hazards to pedestrians and facilities below. Implementing effective icing forecast systems can preemptively activate and preheat thermal de-icing systems before ice formation, preventing the formation of thick ice layers and large ice blocks. This approach is more energy-efficient and easier to remove supercooled water or a thin layer of ice. Therefore, icing forecast devices can enhance the efficiency, safety, and energy-saving potential of active de-icing methods, such as electric heating, microwaving, ultrasonic, and mechanical technologies7.

Current technologies provide early icing signals by detecting ice at its initial formation stages8,9. These ice detection strategies typically monitor changes in conductivity, interface temperature, electrical resistance, and the mechanical properties of detecting materials, all of which are influenced by variations in ice thickness10. Ice formation on surfaces begins with heterogeneous ice nucleation, followed by rapid ice propagation11,12. Once heterogeneous ice nucleation occurs, ice propagates quickly like the domino effect, covering the entire solid surface within several minutes13. Thus, detecting ice formation at early stage does not guarantee sufficient icing forecast time. In contrast, theoretical simulations offer an alternative icing forecast method based on data processing14,15. Optimized algorithms can be employed to deduce potential icing threats. For instance, road icing forecast models have been developed by investigating meteorological factors, such as pavement surface temperature, water depth and wind speed16,17. However, these methods can only consider a limited number of influencing factors based on historical data, always resulting in low icing forecast accuracy.

The ice formation process in nature is influenced by multiple factors, making icing events inherently stochastic and challenging to predict accurately18. In the atmosphere, complex interactions among dust, aerosol particles, and cloud microphysics, including their size and concentration, significantly influence the ice nucleation process19. On solid surfaces, heterogeneous ice nucleation is affected by various surface properties, including surface morphology, roughness, wettability, chemical composition, and surface defects. Consequently, current technologies often fail to provide an accurate icing forecast. However, ice-nucleating proteins (INPs) in nature provide excellent examples for icing forecast, helping cold-resistant plants to avoid freeze injury (Fig. 1a)20,21. INPs can promote heterogeneous ice nucleation in the extracellular spaces at low supercooling temperatures, causing water to move out of the cells due to the lower vapor pressure of ice compared to liquid water. This process safeguards freeze-tolerant plants by preventing intracellular freezing22. This unique anti-icing mechanism of INPs offering a promising strategy to inhibit large-scale freezing by allowing for advance preparation for cold weather, providing valuable insights for the design of effective icing forecast devices23,24,25,26. Inspired by nature, we harnessed the excellent ice nucleation-promoting ability of INPs and combined it with a color-coding concept of icing forecast to design an icing forecast hydrogel (IFH) device that encapsulated INPs. This device offers advanced warning of icing from 1 to 110 min, depending on cooling rates between 0.2 and 15 oC min−1, and works effectively within a wide temperature window as large as 22 oC. To demonstrate its practical application, we integrated the IFH devices into wind turbines, which resulted in an additional 1898 kWh of electricity generated within two h. Our study presents a strategy for designing icing forecast devices that can be expanded to various active anti-icing technologies.

a Mechanisms of avoiding freeze injuries in cold-resistant plants, where icing forecast hydrogels (IFHs) emit visible fluorescence upon freezing. The green squares depict schematic representations of plant cells. The orange dots represent INPs. The blue snowflake symbols represent ice crystals. The blue fluorescent dots represent aggregation-induced emission molecules (AIEgens). The gray long lines illustrate the crosslinked network within the hydrogel. b Photographs of PAM hydrogel and IFH-B1 under 365 nm ultraviolet light irradiation upon freezing. The top row of images represents polyacrylamide (PAM) hydrogel, while the bottom row corresponds to IFH-B1(icing forecast hydrogel containing blue AIEgen and 1 mg mL-1 INPs). c The frozen fractions at various freezing times and the calculation method for the icing forecast time. tA = the freezing time of water in the ambient environment. tI = the freezing time of the IFH device. \({\bar{{{\rm{t}}}}}_{{{\rm{A}}}}\) = the tA when the frozen fraction reaches 50%. \({\bar{{{\rm{t}}}}}_{{{\rm{I}}}}\)= the tI when the frozen fraction reaches 50%. d 100 independent freezing experiments. e 100 cycling tests of freezing experiments on one hydrogel sample. f Schematic diagram illustrating the four grades of the IFH device, combined with the icing forecast time (tF). The images in blue, green, yellow, and red respectively represent icing forecast hydrogel (IFH) incorporated with aggregation-induced emission molecules (AIEgens) of the corresponding colors. The forecast icons with snowflake symbols serve as warning indicators for the severity of icing. Source data is provided as a Source Data file.

Results

Bioinspired icing forecast concept

Drawing inspiration from the role of ice-nucleating proteins (INPs) in providing early ice-warning signals to cells under low-temperature stress, we have designed an IFH device that encapsulates INPs for use in icing forecasts. The incorporation of INPs accelerates freezing of supercooled water, thereby enabling earlier detection and forecasting of freezing conditions. To facilitate clearer observation of freezing events, we synthesized various aggregation-induced emission molecules (AIEgens) and integrated them into the IFH device, which emits specific visible fluorescence in different colors (Fig. 1a)27,28. Upon freezing, AIEgens aggregate at the ice/water interfaces within the hydrogel and emit strong visible fluorescence under 365 nm UV irradiation (Fig. 1b)29. With the utilization of INPs, the blue-colored IFH-B1 (containing blue AIEgen) freezes immediately within 1 minute. In stark contrast, the pure water and polyacrylamide (PAM) hydrogel without INPs do not freeze until 110 minutes (Fig. 1b). These results suggest that the hydrogel encapsulating INPs and AIEgens hold significant potential for the development of effective icing forecast devices.

To further demonstrate the accuracy of the icing forecast time, it is calculated as

where \({\bar{{{\rm{t}}}}}_{{{\rm{I}}}}\) and \({\bar{{{\rm{t}}}}}_{{{\rm{A}}}}\) represent the average freezing times of the IFH device and water in the ambient environment, respectively, when the frozen fraction reaches 50%. Here, tI refers to the freezing time of the IFH device, and tA denotes the freezing time of water in the ambient environment. These values are determined from 100 independent freezing tests. Using IFH-B1 as an example, we conducted 100 freezing experiments for both water and IFH-B1. Based on these results, the icing forecast time (tF) was determined to be 110 min when IFH-B1 was used as the icing forecast device, and the frozen fractions are shown in Fig. 1c.

Furthermore, to validate icing forecast device’s applicability in real-world scenarios, it is essential to demonstrate consistent performance across multiple icing prediction freezing events. Therefore, we performed 100 independent icing forecast trials using IFH-B1. Across these trials, the icing forecast time (tF) was consistently observing tF at approximately 110 min. This demonstrates the repeatability, consistency, and stability of the icing prediction results, as shown in Fig. 1d.

To further assess durability, we conducted cycling tests to evaluate the performance of IFH-B1 over successive icing forecasts. After 100 cycles under identical conditions, IFH-B1 consistently detected the icing forecast time at approximately 110 min. These results, shown in Fig. 1e, indicate that the IFH device could return to its original functional state after each cycle and sustain comparable performance. This durability suggests that the sample remained structurally and functionally stable during freeze-thaw cycles, with no changes observed in the freezing mechanism between cycles. These findings strongly support the IFH device retained its forecasting functionality, indicating its ability to revert to its original state and maintain stable performance, ensuring its long-term ability to provide accurate and consistent results.

Color-coding is a widely used technique in forecast signal observation, including systems for weather, fire, frost, and earthquake forecasts30,31,32. To distinguish different levels of icing hazards, we employed distinct fluorescent colors of AIEgens (blue, green, yellow, and red) to create color icons, as illustrated in Fig. 1f.

It is anticipated that the IFH devices will possess significant theoretical importance and practical engineering value in mitigating various icing disasters and preventing energy loss under diverse conditions.

Color-coding of icing forecast based on INPs and AIEgens

An effective icing forecast device necessitates precise visualization of the ice formation process. However, icing visualization is challenging due to minimal changes in color and appearance when water transits to ice. Recent studies disclosed that AIEgens exhibit strong fluorescence upon freezing due to the restriction of intramolecular rotations in their aggregated states, allowing for real-time visualization of icing29,33,34,35,36. We synthesized sodium 4-(2,5-diphenyl-1H-pyrrol-1-yl) benzoate AIEgen (TPP-Na) and investigated its photoluminescence properties upon freezing (Fig. 2a). The enrichment and assembly of AIEgens at a moving ice front were studied using in situ cryogenic laser confocal microscopy (Fig. 2b), confirming the mechanism behind this freezing-induced emission phenomenon.

a Fluorescence images of a vial containing TPP-Na solution (0.5 mg mL−1) under 365 nm UV light irradiation as ice crystals form via controlled directional freezing. In the real-time images of the bottle, the transparency of the liquid indicates the state of aqueous solution, while the emission of blue fluorescence signifies the state of solid ice. b Enlarged view of fluorescence microscopy images showing the ice growth front with TPP-Na molecules (0.05 mg mL−1) accumulated and aggregated at the ice/water interface. The lines emitting blue fluorescence in the image correspond to the ice/water interface where TPP-Na molecules are aggregated. c Structures of AIEgens and corresponding fluorescence images of IFH-A under 365 nm UV light irradiation before and after freezing. The images of the hydrogel on the right in each row illustrate the fluorescence phenomenon of the IFH hydrogel, which contains the molecules on the left, transitioning from unfrozen to frozen. The IFH-R, IFH-Y, IFH-G, and IFH-B contain AIEgens which can emit red, yellow, green, and blue fluorescence, respectively. d Emission fluorescence spectra of IFH-A at 298 K and 233 K, respectively. The IFH-R, IFH-Y, IFH-G, and IFH-B display freezing-induced turn-on fluorescence in red, yellow, green, and blue, respectively. Source data are provided as a Source Data file.

To improve the accuracy of icing forecast, distinct fluorescent signals are necessary for color-coding, representing different forecast times of icing. We synthesized a series of AIEgens with different conjugated functional groups that emit various colors of fluorescence, including blue, green, yellow, and red, corresponding to TPP-Na, TPE-Na2, TPP, and TVP, respectively (Fig. 2c and Figure S3). These water-soluble AIEgens and INPs were incorporated into polyacrylamide (PAM) hydrogel, thus fabricating different chromatic IFHs (Figure S4). These IFHs display freezing-induced turn-on fluorescence in red, yellow, green, and blue, corresponding to IFH-R, IFH-Y, IFH-G, and IFH-B, respectively. The steady-state FL spectra of IFH-R, IFH-Y, IFH-G, and IFH-B revealed emission peaks at 580 nm, 570 nm, 490 nm, and 450 nm at 233 K, respectively (Fig. 2d). In contrast, the unfrozen IFH-A (IFH incorporating AIEgens) exhibited negligible fluorescence intensity. The fluorescence of different IFH-A upon freezing responds to color-coding signals, providing tiered warning according to the severity of icing.

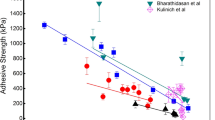

In real systems, ice nucleation predominantly occurs on foreign solid surfaces, a process known as heterogeneous ice nucleation. The initial and critical step of ice formation is inherently random and unpredictable, making it challenging to control. INPs are the most effective ice-nucleating agents, capable of triggering ice formation at relatively high subzero temperatures. By simply regulating the INP content in the IFH, we can accurately control the ice-nucleating temperature (TIN) over a wide temperature range from −6 to −28 oC (Fig. 3a, b). In contrast, the pure water exhibits different but generally lower TIN values on various material surfaces, typically ranging from −26 to −30 oC, depending on the distinct surface properties (Figure S10). The ability of INPs to regulate and promote ice nucleation was further confirmed through differential scanning calorimetry (DSC) measurements (Fig. 3c). Notably, the TIN can be fine-tuned to a precision of 1.7 oC at each grade (Fig. 3d). These findings underscore our capability to precisely control and adjust the TIN of IFH by varying the concentration of INPs.

a Photographs of different IFHs cooling from 0 oC at a rate of 5.0 oC min−1 under 365 nm UV light irradiation. IFH-B1 is IFH with 1 mg mL−1 INPs and emit blue fluorescent. IFH-G6 is IFH with 1 × 10−6 mg mL−1 INPs and emit green fluorescent. IFH-R11 is IFH with 1 × 10−11 mg mL−1 INPs and emit red fluorescent. b The ice-nucleating temperature (TIN) of 100 freezing events in IFH-1, IFH-6, IFH-11 (represent IFH with INP content as 1 mg mL−1, 1 × 10−6mg mL−1, 1 × 10−11mg mL−1), and water droplets. Each data point corresponds to one individual measurement of TIN. c DSC chromatograms of different IFHs and water. Exo represents the exothermic heat flow. d TIN of various IFHs containing different concentration of INPs. The bars represent the average values of three independent measurements, with error bars indicating the standard deviation. IFH−1, IFH-3, IFH-5 IFH-7, IFH-9, IFH-11 represent IFH with INP content as 1 mg mL−1, 1 × 10−3mg mL−1, 1 × 10−5mg mL−1, 1 × 10−7mg mL−1, 1 × 10−9mg mL−1, and 1 × 10−11mg mL−1. Source data is provided as a Source Data file.

Design of icing forecast device

After establishing the fluorescence emission upon freezing and the freezing temperature adjustment of IFHs using spectroscopic techniques, we developed an advanced icing forecast hydrogel device by integrating IFHs with an optical system that includes excitation light sources, as shown in Fig. 4a35. During the freezing process, the IFHs froze sequentially, causing the embedded AIEgens to emit fluorescence, which was transferred to an optical spectrometer via optical fibers. The optical signal was then processed by software to automatically activate de-icing systems, such as heating or ultrasonic treatments, providing a timely anti-icing response. The IFH device exhibited a significant fluorescence contrast before and after freezing, ensuring reliable detection of ice formation (Fig. 4b).

a Schematic illustration of the components and working process of the IFH device. UV Light represents a device that emits ultraviolet light as an excitation light source. b Photographs of IFH-B1 utilized as an icing forecast device. The hydrogel above the light bulb in the figure represents “unfrozen” when transparent and “frozen” when emitting blue fluorescence. c Fluorescence spectra of IFHs at different times (cooling rate 1 oC min−1). d The icing forecast times obtained using Eq. (1). e Variation of the icing forecast time (tF) influenced by INP content and cooling rate. The bars represent the average values of three independent measurements, with error bars indicating the standard deviation. Source data are provided as a Source Data file.

We further investigated the forecast time (tF) of various IFHs using fluorescence spectroscopy. At 273 K, IFH-B1, IFH-G6, and IFH-R11 initially exhibited no fluorescence emission. However, upon freezing, with the temperature uniformly decreased at a rate of 1 oC min−1, they displayed increased fluorescence intensity, with emission peaks at 450 nm, 490 nm, and 580 nm, respectively (Fig. 4c). The freezing times for IFH-B1, IFH-G6, and IFH-R11 were determined to be 7, 11, and 22 min, respectively, compared to 32 min for water with TPP-Na. Consequently, the tF values for IFH-B1, IFH-G6, and IFH-R11 were calculated using Eq. (1) as 25, 21, and 10 min, respectively (Fig. 4d). We found that tF increased with higher INP content at a constant cooling rate, while it decreased with an increasing cooling rate when INP content was held constant (Fig. 4e). These findings indicate that tF is influenced by both INP content and cooling rate, enabling the IFH device to provide consistent forecast signals for icing under various environmental conditions.

Application performance

The IFH device was utilized to forecast icing conditions due to its high sensitivity to ice formation and accuracy in warning signals. In practical applications of ice removal on wind turbines, thermal de-icing with electric heating films is a primary method (Fig. 5a)37. To evaluate the heating efficiency of these electric heating films, we observed that as ambient temperatures decrease, longer heating times are required to raise the surface temperature above 0 oC. Notably, at extremely low temperatures, the surface temperature increase is gradual, ultimately stabilizing at a constant value below 0 oC even after 80 min of heating (Fig. 5b). The phase diagram in Fig. 5c is based on the data in Fig. 5b, providing a clear view of the inverse relationship between ambient temperature and heating time required for the heating film to reach 0 oC. The trend of the curve indicates that a lower ambient temperature demands a longer heating time. When the ambient temperature falls below −20 oC, the surface temperature of the film may fail to reach 0 oC. Therefore, initiating the heating system in advance significantly shortens the de-icing process.

a Schematic diagram of a wind turbine, indicating the position of the IFH device, electric heating film and control system. The IFH device is installed near the root of the blade and on the outer surface of the electric heating film. b Surface temperature changes of the electric heating film with increased heating time at different ambient temperatures. c Phase diagram indicating the influence of ambient temperature and heating time on the surface temperature of the electric heating film. The bars represent the average values of three independent measurements from three different locations on the electric heating film, with error bars indicating the standard deviation. d Real-time fluctuation of temperature, wind speed, and relative humidity of the wind turbines. T temperature, WS wind speed, RH relative humidity, The label of the x-axis represents the time of the day on January 15th, 2024, when the experiment was conducted. e Output power of wind turbines with and without the icing forecast hydrogel (IFH) device, and power consumption of the electric heating film on both wind turbines. OP represent the output power of wind turbines. P represent the power consumption of the electric heating film on the wind turbine. The label of the x-axis represents the time of the day on January 15th, 2024, when the experiment was conducted. f The total power generation (TPG) of wind turbines with and without the IFH device. The label of the x-axis represents the time of the day on January 15th, 2024, when the experiment was conducted. Source data are provided as a Source Data file.

To evaluate the effectiveness of the IFH device in real-world scenarios, where ambient factors are highly complex and variable (Fig. 5d), we analyzed the instantaneous power output data of wind turbines38,39. Two closely located wind turbines, subjected to similar environmental conditions, were compared. The wind turbine without the IFH device experienced a significant decrease in power output during icing conditions due to delayed heating, eventually shutting down completely because of ice accumulation. Despite attempts to restart, it struggled to maintain normal operation. Conversely, the wind turbine equipped with the IFH device activated its de-icing system 70 min earlier, ensuring a power output of up to 2260 kWh in approximately 2 h, compared to only 330 kWh generated by the turbine without the IFH device. The electric heating film consumed less than 32 kWh during this period, which is minimal compared to the additional electricity generated. Considering the net energy output and the cost of the de-icing system, the wind turbine equipped with the IFH device generated an additional 1898 kWh of electricity (Fig. 5e). Figure 5f clearly presents the real-time changes of the total power generation (TPG) and the difference of the two wind turbines during the icing process. These results demonstrate that the utilization of the icing forecast system can significantly improve power generation efficiency by providing timely de-icing even under fluctuating and complex conditions.

Discussion

Inspired by the function of ice-nucleating proteins (INPs) in cold-resistant plants, we have developed a highly efficient and cost-effective icing forecast hydrogel (IFH) device. The fluorescence of aggregation-induced emission molecules indicates the frozen state of the IFHs, while INPs enable precise regulation of the ice-nucleating temperature. When integrated with optical, signal transmission, and program control systems, the IFHs can be applied to various surfaces due to their flexible substrate, achieving a reliable forecast function. Field tests have demonstrated that the IFH device can provide a 70-min forecast time, enabling a wind turbine to produce an additional 1898 kWh of electricity in 2 h. This outcome highlights the effectiveness of the IFH device in real-world scenarios, showcasing its potential for practical applications in de-icing technologies.

Future work will be directed toward refining the IFH device to enhance stability and efficiency in diverse environments. For instance, while IFHs perform effectively in high-humidity environments, their performance may be compromised in dry conditions because of dehydration. Additionally, there are plans to miniaturize and reduce the weight of the device by incorporating wireless technology for signal transmission. The integration of IFH devices into practical applications, such as infrastructure, transportation, power lines, and wind turbines, could significantly improve safety by providing timely and automated responses to icing conditions. Continued innovations in this field could lead to the development of more efficient and adaptable anti-icing systems, with broad implications for various industries affected by icing challenges.

Methods

Synthesis of hydrogels

All the concentrations of the cross-linking agent and INPs mentioned in the main text are referred to the final concentrations of the corresponding compound in the precursor solution. In a typical preparation process, acrylamide (0.711 g, 5.3 M), N, N’-methylenebis (acrylamide) (0.001 g, 0.003 M), and UV-2959 (0.005 g, 0.01 M) were dissolved in an aqueous solution following ultrasonic and degassed for 10 min. The resulting solution was then poured into a PTFE mold (70 mm × 20 mm × 2 mm) and covered with a glass plate. The mold containing the mixture was exposed to UV light (365 nm, 60 mW/cm²) for 5 min to initiate polymerization and form the hydrogel. The prepared hydrogel samples were cleaned with Milli-Q water.

Sensitivity of T IN

Ice-nucleating temperature (TIN) is determined by the precision of both the temperature measurement and the experimental setup, combining a Nikon LV100ND microscope with an Instec HCS621GXY cryo-stage. The cryo-stage provides a temperature resolution of 0.1 oC, ensuring a precisely controlled cooling environment. The microscope enables high-resolution real-time monitoring of changes in optical opacity, facilitating precise tracking of the ice nucleation event.

Fluorescence of AIEgens in hydrogel

Synthesis the three hydrogels (IFH-B1, IFH-G6 and IFH-R11) and prepare samples of 10 mm × 10 mm × 2 mm for testing. The samples are placed in the fluorescence spectrophotometer, with the temperature controlled to decrease from room temperature to −20 oC. A complete spectrum is recorded every 1 min.

Freezing process of aqueous solution in a vial

The TPP-Na aqueous solution (0.5 mg/mL) in a vial was frozen from the bottom at a controlled rate. A cryo-stage was used as the cooling center for freezing the TPP-Na solution. The freezing rate was controlled by the program of the cryo-stage. Fluorescent photos of the solidification of TPP-Na were taken under 365 nm UV irradiation by a portable UV lamp.

Freezing process by a freezing-confocal apparatus

The microscope images of the ice growing front were obtained by a freezing-confocal apparatus. The apparatus was equipped with a Nikon Ti2 Eclipse microscope featuring an air objective and a 3i rotating disk confocal system. The freezing cell was constructed using two glass microscope slides glued together with spacers. Temperature gradients were created using two cooling stages controlled by programmed controllers on the confocal microscope. The samples consisted of TPP-Na solutions sandwiched between glass slides in the freezing cell, with temperature gradients created using two cooling stages controlled by programmed controllers on the confocal microscope. The TPP-Na solution (0.05 mg/mL) was excited using a 405 nm laser. The sample was injected from one side of the cell to fill the entire channel. Both stages were pre-cooled to 7 oC for 10 min, after which one side was set to −4 oC to establish a temperature gradient. Subsequently, the ice/water interface was brought to an equilibrium position under brightfield illumination. One side was then continuously cooled to allow the ice front to advance slowly, which was observed in the fluorescence field.

T IN tested by cryo-stage and high-speed camera

The ice-nucleating temperature (TIN) of hydrogel (5 mm × 5 mm × 2 mm) containing different concentration of INP atop the silicon surface was measured by an optical microscope coupled with a high-speed camera when all the samples were placed inside a closed cell atop a cryo-stage. The resolution of the high-speed camera was 0.1 ms (104 frames/s). The temperature resolution of TIN was maintained below 0.1 oC. The TIN measured on the hydrogel surface corresponded to the temperature at which ice nucleation occurred. The nanoscale dimensions of the ice nucleus are not detectable using conventional optical microscopy. However, the phase transition of the entire hydrogel from liquid to solid can be monitored by observing changes in optical transparency before and after freezing. The complete freezing process of the hydrogel was completed in less than 1 s. Under a controlled cooling rate of 5 oC/min, the difference between the freezing temperature of the entire hydrogel and the TIN was found to be less than 0.1 oC. Consequently, the TIN value effectively represents the freezing temperature of the hydrogel when the cooling rate is maintained within a moderate range. The error bar was determined by the standard error of the mean (SEM).

T IN tested by differential scanning calorimetry (DSC)

The ice-nucleating behavior of the hydrogels was measured by using a differential scanning calorimeter (PE, DSC8500). The sample with a mass of ~4 mg was immediately sealed in an aluminum DSC pan (to avoid variation of the solvent fraction)and then scanned under a nitrogen atmosphere at a cooling/heating rate of 1.0 oC/min. Pure indium was used to calibrate the temperature and heat flow before the experiments. During a cooling process at a uniform rate, water within the hydrogel begins to freeze at a specific temperature, releasing latent heat, which is observed as a freezing peak. DSC monitors this process by recording changes in heat flow. The freezing temperatures were obtained from the onset point of the freezing peak of ice. Each sample was tested with DSC more than three times, and the measured freezing temperatures were consistent.

1H NMR spectra were analyzed by MestReNova. The molecular formulas were drawn using ChemDraw 22.0.0. The data were processed and visualized using Origin software.

Data availability

The data that support the findings of this study are available within the article and Supplementary Information file, or from the corresponding author upon request. Source data can be obtained from Figshare via https://doi.org/10.6084/m9.figshare.26763805. Source data are provided with this paper.

References

Parent, O. & Ilinca, A. Anti-icing and de-icing techniques for wind turbines: critical review. Cold Reg. Sci. Technol. 65, 88–96 (2011).

Hao, Y., Liu, N., Kun, Y., Zhai, F. & Yang, P. Online ice-coating monitoring research on overhead transmission lines with Brillouin optical time ___domain reflectometry. Optical Fiber Technol. 60, 102339 (2020).

Sirui Y. et al. A review of icing prediction techniques for four typical surfaces in low-temperature natural environments. Appl. Therm. Eng. 241, 122418 (2024).

Deng, Y. et al. Functionalized superhydrophobic coatings with electro-photothermal effect for all-day durable anti-icing. Adv. Mater. Interfaces 11, 2300869 (2024).

Jiang, G., Liu, Z. & Hu, J. Superhydrophobic and photothermal PVDF/CNTs durable composite coatings for passive anti-icing/active de-icing. Adv. Mater. Interfaces 9, 2101704 (2022).

McCutchan, A. L. & Johnson, B. A. Laboratory experiments on ice melting: a need for understanding dynamics at the ice-water interface. J. Mar. Sci. Eng. 10, 1008 (2022).

Wang K. et al. Smart hydrogel sensors for health monitoring and early warning. Adv. Sensor Res. 3, 2400003(2024).

Dongo P. D. et al. Detection of ice formation with the polymeric mixed ionic‐electronic conductor PEDOT: PSS for aeronautics. Adv. Electron. Mater. 9, 2300060 (2023).

Owusu, K. P., Kuhn, D. C. S. & Bibeau, E. L. Capacitive probe for ice detection and accretion rate measurement: proof of concept. Renew. Energy 50, 196–205 (2013).

Wei, K., Yang, Y., Zuo, H. & Zhong, D. A review on ice detection technology and ice elimination technology for wind turbine. Wind Energy 23, 433–457 (2019).

Jin, Y. et al. Inhibiting condensation freezing on patterned polyelectrolyte coatings. ACS Nano 14, 5000–5007 (2020).

He, Z. et al. Bioinspired multifunctional anti-icing hydrogel. Matter 2, 723–734 (2020).

He, Z., Liu, K. & Wang, J. Bioinspired materials for controlling ice nucleation, growth, and recrystallization. Acc. Chem. Res. 51, 1082–1091 (2018).

Zhang, Y. et al. An early warning method of transmission line icing based on power grid meteorological monitoring data. J. Phys.: Conf. Ser. 2532, 012008 (2023).

Andersson, T. R. et al. Seasonal Arctic sea ice forecasting with probabilistic deep learning. Nat. Commun. 12, 5124 (2021).

Li, J. et al. Nondestructive detection and early warning of pavement surface icing based on meteorological information. Materials 16, 6539 (2023).

Toms, B. A., Basara, J. B. & Hong, Y. Usage of existing meteorological data networks for parameterized road ice formation modeling. J. Appl. Meteorol. Climatol. 56, 1959–1976 (2017).

Ladino Moreno, L. A., Stetzer, O. & Lohmann, U. Contact freezing: a review of experimental studies. Atmos. Chem. Phys. 13, 9745–9769 (2013).

Holden, M. A. et al. High-speed imaging of ice nucleation in water proves the existence of active sites. Sci. Adv. 5, eaav4316 (2019).

Aslam M. et al. Plant low-temperature stress: signaling and response. Agronomy 12, 702 (2022).

Pandey, R. et al. Ice-nucleating bacteria control the order and dynamics of interfacial water. Sci. Adv. 2, e1501630 (2016).

Bissoyi, A. et al. Ice nucleation properties of ice-binding proteins from snow fleas. Biomolecules 9, 532 (2019).

Hudait, A., Odendahl, N., Qiu, Y., Paesani, F. & Molinero, V. Ice-nucleating and antifreeze proteins recognize ice through a diversity of anchored clathrate and ice-like motifs. J. Am. Chem. Soc. 140, 4905–4912 (2018).

Roeters, S. J. et al. Ice-nucleating proteins are activated by low temperatures to control the structure of interfacial water. Nat. Commun. 12, 1183 (2021).

Bieber, P. & Borduas-Dedekind, N. High- speed cryo- microscopy reveals that ice- nucleating proteins of pseudomonas syringae trigger freezing at hydrophobic interfaces trigger freezing at hydrophobic interfaces. Sci. Adv. 10, eadn6606 (2024).

Hansen, T. et al. Ice nucleation proteins self-assemble into large fibres to trigger freezing at near 0 °C. eLife 12, RP91976 (2023).

Chen, Y., Lam, J. W. Y., Kwok, R. T. K., Liu, B. & Tang, B. Z. Aggregation-induced emission: fundamental understanding and future developments. Mater. Horiz. 6, 428–433 (2019).

Li, Z. et al. Bioinspired simultaneous changes in fluorescence color, brightness, and shape of hydrogels enabled by AIEgens. Adv. Mater. 32, e1906493 (2020).

He, Z. et al. A freezing‐induced turn‐on imaging modality for real‐time monitoring of cancer cells in cryosurgery. Angew. Chem. Int. Ed. 58, 3834–3837 (2019).

He, H. et al. An ultralight self-powered fire alarm e-textile based on conductive aerogel fiber with repeatable temperature monitoring performance used in firefighting clothing. ACS Nano 16, 2953–2967 (2022).

Abdalzaher M. S., Elsayed H. A., Fouda M. M. & Salim M. M. Employing machine learning and IoT for earthquake early warning system in smart cities. Energies 16, 495 (2023).

Lv L.-Y. et al. Smart fire-warning materials and sensors: design principle, performances, and applications. Mater. Sci. Eng. : R: Rep. 150, 100690 (2022).

Zhang, H. et al. Solar anti-icing surface with enhanced condensate self-removing at extreme environmental conditions. Proc. Natl Acad. Sci. USA 118, e2100978118 (2021).

Guan, J. et al. Direct observation of aggregation-induced emission mechanism. Angew. Chem. Int Ed. Engl. 59, 14903–14909 (2020).

Su G. et al. From Fluorescence‐transfer‐lightening‐printing‐assisted conductive adhesive nanocomposite hydrogels toward wearable interactive optical information‐electronic strain sensors. Adv. Mater. 36, 2400085 (2024).

Sui, X. et al. AIE-active freeze-tolerant hydrogels enable multistage information encryption and decryption at subzero temperatures. Engineering 23, 82–89 (2023).

Zhao Z. et al. A biaxial stretchable, flexible electric heating composite film for de-icing. Compos. Part A: Appl. Sci. Manuf. 162, 107124 (2022).

Stoyanov D. B., Nixon J. D. & Sarlak H. Analysis of derating and anti-icing strategies for wind turbines in cold climates. Applied Energy 288, 116610 (2021).

Shu, L. et al. Study of ice accretion feature and power characteristics of wind turbines at natural icing environment. Cold Reg. Sci. Technol. 147, 45–54 (2018).

Acknowledgements

Z.H. thanks the National Key Research and Development Program of China (2024YFA1509600), the National Natural Science Foundation of China Joint Fund for Regional Innovation and Development (Grant No. U24A20495), the National Natural Science Foundation of China (No. 22122206) and Beijing Municipal Science and Technology Program (Special Initiative for Frontier Innovations in New Materials Technology, No. Z231100006023013), the Natural Science Foundation of Beijing Municipality (2232022). X.C. thanks the National Natural Science Foundation of China (No. 23CAA01015). D.W. thanks the National Natural Science Foundation of China (No. 12304098). We thank Prof. Guoying Bai and Prof. Jing Wang for their contributions. We also thank Mr. Yixin Chen and Mr. Shipeng Wan for their help in the freezing rain tests and the fluorescence spectra experiments, respectively. We thank Tianjin Weisi Experimental Instrument Technology Co., Ltd, for the help in the freezing rain tests of this study.

Author information

Authors and Affiliations

Contributions

W.H., X.C. and D.W. contributed equally to this work. W.H., X.C. and Z.H. conceived the idea and designed the experiments. D.W. and W.H. carried out the experiments of application performance. Z.H. and X.C. supervised and administrated the research. Y.C., H.D., G.L., Z.G. and Y.Y. helped characterizations and analyzed the data. C.G., F.H., Z.C., Y.X. provided valuable advice. W.H., X.C. and D.W. co-wrote the manuscript. All authors discussed the results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Xin Cui, Hao-Yang Mi and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hou, W., Chen, X., Wang, D. et al. Chromatic forecasting hydrogels for anti-icing applications. Nat Commun 16, 4881 (2025). https://doi.org/10.1038/s41467-025-58806-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-58806-2