Abstract

Friction is the central cause for about 1/3 of the primary energy dissipation, severely impacting the performance limits of micro and nanoscale mechanical devices. Especially in two-dimensional semiconductor devices, electronic friction energy dissipation becomes particularly pronounced. However, the dynamic mechanisms underlying electronic friction energy dissipation remain unclear due to the ultrafast timescales of electronic behavior. Here, the ultrafast dynamics of electronic friction energy dissipation in monolayer WS2 is observed using femtosecond transient absorption spectroscopy. We find that friction exhibits a significant enhancement as the rate of electron energy dissipation increases. It is experimentally found to be closely related to the generation of atomic defects at the sliding interfaces. These defects capture electrons in picoseconds and provide a new energy dissipation channel, resulting in increased friction. This study reveals the dynamics of electronic friction energy dissipation, which is vital to understand the origin of friction and improve the performance of micro and nanoscale devices.

Similar content being viewed by others

Introduction

Friction is an inherent phenomenon that is widespread across numerous sliding interfaces in mechanical devices, often resulting in considerable energy dissipation and even device failure1,2,3,4. This energy dissipation is particularly exacerbated in micro and nanoscale devices5,6,7. Two-dimensional semiconductor devices are typical micro and nanoscale devices, which have garnered significant attention due to their excellent optoelectronic properties and frictional characteristics8,9,10,11,12,13. In these devices, electron energy dissipation becomes highly critical and has a substantial impact on friction14,15,16,17,18. The most direct evidence for this impact is the abrupt reduction in friction observed below the superconductivity transition temperature, where electron energy dissipation is markedly suppressed19,20,21. Recent studies also revealed a strong correlation between electron density distribution and friction22,23,24,25,26, electron accumulation or depletion can lead to an increase or decrease in friction. These studies mainly demonstrated the contribution of electronic friction energy dissipation under steady-state conditions. However, understanding the underlying dynamic mechanisms remains a challenge.

The primary challenge in understanding the dynamics of electronic friction energy dissipation is that electronic behaviors occur on ultrafast timescales. These dynamics are intrinsically connected to diverse energy dissipation channels and rates of electrons at the sliding interface. More energy dissipation channels and faster energy dissipation rates can enhance overall electron energy dissipation, resulting in increased friction16,27. While conventional tribological instruments have explored the friction mechanisms at steady state, their limited temporal resolution restricts the ability to observe ultrafast electron dynamics at the sliding interface. The limitation hinders the understanding of the energy dissipation channels and rates, resulting in an insufficient comprehension of the ultrafast dynamics of electronic friction energy dissipation.

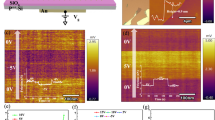

In this study, we experimentally observed the ultrafast dynamics of electronic friction energy dissipation in monolayer WS2, using a femtosecond transient absorption spectroscopy combined with atomic force microscopy in Fig. 1a. The results demonstrate a significant increase in friction with an elevated electron energy dissipation rate. Scanning transmission electron microscopy (STEM) measurements indicate that the increase in friction is dominated by the atomic defects generated by the sliding tip. These defects introduce defect energy levels in monolayer WS2, which capture electrons on a picosecond timescale. It provides a new electron energy dissipation channel in addition to the radiative recombination, accelerating the electron energy dissipation rate (Fig. 1b). Our work gives a direct explanation of the dynamics of electronic friction energy dissipation and provides important guidance for future investigations into ultra-low friction interfaces and semiconductor devices.

a Schematic of the experimental setup. The AFM tip slides on the surface of monolayer WS2, and the dynamics of electrons is detected by a femtosecond ultrafast transient absorption spectroscopy. b Schematic of ultrafast electron dynamics in defective WS2 monolayer. There are two friction energy dissipation channels: the first is the radiative recombination present in the pristine monolayer WS2, while the second involves atomic-level friction defects capture electrons. These friction defects generate at the sliding interface and introduce defect energy levels, which capture electrons. CB: conduction band; VB: valence band. c AFM topography of the monolayer WS2 on SiO2/Si substrate. The underside of WS2 is encapsulated by hexagonal boron nitride. d AFM topography of the monolayer WS2 after tip sliding. The sliding loads from regions 1 to 7 are 100, 500, 1000, 1500, 2000, 2500, and 3000 nN, respectively. The topography experiments were independently repeated three times with similar results. e The relationship between friction coefficient and overall electron energy dissipation rate \({\tau }^{-1}\). The friction coefficient μ is used to represent the relative variation of friction. The electron energy dissipation rate \({\tau }^{-1}\) represents the speed at which excited electrons dissipate energy through various channels. The error bar is obtained by linearly fitting the friction coefficient using the least squares method. Source data of (e) is provided as a Source Data file.

Results

Enhanced friction with increasing electron energy dissipation rate

To investigate electronic friction at the sliding interface, a WS2 film-based sliding interface is established. Its exceptional electronic properties28,29 and ultra-low friction performance1,13 make WS2 an excellent platform for studying electronic friction. Figure 1c shows a topography image of a monolayer WS2 mechanically exfoliated from a bulk crystal and transferred onto a SiO2/Si substrate, with its thickness measured to be 0.84 nm via atomic force microscopy (AFM). The monolayer region is outlined with a blue dashed contour in the optical microscopy image (Supplementary Fig. 1). A multilayer of hexagonal boron nitride is encapsulated beneath the WS2 to provides a flat substrate for the sample30,31,32,33. Another component of the sliding interface is a tip with a high elastic stiffness, which slides on the sample surface using the contact mode AFM. The topography image of the sample after sliding under seven different loads is presented in Fig. 1d. The measurements reveal that there is no obvious topography change in the sliding regions.

To investigate the changes in friction properties at the sliding interface, we established the correlation between the friction coefficient and the electron energy dissipation rate, as presented in Fig. 1e. Although the surface topography of the sample shows no significant alterations following tip sliding, both the friction coefficient and the electron energy dissipation rate exhibit notable variations across seven load regions. Specifically, a clear dependence of the friction coefficient on energy dissipation rate is observed. As the sliding load increases from 100 nN to 3000 nN, the electron energy dissipation rate accelerates, while the friction coefficient exhibits a significant rise. It indicates that the increase in friction is accompanied by a higher electron energy dissipation rate. Considering the close relationship between the electronic properties of monolayer WS2 and its crystalline structure, we hypothesize that the phenomenon is closely related to the microscopic structural changes induced during the sliding process.

The measured friction force maps presents that no obvious microscopic structural changes induced by sliding are observed. To minimize the impact of adsorbate accumulation on friction, we focused analysis on the friction force signals obtained during tip sliding. Some studies suggest that friction force measurements may offer greater resolution in detecting microstructural variations compared to topography maps34,35. The friction force maps under seven sliding loads are shown in Supplementary Fig. 2, revealing no significant microscopic structural changes on the sample surface, such as wrinkles or defects. And the friction force is uniformly distributed across the entire sliding area. It suggests that these factors do not contribute to the increased friction observed in the experiment. To further elucidate the relationship between increased friction and electron behavior, it is essential to examine the more subtle microscopic changes induced by the sliding tip.

Friction enhancement caused by atomic defects

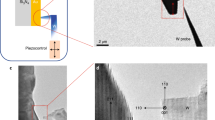

To explore the subtle microscopic structural differences after tip sliding, scanning transmission electron microscopy (STEM) tests are performed to image the atomic structure. Figure 2a presents high-angle annular dark field STEM images of monolayer WS2. A notable number of sulfur vacancies are observed in the sliding regions, which are marked by yellow circles. It is in agreement with previous reports concerning the defect distribution in monolayer WS236,37,38. Comparative analysis of atomic scale images across different sliding load conditions reveals a notable increase in defect density, rising from 0.09 nm−2 to 0.51 nm−2 as the sliding load increased (shown in Supplementary Movie). This observation aligns with other studies of TMDC materials38,39,40, indicating a strong correlation between the generation of sulfur vacancies and the applied load during sliding. Thus, the results clearly demonstrate that atomic defects are introduced on the sample surface during sliding, which can provide a new electron energy dissipation channel.

a High-angle annular dark field (HAADF) STEM images of monolayer WS2 after tip sliding. Sulfur vacancies are marked by yellow circles. The sliding loads are 500, 1000, 2000, and 3000 nN respectively. b Corresponding friction force maps under a constant normal force of 50 nN. c Relationship curve between friction force and normal force of monolayer WS2 in varying defect densities. Error bars represent the standard deviation of the data based on 256 data points. d Friction coefficient diagram under different defect densities is calculated from the line slope in c. The error bar is obtained by linearly fitting the friction coefficient. Source data of c and d is provided as a Source Data file.

To investigate the variations in friction forces across monolayer WS2 with different defect densities, we employ the lateral force module of atomic force microscopy. The friction force is measured under small normal force using a tip with a lower elastic stiffness, so defects generated during this process can be negligible. The friction force maps obtained under a constant normal force of 50 nN are presented in Fig. 2b, which compares the friction forces in regions with varying defect densities under identical testing conditions. Notably, as the defect density increases, a gradual rise in friction force is observed, consistent with trends reported in other studies of disordered materials41,42,43. The phenomenon is typically attributed to factors such as substrate roughness44 and puckering effects12,42. However, there is no disorder observed in the friction force maps shown in Fig. 2b, including phenomena such as wrinkles, wear, or localized increases in friction at defect edges. It presents that the increased friction in our experiment is not primarily driven by disorder-related mechanisms, like substrate roughness or out-of-plane deformation. And we mainly focus on the impact of atomic-level defects at the sliding interface on friction.

To further quantify the frictional properties of defective WS2 monolayer, the friction coefficients of varying defect density regions are measured. The normal forces are selected ranged from 10 to 60 nN, encompassing six distinct levels. The relationship between friction force and normal force is illustrated in Fig. 2c, where the dependence of friction on load is linear within the range of load, allowing the determination of the friction coefficient17,45. And the lateral force traces and topography of defective WS2 monolayer are shown in Supplementary Fig. 3. Consequently, the friction coefficients of monolayer WS2 are obtained to be approximately 10−2, which aligns with results from other studies on monolayer TMDC materials10,46. It also clearly indicates that monolayer WS2 exhibits excellent properties as a solid lubricant. Moreover, as the defect density increased, the friction coefficients enhanced from 0.0102 for the pristine sample to 0.0184, as shown in Fig. 2d. The lateral force traces for defective samples with different defect densities are shown in Supplementary Fig. 4. Frictional characteristics studied by atomic force microscopy demonstrate that the friction coefficients of defective WS2 nearly doubled, which is attributed to atomic-level defects caused by a sliding tip.

Evidence of electrons captured by friction defects

To obtain evidence of electrons captured by defects, we conduct Raman spectroscopy to demonstrate that atomic-level defects disrupt the periodic lattice structure of monolayer WS2, altering its electronic properties. Figure 3a illustrates the evolution of the Raman spectra as the defect density increases, with the A1g peak appearing at approximately 417 cm−1. At lower defect densities, the measured A1g peak shows no significant changes, and the spectra are well-fitted with single-peak Lorentzian curves. When the defect density is relatively high, a shoulder peak is observed in the A1g mode. It is attributed to the breaking of lattice symmetry caused by the atomic defects, referred to as the D mode at around 411 cm−1, and it is associated with sulfur vacancy47,48. As the defect density increases from 0.42 nm−2 to 0.51 nm−2, the intensity of the D peak also increases (Supplementary Fig. 5), agreeing with trends reported in other studies48. The appearance and enhancement of D mode in Raman spectra indicate the electronic properties of defective samples have changed.

a Evolution of Raman spectra with defect density. A defect-induced (D) mode appears when the defect density is higher than 0.42 nm−2. The spectra are fitted with Lorentzian functions. Signals are presented in arbitrary units (arb. units). b PL spectra evolution with defect density. The neutral A-exciton (XA) PL peak is around 1.98 eV. c Correlation between the A-exciton PL intensity and defect density. Error bars are the standard deviation of three measurements from the same sample. d PL spectra of pristine and defective WS2 at 77 K. The neutral A-exciton (XA) and defect-bound exciton (XD) peaks appear at 2.02 eV and 1.75 eV, respectively. These PL peaks correspond to the electron energy dissipation channels of radiative recombination and electron captured by friction defects, respectively. Source data of (a–d) is provided as a Source Data file.

For further investigation of the electronic properties of defective samples, photoluminescence (PL) spectra evolution for regions with varying defect densities is shown in Fig. 3b. In all spectra, the neutral A-exciton PL peak appears at 1.98 eV, corresponding to the direct band gap at the K point of the Brillouin zone for monolayer WS2. It represents the electron energy dissipation channel of radiative recombination. Analysis of the PL spectra presented in Fig. 3c reveals that when the defect density is below 0.17 nm−2, the neutral A-exciton intensities remain virtually unchanged. As the defect density increases, a gradual reduction in the intensity of the A-exciton peak is observed. Compared to Raman spectroscopy, PL spectroscopy can detect atomic defects with lower densities. Notably, the intensity of the A-exciton for the sample with a defect concentration of 0.51 nm−2 decreased by a factor of three compared to the pristine sample. It suggests that fewer electrons at the conduction band dissipate energy through radiative recombination, which is related to more electrons captured by defects.

To acquire the direct evidence of electrons captured by defects, a low-temperature PL measurement is conducted at 77 K. As illustrated in Fig. 3d, the neutral A-exciton peak appears at 2.02 eV in both pristine and defective regions. In the defective region, an additional defect-induced emission peak at 1.75 eV is observed38. The new peak originates from defect energy levels introduced by friction defects49,50, which are capable of capturing electrons. The electrons in these defect energy levels subsequently undergo radiative recombination with holes in the valence band, forming defect-bound excitons (schematic in Supplementary Fig. 6). This process leads to a reduction of electrons participating in the radiative recombination of neutral A-excitons, which is manifested as a decrease in the A-exciton intensity. The PL results demonstrate that, in addition to the electron energy dissipation channel of radiative recombination, the defective WS2 monolayer provides a new electron energy dissipation channel via electrons captured by friction defects.

Ultrafast dynamic of electronic friction energy dissipation

To elucidate the electron dynamics influenced by friction defects, femtosecond transient absorption spectroscopy (shown in the Methods section and Supplementary Fig. 7) is employed to investigate electron energy dissipation. Through the ultrafast spectroscopy technique, we can obtain insights into the electron energy dissipation channels and rates within defective samples. A pump beam of 2.82 eV (440 nm) is utilized to excite electrons in WS2 with a fluence of 2 µJ cm−2, thereby avoiding nonlinear optical phenomena51,52. It is further confirmed by experiments conducted at varying pump fluences, as shown in Supplementary Fig. 8. The thermal effect is negligible in this study, as the relaxation dynamics are independent of pump fluence. A probe energy is selected as 1.98 eV (625 nm), resonating with the neutral A-exciton of WS2, to monitor the electron dynamics at the conduction band. The change in probe beam reflection ΔR (x, y, t) induced by the pump beam is proportional to the electron density n (x, y, t) at the conduction band minimum of WS2.

The electron energy dissipation dynamics can be obtained from transient absorption signal decay traces with different defect densities, as presented in Fig. 4a. It is evident that with the increase in defect density, the electron energy dissipation rate accelerates, indicating that friction defects enhance the electron energy dissipation. For the pristine sample, the decay trace can be well-fitted by a single exponential function, with a lifetime of about 85 ps. Following the generation of friction defects, the electron dynamics is faster than the pristine sample, and a rapid decay component emerges within the first 10 ps. Thus, to obtain the energy dissipation rates of two energy dissipation channels, we employed a biexponential function convolved with the experimental response function for curve fitting. The slow decay component varies little at around 85 ps with increasing defect density, which is attributed to the radiative recombination of neutral A-exciton53,54. Additionally, the fast decay component occurring at 1 to 10 ps (Supplementary Fig. 9) is ascribed to electrons captured by friction defects50,55,56. The result demonstrates there are two friction energy dissipation channels in defective regions.

a Transient absorption decay traces with different defect densities of monolayer WS2. The pump and probe wavelengths are 440 nm and 625 nm, respectively. The smooth lines are the fitting curves with biexponential decays convoluted with an experimental response function. b Lifetime amplitude of fast decay (electrons captured by defects) and slow decay (radiative recombination) components as a function of defect density. c The lifetime of a defective WS2 monolayer with different defect densities. Error bars in b and c are the standard deviation of three measurements from the same sample. d Schematic of ultrafast electron dynamics in defective WS2 monolayer. CB: conduction band; VB: valence band. Source data of (a–c) is provided as a Source Data file.

To further clarify the dynamic mechanism of electronic friction energy dissipation induced by defects, it is essential to obtain the energy dissipation rate of defective WS2. We first need to calculate the average energy dissipation lifetime using the formulas, \({\tau }_{{{{\rm{av}}}}}={A}_{1}{\tau }_{1}+{A}_{2}{\tau }_{2}\), where \({\tau }_{1}\) and \({\tau }_{2}\) are the decay lifetime of radiative recombination and electrons captured by friction defects, respectively; \({A}_{1}\) and \({A}_{2}\) are the corresponding normalized amplitude. Analyzing the fitting curves of the decay traces, the evolution of dissipative component amplitude with defect density is revealed in Fig. 4b. As the defect density increases, the amplitude \({A}_{1}\) of radiative recombination decreases from 100% to 59.8%, while the amplitude \({A}_{2}\) of electrons captured by defects increases. The trend is consistent with the significant reduction observed in the neutral A-exciton intensity of our PL spectra. Therefore, the calculated average lifetime \({\tau }_{{{{\rm{av}}}}}\) in Fig. 4c shortens from 85 ps for the pristine sample to 53 ps for the defective sample. Correspondingly, the overall electron energy dissipation rate \({\tau }^{-1}\) increases markedly, which is the reciprocal of the average lifetime \({\tau }_{{{{\rm{av}}}}}\). It suggests that the friction defects in monolayer WS2 lead to an increase in the electron energy dissipation.

The schematic of ultrafast electron dynamics in defective WS2 monolayer is depicted in Fig. 4d. Electrons are pumped to the conduction band within hundreds of femtoseconds, and their energy dissipation channels and rates are subsequently probed using a 1.98 eV probe beam. A portion of the electrons is captured by friction defects within 10 ps, forming a fast energy dissipation channel (Channel 2). Another portion of electrons dissipates energy through radiative recombination at about 100 ps, constituting a slow energy dissipation channel (Channel 1). In other words, in the pristine WS2 sample, the excited electrons primarily dissipate energy through radiative recombination. In contrast, in the defective sample, friction defects introduce defect energy levels within the band structure, which capture electrons in picoseconds. Consequently, the introduction of friction defects provides a new channel for electron energy dissipation, accelerating the electron energy dissipation rate and resulting in increased friction.

Discussion

In summary, we elucidated the ultrafast dynamics mechanism of electronic friction in defective WS2 monolayer using ultrafast spectroscopy combined with atomic force microscopy. Experimental results indicate that increased friction at the sliding interface is attributed to the accelerated electron energy dissipation rate, which is caused by atomic-scale friction defects. These defects disrupt the material’s lattice structure, generating defect energy levels that capture electrons. This process provides a new channel for electron energy dissipation, leading to an increase in friction. Furthermore, by exploiting the high sensitivity of electron energy dissipation rate to defects, transient absorption spectroscopy has significantly reduced the detection limitation for atomic-scale friction defects. It is of great significance to solve the problem of detecting the initiation and evolution of atomic defects at friction interfaces. Compared to traditional tribological detection instruments such as atomic force microscopy, the performance is improved considerably (Supplementary Fig. 10). It is also worth noting that while electron dissipation plays a critical role in friction enhancement, the contributions of other mechanisms, such as phonon dissipation and substrate’s energy dissipation, are also important topics for further investigation. Future studies aimed at improving measurement techniques and theoretical models will be essential to elucidate and quantify the contributions of various mechanisms to friction enhancement. Our research provides significant support for future investigations into the origins of friction and the realization of ultra-low friction interfaces. It can also provide guidance for improving the performance limit of micro and nanoscale devices.

Methods

Sample preparation

Monolayer WS2 was mechanically exfoliated from a bulk crystal (2D semiconductors), and it was transferred to a few-layer hexagonal boron nitride on SiO2/Si substrate using a dry method by Gel-film (Gelpark). Encapsulating h-BN at the bottom helps to reduce the effect of substrate roughness and impurities on friction force and electron energy dissipation rate, so the sample properties more closely reflect their intrinsic characteristics. The samples were annealed under a high-vacuum condition for 2 h at 300 °C. Optical image were obtained using a 100x microscopic objective (Olympus MPlan N 100x, 0.9 NA).

Atomic force microscope

The sliding tests were conducted using the contact mode AFM (Dimension Icon, Bruker), and a tip with a high elastic stiffness (AC160TS, Olympus, K = 33.6 N/m) slides on the sample surface to obtain the topography and friction force of monolayer WS2. The friction coefficient tests were performed using the same AFM with the tip (HQ:NSC18/Pt, MikroMasch, K = 2.8 N/m). The vertical sensitivity of the AFM cantilever was calibrated by the standard Sader’s method. The lateral sensitivity was calibrated using the modified wedge calibration method. All the measurements were performed under stable environmental conditions (≈20~25 °C, 20~30% relative humidity). The topography images were analyzed using the software Gwyddion 2.65.

Scanning Transmission Electron Microscopy

The monolayer WS2 was prepared on a 400 mesh Cu grid with carbon film (Quantifoil) by using the dry transfer method. STEM images were carried out by FEI Titan Cubed Themis G2 300 operating at 300 kV. A HAADF detector with a collection angle of 61 to 200 mrad and a camera length of 91 mm. Wiener filter is used to eliminate the noise of HAADF-STEM images and enhance the visibility of structural details.

Raman and PL experiments

Raman and PL spectra (room temperature) were obtained by a spectrometer (Evolution, Horiba) with an excitation wavelength of 532 nm. The low temperature (77 K) PL spectrum was performed using a cryogenic chamber (CryoAdvance 50, Montana) with an excitation wavelength of 473 nm.

Transient absorption Microscopy

A Ti: sapphire laser (Coherent Chameleon Ultra II) was used as the light source (140 fs pulse-width, 80 MHz repetition rate, average power of 3.5 W at 800 nm, Gaussian spot). The fundamental output of the laser was split into two beams in an optical parametric oscillator (Coherent Chameleon Compact OPO). One beam served as the pump beam. The other output is used as the probe beam. The pump and probe beams were focused spatially overlapped at the sample with an objective (Zeiss, EC Epiplan 100X, 0.9 NA). The pump beam was modulated at 1 MHz with an acousto-optic modulator (AOM, Gooch, Housego 3080–125). The reflective probe beam was detected with an avalanche photodiode (APD, Hamamatsu C12702-04). The output of the APD was monitored with a lock-in amplifier (Zurich Instruments, HF2LI). Ultrafast pump-probe traces were obtained by delaying the probe to the pump with a mechanical translation stage (Thorlabs, DDS600/M).

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data supporting the findings of this study are available within the paper and the Supplementary Information. Source data are provided with this paper.

References

Hod, O., Meyer, E., Zheng, Q. & Urbakh, M. Structural superlubricity and ultralow friction across the length scales. Nature 563, 485–492 (2018).

Berman, D., Deshmukh, S. A., Sankaranarayanan, S. K. R. S., Erdemir, A. & Sumant, A. V. Macroscale superlubricity enabled by graphene nanoscroll formation. Science 348, 1118–1122 (2015).

Holmberg, K., Andersson, P. & Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 47, 221–234 (2012).

Liu, H., Yang, B., Wang, C., Han, Y. & Liu, D. The mechanisms and applications of friction energy dissipation. Friction 11, 839–864 (2023).

Koren, E., Lörtscher, E., Rawlings, C., Knoll, A. W. & Duerig, U. Adhesion and friction in mesoscopic graphite contacts. Science 348, 679–683 (2015).

Socoliuc, A. et al. Atomic-scale control of friction by actuation of nanometer-sized contacts. Science 313, 207–210 (2006).

Huang, X. et al. Microscale Schottky superlubric generator with high direct-current density and ultralong life. Nat. Commun. 12, 2268 (2021).

Liao, M. et al. UItra-low friction and edge-pinning effect in large-lattice-mismatch van der Waals heterostructures. Nat. Mater. 21, 47–53 (2022).

Li, H. et al. Superlubricity between MoS2 Monolayers. Adv. Mater. 29, 1701474 (2017).

Yang, X., Li, R., Wang, Y. & Zhang, J. Tunable, wide-temperature, and macroscale superlubricity enabled by nanoscale Van Der Waals Heterojunction-to-Homojunction Transformation. Adv. Mater. 35, 2303580 (2023).

Liu, Y. et al. Interlayer friction and superlubricity in single-crystalline contact enabled by two-dimensional flake-wrapped atomic force microscope tips. ACS Nano 12, 7638–7646 (2018).

Lee, C. et al. Frictional characteristics of atomically thin sheets. Science 328, 76–80 (2010).

Berman, D., Farfan-Cabrera, L. I., Rosenkranz, A. & Erdemir, A. 2D materials for durable and sustainable electric vehicles. Nat. Rev. Mater. 9, 527–529 (2024).

Kisiel, M. et al. Mechanical dissipation from charge and spin transitions in oxygen-deficient SrTiO3 surfaces. Nat. Commun. 9, 2946 (2018).

Yildiz, D., Kisiel, M., Gysin, U., Gürlü, O. & Meyer, E. Mechanical dissipation via image potential states on a topological insulator surface. Nat. Mater. 18, 1201–1206 (2019).

Shi, B. et al. Electronic friction and tuning on atomically thin MoS2. npj 2D Mater. Appl. 6, 39 (2022).

Greenwood, G. et al. Dynamically tuning friction at the graphene interface using the field effect. Nat. Commun. 14, 5801 (2023).

Park, J. Y., Ogletree, D. F., Thiel, P. A. & Salmeron, M. Electronic control of friction in silicon pn junctions. Science 313, 186–186 (2006).

Kisiel, M. et al. Suppression of electronic friction on Nb films in the superconducting state. Nat. Mater. 10, 119–122 (2011).

Wang, W., Dietzel, D. & Schirmeisen, A. Single-asperity sliding friction across the superconducting phase transition. Sci. Adv. 6, eaay0165 (2020).

Dayo, A., Alnasrallah, W. & Krim, J. Superconductivity-dependent sliding friction. Phys. Rev. Lett. 80, 1690–1693 (1998).

Langer, M. et al. Giant frictional dissipation peaks and charge-density-wave slips at the NbSe2 surface. Nat. Mater. 13, 173–177 (2014).

Li, Y., Wu, B., Ouyang, W., Liu, Z. & Wang, W. Experimental decoding and tuning electronic friction of Si nanotip sliding on graphene. Nano Lett. 24, 1130–1136 (2024).

Song, A. et al. Fluctuation of interfacial electronic properties induces friction tuning under an electric field. Nano Lett. 22, 1889–1896 (2022).

Sun, J. et al. Charge density evolution governing interfacial friction. J. Am. Chem. Soc. 145, 5536–5544 (2023).

Wolloch, M., Levita, G., Restuccia, P. & Righi, M. C. Interfacial charge density and its connection to adhesion and frictional forces. Phys. Rev. Lett. 121, 026804 (2018).

Dou W. & Subotnik J. E. Perspective: How to understand electronic friction. J. Chem. Phys. 148, 230901 (2018).

Fiori, G. et al. Electronics based on two-dimensional materials. Nat. Nanotechnol. 9, 768–779 (2014).

Mak, K. F. & Shan, J. Photonics and optoelectronics of 2D semiconductor transition metal dichalcogenides. Nat. Photonics 10, 216–226 (2016).

Dean, C. R. et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 5, 722–726 (2010).

Cui, X. et al. Multi-terminal transport measurements of MoS2 using a van der Waals heterostructure device platform. Nat. Nanotechnol. 10, 534–540 (2015).

Tsen, A. W. et al. Nature of the quantum metal in a two-dimensional crystalline superconductor. Nat. Phys. 12, 208–212 (2016).

Ma, Q. et al. Observation of the nonlinear Hall effect under time-reversal-symmetric conditions. Nature 565, 337–342 (2019).

Hopster, J. et al. Damage in graphene due to electronic excitation induced by highly charged ions. 2D Mater. 1, 011011 (2014).

Yang, Y. et al. Atomic defect quantification by lateral force microscopy. ACS Nano 18, 6887–6895 (2024).

Zhang, F. et al. Carbon doping of WS2 monolayers: Bandgap reduction and p-type doping transport. Sci. Adv. 5, eaav5003 (2019).

Chow, P. K. et al. Defect-induced photoluminescence in monolayer semiconducting transition metal dichalcogenides. ACS Nano 9, 1520–1527 (2015).

Carozo, V. et al. Optical identification of sulfur vacancies: Bound excitons at the edges of monolayer tungsten disulfide. Sci. Adv. 3, e1602813 (2017).

Chu, Z. et al. Unveiling defect-mediated carrier dynamics in monolayer semiconductors by spatiotemporal microwave imaging. PNAS 117, 13908–13913 (2020).

Han, X. et al. Atomically engineering metal vacancies in monolayer transition metal dichalcogenides. Nat. Synth. 3, 586–594 (2024).

Sun X.-Y., Wu R., Xia R., Chu X.-H. & Xu Y.-J. Effects of Stone-Wales and vacancy defects in atomic-scale friction on defective graphite. Appl. Phys. Lett. 104, 183109 (2014).

Gajurel, P. et al. Vacancy-controlled contact friction in graphene. Adv. Funct. Mater. 27, 1702832 (2017).

Zambudio, A. et al. Fine defect engineering of graphene friction. Carbon 182, 735–741 (2021).

Ye, Z., Balkanci, A., Martini, A. & Baykara, M. Z. Effect of roughness on the layer-dependent friction of few-layer graphene. Phys. Rev. B 96, 115401 (2017).

McClimon, J. B. et al. The effects of humidity on the velocity-dependence and frictional ageing of nanoscale silica contacts. Tribol. Lett. 72, 105 (2024).

He, F. et al. In-plane potential gradient induces low frictional energy dissipation during the stick-slip sliding on the surfaces of 2D materials. Small 15, 1904613 (2019).

Lee, C. et al. Investigating heterogeneous defects in single-crystalline WS2 via tip-enhanced Raman spectroscopy. npj 2D Mater. Appl. 6, 67 (2022).

Lee, C. et al. Unveiling defect-related raman mode of monolayer WS2 via tip-enhanced resonance Raman Scattering. ACS Nano 12, 9982–9990 (2018).

Hu, Z. et al. The role of oxygen atoms on excitons at the edges of monolayer WS2. Nano Lett. 19, 4641–4650 (2019).

Liu, H., Wang, C., Zuo, Z., Liu, D. & Luo, J. Direct visualization of exciton transport in defective few-layer WS2 by ultrafast microscopy. Adv. Mater. 32, 1906540 (2020).

Yu, Y. et al. Fundamental limits of exciton-exciton annihilation for light emission in transition metal dichalcogenide monolayers. Phys. Rev. B 93, 201111 (2016).

Liu, H. et al. Direct visualization of dark interlayer exciton transport in Moiré superlattices. Nano Lett. 24, 339–346 (2023).

Yuan, L. et al. Photocarrier generation from interlayer charge-transfer transitions in WS2-graphene heterostructures. Sci. Adv. 4, e1700324 (2018).

Yuan, L. et al. Twist-angle-dependent interlayer exciton diffusion in WS2–WSe2 heterobilayers. Nat. Mater. 19, 617–623 (2020).

Chen, K. et al. Experimental evidence of exciton capture by mid-gap defects in CVD grown monolayer MoSe2. npj 2D Mater. Appl. 1, 15 (2017).

Yuan, L., Wang, T., Zhu, T., Zhou, M. & Huang, L. Exciton dynamics, transport, and annihilation in atomically thin two-dimensional semiconductors. J. Phys. Chem. Lett. 8, 3371–3379 (2017).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 52425503 (D.L.), 52475199 (H.L.), and 52350380 (H.L.)).

Author information

Authors and Affiliations

Contributions

R.H. contributed to the experimental design, execution, data analysis, and drafting of the original manuscript. S.C., C.W., and S.H. were responsible for sample preparation and conducting the experiments. H.X., Z.S., and Huixian Liu performed data analysis and contributed to discussions of the results. J.L. provided guidance and critical insights for the project. D.L. supervised and directed the project, managing all aspects of the research. Huan Liu conceptualized and designed the study, oversaw the research process, and contributed significantly to the manuscript’s revision. All authors participated in the writing and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Wengen Ouyang and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Han, R., Chen, S., Wang, C. et al. Ultrafast dynamics of electronic friction energy dissipation in defective semiconductor monolayer. Nat Commun 16, 4615 (2025). https://doi.org/10.1038/s41467-025-59978-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-59978-7