Abstract

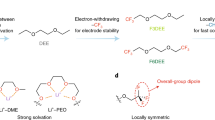

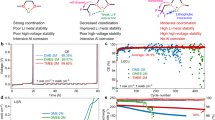

Recent electrolyte solvent design based on weakening lithium-ion solvation have shown promise in enhancing cycling performance of Li-metal batteries. However, they often face slow redox kinetics and poor cycling reversibility at high rate. Here we report using asymmetric solvent molecules substantially accelerates Li redox kinetics. Asymmetric ethers (1-ethoxy-2-methoxyethane, 1-methoxy-2-propoxyethane) showed higher exchange current densities and enhanced high-rate Li0 plating/stripping reversibility compared to symmetric ethers. Adjusting fluorination levels further improved oxidative stability and Li0 reversibility. The asymmetric 1-(2,2,2-trifluoro)-ethoxy-2-methoxyethane, with 2 M lithium bis(fluorosulfonyl)imide, exhibited high exchange current density, oxidative stability, compact solid–electrolyte interphase (~10 nm). This electrolyte exhibited superior performance among state-of-the-art electrolytes, enabling over 220 cycles in high-rate Li (50 μm)||LiNi0.8Mn0.1Co0.1O2 (NMC811, 4.9 mAh cm−2) cells and for the first time over 600 cycles in anode-free Cu | |Ni95 pouch cells (200 mAh) under electric vertical take-off and landing cycling protocols. Our findings on asymmetric molecular design strategy points to a new pathway towards achieving fast redox kinetics for high-power Li-metal batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

27,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

118,99 € per year

only 9,92 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data are included in the paper and its Supplementary Information. Source data are provided with this paper.

Code availability

The code and data used to determine dipole orientations is available at https://github.com/Adi1008/asymmetric-solvents.

References

Albertus, P., Babinec, S., Litzelman, S. & Newman, A. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 3, 16–21 (2018).

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019).

Cheng, X. B. et al. A review of solid electrolyte interphases on lithium metal anode. Adv. Sci. 3, 1500213 (2016).

Sayavong, P. et al. Dissolution of the solid electrolyte interphase and its effects on lithium metal anode cyclability. J. Am. Chem. Soc. 145, 12342–12350 (2023).

Boyle, D. T. et al. Resolving current-dependent regimes of electroplating mechanisms for fast charging lithium metal anodes. Nano Lett. 22, 8224–8232 (2022).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotech. 12, 194–206 (2017).

Hobold, G. M. et al. Moving beyond 99.9% Coulombic efficiency for lithium anodes in liquid electrolytes. Nat. Energy 6, 951–960 (2021).

Xiao, J. et al. Understanding and applying coulombic efficiency in lithium metal batteries. Nat. Energy 5, 561–568 (2020).

Yamada, Y., Wang, J., Ko, S., Watanabe, E. & Yamada, A. Advances and issues in developing salt-concentrated battery electrolytes. Nat. Energy 4, 269–280 (2019).

Qian, J. et al. High rate and stable cycling of lithium metal anode. Nat. Commun. 6, 6362 (2015).

Cao, X., Jia, H., Xu, W. & Zhang, J.-G. Localized high-concentration electrolytes for lithium batteries. J. Electrochem. Soc. 168, 010522 (2021).

Li, G.-X. et al. Enhancing lithium-metal battery longevity through minimized coordinating diluent. Nat. Energy 9, 817–827 (2024).

Zhang, H. et al. Electrolyte additives for lithium metal anodes and rechargeable lithium metal batteries: progress and perspectives. Angew. Chem. Int. Ed. 57, 15002–15027 (2018).

Yang, G. et al. Improving the cyclability performance of lithium-ion batteries by introducing lithium difluorophosphate (LiPO2F2) additive. RSC Adv. 7, 26052–26059 (2017).

Kim, S. C. et al. High-entropy electrolytes for practical lithium metal batteries. Nat. Energy 8, 814–826 (2023).

Wang, Q. et al. High entropy liquid electrolytes for lithium batteries. Nat. Commun. 14, 440 (2023).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Wang, Y. et al. Fluorination in advanced battery design. Nat. Rev. Mater. 9, 119–133 (2024).

Chen, Y. et al. Steric effect tuned ion solvation enabling stable cycling of high-voltage lithium metal battery. J. Am. Chem. Soc. 143, 18703–18713 (2021).

Yu, Z. et al. Rational solvent molecule tuning for high-performance lithium metal battery electrolytes. Nat. Energy 7, 94–106 (2022).

Holoubek, J. et al. Tailoring electrolyte solvation for Li metal batteries cycled at ultra-low temperature. Nat. Energy 6, 303–313 (2021).

Zhang, G. et al. A monofluoride ether-based electrolyte solution for fast-charging and low-temperature non-aqueous lithium metal batteries. Nat. Commun. 14, 1081 (2023).

Ko, S. et al. Electrode potential influences the reversibility of lithium-metal anodes. Nat. Energy 7, 1217–1224 (2022).

Diederichsen, K. M., McShane, E. J. & McCloskey, B. D. Promising routes to a high Li+ transference number electrolyte for lithium ion batteries. ACS Energy Lett. 2, 2563–2575 (2017).

Logan, E. & Dahn, J. Electrolyte design for fast-charging Li-ion batteries. Trends Chem. 2, 354–366 (2020).

Holoubek, J. et al. Toward a quantitative interfacial description of solvation for Li metal battery operation under extreme conditions. Proc. Natl Acad. Sci. USA 120, e2310714120 (2023).

Sheng, L. et al. Suppressing electrolyte-lithium metal reactivity via Li+-desolvation in uniform nano-porous separator. Nat. Commun. 13, 172 (2022).

Liang, P. et al. Competitive coordination of ternary anions enabling fast Li‐ion desolvation for low‐temperature lithium metal batteries. Adv. Funct. Mater. 34, 2309858 (2024).

Yang, X.-G., Liu, T., Ge, S., Rountree, E. & Wang, C.-Y. Challenges and key requirements of batteries for electric vertical takeoff and landing aircraft. Joule 5, 1644–1659 (2021).

Jiao, S. et al. Stable cycling of high-voltage lithium metal batteries in ether electrolytes. Nat. Energy 3, 739–746 (2018).

Li, A.-M. et al. Asymmetric electrolyte design for high-energy lithium-ion batteries with micro-sized alloying anodes. Nat. Energy 9, 1551–1560 (2024).

Von Aspern, N., Röschenthaler, G. V., Winter, M. & Cekic‐Laskovic, I. Fluorine and lithium: ideal partners for high‐performance rechargeable battery electrolytes. Angew. Chem. Int. Ed. 58, 15978–16000 (2019).

Hatherall, O., Barai, A., Niri, M. F., Wang, Z. & Marco, J. Novel battery power capability assessment for improved eVTOL aircraft landing. Appl. Energy 361, 122848 (2024).

Boyle, D. T. et al. Transient voltammetry with ultramicroelectrodes reveals the electron transfer kinetics of lithium metal anodes. ACS Energy Lett. 5, 701–709 (2020).

Boyle, D. T. et al. Correlating kinetics to cyclability reveals thermodynamic origin of lithium anode morphology in liquid electrolytes. J. Am. Chem. Soc. 144, 20717–20725 (2022).

Wang, H. et al. Correlating Li-ion solvation structures and electrode potential temperature coefficients. J. Am. Chem. Soc. 143, 2264–2271 (2021).

Aurbach, D., Gofer, Y. & Langzam, J. The correlation between surface chemistry, surface morphology, and cycling efficiency of lithium electrodes in a few polar aprotic systems. J. Electrochem. Soc. 136, 3198 (1989).

Adams, B. D., Zheng, J., Ren, X., Xu, W. & Zhang, J. G. Accurate determination of Coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2018).

Park, S., Kim, S., Lee, J.-A., Ue, M. & Choi, N.-S. Liquid electrolyte chemistries for solid electrolyte interphase construction on silicon and lithium-metal anodes. Chem. Sci. 14, 9996–10024 (2023).

Huang, A. et al. Low-temperature and fast-charging lithium metal batteries enabled by solvent–solvent interaction mediated electrolyte. Nano Lett. 24, 7499–7507 (2024).

Xu, K. ‘Charge-transfer’ process at graphite/electrolyte interface and the solvation sheath structure of Li+ in nonaqueous electrolytes. J. Electrochem. Soc. 154, A162 (2007).

Xue, W. et al. Ultra-high-voltage Ni-rich layered cathodes in practical Li metal batteries enabled by a sulfonamide-based electrolyte. Nat. Energy 6, 495–505 (2021).

Wu, L.-Q. et al. Unveiling the role of fluorination in hexacyclic coordinated ether electrolytes for high-voltage lithium metal Bbatteries. J. Am. Chem. Soc. 146, 5964–5976 (2024).

Fang, C. et al. Quantifying inactive lithium in lithium metal batteries. Nature 572, 511–515 (2019).

Deng, W. et al. Quantification of reversible and irreversible lithium in practical lithium-metal batteries. Nat. Energy 7, 1031–1041 (2022).

Wang, H. et al. Efficient lithium metal cycling over a wide range of pressures from an anion-derived solid–electrolyte interphase framework. ACS Energy Lett. 6, 816–825 (2021).

Huang, W., Wang, H., Boyle, D. T., Li, Y. & Cui, Y. Resolving nanoscopic and mesoscopic heterogeneity of fluorinated species in battery solid-electrolyte interphases by cryogenic electron microscopy. ACS Energy Lett. 5, 1128–1135 (2020).

Guo, R. & Gallant, B. M. Li2O solid electrolyte interphase: probing transport properties at the chemical potential of lithium. Chem. Mater. 32, 5525–5533 (2020).

Wang, C. et al. Lithium difluorophosphate as a promising electrolyte lithium additive for high-voltage lithium-ion batteries. ACS Appl. Energy Mater. 1, 2647–2656 (2018).

Niu, C. et al. Balancing interfacial reactions to achieve long cycle life in high-energy lithium metal batteries. Nat. Energy 6, 723–732 (2021).

Zheng, J. et al. Regulating electrodeposition morphology of lithium: towards commercially relevant secondary Li metal batteries. Chem. Soc. Rev. 49, 2701–2750 (2020).

Lin, L. et al. Regulating lithium nucleation at the electrolyte/electrode interface in lithium metal batteries. Adv. Funct. Mater. 34, 2315201 (2024).

Eftekhari, A. Energy efficiency: a critically important but neglected factor in battery research. Sustain. Energy Fuels 1, 2053–2060 (2017).

Bai, P., Li, J., Brushett, F. R. & Bazant, M. Z. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ. Sci. 9, 3221–3229 (2016).

Sand, H. J. III. On the concentration at the electrodes in a solution, with special reference to the liberation of hydrogen by electrolysis of a mixture of copper sulphate and sulphuric acid. London Edinburgh Philos. Mag. J. Sci. 1, 45–79 (1901).

Berg, H. & Zackrisson, M. Perspectives on environmental and cost assessment of lithium metal negative electrodes in electric vehicle traction batteries. J. Power Sources 415, 83–90 (2019).

Li, Z. et al. Critical review of fluorinated electrolytes for high‐performance lithium metal batteries. Adv. Funct. Mater. 33, 2300502 (2023).

Ren, X. et al. Enabling high-voltage lithium-metal batteries under practical conditions. Joule 3, 1662–1676 (2019).

Fredericks, W. L., Sripad, S., Bower, G. C. & Viswanathan, V. Performance metrics required of next-generation batteries to electrify vertical takeoff and landing (VTOL) aircraft. ACS Energy Lett. 3, 2989–2994 (2018).

Ko, Y. et al. Omics-enabled understanding of electric aircraft battery electrolytes. Joule 8, 2393–2411 (2024).

Shen, X. et al. The failure of solid electrolyte interphase on Li metal anode: structural uniformity or mechanical strength? Adv. Energy Mater. 10, 1903645 (2020).

Lin, Y. et al. Impact of the fluorination degree of ether-based electrolyte solvents on Li-metal battery performance. J. Mater. Chem. A 12, 2986–2993 (2024).

Frisch, M. E. et al. Gaussian 16, Revision C.01 (Gaussian Inc., 2016).

Dennington, R., Keith, T. A. & Millam, J. M. GaussView v.6.0.16 (Semichem Inc., 2016).

Hanwell, M. D. et al. Avogadro: an advanced semantic chemical editor, visualization, and analysis platform. J. Cheminform. 4, 17 (2012).

Bursch, M., Mewes, J. M., Hansen, A. & Grimme, S. Best‐practice DFT protocols for basic molecular computational chemistry. Angew. Chem. Int. Ed. 61, e202205735 (2022).

Zapata, J. C. & McKemmish, L. K. Computation of dipole moments: a recommendation on the choice of the basis set and the level of theory. J. Phys. Chem. A 124, 7538–7548 (2020).

Jakalian, A., Bush, B. L., Jack, D. B. & Bayly, C. I. Fast, efficient generation of high‐quality atomic charges. AM1‐BCC model: I. Methods J. Comput. Chem. 21, 132–146 (2000).

Humphrey, W., Dalke, A. & Schulten, K. VMD: visual molecular dynamics. J. Mol. Graph. 14, 33–38 (1996).

Cohen, O. A. et al. SolvationAnalysis: a Python toolkit for understanding liquid solvation structure in classical molecular dynamics simulations. J. Open Source Softw. 8, 5183 (2023).

Kim, S. C. et al. Potentiometric measurement to probe solvation energy and its correlation to lithium battery cyclability. J. Am. Chem. Soc. 143, 10301–10308 (2021).

Bruce, P. G. & Vincent, C. A. Steady state current flow in solid binary electrolyte cells. J. Electroanal. Chem. Interfacial Electrochem. 225, 1–17 (1987).

Acknowledgements

We acknowledge support from the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the US Department of Energy (DOE) under the Battery Materials Research (BMR) Program and Battery 500 Consortium. The cryo-TEM work was supported by the US DOE, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering under contract DE-AC02-76SF00515. Part of this work was performed at the Stanford Nano Shared Facilities (SNSF), supported by the National Science Foundation under award ECCS-2026822. DFT calculations and MD simulations were conducted on the Sherlock cluster, operated by Stanford University and the Stanford Research Computing Center, to whom we would like to express our gratitude for their computational resources and support. I.R.C. acknowledges support from Stanford Graduate Fellowship (SGF) and SBS Foundation Fellowship for graduate studies at Stanford University. A.S. is grateful for support from the NSF Graduate Research Fellowship and SGF. S.C.K. acknowledges support from Stanford Energy Postdoctoral Fellowship.

Author information

Authors and Affiliations

Contributions

I.R.C., Z.B. and Y. Cui conceived the idea. I.R.C. conducted the experiments and analysed the results under the guidance of Z.B., Y. Cui, and J.Q. I.R.C. performed synthesis, electrochemical measurements and materials characterization. Y. Chen carried out DOSY NMR. J.F. measured XPS measurements and GEIS. H.L. performed FIB-SEM and made UME. E.Z. performed H2O titration techniques and viscosity measurements. C.S. conducted cryo-TEM. J.H. and A.S. carried out the DFT and MD simulations. J.H.L. conducted SEM images. Y.L. and I.R.C. synthesized and provided EME, MPE and FxEME. S.C.K. and I.R.C. measured solvation energies and entropy. H.P. measured 13C, 19F-NMR and heteronuclear single quantum coherence for solvents. P.Z., and J.L. provided technical help and helpful discussions. I.R.C., Y. Chen, A.S., J.Q., Y. Cui and Z.B. cowrote and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

Z.B., Y. Cui and I.R.C. declare that this work has been filed as US Provisional Patent Application No. 63/689,564 and some molecules in this work have been included in previously filed International Application No. PCT/US2022/047472. A license related to PCT/US2022/047472 has been assigned to Feon Energy, Inc., in which Z.B. and I.R.C. owns equity. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Kai Liu and the other, anonymous, reviewer for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–71 and Tables 1–7.

Supplementary Video 1

Flammability test.

Source data

Source Data Fig. 2

Li || Cu cycling performance data, voltage profile.

Source Data Fig. 3

Voltage profile, Li || Cu cycling performance data, statistical source data, Li || NMC full-cell cycling performance data.

Source Data Fig. 4

Statistical source data, Li || Cu cycling performance data, voltage profile.

Source Data Fig. 5

Statistical source data.

Source Data Fig. 6

Full-cell cycling performance data.

Source Data Fig. 7

Full-cell cycling performance data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Choi, I.R., Chen, Y., Shah, A. et al. Asymmetric ether solvents for high-rate lithium metal batteries. Nat Energy 10, 365–379 (2025). https://doi.org/10.1038/s41560-025-01716-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-025-01716-w