Abstract

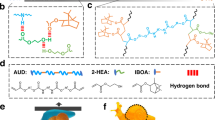

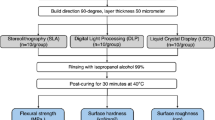

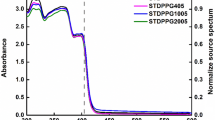

Structures in nature combine hard and soft materials in precise three-dimensional (3D) arrangements, imbuing bulk properties and functionalities that remain elusive to mimic synthetically. However, the potential for biomimetic analogues to seamlessly interface hard materials with soft interfaces has driven the demand for innovative chemistries and manufacturing approaches. Here, we report a liquid resin for rapid, high-resolution digital light processing (DLP) 3D printing of multimaterial objects with an unprecedented combination of strength, elasticity and resistance to ageing. A covalently bound hybrid epoxy–acrylate monomer precludes plasticization of soft domains, while a wavelength-selective photosensitizer accelerates cationic curing of hard domains. Using dual projection for multicolour DLP 3D printing, bioinspired metamaterial structures are fabricated, including hard springs embedded in a soft cylinder to adjust compressive behaviour and a detailed knee joint featuring ‘bones’ and ‘ligaments’ for smooth motion. Finally, a proof-of-concept device demonstrates selective stretching for electronics.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

27,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

269,00 € per year

only 22,42 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available within the Article and Supplementary Information. Raw data files in other formats are available from the corresponding author upon reasonable request. Source data are provided with this paper.

References

Ghazlan, A. et al. Inspiration from Nature’s body armours—a review of biological and bioinspired composites. Composites B 205, 108513 (2021).

Peisker, H., Michels, J. & Gorb, S. N. Evidence for a material gradient in the adhesive tarsal setae of the ladybird beetle Coccinella septempunctata. Nat. Commun. 4, 1661 (2013).

Nazir, A. et al. Multi-material additive manufacturing: a systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 226, 111661 (2023).

Yang, Y. et al. Recent progress in biomimetic additive manufacturing technology: from materials to functional structures. Adv. Mater. 30, 1706539 (2018).

Studart, A. R. Additive manufacturing of biologically-inspired materials. Chem. Soc. Rev. 45, 359–376 (2016).

Montgomery, S. M., Demoly, F., Zhou, K. & Qi, H. J. Pixel-level grayscale manipulation to improve accuracy in digital light processing 3D printing. Adv. Funct. Mater. 33, 2213252 (2023).

Bomar 3D Printing https://bomar-chem.com/markets/3d-printing (2025).

Carbon 3D Printing Materials for Real-World Applications https://www.carbon3d.com/materials (2025).

Mora, S., Pugno, N. M. & Misseroni, D. 3D printed architected lattice structures by material jetting. Mater. Today 59, 107–132 (2022).

Skylar-Scott, M. A., Mueller, J., Visser, C. W. & Lewis, J. A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 575, 330–335 (2019).

Kokkinis, D., Bouville, F. & Studart, A. R. 3D printing of materials with tunable failure via bioinspired mechanical gradients. Adv. Mater. 30, 1705808 (2018).

Zhou, L. et al. Multimaterial 3D printing of highly stretchable silicone elastomers. ACS Appl. Mater. Interfaces 11, 23573–23583 (2019).

Mirzaali, M. J. et al. Mechanics of bioinspired functionally graded soft–hard composites made by multi-material 3D printing. Compos. Struct. 237, 111867 (2020).

Buchner, T. J. K. et al. Vision-controlled jetting for composite systems and robots. Nature 623, 522–530 (2023).

Peng, X. et al. Integrating digital light processing with direct ink writing for hybrid 3D printing of functional structures and devices. Addit. Manuf. 40, 101911 (2021).

Armstrong, C. D. et al. A hybrid additive manufacturing process for production of functional fiber-reinforced polymer composite structures. J. Compos. Mater. 57, 841–850 (2023).

Ge, Q. et al. 3D printing of highly stretchable hydrogel with diverse UV curable polymers. Sci. Adv. 7, eaba4261 (2021).

Xu, Z. et al. Additive manufacturing of two-phase lightweight, stiff and high damping carbon fiber reinforced polymer microlattices. Addit. Manuf. 32, 101106 (2020).

Cheng, J. et al. Centrifugal multimaterial 3D printing of multifunctional heterogeneous objects. Nat. Commun. 13, 7931 (2022).

Han, D., Yang, C., Fang, N. X. & Lee, H. Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit. Manuf. 27, 606–615 (2019).

Yue, L. et al. Single-vat single-cure grayscale digital light processing 3D printing of materials with large property difference and high stretchability. Nat. Commun. 14, 1251 (2023).

Kuang, X. et al. Grayscale digital light processing 3D printing for highly functionally graded materials. Sci. Adv. 5, eaav5790 (2019).

Huang, S. et al. One-pot ternary sequential reactions for photopatterned gradient multimaterials. Matter 6, 2419–2438 (2023).

Ma, Y. et al. Multimaterial thermoset synthesis: switching polymerization mechanism with light dosage. ACS Cent. Sci. 10, 2125–2131 (2024).

Schwartz, J. J. & Boydston, A. J. Multimaterial actinic spatial control 3D and 4D printing. Nat. Commun. 10, 791 (2019).

Cazin, I. et al. Spatially controlling the mechanical properties of 3D printed objects by dual-wavelength vat photopolymerization. Addit. Manuf. 57, 102977 (2022).

Rossegger, E. et al. Wavelength selective multi-material 3D printing of soft active devices using orthogonal photoreactions. Macromol. Rapid Commun. 44, 2200586 (2023).

Gaca, S., Dietliker, K., Rossegger, E. & Schlögl, S. Design of photocurable thiol–epoxy resins for the processing of vitrimers with vat photopolymerisation 3D printing. React. Funct. Polym. 205, 106085 (2024).

Zhu, C., Gemeda, H. B., Duoss, E. B. & Spadaccini, C. M. Toward multiscale, multimaterial 3D printing. Adv. Mater. 36, 2314204 (2024).

Chen, J. et al. 3D-printed anisotropic polymer materials for functional applications. Adv. Mater. 34, 2102877 (2022).

Wallin, T. J., Pikul, J. & Shepherd, R. F. 3D printing of soft robotic systems. Nat. Rev. Mater. 3, 84–100 (2018).

Abueidda, D. W. et al. Mechanical properties of 3D printed polymeric gyroid cellular structures: experimental and finite element study. Mater. Des. 165, 107597 (2019).

Farzaneh, A., Pawar, N., Portela, C. M. & Hopkins, J. B. Sequential metamaterials with alternating Poisson’s ratios. Nat. Commun. 13, 1041 (2022).

Ubaid, J., Schneider, J., Deshpande, V. S., Wardle, B. L. & Kumar, S. Multifunctionality of nanoengineered self-sensing lattices enabled by additive manufacturing. Adv. Eng. Mater. 24, 2200194 (2022).

Geiger, F., Kebbach, M., Vogel, D., Weissmann, V. & Bader, R. Efficient computer-based method for adjusting the stiffness of subject-specific 3D-printed insoles during walking. Appl. Sci. 13, 3854 (2023).

Dwyer, C. M. et al. Impact performance of 3D printed spatially varying elastomeric lattices. Polymers 15, 1178 (2023).

Libanori, R. et al. Stretchable heterogeneous composites with extreme mechanical gradients. Nat. Commun. 3, 1265 (2012).

Wei, R. et al. Revolutionizing wearable technology: advanced fabrication techniques for body-conformable electronics. npj Flex. Electron. 8, 83 (2024).

Ehrmann, K. & Barner-Kowollik, C. Colorful 3D printing: a critical feasibility analysis of multi-wavelength additive manufacturing. J. Am. Chem. Soc. 145, 24438–24446 (2023).

Lu, P. et al. Wavelength-selective light–matter interactions in polymer science. Matter 4, 2172–2229 (2021).

Boynton, N. R. et al. Accessing pluripotent materials through tempering of dynamic covalent polymer networks. Science 383, 545–551 (2024).

Ma, Y. et al. Photoswitching cationic and radical polymerizations: spatiotemporal control of thermoset properties. J. Am. Chem. Soc. 143, 21200–21205 (2021).

Shanmugam, S., Cuthbert, J., Kowalewski, T., Boyer, C. & Matyjaszewski, K. Catalyst-free selective photoactivation of RAFT polymerization: a facile route for preparation of comblike and bottlebrush polymers. Macromolecules 51, 7776–7784 (2018).

Xu, J., Shanmugam, S., Fu, C., Aguey-Zinsou, K. F. & Boyer, C. Selective photoactivation: from a single unit monomer insertion reaction to controlled polymer architectures. J. Am. Chem. Soc. 138, 3094–3106 (2016).

Zhao, Y., Ma, M., Lin, X. & Chen, M. Photoorganocatalyzed divergent reversible-deactivation radical polymerization towards linear and branched fluoropolymers. Angew. Chem. Int. Ed. 59, 21470–21474 (2020).

Frisch, H., Marschner, D. E., Goldmann, A. S. & Barner-Kowollik, C. Wavelength-gated dynamic covalent chemistry. Angew. Chem. Int. Ed. 57, 2036–2045 (2018).

Van De Walle, M., De Bruycker, K., Blinco, J. P. & Barner-Kowollik, C. Two colour photoflow chemistry for macromolecular design. Angew. Chem. Int. Ed. 59, 14143–14147 (2020).

Bialas, S. et al. Access to disparate soft matter materials by curing with two colors of light. Adv. Mater. 31, 1807288 (2019).

Dolinski, N. D. et al. Solution Mask Liquid Lithography (SMaLL) for one-step, multimaterial 3D printing. Adv. Mater. 30, 1800364 (2018).

Mantri, S. P. & Mantri, S. S. Management of shrinkage stresses in direct restorative light-cured composites: a review. J. Esthet. Restor. Dent. 25, 305–313 (2013).

Soares, C. J. et al. Polymerization shrinkage stress of composite resins and resin cements—what do we need to know? Braz. Oral Res. 31, e62 (2017).

Ha, N. S. & Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Composites B 181, 107496 (2020).

Guy, N., Giani, O., Blanquer, S., Pinaud, J. & Robin, J.-J. Photoinduced ring-opening polymerizations. Prog. Org. Coat. 153, 106159 (2021).

Dolinski, N. D. et al. Tough multimaterial interfaces through wavelength-selective 3D printing. ACS Appl. Mater. Interfaces 13, 22065–22072 (2021).

Arivazhagan, G., Elangovan, A., Shanmugam, R., Vijayalakshmi, R. & Karthick, N. K. Study of molecular interaction in the mixtures of benzene + methyl acrylate/butyl acrylate through dielectric and spectroscopic studies. J. Mol. Liq. 214, 357–363 (2016).

González, M. G., Cabanelas, J. C. & Baselga, J. in Infrared Spectroscopy—Materials Science, Engineering and Technology (ed. Theophile, T.) 261–284 (IntechOpen, 2012).

Creton, C., Hu, G., Deplace, F., Morgret, L. & Shull, K. R. Large-strain mechanical behavior of model block copolymer adhesives. Macromolecules 42, 7605–7615 (2009).

Zhang, H. et al. Strain induced nanocavitation and crystallization in natural rubber probed by real time small and wide angle X-ray scattering. J. Polym. Sci. B 51, 1125–1138 (2013).

Allen, M. J. et al. Multimorphic materials: spatially tailoring mechanical properties via selective initiation of interpenetrating polymer networks. Adv. Mater. 35, 2210208 (2023).

Rylski, A. K. et al. Polymeric multimaterials by photochemical patterning of crystallinity. Science 378, 211–215 (2022).

Abraham, A. C., Pauly, H. M. & Haut Donahue, T. L. Deleterious effects of osteoarthritis on the structure and function of the meniscal enthesis. Osteoarthr. Cartil. 22, 275–283 (2014).

Lu, J. et al. Hierarchically mimicking outer tooth enamel for restorative mechanical compatibility. Nat. Commun. 15, 10182 (2024).

Miserez, A., Schneberk, T., Sun, C., Zok, F. W. & Waite, J. H. The transition from stiff to compliant materials in squid beaks. Science 319, 1816–1819 (2008).

Passi, V. et al. Note: Fast and reliable fracture strain extraction technique applied to silicon at nanometer scale. Rev. Sci. Instrum. 82, 116106 (2011).

Acknowledgements

We acknowledge primary support from the Department of Defense under grant W911NF2210115 (J.-W.K., M.J.A., E.A.R., L.M.S., H.L.C., A.U., Z.A.P.; compositional, optical, mechanical and thermal characterization, and materials and supplies). Partial support was provided by the Robert A. Welch Foundation under grants F-2007 (J.-W.K., A.U., Z.A.P.; synthesis) and F-2210 (A.J.A., G.E.S.; digital image correlation and rheology), National Science Foundation (NSF) Directorate for Engineering under grant 2229036 (A.G., W.E., M.A.C.; FEA and electronic device fabrication and testing), US Department of Energy, Office of Science, Basic Energy Sciences through the Center for Materials for Water and Energy Systems (M-WET), an Energy Frontier Research Center under award DE-SC0019272 (M.J.A., B.D.F.; nanoindentation characterization), NSF Graduate Research Fellowship under grant DGE-1610403 (M.J.A.) and Research Corporation for Science Advancement under award 28184 (Z.A.P.). The authors thank J. Rawlins at the University of Southern Mississippi for discussions on standardized aging conditions.

Author information

Authors and Affiliations

Contributions

Conceptualization, J.-W.K., M.J.A., Z.A.P.; methodology, J.-W.K., M.J.A., E.A.R., L.M.S., H.L.C., A.U., A.G., W.E., A.J.A.; investigation, J.-W.K., M.J.A., E.A.R., L.M.S., H.L.C., A.U., A.G., W.E., A.J.A.; visualization, J.-W.K., M.J.A., E.A.R., Z.A.P.; funding acquisition, G.E.S., M.A.C., B.D.F., Z.A.P.; project administration, Z.A.P.; supervision, G.E.S., M.A.C., B.D.F., Z.A.P.; writing—original draft, J.-W.K., M.J.A., Z.A.P.; writing—review and editing, J.-W.K., M.J.A., E.A.R., L.M.S., H.L.C., A.U., A.G., W.E., A.J.A., G.E.S., M.A.C., B.D.F., Z.A.P.

Corresponding author

Ethics declarations

Competing interests

Z.A.P., M.J.A. and J.-W.K. have filed an international patent (application no. PCT/US2024/035169) related to this work. The other authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Thomas Wallin and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Experimental Methods, Characterization, Figs. 1–83, Tables 1–21, Schemes 1 and 2 and Videos 1–15.

Supplementary Video 1

Uniaxial compression of a ‘soft cylinder (no spring)’ structure at a compression rate of 10 µm min−1 until 50 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Fig. 5a and Supplementary Fig. 62.

Supplementary Video 2

Uniaxial compression of a ‘concentric twisted’ structure containing a hard spring (0.9-mm diameter, 4-mm pitch) within a soft cylinder at a compression rate of 10 µm min−1 until 50 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Fig. 5a and Supplementary Fig. 62.

Supplementary Video 3

Uniaxial compression of a ‘concentric twisted’ structure containing a hard spring (0.9-mm diameter, 3-mm pitch) within a soft cylinder at a compression rate of 10 µm min−1 until 50 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Fig. 5a and Supplementary Fig. 62.

Supplementary Video 4

Uniaxial compression of a ‘concentric twisted’ structure containing a hard spring (0.9-mm diameter, 2-mm pitch) within a soft cylinder at a compression rate of 10 µm min−1 until 50 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Fig. 5a and Supplementary Fig. 62.

Supplementary Video 5

Uniaxial compression of a ‘hard spring (no cylinder)’ structure (0.9-mm diameter, 3-mm pitch) at a compression rate of 10 µm min−1 until 0.5 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Fig. 5a inset.

Supplementary Video 6

Uniaxial compression of a ‘concentric twisted’ structure containing a hard spring (0.5-mm diameter, 4-mm pitch) within a soft cylinder at a compression rate of 10 µm min−1 until 50 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Supplementary Fig. 63.

Supplementary Video 7

Uniaxial compression of a ‘concentric twisted’ structure containing a hard spring (0.5-mm diameter, 3-mm pitch) within a soft cylinder at a compression rate of 10 µm min−1 until 50 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Supplementary Fig. 63.

Supplementary Video 8

Uniaxial compression of a ‘concentric twisted’ structure containing a hard spring (0.5-mm diameter, 2-mm pitch) within a soft cylinder at a compression rate of 10 µm min−1 until 50 N was reached. The video is played back at 30× speed. Details of the 3D structure can be found in Supplementary Fig. 63.

Supplementary Video 9

Manual unidirectional bending and recovery of a ‘knee joint’ structure over four cycles followed by the removal of force. The video is played back at 2× speed. Details of 3D structure can be found in Fig. 5b and Supplementary Figs. 66 and 67.

Supplementary Video 10

Uniaxial stretching of a ‘brick-and-mortar’ structure at a strain rate of 10 mm min−1 until macroscopic failure. The video is played back at 2× speed. Details of the 3D structure can be found in Supplementary Figs. 68 and 69.

Supplementary Video 11

DIC for the ‘1,000× modulus central insert’ sample, showing the localized strain distribution under cyclic stretching to a global strain of 30% at a tensile rate of 5 mm min−1. The samples were spray-coated to facilitate DIC analysis. The video is played back at 60× speed.

Supplementary Video 12

DIC for the ‘100× modulus central insert’ sample, showing the localized strain distribution under cyclic stretching to a global strain of 30% at a tensile rate of 5 mm min−1. The samples were spray-coated to facilitate DIC analysis. The video is played back at 60× speed.

Supplementary Video 13

DIC for the ‘10× modulus central insert’ sample, showing the localized strain distribution under cyclic stretching to a global strain of 30% at a tensile rate of 5 mm min−1. The samples were spray-coated to facilitate DIC analysis. The video is played back at 60× speed.

Supplementary Video 14

Uniaxial stretching of a ‘multimaterial device with 1× insert’ structure bearing a white LED at a tensile rate of 5 mm min−1, with global strain reaching 30% over 10 repeated cycles. The video is played back at 60× speed. Details of the 3D structure can be found in Fig. 6d.

Supplementary Video 15

Uniaxial stretching of a ‘multimaterial device with 1,000× insert’ structure bearing a white LED at a tensile rate of 5 mm min−1, with global strain reaching 30% over 10 repeated cycles. The video is played back at 60× speed. Details of the 3D structure can be found in Fig. 6d of the main manuscript.

Source data

Source Data Fig. 1

Statistical source data for Fig. 1c.

Source Data Fig. 2

Statistical source data for Fig. 2b–d.

Source Data Fig. 3

Statistical source data for Fig. 3b–d.

Source Data Fig. 4

Statistical source data for Fig. 4b–d.

Source Data Fig. 5

Statistical source data for Fig. 5a.

Source Data Fig. 6

Statistical source data for Fig. 6b,c.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, JW., Allen, M.J., Recker, E.A. et al. Hybrid epoxy–acrylate resins for wavelength-selective multimaterial 3D printing. Nat. Mater. 24, 1116–1125 (2025). https://doi.org/10.1038/s41563-025-02249-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-025-02249-z