Abstract

Back-contact silicon solar cells, valued for their aesthetic appeal because they have no grid lines on the sunny side, find applications in buildings, vehicles and aircraft and enable self-power generation without compromising appearance1,2,3. Patterning techniques arrange contacts on the shaded side of the silicon wafer, which offers benefits for light incidence as well. However, the patterning process complicates production and results in power loss. We employed lasers to streamline the fabrication of back-contact solar cells and enhance the power-conversion efficiency. Using this approach, we produced a silicon solar cell that exceeded 27% efficiency. Hydrogenated amorphous silicon layers were deposited onto the wafer for surface passivation and to collect light-generated carriers. A dense passivating contact, which differs from conventional technology practice, was developed. Pulsed picosecond lasers operating at different wavelengths were used to create the back-contact patterns. The approach developed is a streamlined process for producing high-performance back-contact silicon solar cells, with a total effective processing time of about one-third that of the emerging mainstream technology. To meet the terawatt demand, we developed indium-less cells at 26.5% efficiency and precious silver-free cells at 26.2% efficiency. Thus, the integration of solar solutions into buildings and transportation is poised to expand with these technological advances.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

27,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

199,00 € per year

only 3,90 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The original data supporting the current study are available from the lead contact on request.

References

Ballif, C., Perret-Aebi, L.-E., Lufkin, S. & Rey, E. Integrated thinking for photovoltaics in buildings. Nat. Energy 3, 438–442 (2018).

Araki, K. et al. State-of-the-Art and Expected Benefits of PV-Powered Vehicles. Report No. IEA-PVPS T17-01:2021 (Eindhoven Univ. of Technology, 2021).

Chu, Y., Ho, C., Lee, Y. & Li, B. Development of a solar-powered unmanned aerial vehicle for extended flight endurance. Drones 5, 44 (2021).

Schwartz, R. J. & Lammert, M. D. Silicon solar cells for high concentration applications. In Proc. 1975 International Electron Devices Meeting (eds Holton, W. C. & and Berglund, C. N.) 350–352 (IEEE, 1975).

King, R. R., Sinton, R. A. & Swanson, R. M. Doped surfaces in one sun, point‐contact solar cells. Appl. Phys. Lett. 54, 1460–1462 (1989).

Lu, M., Bowden, S., Das, U. & Birkmire, R. Interdigitated back contact silicon heterojunction solar cell and the effect of front surface passivation. Appl. Phys. Lett. 91, 063507 (2007).

Nakamura, J. et al. Development of heterojunction back contact Si solar cells. IEEE J. Photovolt. 4, 1491–1495 (2014).

Masuko, K. et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J. Photovolt. 4, 1433–1435 (2014).

Yoshikawa, K. et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2, 17032 (2017).

Lin, H. et al. Silicon heterojunction solar cells with up to 26.81% efficiency achieved by electrically optimized nanocrystalline-silicon hole contact layers. Nat. Energy 8, 789–799 (2023).

Rienäcker, M. et al. Recombination behavior of photolithography-free back junction back contact solar cells with carrier-selective polysilicon on oxide junctions for both polarities. Energy Procedia 92, 412–418 (2016).

Tomasi, A. et al. Simple processing of back-contacted silicon heterojunction solar cells using selective-area crystalline growth. Nat. Energy 2, 17062 (2017).

Xu, M. et al. Simple emitter patterning of silicon heterojunction interdigitated back-contact solar cells using damage-free laser ablation. Sol. Energy Mater. Sol. Cells 186, 78–83 (2018).

Desrues, T., Vecchi, S. D., Souche, F., Muñoz, D. & Ribeyron, P. J. Slash concept: a novel approach for simplified interdigitated back contact solar cells fabrication. In Proc. 38th IEEE Photovoltaic Specialists Conference (ed. Stanbery, B. J.) 001602–001605 (IEEE, 2012).

Vasudevan, R. et al. Laser-induced BSF: a new approach to simplify IBC-SHJ solar cell fabrication. AIP Conf. Proc. 1999, 040024 (2018).

Masuko, K. Method for manufacturing solar cell. International patent WO/2016/152022 (2016).

Brendel, R. & Peibst, R. Contact selectivity and efficiency in crystalline silicon photovoltaics. IEEE J. Photovolt. 6, 1413–1420 (2016).

Reichel, C., Granek, F., Hermle, M. & Glunz, S. W. Investigation of electrical shading effects in back-contacted back-junction silicon solar cells using the two-dimensional charge collection probability and the reciprocity theorem. J. Appl. Phys. 109, 024507 (2011).

Ru, X. et al. 25.11% efficiency silicon heterojunction solar cell with low deposition rate intrinsic amorphous silicon buffer layers. Sol. Energy Mater. Sol. Cells 215, 110643 (2020).

Li, Y. et al. Flexible silicon solar cells with high power-to-weight ratios. Nature 626, 105–110 (2024).

Walch, S. P., Ramalingam, S., Sriraman, S., Aydil, E. S. & Maroudas, D. Mechanisms and energetics of SiH3 adsorption on the pristine Si(001)-(2×1) surface. Chem. Phys. Lett. 344, 249–255 (2001).

von Keudell, A. & Abelson, J. R. Direct insertion of SiH3 radicals into strained Si-Si surface bonds during plasma deposition of hydrogenated amorphous silicon films. Phys. Rev. B 59, 5791–5798 (1999).

Ramalingam, S., Maroudas, D., Aydil, E. S. & Walch, S. P. Abstraction of hydrogen by SiH3 from hydrogen-terminated Si(001)-(2×1) surfaces. Surf. Sci. 418, L8–L13 (1998).

Copel, M. & Tromp, R. M. H coverage dependence of Si(001) homoepitaxy. Phys. Rev. Lett. 72, 1236–1239 (1994).

Jeong, S. & Oshiyama, A. Adsorption and diffusion of Si adatom on hydrogenated Si(100) surfaces. Phys. Rev. Lett. 79, 4425–4428 (1997).

Jeong, S. & Oshiyama, A. Structural stability and adatom diffusion at steps on hydrogenated Si(100) surfaces. Phys. Rev. Lett. 81, 5366–5369 (1998).

Ramalingam, S., Maroudas, D. & Aydil, E. S. Atomistic simulation study of the interactions of SiH3 radicals with silicon surfaces. J. Appl. Phys. 86, 2872–2888 (1999).

Lin, G. H., Doyle, J. R., He, M. & Gallagher, A. Argon sputtering analysis of the growing surface of hydrogenated amorphous silicon films. J. Appl. Phys. 64, 188–194 (1988).

Global semiconductor capacity projected to reach record high 30 million wafers per month in 2024. Semi www.semi.org/en/news-media-press-releases/semi-press-releases/global-semiconductor-capacity-projected-to-reach-record-high-30-million-wafers-per-month-in-2024-semi-reports (2024).

Xu, M. et al. Laser assisted patterning of a-Si:H: detailed investigation of laser damage. Phys. Status Solidi Rapid Res. Lett. 11, 1700125 (2017).

Harrison, S. et al. Back contact heterojunction solar cells patterned by laser ablation. Energy Procedia 92, 730–737 (2016).

Chichkov, B. N., Momma, C., Nolte, S., von Alvensleben, F. & Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 63, 109–115 (1996).

Pal, P., Ashok, A., Haldar, S., Xing, Y. & Sato, K. Anisotropic etching in low-concentration KOH: effects of surfactant concentration. Micro Nano Lett. 10, 224–228 (2015).

Penta, N. K., Amanapu, H. P., Peethala, B. C. & Babu, S. V. Use of anionic surfactants for selective polishing of silicon dioxide over silicon nitride films using colloidal silica-based slurries. Appl. Surf. Sci. 283, 986–992 (2013).

Verlinden, P. J. Future challenges for photovoltaic manufacturing at the terawatt level. J. Renew. Sustain. Energy 12, 053505 (2020).

Deng, R., Chang, N. L., Ouyang, Z. & Chong, C. M. A techno-economic review of silicon photovoltaic module recycling. Renew. Sustain. Energy Rev. 109, 532–550 (2019).

VDMA. International Technology Roadmap for Photovoltaic (ITRPV) 2022 Results 14th edn (VDMA, 2023).

Fellmeth, T. et al. Laser-enhanced contact optimization on iTOPCon solar cells. Prog. Photovolt. Res. Appl. 30, 1393–1399 (2022).

Long, W. et al. On the limiting efficiency for silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 231, 111291 (2021).

Taguchi, M. et al. 24.7% record efficiency HIT solar cell on thin silicon wafer. IEEE J. Photovolt. 4, 96–99 (2014).

Nogay, G. et al. Nanocrystalline silicon carrier collectors for silicon heterojunction solar cells and impact on low-temperature device characteristics. IEEE J. Photovolt. 6, 1654–1662 (2016).

Zhao, Y. et al. Effects of (i)a-Si:H deposition temperature on high-efficiency silicon heterojunction solar cells. Prog. Photovolt. Res. Appl. 31, 1170–1180 (2023).

Yu, C. et al. Industrial-scale deposition of nanocrystalline silicon oxide for 26.4%-efficient silicon heterojunction solar cells with copper electrodes. Nat. Energy 8, 1375–1385 (2023).

Liu, W. et al. Flexible solar cells based on foldable silicon wafers with blunted edges. Nature 617, 717–723 (2023).

Wang, F. et al. Role of hydrogen plasma pretreatment in improving passivation of the silicon surface for solar cells applications. ACS Appl. Mater. Interfaces 6, 15098–15104 (2014).

Mineral Commodity Summaries 2023 (USGS, 2023); https://pubs.usgs.gov/publication/mcs2023.

International Technology Roadmap for Photovoltaic (ITRPV) (VDMA, 2023); www.vdma.org/international-technology-roadmap-photovoltaic.

Acknowledgements

This work has been supported by the National Natural Science Foundation of China (Grant No. 2022YFB4200100).

Author information

Authors and Affiliations

Contributions

H.W. and F.Y. contributed equally to this work in designing the HBC solar cell. Miao Yang, Z.H., X.T., Yong Liu, Ping Li, H.C. and M.Q. developed the PECVD process. F.L., J.Z. and T.Y. developed the wet chemical process. Xiyan Tang, X.D. and S.Z. developed the laser process. Junzhe Wei developed the photolithography process. Q.T., Peng Li, J.C. and B.H. developed the cell metallization. G.W. and H.L. performed the cell simulation. Z.S. performed the laser process simulation. H.Q., Yunpeng Li, L.X., Mingzhe Yu and Q.S. carried out the characterization and data analysis. B.L. and F.P. managed the cell measurements. Y.Y., X.R. and Jianbo Wang developed the cells for the module. Jun Duan assembled the solar module. Q.X., C.L. and S.Y. developed the indium-less TCO layers. C.S., Y.W., H.D. and Tian Xie provided the high-quality wafer. C.X. and X.X. developed the ESMRC model. C.X., H.W., L.X. and C.S. prepared the manuscript. P.G., Q.K., Y.Z., H.Y., N.Y. and Jianning Ding supervised the study. L.C. and J.L. supported the team operation. L.F., Z.L. and X.X. established the research and development plan and led the team in achieving the record efficiency. All authors provided feedback and comments.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Xinbo Yang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

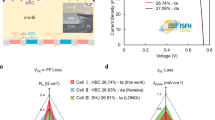

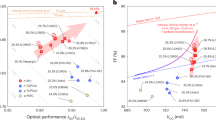

Extended Data Fig. 1

A complete fabrication process flow of the HBC solar cell. The cell fabrication process comprises 12 major steps including 1. N-contact formation, 2. Mask deposition, 3. Laser patterning 1, 4. Wet chemical cleaning 1, 5. P-contact formation, 6. Laser patterning 2, 7. Wet chemical cleaning 2, 8. Front passivation, 9. Wet chemical cleaning 3, 10, TCO deposition, 11, Laser patterning 3, and 12. Metallization.

Extended Data Fig. 2 Contact resistivity measurement.

a. Diagram depicting sample configuration for the measurement. The diameters of the disks are in millimetre. b. Current-voltage curves obtained for samples with different R* values.

Extended Data Fig. 3

Effect of high-intensity illuminated annealing on N-contact. a, Vertical contact resistivity of i/n/ITO/Ag. b, Effective lifetime at ∆n = 5 × 1015 cm3 measured on samples symmetrically passivated by i-a-Si:H/n-a-Si:H, before and after high-intensity illuminated annealing. The top lines, bottom lines, lines in the box, and boxes represent maximum values, minimum values, median values, and 25–75% distributions, respectively.

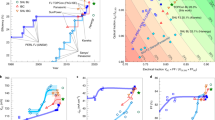

Extended Data Fig. 4 The evolution of P-contact temperature and resulting features in laser spots at various laser fluence in P2 patterning, and IV performance of solar cells fabricated via all laser patterning processes compared to photolithography processes.

a. Simulated P-contact temperature at increasing laser fluence. b. Features post-laser spallation at increasing energy deposition observed under an optical microscope. The bold red numbers 184 and 243 mark correspond to the first and second inflection points in Fig. 3c. c to f, solar cells’ PCE, FF, Jsc and Voc are plotted using grouped box charts, with median value lines displayed in each group. The “Laser” group shows devices using complete laser patterning, and those in the “photolithography (photo)” group use photolithography for P3 but the same laser processes for P1 and P2. In c-f, the top lines, bottom lines, lines in the box, and boxes represent maximum values, minimum values, median values, and 25–75% distributions, respectively.

Extended Data Fig. 5 The formation of undercut and its influence on solar cell’s Voc.

a. Illustration of the P1 and WET process for undercut formation. b. Scanning electron microscopy (SEM) image showing the undercut between SiNx layer and the c-Si substrate. c. Schematic of SDBS additive controlling undercut. d. SEM image showing controlled undercut. e. The relationship between undercut depth and Voc, obtained by four groups of solar cells by varying alkaline etching conditions. Cross-section SEM images of 6 samples in each group were taken to assess the undercut depth (median values). The top lines, bottom lines, lines in the box, and boxes represent maximum values, minimum values, median values, and 25–75% distributions, respectively.

Extended Data Fig. 6 The HBC solar module performance.

a. The IV and PV curves of HBC module (testing laboratory: TÜV Rheinland (Suzhou) Co.,Ltd.). b. Electron luminescence (EL) image of the tested module. c. Front view of the tested module. The module is assembled of 144 pieces of 182 mm×91 mm cells with a median efficiency of 26.8%.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, H., Ye, F., Yang, M. et al. Silicon heterojunction back-contact solar cells by laser patterning. Nature 635, 604–609 (2024). https://doi.org/10.1038/s41586-024-08110-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-024-08110-8

This article is cited by

-

The state of the art in photovoltaic materials and device research

Nature Reviews Materials (2025)

-

Highlights of mainstream solar cell efficiencies in 2024

Frontiers in Energy (2025)

-

Effective surface passivation on n-type crystalline silicon of AlOx thin films by thermal atomic layer deposition

Journal of Materials Science: Materials in Electronics (2025)

-

Perovskite/silicon tandem solar cells with bilayer interface passivation

Nature (2024)