Abstract

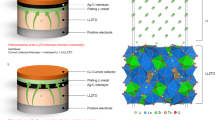

Lithium (Li) metal batteries (LMBs) are promising for high-energy-density rechargeable batteries1,2,3. However, Li dendrites formed by the reaction between highly active Li and non-aqueous electrolytes lead to safety concerns and rapid capacity decay4,5,6,7. Developing a reliable solid–electrolyte interphase is critical for realizing high-rate and long-life LMBs, but remains technically challenging4,8. Here we demonstrate that adding excess m-Li2ZrF6 (monoclinic) nanoparticles to a commercial LiPF6-containing carbonate electrolyte of LMBs facilitates the release of abundant ZrF62– ions into the electrolyte driven by the applied voltage, converting to t-Li2ZrF6 (trigonal) and creating a stable solid–electrolyte interphase in situ with high Li-ion conductivity. Computational and cryogenic transmission electron microscopy studies revealed that the in situ formation of the t-Li2ZrF6-rich solid–electrolyte interphase markedly enhanced Li-ion transfer and suppressed the growth of Li dendrites. As a result, LMBs assembled with LiFePO4 cathodes (areal loading, 1.8/2.2 mAh cm−2), three-dimensional Li–carbon anodes (50-µm-thick Li) and Li2ZrF6-based electrolyte displayed greatly improved cycling stability with high capacity retention (>80.0%) after 3,000 cycles (1C/2C rate). This achievement represents leading performance and, thus, delivers a reliable Li2ZrF6-based electrolyte for durable LMBs under practical high-rate conditions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

27,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

199,00 € per year

only 3,90 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon request. Source data are provided with this paper.

References

Lin, D. C., Liu, Y. Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Tan, J., Matz, J., Dong, P., Shen, J. F. & Ye, M. X. A growing appreciation for the role of LiF in the solid electrolyte interphase. Adv. Energy Mater. 11, 2100046 (2021).

Liu, Y. J. et al. Self-assembled monolayers direct a LiF-rich interphase toward long-life lithium metal batteries. Science 375, 739–745 (2022).

Cheng, X. B., Zhang, R., Zhao, C. Z. & Zhang, Q. Toward safe lithium metal anode in rechargeable batteries: review. Chem. Rev. 117, 10403–10473 (2017).

Xu, R. et al. Artificial interphases for highly stable lithium metal anode. Matter 1, 317–344 (2019).

Xiao, J. How lithium dendrites form in liquid batteries. Science 366, 426–427 (2019).

Lee, M. J. et al. Elastomeric electrolytes for high-energy solid-state lithium batteries. Nature 601, 217–222 (2022).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Weber, R. et al. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte. Nat. Energy 4, 683–689 (2019).

Luo, Z. et al. Interfacial challenges towards stable Li metal anode. Nano Energy 79, 105507 (2021).

Hu, A. J. et al. An artificial hybrid interphase for an ultrahigh-rate and practical lithium metal anode. Energy Environ. Sci. 14, 4115–4124 (2021).

Liu, S. F. et al. An inorganic-rich solid electrolyte interphase for advanced lithium-metal batteries in carbonate electrolytes. Angew. Chem. Int. Ed. 60, 3661–3671 (2021).

Yan, C. et al. Lithium nitrate solvation chemistry in carbonate electrolyte sustains high-voltage lithium metal batteries. Angew. Chem. Int. Ed. 57, 14055–14059 (2018).

Li, X. et al. Dendrite-free and performance-enhanced lithium metal batteries through optimizing solvent compositions and adding combinational additives. Adv. Energy Mater. 8, 1703002 (2018).

Zheng, J. M. et al. Electrolyte additive enabled fast charging and stable cycling lithium metal batteries. Nat. Energy 2, 17012 (2017).

Chen, C. et al. Phenoxy radical-induced formation of dual-layered protection film for high-rate and dendrite-free lithium-metal anodes. Angew. Chem. Int. Ed. 60, 26718–26724 (2021).

Xu, Q. S. et al. Air-stable and dendrite-free lithium metal anodes enabled by a hybrid interphase of C60 and Mg. Adv. Energy Mater. 10, 1903292 (2020).

Lin, D. C. et al. Conformal lithium fluoride protection layer on three-dimensional lithium by nonhazardous gaseous reagent freon. Nano Lett. 17, 3731–3737 (2017).

Wang, H. S., Lin, D. C., Liu, Y. Y., Li, Y. Z. & Cui, Y. Ultrahigh-current density anodes with interconnected Li metal reservoir through overlithiation of mesoporous AlF3 framework. Sci. Adv. 3, 170130 (2017).

Lang, J. L. et al. One-pot solution coating of high quality LiF layer to stabilize Li metal anode. Energy Storage Mater. 16, 85–90 (2019).

Wang, Y. L. et al. Electroless formation of a fluorinated Li/Na hybrid interphase for robust lithium anodes. J. Am. Chem. Soc. 143, 2829–2837 (2021).

Markevich, E., Salitra, G., Chesneau, F., Schmidt, M. & Aurbach, D. Very stable lithium metal stripping-plating at a high rate and high areal capacity in fluoroethylene carbonate-based organic electrolyte solution. ACS Energy Lett. 2, 1321–1326 (2017).

Yoo, D. J., Yang, S., Kim, K. J. & Choi, J. W. Fluorinated aromatic siluent for high-performance lithium metal batteries. Angew. Chem. Int. Ed. 59, 14869–14876 (2020).

Zhang, X. Q. et al. Highly stable lithium metal batteries enabled by regulating the solvation of lithium ions in nonaqueous electrolytes. Angew. Chem. Int. Ed. 57, 5301–5305 (2018).

Zhang, X. Q., Cheng, X. B., Chen, X., Yan, C. & Zhang, Q. Fluoroethylene carbonate additives to render uniform Li deposits in lithium metal batteries. Adv. Funct. Mater. 27, 1605989 (2017).

He, M. F., Guo, R., Hobold, G. M., Gao, H. N. & Gallant, B. M. The intrinsic behavior of lithium fluoride in solid electrolyte interphases on lithium. Proc. Natl Acad. Sci. USA 117, 73–79 (2020).

Ahmad, Z., Venturi, V., Hafiz, H. & Viswanathan, V. Interfaces in solid electrolyte interphase: implications for lithium-ion batteries. J. Phys. Chem. C 125, 11301–11309 (2021).

Gao, Y. et al. Low-temperature and high-rate-charging lithium metal batteries enabled by an electrochemically active monolayer-regulated interface. Nat. Energy 5, 534–542 (2020).

Heiskanen, S. K., Kim, J. & Lucht, B. L. Generation and evolution of the solid electrolyte interphase of lithium-ion batteries. Joule 3, 2322–2333 (2019).

Liu, B. et al. High-throughput computational screening of Li-containing fluorides for battery cathode coatings. ACS Sustain. Chem. Eng. 8, 948–957 (2020).

Ramasubramanian, A. et al. Lithium diffusion mechanism through solid-electrolyte interphase in rechargeable lithium batteries. J. Phys. Chem. C 123, 10237–10245 (2019).

Zhan, Y. X. et al. Failure mechanism of lithiophilic sites in composite lithium metal anode under practical conditions. Adv. Energy Mater. 12, 2103291 (2022).

Yan, K. et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016).

Wang, L. et al. Identifying the components of the solid-electrolyte interphase in Li-ion batteries. Nat. Chem. 11, 789–796 (2019).

Zhuang, G. R. V., Xu, K., Yang, H., Jow, T. R. & Ross, P. N. Lithium ethylene dicarbonate identified as the primary product of chemical and electrochemical reduction of EC in 1.2 M LiPF6/EC:EMC electrolyte. J. Phys. Chem. B 109, 17567–17573 (2005).

Aurbach, D. et al. Recent studies on the correlation between surface chemistry, morphology, three-dimensional structures and performance of Li and Li-C intercalation anodes in several important electrolyte systems. J. Power Sources 68, 91–98 (1997).

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019).

Lin, D. C. et al. Layered reduced graphene oxide with nanoscale interlayer gaps as a stable host for lithium metal anodes. Nat. Nanotechnol. 11, 626–632 (2016).

Li, D. D., Gao, Y., Xie, C. & Zheng, Z. J. Au-coated carbon fabric as Janus current collector for dendrite-free flexible lithium metal anode and battery. Appl. Phys. Rev. 9, 011424 (2022).

Meng, J. K. et al. Cotton-derived carbon cloth enabling dendrite-free Li deposition for lithium metal batteries. J. Power Sources 465, 228291 (2020).

Wang, X. S. et al. Infiltrating lithium into carbon cloth decorated with zinc oxide arrays for dendrite-free lithium metal anode. Nano Res. 12, 525–529 (2019).

Chen, C., Liang, Q. W., Wang, G., Liu, D. D. & Xiong, X. H. Grain-boundary-rich artificial SEI layer for high-rate lithium metal anodes. Adv. Funct. Mater. 32, 2107249 (2022).

Niu, C. J. et al. High-energy lithium metal pouch cells with limited anode swelling and long stable cycles. Nat. Energy 4, 551–559 (2019).

Acknowledgements

This work was supported by the Department of Science and Technology of Guangdong Province (grant nos. 2019ZT08L075 and 2019QN01L054), National Natural Science Foundation of China (grant nos. 52225208, 22176063, 22393904, U21A20174, U1910208 and 22393900), National Key Research and Development Program of China (grant nos. 2022YFB2502000 and 2018YFA0209600), Leading Innovative and Entrepreneur Team Introduction Program of Zhejiang (grant no. 2020R01002) and Beijing Engineering Research Center of Advanced Solid Batteries. G.I.N.W. is supported by a James Cook Research Fellowship from New Zealand Government funding, administered by the Royal Society Te Apārangi.

Author information

Authors and Affiliations

Contributions

Y.Q. and K.Y. led the project. Q.X., Y.Q., H.L., K.Y. and L.G. conceived the idea and drafted the manuscript. T.L. performed the DFT calculations. Q.X., L.G., H.L., K.Y. and Y.Q. designed and performed the experiments and analysed the data. X.T., K.Y., G.C., X.L., Q.X., G.I.N.W., Y.L. and G.Z. helped to develop the action mechanism. Z.J., Q.X. and X.T. performed the cryo-TEM characterizations. All authors discussed the results and revised the manuscript. All the authors express sincere condolences for the passing of author Y.Q. (who was originally a corresponding author) and acknowledge his invaluable contribution.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Tao Cheng and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, Q., Li, T., Ju, Z. et al. Li2ZrF6-based electrolytes for durable lithium metal batteries. Nature 637, 339–346 (2025). https://doi.org/10.1038/s41586-024-08294-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-024-08294-z

This article is cited by

-

Inhibiting and rejuvenating dead lithium in battery materials

Nature Reviews Chemistry (2025)

-

Bilayer solid electrolyte interphase for stable lithium metal batteries

Science China Chemistry (2025)