Abstract

MXenes, a novel class of two-dimensional (2D) materials known for their excellent electronic conductivity and hydrophilicity, have emerged as promising candidates for lithium-ion battery anodes. This study presents a simple wet-chemical method for depositing interconnected SnO2 nanoparticles (NPs) onto MXene sheets. The SnO2 NPs act as both a high-capacity energy source and a spacer to prevent MXene sheets from restacking. The highly conductive MXene facilitates rapid electron and lithium-ion transport and mitigates the volume changes of SnO₂ during the lithiation/delithiation process by confining the SnO₂ NPs between the MXene layers. This composite anode, SnO2@MXene, leverages the high capacity of SnO2 and the structural and mechanical stability MXene provides. The SnO2@MXene anode exhibits superior electrochemical performance, with a high specific capacity of 678 mAh g− 1 at a current rate of 2.0 A g− 1 over 500 cycles, outperforming pristine MXenes and SnO2 nanoparticles.

Similar content being viewed by others

Introduction

LIBs are utilized to power a diverse range of portable electronic devices. In recent years, there has been a growing need for enhanced battery performance to facilitate the development of new types of layered-structure materials. To this end, several studies have explored the potential of oxide, transition metal, carbide, and sulfide families in improving LIBs1,2,3. It is widely recognized that two-dimensional (2D) materials facilitate the transportation of metal ions by significantly restraining volumetric changes, resulting in higher storage capacity and superior cycling stability4. The primary function of 2D materials is to modify their surface chemistries, which promotes more effective interaction between metal ions, consequently enhancing the voltage window and charge storage capacity, which has been observed in 2D MXene-based materials for energy storage5,6,7.

The typical MXene formula is Mn+1XnTx, where M denotes a transition metal, X denotes carbon or nitrogen, n = 1, 2, or 3, and Tx represents functional groups such as − OH = O or –F 8,9,10,11,12,13,14. The low cost, easy availability, and large production scale of MXene (Ti3C2) make it one of the most widely used phases15,16. Multiple research endeavours have highlighted the constrained electrochemical performance of pristine MXene (Ti3C2) due to the attachment of functional chemical groups and their impact on stable capacities17,18,19. MXenes are widely used as electrode material in energy storage applications, like SIBs20,21, supercapacitors22, and LIBs23,24 for electrochemical water purification25, sensors26,27, and electromagnetic interference shielding28. The electrochemical and mechanical stability of MXenes is promising but has a relatively low specific capacity for practical LIB applications. For example, Li et al. oxidized Ti3C2Tx at high temperatures, and a TiO2-based composite was fabricated, which achieved a specific capacity of 155 mAh g− 1 at 1 C29. It has been observed that surface oxidation reduces the conductivity of Ti3C2Tx, resulting in a negative rate response30. By growing MoS2 nanosheets on Ti3C2, Guo and colleagues fabricated a multi-step sandwich structure31. Therefore, a simple approach and investigation of potential materials are needed to enhance electrochemical performance and achieve significant performance in LIBs.

Considering the above studies, SnO2 is a promising anode material for lithium-ion batteries (LIBs) due to its high theoretical capacity, conversion functionality, and alloy-type electrode properties32. However, it still confronts notable challenges. Likely, volume change during the lithiation and delithiation process negatively impacts rate capability and capacity retention in the electrochemical performance of LIB anodes33,34. Several studies have investigated SnO2 hybridization coated with carbon to improve their electrochemical performances35,36. In the future, Ti3C2 may be employed as an alternative matrix, providing a buffer and restricting volume expansion or developing SnO2 involved in the electrochemical properties. It is believed to expand the performance rate and require further capacity retention for future improvements in LIBs.

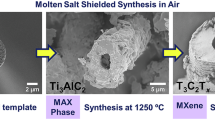

In this study, the MAX phase was exfoliated using LiF and HCl etching via ultrasonication to prepare MXene. Following this, a hydrothermal process was employed to uniformly deposit interconnected SnO2 nanoparticles on the exfoliated layers of the Ti3C2 MXene matrix, and the final product obtained SnO2@MXene nanocomposite after annealing. Herein, MXene layers enclosure effectively confines SnO2 NPs within a confined space, mitigating the volume expansions experienced by SnO2 during the charge/discharge process. This network can speed up electron transport and prevent a drastic loss in capacity during the cycle feeding. The SnO2 NPs, deposited onto and interacting more strongly with the MXene exfoliated layers, exhibited high-capacity dominating properties and outstanding rate performance. The SnO2@MXene composites exhibited high specific capacities, excellent rate characteristics, and long cycle stability, making them promising for LIBs applications.

Experimental

Exfoliation of the Ti3AlC2

Ti3AlC2 powder (3 g) was etched in 50 mL hydrochloric acid (HCl, 40 wt%) and LiF (3 g) for 60 h at 40 °C and stirred at 200 rpm. After stirring, the mixture was centrifuged and sonicated for 1 h under an argon atmosphere. The prepared mixture underwent multiple washes with deionized (DI) water and ethanol until reaching a neutral pH of 7. A multilayer pristine Ti3C2 was produced after vacuum drying the mixture for 12 h at 60 °C. Until further experiments were conducted, the final product was kept at − 4 °C.

Synthesis of SnO2@MXene composites

The as-prepared Ti3C2 powder (0.3 g) was treated for 1 h with 40 mL DI water and SnCl2.5H2O (0.25 g) while stirring for 24 h. Cetyltrimethylammonium bromide (CTAB) 0.4 g was gradually added over half an hour. To reduce the possible oxidiation added few drop hydrazine. The wet-chemical method was used to produce SnO2@MXene nanocomposite at 120 °C for 4 h at oil bath. After rinsing with water and ethanol, the product dried at 70 °C for 10 h, followed by annealing at 200 °C for two hours under argon. Further details regarding materials characterization and electrochemical evaluation are shown in supporting information (Sects. 1 and 2).

Results and discussion

Structural characterizations of SnO2@MXene

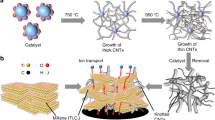

The proposed fabrication is shown in Fig. 1, the deposition growth of interconnected SnO2 NPs on MXene exfoliated multi-layers. Two steps were involved: first, the Ti3AlC2 powders were etched using HCl and LiF solutions, which formed 2D Ti3C2, exfoliated multi-layer structure, and second, interconnected SnO2 NPs were successfully deposited on the surface of MXene layers. Consequently, sufficient SnO2 particles were deposited and encapsulated in the open-layered structure of Ti3C2. Finally, after washing and annealing, SnO2@MXene nanocomposites were obtained.

Schematic presentation for the preparation of MXene and SnO2@MXene nanocomposite [The diagram was created using Microsoft PowerPoint (2020 version), Available at: https://www.microsoft.com/en-us/microsoft-365/free-office-online-for-the-web]

To study the surface morphology in Fig. 2, which is exhibited for multi-layer structures of the SnO2, MXene, and SnO2@MXene samples. Figure 2a shows SnO₂ nanoparticles (NPs) that are randomly distributed and primarily interconnected. After treatment with MXene, most particles appear to be tightly connected. The exfoliated layers shown in Fig. 2b and (c) contain a larger space between the layers for the deposition of the SnO2 NPs on the conductive matrix. The interconnected SnO2 NPs were well placed in free space areas, as shown in Fig. 2d–f, due to the exposed multilayers of the MXene conductive matrix, which facilitated a high surface area phenomenon26,37. Additionally, as shown in Fig. 2f, the SnO2@MXene sample had a large free space layers structure. A closer examination (Fig. 2f) revealed several SnO2 NPs deposited the bulk of the MXene exfoliated layers. Further morphology of pristine MXene and SnO2@MXene are shown in Fig. S1. In brief, for Fig. 2g, the specified area showed the SEM mapping visualizes the deposition of wanted elements across the sample surface (desired Sn, O, C, and Ti elements) for improved anode lithium storage. Overall, particles are well deposited of all the desired constituents, resulting in the superior electrochemical performance of the SnO2@MXene nanocomposite.

Shows (a) FE-SEM images of SnO2 NPs and (b, c) MXene, (d–f) SnO2@MXene, (g) elemental mapping of the hybrid SnO2@MXene composite, and (g) SEM elemental mapping of SnO2@MXene of Sn, O, C and Ti elements. [The surfaces were investigated using field-emission scanning electron microscopy (FE-SEM, JEOL-4001, Tokyo, Japan). Available at: https://www.jeol.com/products/scientific/sem/]

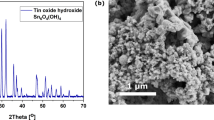

The phase structures of the prepared SnO2@MXene hybrids were confirmed using XRD, as shown in Fig. 3a. The MXene displays major peaks at (002), (004), (006), (103), and (110). The (002) plane of MXene is at 2θ = 8.29°, which corresponds to an interplanar spacing of 1.18 nm. Additionally, the pure phase of crystalline SnO2 is located at 26.4°, 34.2°, and 52.1°, corresponding to the (110), (101), and (211) planes, respectively. The XRD patterns show both MXene and the SnO2 NpS, confirming the successful formation of SnO2@MXene hybrids38,39. These results indicate that SnO2 NPs were well deposited in the conductive MXene multi-layered structure. Further structural analysis was performed using HR-TEM, as shown in Fig. 3f. Furthermore, Fig. 3b and c showed the TEM images of the hybrid composition SnO2@MXene, showing the interconnected SnO2 NPs also embedded in MXene multilayers. The multi-layered framework allows SnO2 NPs are uniformly deposited and facilitate the NPs to intercalate within the layers. This frame of networking plays important role in the electrode/electrolyte interactions. It is also observed in Fig. 3d, the hybrid SnO2@MXene composite, the particles are deposite on the surface of the Ti3C2 layers, suggesting a strong link between the surface and the particles, as can also seen in Fig. S3. In the TEM image, Fig. 3e presented the d-spacing of SnO2@MXene, as highlighted in the a and b regions, indicating two distinct areas of MXene and high SnO2 crystallinity in Fig. 3f. Furthermore, Fig. 3h shows the selected area of SnO2 NPs and MXene crystallinity, which is further explained in Fig. 3g, facilitating the Li + transportation in LIBs. Following the d-spacing 1.18 nm planner corresponds to the crystal plane (002) of Ti3C2 in SnO2@MXene composite, depicted in the XRD pattern (Fig. 3a). The d-spacing in Fig. 3f and g are calculated to be approximately 0.338 nm, belonging to (110) plane of SnO2. Additionally, the schematic diagram in Fig. 3i shows the deposit of SnO2 particles and the extensive development mechanism. To study the elemental composition, Fig. 3j showed the elemental mapping of SnO2@MXene, the desired elements of Sn, O, C, and Ti. The particle distribution suggests a well-deposited, which could contribute to the Li-ion anode’s high performance.

(a) XRD pattern of MXene and SnO2@MXene, (b and c) HR-TEM image of MXene (Ti3C2) multi-layered structured, (d) SnO2 particles deposited on MXene, (e) selected zone (a and b) showing the d-spacing of SnO2@MXene, (f) High resolutions TEM of SnO2 and MXene, and (g) High resolution of SnO2 NPs and MXene crystallinity, (h) Selected two distinct zone of SnO2@MXene, (i) schematic diagram of SnO2 NPs and MXene layers and (j) elemental mapping of the SnO2@MXene sample. [High-resolution transmission electron microscopy (HR-TEM, JEOL JEM-2000), scanning TEM (STEM), Tokyo, Japan. Available at: https://www.jeol.com/products/scientific/tem/JEM-2100.php]

Material properties

To investigate the material properties of three samples, Raman spectra were performed to analyze the SnO2, MXene, and SnO2@MXene. Figure 4a exhibited that SnO2@MXene has the same peaks as SnO2 NPs at 271 cm− 1 and the peaks as MXene at approximately 199 cm− 1 and Ti 620 cm− 1. The TGA curve indicates a significant weight loss around 300 °C to 450 °C, which corresponds to the decomposition of MXene. Based on the analysis, approximately 60% of the total weight is attributed to MXene, while the remaining 40% corresponds to the stable SnO₂ content after the thermal decomposition shown in supplementary Fig. S5. Herein, the specific surface area carried via BET characterization was compared with MXene. The surface area of MXene is 31.3 m2 g− 1, versus SnO2@MXene is approximately 45.2 m2 g− 1, shown in (Fig. 4b), which is comparatively larger. This increased surface area promotes extensive contact between active materials and electrolytes, bolstering battery capacity performance. The XPS survey spectrum shows C, Ti, Sn, and O coexistence in composite SnO2@MXene, as shown in Fig. 4c XPS survey spectra of required elements. The Ti 2p XPS spectra and corresponding fitted peaks are shown in Fig. 4d. The binding energies of the Ti–C 2p3/2, Ti2+ 2p3/2, Ti3+ 2p3/2, T–C 2p1/2, Ti2+ 2p1/2, and Ti3+ 2p1/2 peaks are 455.3, 455.7, 456.9, 458.7, 461.5, and 462.6 eV, respectively40. Figure 4e displays the Sn 3d spectrum. Tin oxide can be seen at the two peaks at 486.11 and 494.2 eV, which are attributed to the Sn 3d5/2 and Sn 3d3/2, respectively41,42. As shown in Fig. 4f, the presence of carbon suggests the C 1s peak at (C–C) 284.3 eV, (C–O) 286.1 eV, and the C–Ti bond belongs to a peak at 281.1 eV, corresponding to Ti3C2 multilayers43. The O–C = O bonds are responsible for the strong interaction peak at 288.3 eV44,45. For the O 1s XPS peaks shown in Fig. S2, the observations indicate the presence of SnO2 transformation. The XPS results indicate the successful deposition of SnO2 onto the surface of the Ti3C2 layers. The large surface area helps fasten electrolyte diffusion and adjust for volume changes in SnO2 NPs during charging and discharging, leading to better lithium storage performance.

Electrochemical analysis of SnO2@MXene

Regarding lithium storage performance, SnO2@MXene anode materials are promising candidates for LIBs due to their unique structural characteristics, as illustrated in Fig. 5. In Fig. 5a, the cyclic voltammetry (CV) plots depict the behavior of the SnO2@MXene nanocomposite, and also for pure SnO2 CV plot is shown in Fig. S4a. During the initial cathodic scan of the SnO2@MXene electrode, four distinct peaks were identified at potentials of 1.71, 1.37, 0.56, and 0.01 V, respectively. Two notable anodic peaks were observed during the anodic scan, occurring at 1.00 and 0.85 V, indicating the extraction of Li ions from the MXene matrix23,46. In the second peak from 0.63 V related to the development of LixSn alloys (Eq. (2))47, further Li+ intercalated in Ti3C2 to form Ti3C2Lix (Eq. (3))4,48.

The distinct peak observed between 0.01 and 0.56 V is associated with the formation of LixSn alloy49. This alloying and de-alloying process is highly reversible, playing a significant role in the overall lithium storage capacity. The reaction, which occurs over the range 0 ≤ x ≤ 4.4, can be expressed by the following equation49.

In addition, the reversed anodic process exhibited a major peak during the dealloying of LixSn50. The peaks at 0.85 and 1.00 V are associated with the extraction of Li+ ions from the MXene layers, while the peak at 0.56 V is linked to the electrochemical oxidation of Sn. Additionally, for bare SnO2, the peak at 1.32 V, which becomes more apparent in the second CV cycle (as shown in Fig. S4a), corresponds to the reversible interaction between Li+ ions and SnO₂. This limited reversibility of SnO₂ significantly contributes to the poor cycling stability of traditional SnO₂-based anodes. This limited reversibility of SnO2 significantly contributes to the poor cycling stability of traditional SnO2-based anodes. While MXene itself may not directly undergo a phase change, it plays a crucial role by providing. A highly conductive matrix for rapid electron transport during the lithiation and delithiation processes. Structural support buffers the significant volume expansion and contraction of Sn during alloying and de-alloying.

Figure 5b shows the typical galvanostatic charge-discharge curves for all three materials at 0.01–3.00 V (vs. Li/Li+). The recorded coulombic efficiency (CE) was notably low at 50.7%, contrasting with the initial discharge-charge capacity of 822/290 mAh g− 1 for pristine MXene. The SnO2 sample exhibited a substantial discharge-charge capacity of 1556/988 mAh g− 1, highlighting its superiority over the MXene electrode. The hybrid SnO2@MXene showed initial discharge-charge capacities of 1210/712 mAh g− 1, with a CE of 58.6%. However, in Fig. 5c, the pure SnO2 NPs initially reach a capacity of 988 mAh g− 1, but this rapidly declines due to severe pulverization during charge/discharge cycles, leaving only 200.6 mAh g− 1 after 10 cycles (17% retention). In contrast, SnO2@MXene hybrids, formed by electrostatic self-assembly on 2D MXene layers, exhibit significantly improved cycle stability. SnO2@MXene achieves 759.8 mAh g− 1 with 91% retention after 80 cycles, outperforming pristine SnO2 and MXene. The results highlighting the importance of sufficient MXene substrate for optimal performance. In addition, the Ti3C2 sample exhibited remarkable cycle stability with a low capacity of 280 mAh g− 1 for 80 cycles. The electrochemical peformance of the SnO2@MXene electrodes is shown in Fig. 5d at current rate of 2.0 A g− 1, which delivered a stable capacity after 500 cycles. In Fig. 5e, at each current rate, the discharge–charge capacities of the deposite SnO2@MXene anode were significantly higher than those of Ti3C2. At various current rates, the SnO2@MXene composite-related discharge-charge curves are shown in Fig. 5e. Specific capacities for the SnO2@MXene were found to be 850, 678, 601, 460, 396, and 678 mAh g− 1 at current densities of 1.0, 2.0, 2.5, 3.0, 4.0, and 1.0 A g− 1. Furthermore, for pristine MXene electode 1.0, 2.0, 2.5, 3.0, 4.0, and 1.0 A g− 1 current densities for pristine MXene (Ti3C2), the specific capacities were 580, 500, 480, 400, and 295 mA h g− 1, which are relatively low performances. To compare the kinetic response between bare SnO2 and SnO2@MXene, electrochemical impedance spectroscopy was used. Both electrodes exhibit a compressed semicircle in the intermediate frequency range and a diagonal line in the low-frequency range, as shown in Fig. 5f. According to the calculations, the Rct values for the SnO2@MXene and SnO2 electrodes were 128.3Ω and 261.2Ω, respectively. In comparison with pure SnO2, SnO2@MXene possesses a much lower Rct value. As a result of its deposited structure and high electrical conductivity, MXene undergoes a fast charge diffusion reaction. The charge transfer resistance of the MXene was notably the lowest, approximately 40Ω, as expected. The SnO2@MXene nanocomposite Rct and electric conductivity guarantee its high-power capabilities, as shown in Fig. 5g. It is also suggests that the specific capacity gradually increases even SnO2@MXene cycles after at a high current rate of 2.0 A g− 1, and stable at approximately 678 mAh g− 1 for 500 cycles, and also for long cycling upto 1000 cycles shown in Fig. S4c. This modest capacity increase with cycling is common for several other metal oxide-based anodes. The reversible development of organic polymeric layers that resemble gels can be implicated in electrolyte decomposition51. The schematic representation in Fig. 5h exhibits the rapid electron and Li-ion transportation of SnO2@MXene. This alloying process involves significant volume expansion of the Sn particles, which can lead to mechanical stress and degradation over repeated cycles. MXene acts as a conductive matrix that mitigates this degradation by offering structural support, buffering the volume changes of Sn, and improving electronic conductivity. The MXene’s layered structure also facilitates faster lithium-ion diffusion.During de-lithiation (discharging), lithium de-alloys from the Sn, partially reverting the Sn back to its original state, and the lithium ions move back into the electrolyte. This process is repeatable, but without the MXene matrix, the volume changes during alloying/de-alloying would typically cause performance degradation in SnO₂-based anodes.Thus, SnO₂@MXene provides a stable, conductive network that enhances battery performance by managing the phase changes during lithiation and de-lithiation. For pure SnO2 electrochemical performances are illustrated in Fig. S4b. The multi-layered network enabled the rapid transport of electrons, leading to the short diffusion of Li-ions and providing excellent performance for the anode. Owing to the free traffic between the highly conductive Ti3C2 and high-capacity SnO2, the deposited nanocomposite (SnO2@MXene) has excellent capacity retention during cycling, delivering excellent performance to other Sn-based MXene hybrid composite materials (Table 1).

(a) CV of SnO2@MXene first three cycles, (b) charging /discharging profile of Ti3C2, SnO2, and SnO2@MXene, (c) cycling performance of three samples for comparison, (d) discharge–charge profile of SnO2@MXene (500 cycles), (e) different current rate performance of MXene and SnO2@MXene, (f) EIS Nyquist plots of MXene, SnO2, and SnO2@MXene, (g) long cycling performance of SnO2@MXene, and (h) schematic diagram of rapid electron and Li-ion transportation.

For structural stability, Fig. 6a and b show the surface morphology of SnO2@MXene after 200 and 500 cycles, respectively. The SEM images showed that most particles retained their original shape after cycling, with no apparent cracks or ruptures (Fig. 6a–c). As shown in Fig. 6c, The excellent electrochemical performance is due to the synergistic effect between MXene nanosheets and SnO2 NPs. MXene layers act as 2D substrates, evenly anchoring SnO2 NPs and preventing their aggregation. They also provide an elastic buffer to accommodate the volume changes of SnO2 during charge and discharge, resulting in good cycle stability. Furthermore, it is also observed in Fig. 6(d, e), the particles and MXene matrix are clearly visible suggesting the structure stability. In Fig. 6f reveals that SnO2@MXene, at various resolutions, maintains a crystalline structure after 500 cycles, which is highly effective for the unimpeded transport of electrons within the electrode. These findings indicate that layered structure can also effectively limit volume variation throughout the lithiation and delithiation processes51, and multilayered MXene and interconnected SnO2 NPs networks may significantly improve the performance of Li-ion anode.

Conclusion

In conclusion, a hybrid SnO2@MXene nanocomposite architecture was successfully developed using a simple wet-chemical route, with SnO2 NPs deposited in the MXene multilayered structure. The composite design of the SnO2@MXene electrode offers a substantial capacity attributed to the conversion reaction of SnO2, with the MXene multilayered structure facilitating a conductive network capable of accommodating the significant volume changes inherent in SnO2 during battery charge and discharge cycles. As a result of their unique structural components and characteristics, the SnO2@MXene electrode delivered a specific capacity of 678 mAh g− 1 capacity at a current density of 2.0 A g− 1 after 500 cycles. This study on oxide deposition on MXene multilayered introduces new pathways for enhancing the cycling stability of LIBs and other generation batteries.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Bai, J. et al. Construction of hierarchical V4C3-MXene/MoS2/C nanohybrids for high rate lithium-ion batteries. Nanoscale. 12, 1144–1154. https://doi.org/10.1039/C9NR07646H (2020).

He, L. et al. A β-FeOOH/MXene sandwich for high-performance anodes in lithium-ion batteries. Dalton Trans. 49, 9268–9273. https://doi.org/10.1039/D0DT01531H (2020).

Zhao, N. et al. Unveiling the SEI layer formed on pillar-structured MXene anode towards enhanced Li-ion storage. Scripta Mater. 202, 113988. https://doi.org/10.1016/j.scriptamat.2021.113988 (2021).

Ahmed, B., Anjum, D. H., Gogotsi, Y. & Alshareef, H. N. Atomic layer deposition of SnO2 on MXene for Li-ion battery anodes. Nano Energy. 34, 249–256. https://doi.org/10.1016/j.nanoen.2017.02.043 (2017).

An, Y., Tian, Y., Feng, J. & Qian, Y. MXenes for advanced separator in rechargeable batteries. Mater. Today. 57, 146–179. https://doi.org/10.1016/j.mattod.2022.06.006 (2022).

Bhat, A. et al. Prospects challenges and stability of 2D MXenes for clean energy conversion and storage applications. npj 2D Mater. Appl. 5 https://doi.org/10.1038/s41699-021-00239-8 (2021).

Aslam, M. K., Niu, Y., Xu, M., Na, K. & Ca MXenes for Non-Lithium-Ion (, Mg, and Al) Batteries and Supercapacitors. Advanced Energy Materials 11, 2000681 (2021). https://doi.org/10.1002/aenm.202000681

Simon, P. Two-dimensional MXene with controlled interlayer spacing for Electrochemical Energy Storage. ACS Nano. 11, 2393–2396. https://doi.org/10.1021/acsnano.7b01108 (2017).

Yu, L. et al. MXene-Bonded activated Carbon as a flexible electrode for high-performance supercapacitors. ACS Energy Lett. 3, 1597–1603. https://doi.org/10.1021/acsenergylett.8b00718 (2018).

Zhang, C. et al. Synthesis and charge storage properties of hierarchical niobium pentoxide/carbon/niobium carbide (MXene) hybrid materials. Chem. Mater. 28, 3937–3943. https://doi.org/10.1021/acs.chemmater.6b01244 (2016).

Zhang, C. et al. Layered Orthorhombic Nb2O5@Nb4C3Tx and TiO2@Ti3C2Tx hierarchical composites for high performance Li-ion batteries. Adv. Funct. Mater. 26, 4143–4151. https://doi.org/10.1002/adfm.201600682 (2016).

Zhang, C. et al. Oxidation stability of colloidal two-dimensional titanium carbides (MXenes). Chem. Mater. 29, 4848–4856 (2017).

Zhao, M. Q. et al. Flexible MXene/Carbon nanotube composite paper with high volumetric capacitance. Adv. Mater. 27, 339–345. https://doi.org/10.1002/adma.201404140 (2015).

Xie, X., Wang, S., Kretschmer, K. & Wang, G. Two-dimensional layered compound based anode materials for lithium-ion batteries and sodium-ion batteries. J. Colloid Interface Sci. 499, 17–32. https://doi.org/10.1016/j.jcis.2017.03.077 (2017).

Eom, W. et al. Large-scale wet-spinning of highly electroconductive MXene fibers. Nat. Commun. 11, 2825. https://doi.org/10.1038/s41467-020-16671-1 (2020).

Zhang, H. et al. Hierarchically porous MXene decorated carbon coated LiFePO4 as cathode material for high-performance lithium-ion batteries. J. Alloys Compd. 876, 160210. https://doi.org/10.1016/j.jallcom.2021.160210 (2021).

Zhang, R. et al. NiCo-LDH/Ti3C2 MXene hybrid materials for lithium ion battery with high-rate capability and long cycle life. J. Energy Chem. 50, 143–153. https://doi.org/10.1016/j.jechem.2020.03.018 (2020).

Wu, Y., Nie, P., Wu, L., Dou, H. & Zhang, X. 2D MXene/SnS2 composites as high-performance anodes for sodium ion batteries. Chem. Eng. J. 334, 932–938. https://doi.org/10.1016/j.cej.2017.10.007 (2018).

Gu, J. et al. Heteroatom immobilization engineering toward high-performance metal anodes. ACS Nano. https://doi.org/10.1021/acsnano.4c08831 (2024).

Aslam, M. K. et al. 2D MXene materials for sodium Ion batteries: A review on energy storage. J. Energy Storage. 37, 102478. https://doi.org/10.1016/j.est.2021.102478 (2021).

Tang, H. et al. MXene–2D layered electrode materials for energy storage. Progress Nat. Science: Mater. Int. 28, 133–147. https://doi.org/10.1016/j.pnsc.2018.03.003 (2018).

Hu, X. et al. N-Terminalized Ti3C2Tx MXene for Supercapacitor with extraordinary pseudocapacitance performance. Small. 20, 2306997. https://doi.org/10.1002/smll.202306997 (2024).

Chen, Z., Huang, S., Yuan, X., Gan, X. & Zhou, N. A comparative study of M2CS2 and M2CO2 MXenes as anode materials for lithium ion batteries. Appl. Surf. Sci. 544, 148861. https://doi.org/10.1016/j.apsusc.2020.148861 (2021).

Gu, J. et al. Single zinc atoms immobilized on MXene (Ti3C2Clx) layers toward dendrite-free lithium metal anodes. ACS Nano. 14, 891–898. https://doi.org/10.1021/acsnano.9b08141 (2020).

Al-Hamadani, Y. A. J. et al. Applications of MXene-based membranes in water purification: A review. Chemosphere. 254, 126821. https://doi.org/10.1016/j.chemosphere.2020.126821 (2020).

He, T. et al. MXene/SnO2 heterojunction based chemical gas sensors. Sens. Actuators B. 329, 129275. https://doi.org/10.1016/j.snb.2020.129275 (2021).

Wu, M. et al. Ti(3)C(2) MXene-Based sensors with high selectivity for NH(3) detection at Room temperature. ACS Sens. 4, 2763–2770. https://doi.org/10.1021/acssensors.9b01308 (2019).

Iqbal, A., Sambyal, P. & Koo, C. M. 2D MXenes for electromagnetic shielding: A review. Adv. Funct. Mater. 30, 2000883. https://doi.org/10.1002/adfm.202000883 (2020).

Li, L. et al. Hierarchical Ti3C2@TiO2 MXene hybrids with tunable interlayer distance for highly durable lithium-ion batteries. Nanoscale. 12, 10369–10379. https://doi.org/10.1039/D0NR01222J (2020).

Agresti, A. et al. Titanium-carbide MXenes for work function and interface engineering in perovskite solar cells. Nat. Mater. 18, 1228–1234. https://doi.org/10.1038/s41563-019-0478-1 (2019).

Chandran, M., Thomas, A., Raveendran, A., Vinoba, M. & Bhagiyalakshmi, M. MoS2 confined MXene heterostructures as electrode material for energy storage application. J. Energy Storage. 30, 101446. https://doi.org/10.1016/j.est.2020.101446 (2020).

Du, F. H. et al. Incorporation of heterostructured Sn/SnO nanoparticles in crumpled nitrogen-doped graphene nanosheets for application as anodes in lithium-ion batteries. Chem. Commun. 50, 9961–9964. https://doi.org/10.1039/C4CC04187A (2014).

Rehman, W. et al. Bouquet-Like Mn2SnO4 nanocomposite engineered with graphene sheets as an advanced lithium-ion battery anode. ACS Appl. Mater. Interfaces. 10, 17963–17972. https://doi.org/10.1021/acsami.8b04164 (2018).

Fu, W. et al. In situ growth of ultrafine tin oxide nanocrystals embedded in graphitized carbon nanosheets for use in high-performance lithium-ion batteries. J. Mater. Chem. A. 2, 6960–6965. https://doi.org/10.1039/C4TA00021H (2014).

Zhang, H. et al. Controllable synthesis of SnO2@carbon hollow sphere based on bi-functional metallo-organic molecule for high-performance anode in Li-ion batteries. Appl. Surf. Sci. 442, 65–70. https://doi.org/10.1016/j.apsusc.2018.01.184 (2018).

Min, X. et al. A textile-based SnO2 ultra-flexible electrode for lithium-ion batteries. Energy Storage Mater. 16, 597–606. https://doi.org/10.1016/j.ensm.2018.08.002 (2019).

Wang, Z. et al. SnO-SnO2 modified two-dimensional MXene Ti3C2Tx for acetone gas sensor working at room temperature. J. Mater. Sci. Technol. 73, 128–138. https://doi.org/10.1016/j.jmst.2020.07.040 (2021).

Wang, Y. et al. MXene-Modulated Electrode/SnO2 Interface Boosting Charge Transport in Perovskite Solar cells. ACS Appl. Mater. Interfaces. 12, 53973–53983. https://doi.org/10.1021/acsami.0c17338 (2020).

Zhang, H. et al. 3D d-Ti3C2 xerogel framework decorated with core-shell SnO2@C for high-performance lithium-ion batteries. Electrochim. Acta. 285, 94–102. https://doi.org/10.1016/j.electacta.2018.07.198 (2018).

Niu, S. et al. MXene-Based electrode with enhanced pseudocapacitance and volumetric capacity for power-type and Ultra-long Life Lithium Storage. ACS Nano. 12, 3928–3937. https://doi.org/10.1021/acsnano.8b01459 (2018).

Böhme, S., Philippe, B., Edström, K. & Nyholm, L. Photoelectron spectroscopic evidence for overlapping redox reactions for SnO2 electrodes in lithium-ion batteries. J. Phys. Chem. C. 121, 4924–4936. https://doi.org/10.1021/acs.jpcc.7b01529 (2017).

Ferraresi, G. et al. SnO(2) model electrode cycled in li-ion battery reveals the formation of Li(2)SnO(3) and Li(8)SnO(6) phases through conversion reactions. ACS Appl. Mater. Interfaces. 10, 8712–8720. https://doi.org/10.1021/acsami.7b19481 (2018).

Liu, G. et al. Synthesis, characterization and photocatalytic evaluation of visible light activated C-doped TiO2nanoparticles. Nanotechnology. 23, 294003. https://doi.org/10.1088/0957-4484/23/29/294003 (2012).

Zhang, F. Y. et al. Quantitative characterization of catalyst layer degradation in PEM fuel cells by X-ray photoelectron spectroscopy. Electrochim. Acta. 54, 4025–4030. https://doi.org/10.1016/j.electacta.2009.02.028 (2009).

Zhang, L., Chen, G., Hedhili, M. N., Zhang, H. & Wang, P. Three-dimensional assemblies of graphene prepared by a novel chemical reduction-induced self-assembly method. Nanoscale. 4, 7038–7045. https://doi.org/10.1039/C2NR32157B (2012).

Zhang, P. et al. Interface-Engineered Fe3O4/MXene heterostructures for enhanced Lithium-ion storage. ACS Appl. Energy Mater. 4, 11844–11853. https://doi.org/10.1021/acsaem.1c02649 (2021).

Wang, Z., Chen, J. S., Zhu, T., Madhavi, S. & Lou, X. W. One-pot synthesis of uniform carbon-coated MoO(2) nanospheres for high-rate reversible lithium storage. Chem. Commun. (Camb). 46, 6906–6908. https://doi.org/10.1039/c0cc01174f (2010).

Wang, F. et al. Facile synthesis SnO2 nanoparticle-modified Ti3C2 MXene nanocomposites for enhanced lithium storage application. J. Mater. Sci. 52, 3556–3565. https://doi.org/10.1007/s10853-016-0369-7 (2017).

Jiang, Y., Yuan, T., Sun, W. & Yan, M. Electrostatic spray deposition of porous SnO2/graphene anode films and their enhanced lithium-storage properties. ACS Appl. Mater. Interfaces. 4, 6216–6220. https://doi.org/10.1021/am301788m (2012).

Cheng, Y., Huang, J., Li, J., Cao, L. & Qi, H. Hydrothermal synthesis of shape-controlled SnO as anode material for Li-ion batteries. Micro Nano Lett. 13, 257–260. https://doi.org/10.1049/mnl.2017.0550 (2018).

Ma, Z., Zhou, X., Deng, W., Lei, D. & Liu, Z. 3D porous MXene (Ti3C2)/reduced graphene oxide hybrid films for advanced lithium storage. ACS Appl. Mater. Interfaces. 10, 3634–3643. https://doi.org/10.1021/acsami.7b17386 (2018).

Zuo, D. et al. Synthesis of sandwich-like structured Sn/SnOx@MXene composite through in-situ growth for highly reversible lithium storage. Nano Energy. 62, 401–409. https://doi.org/10.1016/j.nanoen.2019.05.062 (2019).

Wang, L. et al. SnO2 Quantum dots interspersed d-Ti3C2Tx MXene heterostructure with enhanced performance for Lithium Ion Battery. J. Electrochem. Soc. 167, 116522. https://doi.org/10.1149/1945-7111/aba705 (2020).

Wang, K. et al. Self-Standing Hybrid Film of SnO2 nanotubes and MXene as a high-performance Anode Material for Thin Film Lithium-Ion batteries. ChemistrySelect. 4, 12099–12103. https://doi.org/10.1002/slct.201903537 (2019).

Li, J. et al. MXene-decorated SnS2/Sn3S4 hybrid as anode material for high-rate lithium-ion batteries. Chem. Eng. J. 380, 122590. https://doi.org/10.1016/j.cej.2019.122590 (2020).

Yang, Q. et al. Uniformly depositing Sn onto MXene nanosheets for superior lithium-ion storage. J. Alloys Compd. 859, 157799. https://doi.org/10.1016/j.jallcom.2020.157799 (2021).

Liu, Y. T. et al. Self-Assembly of Transition Metal Oxide Nanostructures on MXene Nanosheets for fast and stable Lithium Storage. Adv. Mater. 30, 1707334. https://doi.org/10.1002/adma.201707334 (2018).

Luo, J. et al. Pillared structure design of MXene with ultralarge interlayer spacing for high-performance lithium-ion capacitors. ACS Nano. 11, 2459–2469. https://doi.org/10.1021/acsnano.6b07668 (2017).

Acknowledgements

The authors appreciate that work is supported by the Program for Science and Technology Innovation Team in Colleges of Hubei Province (Grant No. T2021012).

Author information

Authors and Affiliations

Contributions

Wasif ur Rehman, Zahoor khan, Fatima Zahra Ait Laaskri: Conceptualization, Methodology, Software, Visualization, Investigation, Writing- Original draft preparation. Habib khan: Data curation, Validation, Supervision, Resources, Writing - Review & Editing. Umar Farooq, Mohit Bajaj & Ievgen Zaitsev: Project administration, Supervision, Resources, Writing - Review & Editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rehman, W.u., khan, Z., Zahra, F. et al. Preparation of interconnected tin oxide nanoparticles on multi-layered MXene for lithium storage anodes. Sci Rep 14, 25107 (2024). https://doi.org/10.1038/s41598-024-76364-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-76364-3