Abstract

The superimposed disaster of water and sand collapse and strong ore pressure appearance in the two coal bases of Huanglong and Ningdong mining areas in western China is a kind of dynamic sand collapse disaster of weakly consolidated rock strata in the roof of thick bedrock mining. This type of disaster is a new type of stope roof disaster, which is different from the previous non-dynamic water and sand collapse disasters in shallow buried and near loose layer stope in terms of appearance, material source and power source. As this type of disaster is sudden, destructive and powerful, it poses a serious threat to the safety of production, so how to effectively prevent and control the recurrence of disasters has become a difficult problem to be solved in many mining areas. By means of theoretical analysis, numerical calculation and laboratory tests, this paper analyzes and studies the overlying rock failure characteristics of stope, hydraulic gradient conditions of aquifer, physical and mechanical characteristics of weakly consolidated formation and its mineral composi-tion from the perspective of the source and power source of disaster formation, etc., and reveals the internal relationship between mine pressure of accident stope and the disaster caused by weakly consolidated formation. The typical overburden formation structure characteristics of dynamic sand collapse disaster in weakly consolidated formation are put forward, and the necessary conditions for disaster occurrence are the mudstone roof strata of weakly consolidated Zhiluo Formation containing a large number of hydrophobic minerals (provenance) and the slide and instability of composite key strata (power source). The research results will provide theoretical support for the construction of prevention and control technology system for the disaster caused by water and sand collapse of stope roof and the occurrence of strong mine pressure, and ensure the large-scale safety development of coal fields in western China.

Similar content being viewed by others

Introduction

Due to the rich reserves of coal resources, the mining area in western China has become the main source of national coal resources. However, the coal-forming age in the main coal-rich regions of the mining of the west area is dominated by the relatively late early-Middle Jurassic1, resulting in the lack of consolidation of the Jurassic sand-mudstone strata in the coal measure strata, with typical mechanical characteristics such as low strength and easy disintegration2,3. Therefore, the weakly consolidated rock formation in the western mining area has always been a hot spot and difficult problem for engineers, technicians, and scientific researchers of coal enterprises4,5,6,7,8. Among the 14 large coal bases planned in China, multiple coal mines in Huanglong and Ningdong coal bases have concurrent disasters of stope roof water and sand collapse and strong mine pressure9,10,11. This kind of disaster has caused huge economic losses or casualties to coal mines, seriously restricting the efficient and safe development of coal resources. This kind of sand collapse disaster in a deep mining site of hundreds of meters to kilometers is not only different from sand collapse disaster in shallow mining faces and near loose layers but also different from water gusher disaster in mine roofs. It is a new type of dynamic sand collapse disaster of weakly consolidated rock stratum in thick bedrock mining sites in western China.

The sand collapse that occurred in the past is a kind of mine geological disaster in which the water–sand mixed fluid with a high sand content (generally more than 50%) is induced by mining activities to break into the underground coal face or driving face due to nearby loose layer or overlying neogenetic water-bearing sand layer, resulting in property losses and casualties12,13,14,15,16. For example, the sand collapse caused by the Neogene sand layer was channeled by the driving head of a backwind dark inclined shaft in a mine in Shandong, China in 2018, and the sand collapse caused by quaternary loose sand layer in the stope of Halagou Coal Mine in Shendong, China in 201017. The forming power of this type of sand collapse disaster is only self-weight and water pressure, lack of external mine pressure as the driving force, which belongs to non-dynamic sand collapse. Sand collapse of weakly consolidated rock strata in stope roof is a kind of sudden strong, destructive, and impact mine disaster caused by mining disturbance and deterioration of weakly consolidated rock strata under the effect of ore pressure development caused by the breaking of hard rock above and the instability of basic roof below. Its essence is the dynamic sand collapse of the roof under the effect of hard rock breaking and instability induced by the deterioration of weakly consolidated strata. For example, the dynamic sand collapse disaster of the roof of Zhaojin Coal Mine in Huanglong Coal field, Shaanxi, China in 201618.

There are obvious differences in the source, appearance, and power source between the dynamic sand failure of weakly consolidated rock and the previous non-dynamic sand failure. In the past, the source of the non-dynamic water and sand collapse disaster in shallowly buried stopes was a loose layer or near loose layer stratum19,20. However, due to the thick overlying rock of the stope in the dynamic sand collapse disaster of weakly consolidated rock, according to the measured and statistical results of literature21,22,23 on the height of the water-conducting fracture zone of coal seam in Huanglong and Ningdong mining areas in China, the height of the water-conducting fracture zone formed after coal seam mining cannot spread to the loose layer or the strata near the loose layer. Therefore, The source of the gusher cannot come from the unconsolidated layer or the strata near the unconsolidated layer (the source is different). In addition to the sand collapse disaster of the roof cut through the loose layer in shallowly buried stope or near the loose layer in the strong ore pressure24, the sand collapse disaster of the roof rarely occurs in the strong ore pressure development of the stope with thicker overlying rock (greater than the height of the water-carrying fracture zone)25,26 (the appearance is different). The driving forces of sand collapse disaster in loose or near loose strata are only water pressure and dead weight, and there is no overburden condition with mine pressure as the driving force (different power sources). In the dynamic sand collapse disaster of weakly consolidated strata, there is a significant relationship and influence between the roof sand collapse force and the strong ore pressure of overburdened rock in the sand source formation.

At present, there are relatively few studies on sand collapse of weakly consolidated roofs under thick bedrock mining. The existing few studies9,10,11,12 only refer to previous sand collapse disasters in shallow buried and near-loose strata mining, mainly focusing on shallow buried coal seams in northwest China and areas near loose strata in mining areas in East and North China. Literature27 studies the formation mechanism of water burst sand (sand) disaster in shallow buried mining areas in Northwest China. The risk zoning standard of water bursts and sand bursts in the Yushenfu mining area is put forward. Literature28,29,30,31,32 used model tests to analyze the critical conditions of water-burst sand (sand) and their relationship with fracture size, characteristics of sand burst particles, pore water pressure, and other factors, literature33,34,35 theoretically analyzed the influencing factors such as particle force, surge channel and hydraulic slope in water burst sand (sand), and established the discrimination method and starting conditions of sand burst (sand). It is concluded from the literature36 that the through fissure caused by the ore pressure display in shallow coal seam is the main factor in producing water burst and sand (sand). However, the above-related research content and ideas lack analysis and discussion on the effect of mine pressure.

Therefore, the mechanism and law of the new roof water damage have not been fully understood, and the existing theories and technologies have encountered bottlenecks, which can not form effective prevention and control of disasters. To reveal the internal mechanism of disaster formation is the primary problem for effective disaster prevention and control at present. Taking the dynamic sand collapse disaster in the Zhaojin Coal mine in the Huanglong Coal field of China as a case study, the author analyzes the structural characteristics of the roof overburden of the dynamic sand collapse disaster in the thick bedrock stope, the properties and influencing factors of the water deterioration of weakly consolidated strata, and the dynamic characteristics of weakly consolidated rock collapse. The relevant research results will have important theoretical significance and engineering application value.

Survey of geological conditions of sand collapse accident of weakly consolidated rock stratum in stope roof

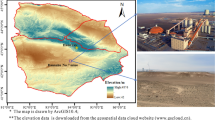

Zhaojin Coal Mine is located in Xunyao mining area, Huanglong coal field, Shaanxi Province, China, mainly mining Jurassic No.4–2 coal seam. The geological structure of the well field is simple, and there is no large fracture structure. The strata from new to old are: Quaternary (Q), Cretaceous Luohe Formation (K1l), Yijun Formation (K1y), Jurassic Zhiluo Formation (J2z), Yan’an Formation (J2y) and Fuxian Formation (J1f). The Zhiluo Formation is an interlayer of sand mudstone with low strength and is a weakly consolidated formation37. The minefield is divided into two mining areas, the first mining area on the east side and the second mining area on the west side, and the accident working face is the second working face in the second mining area (that is, the b working face, as shown in Fig. 1). Its strike length is 1470 m, dip length is 150 m, and the average coal thickness is 9.7m. Fully mechanized top coal caving technology and natural caving methods are adopted to manage the roof. The comprehensive column shape of the working face is shown in Fig. 2.

When working face b is mined to 1145m, there is a phenomenon of cutting the top of the coal wall of the pressure frame and support in many places, and a large amount of mud, sand, and stone suddenly breaks into the working face and deposits in the stope and roadway. The total amount of mud, sand, and stone breaks into the working face is 2291.65 m3, and the instantaneous water breaks into 3816.8 m3. There are mud, sand, rock blocks, and coal blocks in the sludge deposits, and the rock blocks are of different sizes. The composition is mainly mudstone and sandy mudstone, and the cement is loose and easily broken upon light contact. The content of mud and sand in the solid material accounts for 50–60% (Fig. 3).

Dynamic analysis of weakly consolidated formation collapse in the roof of accident stope

Analysis of pressure development characteristics in overburden broken mine

Theoretical analysis

There are multiple layers of rock with different thickness and strength above the immediate top, among which the rock layer that controls the activity of the rock layer locally or up to the surface of the stope is called the key layer, the former is called the sub-key layer, and the latter is called the main key layer. The fracture of the key layer will cause whole movement of all or a significant part of the overlying strata38. The existence of key layer directly affects the mine pressure development and stress distribution in stope. Based on the key layer theory38, the overlying rock key layer is analyzed and calculated according to the criterion of load and fracture distance.

Load criterion:

where \(\left. {q_{1} (x)} \right|_{{n{ + }1}}\) and \(\left. {q_{1} (x)} \right|_{n}\), is the load on the key layer of the first layer when the n + 1 layer and the n layer are calculated respectively where \(\left. {q_{1} (x)} \right|_{n} = E_{1} h_{1}^{3} {{\left( {\sum\limits_{i = 1}^{n} {\gamma_{i} h_{i} } } \right)} \mathord{\left/ {\vphantom {{\left( {\sum\limits_{i = 1}^{n} {\gamma_{i} h_{i} } } \right)} {\left( {\sum\limits_{i = 1}^{n} {E_{i} h_{i}^{3} } } \right)}}} \right. \kern-0pt} {\left( {\sum\limits_{i = 1}^{n} {E_{i} h_{i}^{3} } } \right)}}\), where \(E_{1}\) and \(E_{i}\) are respectively the elastic modulus of layer 1 and Layer i, \(h_{1}\) and \(h_{i}\) are the thickness of layer 1 and layer i respectively, \(r_{i}\) is the bulk density of layer i, by substituting it into Eq. (1), we get

Breaking distance criterion:

ln is the breaking distance of the n layer. k is the number of hard rock layers determined by formula (1); Where and where are the ultimate tensile strength and thickness of the rock layer respectively. After calculation and analysis by substituting (3), the position of the key layer can be obtained (Table 1).

It can be seen from Table 1 that there are five key layers in the overlying rock of working face b, among which the 134 m thick medium conglomerate in Luohe Formation is the main key layer, and there are four sub-key layers under it. The measured development height of the water-conducting fracture zone in the working face b is 175 m, and the fissure production ratio is 17.5, which is in the middle of the medium-grained rock in the sub-critical layer IV and has not affected the main key layer. This is consistent with the phenomenon that there is no surface collapse, ground fractures and still running water in gullies and streams, indicating that the key layers affected by the complex rock failure range are key layers I, II, and III.

In the mining of the first mining area of the mine, there was no disaster of cutting the top and pressing the shelf. Therefore, to compare and analyze the formation mechanism of the accident in the b working face, a certain working face in the first mining area was selected to analyze the key layer of overlying rock (Table 2). There are four key layers in the overlying rock of the working face in the first mining area. According to the coal thickness of 7.5 m and the fracture ratio of 17.5, the water-conducting fracture zone has not affected the sub-key layer III and the main key layer. Therefore, the key layers affected by the failure range of the overlying rock are key layers I and II.

According to the key layer theory38, when there are multiple layers of hard rock in mining overlying rock, some adjacent hard rock layers may produce composite effects, which have much greater control over rock layers than those of two single hard rock layers. This interaction between two key layers is called the composite effect of key layers. It can be seen from the above calculation that key layers II and III of working face b in mining area 2 have similar distances, same lithology, and similar thickness, resulting in a similar fracture distance, which makes it easy to produce composite fractures. Therefore, they are composite key layers, which can be judged by Eq. (4)@@11. The calculated result on the left side of Eq. (4) is 1.091, exceeding the threshold value of 1 on the right. It indicates that key layer II and key layer III are prone to composite failure. On the other hand, the critical layer of the working face in the first mining area does not meet the conditions of the composite critical layer, and there is no composite failure of the key layer. Therefore, the composite fracture of the key layer is one of the main reasons for the top-cutting phenomenon of the press frame in the b working face.

where \(\sigma_{1}\) and \(\sigma_{2}\) are the tensile strength of key layer II and key layer III respectively; Where, \(E_{1,j}\), \(h_{1,j}\)、\(r_{1,j}\) is the elastic modulus, thickness and bulk density of each layer of the soft rock formation above the key layer II, when, \(j = 0\), that is, the elastic modulus, thickness and bulk density of the key layer II; Where, \(E_{2,j}\)、\(h_{2,j}\)、\(r_{2,j}\), is the elastic modulus, thickness and bulk density of each layer of the soft rock formation above key layer III, when, \(j = 0\), that is, the elastic modulus, thickness and bulk density of key layer III; \(H\) is the thickness of the topsoil layer; \(\gamma\) is the bulk density of the topsoil layer.

In order to analyze the influence of the composite fracture effect of the above key layer on the lower rock layer and the working face, the composite fracture effect is analyzed according to the literature39. The elastic strain energy actually stored in a rock formation before fracture instability

Among them, the ultimate span of rock strata:

Initial yield span:

The elastic strain energy (We) stored in the instant fracture of the rock formation is transformed into the surface energy (Wf) of the fracture surface and the initial kinetic energy (Ek) of the broken rock mass. When the rock formation thickness is constant, the surface energy required to generate the vertical fracture surface is certain, accounting for less than 1, so the elastic strain energy stored in the instant fracture of the rock formation is transformed into the strain energy of the initial kinetic energy

where \(\alpha\) is the energy conversion coefficient.

According to the physical and mechanical properties of medium grained sandstone, the brittleness drop coefficient β = 0.75 is selected, and the ultimate span Lmax of key layer II is 31.07m and the initial yield span is 20.71m according to Eq. (6) and (7). In addition, Poisson’s ratio = 0.25, unit width was selected, and other parameters were selected as shown in Table 1. Therefore, the elastic strain energy stored in key layer II was calculated to be 1.52 × 106 J. As 0.5 is selected, the initial kinetic energy of key layer II breaking is 0.76 × 106 J. In the same way, the initial kinetic energy of key layer III breaking is 1.015 × 106 J. According to the kinetic energy theorem40, it can be calculated that the initial velocity after composite failure of key layers II and III is 0.782m/s, and the cumulative deformation of the lower layers after the composite failure of the upper key layers is 0.5m, so the time for the key layers II and III to act on the lower layers is 0.64s. According to the momentum theorem

where m is the mass of the basic top rock block, G is the gravity of the basic top rock block, t is the impact action time, and F is the impact force. By substituting the above relevant parameters into (9), it can be obtained that the instantaneous force generated by the breaking of the key layer of 2 layers per unit width is 65,143 kN.

According to the literature41, the load generated by the failure of key layers II and III only partially acts on the lower strata, and the ratio of the load on the lower strata to the force generated by the upper hard rock and above is the load transfer coefficient. According to the calculation of literature42, the load transfer coefficient generated by key layers II and III on the lower key layer I is 0.29. As a result, the concentration of static loads acting on the lower strata after the failure of key layers II and III is approximately 17,618 kN.

To sum up, the dynamic load force and static load force of key layers II and III after breaking are both greater than the rated working resistance of the working face, so they are the main power source that causes the top cutting of the working face. The dynamic load impact effect generated during the breaking of key layers II and III causes the downward kinetic energy of the lower sand body formation. Therefore, the composite fracture of key layers II and III is the power source of the top cutting and sand collapse of the working face.

Numerical calculation

UDEC software is used to build a model to calculate the plastic failure and stress distribution characteristics of overlying rock during the mining of b face. The model is 600 m long and 313m wide. The rock formation parameters are shown in Table 1. The Moore-Coulomb contact slip model is adopted for the model joints. The left and right boundary of the model is the deformation constraint boundary, and the displacement in the X direction is defined as 0. The lower boundary is fixed, and the displacement in the X and Y directions is 0. The upper boundary is free. The formation between the upper boundary of the model and the surface is transformed into a vertical uniform load and applied to the upper boundary. The gravitational acceleration g is 9.8 m/s2, and the applied stress is 4.66 MPa (Fig. 4). To avoid the boundary effect caused by coal seam mining, the excavation boundary is set reasonably according to the movement Angle range of coal seam mining rock. In this model, mining starts from the left boundary of 115m, and the stopping step is 50 m. Three measuring lines are arranged in the model. Measuring line 1 is located at the top interface of No.4–2 coal, measuring line 2 is 49 m away from the top interface of No.4–2 coal, and measuring line 3 is 99m away from the top interface of medium sandstone. The number of measuring points in the 3 measuring lines is 40 (Fig. 5).

It can be seen from the calculation results that: (1) Composite fracture occurs in the key layer. When the mining face is only 100 m, the shale stratum of the coal seam roof appears plastic failure (Fig. 6a); when the mining reaches 140 m, the sandstone at the bottom of the Luohe Formation appears plastic failure; when the mining reaches 160 m, the plastic zone fully develops and the medium-grain sandstone in both layers simultaneously occurs plastic failure (Fig. 6b). It indicates that key layers II and III are broken synchronously. (2) The downward load transfer effect occurs after a composite fracture. As can be seen from Fig. 7, the vertical stress measurement of line 1, line 2, and line 3 of the measurement point before excavation is 11MPa, 9.76 MPa, and 8.42 MPa; after excavation, line 1 is 24.9 MPa, line 2 is 22.5 MPa and line 3 is 14.5 MPa. The maximum stress concentration coefficients are 2.14, 1.98 and 1.92 respectively. Therefore, the closer the vertical seam is to the coal seam, the greater the stress concentration coefficient is, and the greater the reaction force on the working face support is. In the above numerical calculation, the compound fracture and downward load transfer effect of the key layer appear, resulting in strong ore pressure in the stope, which is consistent with the theoretical analysis.

Model test

The test bench with a length × width × height of 2.8 m × 0.2 m × 1.4 m was used to load the metal counterweight, and the data were collected using an optical speckle, digital camera, and pressure box. The average height of the 4–2 coal seam in the 202 working face of Zhaojin Coal Mine, measured from the ground, is 489 m, while the height of the test platform stands at 1.4 m. Taking into account the boundary effect of the model and leveraging our experimental laying experience, we have set the geometric similarity ratio for the model experiment at 150:1. Consequently, the simulated actual height is 313 m, while the experimental laying height is 1260 mm. This actual height dimension aligns with the dimensions of the numerical calculation model mentioned earlier. The remaining upper part is loaded using metal blocks, a process achieved through vertical stress loading in our previous numerical calculation model. Furthermore, based on our model experimental experience, we have determined the bulk density similarity ratio to be 1.5:1. According to the similarity criterion, the stress similarity ratio is calculated as the product of the geometric similarity ratio and the bulk density similarity ratio. Therefore, we have set the stress similarity ratio at 225:1. Additionally, considering geological conditions, we have assumed a coal thickness of 10 m and an inclination angle of 0 degrees. We have arranged two stress collection lines beneath the direct roof and key layer II.

During the test, the roof showed a cutting and subsidence phenomenon, and a longitudinal through-going fissure was generated. Figure 8a and b respectively show the overburden failure diagrams when the model was mined for 120 m and 180 m. When the mining reached 180 m, the overburden failure affected the key layer II and key layer III, and these two key layers broke synchronously. Figure 9 shows the overburden speckle displacement when the model was excavated for 180 m. The displacement differences of the upper broken rock blocks were relatively small, basically changing synchronously. Longitudinal fissures through the working face appeared in the lower rock strata, providing a channel for sand outburst formation.

Figure 10 shows the stress change data curve collected by stress box No.2398 of the measuring line at the lower part of key layer II. It can be seen that the stress in the stress box of key layer II increased sharply when it was broken, increasing by about 0.0041 MPa, an increase of about 20 times, and then rapidly decreased to 0.0026 MPa, an increase of about 13 times compared with before the break. Although there is a big gap between the model test and the actual formation situation, it can still provide a qualitative reference for the failure phenomenon of mining overlying rock. Therefore, the stress box stress changes show that the impact load of key layer II will be generated on the lower rock layer when it is broken, and the load will be transferred to the lower formation after the fracture, resulting in stress concentration. The simulation results of the composite fracture of the key layer and the impact load effect after fracture are consistent with the results of theoretical analysis and numerical calculation.

Analysis of hydrodynamic characteristics of roof aquifer

The hydraulic gradient of Luohe Formation aquifer in the second mining area (Fig. 11) is analyzed by using the triangular diagram method, and the hydraulic gradient of the west wing of the second mining area (including the accident working face) is 1.413%, and that of the east wing of the second mining area (excluding the accident working face) is 0.793. The west wing of the second mining area has large hydraulic gradient and good hydrodynamic conditions, which is the discharge point area of Luohe aquifer. According to the measured results of in-situ overlying rock failure range and previous research results, the mining fracture range extends to the Luohe aquifer with a thickness of up to 115m and a water pressure of more than 1MPa, resulting in the groundwater in the aquifer rapidly entering the primary or secondary fractures of mudstone formation of Zhiluo Formation under the action of self-weight along the mining fracture. As a result, the physical and mechanical properties of the stratum decrease and collapse and slime occur after water encounter, which provides sufficient water source for the formation of sand collapse. According to the criterion of the initiation of mud and sand under hydrodynamic action in literature35, the hydraulic gradient conditions of the Luohe Formation aquifer meet the hydrodynamic conditions of the collapse sand body of the mudstone formation of Zhiluo Formation under the condition of having a channel. Therefore, the Kedelo aquifer provides sufficient water source and hydrodynamic conditions for the formation of sand collapse.

Analysis on the characteristics and influencing factors of water degradation of weakly consolidated rock

Weakly consolidated formation and its water deterioration properties are closely related to cementation composition, clay mineral content, and void characteristics. Foreign scholars have relatively few studies on the properties of weakly consolidated sedimentary strata, and some studies have shown that the destruction of cement by plastic deformation is the main mechanism for the degradation of mechanical properties of weakly consolidated sandstone43. Similarly, the study on the properties of sedimentary rocks shows that the evolution of sandstone properties is closely related to the clay phase identified in the matrix, and clay minerals can affect the properties of stones when the water content is low44. With the increase of saturation level, the mechanical and fracture toughness of sedimentary sandstone generally decreases45. In addition, the adsorption behavior of limestone is mainly determined by the number of montmorillonite layers with a large specific surface area, and the mechanical strength loss rate is linearly related to the adsorption capacity46.

According to relevant studies6,8,47, the weakly consolidated formations in the mining areas of western China are mainly sandstone, sandy mudstone, and mudstone, and most of the cement is argillaceous, characterized by large porosity, poor cementation, and high clay mineral content. The rock strength is generally low, and it is easy to disintegrate and argillate after contact with water. The above characteristics are closely related to the composition and structure of rocks and minerals. The uniaxial compressive strength and elastic modulus of weak mudstone decrease with the increase of clay mineral content, and the water-contact weakening index of mudstone increases with the increase of clay mineral content48. Jurassic weakly consolidated sandstone and mudstone skeleton particles absorb water, expand, and soften themselves, and the adhesion between skeleton particles deteriorates and the degree of cementation decreases49,50. A large number of laboratory tests have shown that there is a quantitative relationship between mineral composition and physical and mechanical parameters in intact sandstone and mudstone of Jurassic weakly consolidated coal measure strata51.

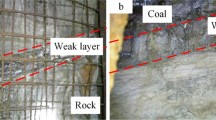

The Zhiluo Formation, which lies between the key layers I and II on the roof of Zhaojin Coal Mine, belongs to fluvial facies deposits in semi-arid climates and is mainly mudstone strata. The b working face is located in the axis of the syncline structure, stress is concentrated, the roof rock is broken, and the solid rock composition of the silt accumulation after the accident is mainly mudstone and sandy mudstone, accounting for 40% ~ 50% of the solid material, so it can be judged that the accident gusher sand body mainly comes from the Zhiluo formation and the coal seam directly overlying Yan 'an formation.

Influence analysis of mechanical properties

The formation of Zhiluo Formation above the b working face is very weak in water richness, there are ancient riverbed facies with loose bodies, the RQD value is 48% on average, and the rock quality and integrity are poor. Indoor compressive strength is 2.10–27.57 MPa, average 15.86 MPa; The tensile strength is 0.25–1.19 MPa, with an average of 0.73 MPa, belonging to the weak rock class. The softening coefficient of mudstone is 0.35–0.51, with an average of 0.45. The softening coefficient of sandy mudstone is 0.34–0.71, with an average of 0.53. The softening coefficient of siltstone is 0.52; The softening coefficient of argillaceous siltstone is 0.49. It can be seen that the formation of Zhiluo formation above the b working face has poor cementation and mechanical properties, and its physical and mechanical properties are reduced after encountering water, and it is easy to deform and destroy in the mining process, resulting in a large number of cracks.

Analysis of the influence of mineral composition

The D/max-2500 X-ray diffractometer was used to conduct X-ray diffraction tests on 9 groups of samples to analyze and compare the composition of Jurassic shale rock and ore in stope roof, to analyze the composition of shale rock and ore and identify its micro and macro characteristics.

According to the change of characteristic peaks of each sample after X-ray diffraction, the quantitative analysis of each sample was carried out. As shown in Fig. 12, the results show that the composition of Jurassic mudstone ore is mainly quartz, and the content percentage is 62.5–80.6%. Followed by kaolinite (6–16.5%) and illite (2–24%), in addition to hematite, potassium feldspar, anatase, and so on. At the same time, although the colors of mudstone strata are different, their mineral composition is similar. Therefore, the mineral composition of Jurassic mudstone in the stope roof in the study area is mainly kaolinite and illite besides quartz. Because kaolinite, illite, and other minerals have small particles and good hydrophilicity, when water enters the pores and cracks of the rock, the adsorbed water film of the rock particles thickens, causing the volume expansion of the rock, and this expansion is uneven, resulting in uneven stress in the rock, causing part of the cement to be diluted, softened or dissolved, so the rock particles are fragmented52,53.

Impact analysis of disintegration rate

Two groups of intact mudstone samples without macroscopic cracks were selected in the disintegration experiment. The average mass of the first group was 155.09 g, and that of the second group was 14.95 g. Put the sample into the sample box with water, set the observation interval of 1 to 5 min, and weigh the residual sample quality. The disintegration resistance index was calculated by the ratio of the residual mass of the disintegrating sample to the total mass of the sample, and the disintegration characteristics of each sample were evaluated.

Figure 13 shows the change curve of the disintegration rate of mudstone samples. In the test, mudstone quickly disintegrated after encountering water, and the disintegration rate reached its maximum value in 0.8–1.2 min. After 4 min, it completely disintegrated and the disintegration rate was high, indicating that mudstone strata of the Zhiluo Formation were very easy to disintegrate and argillate after encountering water. This is consistent with the characteristics of loose cement and fragile upon light contact.

The thickness of the Zhiluo Formation gradually thinned from the second mining area to the first mining area, and the first mining area was missing, which was the main reason why no dynamic sand failure occurred in the first mining area.

Microstructure of weakly consolidated rock

SEM tests were carried out in the Continental Dynamics Laboratory of Northwestern University, and 9 groups of samples were tested by the FEI Quanta 400 FEG environmental scanning electron microscope system. The microstructure of the sample was tested before and after being saturated with water. The electrical image dispersion is less than or equal to 50μm, and the maximum magnification can reach 1,000,000 times.

The scanning electron microscope system was used to conduct SEM tests on the samples, and the sandstone magnification was selected to be × 100 times and × 1000 times, and the mudstone sample was selected to be × 100 times and × 2000 times, and the structural characteristics of the samples before and after filling with water were observed and compared from the whole and local aspects (Figs. 14, 15 and 16).

By comparing the intact samples and the saturated samples, it is found that a small number of cracks occur after the sand is air-dried with water, but the surface structure of the sand has no obvious change. After the mudstone formation is dried by water, there are a lot of micro-cracks on the surface, and the structure is very loose, which can not guarantee the stability of the macro-rock mass.

The test and analysis results show that the coal seam roof of ZF202 face in Zhaojin Coal Mine is covered with thick mudstone stratum, which contains a large amount of montmorillonite and potassium feldspar clay minerals, and the structure is loose in water and easy to collapse. This mudstone is the main material source of mud and sand gushing disaster in ZF202 working face, and its special physical and mechanical properties affect the overburden failure characteristics of coal mining to a certain extent.

Formation mechanism of dynamic sand collapse of weakly consolidated rock strata in thick bedrock stope roof

Based on the research on the power source and material source of the roof water and sand collapse and the occurrence of strong ore pressure in the Zhaojin coal mine in the Huanglong Coal field (Fig. 17), it is found that the source of sand collapse is the mudstone formation of the Jurassic Zhiluo Formation. Besides the dead weight of the gusher and the water pressure of the aquifer, the power source also includes the mine pressure generated by the sandstone breaking of the upper part of the weakly consolidated Jurassic Luohe Formation. Moreover, tests have proved that weakly consolidated strata are easy to disintegrate and deteriorate when exposed to water18. The above indicates that the water degradation of weakly consolidated formation induces the upper hard rock to break, which provides the driving force for sand collapse, and the transfer load of rock stratum breaking and the incremental load of water absorption of weakly consolidated formation cause the basic top to lose stability, and then cut the top to form a sand collapse channel.

According to statistics, the overlying rock of coal mine where the dynamic sand failure of weakly consolidated formation occurred is widely characterized by a layer structure similar to a “sandwich cake” of “lower basic top—medium weakly consolidated formation—upper hard rock formation” (Fig. 18), in which the weakly consolidated formation is not only the foundation of the upper hard rock formation but also the load of the lower basic top.

For example, the pore and fissure aquifers of the Cretaceous Luohe and Yijun formations overlying the coal seam in the Huanglong coalfield have large thicknesses (100–350 m) and moderate water richness54,55,56. The strata are of obvious integrity and are mostly interlayered structures of sand and conglomerate, with calcareous cementation and high strength, and their failure and instability can easily cause a strong ore pressure appearance (upper hard rock). There are mainly sandstone and mudstone between the coal seam and the aquifer of the Cretaceous Luohe Formation, and they show an interactive structure (the proportion of mudstone in some strata is as high as 88%). Due to the short deposition time and the diagenetic environment of inland fluvial lacustrine facies, the rock cements are mostly argillaceous, which are characterized by low strength, high porosity, poor cementation, and high clay mineral content. After water immersion, rock mass degradation such as disintegration and argillation is prone to occur (weakly consolidated strata)8. Similarly, the thick Jurassic water-rich sandstone (commonly known as Qilizhen sandstone) is widely developed on the coal seam of Ningdong coal base, and the weakly consolidated mudstone strata of Jurassic are mainly developed between it and the coal seam. Therefore, the “moderately weakly consolidated formation” is the Jurassic weakly consolidated sand-mudstone formation, and the "upper hard rock" is the Cretaceous thick layer of water-rich sandstone (Huanglong Coalfield) or the Jurassic thick layer of water-rich sandstone (Ningdong coalfield), and both of them are within the mining failure range. The results show that the material source and power source of sand collapse in the concurrent disasters of water and sand collapse and strong ore pressure are from the mining pressure of the Jurassic weakly consolidated sand mudstone formation and the upper sandstone fracture respectively.

Conclusions

-

(1)

The occurrence characteristics of key layers in overlying rock of working face b are studied by theoretical analysis, and it is found that there are 5 key layers in overlying rock of working face b, and the mining failure swept key layers I,II and III, and the key layers II and III are composite key layers, whose breaking is easy to produce composite effects, and they are quantified from the perspective of energy. The results of numerical simulation and model test are in agreement with the theoretical analysis.

-

(2)

Through the analysis of the solid material of the underground sand collapse body, it is found that its source is the mudstone formation of Zhiluo Formation, and the characteristics and reasons of its easy disintegration and softening are revealed by means of disintegration test and mineral composition analysis.

-

(3)

The typical overburden formation structure characteristics of dynamic sand collapse disaster in weakly consolidated formation are put forward, that is, the formation structure of "lower basic top—medium weakly consolidated formation—upper hard rock";

-

(4)

Dynamic sand collapse of weakly consolidated rock strata in stope roof is a kind of sudden strong, destructive and impact-heavy mine disaster in which weak consolidated rock strata deteriorated by mining disturbance produce gushing under the ore pressure effect caused by hard rock breaking above it and basic roof instability below it. Its essence is dynamic sand collapse of roof under the effect of hard rock breaking and instability induced by weak consolidated roof deterioration.

Data availability

Data is provided within the manuscript.

References

Xu, Z. et al. A study of conditions of water bearing media and water dynamics in typical Jurassic coal rich regions in western China. J. China Coal Soc. 42(2), 444–451. https://doi.org/10.13225/j.cnki.jccs.2016.6024 (2017).

Chai, Z. Y., Zhang, Y. T. & Zhang, X. Y. Experimental investigations on correlation with slake durability and mineral composition of mudstone. J. China Coal Soc. 40(5), 1188–1193. https://doi.org/10.13225/j.cnki.jccs.2014.0897 (2015).

Wei, J. C. et al. Development characteristic of water flowing fractured zone under semi-cemented medium-lowstrength country rock. J. China Coal Soc. 41(4), 974–983. https://doi.org/10.1155/2018/9035654 (2016).

Wang, W. M., Zhao, Z. H. & Wang, L. Elastic-plastic damage analysis for weakly consolidated surrounding rock regarding stiffness and strength cracking. J. Min. Saf. Eng. 30(5), 679–685 (2013).

Cai, J. L., Tu, M. & Zhang, H. L. Deformation and instability mechanism and control technology of mining gateway for Jurassic weak-cemented soft rock roadways. J. Min. Saf. Eng. 37(6), 1114–1122 (2020).

Ji, H. G. et al. Analysis on the microstructure evolution and frcture morphology during the softening process of weakly cemented sandstone. J. China Coal Soc. 43(4), 993–999 (2018).

Hao, Y. X. et al. Large deformation control technology for expansive and weak-cemented soft rock roadways in Shajihai coal mine. J. Min. Saf. Eng. 33(4), 684–691 (2016).

Sun, L. H., Ji, H. G. & Yang, B. S. Physical and mechanical characteristic of rocks with weakly cemented strata in Western representative mining area. J. China Coal Soc. 44(3), 865–873. https://doi.org/10.13225/j.cnki.jccs.2018.6039 (2019).

Lv, Y. G., Xiao, Q. H. & Cheng, J. L. Mechanism and prevention of water-sand inrush in soft rock with weakly abundant water: A case study in Shanghai temple mining area. J. China Coal Soc. 44(10), 3154–3163. https://doi.org/10.13225/j.cnki.jccs.2018.1403 (2019).

Qiao, W. et al. Formation mechanism, disaster-causing mechanism and prevention technology of roof bed separation water disaster in coal mines. J. China Coal Soc. 46(2), 507–522 (2021).

Pan, J. F. et al. Geological characteristic and control of rock burst of huanglong jurassic coal mine field. J. Coal Min. Technol. 24(1), 110–115 (2019).

Sui, W. H. et al. Study status and outlook of risk evaluation on water inrush and sand inrush mechanism of excavation and mining. J. Coal Sci. Technol. 39(11), 5–9 (2011).

Sui, W. H. et al. A review on disaster mechanism of quicksand with a high potential energy due to mining and its prevention and control. J. China Coal Soc. 44(8), 2419–2426. https://doi.org/10.13225/j.cnki.jccs.KJ19.0570 (2019).

Dong, Q. H. et al. Risk mechanism of water and sand burst under the Neogene and thin bedrock: The influence of ancient erosion surface undulation and weather degree. J. China Univ. Min. TecShnol. 53(5), 889–990 (2024).

Zeng, Y. F. et al. Disaster-causing mechanism and prevention and control path of different types of coal seam roof water disasters in China. J. China Coal Soc. 49(3), 1539–1555 (2024).

Dong, S. N. et al. Characteristics and prevention and control techniques of typical water hazards in coal mines in Shaanxi Province. J. China Coal Soc. 49(2), 902–916 (2024).

Song, Y. X. Water Inrush and sand inrush mechanism and prevention technology during the initialmining period in 22402 working face of halagou coal mine. J. Saf. Coal Mines 43(12), 91–93 (2012).

Liu, Z. X. et al. Formation mechanism and prevention and control of underground debris flow induced by roof-cutting of pressured support in deep-buried face. J China Coal Soc. 44(11), 3515–3528. https://doi.org/10.13225/j.cnki.jccs.2019 (2019).

Zhang, H. L. et al. Study on mechanism of stope roof fracture in deep-buried coal seam with thin bedrock. J. Min. Saf. Eng. 34(5), 825–831 (2017).

Miao, X. X., Wang, C. S. & Bai, H. B. Hydrogeologic characteristics of mine water hazards in Shendong mining area. J. Min. Saf. Eng. 27(3), 285–291 (2010).

Li, C. F. Characteristics of height of water flowing fractured zone caused during fully-mechanized caving mining in Huanglong coalfield. J. Coal Geol. Explor. 47(2), 129–136 (2019).

Liu, Y. F., Wang, S. D. & Wang, X. L. Development characteristics of water flowing fractured zone of overburden deep buried extra thick coal seam and fully-mechanized caving mining. J. China Coal Soc. 39(10), 1970–1976 (2014).

Sun, Q. X., Mou, Yi. & Yang, X. L. Study on “two-zone” height of overlying of fully-mechanized technology with high mining height at Hongliu coal mine. J. China Coal Soc. 38(S2), 283–286 (2013).

Du, F. et al. Types and mechanism of water-sand inrush disaster in west coal mine. J. China Coal Soc. 42(7), 1846–1853 (2017).

Xu, J. L., Zhu, W. B. & Ju, J. F. Supports crushing types in the longwall mining of shallow seams. J. China Coal Soc. 39(8), 1625–1634 (2014).

Guo, W. B. et al. Analyses of support crushing accidents and support working resistance in large mining height workface with hard roof. J. China Coal Soc. 39(7), 1212–1219. https://doi.org/10.13225/j.cnki.jccs.2013 (2014).

Fan, L. M. Environmental geology in Shenmu mining area. J. Hydrogeol. Eng. Geol. 19(6), 37–40 (1992).

Liang, Y. & Tan, Z. D. Simulation test research on water and soil outbursts of weak binding soil. J. Xi’an Highw. Univ. 16(1), 37–40 (1996).

Zhang, M. J. et al. Study on the inrushing mechanism of weak cemented quicksand layer and its forecasting. J. Metal Mine 10, 48–50 (2002).

Sui, W. H., Cai, G. T. & Dong, Q. H. Experimental research on critical percolation gradient of quicksand across overburden fissures due to coal mining near unconsolidated soil layers. J. Chin. J. Rock Mech. Eng. 26(10), 2084–2091 (2007).

Xu, Y. C., Wang, B. S. & You, S. W. Mechanism and criteria of crushing sand near loosening sand stone aquifer. J. Xi’an Univ. Sci. Technol. 32(1), 63–69 (2012).

Sui, W. H. & Dong, Q. H. Variation of pore water pressure and its precursor significance for quicksand disasters due to mining near unconsolidated formations. J. Chin. J. Rock Mech. Eng. 27(9), 1908–1916 (2008).

Yang, X. et al. Incipience condition and migration characteristics of aeolian-sand aquifer in a typical western mine. J. Rock Soil Mech. 39(1), 21–28 (2018).

Zhang, Y. J., Kang, Y. H. & Liu, X. Predicting on inrush of sand of mining under loosening sandstone aquifer. J. China Coal Soc. 31(4), 429–432 (2006).

Wu, Y. P. & Lu, M. S. Analysis of sand inrush generation condition in coal mining of shallow coal seam. J. Gr. Press. Strata Control 20(3), 57–58 (2004).

Jia, H. S., Ma, N. J. & Li, X. D. “Open-close” law of longitudinal transfixion cracks in shallow buried coal face with thin bedrock. J. China Coal Soc. 40(12), 2787–2793 (2015).

Sun, L. H. et al. Experimental study on characteristics of broken caving and regularity of compaction deformation of rocks in caving zone in the weakly cemented strata. J. China Coal Soc. 42(10), 2565–2572 (2017).

Xu, J. L. & Qian, M. G. Method to distinguish key strata in overburden. J. China Univ. Min. Technol. 29(05), 21–25 (2000).

Wang, J. C. & Wang, Z. H. Impact effect of dynamic load induced by roof in high-intensity ming face. J. Chin. J. Rock Mech. Eng. 34(9), 3987–3997 (2015).

Ye, W. G. & Yu, G. X. College Physics. (Beijing, Tsinghua University Press, 2012).

Kang, L. X. & Zhai, Y. D. Stress transmission in blocky rock mass and load calculation of basic roof structure of stope. J. Chin. J. Rock Mech. Eng. 23(10), 1720–1723 (2004).

Li, J. H. et al. Study on load transmission characteristics of overburden rock above coal mining face in thin bedrock of super thick unconsolidated stratum. J. Coal Sci. Technol. 45(11), 95–100 (2017).

Mojtaba, R., Dave, C. & Nouri, A. Constitutive model for monotonic and cyclic responses of loosely cemented sand formations. J. Rock Mech. Geotech. Eng. 10(4), 740–752 (2018).

Tiennot, M., Mertz, J. D. & Bourges, A. Influence of clay minerals nature on the hydromechanical a nd fracture behaviour of stones. J. Rock Mech. Rock Eng. 52, 1599–1611 (2019).

Roy, D. G. et al. Effect of water saturation on the fracture and mechanical properties of sedimentary rocks. J. Rock Mech. Rock Eng. 50, 2585–2600 (2017).

Cherblanc, F. et al. Influence of water content on the mechanical behaviour of limestone: Role of the clay minerals content. J. Rock Mech. Rock Eng. 49, 2033–2042 (2016).

Li, T. C. et al. Deformation and failure process analysis of rectangular roadway in muddy weakly cemented soft rock strata. J. Rock Soil Mech. 35(4), 1077–1083 (2014).

Li, G. C. et al. Macro and meso scale simulation study of the strength-weakening property of soft mudstone affected by water. J. China Univ. Min. Technol. 48(5), 935–942 (2019).

Song, Z. Y. et al. Morphology and failure mechanism of the shear fracture surface of weakly cemented sandstone with water saturation. J. China Coal Soc. 43(9), 2444–2451 (2018).

Qiao, W. G. et al. The deformation failure mechanism of very weakly cemented soft rock formed during jurassic-cretacenous period in road ways. J. Shandong Univ. Sci. Technol. 32(4), 1–6 (2013).

Wang, Z. K. et al. Relationships between the petrographic, physical and mechanical characteristics of sedimentary rocks in Jurassic weakly cemented strata. J. Environ. Earth Sci. 78(5), 131 (2019).

Liu, C. W. & Lu, S. L. Research on mechanism of mudstone degradation and softening in water. J. Rock Soil Mech. 21(5), 28–31 (2000).

Sun, L. H. et al. Support failure of a high-stress soft-rock roadway in deep coal mine and the equalized yielding support technology: A case study. J. Int. J. Coal Sci. Technol. 2(4), 279–286 (2015).

Lin, Q. & Qiao, W. Water prevention and control technology of roof bed separation in Cuimu mine. J. Coal Sci. Technol. 44(3), 129–134 (2016).

He, H. et al. Mechanism of stress disturbance and rock burst induced by large flow drainage of ultra-thick overlying aquifer. J. Min. Saf. Eng. 42(1), 108–116 (2025).

Li, J. H. Study on separated layer water burst mechanism for weakly cemented giant thick glutenite. Coal Sci. Technol. 52(2), 209–218 (2024).

Funding

Key projects supported by the National Natural Science Foundation Enterprise Innovation and Development Joint Fund (U24B2041), the National Natural Science Foundation of China (52104240), General Project of Basic Research Plan of Natural Science in Shaanxi, China Province (2025JC-YBMS-541).

Author information

Authors and Affiliations

Contributions

Conflict of interest The authors have the appropriate permission from responsible authorities to do the study on-site and have no conflict of interest.Author Contribution Liu Zhaoxing: Supervision, Writing-review & editing,Data curation, Methodology, Writing-original draft. Dong Shuning: Conceptualization, Project administration, Supervision. Guo Xiaoming: Project administration, Resources. Li Xiaolong: Conceptualization, Writing-original draft. Liu Yingfeng: Project administration, Resources. Guo Kang: Writing-original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhaoxing, L., Shuning, D., Xiaoming, G. et al. Study on dynamic sand collapse mechanism of weakly consolidated rock strata in thick bedrock stope in western China. Sci Rep 15, 20353 (2025). https://doi.org/10.1038/s41598-025-04132-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-04132-y