Abstract

Air conditioning systems are essential for ensuring indoor thermal comfort in commercial buildings; however, they are also significant consumers of electrical energy, contributing to increased environmental impact. Optimizing the design of mechanical ventilation (MV) systems through multi-objective approaches can greatly improve both energy efficiency and cost-effectiveness. This study presents an advanced optimization strategy for MV in both a classical reference case and a real-world commercial installation. The methodology integrates principles of fluid mechanics with computational modeling to perform mass and pressure balances, combined with a simulated annealing algorithm for system optimization. The results demonstrate notable reductions in energy consumption, installation costs, and root mean square deviation of airflow rates from design targets. Furthermore, the proposed approach enables effective airflow distribution without the use of dampers. These findings highlight the potential of optimization techniques, particularly simulated annealing, in enhancing the performance, economic feasibility, and environmental sustainability of HVAC systems in commercial applications.

Similar content being viewed by others

Introduction

The costs associated with electrical energy consumption in air conditioning systems are a critical factor in the operational expenses of commercial buildings1,2. According to Kreider1, energy usage related to air conditioning accounts for approximately 37% of a building’s total energy consumption, with an additional 5% attributed to ventilation systems. Given the substantial energy demands of these systems, optimizing their design is essential for improving energy efficiency and reducing operational costs.

Commercial and institutional buildings often feature diverse thermal and ventilation requirements across various spaces, making it challenging to design a mechanical ventilation system that ensures uniform airflow distribution while preserving architectural integrity. Accurate duct sizing is essential to meet these demands efficiently, providing thermal comfort without incurring excessive energy consumption or requiring unnecessary structural alterations.

A comprehensive analysis of duct sizing in mechanical ventilation systems can lead to significant cost savings throughout the operational lifespan of a building. In Brazil, the design of air conditioning and ventilation systems is commonly guided by ABNT NBR 16,4013, which establishes fundamental principles and key regulations for centralized and decentralized HVAC systems. This standard aligns with methodologies outlined in the ASHRAE Fundamentals4 and advocates for various design approaches, including the static regain method, the equal friction method, and the T method.

The T method, in particular, utilizes dynamic programming techniques to determine optimal duct sizes by balancing installation costs and energy efficiency, thereby enabling the design of cost-effective HVAC systems. Besant and Asiedu5 emphasize the importance of life cycle cost assessment in HVAC system design and introduce a graphical approach for duct sizing based on long-term economic considerations. Their work also serves as the foundation for the Initial duct size, Pressure augmentation and Size augmentation method, IPS, which is widely used for duct sizing and pressure balancing in ventilation systems.

In a related study, Jorens et al.2 presented a methodology for the optimization of air distribution systems, encompassing both duct dimensions and layout considerations, by leveraging metaheuristic approaches to optimize the costs associated with ducts and fans. The authors employed the G-chart representation of the layout and implemented a steepest descent-mildest ascent approach to optimize the duct configuration. The developed program proved to be efficacious in identifying the most cost-effective layout for air distribution systems.

The utilization of computational tools coupled with optimization methods can significantly enhance research efforts aimed at enhancing comfort levels and reducing energy consumption within buildings. Chen and Yang6 conducted a sensitivity analysis to streamline the variables used in optimizing energy consumption related to lighting and ventilation systems in buildings located in hot and humid climates. The study implemented a genetic algorithm in conjunction with the energy plus software. Through the utilization of Pareto frontier chart, the researchers successfully attained one optimal condition.

Ye et al.7 conducted a multi-objective optimization study involving airflow discomfort, temperature variance, air renewal efficiency, and energy utilization coefficient of a collision jet ventilation system. The research utilized the Taguchi method to optimize individual comfort variables, as well as multi-objective optimization employing gray relational analysis on design parameters such as height, speed, air supply temperature, and return vent height. Anova analysis of variance was employed to conduct sensitivity analysis on the optimizations, revealing the methodology’s potential in enhancing thermal comfort outcomes. Significant factors influencing optimization included the air supply height and return height.

Gupta and Khare8 undertook an in-depth analysis utilizing Computational Fluid Dynamics (CFD) to understand variations in temperature, speed, and humidity for natural ventilation scenarios in diverse environmental conditions in India. The simulations covered simple side, cross ventilation, and night ventilation, showcasing substantial results in temperature reduction with night ventilation and speed enhancement with cross ventilation.

Kabbara et al.9 proposed a simulation-based ductwork design strategy that employs metaheuristic optimization techniques to generate optimized ductwork configurations for retrofitted HVAC systems. Their approach provides an automated solution for designing efficient ductwork layouts. The method was applied to a case study of a two-story school building repurposed for a different use. The results demonstrated a significant 17% reduction in life cycle cost and achieved a well-balanced design.

Tang et al.10 developed a rule-based optimization design method for the ductwork of diffuser systems in open spaces. This method enables the automatic generation of the entire duct routing for air distribution systems in open spaces. The duct size optimization follows a "filtering first, optimizing later" strategy, which reduces the number of ductwork routes involved in optimization and enhances the computational efficiency of duct size optimization.

Thus, studies highlight the importance of dynamic programming methods for the appropriate energy and financial sizing of ducts in mechanical ventilation systems in HVAC. However, the way in which mass and energy balances are accounted for, as well as the modeling approach to the environment or ventilation ducts, are highly relevant to the analysis. Some methods employ well-established software such as EnergyPlus6, CFD tools7,8, or approximate methods like the T-method and the approach used by Tang et al.10 to determine these balances. Others rely simply on velocity or pressure criteria in the ducts, as seen in the work of Kabbara et al.9.

Nevertheless, the nonlinear nature of the coupling between mass and energy makes the application of CFD tools or other computationally intensive methods particularly challenging to integrate with dynamic programming approaches, given the need to evaluate multiple ventilation conditions.

The use of dynamic programming tools, such as the simulated annealing method, offers significant advances in optimizing ducts and ventilation systems. These approaches aim to reduce energy consumption and enhance the financial viability of the installation while ensuring performance standards are met.

Over the past two decades, research interest in optimization methods for HVAC systems has grown significantly, as reflected in the increasing number of publications on this topic. As shown in Fig. 1 the number of papers published annually has risen significantly, particularly in recent years. This steady growth in scientific output underscores the growing recognition of optimization techniques as essential for enhancing the efficiency and performance of HVAC systems.

Number of publications over the years (keywords: Genetic algorithm, multi-objective and simulated annealing. Database: www.sciencedirect.com).

Thus, this research aimed to develop a tool for evaluating the operating conditions of ventilation systems, specifically focusing on energy balance and mass flow in ducts, based on ASHRAE Fundamentals methodology for ventilation ducts, integrated with the simulated annealing method to optimize the design of mechanical ventilation commercial installations based on both technical and financial analyses.

The significance of this work lies in the innovative application of dynamic programming tools, particularly the simulated annealing method, which has seen limited use in the context of ventilation systems, combined with a simplified computational code for mass and energy balance analysis. This integrated approach allows for the determination of pressure and mass flow distributions throughout the entire ventilation network.

A key feature of the proposed methodology is a multi-objective function that incorporates both technical and economic criteria into the design of mechanical ventilation systems. From a technical perspective, the function ensures occupant comfort by meeting the required airflow rates in each room and facilitates the elimination or reduction of dampers through accurate mass and energy balance calculations across the ductwork. From a financial standpoint, the model takes into account operational and maintenance costs, manufacturing and installation expenses, and potential logistical constraints.

Furthermore, the designer is provided with the flexibility to prioritize different aspects of the project by adjusting the weights in the multi-objective function, allowing for tailored optimization according to specific design goals.

Problem description

The methodology involved developing a computational code to perform mass and pressure balance calculations within the ventilation ducts, integrated with a simulated annealing algorithm to optimize duct sizing and fan speed selection. This approach was applied to two case studies: a reference installation from the ASHRAE Fundamentals4 and a commercial air conditioning system serving a food retail store located in a shopping mall in Goiania, Brazil. The store features an air-conditioned area of 53.81 m2, maintained at a temperature of 24 ± 2 °C, with a thermal load of 22,947 kcal/h and an air supply rate of 5600 m3/h.

The multi-objective function employed accounts for the effects of the variation in airflow calculated at each air supply point concerning the design flow rate, the electrical energy costs of the fan, and the installation cost. The design variables used were the duct dimensions and the fan speed, employing a multivariable objective function as per Eq. 1.

where, \({w}_{1}\), \({w}_{2}\) and \({w}_{3}\) are the weights of the objective functions; \(\sqrt {\sum {\left( {Q - Q_{design} } \right)^{2} } }\) is mean square deviation of the air flow rate, Q, in relation to the design air flow rate, Qdesign. \(F_{target - Q}\), \(F_{target - Energy}\) and \(F_{target - Installation}\) represent the target values related to the deviation of flow rates, energy consumption costs, and installation costs, respectively; and the values of \(F_{Energy}\) and \(F_{Installation}\) are the energy consumption and installation costs determined by the mass and pressure balance calculation routine.

Analysis of incompressible viscous flow in ducts

The study of fluid flow in ventilation systems employs the analysis of incompressible fluid flow and the basic equations of mass and energy conservation for steady-state conditions, see Çengel and Cimbala11. Mass conservation for the different ducts in ventilation systems can be given as:

To quantify the relationship between flow quantities, such as pressure, velocity, and fluid height, the energy equation is used with the same piezometric notation as Bernoulli’s equation, considering negligible variations in internal energy and heat exchange, as follows:

where \({\text{h}}_{\text{e}}\) and \({h}_{p}\) are respectively the piezometric height terms of the fan motor power and the viscous work or head loss in the piping. The term, \(\frac{{P}_{i}}{\gamma }\), is called pressure height, the term, \(\frac{{V_{i}^{2} }}{2 \cdot g}\), is designated as velocity height and \(z_{i}\) is the physical height.

Head loss in the piping, \({h}_{p}\) is given by the Darcy equation in the form:

This equation accounts for both losses in straight lengths, \(\frac{\text{f}{\cdot }_{.}\text{L}}{\text{d}}\), and localized head losses in the piping due to fittings, \(\sum K\). Where \(f\) is the friction factor given by the Colebrook equation for turbulent flow.

The energy analysis of coupling the ventilation piping with the fan is a dynamic process, as highlighted by Viana et al.12, where the operating point is determined by the intersection of the fan characteristic curve with the installation operation curve.

Due to the significant costs of installations and the complex air distribution network in air conditioning installations by ventilation ducts, a computational routine was developed to perform the coupling of mass and pressure balances to determine the actual amount of mass flows in each duct and consequently in the environments. The computational routine also allows determining the material costs of the installation and the electrical energy costs for operating the ventilation system.

Simulated annealing method

The simulated annealing method belongs to the class of probabilistic methods that seek to simulate natural processes to achieve the minimum of the objective function; in the case of maximizing, it is necessary to set the objective function with a negative sign. The method is analogous to the annealing process of metals, in which the material is heated to a high temperature and then slowly cooled so that the crystalline structure reaches the minimum energy.

According to Aarts et al.13, the simulated annealing method is a class of local search algorithms that has been very successful in practical problem applications, and it also features a stochastic component that facilitates the theoretical analysis of its asymptotic convergence. According to Rao14, the method is characterized by good quality of the final solution, convergence is not affected by the characteristics of the functions or even the convexity of the feasible space, and it allows solving problems with discrete or continuous variables as well as evaluating problems with constraints.

Yuxin et al.15 introduced a Modified Simulated Annealing algorithm to optimize a support vector regression model for air conditioning load prediction. The modified approach improved the annealing plan and disturbance range. Compared to two other models: Simulated Annealing without modification and Very Fast Simulated Annealing, both using support vector regression. The Modified Simulated Annealing method demonstrated superior global optimization capability, robustness, and computational efficiency. Additionally, it exhibited stronger generalization ability, effectively enhancing the accuracy of air conditioning load prediction.

Although the simulated annealing method is no usually applied methodology for application in mechanical ventilation systems for air conditioning, as the computational cost of evaluating the objective function is low and it allows reaching global optimal conditions.

In terms of the simulation parameters used in the simulated annealing algorithm, ten temperature levels were employed, with 300 iterations at each temperature and 50 setback iterations. The Boltzmann distribution temperature was set to 1 × 10–3. Higher initial temperatures were assigned to the main ducts and fan rotation, around 200, while lower initial temperatures, around 50, were used for the secondary ducts.

Validation for numerical methods

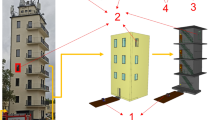

The validation of the computational code was carried out using the reference installation defined in the ASHRAE Fundamentals4. The airflow rates and duct dimensions initially established by ASHRAE are shown in Fig. 2.

Source: Adapted from ASHRAE Fundamentals 4.

Details of the Air Conditioning installation.

Table 1 presents the airflow data in the ducts as provided in ASHRAE Fundamentals4, considering the sections upstream of the fan and their respective flow rates. The mass balances account for both the air demand in each section of the installation and the sum of the flow rates in the branches feeding those sections.

The pressures calculated based on flow demand using the computational code for the different branches and sections were compared to the results presented in the ASHRAE reference installation4, as shown in Fig. 3.

Figure 3 shows minor pressure deviations in the peripheral branches when compared to the reference installation, particularly in Branch 2, Section II (R2-II), and Branch 5, Section I (R5-I). These deviations are associated with the lack of full coupling between the pressure and mass balances.

The results of the mass balance used to couple the pressure and mass balances are shown in Table 2.

When comparing the air conditioning demand through the airflow estimated by the mass balance (as shown in Tables 1 and 2), small differences in mass flow are observed, generally with higher flow rates than those in Table 1, except in Branches 6 and 7.

Similarly, the results of the pressure balance for the coupled mass and pressure analysis are presented in Fig. 4.

Figure 4 shows no significant differences compared to the reference installation. However, it is notable that the outlets of all peripheral branches are close to atmospheric pressure, i.e., zero-gauge pressure. Another relevant observation from the figure is the varying slopes of the curves for the different branches and sections, indicating that the duct sizing criterion does not follow an equal pressure drop approach.

Overall, it can be observed that the sizing of the installation meets the ventilation demand specified by the comfort conditions. However, ventilation deficiencies are noted in the more peripheral branches.

Results

Ashrae reference installation

The simulated annealing optimization method was initially applied to the ASHRAE reference installation4. The results of the optimized duct sizing using multi-objective criteria are presented in Table 3, which lists the duct dimensions for four different weighting schemes in the objective function: (i) equal weighting, (ii) greater emphasis on ensuring airflow to the rooms, (iii) greater emphasis on energy consumption, and (iv) greater emphasis on installation cost.

Table 3 shows that, relative to the reference installation, the equal weighting criterion results in smaller peripheral branches and larger main and intermediate branches, except for Branch 1-I. Under the second criterion, there is a general trend of reduced duct dimensions compared to the reference installation, except for peripheral branches 1-III and 7-I. The third criterion results in larger main and intermediate branches compared to the other design strategies, while the peripheral branches have dimensions similar to the reference, except for Branch 7-I, which is larger. The fourth criterion yields the smallest duct dimensions among all analyzed configurations.

Table 4 presents the design airflow rates and the values achieved through the mass and pressure balances for the four objective function weighting strategies previously defined.

Table 4 demonstrates that the sizing method using optimization techniques achieves design airflow values that are generally superior to those in Table 2. Most flow rates exceed the design target, with slight underperformance observed only under the third optimization criterion.

Table 5 presents the fan speed, the root-mean-square deviation of the airflow rates compared to the values provided by ASHRAE Fundamentals4, the energy consumption, and the estimated installation cost for the different optimization scenarios.

Table 5 demonstrates that the design criteria significantly influence key installation parameters. Regarding fan speed, the design criterion focused on minimizing installation cost results in the highest rotation speed, while the criterion aimed at reducing annual energy consumption yields the lowest rotation speed. In terms of the root-mean-square (RMS) deviation of airflow, the optimized duct configurations show lower deviations, as also highlighted in Table 4.

Noise effects were evaluated in accordance with the ASHRAE Applications16 standard. The assessment was based on an analysis of the maximum air velocity in the main duct branches, considering a design Room Criteria (RC) rating of 45. For rectangular ducts, the recommended velocity ranges from 18 m/s for ducts located in shafts or above drywall ceilings to 10 m/s for those installed in occupied spaces. For branch ducts, a reference velocity equal to 80% of the main duct velocity was adopted.

In the reference installation, the maximum air velocities in the main and secondary ducts were approximately 10.2 m/s and 10.8 m/s, respectively. In general, the optimization scenarios led to reduced duct velocities, except in the case where installation cost was prioritized. This latter configuration does not meet the recommended velocity limits for effective noise control and, therefore, is not considered suitable for practical application. An additional important factor in noise mitigation is the proper balancing of airflow rates within the duct network, which can eliminate the need for dampers in the optimized designs.

Another important observation from Table 5 is the impact of the objective function weights on system performance indicators. For instance, the third criterion results in the lowest energy consumption, while the fourth criterion achieves the lowest overall installation cost. The only exception is the second criterion, which did not yield a lower RMS deviation in comparison to the first criterion.

Comercial installation

ABNT NBR 16401 evaliation

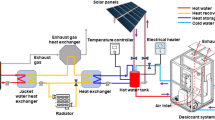

The commercial installation used for the optimization study is illustrated in Fig. 5, and its design followed the sizing guidelines of the ABNT NBR 16401 standard3. In the simulation, the weights in the objective function were set as equal, as no specific technical or financial aspect was prioritized during the optimization process.

Figure 5 shows that the installation has a 7.5 TR Fan coil type air conditioning system with a main air distribution duct and 10 branches with designed flow rate of 625 m3/h, 8 of which use a 200 mm diameter flex duct. The dimensions of the ventilation ducts in the installation are shown in Table 6.

Using these duct dimensions, a rotation of 1400 rpm from the OTAM LMD-Q 450 fan operating curve was selected to determine the flow rate and pressure balance in the installation. The mass balance results are presented in Table 7.

Table 7 shows that for a rotation of 1400 rpm, the system met the minimum demand for all branches, but with significantly higher flows for branch 2, with a root mean square deviation of the design flow of 725.44 m3/h. Under this condition, the annual cost of ventilation electricity consumption was defined as USD 337.00, and the cost of the Fancoil and duct construction was USD 2,115.00. Figure 6 presents the pressure distribution considering the mass and pressure balances in the ventilation ducts.

Figure 6 shows an abrupt pressure loss in duct 1-I due to the reduced dimensions of the ducts and piping accessories at the Fancoil system outlet. Sections II to V in duct 1 do not observe significant head losses. Due to similar dimensions, ducts 3 to 10 exhibit similar length losses, which is not observed in duct 2 due to its distinct configuration.

Simulated annealing method evaliation

The results for the simulated annealing method of the optimized duct dimensions are shown in Tables 8 and 9 presents the flow values achieved by the method.

Table 8 shows a relative increase in dimensions from Table 1 in section III and a reduction in sections III and IV of duct 1. For the other ducts, an increase in dimensions compared to Table 6 is observed, except in duct 2, which saw a reduction in dimensions.

The flow rates in the ducts using the simulated annealing method are presented in Table 9. As shown, the flow rates are close to the design target of 625 m3/h in the branches, with a root mean square deviation of only 1.05 m3/h. For the optimized fan speed of 1180.08 rpm, the ventilation energy consumption was reduced by 68.0%, reaching USD 200.00. Meanwhile, the installation cost amounted to USD 2,120.00, reflecting a modest increase of 0.50%.

The pressure distribution in the ducts for the simulated annealing method is depicted in Fig. 7. Compared to Figs. 6 and 7 shows an overall reduction in duct pressure, likely attributed to the decrease in fan power achieved through optimization. Additionally, differences in the slopes of the pressure difference curves over distance in Sections II to V suggest that the pressure-based sizing criterion may not necessarily represent an optimal condition.

The initial design, based on ABNT NBR 164013, specified the use of flexible ducts with discrete commercial diameters ranging from 86 mm (3″) to 610 mm (24″). Consequently, the optimization was performed using these discrete duct sizes within the simulated annealing framework.

Table 10 presents the results of the optimized duct dimensions, revealing that a reduction in branching occurs only in the extreme ducts. Additionally, the main branch undergoes a size adjustment, as indicated in Table 9, to accommodate volumetric airflow across different sections. The mass balance for the installation with these discrete duct dimensions is detailed in Table 11.

Table 11 demonstrates that the flow rates remain close to the design target of 625 m3/h in the branches, with a root mean square deviation of just 0.59 m3/h. For the optimized fan speed of 1,266.73 rpm, energy consumption was reduced by 36.3%, reaching USD 250.00. Meanwhile, the installation cost increased slightly to USD 2120.00, reflecting a modest rise of 0.55%. Comparatively, Tsal and Behls17 reported an energy consumption reduction of up to 62.1% using the T method; however, their study did not address whether the air demand requirements of the installation were met.

Using the same noise criteria and referencing the ASHRAE Aplications16 installation, the non-optimized configuration exhibited maximum air velocities of approximately 13 m/s in the main ducts and 7.9 m/s in the branch ducts. In contrast, under optimized conditions, these velocities were reduced to 10.4 m/s and 6.1 m/s, respectively, resulting in improved acoustic performance of the ventilation system. An analysis of the solutions obtained through the simulated annealing method reveals that this approach provides a more suitable solution, as it effectively meets the design airflow requirements, thereby ensuring better comfort in air-conditioned environments. Another key observation from the optimization analysis is that the duct dimensions remain relatively consistent with the initial design, indicating a well-conceived original installation.

Nevertheless, the precise selection of fan speed is a critical variable in air distribution system design, as highlighted in Figs. 6 and 7. Fan speed directly influences pressure distribution within the ducts, which in turn affects airflow rates.

Conclusions

Although the installation of air conditioning systems is often perceived as a straightforward task, the implementation of artificial climate control involves several complex challenges that require thorough technical and economic analysis. By integrating fundamental principles of fluid mechanics with financial evaluation tools, it is possible to design cost-effective air distribution systems that meet both performance and budgetary requirements.

The growing importance of well-designed climate control systems is evident, as indoor air quality and thermal comfort significantly influence productivity and occupant well-being. However, the financial burden associated with installation and operation often leads organizations to adopt suboptimal solutions, which can compromise long-term air quality and health.

Computational modeling for mass and pressure balances plays a critical role in accurately assessing system performance and enables the adjustment of airflow distribution to maintain optimal comfort conditions. The results revealed that some duct branches operate below the intended flow rates, highlighting the importance of precise calibration in system design.

Optimization techniques have shown significant potential to enhance system performance, particularly by enabling fan speed adjustments that eliminate the need for dampers. The analysis of objective function weights demonstrated strong sensitivity to user-defined priorities, allowing for targeted reductions in both energy consumption and installation costs. Among the methods evaluated, simulated annealing stood out for achieving minimal deviations from design airflow while effectively reducing energy use—performing comparably to established methods such as the T-method.

In terms of noise analysis in the installation, the optimization reduced noise levels overall. However, in the design condition that prioritizes installation costs, this reduction was not as effective. Therefore, it is recommended to conduct a careful noise assessment for this design condition to ensure that noise levels remain within acceptable limits.

These findings reinforce the relevance of applying advanced optimization algorithms to improve the energy efficiency, economic feasibility, and overall effectiveness of mechanical ventilation systems in commercial air conditioning applications.

Data availability

All data generated or analysed during this study are included in this published article (and its Supplementary Information files).

Abbreviations

- \(\gamma\) :

-

Specific weight, N/m3

- \(d\) :

-

Hydraulic diameter, m

- f :

-

Friction factor

- F :

-

Objective function cost parameters

- F target :

-

Objective function target values

- g :

-

Gravity, m/s2

- h e :

-

Piezometric height fan power, m

- h p :

-

Head loss, m

- K :

-

Localized head losses

- P :

-

Pressure, Pa

- Q :

-

Flow rate m3/s

- \(\dot{m}\) :

-

Mass flow rate kg/s

- V :

-

Velocity vector, m/s

- z:

-

Physical height, m

- w:

-

Weights of the objective functions

References

Kreider, J. F. Handbook of Heating, Ventilation, and Air Conditioning (CRC Press, 2001). https://doi.org/10.1201/9781420036466.

Jorens, S., Verhaert, I. & Sörensen, K. Design optimization of air distribution systems in non-residential buildings. Energy Build. 175, 48–56. https://doi.org/10.1016/j.enbuild.2018.07.018 (2018).

ABNT, ABNT NBR 16401. Air conditioning installations—Central and unitary systems Part 1: Facility projects, (2008).

ASHRAE Handbook Fundamentals. Atlanta, GA: ASHRAE American Society of Heating Refrigerating & Engineers, A. ASHRAE, (2021).

Besan,t R. W. & Asiedu, Y. Sizing and balancing Air duct systems’, ASHRAE J. 24–36 (2000).

Chen, X. & Yang, H. Sensitivity analysis and optimization of a typical passively designed residential building with hybrid ventilation in hot and humid climates. Energy Procedia 142, 1781–1786. https://doi.org/10.1016/j.egypro.2017.12.563 (2017).

Ye, X. et al. Study of multi-objective optimization of overall ventilation performance for an impinging jet ventilation system using Taguchi-based grey relational analysis. Build. Environ. 188, 107431. https://doi.org/10.1016/j.buildenv.2020.107431 (2021).

Gupta, D. & Khare, V. R. Natural ventilation design: Predicted and measured performance of a hostel building in composite climate of India. Energy Built. Environ. 2(1), 82–93. https://doi.org/10.1016/j.enbenv.2020.06.003 (2021).

Kabbara, Z., Jorens, S., Seuntjens, O. & Verhaert, I. Simulation-based optimization method for retrofitting HVAC ductwork design. Energy Build. 307, 113991. https://doi.org/10.1016/j.enbuild.2024.113991 (2024).

Tang, X., Zhang, J. & Hou, B. An optimization design method for ductwork of air distribution systems in open spaces. Build. Environ. 271, 112596. https://doi.org/10.1016/j.buildenv.2025.112596 (2025).

Cengel, Y. A. & Cimbala, J. M. Fluid Mechanics—Fundamentals and Applications, 3rd ed. (2015).

Viana, A. N. C. et al. Energy Efficiency: Fundamentals and Applications, 1st (Elektro, 2012).

Aarts, E. H. L., Korst, J. H. M. & van Laarhoven, P. J. M. Simulated annealing. In Local Search in Combinatorial Optimization 91–120 (Princeton University Press, 2018). https://doi.org/10.2307/j.ctv346t9c.9.

Rao, S. S. Engineering Optimization Theory and Practice (Wiley, 1996). https://doi.org/10.1002/9781119454816.

Tao, Y., Yan, H., Gao, H., Sun, Y. & Li, G. Application of SVR optimized by modified simulated annealing (MSA-SVR) air conditioning load prediction model. J. Ind. Inf. Integr. 15, 247–251. https://doi.org/10.1016/j.jii.2018.04.003 (2019).

ASHRAE HANDBOOK Heating, Ventilating, and Air-Conditioning APPLICATIONS. Atlanta, GA: ASHRAE American Society of Heating Refrigerating & Engineers, A. ASHRAE, (2019).

Tsal, R. J. & Bebls, H. F. Using the T-method for duct system design. ASHRAE J. 30–45 (1990).

Acknowledgements

This article has been produced with the financial support of the European Union under the REFRESH – Research Excellence for Region Sustainability and High-tech Industries project number CZ.10.03.01/00/22_003/0000048 via the Operational Programme Just Transition. Additionally, the authors would like to express their gratitude to FAPEMIG and CAPES for their support, and to Ar Oeste Engenharia & Clima for providing the data used in this study. The first author acknowledges the whole support of Prince Mohammad Bin Fahd University (PMU).

Author information

Authors and Affiliations

Contributions

Enio Pedone Bandarra Filho: Conceptualization, Methodology, Formal analysis, Resources, Writing—Review & Editing, Visualization, Project administration. Gleyzer Martins: Conceptualization, Methodology, Software, Validation, Formal analysis, Data Curation, Writing—Original Draft, Writing—Review & Editing. Muhammad Bilal Riaz: Formal analysis, Resources, Writing—Review & Editing. Sardar Muhammad Bilal: Methodology, Validation, Writing—Review & Editing, Visualization. Oscar Saul Hernandez Mendoza: Conceptualization, Methodology, Formal analysis, Writing—Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bandarra Filho, E.P., Martins, G., Riaz, M.B. et al. Optimization of air conditioning mechanical ventilation using simulated annealing for enhanced energy efficiency and cost reduction. Sci Rep 15, 23429 (2025). https://doi.org/10.1038/s41598-025-07640-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-07640-z