Abstract

Electrocatalytic materials with dual functions of oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) have received increasing attention in the field of zinc-air batteries (ZABs) research. In this study, bifunctional CoNC@NCXS catalysts were prepared by anchoring Co and N co-doped CoNC on N-doped carbon xerogel sphere (NCXS) based on the spatially confined ___domain effect and in-situ doping technique. CoNC@NCXS exhibited excellent ORR/OER activity in alkaline electrolytes with the ORR onset potential of 0.99 V, the half-wave potential (E1/2) of 0.78 V at 10 mA cm−2 and the OER overpotential of 360 mV at 10 mA cm−2. These excellent catalytic activities were derived from constructing composite active structures and enhancing electrocatalytic efficiency. The ZAB assembled with CoNC@NCXS catalyst had a discharge specific capacity of 710 mAh g−1 at a current density of 10 mA cm−2, which was superior to that of the Pt/C&RuO2 catalyst-assembled battery (667 mAh g−1). After running for 150 h, the charge and discharge efficiency of the CoNC@NCXS battery decreased by only 12.8%, which confirmed the excellent stability of the CoNC@NCXS catalyst. The free energy diagrams showed that, CoNC@NCXS has lower energy barriers and higher potential than CoNC in key reaction steps. This study provides a new perspective for the structural design of highly active composite catalysts in energy storage and conversion.

Similar content being viewed by others

Introduction

The development of sustainable energy conversion and storage systems plays a crucial role in mitigating the fossil fuel crisis and environmental pollution. Zinc-air batteries (ZABs), as one of the most competitive candidates in the field of large-scale energy storage, have attracted widespread attention due to their environmentally friendliness, low cost and high energy density characteristics1,2,3. Nevertheless, the slow kinetics of oxygen reduction reaction/oxygen evolution reaction (ORR/OER) at the air electrode of ZABs results in poor energy efficiency and cycling properties of ZABs4,5. Although precious metals and their alloys such as platinum (Pt), ruthenium dioxide (RuO2), and iridium dioxide (IrO2) have shown outstanding ORR/OER activities in the ZABs, their high cost, unsatisfactory durability and poor methanol-toxicity resistance limit their application. The low-cost, highly conductive, and structurally tunable non-precious metal carbon-based electrocatalysts have received widespread attention6,7,8,9. To enhance the electrocatalytic activity of non-precious metal carbon-based catalysts, the optimization of their morphological features and electronic structures is the key to research. Recently, metal-organic frameworks (MOFs), including zeolitic imidazolate frameworks (ZIF-8, ZIF-67, etc.), have become a research hotspot due to their simple controllable preparation and required structure & function10,11,12,13. However, the ZIF-67 derived CoNC catalysts reported currently often exhibit a heterogeneous morphology and collapsed pores after high-temperature pyrolysis. This leads to a relatively low utilization efficiency of active sites and restricts mass transfer14,15,16,17. Therefore, rationally designing the pore structure and distribution of carbon materials through pore engineering is of crucial significance for reducing the hidden rate and enhancing the contact area with the electrolyte of active sites, thereby improving the catalytic performance of CoNC electrocatalytic materials18,19,20,21,22.

Metal-organic gels (MOGs) are self-assembled super-molecular coordination polymers. They directly assembles metal ions and suitable organic ligands through intermolecular forces such as metal-coordination bonds, hydrogen bonds, π-π stacking, van der Waals forces, and ionic interactions to form an interlaced three-dimensional network structure23,24,25,26. Due to the high surface area, stable spatial structure, low density, its own open metal site, good compatibility, simple and scalable preparation method, MOGs have shown excellent performance as the precursor of electrocatalytic materials in previous studies27,28.

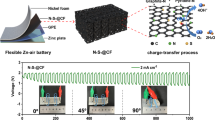

In this study, Co and N ions were efficiently embedded into the structure of MOGs by incorporating MOFs (ZIF-67) into sol-gel precursors using spatial limiting effect and in-situ doping techniques. The electrocatalysts with ZIF-67 derived CoNC anchored on N-doped carbon xerogel sphere (CoNC@NCXS) were synthesized by the solvothermal-pyrolysis method. The highly dispersed metal-organic framework was constructed by utilizing the ___domain-limiting effect of the three-dimensional organized spherical lattice, and the nitrogen atoms were anchored in situ using metal-nitrogen chelation to achieve the dual effect of nitrogen and cobalt atoms preparation & doping. This hybrid material has enhanced porosity and electrocatalytic activity while effectively preventing ZIF-67 collapse and aggregation.

Experimental section

Samples preparation

Chemicals and reagents

Cobalt nitrate hexahydrate (Co(NO3)2·6H2O, A.R. 99%), 2-methylimidazole (2-MIM, C4H6N2, A.R. 98%), N, N-dimethylformamide (C3H7NO, A.R. 99.5%), resorcinol (C6H6O2, A.R. 99.5%), formaldehyde solution (CH2O, A.R. contains 10–15% methanol as stabilizer), ethanol (CH3CH2OH, A.R. 75%), ammonia solution (H5NO, A.R. 25%), potassium hydroxide (KOH, A.R. 85%) was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., China. Nafion solution (5 wt%) was purchased from DuPont Co., Ltd., USA. Pt/C catalyst (20 wt%) was purchased from Johnson Matthey Co., Ltd., UK. All reagents were used as received without further purification.

The synthesis of ZIF-67

Firstly, 2-MIM (3.284 g, 40.0 mmol) was dissolved in 50 mL of DMF and dispersed by ultrasonication for 10 min, and then Co(NO3)2·6H2O (1.456 g, 5.0 mmol) solid was added into the above solution with continuous stirring for 2 h. After centrifugation with ethanol and deionized water three times each, the resulting purple solid ZIF-67 sample was dried in an vacuum drying oven.

The synthesis of CoNC@NCXS

Ammonia (0.1 mL), ethanol (8 mL), deionized water (20 mL), and resorcinol (0.2 g) were mixed and stirred continuously for 30 min to form a gel solution. ZIF-67 (0.2 g) and formaldehyde solution (0.28 mL) were added sequentially and stirred at room temperature for 24 h. The mixture was then allowed to stand for 24 h. The mixture was transferred to a teflon-lined airtight container and heated to 100 °C with a heating rate of 5 ℃ min – 1 for 24 h to allow the intermediates to cross-link and react in the droplets. After the reaction was cooled to room temperature, the products were collected by centrifugation, washed three times with deionized water and ethanol, and dried to obtain ZIF-67@MOG. The samples were heat-treated with a tube furnace at a ramping rate of 5 ℃ min −1 for 2 h in an argon atmosphere and then cooled to room temperature to obtain the CoNC@NCXS catalysts. The samples obtained at different heat-treating temperatures were labeled as CoNC@NCXS-700, CoNC@NCXS-800 and CoNC@NCXS-900, respectively. N-doped carbon xerogel sphere (NCXS) was prepared as described above at 800 °C without ZIF-67 adding into the precursor. ZIF-67 derived Co and N doped carbon (CoNC) was prepared by heat-treating ZIF-67 in a tube furnace at 800 °C in argon for 2 h.

Materials characterization

The catalyst surface morphology was observed by Nova Nano SEM450 instrument (FEI) and SU1510 (Hitachi) SEM. The bulk phase morphology of the samples was observed by Talos F200X (FEI) transmission electron microscope (TEM). The crystalline structure of the samples was obtained by Cu Kα radiation (λ = 0.154 nm) X-ray diffraction (XRD) in the range of 10–90 degrees. X-ray photoelectron spectroscopy (XPS) was performed on an Axis Ultra DLD (Shimadzu) to analyze the surface state composition of the samples.

Electrochemical measurements

Electrode preparations

The electrocatalyst slurry was prepared as follows: 1 mg of catalyst + 10 µL of Nafion + 90 µL of ethanol were mixed homogeneously by shaking, and the slurry was ultrasonicated for 30 min until the slurry had no obvious precipitation. 10 µL of the slurry was added onto the glassy carbon electrode (rotating disk electrode, RDE, 5 mm of diameter, 0.196 cm2 of area; rotating ring disk electrode, RRDE, 4 mm of diameter, 0.126 cm2 of area; L-type glassy carbon electrode, L-GCE, 5 mm of diameter, 0.196 cm2 of area) dropwise and dried at room temperature. The loading of the catalyst was 0.51 mg cm−2 on RDE and L-GCE, and 0.79 mg cm−2 on RRDE. Commercial Pt/C (20 wt%) was used as a control standard for ORR, while commercial RuO2 was used as a control standard for OER.

Testing conditions

Electrochemical tests were performed with an electrochemical workstation (CS2350M, Corrtest Instruments Co.) in a conventional three-electrode system. The RRDE covered with a thin film catalytic layer was used as the working electrode for the electrochemical tests, while an L-GCE was used for the OER tests. The Hg/HgO electrode and the platinum wire electrode were used as reference and counter electrodes, respectively. All measured potential values were converted to a reversible hydrogen electrode (RHE) by the following equation: Evs. RHE = Evs. Hg/HgO + 0.098 + 0.0591 pH. The test electrolytes were 0.1 M KOH solution for ORR tests and 1 M KOH solution for OER tests.

ORR tests

Cyclic voltammetry (CV) was measured in 0.1 M KOH solution saturated with N2 or O2, respectively, at a scan rate of 5 mV s−1. Linear scanning voltammetry (LSV) was measured under the same test conditions as CV at a scan rate of 5 mV s−1 using different rotational speeds ranging from 400 to 2025 rpm. RDE/RRDE was measured at a scan rate of 5 mV s−1 with a constant voltage of 1.35 V (vs. RHE) on the ring of RRDE.

The accelerated aging life test was performed using CV1000 cycles at a scan rate of 50 mV s−1 in N2-saturated 0.1 M KOH solution, and the performance was evaluated by the LSV in 0.1 M KOH solution saturated with oxygen before and after the CV1000 cycles test, respectively.

The electron transfer number (n) was calculated by the Koutecky-Levich (K-L) equation as follows.

where j is the current density, jl is the diffusion-limited current density, jk is the dynamic current density, ω is the rotational speed (rpm), and B can be calculated by the following equation.

where n is the transfer number, F is the Faraday constant (96,485 C mol−1), C0 (1.2 × 10−6 mol cm−3) and D0 (1.9 × 10−5cm−2s−1) are the bulk concentration and diffusion coefficients of O2 in 0.1 M KOH. υ (0.01 cm−2s−1) is the kinetic viscosity of a 0.1 M KOH solution.

The electron transfer number (n) can be calculated from the disk current (Id) and ring current (Ir) measured from RRDE by the following equation:

The peroxide percentage (H2O2%) was calculated according to the following formula:

where N is the current collection efficiency of the Pt ring, taken as 0.424.

OER test

LSV is measured at a scan rate of 5 mV s−1 in O2-saturated 1 M KOH solution using an L-GCE as the working electrode. The potential is converted to an RHE using the same equation as for the ORR test. Electrochemical impedance spectroscopy (EIS) was performed using the potential at a current density of 10 mA cm−2 as the initial potential (vs. RHE) at a test frequency ranged from 105 to 0.01 Hz.

Zinc-air batteries

The application performance test of the catalyst was carried out on the self-assembled zinc-air batteries (ZABs). The air electrodes of the ZABs consisted of a catalytic layer (CL) and a nickel foam collector with a gas diffusion layer (GDL) attached. First, an electrocatalyst slurry was formulated with the same method of preparation and proportions as before. The electrocatalyst slurry was uniformly coated onto the carbon paper of the diffusion layer to form the CL. The effective geometric area of the air electrode was 1 cm−2 and the catalyst loading was 1.0 mg cm−2. The ZABs were equipped with polished zinc sheets as the anode, the air electrode as the cathode, and the 6 M KOH as the electrolyte solution. Meanwhile, the Pt/C-RuO2 catalyst slurry was prepared by the same method to make an air electrode as the contrast electrode. All cell tests were performed at room temperature in an atmospheric environment. The open circuit potential test (OCPT) was performed on the electrochemical workstation for 400 s. The battery charge and discharge curve sweeps were measured using the electrochemical LSV technique with a sweep rate of 10 mV s−1. The battery was subjected to a prolonged, galvanostatic charge discharge (GCD) test using the LAND test system under the following conditions: 10 min charging and 10 min discharging, with a current density of 10 mA cm−2. A commercially available light-emitting diode (LED, 1.4 V) was used for battery power capability testing. Both current density and power density were normalized based on the geometric surface area of the CL. Batteries discharged at a current density of 10 mA cm−2 were used to calculate the specific capacity. The specific capacity was calculated using the following formula:

Density functional theory (DFT) calculations

In this theoretical study, the Vienna ab initio simulation package was used for spin-polarized density functional theory calculations. Projector augmented wave potentials and Perdew-Burke-Ernzerhof (PBE) functional within the generalized gradient approximation (GGA) were used for the calculation29,30,31,32. A 6 × 6 × 1 supercell monolayer graphene was established for as a support for CoNC. Then the heterogeneous structure model of CoNC@NCXS was constructed. The vacuum space along the z direction is set to be 15 Å. The cutoff energy was set to be 450 eV, and k-point sampling grid is 2 × 2 × 1. The convergence tolerances of energy and force is set 1.0 × 10−5 eV and 3.0 × 10−2eV/Å. Moreover, the DFT-D3 method is used to describe van der Waals interaction33. The Gibbs free energy change (ΔG) of the elementary step was calculated by:

Where ∆E represents the total energy difference, ΔEZPE and ΔS were the change in the zero-point energy and the entropy, respectively. U is the applied bias and in this work is 0 eV. n is the number of electrons transferred during the reaction.

Result and discussion

Material synthesis and characterizations

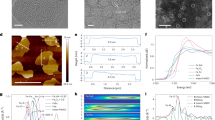

Figure 1a shows a schematic diagram of the preparation process of the CoNC@NCXS catalyst. First, ZIF-67, which was pre-synthesized by the liquid-phase method, was added into the gel reaction precursor solution, followed by the formation of ZIF-67@MOG composite precursor in the sol-gel reaction that occurred during the solution heat process. Finally, during pyrolysis, spherical CoNC@NCXS materials with surface particle distribution were formed. SEM electron micrographs of the CoNC samples derived from ZIF-67 carbonation are shown in Fig. 1b, which shows that the CoNC samples present a granular shape with a slight agglomeration in the distribution. The SEM morphology of the NCXS sample is shown in Fig. 1c, which shows that the NCXS sample has a regular spherical shape and multiple NCXS spheres are clustered together, similar to the shape of a bunch of grapes. The diameter of the NCXS spheres is about 50 μm. Comparing the SEM morphology with that of the NCXS sample, it can be seen that the CoNC@NCXS-800 sample prepared has a structure of small particles wrapped in carbon spheres (Fig. 1d), where the small particles are CoNC and the large carbon spheres are NCXS. however, the carbon spheres formed by CoNC@NCXS-800 are smaller compared to the NCXS spheres, with diameters less than 1/50 (0.5–1 μm) of the NCXS spheres. This may be due to the effect of polycondensation reaction inhibition. Specifically, during the polycondensation reaction between resorcinol and formaldehyde, the incorporation of ZIF-67 particles adsorbed on the surface of the formed microspheres, thereby inhibiting the growth of the microspheres, and thus the diameters of the microspheres became smaller. This was further confirmed by TEM characterization. As shown in Fig. 1e, the TEM image of the CoNC@NCXS-800 sample shows that the sample presents a relatively regular spherical shape, with the diameter of the sphere of about 500 nm. A large number of irregular dark-colored particles can be clearly seen in its spherical region, which is likely to be the metallic Co elements in the CoNC attached to the NCXS spheres. From the locally magnified high-resolution TEM image (Fig. 1f), it can be seen that the corresponding cell spacing of 0.341 nm in the sample is the C (002) crystal plane, and the cell spacing of 0.237 nm is the Co (111) crystal plane. The elemental mapping diagram further verifies the presence and distribution of Co and N (Fig. 1g). It can be seen that all three elements C, N, and Co show a relatively uniform distribution in CoNC@NCXS-800. At the same time, the sample in the picture showed Co nanocluster distribution locally, which further confirms that CoNC particles are in situ attached to NCXS spheres.

XRD patterns of the samples are shown in Fig. 2. CoNC@NCXS-700, CoNC@NCXS-800 and CoNC@NCXS-900 all show distinct diffraction peaks at angles 44°, 51°and 76°, which are attributed to the (111), (200) and (220) crystal planes of metallic Co (Co PDF# 15–0806), respectively. In addition, it can be seen from Fig. 2 that CoNC@NCXS-800 and CoNC@NCXS-900 have obvious diffraction peaks of C(002) centered at 26.3°, while the diffraction peak of CoNC@NCXS-700 is not obvious. This may be due to the obvious formation of C(002) crystal faces as the degree of graphitization of the sample increases with the increase of carbonization temperature. The surface chemical states of the CoNC@NCXS-800 sample were examined by XPS. The measured spectra of CoNC@NCXS-800 showed C1s, N1s, O1s and Co2p signals as shown in Fig. 3a. The high-resolution spectra of different elements (C1s, N1s, and Co2p) in CoNC@NCXS-800 are given in Fig. 3b-d. Split-peak fitting of the high-resolution C1s spectra of CoNC@NCXS-800 yielded three fitted peaks, C-N (285.4 eV), C = C (284.8 eV) and C = O (287.6 eV) (Fig. 3b). Split-peak fitting of the N1s peaks of the catalyst yields four fitted peaks (Fig. 3b) corresponding to pyridinic N+-O- (403.16 eV), graphitic N (401.03 eV), pyrrolic N (399.35 eV) and pyridinic N (398.43 eV), respectively. The relative percentage of these N-moieties is described in Table S1. Among the four fitted chemical states, the nitrogen content of graphitic N and pyridinic N which are usually considered to be electrocatalytically active accounts for 64.85% of the total nitrogen content. Graphitic N and pyridinic N, serving as active constituents, are capable of augmenting the electron transfer capacity and optimizing the local electronic structure. This, in turn, leads to the enhancement of conductivity and surface-wetting characteristics, and remarkably facilitates the improvement of reversible oxygen electrocatalytic activity19,20. Meanwhile, the results of Co2p split-peak fitting in CoNC@NCXS-800 are shown in Fig. 3d for Co 2p1/2 at 796.6 eV, Co 2p3/2 at 780.8 eV and their satellite peaks. The Co 2p3/2can be further deconvoluted into Co-Nx, which has been reported to constitute the most active site in relation to ORR20,21. In virtue of the existence of N-doped carbon encapsulated Co nanoparticles and a substantial quantity of active sites such as graphitic-N, pyridinic-N, and Co − Nx, it is highly probable that the CoNC@NCXS-800 will exhibit an excellent ORR performance. The atomic content of each element relative to C1s is shown in Table S1.

Oxygen electrocatalytic performance

The ORR performance of CoNC@NCXS-800 and commercial Pt/C (20 wt%) was first evaluated using a three-electrode system in 0.1 M KOH solution. The CV curves of CoNC@NCXS at different temperatures showed obvious oxygen reduction peaks in O2-saturated electrolytes and no peaks in N2-saturated electrolytes (Fig. 4a and Fig. S1). The LSV curve of CoNC@NCXS-800 electrocatalyst at a rotational speed of 1600 rpm is shown in Fig. 4b. For comparison, CoNC@NCXS-700, CoNC@NCXS-900, CoNC, NCXS and commercial Pt/C (20 wt%) were measured under the same test conditions. CoNC@NCXS-800 showed excellent ORR performance with an onset potential of 0.99 V and a half potential of 0.78 V. The onset potential and half-wave potential of CoNC@NCXS-800 are almost comparable to that of commercial Pt/C (0.99 V, 0.80 V), indicating that the ORR performance of CoNC@NCXS-800 is very competitive (Table S2). Both CoNC@NCXS-700 and CoNC@NCXS-900 showed lower activities than CoNC@NCXS-800 (Fig. 4b). The carbonization temperature has a significant effect on the performance of CoNC@NCXS catalysts. This may be due to the fact that the graphitization degree of catalyst is not high, and the structure of active site is not completely formed and fully exposed at low carbonization temperatures, resulting in low conductivity and few active sites, thus affecting the electrocatalytic performance. With the increase of carbonization temperature, the crystallinity and porosity of the catalyst will increase. This helps to improve electron transport efficiency and expose sufficient active sites, thus enhancing electrocatalytic activity. However, excessive carbonization temperature may severely damage the original mesoporous structure, affecting the mass transfer performance of the catalyst and accelerating the loss of active sites, which in turn affects the catalytic performance34. The oxygen reduction kinetics of the catalysts were analyzed using the Tafel slope. As can be seen from Fig. 4c, the Tafel slope of CoNC@NCXS-800 was calculated as 124 mV dec−1, which is significantly lower than that of CoNC@NCXS-700 (194 mV dec−1), CoNC@NCXS-900 (137 mV dec−1), CoNC (130 mV dec−1) and NCXS (224 mV dec−1), and was very close to Pt/C (118 mV dec−1). It indicates that CoNC@NCXS-800 has excellent ORR kinetic performance. To further investigate the ORR mechanism of CoNC@NCXS-800, according to the data in Fig. 4d, the electron transfer number n calculated by the K-L equation was 3.9, which was close to 4 electrons. The results show that most of the transfer pathway of the ORR is a 4-electron reaction to generate water, and a very small amount of it is generated by a 2-electron process to produce H2O2. Meanwhile, based on the results of the RRDE test (Fig. 4e), the calculations further indicated that ORR occurs mainly through the four-electron transfer pathway number (n ≈ 4), and the hydrogen peroxide yield is lower than 15%. In addition, the electrochemical stability of the CoNC@NCXS-800 catalyst was analyzed using accelerated aging test. After 1000 CV cycles test, the activity decay of the CoNC@NCXS-800 catalyst was very small (≈ 21 mV) (Fig. 4f), which was significantly lower than that of Pt/C (≈ 45 mV) (Fig. S2). In addition, compared with literature works, the ORR performance of CoNC@NCXS-800 is competitive (Table S3).

(a) CV curves of CoNC@NCXS-800 in 0.1 M KOH saturated with N2 and O2; (b) ORR polarization curves of the electrocatalyst in 0.1 M KOH solution; (c) Corresponding Tafel effect plots; (d) LSV curves of CoNC@NCXS-800 at different rotational speeds; (e) RRDE measurements corresponding to disc and ring currents (inset) and peroxide yield (H2O2%) and electron transfer number (n) of CoNC@NCXS-800 calculated from RRDE measurements; (f) ORR polarization curves of CoNC@NCXS-800 before and after 1000 CV cycles test; (g) OER polarization curves; (h) Corresponding Tafel effect plots; (i) Bifunctional catalytic activity of the electrocatalysts for ORR and OER.

To investigate the bifunctional catalytic performance of CoNC@NCXS-800, an OER test was performed in a 1 M KOH electrolyte. LSV showed that CoNC@NCXS-800 had an overpotential of 360 mV (Fig. 4g), which is superior to those of CoNC@NCXS-700 (370 mV), CoNC@NCXS-900 (430 mV), CoNC (460 mV), and NCXS (510 mV), and very close to commercial RuO2 (330 mV). Meanwhile, the OER current density of CoNC@NCXS-800 at high potentials even exceeded that of commercial RuO2 catalysts, indicating that CoNC@NCXS-800 catalyst has excellent OER electrocatalytic performance. In addition, the Tafel slope of CoNC@NCXS-800 (140 mV dec−1) was the smallest among all CoNC@NCXS catalysts with different carbonization temperatures (Fig. 4h), indicating its fast OER kinetic performance. To further understand the OER performance of electrocatalysts, the electrochemical impedance spectra (EIS) of the samples were measured. It can be seen from Fig. S3 that the EIS of CoNC@NCXS composite catalysts is significantly lower than that of non-composite catalysts (NCXS, CoNC). This indicates that the synergistic effect among various materials of the composite catalysts is good and the conductive effect is significantly improved. In addition, with the heat treatment temperature increasing, the material resistivity decreases, being closely related to the degree of graphitization of the material. The voltage gap ΔE between the OER potential at 10 mA cm−2 and the ORR half-wave potential (ΔE = EJ=10 - E1/2) can be used to evaluate the bifunctional catalytic performance of the catalyst. It can be observed from Fig. 4i that the ΔE (with a value of 0.82 V) for CoNC@NCXS-800 is significantly less than that for CoNC@NCXS-700 and CoNC@NCXS-900, and is very close to the ΔE (with a value of 0.72 V) for Pt/C + RuO2, and this indicates that CoNC@NCXS-800 catalyst has promising bifunctional catalytic performance. It is mainly attributed to the excellent electrical conductivity of the composite material which can ensure the effective electron transfer between the electrode and the electrolyte, thus improving the efficiency of the electrocatalytic reaction. In addition, the interaction between the Co metal and non-metallic N and C components in CoNC@NCXS-800 can regulate the electronic structure and surface properties of the catalyst, thus exerting a synergistic catalytic effect and improving the electrocatalytic performance of the material. High-temperature carbonization significantly affects the microenvironment and morphology of the catalyst, including the pore structure, dispersion effect and surface defects, which are also crucial for its electrocatalytic performance. Appropriate pore structure helps to improve the mass transfer efficiency of reactants and products, while surface defects and dispersion effect may contribute to the full exposure of active sites and further help to accelerate the electrochemical reaction35. The rigid structure of ZIF-67 prevents the metal from aggregating during high-temperature pyrolysis, which makes it easy to generate single-atom sites36. Single-atom catalysts (SACs), due to the atomic-level dispersion of the metal sites, make the active centers easily accessible during electrocatalysis, thus reducing the number of metal species required and the corresponding cost, while maintaining high catalytic performance. CoNC@NCXS-800 may also embody a similar design effect, which allows cobalt atoms to be highly dispersed in a nitrogen-doped carbon matrix, improving its electrocatalytic efficiency37,38,39.

Zinc-air batteries performance

To deeply investigate the bifunctional catalytic activity of CoNC@NCXS-800 in practical application scenarios, CoNC@NCXS-800 was assembled into the catalytic layer of the air electrode of rechargeable ZABs40,41,42,43. The ZAB containing a commercial Pt/C + RuO2 air electrode was also constructed for performance comparison. CoNC@NCXS-800 reveals 1.44 V in the OCPT, which is almost comparable to the open-circuit voltage of 1.43 V of Pt/C + RuO2 (Fig. 5a). The battery with the Pt/C + RuO2 catalyst achieved a maximum peak power density of 87 mW cm−2, which is slightly higher than that performance of CoNC@NCXS-800 (67 mW cm−2) (Fig. 5b,c). In addition, when discharged at a current density of 10 mA cm−2, the discharge-specific capacity of CoNC@NCXS-800 is 710 mAh g−1 (Fig. 5d), which exceeds that of the battery using the Pt/C + RuO2 catalyst (667 mAh g−1). To evaluate the durability of the air electrodes, constant-current charge/discharge tests were performed at a current density of 10 mA cm−2. According to the GCD data in Fig. 5e, the CoNC@NCXS-800 showed minimal change in voltage after 150 h of operation (12.8% decay in charge/discharge efficiency). In contrast, the Pt/C + RuO2 system shows a significant performance degradation after 30 h, which reconfirms the excellent stability of CoNC@NCXS-800 catalyst. As further evidence of its potential application, (Fig. 5f) a ZAB assembled from CoNC@NCXS-800 was able to easily drive a blue LED light (1.4 V), indicating that the CoNC@NCXS-800 material has great application prospects for applications in energy storage and conversion.

(a) OCPT curves of CoNC@NCXS-800 and Pt/C + RuO2; (b) Discharge and Charging curves; (c) Discharge polarization curves and corresponding power density plots; (d) Specific capacity at 10 mA cm−2 and (e) GCD of ZABs with CoNC@NCXS-800 and Pt/C + RuO2; (f) Photo of the LED lamp powered by the ZAB assembled by CoNC@NCXS-800.

DFT calculations

The origin of the excellent activity and kinetics of CoNC@NCXS in the ORR process was investigated by DFT calculations. As shown in Fig. 6a, the active center of CoNC@NCXS is a typical Co-N4 model (one Co atom with four adjacent N atoms in the same plane). A model diagram of the ORR reaction pathway in the CoNC@NCXS configuration in 0.1 M KOH electrolyte, and the related mechanism of the Co single-atom catalyst for promoting the ORR reaction proceeds via O2(g), *OOH, *O, *OH, and H2O(l) was proposed as illustrated in Fig. 6b44. As can be seen from Fig. 6c, both CoNC@NCXS and CoNC catalyzed ORR reactions are thermodynamically downhill at U = 0 V, all the basic steps that occur at the active sites are exothermic and can proceed spontaneously45. The fourth step (desorption of *OH) shows the smallest value of free energy change |△G| among the four steps, which means that it is the ORR rate-determining step (RDS)46. The electric potential predicted theoretically for CoNC@NCXS and CoNC active sites according to the free energy diagram of ORR are 0.942 eV and 0.904 eV. At U = 0 V (Fig. 6c), CoNC@NCXS exhibited a higher fourth step potential (0.942 eV) and lower RDS energy barrier than CoNC (0.904 eV), and at U = 1.23 V (Fig. 6d), the RDS energy barrier for CoNC@NCXS (0.288 eV) was also smaller than that for CoNC (0.326 eV), which is consistent with the results of electrochemical tests. Therefore, the obtained DFT results once again confirms that CoNC@NCXS is more active towards ORR compared to CoNC.

Conclusion

In this study, a CoNC@NCXS electrocatalyst with ORR/OER catalytic activities was designed and constructed by in-situ anchoring ZIF-67-derived CoNC on N-doped carbon xerogel sphere. Investigations have revealed that CoNC@NCXS-800 catalyst obtained after carbonization at 800 °C showed excellent ORR and OER bifunctional electrocatalytic activities in alkaline system. The current density of OER catalyzed by CoNC@NCXS-800 at elevated potentials surpassed even that of the commercial RuO₂ catalyst. The activity decay of the CoNC@NCXS-800 catalyst during the electrochemical stability test was only 21 mV, which is significantly lower than that of the Pt/C catalyst. The decay rate in charge/discharge efficiency of ZAB assembled with CoNC@NCXS-800 catalyst is only 12.8% after 150 h GCD test. The CoNC@NCXS-800 catalyst shows significantly better stability than commercial catalysts in both electrochemical tests and ZABs application tests. According to DFT calculations, as a catalyst for ORR, composite material CoNC@NCXS has lower energy barriers and higher potential than CoNC in key reaction steps, thus exhibiting better catalytic activity. In conclusion, CoNC@NCXS electrocatalysts represent a promising non-precious metal alternative with great potential to replace commercial Pt/C and RuO₂ in the field of energy conversion. This study also provides new perspectives for the design and development of novel bifunctional catalysts with composite Co, N and other multi-elements.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Song, Y., Li, W., Zhang, K., Han, C. & Pan, A. Progress on bifunctional carbon-based electrocatalysts for rechargeable zinc-air batteries based on voltage difference performance. Adv. Energy Mater. 14, 202303352 (2024).

Nazir, G. et al. A review of rechargeable zinc–air batteries: Recent progress and future perspectives. Nano-Micro Lett. 16, 138 (2024).

Wang, Q., Kaushik, S., Xiao, X. & Xu, Q. Sustainable zinc-air battery chemistry: Advances, challenges and prospects. Chem. Soc. Rev. 52, 6139–6190 (2023).

Li, Z., Li, B. & Yu, C. Atomic aerogel materials (or single-atom aerogels): An interesting new paradigm in materials Science and Catalysis Science. Adv. Mater. 35, 2211221 (2023).

Li, Z. et al. Engineering the morphology and electronic structure of atomic cobalt-nitrogen-carbon catalyst with highly accessible active sites for enhanced oxygen reduction. J. Energy Chem. 73, 469–477 (2022).

Ahmed, S., Ali, A., Asif, M., Shim, J. & Park, G. Exploring innovative trends and advancements in rechargeable zinc-air batteries. Inorg. Chem. Commun. 170, 113288 (2024).

Li, B. et al. A strategy for understanding the enhanced anaerobic co-digestion via dual-heteroatom doped bio-based carbon and its functional groups. Chem. Eng. J. 425, 130473 (2021).

Xu, H. et al. Carbon-based bifunctional electrocatalysts for oxygen reduction and oxygen evolution reactions: Optimization strategies and mechanistic analysis. J. Energy Chem. 71, 234–265 (2022).

Shao, W. et al. Carbon-based electrodes for advanced zinc-air batteries: Oxygen-catalytic site regulation and nanostructure design. Electrochem. Energy Rev. 6, 532–572 (2023).

Wang, H. F., Chen, L., Pang, H., Kaskel, S. & Xu, Q. MOF-derived electrocatalysts for oxygen reduction, oxygen evolution and hydrogen evolution reactions. Chem. Soc. Rev. 49, 1414–1448 (2020).

Zhou, Z. et al. ZIF-8‐Derived dual metal (Fe, Ni)‐nitrogen‐doped porous carbon for superior ORR performance in universal acid‐base properties solutions. Isr. J. Chem. 63, 1–9 (2023).

Shen, L. L. et al. Recent progress in ZIF-derived carbons for enhanced oxygen reduction reaction electrocatalysis. ChemCatChem 16, 1 (2024).

Tong, H. et al. Energetic metal-organic frameworks derived highly nitrogen-doped porous carbon for superior potassium storage. Small 16, 2002771 (2020).

Duan, X. et al. MOF-derived Co-MOF,O-doped carbon as trifunctional electrocatalysts to enable highly efficient Zn–air batteries and water-splitting. J. Energy Chem. 56, 290–298 (2021).

Ahmed, S., Shim, J., Sun, H. & Park, G. Transition metals (Co or Ni) encapsulated in carbon nanotubes derived from zeolite imidazolate frameworks (ZIFs) as bifunctional catalysts for the oxygen reduction and evolution reactions. Phys. Status Solidi (A). 12, 217 (2020).

Ahmed, S., Shim, J. & Park, G. Co on porous carbon network derived from ZIF-8 for oxygen reduction and evolution reaction in alkaline solution. Mater. Lett. 334, 133727 (2023).

Du, L., Xing, L., Zhang, G. & Sun, S. Metal-organic framework derived carbon materials for electrocatalytic oxygen reactions: Recent progress and future perspectives. Carbon 156, 77–92 (2020).

Li, Z. et al. Construction of heteroatom-doped and three-dimensional graphene materials for the applications in supercapacitors: A review. J. Energy Storage 44, 103437 (2021).

Hu, C., Paul, R., Dai, Q. & Dai, L. Carbon-based metal-free electrocatalysts: From oxygen reduction to multifunctional electrocatalysis. Chem. Soc. Rev. 50, 11785–11843 (2021).

Irmawati, Y. et al. Cobalt nanoparticles encapsulated with N-doped Bamboo-like carbon nanofibers as bifunctional catalysts for oxygen reduction/evolution reactions in a wide pH range. ACS Appl. Nano Mater. 6, 2708–2718 (2023).

Zhao, C. X., Li, B. Q., Liu, J. N. & Zhang, Q. Intrinsic electrocatalytic activity regulation of M-N-C single-atom catalysts for the oxygen reduction reaction. Angew. Chem. Int. Ed. 60, 4448–4463 (2021).

Guo, S., Wang, J., Sun, Y., Peng, L. & Li, C. Interface engineering of Co3O4/CeO2 heterostructure in-situ embedded in Co/N-doped carbon nanofibers integrating oxygen vacancies as effective oxygen cathode catalyst for Li-O2 battery. Chem. Eng. J. 452, 139317 (2023).

Zhang, X. et al. Facile coordination driven synthesis of metal-organic gels toward efficiently electrocatalytic overall water splitting. Appl. Catal. B 299, 120641–120649 (2021).

Ke, F. et al. MOG-derived porous FeCo/C nanocomposites as a potential platform for enhanced catalytic activity and lithium-ion batteries performance. J. Colloid Interface Sci. 522, 283–290 (2018).

Cao, Z., Jiang, Z., Li, Y., Huang, C. & Li, Y. Metal-organic gel-derived multimetal oxides as effective electrocatalysts for the oxygen evolution reaction. ChemSusChem 12, 2480–2486 (2019).

Shijina, K. et al. Chitosan intercalated metal organic gel as a green precursor of Fe entrenched and Fe distributed N-doped mesoporous graphitic carbon for oxygen reduction reaction. ChemistrySelect 2, 8762–8770 (2017).

Jin, H. et al. Enhanced electrocatalytic performance of N-doped carbon xerogels obtained through dual nitrogen doping for the oxygen reduction reaction. RSC Adv. 12, 13440–13447 (2022).

Pi, L., Jin, H., Zhou, L. & Pan, H. Facile in situ fabrication of a Co-Fe bimetallic N-doped carbon xerogel as an efficient electrocatalyst for oxygen reduction reaction in acidic and alkaline media. Int. J. Electrochem. Sci. 220669 (2022).

Kresse, G. & Joubert, D. J. From ultrasoft pseudopotentials to the projector augmented wave method. Phys. Rev. 59, 1758 (1999).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. 54, 11169 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Lee, K., Murray, É. D., Kong, L., Lundqvist, B. I. & Langreth, D. C. Higher accuracy Van Der Waals density functional. Phys. Rev. B 82, 081101 (2010).

Gao, Y. et al. Subtle tuning of nanodefects actuates highly efficient electrocatalytic oxidation. Nat. Commun. 14, s41467–s41023 (2023).

Zou, J. et al. Laser-induced rapid construction of Co/N-doped honeycomb-like carbon networks as oxygen electrocatalyst used in zinc-air batteries. Carbon 200, 462–471 (2022).

He, Y. et al. Highly active atomically dispersed CoN4 fuel cell cathode catalysts derived from surfactant-assisted MOFs carbon-shell confinement strategy. Energy Environ. Sci. 12, 250–260 (2019).

Zhang, J. et al. Highly dispersed Co atoms anchored in porous nitrogen-doped carbon for acidic H2O2 electrosynthesis. Chem. Eng. J. 438, 135619 (2022).

Liu, X. et al. Utilizing solar energy to improve the oxygen evolution reaction kinetics in zinc-air battery. Nat. Commun. 10, 4767 (2019).

Yang, F. et al. Cobalt single atoms anchored on nitrogen-doped porous carbon as an efficient catalyst for oxidation of silanes. Green Chem. 23, 1026–1035 (2021).

Pan, Y. et al. Constructing nitrogen-doped carbon hierarchy structure derived from metal-organic framework as high-performance ORR cathode material for Zn-air battery. Small 20, 2304594 (2024).

Flores-Lasluisa, J. X., Garcia-Rodriguez, M., Cazorla-Amoros, D. & Morallon, E. In-situ synthesis of encapsulated N-doped carbon metal oxide nanostructures for Zn-air battery applications. Carbon 225, 119147 (2024).

Hu, X., Chen, X., Li, X. & Xu, C. Engineering the electronic interaction between single Au atoms and CoN through nitrogen-coordination bonding as an efficient bifunctional electrocatalyst for rechargeable Zn-air batteries. Adv. Funct. Mater. 34, 2316699 (2024).

Lv, C. et al. A MOF-plus-MOF strategy to synthesize Co-N3C1 single-atom catalyst for rechargeable Zn-air battery. Chem. Eng. J. 495, 153670 (2024).

Chen, C. et al. g-C3N4promoted MOF-derived Fe single atoms anchored on N-doped hierarchically porous carbon for high-performance Zn-air batteries. J. Colloid Interface Sci. 653, 551–560 (2024).

Liu, Y. et al. Fe, N-inducing interfacial electron redistribution in NiCo spinel on biomass-derived carbon for bi-functional oxygen conversion. Angew. Chem. 63, e202319983 (2024).

Li, W. et al. Expediting oxygen evolution by optimizing cation and anion complexity in electrocatalysts based on metal phosphorous trichalcogenides. Angew. Chem. Int. Ed. 62, e202214570 (2023).

Acknowledgements

The authors gratefully acknowledge the financial support from the Jiangxi Provincial Natural Science Foundation (20224BAB204009, 20224BAB214023, 20224BAB204017) and the Science & Technology Research Project of Jiangxi Provincial Department of Education (GJJ2202205, GJJ212319).

Author information

Authors and Affiliations

Contributions

Hong Jin and Dejian Lin wrote the main manuscript text. Laihong Zhou performed analyses and prepared figures. Guojun Zha and Shuigen Li provided equipment and supervision on the electrochemistry section. Minhua Jiang and Ping Huang provided equipment and supervised materials preparation. Huanwen Wu and Haijiao Xie carried out the DFT data analysis and interpretation. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jin, H., Lin, D., Zhou, L. et al. In situ construction of MOF derived CoNC anchored on N-doped carbon xerogel sphere as efficient bifunctional ORR/OER electrocatalyst for Zn-air batteries. Sci Rep 15, 3480 (2025). https://doi.org/10.1038/s41598-025-87952-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-87952-2