Abstract

Taking the granite specimen with multiple fissures as the main research object, the mechanical response and failure mechanism of the granite specimen under uniaxial compression tests were analyzed by constructing a numerical analysis model based on cohesive element and Voronoi polygons techniques. Furthermore, the effects of geometric characteristics (spacing, length, width) on the peak mechanical response, damage energy, number and proportion of micro-cracks, failure mode and so on are further studied. The results show that the numerical analysis model can accurately reproduce the complex intergranular occlusion and multi fissures network structure of granite specimens, and reveal the dominant role of fissure angle on the failure mode, and the significant influence of fissure geometric characteristics on the number and proportion of micro-cracks, peak mechanical response and damage energy. The crack path and failure mode are significantly affected by the change of fissure angle and spacing, while the increase of fissure length and width leads to more rapid failure and lower peak mechanical response. The damage energy increases gradually with the increase of fissure spacing, but decreases with the increase of fissure length and width. This study not only deepens the understanding of the mechanical behavior of granite samples under complex geological environments, but also provides theoretical support for accurate assessment and effective reinforcement of rock mass stability in engineering practice.

Similar content being viewed by others

Introduction

In the field of rock mechanics, the study of the mechanical behavior of complex fissures within rocks, which vary significantly in size, quantity, and inclination, is a pivotal research area1,2,3,4,5,6. This topic holds paramount importance not only for the accurate assessment of rock mechanical properties7,8,9,10,11,12,13,14 but also for various engineering applications, including tunnel excavation, slope stability, and underground storage construction. Hence, an exhaustive investigation into the mechanical behavior of rocks containing complex fissures is of utmost significance.

In recent years, numerous scholars have conducted extensive in-depth studies on the mechanical behavior of fissure rocks. The majority of these researches has focused on rock specimens with single fissure15,16,17,18 or with a single variation in geometric characteristics19,20,21,22 through experimental or numerical simulation methods.

In experimental research, researchers have designed diverse test schemes to observe and analyze the crack initiation, propagation, and failure processes of rocks under different loading conditions. These experiments have not only revealed the influence of fissure characteristics on rock mechanical behavior but also provided valuable experimental data for numerical simulations. Gao et al.23 employed an improved Kachanov method to explore the crack interaction in collinear and equal-length fissure models under compression, verifying the model’s effectiveness in describing rock crack behavior and providing a new approach for mechanical analysis of fissured rocks. Miao et al.24 focused on the semicircular prefabricated single-fissure granite samples, observing their crack initiation and propagation processes under monotonic and cyclic loading. Through detailed analysis of the changes in the fissure process zone and stress intensity factor, the micro-mechanism of crack propagation was revealed. Wang et al.25 analyzed the mechanical response of granite samples with a circular hole and two fissures of different bridge lengths under the cyclic uniaxial increasing-amplitude decreasing-frequency loading test combined with CT reconstruction technology, discovering three failure modes: single tension coalescence, single shear coalescence, and double shear coalescence, providing an important basis for understanding the failure mechanisms of complex fissured rocks. Li et al.26 explored the fissure characteristics of pre-notched semi-circular bend granite specimens under pre-static loading through dynamic fracture tests, demonstrating that increased pre-static loading leads to an increase in the fractal dimension of fracture surfaces, revealing the effect of preloading on rock fracture behavior. Li et al.27 investigated the mechanical properties and failure mechanisms of roadway surrounding rock under different confining pressures and fissure angles through triaxial cyclic tests, revealing the variation laws of strength, deformation, and failure modes, offering new insights into the mechanical analysis of fissured rocks. Wen et al.28 studied the effect of bolts on the mechanical behavior of granite specimens with prefabricated fissures through uniaxial compression tests, showing that bolts can control deformation and enhance specimen strength, with the effect being directly related to fissure angle. Zhang et al.29 conducted the uniaxial compression tests on brittle rock specimens with non-equidistant fissures, revealing the failure mechanism of brittle rocks through non-destructive detection techniques, providing an important reference for understanding the failure of complex fissure networks in rocks.

In numerical simulations, researchers have developed various numerical models to simulate the mechanical behavior of rocks under different conditions and analyze their failure modes and mechanical properties30,31,32. These models have not only enhanced our understanding of rock mechanical characteristics but also provided strong support for engineering practices. Hu et al.33 proposed an extended grain-based phase field method (GB-PFM) based on Voronoi tessellation technology, considering the heterogeneity of materials and the complexity of microstructures at the grain scale. This method offers a new perspective for simulating grain interlocking effects and their impact on rock mechanical properties. Wang et al.34 studied the mechanical response of specimens with different fissure sizes and spacings using a three-point bending model, observing stepped features in crack propagation paths and identifying the primary locations of tensile and shear fissures. Wu et al.35 investigated the effects of straight and arcuate fissures on the stress–strain curves and failure modes of granite specimens through numerical simulations, finding that the arcuate fissures have a lesser impact on mechanical parameters, providing important references for numerical simulations of fissured rocks. Lv et al.36 explored the mechanical properties and failure modes of coal-gangue mixtures with multiple-inclined single fissures under uniaxial compression, revealing a significant influence of fissure angle on compressive strength, particularly at a 45° inclination where compressive strength reaches a minimum. Tang et al.37 studied the effects of confining pressure and fissure angle on the mechanical behavior of single-fissured rock masses through compression tests and numerical simulations, demonstrating the confining pressure’s strengthening effect and the threshold angle for shear failure, providing essential foundations for stability analysis of fissured rocks. Zou et al.38 investigated the cracking process of prefabricated fissured marble specimens under dynamic and quasi-static loading conditions through experimental and numerical studies, revealing the shear deformation-dominated cracking mechanism and diversity of crack types under dynamic loading. Bahaaddini et al.39 explored the influence of joint geometric parameters on rock mass failure mechanisms through numerical modeling, validating the SRM model’s effectiveness in reproducing failure modes and strengths through comparisons with experiments. Cao et al.40 systematically studied the peak strength and failure characteristics of multi-fissured rock materials using similar material tests and the discrete element method (PFC2D), revealing the significant effects of fissure angle and number on material mechanical properties and the formation mechanisms of different failure modes.

Despite advancements in the study of rock mechanical properties, numerical simulation methods for modeling specimens with distinct grain structures (like granite) have not fully and systematically incorporated the intricate interlocking mechanisms between grains, particularly when examining the specimens’ mechanical behavior in the presence of numerous fissures with varying angles and geometric attributes (including fissure spacing (S), length (L), and width (W)). Additionally, inadequate exploration of the damage energy release mechanisms during failure processes has constrained a profound comprehension of rock mechanical response under failure conditions.

This study develops a numerical analysis model for fissured granite specimens, systematically analyzing the mechanical behavior of granite under uniaxial compression tests for fissure counts of N = 1 and N = 55. Furthermore, an intensive investigation is conducted into the failure mechanisms of granite specimens with N = 55 fissures. Subsequently, a multi-faceted analysis is undertaken to elucidate the multi-dimensional effects of geometric characteristics (S, L, W) of fissures with multiple angles (A = 0°, 30°, 45°, 60°, 90°) on granite’s mechanical behavior under uniaxial compression. This analysis encompasses the peak mechanical responses, variations in damage energy, the quantity and proportion of microcracks, and the evolution of failure modes, thereby shedding light on the intricacies and underlying failure mechanisms of fissured granite’s mechanical behavior under the coupled influence of multiple factors.

Model construction of prefabricated fissured granite

Numerical analysis model for prefabricated fissured granite specimens

The distribution of fissures in granite exhibits complexity and diversity, encompassing variations in size and a significant number of fissures. These fissure characteristics have a profound influence on the mechanical properties and failure modes of rocks. To investigate these effects, the ABAQUS finite element analysis software is utilized to develop a cohesive zone model of fissured granite. This model accurately simulates the intricate and variable characteristics of natural rock fissures.

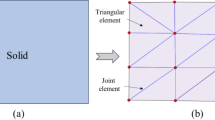

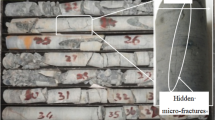

A self-developed plugin is employed to propose a polygonal model, leveraging Voronoi tessellation technology, for constructing numerical simulation specimens with dimensions of 50 mm × 100 mm (refer to Fig. 1a). Based on the laboratory tests, the grain size is approximated to an average side length of 2 mm to maintain model fidelity and mirror the granular structure of granite. The granite specimen is mainly composed of 4 distinct minerals, and each mineral proportion is as follows: quartz (13%), feldspar (52%), biotite (22%), hornblende (13%). Within the generated geometric model, these 4 distinct minerals are randomly distributed in accordance with their actual proportions (refer to Fig. 1b). This step is facilitated by the self-developed plugin, ensuring the randomness and authenticity of mineral placement. Subsequently, the entire model undergoes meshing (refer to Fig. 1c), with a mesh size of 0.5 mm, ensuring sufficient refinement to capture the intricate internal structures of the rock. Zero-thickness cohesive elements are then inserted throughout the model (refer to Fig. 1d), simulating mechanical behaviors such as crack opening, closure, and sliding.

Simulation of uniaxial compression process for granite

In order to further study the effect of fissures on the uniaxial compression mechanics of granite, uniaxial compression tests should be carried out on granite specimens with fissures. The matrix particles of each mineral in granite follow the elastic constitutive relationship, which ensures that the stress–strain response of the material during loading can accurately reflect its mechanical properties. The test loading system is composed of two rigid pressure plates, which are respectively used as the loading end and the fixed end. In order to simulate the mechanical environment of uniaxial compression, the loading rate is precisely controlled by one-way displacement loading method. The lower pressing plate implements strict fixed constraints to ensure that no displacement occurs at the bottom of the specimen during the whole loading process, thus ensuring the uniformity of displacement and the stability of the specimen during the loading process. In this paper, quasi-static loading of 0.02 mm/sec is adopted in uniaxial compression test, and the numerical simulation conditions are the same as the test conditions.

In order to accurately simulate the influence of fissure on the mechanical behavior of specimens during loading, a zero-thickness cohesive element is introduced. The element captures the tractor-separation response at the interface of granite grains and grain matrix, and uses the maximum principal stress criterion (Maxs Damage) to simulate the damage evolution. When the maximum principal stress at the interface reaches or exceeds the strength of the cohesive element, the damage begins to accumulate, and gradually leads to the opening, closing, sliding of the grain and the grain matrix, and even the final failure of the specimen. This process can not only reflect the significant influence of fissures on the overall mechanical properties of specimens, but also reveal the failure mechanism of rock materials under complex stress states. Figure 2 shows the uniaxial compression model of fissured granite.

Study on the influence of uniaxial compressive mechanical properties of multi-angle prefabricated fissured granite

Parameter calibration

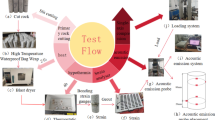

In order to ensure that the simulation results can accurately and comprehensively reflect the complex mechanical behavior of standard rock samples, a method based on the depth calibration of test data is adopted during the numerical simulation of uniaxial compression test. The core of this method is to calibrate the parameters by using the stress–strain curve and macroscopic failure characteristics obtained in the test.

The granite blocks were taken from Yimin tunnel of Rongan-Congjiang Express in China. Subsequently, the blocks sampled in the tunnel field were processed into 50*100 cylinder specimens for uniaxial compression tests by MTS 816 mechanical test loading system. The loading rate is set 0.02 mm/sec. The granite sample is relatively dense and homogeneous. The main mechanical parameters are as follows: uniaxial compressive strength is 83.35 MPa, elastic modulus is 6.63 GPa, and peak strain is 1.56*10–2. As an intuitive expression of the mechanical properties of the sample, the stress–strain curve not only reflects the complete process of the rock from the elastic stage to the plastic deformation to the final failure, but also profoundly reveals the key mechanical indexes such as the stiffness and strength of the rock. By repeatedly comparing the agreement between the simulation results and the test data, and fine-tuning the grain parameters (density and Young’s modulus) and cohesive element parameters (strength, stiffness, failure displacement) in the simulation, the rock mechanical response in the simulated environment can be closely approximated to the sample condition. The stress–strain curves of the test and numerical simulation and the final failure mode are shown in Fig. 3.

Meanwhile, macroscopic failure characteristics are another important index to verify the accuracy of the simulation. Therefore, in the process of calibration, the simulated rock failure mode is constantly compared with the actual failure mode observed in the test, paying special attention to the initial ___location of the crack, the direction of expansion and the final failure mode. By adjusting the cohesive element parameters of grain and matrix repeatedly, the simulation failure process is consistent with the experimental results not only in the stress–strain curve, but also in morphology.

Through the above detailed verification and comparative analysis, the constructed numerical model is highly consistent with the experimental results in terms of mechanical properties and failure characteristics, which can be applied to subsequent scientific research and engineering practice. The numerical simulation parameters after calibration are shown in Tables 1 and 2.

Peak mechanical response and damage energy

Figure 4 shows the influence of fissure angle on peak stress, peak strain and damage energy. It can be seen from the figure that:

-

(1)

When the number of fissures N = 1 and 55, the change trend of peak strain is not obvious with the increase of fissure angle, but the whole strain shows a certain fluctuation, and the fluctuation of N = 55 is larger than that of N = 1, because the existence of a large number of fissures increases the heterogeneity and complexity of the rock interior, resulting in a certain amplitude fluctuation of peak strain.

-

(2)

When N = 1, the peak stress and damage energy increase first and then decrease with the increase of fissure angle, and reach the maximum when A = 60°. This is because when the angle is small, the fissure has a relatively small weakening effect on the strength of the rock. When the angle is high, the fissure is more likely to lead to the destruction of the rock, thus reducing the peak stress and damage energy. When N = 55, the trends of peak stress and damage energy behave clear differences with the increase of fissure angle. The peak stress and damage energy increase monotonically with the increase of the fissure angle. This mainly because that when N = 1, the failure of granite specimen is simple and mainly controlled by the single fissure angle. When N = 55, The fissure network will become more complex. The failure of granite specimen will not only be affected by the fissure angle, but also the crack propagation between different fissures has a great effect on the failure of granite specimen.

Research on failure mechanism

Evolution process

In order to further explore the influence of different fissure angles (A = 30°, 60°, 90°) on the microscopic failure mechanism under uniaxial compression test, the global evolution of the number of microcracks, damage energy, and fissure mode with stress and strain when N = 55 is shown in Fig. 5. The analysis is as follows:

-

(1)

Under different fissure angles, the crack propagation and evolution showed some similarities, but the change of fissure angle significantly affected the damage degree inside the specimen. In general, with the gradual increase of fissure angle, the number of microcracks inside the specimen increases significantly, which reflects that the larger dip angle promotes the initiation and propagation of microcracks. According to the crack nucleation theory, a larger inclination angle may lead to more stress concentration at the crack tip, accelerate the nucleation and propagation of microcracks, and further promote the development of damage.

-

(2)

At the same time, no matter how the angle changes, the crack distribution characteristics tend to be about 2.0 times the number of transgranular cracks than the number of intergranular cracks, which is related to the microstructure characteristics and loading conditions of the rock. During the loading process, with the increase of stress, micro-cracks start to sprout in the crack tip and the surrounding area, and gradually develop into nucleation area. The microcracks in these nucleation regions are connected with each other and expand, resulting in the formation of macroscopic cracks.

-

(3)

When the displacement is loaded to point a, certain deformation has appeared in different areas of the specimen, especially in the middle of the left edge at A = 30° and 90°, and the lower part of the left edge at A = 60°. For A = 30° and 60°, intergranular cracks and transgranular cracks appear almost simultaneously, and show similar growth rates, indicating that the specimen has undergone a certain degree of plastic deformation. At this time, the process of nucleation and expansion of microcracks is accelerating, and the damage degree inside the specimen is gradually increasing. However, at A = 90°, the total crack number is almost 0, which indicates that the specimen is still in the stage of elastic change, and the nucleation process of micro-cracks has not been fully developed.

-

(4)

With the continuation of displacement loading (points b, c, d), the number of transgranular cracks is significantly higher than that of intergranular cracks, and the cracks mainly propagate upward in a direction parallel to their respective fissure angles, forming an ordered crack network. This process is consistent with the theory of crack nucleation, that is, microcracks gradually expand and connect in the nucleation region, and finally form a macroscopic crack network. At the same time, secondary macroscopic cracks perpendicular to the cracks also begin to appear, which is caused by the interaction of micro-cracks in different directions during the propagation process. At the initial position of crack initiation and propagation, grain spalling occurs in the local region of the specimen, which aggravates the damage degree of the material, and promotes the rapid growth of damage energy, total crack number, transgranular crack number and intergranular crack number.

-

(5)

When the loading reaches point e, the width of the main crack increases significantly, indicating the emergence of a large number of open cracks. Serious intra and inter grain boundary cleavage occurs along the direction of the main crack, and the damage is further aggravated. At this time, the fissure angle is the key parameter, and its variation not only affects the number and distribution characteristics of cracks, but also profoundly reflects the damage evolution mechanism of the specimen under complex stress environments.

Failure mode

Figure 6 shows the failure modes of granite specimens with different fissure numbers (N = 1, N = 55) (the failure modes in this paper all take 0.7 compressive strength after peak). It can be seen from the figures that:

-

(1)

When N = 1, the specimen showed obvious open type cracks in the in-depth analysis, and these main cracks intersected with the prefabricated single fissure in the center of the specimen, forming a complex crack network. At the same time, the composite crack characteristics of tear crack and slip crack co-exist in local areas, which further enrich the complexity and variability of crack growth. With the change of the angle of single fissure in the center, the main crack propagation path tends to extend towards the bottom of the specimen. This phenomenon not only highlights the sensitivity of crack propagation path to the change of fissure angle, but also reveals the complex interaction between stress distribution and stress transfer mechanism inside the material. At the same time, the change of fissure angle not only leads to the physical change of crack growth path, but also profoundly affects the evolution of fissure mode and crack type of specimens. The integrity of the specimen increases with the increase of fissure angle, which may be closely related to the optimization of crack propagation path, the equalization of internal stress release, and the adaptive adjustment of the material’s own resistance to failure.

-

(2)

When N = 55, there is a significant difference in the distribution of damage areas compared with N = 1. The most significant macroscopic manifestation is: the destructive activities are highly concentrated in the loading area; When A is in the range of 30° to 60°, a highly oriented failure mode is formed, and all cracks strictly follow the path in the same direction as the prefabricated fissure until they penetrate the specimen completely. This phenomenon shows that when A is 30° to 60°, the fracture process of the specimen is affected by the obvious stress concentration effect, and also indicates that the fissure angle can be used as a key factor to regulate the crack growth path. Compared with the simulation results when N = 1, the opening displacement of the crack in the failure region is also significantly reduced, which indicates that the opening mechanism of the crack is significantly inhibited.

It can be seen that the difference between N = 1 and N = 55 specimens is not only manifested in the concentration degree of the failure region and the propagation path of the crack, but also in the difference fissure angles on the crack type and propagation behavior. This provides an important theoretical reference for predicting and controlling the fracture behavior of granite under specific loading conditions.

Changes in the number of micro-cracks and the proportion of cracks

The statistics of the number of microcracks, the proportion of tensile and shear cracks are very important for understanding the failure mechanism and mechanical performance of granite specimens, which can not only directly reflect the cumulative damage degree inside the specimen, but also affect the strength, deformation and final failure mode of granite specimens, so it is necessary to conduct in-depth analysis. Figure 7 shows the number and distribution of micro-cracks under the different fissure numbers, Fig. 8 shows the proportion of intergranular and transgranular tensile and shear cracks under different fissure numbers, and Fig. 9 shows the proportion of tensile and shear cracks under different fissure numbers. As can be seen from Fig. 7 that:

When N = 1, with the increase of fissure angle, the total crack number increases first, then decreases and then increases, and reaches the maximum value at A = 60°. This indicates that the existence of fissure may aggravate the initiation and propagation of cracks at a certain angle (A = 60°). The number of transgranular cracks is relatively high between A = 45° and 60°, while the number of intergranular cracks reaches a local maximum at A = 60°. When N = 55, the total number of cracks increases with the increase of fissure angle. When the fissure angle reaches 90°, the number of micro-cracks reaches the peak value. However, compared with the single fissure angle, the total number of micro-cracks observed at each angle is generally lower. The central mechanism of this phenomenon is that as the number of fissures increases (N = 55), the stress field becomes significantly concentrated around these cracks, creating a so-called “stress concentration” effect. This concentration not only does not promote the initiation of new cracks, but also intensifies the accumulation and release of stress in the existing fissures, leading to crack growth mainly along the existing fissure path, thus limiting the formation of more microcracks. Therefore, although the overall damage degree is increased due to stress concentration, the total number of microcracks does not increase with the increase of the number of fissures, but decreases. This process deeply reflects the complexity of crack network in rock mechanics and its nonlinear influence on the overall mechanical properties of materials.

It can be seen from Figs. 8 and 9 that:

The transgranular cracks occupy a dominant position in the total cracks, especially the transgranular shear cracks, the proportion of which is generally higher than other types of cracks, indicating that the granite specimens are more inclined to form transgranular shear cracks under uniaxial compression. The fissure angle has a significant effect on the proportion of all kinds of cracks: when N = 1, the proportion of transgranular opening cracks gradually decreases with the increase of fissure angle, while the proportion of transgranular shear cracks reaches a high level at A = 45° and 60°, and then decreases slightly. The proportion of intergranular cracks (tensile type and shear type) also fluctuates slightly with the change of fissure angle. When N = 55, this trend still exists, but the change is more complex, which is related to the interaction between fissures. When the number of fissures changes from N = 1 to N = 55, the proportion of all kinds of cracks changes significantly. The proportion of transgranular tensile cracks decreases generally, while the proportion of intergranular cracks (especially intergranular tensile cracks) increases. This is because the increasing number of fissures makes the stress field more complex and the crack growth path more diversified, thus promoting the formation of intergranular cracks.

In summary, the number and proportion of microcracks in granite specimens are significantly affected by the fissure angle and number: when there is a single fissure (N = 1), the cracks at A = 60° are the most. When there are multiple fissures (N = 55), stress concentration restricts the formation of new cracks, but the total number of cracks decreases, and the increase of fissures promotes the number of intergranular cracks and reduces the transgranular opening cracks, reflecting the complexity of crack network and nonlinear mechanical effects. Therefore, it is necessary to further study the mechanical behavior of granite in the multi-fissure state.

Study on the influence of prefabricated fissure geometric characteristics on the mechanical behavior of granite under uniaxial compression test

Peak mechanical response

In order to further explore the peak mechanical response of S, L and W to granite specimens, Figs. 10 and 11 show the influence of fissure geometric characteristics on peak stress and peak strain respectively.

-

(1)

As can be seen from Fig. 10, with the increase of S, the peak stress presents a change law of first increasing and then decreasing, and with the increase of fissure angle, the change amplitude of peak stress becomes smaller, which indicates that the sensitivity of peak stress to fissure spacing decreases. With the increase of L and W, the peak stress shows an obvious downward trend. The main reason is that the increase of L and W provides more space for rock stress release, which causes rock failure at a lower stress level.

-

(2)

As can be seen from Fig. 11, the influence of S increasing on peak strain presents a trend of first increasing and then decreasing, but the amplitude of increase and decrease is not obvious. With the increase of L and W, the peak strain generally shows a downward trend. When L and W continue to increase, the change of peak strain eventually tends to be flat. The main reason is that the longer and wider fissures are more likely to become the area of stress concentration, resulting in the failure of granite at a lower stress level.

It can be seen that the geometric characteristics of fissures have a significant influence on the peak stress and strain of granite, in which the increase of L and W has a particularly significant effect on the peak mechanical response of granite, while the increase of fissures S and A weakens the sensitivity of this influence to a certain extent.

Damage energy

In order to study the correlation between damage energy and fissure geometric characteristics, Fig. 12 shows the influence of fissure geometric characteristics on damage energy. It can be seen from the figure that:

-

(1)

The damage energy basically increases with the increase of S. The main reasons are as follows: the increase of S changes the stress distribution inside the specimen. When S is smaller, the interaction between fissures leads to more concentrated stress, which makes the specimen fail at a lower energy level. With the increase of S, this interaction weakens, and the specimen needs to accumulate more energy to reach the critical point of failure.

-

(2)

With the increase of L and W, the damage energy shows a monotonically decreasing trend. The main reasons are as follows: the increase of L and W increases the defect area and the number of potential failure surfaces inside the specimen, which makes the specimen more prone to failure and releases more energy when subjected to external forces. In addition, the larger the fissure angle is, the higher the damage energy is.

It can be seen that S, L and W have significant effects on the damage energy of granite specimens during uniaxial compression test. The increase of S usually leads to the increase of damage energy, while the increase of fissure L and W directly leads to the monotonically decreasing damage energy. The study of these influencing mechanisms is of great significance for optimizing engineering design and predicting the stability of rock engineering.

Failure mode

Small changes in geometric characteristics can significantly affect the failure modes of granite specimens. Figures 13, 14, 15 shows the changes of failure modes with the fissure geometric characteristics (S, L, W) under different fissure angles.

Influence of fissure spacing

As can be seen from Fig. 13 that:

-

(1)

When A = 30°, the stress distribution is obviously uneven during the loading process, resulting in a high stress concentration at the fissure tip. When S = 7.5 mm ~ 10 mm, the integrity of the granite specimen is greatly damaged, the fissures play a leading role in the mechanical behavior of the granite, and the stress is mainly concentrated at the fissure tip, and the interaction between the fissures is strong, and the final performance is local failure and brittle failure along the angle of the fissure. When S = 15 mm ~ 25 mm, with the increase of fissure spacing, the interaction between fissures is weakened, the stress distribution tends to be uniform, the integrity of the rock is gradually restored, the influence of prefabricated fissures on the local failure mode of the specimen is gradually weakened, the specimen gradually shows the overall mechanical response, the main crack path turns perpendicular to the direction of the prefabricated fissure, the failure mode changes from brittle to ductile, and the plastic failure phenomenon is prominent.

-

(2)

When A = 60°, different from A = 30°, the main cracks tend to develop along the direction of fissure angle. When S = 7.5 mm ~ 10 mm, the brittle failure phenomenon of all specimens was significantly intensified, and the local failure range was significantly expanded. When S = 15 mm ~ 25 mm, with the increase of fissure spacing, the plastic failure phenomenon of each specimen gradually weakens. When S = 25 mm, there are obvious cross-type cracks perpendicular to the fissure direction, and the crack morphology becomes more complex and diverse.

-

(3)

When A = 90°, the failure range gradually increases with the increase of S (the same as that of A = 30°), and the main crack paths are oblique to the fissure direction. When S = 7.5 mm ~ 10 mm, the brittle failure phenomenon is serious, but the failure range is small. The main reason is that the loading direction is parallel to the fissure direction, resulting in a high concentration of stress at the crack tip, significant plastic deformation and local stress release, and then the local spalling phenomenon of crystal particles near the loading end. When S = 15 mm ~ 25 mm: With the increase of fissure spacing, the brittle failure characteristic is gradually weakened, and the failure gradually appears at the bottom of the specimen, and the plastic failure phenomenon is significantly weakened compared with A = 30° and 60°.

The increase of fissure spacing S will weaken the interaction between fissures and make the stress distribution tend to be uniform, which will affect the failure mode and mechanical response. Different fissure angles (A = 30°, 60°, 90°) lead to significant differences in the main crack paths and failure modes. When A = 30° and 90°, the main crack path is not strictly consistent with the fissure direction. When A = 60°, the main crack is more inclined to develop along the fissure angle direction, showing a strong consistency. With the increase of S, the brittle failure characteristics gradually weaken, and the plastic failure characteristics gradually appear.

Influence of fissure length

As shown in Fig. 14, with the increase of fissure length, the extension direction of the main crack gradually tends to be consistent with the fissure direction. This is because longer fissures provide more room for the crack to grow. During the loading process, cracks are more likely to propagate along the existing fissure path, and the failure condition is achieved with minimal energy consumption. When the fissure length is small, the fissure becomes the key area of stress concentration. However, with the increase of fissure length, the area in which the stress can be dispersed in the specimen increases correspondingly. This makes it possible to limit the rate of expansion and scope of damage during loading, although major cracks may still form. In addition, the longer fissure disperses the energy of the failure, making the scope of the failure relatively small. At the same time, due to the increase of the non-uniformity of stress distribution, the specimen is more prone to the whole brittle failure, showing more obvious brittle failure characteristics.

When the fissure angle is small, the main crack usually does not extend directly along the fissure direction, but oblique with the fissure. This is because there is a certain angle between the fissure plane and the principal stress direction due to the small fissure angle, which leads to the redistribution of stress at the fissure tip and the formation of a complex stress field. This stress field causes the crack to expand in an oblique direction to release the accumulated strain energy. With the increase of A, the direct influence of fissure on the failure path decreases. This is because the larger fissure angle increases the angle between the fissure plane and the direction of the principal stress, and the stress distribution becomes more uniform. Therefore, the local failure phenomenon is gradually weakened, while the overall brittle failure phenomenon is gradually strengthened.

Influence of fissure width

As shown in Fig. 15:

-

(1)

When A = 30°, the crack propagation may be affected by many complex factors such as the internal microstructure of the rock and unequal stress distribution, resulting in a relatively complex crack path. However, with the increase of W, the loading stress gradually takes the dominant position, prompting the crack to expand along the direction of the most favorable energy release, that is, the direction orthogonal to the fissure. This is because the crack propagation in the orthogonal direction can effectively disperse and release the stress, and reduce the energy state of the specimen.

-

(2)

When A = 60°, the angle between the loading direction and the fissure decreases further, which increases the component of the loading stress in the fissure direction, promotes the crack to expand rapidly along the path consistent with the fissure direction, and passes through the whole specimen. At this time, the crack propagation direction is basically parallel to the fissure direction, indicating that the loading stress has a stronger control effect on the crack propagation path. When A = 30° and A = 60°, although the fissure angle is different, the crack propagation speed and damage degree will increase with the increase of W, but the specific failure mode and path have been analyzed in the previous paragraph.

-

(3)

When A = 90°, with the increase of W, the failure position gradually moves to the bottom of the specimen. This is that because the bottom region is more likely to form a stress concentration zone under vertical loading, resulting in the crack preferentially propagating in this region. In this case, the direction of the main crack is oblique to the direction of the fissure. Under vertical loading conditions, although the local stress concentration will affect the initial ___location of the crack, the integrity of the specimen is still strong, and the propagation path of the crack is restricted by the overall mechanical properties of the rock material.

It can be seen that the S, L and W have significant effects on the failure modes of rock specimens under different fissure angles. The propagation direction of the main crack is determined by the fissure angle. When A = 30° and 90°, the main crack is oblique to the fissure. The main crack is inclined to propagate along the fissure direction when A = 60°. With the increase of S, the interaction between fissures will be weakened, the stress distribution will be more uniform, and the failure mode will change from local brittle failure to overall ductile failure. With the increase of L, the main crack tends to expand uniformly with the fissure, while the change of A determines the crack growth path, and the larger fissure angle weakens the local failure of the specimen and enhances the overall brittle failure. The increase of W promotes crack propagation along the most favorable direction of energy release, and at different fissure angles, the initial position and propagation path of the crack are different, but on the whole, the specimens all show strong overall failure characteristics.

Number of micro-cracks and proportion of crack types

The mechanical properties and failure modes of rock materials can be controlled and optimized by adjusting the spacing of prefabricated fissures and the angle between the loading direction and the fissures. Meanwhile, the analysis of crack types and their proportions is also helpful to further understand the failure mechanism and crack propagation law of rock. Figures 16, 17 and 18 shows the change of the number of microcracks in granite specimens under different fissure angles, and Figs. 19, 20, 21, 22, 23 and 24 shows the change of the proportion of microcracks in granite specimens under different fissure angles.

Influence of fissure spacing

It can be seen from Figs. 16, Fig. 19 and 22 that:

-

(1)

With the increase of S, the total crack number generally shows an upward trend, which reveals that the increase of fissure spacing reduces the local stress concentration to some extent, thus providing a more favorable environment for crack initiation and propagation. Specifically, the larger S reduces the mutual influence between adjacent fissures, making the stress of the specimen more uniform, and thus promoting the formation and expansion of more cracks. Therefore, the increase of S will directly affect the formation of internal crack network of granite specimens.

-

(2)

The number of transgranular cracks and intergranular cracks also mostly increases with the increase of fissure spacing. When A = 30°, the proportion of transgranular tensile cracks is relatively high, which is related to the characteristics of stress distribution at this angle, and also makes open type cracks more easily formed in the grain. When A = 60°, the proportion of transgranular shear cracks and intergranular shear cracks increases relatively. When A = 90°, that is, when the loading direction is parallel to the fissure, the proportion of intergranular shear cracks is generally higher, mainly because the cracks are easier to expand and form shear planes at this fissure angle.

Influence of fissure length and width

As shown in Figs. 17, 18, 20, 21, 23 and 24:

-

(1)

With the increase of L and W, the number of microcracks will decrease. The main reasons are: as a channel for stress release, fissures reduce stress concentration in a local area, and stress release reduces the dynamic force of crack initiation and expansion in the region. Meanwhile, longer fissures also change the distribution of stress field, resulting in stress redistribution in a larger area. With the increase of L and W, crack initiation and expansion will make adjacent cracks connect or merge with each other, forming larger fissure systems. As a result, the number of cracks decreases with the increase of L and W.

-

(2)

When A = 30°, the proportion of transgranular tensile cracks is relatively high. Because the existence of fissures provides the starting point for crack initiation, the component of tensile stress is relatively large. When A = 60°, the proportion of transgranular shear cracks is relatively high, because at this angle, cracks tend to propagate along the direction consistent with the fissure angle. When A = 90°, that is, when the loading direction is parallel to the fissure, the shear stress component becomes dominant. Since the fissure provides a natural weak plane for the expansion of the shear crack, the crack is more likely to expand along the fissure plane or the grain boundary to form a shear plane, so the proportion of intergranular shear cracks is generally high.

It can be seen from Sections "Influence of fissure spacing" and "Influence of fissure length and width" that the changes of S, L and W will have a significant impact on the formation of internal crack network of granite specimens. These effects involve stress release and redistribution, crack consolidation and propagation path change, and the interaction between different stress components. Therefore, in rock engineering, it is necessary to consider these factors comprehensively to optimize the design, in order to achieve effective control of rock material properties.

Discussion

This paper is to study the effects of fissure geometric characteristics on the on the mechanical behavior and failure mechanism of granite under uniaxial compression test by a developed numerical model. The developed numerical model can reconstruct the microstructure of granite precisely. The numerical model still has limitations at the same time. In this study, the strength properties of all minerals are set the same, which is different from the actual situation. In our future work, further improvements of the numerical model will be made to simulate the granite microstructure in greater detail.

As we all know, the cracked rock mass in deep underground engineering is often in a complicated stress state. Due to the limitation of space in this paper, only the mechanical behavior and failure mechanism of fissured granite under uniaxial compression tests have been simulated. In our next work, study on the mechanical behavior of fissured granite under different loading paths will be considered.

Conclusions

In this paper, a granite numerical model with prefabricated fissure using cohesive elements combined with Voronoi polygons is constructed to accurately reproduce the complex network structure characteristics of the interlocking between granite specimen grains and internal multiple fissures. The failure mechanism of fissured granite specimens is revealed through comparative analysis of the failure mode, micro-crack evolution process, the number and proportion of micro-cracks in total cracks, peak mechanical response and damage energy changes of granite specimens under different fissure angles. The effects of fissures S, L and W on the mechanical behavior of granite are further discussed, and the following conclusions are drawn:

-

(1)

The numerical model with prefabricated fissure using cohesive element and Voronoi polygons can accurately reproduces the tight inter grain occlusion of granite specimens and the complex network structure of multiple internal fissures. At the same time, it can directly show the dynamic changes of the cohesive elements of intergranular crack and transgranular crack under external load, including its opening, closing and sliding process, which enhances the authenticity of the simulation results.

-

(2)

Changes in geometric characteristics significantly affect the peak stress and strain of granite specimens. The increase of L and W has a particularly significant effect on the peak mechanical response of granite, while the increase of fissures S and A weakens the sensitivity of this influence to a certain extent.

-

(3)

The total crack number, transgranular crack number and intergranular crack number increase with the increase of S, but decrease with the increase of L and W. When A = 30°, the proportion of transgranular tensile cracks is relatively high. When A = 60°, the proportion of transgranular shear cracks and intergranular shear cracks increases relatively. When A = 90°, the proportion of intergranular shear cracks is generally higher.

-

(4)

Under multiple fissure angles, the spacing S, length L and width W significantly affect the failure mode of the granite specimen: fissure angle determines the crack path, S affects the stress distribution and failure mode transformation, L promotes the consistent propagation of cracks and fissures angle, and W dominates the direction of energy release.

-

(5)

With the increase of S, the damage energy of the granite specimen increases gradually, especially when the fissure angle is 90°, the damage energy reaches the maximum. On the contrary, with the increase of fissures L and W, although the internal defect area and potential failure surface increase, the specimen is more likely to fail under low stress state, resulting in a decrease in damage energy.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Fei, Z., Qiang, S. & Xiaohua, P. Effects of pre-existing fissures on surface macro-crack characteristics of granite subjected to elevated temperatures. Acta Geodynamica Et Geomaterialia. 16(4), 441–450 (2019).

Xuesong, W. et al. Mode I crack morphology and fracture surface roughness of granite under impact. Rock Soil Mech. 44(7), 1 (2023).

Jie, Z. et al. Experimental investigation of failure mechanisms of granites with prefabricated fractures induced by cyclic-impact disturbances. Energies 15, 3680 (2022).

Xin, G., Cheng, Z. & Weiyun, Z. Study on the failure characteristics of fractured rock with different topologies under uniaxial compression. Iop Conf. Ser. Earth Environ. Sci. 861, 072082 (2021).

Zhenyu, H., Diyuan, Li. & Xibing, Li. Effects of axial pre-force and loading rate on Mode I fracture behavior of granite. Int. J. Rock Mech. Min. Sci. 157, 105172 (2022).

Yong, N., Xiaoping, Z. & Berto, F. Evaluation of fracture mode classification in flawed red sandstone under uniaxial compression. Theoret. Appl. Fract. Mech. 107, 102528 (2020).

Kun, Du., Xuefeng, Li. & Ming, T. Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int. J. Rock Mech. Min. Sci. 133, 104411 (2020).

Shams, G., Rivard, P. & Moradian, O. Micro-scale fracturing mechanisms in rocks during tensile failure. Rock Mech. Rock Eng. 56, 4019–4041 (2023).

Ping, C., Taoying, L. & Chengzhi, Pu. Crack propagation and coalescence of brittle rock-like specimens with pre-existing cracks in compression. Eng. Geol. 187, 113–121 (2015).

Niu, Y., Zhou, X. P., Zhang, J. Z. & Qian, Q. H. Experimental study on crack coalescence behavior of double unparallel fissure-contained sandstone specimens subjected to freeze-thaw cycles under uniaxial compression. Cold Regions Sci. Technol. 158, 166–181 (2019).

Zafar, S., Hedayat, A. & Moradian, O. Micromechanics of fracture propagation during multistage stress relaxation and creep in brittle rocks. Rock Mech. Rock Eng 55, 7611–7627 (2022).

Yanlin, Z., Jian, L. & Yixian, W. Crack coalescence patterns and local strain behaviors near flaw tip for rock-like material containing two flaws subjected to biaxial compression. Arab. J. Geosci. 13, 1251 (2020).

Rihong, C., Ping, C. & Lin, H. Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: Experimental studies and particle mechanics approach. Rock Mech. Rock Eng. 49, 763–783 (2016).

Asadizadeh, M., Hossaini, M. F. & Moosavi, M. Mechanical characterisation of jointed rock-like material with non-persistent rough joints subjected to uniaxial compression. Eng. Geol. 260, 105224 (2019).

Shengqi, Y., Wenling, T. & Yanhua, H. Experimental and discrete element modeling on cracking behavior of sandstone containing a single oval flaw under uniaxial compression. Eng. Fract. Mech. 194, 154–174 (2018).

Chang, Xu., Tengfei, G. & Zhang, S. Cracking behaviours of layered specimen with an interface crack in Brazilian tests. Eng. Fract. Mech. 228, 106904 (2020).

Tao, D., Wang, Ju. & Weiming, G. Crack coalescence mechanism and crack type determination model based on the analysis of specimen apparent strain field data. Rock Mech. Rock Eng. 57, 3681–3705 (2024).

Zhonghui, Li., He, T. & Yue, N. Study on the acoustic and thermal response characteristics of coal samples with various prefabricated crack angles during loaded failure under uniaxial compression. J. Appl. Geophys. 200, 104618 (2022).

Yixian, W., Hui, Z. & Hang, L. Mechanical behavior and failure analysis of fracture-filled gneissic granite. Theor. Appl. Fract. Mech. 108, 102674 (2020).

Chang, Xu., Faning, D. & Jiacheng, P. Failure behaviors of rock specimens containing a filled fissure under cyclic compression. Pure Appl. Geophys. 79, 4541–4554 (2022).

Wenling, T., Shengqi, Y. & Yanhua, H. Fracture behavior of granite specimen containing a single fissure under uniaxial compression by grain-based model 3D. Acta Mech. Sinica 38, 1–14 (2022).

Tao, Z., Jiarong, C. & Heping, X. Failure and mechanical behaviors of sandstone containing a pre-existing flaw under compressive–shear loads: Insight from a digital image correlation (DIC) analysis. Rock Mech. Rock Eng. 55, 4237–4256 (2022).

Ansen, G., Chengzhi, Qi. & Renliang, S. AE characteristic and mechanical behaviors of red sandstone with two prefabricated close-collinear-equal length cracks under compression. Acs Omega 8, 2476–2484 (2023).

Shuting, M., Pengzhi, P. & Wenbo, H. Stress intensity factor evolution considering fracture process zone development of granite under monotonic and stepwise cyclic loading. Eng. Fract. Mech. 273, 108727 (2022).

Wang, Y., Yang, H. N. & Han, J. Q. Effect of rock bridge length on fracture and damage modelling in granite containing hole and fissures under cyclic uniaxial increasing-amplitude decreasing-frequency (CUIADF) loads. Int. J. Fatigue 158, 106741 (2022).

Youzhen, Li., Feng, D. & Yi, L. Effects of pre-static loads on the dynamic pure mode I and mixed mode I-II fracture characteristics of rocks. Eng. Fract. Mech. 279, 109047 (2023).

Kesheng, Li., Yiquan, L. & Shengqi, Y. An experimental investigation on the failure behavior of sandstone with filled fissure under triaxial multilevel cyclic loading. Fatigue Fract. Eng. Mater. Struct. 47, 3375–3391 (2024).

Wen Guanping, H., Jianhua, W. J., Dongjie, Y. & Rui, X. Characteristics of stress, crack evolution, and energy conversion of anchored granite containing two preexisting fissures under uniaxial compression. Bull. Eng. Geol. Environ. https://doi.org/10.1007/s10064-022-03002-5 (2023).

Jianzhi, Z., Xiaoping, Z. & Lunshi, Z. Progressive failure of brittle rocks with non-isometric flaws: Insights from acousto-optic-mechanical (AOM) data. Fatigue Fract. Eng. Mater. Struct. 42, 1787–1802 (2019).

Hu, X. et al. Predicting triaxial compressive strength of high-temperature treated rock using machine learning techniques. J. Rock Mech. Geotech. 15(8), 2072–2082 (2023).

Hu, X., Xie, N., Zhu, Q., Chen, L. & Li, P. Modeling damage evolution in heterogeneous granite using digital image-based grain-based model. Rock Mech. Rock Eng. 53(11), 4925–4945 (2020).

Hu, X. et al. The influence of mechanical heterogeneity of grain boundary on mechanical and microcracking behavior of granite under mode I loading using a grain-based model. Rock Mech. Rock Eng. 57(5), 3139–3169 (2024).

Xunjian, Hu., Xiaonan, G. & Xie, Ni. Modeling crack propagation in heterogeneous granite using grain-based phase field method. Theor. Appl. Fract. Mech. 117, 103203 (2022).

Longcan, W., Zhendong, C. & Ruidong, P. Numerical simulations on the structural heterogeneity and fracture bias effect of three-point bending specimen. Theor. Appl. Fract. Mech. 132, 104466 (2024).

Shiyan, Wu. & Yanhua, H. Macro and meso crack evolution of granite specimens with non-straight fissures: A comparison between two bond models. Theor. Appl. Fract. Mech. 125, 103890 (2023).

Huayong, Lv., Defeng, W., Zhanbo, C., Yaning, Z. & Tao, Z. Study on mechanical characteristics and failure modes of coal–mudstone combined body with prefabricated crack. Mathematics 10, 177 (2022).

Jinzhou, T., Shengqi, Y. & Elsworth, D. Three-dimensional numerical modeling of grain-scale mechanical behavior of sandstone containing an inclined rough joint. Rock Mech. Rock Eng. 54, 905–919 (2021).

Chunjiang, Z., Maruvanchery, V. & Xiaobao, Z. Change of crack mode in rock cracking process under quasi-static and dynamic loadings. Geomech. Geophys. Geo-energy Geo-resour. 8, 20 (2022).

Bahaaddini, M., Sharrock, G. & Hebblewhite, B. K. Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput. Geotech. 49, 206–225 (2013).

Rihong, C., Ping, C. & Hang, L. Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: Experimental studies and particle mechanics approach. Rock Mech. Rock Eng. 49, 763–783 (2016).

Acknowledgements

This work is financially supported by National Natural Science Foundation of China (Nos. 52278472), Beijing Municipal Natural Science Foundation (No. 8232004).

Author information

Authors and Affiliations

Contributions

Zhaolong Sang: Conceptualization, Methodology, Writing-Original draft preparation. Donghui Ma: Supervision, Funding acquisition, Writing-Review and Editing. Yaoyao Meng: Supervision, Writing-Review and Editing. Qian Yin: Investigation, Formal analysis. Xiaowei Liu: Validation. Zhimin Sun: Methodology. Wei Wang: Supervision, Funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sang, Z., Ma, D., Meng, Y. et al. Study on the effects of fissure geometric characteristics on the mechanical behavior and failure mechanism of granite under uniaxial compression test. Sci Rep 15, 3981 (2025). https://doi.org/10.1038/s41598-025-88278-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-88278-9