Abstract

This study offers a compact size, highly sensitive, and reliable split ring resonator-based sensor for microwave sensing applications. The designed unit cell is assembled on a 1.575 mm width of low-cost dielectric substrate Rogers RT5880. CST software is employed to design and analyze the proposed sensor. The size of the sensor is 8\(\:\times\:\)8 mm2 which is very small and it’s a low price. Also, the CST-simulated model was validated using ADS software. The MATLAB is used to extract the effective parameters of the suggested unit cell. Then the prototype is fabricated, and the laboratory measurements are done to validate the simulated results. The obtained resonances from the designed sensor are 2.77, 5.78, 9.82, and 12.29 GHz. Sensing performance is examined by using various materials and thicknesses of FR-4 material. After analysis, the sensor’s EMR, quality factor, and figure of merit (FoM) are found to be 13.54, 325, and 6.15 respectively which are effective. The sensitivity of the sensor is 12.03% which means the sensor performance is optimum. The resonances are shifted to 210, 600, and 810 MHz due to permittivity change and 290, 270, and 560 MHz due to materials thickness change. All laboratory results are perfectly matched with the simulated results. Due to its small size, low cost, high sensitivity, and superior performance, the suggested sensor can be used for sensing material thickness as well as glass, plastic, and substrate materials.

Similar content being viewed by others

Introduction

Metamaterials are artificially engineered structures possessing unique properties which are absent in natural materials1. Single negative (SNG) structures are those with negative permeability or permittivity, whereas double negative (DNG) or left-handed (LH) structures are those with negative permittivity and permeability. In the last few years, Metamaterials have emerged as a promising field with significant potential for developing highly sensitive sensors. The unique properties of metamaterials have led to their diverse applications, including antennas2,3,4,5, clocking6, perfect absorbers7,8,9,10, biosensors11,12,13, super-resolution14,15, and energy harvesting technologies16,17,18. Incorporating metamaterial structures in sensing has revolutionized the field, leading to the development of innovative, highly sensitive, and compact devices for various applications of sensors, i.e., strain19, displacement20, angular displacement21, temperature22, mass flow23, and material characterization24,25,26. These sensors tend to be bulky, and the quality factor is low. Several articles on metamaterial sensors were presented in13,27,28 for dielectric characterization. The overall performance of these sensors is not satisfactory level i.e., low sensitivity and quality factor. A planar transmission line-based metamaterial sensor was first implemented in29, in the study, a twin complementary SRR-loaded MTL sensing platform was used. MTL and CSRR design parameters are used to adjust the resonance frequency of the passive structure, which is a stopband filter used to determine the relative permittivity of a homogeneous dielectric sample. Several metamaterial structures were described in30,31,32 for numerous wireless applications. All these structures are large in size, also the EMR is quite low. To determine the complicated permittivity of liquid samples, a team of researchers used SRR-based sensors33 and CSRR-based sensors27 and reported their overall outcomes in two scientific papers. The proposed sensors confirmed the capacity of the meta-resonator-based sensors to differentiate between different microfluidics with various complicated permittivity values.

A modified SRR-based sensor was used in34, and it is based on the double SRR’s edge being excited by two distinct MTL strips. For the proposed sensor, a tiny microfluidic channel was made, and it was positioned in the same plane as the substrate. A dual circular metamaterial sensor is presented in35 for textile material recognition. All performance parameters are good, but the EMR value is undefined. As a microfluidic ethanol chemical sensor, a CSRR-loaded patch was proposed36. The size of the structure is 12\(\:\times\:\)11.3 mm2. In this sensor, a distinguishable frequency response was found due to the change in concentration of ethanol from 10 to 100%. The concept of a meta-resonator crack detection sensor was initially put forth in37. The double CSRR and MTL are put into the proposed sensor. On the higher plane of an aluminum block, a straight, little crack that had been intentionally produced was discovered using it. Few metamaterial unit cells were presented in38,39 for radar and Wi-Fi applications, but the experimental validation is not described. The identification and representation of surface fractures on metallic and non-metallic surfaces using an MTM sensor was proposed in40. A metamaterial absorber is presented in41 for bio-plastic sensing. All working parameters are moderate level. For the detection of complex permeability and complex permittivity, a single MTM sensor was suggested in42. In the sensor’s design, a modified dual CSRR loaded to MTL was employed. Every MUT underwent two tests: one to measure its permittivity and the other to measure its permeability. Also, a variety of MTM sensors have been successfully utilized in various applications across the tri-frequency band sensors, such as microfluidic43,44,45, liquid46,47,48 permittivity49, thickness50,51, and temperature sensors52,53. Although these sensors demonstrate satisfactory performance, their sensitivity, and Q-factors remain relatively low and moderate respectively.

In this paper, a novel compact split-ring resonator-based sensor is designed, analyzed, and fabricated for industrial applications. The design sensor is optimal, as evidenced by the extremely high effective medium ratio (EMR) that was obtained. This research involves two distinct phases: initially, designing and studying the resonator structure, followed by its utilization as a sensor. The sensor’s functionality has been validated both numerically and experimentally. A comprehensive parametric study aids in selecting the optimal design, with analyses encompassing the equivalent circuit, effective medium ratio (EMR), Q-factor, the figure of merit (FoM), and sensitivity (S). Changes in total resonance frequency can be used to accurately determine a material’s permittivity and the thickness of materials is sensed in real-time, changing the response of the designed model to the EM properties of the MUTs. The proposed sensor’s originality is its high sensitivity, high-quality factor, unique structure, and ease of use. The structure reacts to variations in resonance frequency and is responsive to the material’s dielectric properties.

Design and simulations

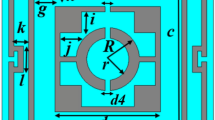

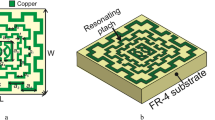

The Rogers RT5880, an easily accessible and inexpensive material, was used in the construction of the proposed asymmetric cross SRR-based MTM sensor. The utilized Rogers RT5880 has a dielectric constant of 2.2, a substrate thickness of 1.575 mm, and uses 0.035 mm copper on the front side with no copper on the reverse. A resonator made of annealed copper with a conductivity of 5.8\(\:\times\:\)107 S/m is employed. The sensor’s front side is made up of a three-square SRR and the size of the main structure is 8 by 8 square millimeters. Since we can fabricate the size of the metamaterial structure in the mm range, so the targeted frequency range is GHz. The size of the metamaterial is inversely proportional to the resonance frequency i.e., when the MTM size is large then the resonance frequency is lower. In this design, the MTM structure is small although the resonance is optimum and covers the maximum 4 frequency band, so we choose the frequency range 2–14 GHz. The front and side 3D images of the sensor are shown in Fig. 1(a, b) which was obtained from CST software. The parameter sizes of the structure are L = 8, W = 8, D = 0.5, l = 3, w1 = 7, w2 = 5, w3 = 0.5, w4 = 1.5, and g = 0.5 mm.

The simulation setup is displayed in Fig. 2 which was obtained from CST software. The wave propagates along the axis (Z), with electric conductors (perfect) aligned sequentially on the X- and Y-axes. The side-wall waveguide is appropriate for a range of boundary conditions, including open space, periodic distribution, PEC/PMC, and PEC, because it is made of metal43. With a frequency range between 2 and 14 GHz, the simulation is run. We have achieved the circumstances of the experimental setup, which is the primary justification for employing PEC boundary conditions in the simulation investigation. In this case, the waves are indicated by the letters “I” for incident, “R” for reflected, and “T” for transmitted.

Simulation framework of the suggested sensor using Computer Simulation Technology (CST) software (Version-2019) (https://www.3ds.com/products/simulia/cst-studio-suite)54.

First, the shape of the resonator has been started so that three or four resonances are obtained. For this reason, various configurations of the resonator are placed on the substrate material which is shown in Fig. 3(a) and Fig. 3(b) observing the corresponding outcome of \(\:{S}_{21}\). In step 1, the \(\:{S}_{21}\) resonance is 4.8 GHz with an amplitude of -42.75 dB which exists in the C-band. For the second step, the resonances are 3.72 and 7.52 GHz with notches − 36.67 and − 39.40 dB which covers S- and C-band. The resonances are 2.77, 7.23, and 10.57 GHz with gain − 21.64, -41.72, and − 15.56 dB whose covering bands are S-, C-, and X- for step 3. For the next step, the resonances are 2.78, 6.87, and 13.26 GHz, notches are − 20.09, -40.10, and − 21.10 dB and the existing bands are S-, C-, and Ku-. For the fifth step, the resonances are 2.56, 5.56, 9.53, and 11.95 GHz with magnitudes of -18.78, -35.73, -24.35, -and 23.97 dB which exists in the S-, C-, and X-bands. For the last step, the resonances are 2.56, 5.56, 9.53, and 11.95 GHz with gain − 20.54, -36.79, -25.26, and − 23.62 dB whose covering bands are S-, C-, and X-. After analyzing all the steps, it is displayed that the overall result of the last step is better than the previous steps, so the last step is selected as the final design.

Methods and techniques

This section covers effective parameter extraction techniques, the metamaterial properties of the unit cell under consideration, and comparable circuit analysis.

Efficient approaches for parameter extraction

The Nicolson-Ross-Weir (NRW) technique was utilized to calculate the refractive index \(\:\left({n}_{r}\right)\), permeability \(\:\left({\mu\:}_{r}\right)\), permittivity \(\:\left({\epsilon\:}_{r}\right)\) to determine the EM properties of the MTMs. Utilizing MATLAB code, the effective parameters were retrieved55. The MATLAB findings were then compared to the CST results.

The NRW technique was used to estimate effective parameters from the typical incidence of propagating restriction data56.

The NRW approach starts with the \({V_1}\) and \({V_2}\) compound

The relative permittivity is\({\varepsilon _r}\), permeability is \({\mu _r}\)and refractive index is \({n_r}\). \({k_0}\) and d are the wave number and substrate thickness.

Metamaterial characteristics of the designed unit cell

The CST simulator’s output for transmission amount (\(\:{S}_{21}\)) and reflection magnitude (\(\:{S}_{11}\)) is shown in Fig. 4(a). “Three square SRRs, a single internal stripline, two connecting strip lines, and four resonance frequencies were discovered, covering the maximum frequency bands, in the suggested design. 2.77 GHz resonance is detected for the first square ring, followed by 5.78 GHz resonance for the second square ring, 9.82 GHz resonance for the third square ring, and 12.29 GHz resonance for the inside stripline. Given that size and resonance are inversely correlated, strong resonance is obtained when the patch is tiny in size. The unit cell’s S11 results exhibit four resonance frequencies at 3.18 GHz, 7.01 GHz, 10.37 GHz, and 12.77 GHz, with corresponding magnitudes of -29.19 dB, -28.78 dB, -18.81 dB, and − 13.71 dB respectively. Additionally, the S21 results of the unit cell also reveal four resonance frequencies at 2.77 GHz, 5.78 GHz, 9.82 GHz, and 12.29 GHz with magnitudes of 20.54 dB, 36.79 dB, 25.26 dB, and − 23.62 dB respectively. For the corresponding, the − 10 dB bandwidth of \(\:{S}_{21\:}\)is 30 MHz, 420 MHz, 160 MHz, and 220 MHz. The results of \(\:{S}_{11}\:\)and \(\:{S}_{21}\)are used to calculate the effective parameters using the MATLAB code based on Eqs. (6)–(8), as depicted in Fig. 4(b-d). The permittivity vs. frequency curve is illustrated in Fig. 4(b). 2.66–2.81, 5.63–6.47, 9.73–9.94, and 12.41–12.54 GHz are the four negative frequency ranges displayed by the real value of \(\:{\mu\:}_{r}\:\), whereas the imaginary value of \(\:{\epsilon\:}_{r}\) displays all positive over the whole frequency range. Figure 4(c) shows the relative permeability vs. frequency curve. In addition, the imaginary component of \(\:{\mu\:}_{r}\:\)also demonstrates four negative frequency ranges: 2.71–2.82 GHz, 5.62–6.75 GHz, 9.72–10.04 GHz, and 12.40–12.60 GHz. The real value of \(\:{n}_{r}\) displays four negative frequency ranges: 2.69–2.78 GHz, 5.51–5.98 GHz, 9.68–9.88 GHz, and 12.31–12.49 GHz. The proposed metamaterial possesses negative features, and the double negative frequency sections are 2.69–2.78, 5.63–6.47, 9.73–9.94, and 12.41–12.49 GHz. Figure 4(d) displays the graph of frequency vs. refractive index. There are four negative frequency ranges visible in the real value of \(\:{n}_{r}\): 2.67 to 2.79 GHz, 5.62 to 6.37 GHz, 9.70 to 9.869 GHz, and 12.39 to 12.50 GHz. Along with the imaginary component of \(\:{n}_{r}\), multiple negative frequency ranges are also displayed: 5.67 to 6.37 GHz, 9.75 to 9.89 GHz, 12.43 to 12.51 GHz, and 2.71–2.82 GHz.

LC circuit analysis

The equivalent circuit of the compact asymmetric cross SRR structure is designed by using the Advanced Design System (ADS) software (Version 2016) (https://www.keysight.com/de/de/products/software/pathwave-design-software/pathwave-advanced-design-system.html) which is shown in Fig. 5(a). Combining capacitance (C) and inductance (L) yields this circuit. Capacitance is represented by a ring-split gap of the asymmetric cross SRR structure, whereas inductance is represented by a metallic line of the structure57. The resonance frequency (\(\:{f}_{r}\)) for the LC circuit is represented by the following equation58:

L can be calculated using the principle of transmission line59.

C was determined using the following formula59.

Where, \(\:{\epsilon\:}_{0}=8.854\times\:{10}^{-12}\:F/m,\)\(\:{\mu\:}_{0}=4\pi\:\times\:{10}^{-7}\)\(\:H/m,\)\(\:w=\) strip width, \(\:h=\) substrate thickness, \(\:t=\) copper thickness, \(\:g=\:\)split gap, \(\:d=\:\)distance between two strips, and \(\:l=\:\)length of the strip.

From Eq. (9) it is seen that the resonance frequency is inversely proportional to the inductance and capacitance, again from Eqs. (10) and (11) it is also seen that the inductance and capacitance are directly proportional to the permittivity and permeability values of them. Therefore, the resonance frequency is dependent on the change in electric and magnetic properties of MUT.

A circuit model is presented in60 for measuring the permittivity of liquid materials. The analysis of the model is perfect but the \(\:{S}_{21}\:\)result of the circuit was not mentioned. The equivalent circuit model employs inductors (labeled as L1-L6) and capacitors (labeled as C1-C6) to represent the structural elements. The CST simulation result is validated by comparison with the ADS result. Capacitance C1 and inductance L1 are created by the outer square SRR, followed by L2 and C2 and L3 and C3 by the second and third square SRRs. The first and second outer square SRR’s coupling capacitor C5 and inductor L5 are provided by the inner strip line, while the second and third square SRR’s coupling inductance and capacitance are provided by the inner strip line’s L6 and C6. The component values in ADS have been configured to provide \(\:{S}_{21}\:\)resonances from the “CST and HFSS that are the same. Specifically, L3 and C4 were adjusted for the 2.77 GHz resonance, L4 and C6 for 5.78 GHz, and L5 and C5 for 9.82 GHz. The fourth \(\:{f}_{r}\), or 12.29 GHz, is altered through tuning. The CST and ADS simulated\(\:{\:S}_{21}\)are illustrated in Fig. 5(b) as a last point, and these three results are extremely close.

Analysis of the effect of internal parameter

The internal parameters of the selected structure are varied to get the best performance. The required parameters are fixed after analyzing the five steps of each parameter. To show the transmission coefficient (\(\:{S}_{21}\)) resonance frequency \(\:\left({f}_{r}\right)\) and its corresponding gain we changed the value of the parameter i.e., metamaterial array, resonator width \(\:\left(w\right)\), split gap \(\:\left(g\right)\), substrate material. All analysis has been discussed below.

Effect of the split gap on the proposed structure

Figure 6 represents the \(\:{S}_{21}\:\)resonances with corresponding gain for different split gaps. For the value of \(\:g\)=0.15, the \(\:{S}_{21}\) resonances are 2.54, 5.48, 9.35, and 11.71 GHz with the corresponding amplitude of -18.06, -36.05, -21.71, and − 22.83 dB which exists in the S-, C-, and X- bands. For the second step \(\:g\)=0.25 mm, the resonances are 2.77, 5.78, 9.82, and 12.29 GHz with notches − 20.54, -36.79, -25.26, and − 23.62 dB which covers S-, C-, X-, and Ku-band. The resonances are 2.83, 5.84, 9.93, and 12.48 GHz with gain − 21.05, -37.12, -24.89, and − 23.67 dB whose covering bands are S-, C-, X-, and Ku-for the value of \(\:g\)=0.40 mm. In the next step, the resonances are 2.87, 5.92, 9.99, and 12,59 GHz, respective notches are − 21.38, -36.87, -25.03, and − 24.06 dB and the existing bands are S-, C-, X-, Ku- for \(\:g\)=0.50 mm. For the fifth step, the resonances are 2.95, 6.01, 10.08, and 12.69 GHz with magnitudes of -21.88, -37.03, -24.86, and − 23.77 dB which exist in the 4 bands (S-, C-, X-, and Ku-) for \(\:g\)=0.25 mm. After analyzing all split gaps, it is seen that the overall result for the \(\:g\)=0.25 mm is better than the other values of \(\:g\), so the value of \(\:g\) is 0.25 mm is selected in the final structure.

We also analyzed the proposed structure for the different values of resonator width, after analyzing resonator widths, it is seen that there is no significant variation in overall results, so it was not mentioned here.

Effect of the array on the proposed structure

\(\:{S}_{21}\:\)resonances with corresponding amplitude for the different arrays depicted in Fig. 7. In this analysis, three types of arrays are used to show the response of\(\:\:{S}_{21}\:\). For the unit cell, the \(\:{S}_{21}\) resonances are 2.77, 5.78, 9.82, and 12.29 GHz with the corresponding magnitude of -20.54, -36.79, -25.26, and − 23.62 dB. The resonances are 2.82, 5.83, 9.87, and 12.34 GHz with notches − 20.84, -37.09, -25.56, and − 23.91 dB for the 1\(\:\times\:\)2 array. The resonances are 2.75, 5.74, 9.72, and 12.28 GHz with gain − 21.04, -37.29, -25.76, and − 24.11 dB for the 2\(\:\times\:\)2 array. For the 3\(\:\times\:\)3 array, the resonances are 2.76, 5.75, 9.80, and 12.27 GHz with the corresponding notches are − 21.34, -37.59, -26.06, and − 24.42 dB. All configurations cover S-, C-, X- and Ku- bands. There are some variations among the unit cell and other arrays due to the resonator’s coupling effect.

Prototype fabrication and analysis of the experimental results

The CST results have been validated by building and experimentally measuring the suggested unit cell. When being measured, the unit cell is positioned halfway between two waveguide ports. The vector network analyzer is connected to these waveguide ports. Figure 8(a–b) displays the fabricated unit cell and 16-by-16 array prototype. Figure 9(a) depicts the unit cell experimental setup, while Fig. 9(b) shows the measurement setup for the 16-by-16 array.

The array prototype is positioned in the center of two horn antennas in the experimental setup, with the antennas spaced 40 cm apart. The array performance is measured using A.H. systems’ double ridge guided horn antennas, SAS-571. Each antenna is 27.9 × 14.2 × 24.4 cm3 in size and operates between 700 MHz and 18 GHz. Radiating near field distance for an antenna is \(\:\le\:2{D}^{2}/\lambda\:\)61, where D is the antenna’s dimension and λ is the radiation’s wavelengths, respectively. The horn antenna’s radiating near field distance will be ≤ 36.21 cm at a lower cut-off frequency of 700 MHz and a dimension of 27.9 cm. As a result, two antennas spaced 40 cm apart verify their far-field distance. So, the metamaterial array is positioned 20 cm from each horn antenna, in the center of the array.

Figure 10(a) shows the simulated and measured values for the \(\:{S}_{21}\:\)of the asymmetric cross SRR-based unit cell. While the observed resonances are at 2.73, 5.88, 9.87, and 12.43 GHz, the computed resonances are at 2.77, 5.78, 9.82, and 12.29 GHz. The measured notches are − 16.04, -29.53, -20.36, and − 19.66 dB, compared to the computer-generated notches of -20.54 dB, -36.79 dB, -25.26 dB, and − 23.62 dB. The results obtained from the measurements and the computer-generated differ slightly. This phenomenon could have several causes. First, the difference between the measured and simulated results was caused by an error in the calibration of the Agilent N5227A VNA using the Agilent N4694 60,001 Ecal. Additionally, it might be the outcome of tiny errors that were committed during the fabrication of the recommended substrate layer. The array’s results also show a little fluctuation in the resonance frequencies in Fig. 10(b). However, there is a distinct and compelling similarity between the array’s and the unit cell’s results. The minor discrepancy may be caused by a manufacturing error or the interconnection of the array’s cells. Although this, the array’s output reaches the intended S, C, X, and Ku band characteristics.

Effective medium ratio (EMR) evaluation

The EMR represents the size of the MTM8,62. The flawless MTM design and criterion fulfillment are shown in the high EMR. The EMR is calculated by Eq. (12).

\(\:\lambda\:\) = wavelength and \(\:L\) = length of the cell.

Given that \(\:L\) = 8 mm and \(\:\lambda\:\) = 0.1083 m at 2.77 GHz, the EMR of the planned structure is 13.54.

Table 1 shows the overall performance comparison.

Sensing results analysis

Metamaterial sensing has recently undergone extensive research. Even though this field has a great deal of interest for researchers, the sensing application of various bands has been studied with the final metamaterial sensor. Microwave sensors can detect chemical processes as well as the moisture content, density, structural composition, and form of materials by analyzing the properties of materials based on microwave contact with matter. In comparison to conventional sensors, microwave sensors provide several benefits, including rapid and precise measurement that is not damaging, total computerization, and the possibility of being produced in a lab. The sensor under consideration for material and thickness representations is shown in Fig. 11(a) which was generated by the CST software. Figure 11(b, c) displays the sensor’s layer configuration and measured layer between two unit cells. Five layers make up the configuration: a MUT layer, two substrates, and two copper patches. MUT layers are positioned between two waveguide ports and two metamaterial structures. Altering the sensing MUTs’ dielectric constant allowed researchers to examine the performance of the sensors. This modification results in shifting the \(\:{f}_{r}\) and considerably impacts microstrip line capacitance. The entire process of MUT sensing employing compact MTM structures is shown in Fig. 12 The MUT sample is created and inserted between the MTM sensor. The MUT is then positioned within two waveguide ports, forming a sandwich configuration. Then the VNA is used to measure the sandwich configuration. To evaluate the sensor’s accomplishment, three MUTs were chosen: FR-4, Rogers RO4350B, and RT5880. Also, three distinct thicknesses (1 mm, 1.5 mm, and 2.3 mm) of FR-4 were used to assess the sensing performance. The scattering parameters for each MUT are obtained after the experimental setup is complete, and graphs are made utilizing the obtained data.

Figure 13(a, b) illustrates the sensor simulated and measured behavior as it relates to variations in the dielectric constant. These modifications were made as a result of the patch’s altered coupling and mutual capacitance. Table 2 provides an overview of the sensor’s overall performance for different material characterization.

According to Table 2, the permittivity change causes the resonances between RO4350B and FR-4, RO4350B and RT5880, and FR-4 and RT5880 to shift by 210 MHz, 600 MHz, and 810 MHz, respectively.

Another application for the proposed MTM-based sensor architecture is the measurement of material thickness. We tested the thicknesses of three different types of FR-4: 1, 1.5, and 2.3 mm to assess the performance of the thickness sensing system. The collected data was then used to make graphs. Figure 14(a, b) illustrates the simulated and measured impact of changes in the dielectric constant on the sensor’s behavior. These modifications were achieved by adjusting the mutual and coupling capacitance within the patch. Demonstrating that the resonance frequency changed towards the lower frequency as the DK of the sensor layer rose, proves a relationship between frequency and DK. The resonances of FR-4 at 290 MHz concerning 1 mm and 1.5 mm, 270 MHz concerning 1.5 mm and 2.3 mm, and 560 MHz concerning 1 mm and 2.3 mm thicknesses are displayed in Table 3 as a function of permittivity variations.

The sensing results are analyzed in the first frequency band (2 to 3 GHz), after analyzing it is seen that there is no significant variation in overall results at the first resonance frequency, so it was not mentioned in the manuscript.

Quality factor and sensitivity analysis

The quality factor is an important performance parameter for the microwave sensor. The quality factor (\(\:Q)\) is determined by the following equation63:

Where \(\:{f}_{r}\) stands for resonance frequency and \(\:\varDelta\:f\) denotes + 3 dB bandwidth. In the context of FR-4 materials, the maximum quality factor has been discovered. The aforementioned algorithm has been used to determine the Q-factor, and the result is 325.

To assess the impact of various substrate thicknesses and materials, an extensive sensitivity study is conducted. The obtained sensitivities \(\:S\left(\%\right)\:\)is well-defined as follows64,65:

Where, \(\:{f}_{0}=\) primary frequency (MUT is air), \(\:f=\) changed frequency and \(\:{\epsilon\:}_{r}=\:\)materials permittivity value.

Figure 15(a, b) shows the relative permittivity versus sensitivity (%) curves and thickness versus sensitivity (%) curves. From Eq. (14), it is seen that the sensitivity value is inversely proportional to the substrate permittivity value, so the lower substrate permittivity value shows the higher sensitivity. The obtained simulated sensitivity results have been compared to the measured results as shown in Fig. 15(a).

The overall sensing performance of different MTM sensors is listed in Table 4.

Conclusion

For microwave sensing applications, this study provides a miniature, very sensitive, and dependable metamaterial sensor based on an asymmetric cross-split ring resonator. The suggested metamaterial sensor is created and analyzed using CST-2019 software and integrated on a 1.575 mm wide, low-cost dielectric substrate material Rogers RT5880. Additionally, the CST simulated model is validated using the ADS program. The MATLAB software is used to derive the effective parameters of the suggested unit cell. Simulated results were then validated using laboratory measurements. The tiny, 8\(\:\times\:\)8 mm2 optimized cell has resonances at 2.77, 5.78, 9.82, and 12.29 GHz with notches at 20.54, 36.79, 25.26, and 23.62 dB, respectively. The acceptable range of the dielectric coefficient is 0.25 to 4.5 and the thickness of the sample layer is 0.1 mm to 5 mm which can be measured by the proposed sensor. The sensing capabilities of the developed sensor are examined using three distinct substrate materials and thicknesses. Analysis of the EMR, sensitivity, and quality factor of the sensor yields values of 13.54, 12.03, and percent 325, respectively. Since the sensitivity (S), the figure of merits (FOM), and the quality factor (Q), impact the effectiveness and performance of any sensor type. Due to changes in permittivity and material thickness, the resonances are displaced to 210, 600, and 810 MHz and 290, 270, and 560 MHz, respectively. Every single laboratory result matches the simulated results exactly. Due to its small size, low cost, high sensitivity, and superior performance, the suggested sensor can be used for sensing material thickness as well as glass, plastic, and substrate materials.

Limitations and future work

This work analyses the inherent properties of metamaterial with several key challenges that are developed in some aspects. There are some variations between simulated and measured results, also some unwanted resonance exists in the array output. It is difficult to identify the resonance when the electrical property of the samples is very close. In future work, we will try to reduce the variation between simulated and measured results and unwanted resonance. We will also try to identify the resonance although the permittivity value is very close. The proposed metamaterial will be industrialized by enhancing its field response and required sensing frequency zone using different types of substrates. Further modifications need to be made in terms of sensitivity and quality factor to be implemented in electromagnetic sensing devices in the real world.

Data availability

All data has been included in this manuscript.

References

Itoh, T. & Caloz, C. Electromagnetic Metamaterials: Transmission line Theory and Microwave Applications (Wiley, 2005).

Johnson, M. C., Brunton, S. L., Kundtz, N. B. & Kutz, J. N. Sidelobe canceling for reconfigurable holographic metamaterial antenna. IEEE Trans. Antennas Propag. 63, 1881–1886 (2015).

Nasimuddin, N., Chen, Z. N. & Qing, X. Bandwidth enhancement of a single-feed Circularly Polarized Antenna using a Metasurface: Metamaterial-based wideband CP rectangular microstrip antenna. IEEE Antennas Propag. Mag. 58, 39–46 (2016).

Misran, N., Yusop, S. H., Islam, M. T. & Ismail, M. Y. Analysis of parameterization substrate thickness and permittivity for concentric split ring square reflectarray element. Jurnal Kejuruteraan (Journal Engineering). 23, 11–16 (2012).

Islam, M. R. et al. Square enclosed circle split ring resonator enabled Epsilon negative (ENG) near zero index (NZI) metamaterial for gain enhancement of multiband satellite and radar antenna applications. Results Phys. 19, 103556 (2020).

Ramaccia, D., Sounas, D. L., Alù, A., Bilotti, F. & Toscano, A. Nonreciprocity in antenna radiation induced by space-time varying metamaterial cloaks. IEEE Antennas. Wirel. Propag. Lett. 17, 1968–1972 (2018).

Xiong, H., Long, T. B., Shi, T., Jiang, B. X. & Zhang, J. T. Wideband and polarization-insensitive metamaterial absorber with loading lumped resistors. Appl. Opt. 59, 7092–7098 (2020).

Islam, M. S. et al. A gap coupled hexagonal split ring resonator based metamaterial for S-band and X-band microwave applications. IEEE Access. 8, 68239–68253 (2020).

Islam, M. R., Islam, M. T., Moniruzzaman, M., Samsuzzaman, M. & Arshad, H. Penta band single negative meta-atom absorber designed on square enclosed star-shaped modified split ring resonator for S-, C-, X-and Ku-bands microwave applications. Sci. Rep. 11, 1–22 (2021).

Hakim, M. L., Alam, T., Almutairi, A. F., Mansor, M. F. & Islam, M. T. Polarization insensitivity characterization of dual-band perfect metamaterial absorber for K band sensing applications. Sci. Rep. 11, 1–14 (2021).

Withayachumnankul, W., Jaruwongrungsee, K., Fumeaux, C. & Abbott, D. Metamaterial-inspired multichannel thin-film sensor. IEEE Sens. J. 12, 1455–1458 (2011).

Vafapour, Z., Hajati, Y., Hajati, M. & Ghahraloud, H. Graphene-based mid-infrared biosensor. JOSA B. 34, 2586–2592 (2017).

Bakir, M. Electromagnetic-based microfluidic sensor applications. J. Electrochem. Soc. 164, B488 (2017).

Helsing, J., McPhedran, R. C. & Milton, G. W. Spectral super-resolution in metamaterial composites. New J. Phys. 13, 115005 (2011).

Liu, A., Zhou, X., Huang, G. & Hu, G. Super-resolution imaging by resonant tunneling in anisotropic acoustic metamaterials. J. Acoust. Soc. Am. 132, 2800–2806 (2012).

Bakir, M. et al. Tunable energy harvesting on UHF bands especially for GSM frequencies. Int. J. Microw. Wirel. Technol. 10, 67 (2018).

Bağmancı, M. et al. Wide band fractal-based perfect energy absorber and power harvester. Int. J. RF Microw. Computer‐Aided Eng. 29, e21597 (2019).

Bakir, M., Karaaslan, M., Dincer, F., Akgol, O. & Sabah, C. Electromagnetic energy harvesting and density sensor application based on perfect metamaterial absorber. Int. J. Mod. Phys. B. 30, 1650133 (2016).

Melik, R. et al. Nested metamaterials for wireless strain sensing. IEEE J. Sel. Top. Quantum Electron. 16, 450–458 (2009).

Wu, W., Ren, M., Pi, B., Cai, W. & Xu, J. Displacement sensor based on plasmonic slot metamaterials. Appl. Phys. Lett. 108, 073106 (2016).

Naqui, J., Coromina, J., Karami-Horestani, A., Fumeaux, C. & Martín, F. Angular displacement and velocity sensors based on coplanar waveguides (CPWs) loaded with S-shaped split ring resonators (S-SRR), sensors, 15, pp. 9628–9650, (2015).

Karim, H. et al. Metamaterial based passive wireless temperature sensor. Adv. Eng. Mater. 19, 1600741 (2017).

Schueler, M., Mandel, C., Puentes, M. & Jakoby, R. Metamaterial inspired microwave sensors. IEEE. Microw. Mag. 13, 57–68 (2012).

Park, S., Cha, S., Shin, G. & Ahn, Y. Sensing viruses using terahertz nano-gap metamaterials. Biomedical Opt. Express. 8, 3551–3558 (2017).

Alotaibi, S. A. A. Ultrasenstive Microwave Planar Metamaterial Sensors for Materials Characterization (Georgia Institute of Technology, 2020).

Islam, M. R. et al. ,., Metamaterial Sensor Based on Reflected Mirror Rectangular Split Ring Resonator for the Application of Microwave Sensing, Measurement, p. 111416, (2022).

Ebrahimi, A., Withayachumnankul, W., Al-Sarawi, S. & Abbott, D. High-sensitivity metamaterial-inspired sensor for microfluidic dielectric characterization. IEEE Sens. J. 14, 1345–1351 (2013).

Bakır, M. et al. Metamaterial sensor for transformer oil, and microfluidics. Appl. Comput. Electromagnet. Soc. J. (ACES), pp. 799–806, (2019).

Boybay, M. S. & Ramahi, O. M. Material characterization using complementary split-ring resonators. IEEE Trans. Instrum. Meas. 61, 3039–3046 (2012).

Hoque, A. et al. U-joint double split O (UDO) shaped with split square metasurface absorber for X and Ku band application. Results Phys. 15, 102757 (2019).

Islam, M., Islam, M. T., Bais, B., Almalki, S. H. & Alsaif, H. Metamaterial sensor based on rectangular enclosed adjacent triple circle split ring resonator with good quality factor for microwave sensing application. Sci. Rep. 12, 1–18 (2022).

Ahamed, E., Faruque, M. R. I., Mansor, M. F. B. & Islam, M. T. Polarization-dependent tunneled metamaterial structure with enhanced fields properties for X-band application. Results Phys. 15, 102530 (2019).

Withayachumnankul, W., Jaruwongrungsee, K., Tuantranont, A., Fumeaux, C. & Abbott, D. Metamaterial-based microfluidic sensor for dielectric characterization. Sens. Actuators A: Phys. 189, 233–237 (2013).

Abduljabar, A. A., Rowe, D. J., Porch, A. & Barrow, D. A. Novel microwave microfluidic sensor using a microstrip split-ring resonator. IEEE Trans. Microwave Theory Tech. 62, 679–688 (2014).

Alsaif, H. et al. Dual circular complementary split ring resonator based metamaterial sensor with high sensitivity and quality factor for textile material detection. APL Mater., 12, (2024).

Salim, A. & Lim, S. Complementary split-ring resonator-loaded microfluidic ethanol chemical sensor, Sensors, vol. 16, p. 1802, (2016).

Albishi, A. M., Boybay, M. S. & Ramahi, O. M. Complementary split-ring resonator for crack detection in metallic surfaces. IEEE Microwave Wirel. Compon. Lett. 22, 330–332 (2012).

Hoque, A. et al. A Polarization Independent Quasi-TEM Metamaterial Absorber for X and Ku Band Sensing Applications, sensors, vol. 18, p. 4209, (2018).

Sunbeam Islam, S., Rashed Iqbal, M., Faruque & Tariqul Islam, M. An ENG metamaterial based wideband electromagnetic cloak. Microw. Opt. Technol. Lett. 58, 2522–2525 (2016).

Albishi, A. & Ramahi, O. M. Detection of surface and subsurface cracks in metallic and non-metallic materials using a complementary split-ring resonator, Sensors, vol. 14, pp. 19354–19370, (2014).

Billa, M. B. et al. Polarization insensitive multiband metamaterial absorber for bio-plastic sensing application. Mater. Today Sustain. 26, 100738 (2024).

Saadat-Safa, M., Nayyeri, V., Khanjarian, M., Soleimani, M. & Ramahi, O. M. A CSRR-based sensor for full characterization of magneto-dielectric materials. IEEE Trans. Microwave Theory Tech. 67, 806–814 (2019).

Abdulkarim, Y. I. et al. Design and study of a metamaterial based sensor for the application of liquid chemicals detection. J. Mater. Res. Technol. 9, 10291–10304 (2020).

Altintas, O. et al. Fluid, strain and rotation sensing applications by using metamaterial based sensor. J. Electrochem. Soc. 164, B567 (2017).

Kumari, R., Patel, P. N. & Yadav, R. An ENG resonator-based microwave sensor for the characterization of aqueous glucose. J. Phys. D. 51, 075601 (2018).

Zhang, W., Li, J. Y. & Xie, J. High sensitivity refractive index sensor based on metamaterial absorber. Progress Electromagnet. Res. M. 71, 107–115 (2018).

Bakir, M. et al. Sensory applications of resonator based metamaterial absorber, Optik, vol. 168, pp. 741–746, (2018).

Islam, M. R. et al. Tri Circle Split Ring Resonator shaped Metamaterial with Mathematical modeling for oil concentration sensing. IEEE Access. 9, 161087–161102 (2021).

Salim, A., Memon, M. U. & Lim, S. Simultaneous Detection of Two Chemicals Using a TE20-Mode Substrate-Integrated Waveguide Resonator, Sensors, vol. 18, p. 811, (2018).

Altintas, O., Aksoy, M., Unal, E., Karakasli, F. & Karaaslan, M. A split meander line resonator-based permittivity and thickness sensor design for dielectric materials with flat surface. J. Electron. Mater. 47, 6185–6192 (2018).

Islam, M. T., Islam, M. R., Islam, M. T., Hoque, A. & Samsuzzaman, M. Linear regression of sensitivity for meander line parasitic resonator based on ENG metamaterial in the application of sensing. J. Mater. Res. Technol. 10, 1103–1121 (2021).

Bakır, M., Karaaslan, M., Dinçer, F., Delihacioglu, K. & Sabah, C. Tunable perfect metamaterial absorber and sensor applications. J. Mater. Sci.: Mater. Electron. 27, 12091–12099 (2016).

Zhang, W., Li, J. Y. & Xie, J. High sensitivity refractive index sensor based on metamaterial absorber. Progress Electromagnet. Res. 71, 107–115 (2018).

Studio, C. M. CST Studio suite. Comput. Simul., (2010).

Rothwell, E. J., Frasch, J. L., Ellison, S. M., Chahal, P. & Ouedraogo, R. O. Analysis of the Nicolson-Ross-Weir method for characterizing the electromagnetic properties of engineered materials. Progress Electromagnet. Res. 157, 31–47 (2016).

Luukkonen, O., Maslovski, S. I. & Tretyakov, S. A. A stepwise Nicolson–Ross–Weir-based material parameter extraction method. IEEE Antennas. Wirel. Propag. Lett. 10, 1295–1298 (2011).

Paul, C. R. Inductance: Loop and Partial (Wiley, 2011).

Gay-Balmaz, P. & Martin, O. J. Electromagnetic resonances in individual and coupled split-ring resonators. J. Appl. Phys. 92, 2929–2936 (2002).

Chen, T. S. Determination of the capacitance, inductance, and characteristic impedance of rectangular lines. IRE Trans. Microw. Theory Techniques. 8, 510–519 (1960).

Karami, M., Rezaei, P., Kiani, S. & Sadeghzadeh, R. Modified planar sensor for measuring dielectric constant of liquid materials. Electron. Lett. 53, 1300–1302 (2017).

Moniruzzaman, M., Islam, M. T., Islam, M. R., Misran, N. & Samsuzzaman, M. Coupled ring split ring resonator (CR-SRR) based Epsilon negative metamaterial for multiband wireless communications with high effective medium ratio. Results Phys. 18, 103248 (2020).

Islam, M. R., Samsuzzaman, M., Misran, N., Beng, G. K. & Islam, M. T. A tri-band left-handed meta-atom enabled designed with high effective medium ratio for microwave based applications. Results Phys. 17, 103032 (2020).

Omer, A. E. et al. Low-cost portable microwave sensor for non-invasive monitoring of blood glucose level: novel design utilizing a four-cell CSRR hexagonal configuration. Sci. Rep. 10, 1–20 (2020).

Abdolrazzaghi, M., Daneshmand, M. & Iyer, A. K. Strongly enhanced sensitivity in planar microwave sensors based on metamaterial coupling. IEEE Trans. Microwave Theory Tech. 66, 1843–1855 (2018).

Abdolrazzaghi, M., Katchinskiy, N., Elezzabi, A. Y., Light, P. E. & Daneshmand, M. Noninvasive glucose sensing in aqueous solutions using an active split-ring resonator. IEEE Sens. J. 21, 18742–18755 (2021).

Meyne, N., Fuge, G., Zeng, A. P. & Jacob, A. F. Resonant microwave sensors for picoliter liquid characterization and nondestructive detection of single biological cells. IEEE J. Electromagnet. RF Microwaves Med. Biology. 1, 98–104 (2017).

Massoni, E., Siciliano, G., Bozzi, M. & Perregrini, L. Enhanced cavity sensor in SIW technology for material characterization. IEEE Microwave Wirel. Compon. Lett. 28, 948–950 (2018).

Wu, J. et al. Design and validation of liquid permittivity sensor based on RCRR microstrip metamaterial. Sens. Actuators A: Phys. 280, 222–227 (2018).

Jun, S. Y., Izquierdo, B. S. & Parker, E. A. Liquid sensor/detector using an EBG structure. IEEE Trans. Antennas Propag. 67, 3366–3373 (2019).

Gargari, A. M., Zarifi, M. H. & Markley, L. Passive matched mushroom structure for a high sensitivity low profile antenna-based material detection system. IEEE Sens. J. 19, 6154–6162 (2019).

Kiani, S., Rezaei, P. & Navaei, M. Dual-sensing and dual-frequency microwave SRR sensor for liquid samples permittivity detection, Measurement, vol. 160, p. 107805, (2020).

Kazemi, N., Abdolrazzaghi, M., Musilek, P. & Baladi, E. A planar compact absorber for microwave sensing based on transmission-line metamaterials. IEEE Sens. J., (2024).

Abdolrazzaghi, M., Kazemi, N., Nayyeri, V. & Martin, F. AI-assisted ultra-high-sensitivity/resolution active-coupled CSRR-based sensor with embedded selectivity, Sensors, vol. 23, p. 6236, (2023).

Acknowledgements

The authors would like to acknowledge to the Fundamental Research Grant Schemes (FRGS) under the grant number FRGS/1/2022/TK07/UKM/01/3. Also, the authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through Project number (TU-DSPP-2024-11).

Funding

The authors acknowledge the Fundamental Research Grant Schemes (FRGS), grant number FRGS/1/2022/TK07/UKM/01/3 funded by the Ministry of Higher Education (MOHE), Malaysia. Also, this research was funded by Taif University, Saudi Arabia, Project No. (TU-DSPP-2024-11)

Author information

Authors and Affiliations

Contributions

Conceptualization, M.R.I., M.T.I., A.H., and B.B.; Data curation, M.R.I., A.H., B.B., and M.S.I.; Formal analysis, M.R.I., M.T.I., and B.B.; Funding acquisition, M.T.I., B.B., M.S.S., and M.S.I.; Investigation, M.R.I., M.S.I., and B.B.; Methodology, M.R.I., M.T.I., and H.A.; Visualization, M.R.I., M.T.I., H.A., and M.S.S.; Writing—original draft, M.R.I., M.T.I., A.H., and B.B.; Writing—review and editing, B.B., M.S.I., H.A., and M.S.I.; Software and Resources, M.T.I.; Supervision, M.T.I.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Islam, M.R., Islam, M.T., Hoque, A. et al. Quad-band split ring resonator-based sensor for microwave sensing application. Sci Rep 15, 6888 (2025). https://doi.org/10.1038/s41598-025-90245-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-90245-3