Abstract

The instability of the electrode/electrolyte interface and the metal-ions dissolution of high-voltage LiNi0.5Mn1.5O4 (LNMO) material lead to significant degradation of cycling performance, thereby limiting the large-scale application of LNMO-based batteries. Here, inorganic Mg/Ca/Sr-contained phosphates (MgHPO4, CaHPO4, and SrHPO4) are used individually as functional additives of standard electrolytes to enhance the cycling performance of LNMO. Combined with theoretical calculations, a series of electrochemical measurements and characteristics corroborate that the MgHPO4 is the optimal additive and can preferentially undergo oxidation and reduction decomposition over carbonate solvents. Electrochemical results reveal that the LNMO/Li half-cell containing the MgHPO4 additive shows a capacity retention of 91.9% after 500 cycles at 5 C, higher than that obtained with STD (76.5%). In addition, the LNMO/graphite (Gr) full-cell with MgHPO4 additive increases the capacity retention from 70.8 to 78.0% after 100 cycles at 0.5 C. The addition of MgHPO4 allows a thin, uniform, and conductive cathode-electrolyte interphase (CEI) and solid-electrolyte interphase (SEI) film to be formed on the LNMO cathode and graphite anodes. Furthermore, the preferential reduction of MgHPO4 inhibits the lithium dendritic growth and enables the formation of a more stable SEI on the Li anode. Besides, the MgHPO4 additive serves as a scavenger of detrimental HF, thus suppressing the Ni/Mn ions dissolution and improving the structural stability of LNMO. This study provides a cost-effective strategy involving the use of an inorganic additive for improving the electrochemical performance of high-voltage lithium-ion batteries.

Similar content being viewed by others

Introduction

With the rise of global environmental awareness and the transformation of the energy structure, new-energy vehicles (NEVs) including pure-electric vehicles (EVs) and hybrid-electric vehicles (HEVs) have been increasingly developed1,2. However, NEVs currently underperform fuel vehicles in terms of cruising range, safety, and cost. The development of NEVs relies mostly on the improvement of lithium-ion batteries (LIBs), one of the core components of NEVs accounting for more than 40% of the total vehicle cost3,4,5,6,7. Hence, high-energy LIBs have become a hot topic in recent years. LNMO benefits from a high energy density (610 Wh/kg), high operating voltage (4.7 V), fast three-dimensional Li+ diffusion channels, and a low cost, which is considered as a cathode material with great application prospect8. However, some difficulties still need to be solved in this system. (i) The redox potential of Ni2+/Ni4+ in LNMO material exceeds that required for preserving the stability of the industrial electrolyte system (at ca. 4.3 V). Thus, the surface of the electrode material undergoes violent side reactions by the electrolyte decomposition during the charge/discharge process, which leads to a thicker and more uneven CEI film on the LNMO surface, thus hindering Li+ transmission and increasing the battery impedance. (ii) The oxidation decomposition of electrolyte under high voltage will produce harmful HF, which is highly corrosive towards the cathode and cause the dissolution of transition metal ions (Ni and Mn). The Ni and Mn elements will migrate to the Gr anode in the LNMO/Gr full-cell, which reduces Li+ ions in LNMO cathode and deteriorates SEI film on graphite, leading to capacity degradation and sharp decline in cycling performance of the battery. (iii) The electrolyte-reduction decomposition can induce the growth of lithium dendrites in the LNMO/Li half-cell, which also gives rise to the formation of a nonuniform SEI film on the Li anode. These aforementioned difficulties can lead to degradation of batteries cycling performance, ultimately limiting the large-scale commercialization of LNMO materials9,10. Therefore, it is urgent to develop a high-voltage electrolyte system compatible with LNMO to construct a stable electrode/electrolyte interface film to improve the cyclability of the batteries.

According to the previous reports, there are several methods to obtain high-voltage electrolyte system, including increasing the concentration of lithium salt11, adding functional electrolyte additives12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39, and developing new electrolyte systems (such as all-fluorinated electrolytes40,41,42 and sulfone-based electrolytes43,44. Among them, the addition of a small amount of functional electrolyte additives, such as lithium salts derivatives12,13,14,15, phosphorous compounds16,17,18,19,20,21, sulfur-containing compounds22,23, boron-containing compounds24,25,26,27, silane and its derivatives28,29,30,31, nitrogen-derivatives32,33,34, and unsaturated carbon compounds35,36,37,38,39, to the carbonate-based electrolyte represents the simplest, most cost-effective, and most feasible way to reduce the parasitic reactions and stabilize the CEI and SEI films45,46. Among these additives, the phosphorous compounds are the most relevant because of their unique advantages in stabilizing the structure of the cathode materials and their flame retardancy. For example, Zhu et al. synthesized diethyl 2-(thiophenemethyl)phosphonate (DTYP) as a multifunctional cathode film-forming additive. Upon addition of 0.5 wt% of DTYP, the LNMO/Li cell with 0.5 wt% of DTYP additive delivered a capacity retention of 85% after 280 cycles at a high temperature of 60 °C and 1 C. Moreover, DTYP also reduces the electrolyte self-extinguishing time from 88 s to 77 s. Nevertheless, DTYP failed to prevent Li dendrite growth on the surface of Li anode16. Kim et al. demonstrated that lithium bis(trimethylsilyl) phosphate (LiTMSP) as a bifunctional additive for LNMO/Gr full-cells. The LiTMSP additive not only generated the SEI film on the graphite anode but also scavenged HF by generating TMS-F. The LNMO/Gr full-celll with 0.5 wt% LiTMSP improved the capacity retention from 21.8% (STD electrolyte) to 39.6% at 45 °C17. However, most phosphorous compounds are organic additives, which may require a sophisticated synthesis procedure and high synthesis cost. In addition, most of these organic phosphorus compounds are cathode film-forming additives and do not have a positive effect on graphite anode. Given the beneficial effects of the phosphorous additives, additional inorganic phosphorous as the multifunctional cathode and anode film-forming additives should be developed to improve the electrochemical properties of LNMO batteries. Pioneering work with inorganic phosphorous additives have been reported47,48. For example, Lee et al. used inorganic NaH2PO4 as a cathode film-forming additive to improve the electrochemical performances of LiNi0.8Co0.1Mn0.1O2/Gr and LiMn2O4/Gr batteries, respectively47,48. However, NaH2PO4 did not involve in the film formation on the graphite anode. In our previous report, the inorganic LiPO3 additive was used as a cathode film-forming additive to enhance the electrochemical performance of LNMO/Li and LNMO/LTO batteries. Disappointingly, the LiPO3 did not work on the graphite anode49.

To further enhance the cyclability of LNMO-based LIBs, we herein proposed three inorganic phosphates composed of Mg2+/Ca2+/Sr2+ cations and HPO42− anions-MgHPO4, CaHPO4, and SrHPO4-as electrolyte additives. Especially for the electrolyte contained MgHPO4 additive, it not only keeps a capacity retention of 91.9% after 500 cycles at 5 C in LNMO/Li half-cell, which is higher than that obtained with STD (76.5%), but also can increase the cyclic stability of LNMO/Gr full cell (78.0% capacity retention) after 100 cycles at 0.5 C. The addition of MgHPO4 allows a thin, uniform, and conductive CEI and SEI films to be formed on the surface of LNMO and Gr. Furthermore, the preferential reduction of MgHPO4 inhibits the lithium dendritic growth and enables a more stable SEI film generated on the Li anode. The participation of MgHPO4 in constructing the CEI/SEI films and improving the electrochemical properties of LNMO/Li half-cells and LNMO/Gr full-cells were revealed in detail by physic-chemical characterizations. In addition, MgHPO4 exhibited the strongest binding energy with HF compared with CaHPO4, SrHPO4, and carbonate solvents, which suppressed the transition metal ions dissolution and enhanced the structural stability of LNMO.

Results and discussions

Electrochemical activity of the MgHPO4, CaHPO4, and SrHPO4additives and the electrochemical performance of LNMO/Li cells

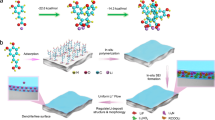

In general, the frontline molecular orbital theory is used to predict the oxidation and reduction trends of compounds. Based on this theory, the higher the HOMO energy level of compounds, the lower their oxidation potential and the more easily they are oxidized. Conversely, the lower the LOMO energy level of compounds, the higher their reduction potential and the more easily the compounds can be reduced46. The HOMO and LOMO energies of DMC, EMC, EC, MgHPO4, CaHPO4, and SrHPO4 were calculated by DFT (Fig. 1a). Compared with the carbonate solvents of DMC (− 8.23 eV), EMC (− 8.18 eV), and EC (− 8.47 eV), all of the inorganic additives (including MgHPO4 (− 7.34 eV), CaHPO4 (− 6.72 eV), and SrHPO4 (− 6.55 eV)) exhibited higher HOMO energies, thereby revealing that MgHPO4, CaHPO4, and SrHPO4 additives are prone to be oxidized at a lower potential during the charging process. Furthermore, all the inorganic MgHPO4, CaHPO4 and SrHPO4 additives also exhibited lower LOMO energies than the carbonate solvents, and the sequence of molecular reduction trends was MgHPO4 > SrHPO4 > CaHPO4 > DMC = EMC > EC, thereby revealing that MgHPO4 is more prone to be reduced at a higher potential on the anode surface during the discharging process. To confirm the DFT calculation results, LSV tests of STD, STD-Mg, STD-Ca, and STD-Sr electrolytes were performed at 0.5 mV s− 1 to examine the oxidation capability of the additives (Fig. 1b). The oxidation peaks of STD-Mg, STD-Ca, and STD-Sr were located at ca. 3.5, 3.4, and 3.8 V, below the STD point (4.0 V) and the enlarged LSV curves were shown in Figure S1(a), indicating the additives preferentially undergo oxidative decomposition before solvent molecules, in line with the DFT calculations.

(a) The calculated HOMO and LUMO energies of DMC, EC, EMC, MgHPO4, CaHPO4 and SrHPO4; (b) LSV curves of STD, STD-Mg, STD-Ca, and STD-Sr electrolytes; (c) CV curves for the graphite/Li half cells in the four electrolytes at 0.05 mV s− 1 in the first cycle; (d) voltage profiles of the Li||Li symmetric cells in the four electrolytes obtained a current density of 1 mA∙cm− 2 and an areal capacity of 1 mAh∙cm− 2; (e) CA curves of LNMO/Li half-cells in the four electrolytes; (f) Self-discharged curves of LNMO/Li half cells in the four electrolytes for 90 h.

Figure 1c showed the CV tests of Gr/Li cells to study the effects of reduction activity of MgHPO4, CaHPO4, and SrHPO4 additives on the Gr anode. The CV curve using STD electrolyte showed a reduction peak at around 0.7 V in the first cycle, which was ascribed to the reduction decomposition of the carbonate solvents and thus generated a SEI film on the Gr surface. However, the addition of MgHPO4, CaHPO4, and SrHPO4 additives caused the initial reduction potential to shift to a higher potential (at ca. 0.77 V), revealing that the three additives prompted the formation of SEI film on graphite in advance50. Compared with the CV curves with STD, STD-Ca, and STD-Sr electrolytes, the peaks of carbonate solvents decomposition at 0.7 V were significantly lower in intensity with the STD-Mg electrolyte, indicating that MgHPO4 exhibits the strongest reduction activity, corresponding to the DFT calculations. Figure S1(b) shows the diagrams of Gr/Li cells during the second cycle. The peaks of carbonate solvents decomposition at 0.7 V are also absent for the four electrolyte systems, revealing that the SEI film already formed in the first circle51. To further evaluate the effect of the additives on the Li electrode, the Li||Li symmetric cells tests were performed and the voltage-time profiles were obtained with various electrolytes in Fig. 1d. The Li||Li symmetric cell failed to work in STD after ca. 310 h, probably because of the generation of Li dendrite and the internal short circuit10, while the cell in STD-Mg exhibited a more stable Li plating/stripping behavior and delivered the optimal stability for ca. 500 h compared with those in STD-Ca and STD-Sr. The improvement electrochemical stability of the Li||Li cell with MgHPO4 may be attributed to the Mg2+ being reduced to Mg on the Li surface, which not only inhibited the lithium dendritic growth but also facilitated Li+ transmission52. Therefore, MgHPO4 is the optimal additive that can preferentially undergoes electrochemical oxidation/reduction decomposition to form protective films on LNMO, Gr and Li electrodes to inhibit electrolyte decomposition.

To study the effect of MgHPO4, CaHPO4, and SrHPO4 additives on the inhibition of electrolyte decomposition, CA tests of the LNMO/Li cell were carried out. The larger the leakage current value, the more obvious the electrolyte oxidation decomposition. The leakage current in the STD electrolyte was larger than those in STD-Mg, STD-Ca, and STD-Sr electrolytes in Fig. 1e. Also, the LNMO/Li cell in STD-Mg delivered the smallest leakage current, revealing that the MgHPO4, CaHPO4, and SrHPO4 additives were effective in reducing the electrolyte decomposition, and MgHPO4 exhibited the strongest passivation ability at high temperature. Notably, the leakage current in STD increased during the first 2 h of the experiment, probably because more HF was generated at high voltage and temperature, which exacerbates the electrolyte oxidative decomposition39. Figure 1f showed the self-discharges of the LNMO/Li cells in the four electrolytes for 90 h at 60 °C. The voltage plateaus at ca. 4.7 V was ascribed to the reduction reaction of Ni4+ to Ni2+. Moreover, the plateaus at ca. 4.0 and 2.7 V corresponded to the reduction reaction of Mn4+ to Mn3 + 53. Obviously, the potential of the LNMO/Li cell in STD suffered great decline after the high temperature storage. On the contrary, the LNMO/Li cells with additive electrolytes suffered slightly potential declines, especially the LNMO/Li cell with STD + Mg electrolyte remaining the voltage platform at 4.7 V after storage. These phenomena indicate that the MgHPO4 additive generates more protective CEI/SEI films at the initial cycle, which protects the electrodes and inhibit the continuous electrolyte decomposition.

To evaluate the HF removal ability of the additives, 1vol% H2O was individually added to STD, STD-Mg, STD-Ca, and STD-Sr electrolytes and then the electrolytes were stored in a glove box for 15 days before the 19F and 31P NMR tests. Figure 2a and shows the19F NMR spectra of all electrolytes. STD showed a peak at around − 155 ppm ascribed to HF, which was produced by the hydrolysis of LiPF649,51. However, the HF peaks are very small in STD-Mg electrolyte, and the peak intensity of HF in STD-Ca and STD-Sr electrolytes was lower than that in STD electrolyte47,48. The31P NMR spectra revealed peaks of PO2F− 2 (located at around − 16.6, − 15.5, and − 12.1 ppm) and PO3F − 2(centered at around − 9.4 and − 5.5 ppm) species as decomposition products of LiPF6 (Fig. 2b). The peak intensities of PO3F − 2and PO2F− 2 in STD-Mg and STD-Ca are lower than those in STD-Sr and STD electrolytes, while the peak intensities of LiPF6 in STD-Mg were the highest among all the electrolytes. These results indicate that all the MgHPO4, CaHPO4, and SrHPO4 additives can remove HF from the electrolytes and inhibit LiPF6 decomposition, with the HF removal ability following the trend MgHPO4 > CaHPO4 > SrHPO4. It is well known that the presence of HF in the electrolyte can inevitably accelerate the Ni/Mn transition metal ions dissolution from LNMO material, especially at high temperature31. The Ni/Mn dissolution behavior of LNMO powders in different electrolytes was studied by ICP-OES tests in Fig. 2c. The amounts of Ni/Mn dissolution were 0.495/0.924, 0.413/0.274, 0.382/0.442, and 0.590/0.819 ppm in STD, STD-Mg, STD-Ca, and STD-Sr electrolytes, respectively. These results reveal that the MgHPO4 additive exhibits the optimal ability to inhibit the Ni/Mn dissolution (especially Mn ions), in line with the above results. Figure 2d shows the binding energies of HF with carbonate solvents and additives obtained by DFT. The bonding ability trend was MgHPO4-HF (− 49.21 KJ mol− 1) > EMC-HF (− 27.98 KJ mol− 1) = DMC-HF (− 27.02 KJ mol− 1) > EC-HF (− 28.94 KJ mol− 1) > CaHPO4-HF (− 19.30 KJ mol− 1) > SrHPO4-HF (− 16.40 KJ mol− 1), suggesting that MgHPO4 possessed the highest ability as HF scavenger, in line with the NMR and ICP-OES results.

(a, b) 19F NMR spectra of STD, STD-Mg, STD-Ca, and STD-Sr electrolytes with H2O after storage for 15 days at 25 °C; (c) The content of Ni/Mn elements in the electrolytes after immersing the fresh LNMO powders in the four electrolytes for 25 days at 60 °C; (d) Optimized structures and binding energies of HF with DMC, EC, EMC, MgHPO4, CaHPO4 and SrHPO4.

The rate capabilities of LNMO/Li cells in the four electrolytes were shown in Fig. 3a. Obviously, the MgHPO4 was more effective at high C-rates than CaHPO4 and SrHPO4, and that LNMO/Li cells with MgHPO4 additive exhibited the best rate performance. Particularly, the discharge capacities of the LNMO/Li cell in STD + Mg were measured to be 104.3 and 83.8 mAh g− 1 at 5 and 7 C, respectively, while the LNMO/Li cell in STD electrolyte were only 80.3 and 61.7 mAh g− 1, respectively and the discharge capacities at various C-rates are listed in Table 1. Both the coulomb efficiency at the first cycle at 0.2 C (Fig. 3b) and the charge-discharge curves with and without additives (Figure S2(a-d)) revealed LNMO/Li cell with MgHPO4 additive exhibited the largest coulomb efficiency and the smallest electrode polarization. According to the previous reports, the LNMO/Li cell with a thick and unstable CEI films on the electrodes during the charge/discharge process typically resulted in higher levels of electrode polarization and thereby impeded the Li+ transport at the electrode-electrolyte interface, leading to poor rate performance46. Compared with STD, the LNMO/Li cells containing CaHPO4 and SrHPO4 delivered lower discharge capacities at 7 and 10 C, probably because the CEI film derived from CaHPO4 and SrHPO4 additives were unstable and cannot inhibit the interfacial parasitic reaction during Li+ intercalation/deintercalation process. It can be speculated that the MgHPO4 additive may facilitate the generation of a stable and conductive CEI film, stabilizing the electrode-electrolyte interface and thus improving the rate capability of the LNMO/Li cell49.

(a) Rate capability of LNMO/Li cells in the four electrolytes from 0.2 C to 10 C; (b) corresponding coulombic efficiency of LNMO/Li cells in the four electrolytes; (c) Cycling performances of LNMO/Li cells in the four electrolytes for 500 cycles at 1 C between 3.5 and 5.0 V; (d) The galvanostatic charge/discharge curves of LNMO/Li cells in the electrolytes in the 500th cycle at 1 C; (e) Cycling performances of LNMO/Li cells in different electrolytes for 500 cycles at 5 C; (f) The galvanostatic charge/discharge curves of LNMO/Li cells in the electrolytes in the 500th cycle at 5 C.

The cycling performance curves of the LNMO/Li cells with and without additives at 1 C after 500 cycles were shown in Fig. 3c. The LNMO/Li cells with additive electrolytes displayed better cycling performances than the cell with STD. The LNMO/Li cell with MgHPO4 exhibited the optimal discharge capacity (112.8 mAh g− 1) and capacity retention (86.0%) after cycling stability with a highest 500 cycles, while the LNMO/Li cell in STD only maintained the discharge capacity and capacity retention of 75.6 mAh g− 1 and 65.4%, respectively (Table 2). The cycling results indicate that MgHPO4 can suppress the electrolyte-interface parasitic reaction and generate a more stable CEI film on the LNMO surface. The cyclic stability at high C-rate is an important indicator revealing the practical application of LNMO material. Figure 3d shows the cycling property of LNMO/Li cells after 500 cycles at 5 C. The LNMO/Li cell in STD + Mg also showed the highest capacity retention (91.9%) among the four electrolytes, whereas the LNMO/Li cell with STD electrolyte merely maintained a capacity retention of only 76.5%. Figure 3e,f show the charge/discharge curves of LNMO/Li cells with the four electrolytes in the 500th cycles at 1 C and 5 C, respectively. These results indicated that the LNMO/Li cell containing the MgHPO4 additive exhibited the smallest potential differences, suggesting that the MgHPO4 reduced the electrode polarization and increased the stability of the electrode/electrolyte interface during cycling.

To investigate the effects of MgHPO4 on the LNMO surface, SEM and TEM tests were performed by extracting the LNMO cathode from the LNMO/Li cell after 500 cycles at 5 C. The LNMO electrode before cycling exhibits a smooth surface with clear edge in Fig. 4a,b. Figure 4c revealed that the LNMO particles with STD electrolyte were wrapped with more rough sediments and some particles were cracked and damaged, which was ascribed to the HF attack to LNMO particles during cycling21,36. The coverage on the surface of LNMO was also nonuniform and thick, according to TEM observations in Fig. 4d. In contrast, the LNMO particles in the STD + Mg electrolyte maintained a complete octahedral shape and possessed relatively less sediments in Fig. 4e. Furthermore, TEM revealed a more continuous, uniform, and thinner CEI film coated on the surface of the LNMO (Fig. 4f. Furthermore, the EDX mapping of the cycled LNMO with STD + Mg electrolyte at 0.2 C after 3 cycles in Figure S3 revealed the presence of the C, O, F, Ni, Mn, P and Mg elements in the cycled LNMO. These results reveal that both the Mg2+ and HPO42− ions from MgHPO4 additive participated in the CEI film formation. This CEI film not only effectively inhibited the electrolyte decomposition but also protected LNMO particles from the HF erosion, thereby prompting the Li+ diffusion and reducing the electrode impedance of the battery as discussed below in Fig. 7.

SEM and TEM images of LNMO electrodes, (a, b) before cycling; (c, d) after 500 cycles at 5 C in STD electrolyte; (e, f) after 500 cycles at 5 C in STD + Mg electrolyte; The XPS spectra of LNMO electrodes in STD and STD + Mg electrolytes after 500 cycles at 5 C, (g) C 1s, (h) O 1s, (i) F1s, (j) P 2p.

To analyze the composition of CEI film on the surface of LNMO, XPS tests were conducted on the LNMO electrodes with and without the MgHPO4 additive after 500 cycles at 5 C. The XPS spectra of C 1s in the CEI film of the cycled LNMO cathodes as well as that of the fresh LNMO were shown in Fig. 4g. The characteristic peaks of C–F, C–O, C–H, and C–C species were located at 291.2, 286.8, 285.0, and 284.8 eV respectively. Among them, the peak corresponding to C–C is the conductive agent SP and C–O is the carbon oxide resulting from SP, while the peaks of C–F and C–H correspond to PVDF51. After cycling, the C 1s spectra appeared the C = O (289.9 V) peaks, indicating the presence of alkyl lithium salts such as ROLi and RCO3Li, mainly owing to the oxidative decomposition products of solvents and LiPF625. Comparatively, the peaks of C = O with STD are more intense compared to than those obtained with STD + Mg, indicating that the MgHPO4 additive can inhibit the electrolyte decomposition, in line with the above characterizations and electrochemical results. In the O 1s spectra, the peaks of Me–O (530.2 eV) were visible on the fresh LNMO surface in Fig. 4h. Regardless of the additives added, the Me–O peak nearly disappeared compared with the fresh electrode, which is caused by the sediments wrapped around the LNMO particles. However, the peak intensities of C–O and C = O are obviously lower with the STD + Mg electrolyte than that with STD, in line with the C 1s spectra results. Figure 4i showed that the F 1s spectra contains characteristic peaks of PVDF (688.2 eV), LixPFyOz/LixPFy (687.3 eV), and LiF (685.2 eV). The LixPFyOz/LixPFy and LiF were mainly produced by the electrolyte decomposition after cycling, and more LiF will lead to the increase of electrode polarization and interface impedance of LNMO/Li cell37. The intensities of the peaks of LixPFyOz/LixPFy and LiF with STD + Mg were significantly lower than those obtained with STD electrolyte, which matches well with the EIS results, as discussed below. Similarly, the peak intensities of LixPFyOz (134.3 eV) and LixPFy (135.5 eV) with the STD electrolyte were obviously higher than those with STD + Mg electrolytes in the P 2p spectra. Moreover, the P–O peak (133.8 eV) was only visible with STD + Mg electrolyte, being absent for the STD electrolyte (Fig. 4j)23.

TOF-SIMS tests of the cycled LNMO electrodes in STD and STD + Mg electrolytes were performed to explicate the effect of MgHPO4 additive on the composition of CEI film and the 2D distributions of CH2+, Li2F+, Mn+, and Ni+ species are shown in Fig. 5a,b. As known, the CH2+ and Li2F+ spectra are corresponding to the fragment ions of the electrolyte decomposition products of carbonate solvents and LiPF6 salts, respectively49. Notably, the contents of CH2+ and Li2F+ species on the CEI film with STD + Mg were less than those with STD electrolyte, corroborating that the incorporation of MgHPO4 inhibited the decomposition reactions of electrolyte, consistent with the XPS results of C1s and F1s spectra. Besides, the higher contents of Mn+ and Ni+ species on the CEI film with STD were attributed to the terrible shuttle effect of transition metal ions, in agreement with both of the XPS spectra of Ni/Mn 2p and ICP-OES results of Li anode after 500 cycles as below.

Figure 6a–c showed the SEM images of Li anodes after 500 cycles at 5 C. Compared with the fresh Li anode with a clean surface, the Li surface with STD electrolyte was found to be covered with some sediments with rod-shaped structures and delivered a thick and loose SEI film in Fig. 6b, resulting in the increased interface impedance. Moreover, the Li dendrities formed on the Li anode owing to the unevenness of Li+ plating, which could lead to an internal short circuit and fast capacity fading of the cell10,49. Surprisingly, the Li anode in STD + Mg electrolyte showed a thin and flat surface morphology, with no obvious Li dendrities formation in the generated deposition products (Fig. 6c), demonstrating that the MgHPO4 additive can generate a passivation and stable SEI film on the Li anode, thereby favoring the Li+ transmission and prolongs the LNMO/Li cell cycle life49. The composition of the SEI film on the Li surface was analyzed by XPS, as shown in Fig. 6d–g. In the P 2p spectra, the peak intensities of LiPxFy and LixPOyFz and LiF in F1s spectra with STD + Mg were significantly lower than those obtained with the STD electrolyte, demonstrating that the reductive decomposition of the MgHPO4 additive suppressed the electrolyte decomposition and generated a thin SEI film on the Li anode, thus reducing the electrode polarization and beneficial for the cycling performances of LNMO/Li cells at 1 and 5 C. Figure 6f,g showed the XPS spectra of Ni 2p and Mn 2p on the Li anode, resulting from the Ni and Mn dissolution from LNMO during the charge/discharge process. The peak intensities of Ni 2p and Mn 2p in STD + Mg electrolyte were lower than those in STD. The contents Ni and Mn ions on the Li anode detached from the LNMO/Li cells were also examined through the ICP-OES test (Figure S4). The values of Ni/Mn (1.0/4.2 ppm) with STD + Mg were much lower than those with STD electrolyte (5.9/2.7 ppm) These results further confirmed that the dissolution of Ni and Mn ions was effectively suppressed via the redox reaction of MgHPO4 additive formed the protective CEI/SEI films on the electrodes54. In addition, the EDX-mapping of the cycled Li electrode showed the presence of C, O, F, P, and Mg elements in Figure S5. SEM, TEM, XPS and TOF-SIMS results of the LNMO cathode and Li anode electrodes confirmed that the MgHPO4 additive participated in the construction of a thin CEI film composed of Mg-derivative and P–O derivative and SEI film containing Mg-derivative through its redox decomposition, which helps stabilize the electrode/electrolyte interface and suppresses the growth of lithium dendrites, thereby enhancing the electrochemical property of the LNMO/Li cell.

The XRD patterns of fresh LNMO and the cycled LNMO electrodes after 500 cycles with and without MgHPO4 additive were shown in Fig. 7a. The intensities of diffraction peaks with the cycled LNMO were lower than those of the fresh electrode. Moreover, the cycled LNMO in the STD electrolyte showed weaker diffraction peaks, while the LNMO in STD + Mg electrolyte exhibited relatively strong diffraction peaks. Besides, the enlarged (400) diffraction peak of LNMO with STD shifted to larger angles in Fig. 7b, which may be produced by Mn3+dissolution from the bulk structure disrupting the structure stability of LNMO and lowering the crystal cell parameters25,49. In contrast, the (400) diffraction peak with STD + Mg electrolyte showed a shift slightly toward a large angle, indicating that the MgHPO4 additive inhibited the dissolution of Mn3+, in line with the NMR and ICP-OES results. CV tests of the LNMO/Li cells were performed to elaborate how the MgHPO4 additive affected kinetic reversibility, as shown in Fig. 7c,d. The CV curves in STD and STD + Mg electrolytes exhibit similar profiles, with a large redox peaks at ca. 4.7 V and a small redox peaks at ca. 4.0 V during the delithiation/lithiation processes. In general, the potential difference between the Ni2+/Ni4+ redox couple resulted from the occurrence of side reactions reflects the electrochemical reversibility. The potential differences of LNMO/Li cells in STD at each scan rate were larger than those in STD + Mg electrolyte (Table 3), revealing the LNMO/Li cell in STD + Mg electrolyte to have lower electrode polarization and better electrochemical reactivity and reversibility. Figure 7e showed the linear relationship of ip and v1/2. The Li+ diffusion coefficients were calculated by the Randles–Sevcik formula (ip = (2.69 × 105) × A × n3/2 × DLi1/2 × C × v1/2). The Li+ diffusion coefficients (5.75 × 10− 11/6.45 × 10− 11) of the LNMO/Li cell with STD + Mg electrolyte during the delithiation/lithiation processes were higher than those with STD (4.17 × 10− 11/4.38 × 10− 11), which confirmed that the MgHPO4-derived CEI/SEI films delivered larger ionic conductivity that facilitated the rate capability of LNMO/Li cell49. Figure 7f showed the EIS measurements of LNMO/Li cells in the two electrolytes after 200 cycles at 5 C. The Nyquist plots contained one semicircle and a slope, where Rsf represented the surface film resistance, Rct refered to the charge transfer resistance, and the corresponding equivalent circuit model was presented in Figure S648. The LNMO/Li cell using STD + Mg electrolyte exhibited a smaller Rct (59.4 Ω) than the STD electrolyte (140.8 Ω). The results of ZK and CV tests demonstrate that the participation of MgHPO4 in film-forming on both cathode and anode that possessing a higher Li+ transport kinetics can promote charge transfer, improve the electrochemical reactivity, and prevent electrolyte from continuous decomposition, all of them accounting for the excellent electrochemical performances.

(a) XRD patterns of LNMO electrodes in STD and STD + Mg electrolytes after 500 cycles at 5 C, (b) the enlarged (400) diffraction peaks of LNMO electrodes; (c, d) CV curves for LNMO/Li cells in STD and STD + Mg electrolytes at scan rates from 0.1 mV s− 1 to 0.5 mV s− 1; (e) the plotting of peak current (ip) vs. square root of scan rate (v1/2) for LNMO/Li cells; (f) the EIS spectra of LNMO/Li cells in STD and STD + Mg electrolytes after 200 cycles at 5 C.

Electrochemical performance of Gr anode and LNMO/Gr full-cell with MgHPO4 additive

Figure 8a showed the cycling performance of Gr/Li half-cell at 1 C after 500 cycles in STD and STD + Mg electrolyte. The Gr/Li cell with MgHPO4 exhibited a higher capacity retention of 61.2% than that with STD (40%). Furthermore, the Gr/Li cell with MgHPO4 possessed a smaller electrode polarization compared with STD in the charge/discharge curves in Figure S7(a, b), demonstrating that the MgHPO4 additive could also be preferentially reduced to participate in the formation of SEI film on Gr anode, which suppressed the continuous electrolyte reduction decomposition. Figure 8b showed the EIS spectra of Gr/Li cells in STD and STD + Mg electrolytes after 100 cycles at 2 C. The Nyquist curves consisted of two semicircles in high and medium frequencies, ascribed to the surface film resistance (Rsf) and the charge transfer resistance (Rct), respectively55. The Gr/Li cells with STD + Mg showed lower Rsf (3.5 Ω) and Rct (11.6 Ω) values compared to that with STD (38.6 and 25.1 Ω), suggesting the SEI layer derived from MgHPO4 additive inhibited the electrolyte reduction decomposition and promoted the Li+ migration in Gr/Li cell.

(a) Cycling performances and coulombic efficiency of Gr/Li half cells in STD and STD + Mg at 1 C after 500 cycles between 0 and 1.5 V; (b) EIS spectra of Gr/Li cells in the two electrolytes after 100 cycles at 2 C; (c) Cycling performances and coulombic efficiency of LNMO/Gr full cells in the two electrolytes after 100 cycles at 0.5 C between 3.5 and 4.9 V; (d) The galvanostatic charge/discharge curves of LNMO/Gr full cells in STD and STD + Mg electrolytes in the 1st and 100th cycles; (e) XRD patterns of LNMO cathodes disassembled from LNMO/Gr full cells in the two electrolytes after 100 cycles at 0.5 C; (f) XRD patterns of Gr anodes disassembled from LNMO/Gr full cells in in the two electrolytes after 100 cycles at 0.5 C.

The LNMO/Gr full-cells were assembled to evaluate the practical application of the MgHPO4 additive. Figure 8c showed the cycling curves of LNMO/Gr full-cells with the two electrolytes. The LNMO/Gr cell containing the STD + Mg electrolyte delivered a discharge capacity of 85.7 mAh g− 1 and capacity retention of 78.0%, higher than those in STD electrolyte (61.5 mAh g− 1 and 70.8%, respectively) in Table 4. Furthermore, compared to STD electrolyte, the LNMO/Gr cell with MgHPO4 exhibited a smaller electrode polarization along with the cycle number increase (Fig. 8d). The XRD patterns of the LNMO cathodes and Gr anodes extracted from LNMO/Gr cells were shown in Fig. 8e,f. The diffraction peaks of the cycled LNMO cathodes and Gr anodes with STD + Mg electrolyte were more intense than those with STD. Besides, both the enlarged (400) diffraction peak of LNMO and (002) diffraction peak of Gr with STD + Mg electrolyte exhibited slight shifting, confirming that the MgHPO4-deriverd CEI/SEI film can simultaneously stabilize the crystal structure of LNMO and Gr electrodes and prevent the electrodes against damage arising from electrolyte decomposition.

Figure S8(a-l) showed the surface morphologies of LNMO cathode and Gr anode extracted from the LNMO/Gr cell. The surface of LNMO showed a thick CEI film with obvious cracks and collapses with STD electrolyte, as shown in Figure S8(b and e), in line with the SEM test of LNMO disassembled from LNMO/Li cell. On the contrary, the LNMO surface delivered a more uniform and thinner CEI film with a significantly lower number of deposits in the STD + Mg electrolyte (Figure S8(c and f)), Likewise, a more uneven and thicker SEI film was generated on the cycled Gr anodes with STD electrolyte in Figure S8(h and k), while the coverage on the surface of Gr anode with STD + Mg electrolyte was thin and uniform (Figure S8(i and l))55. Moreover, the cross-sectional SEM images of the LNMO electrode disassembled from the LNMO/Gr full cells after 100 cycles at 0.5 C were shown in Figure S9(a-d). Compared with STD electrolyte, the LNMO particles with STD + Mg electrolyte delivered less cracks and damages, indicating that the MgHPO4 additive could improve the structural integrity of LNMO. Notably, the cycled LNMO and Gr electrodes (3 cycles at 0.2 C) with STD + Mg electrolyte showed the Mg 1s spectra at 1305.2 and 1304.5 eV, respectively (Figure S10(a, b)). Figure S11(a–c) shows XPS results of the cycled Gr electrodes extracted from the LNMO/Gr cell in the two electrolytes. In the C1s spectra, the peak intensities of C-C, C-H, C–O and C = O were obviously lower with STD + Mg electrolyte than those with STD (Figure S11(a)). Besides, in contrast with STD electrolyte, lower peak intensities of LiPFy/LixPOyFz and LiF on the Gr anode with STD + Mg electrolyte were obtained in the F 1s spectra (Figure S11(b)). The results suggested that MgHPO4 suppressed electrolyte decomposition on the Gr electrode. Moreover, in the Mn 2p spectra (Figure S11(c)), the peak intensities were lower with STD + Mg electrolyte compared with STD electrolyte, suggesting that the MgHPO4 inhibited the dissolution of transition metals and subsequent deposition on the anode surface. These results indicated that the MgHPO4 participated in the construction of a stable CEI and SEI films, which effectively suppressed parasitic reactions on both LNMO cathode and Gr anode and thus improve the cycling performance of LNMO/Gr cell.

According to the discussion above, the action mechanism of MgHPO4 additive on LNMO-based batteries can be explained as follows. First, carbonate solvents directly decompose under high voltage after long-term cycling in the STD electrolyte, thereby forming an uneven and thick CEI/SEI films on the electrodes (LNMO, Li and Gr) surface. As for the LNMO/Li cell, Li dendrites gradually form on the Li anode, leading to the production of dead lithium, which negatively affects the cycling performance of the battery. Besides, the HF generated by electrolyte decomposition can corrode the LNMO particles, resulting in the consumption of active Li+ ions and deterioration/reformation of the SEI film on Gr surface. On the contrary, the MgHPO4 additive preferentially undergoes redox reactions in the initial cycle with STD + Mg electrolyte. The thin and stable CEI/SEI films on both the LNMO cathode, Gr and Li anodes surfaces can inhibit interfacial side reactions and structural changes of electrodes, thereby reducing charge impedance, improving the Li+ diffusion kinetic, suppressing the dissolution of Ni and Mn ions, and finally improving the rate and cycling performance of the battery.

Conclusions

In summary, inorganic Mg/Ca/Sr-contained phosphates (MgHPO4, CaHPO4, and SrHPO4) are individually used as functional additives of electrolytes to enhance the cycling performance of LNMO-based battery. In particular, the MgHPO4 is the optimal additive and the rate capabilities of the LNMO/Li cell with STD + Mg electrolyte were significantly enhanced at 5 and 7 C compared with the same cell without additive (STD). Simultaneously, the LNMO/Li cell with MgHPO4 increased the capacity retentions from 65.4 to 86.0% at 1 C and 76.5 to 91.9% at 5 C after 500 cycles, respectively. The LNMO/Gr cell exhibited a higher discharge capacity of 85.7 mAh g− 1 and capacity retention of 78.0% than that with STD (61.5 mAh g− 1 and 70.8%). This electrochemical enhancement may be ascribed to the addition of MgHPO4, which reconstructs more continuous, conductive, and thinner CEI/SEI films on the surface of LNMO cathode, Gr and Li anode. These films not only effectively suppress the electrolyte decomposition but also protect LNMO particles from HF erosion. Moreover, the MgHPO4-derived CEI/SEI films can improve the electrochemical reversibility and reactivity, which is beneficial for Li+ diffusion. Besides, the SEI film inhibits the Li dendrite growth and promotes uniform Li deposition on the Li anode. This research describes a novel way using the inorganic MgHPO4 additive to enhance the electrochemical performance of a high-voltage cathode.

Methods

Electrode and electrolyte preparation

The LNMO cathode were prepared by blending the LNMO (Sichuan Xingneng Co., Ltd.), Super P (SP), and polyvinylidene fluoride (PVDF) with a mass proportion of 8:1:1 on Al foil. For LNMO/Li (Tianjin Zhongneng Lithium Industry Co., Ltd) half-cell, the mass loading was ca. 3.0 mg cm− 2 on the LNMO cathode. As for the LNMO/Gr full-cell, the Gr (BTR Co. limited.) anode was composed of Gr (89 wt%), SP (4 wt%), and PVDF (7 wt%) on Cu foil with a mass loading of ca. 7.04 mg∙cm− 2. The LNMO cathode possessed a mass loadings of ca. 3.24 mg∙cm− 2. The capacity calculated at 140 and 350 mAh g− 1 for LNMO and Gr, respectively. The standard electrolyte (STD) was obtained by adding 1 M LiPF6 in a mixed solvent with EC, EMC, and DMC (1/1/1 in volume) under an Ar-filled glovebox (the contents of H2O and O2 were less than 0.1ppm). Anhydrous MgHPO4, CaHPO4, and SrHPO4 were obtained from Aladdin. 0.5 wt% MgHPO4, CaHPO4, or SrHPO4 were added into the STD to obtain the saturated MgHPO4-, CaHPO4-, or SrHPO4- containing electrolytes (named STD-Mg, STD-Ca, and STD-Sr), respectively. The moisture in the electrolyte was controlled to be less than 20 ppm by using a moisture meter (831, Metrohm).

Electrochemical characterization

Linear sweep voltammetry (LSV) tests were performed by using a three-electrode system (the Li metals were both counter and reference electrodes and Pt represented the working electrode) at the linear sweep rate of 0.5 mV s− 1 between 2.5 and 6.5 V. 2032 coin-cells of LNMO/Li, Gr/Li, LNMO/Gr and Li||Li with the amount of 60 uL electrolyte were assembled in the glove box. The electrochemical measurements of the LNMO/Li half-cell (3.5–5.0 V) and LNMO/Gr (3.5–4.9 V) full-cells were conducted on a LAND CT3200A test system and all of the cells were tested under 0.2 C for the first 3 cycles and then subsequently cycled at different C-rates. The Gr/Li half-cell (0–1.5 V) was also first cycled at 0.1 C for three times and then at a 1 C rate for 500 cycles. The Interface 1000 (Gamry, USA) electrochemical workstation was applied for the Cyclic voltammetry (CV, 0.1 − 0.5 mV s− 1), electrochemical impedance spectroscopy (EIS, a frequency range of 0.1 Hz–100 kHz with an amplitude of 5 mV) and chronoamperometry (CA) tests of the LNMO/Li cells. The CA tests conditions of LNMO/Li cells were as follows: the cells were cycled at 0.2 C and 25 °C for three times and then charged to 5.0 V at 0.2 C and 60 °C. Finally, the voltage was maintained at 5.0 V for 24 h at 60 °C to observe the change in current. Besides, the self-discharge tests of LNMO/Li cells were hold at the fully charged state of 5 V for 90 h at 60 °C to evaluate the electrolytes with and without additives.

The cycled LNMO and Li metal extracted from LNMO/Li cells were rinsed with the DMC solvent in a glovebox and subsequently dried in a vacuum oven for 8 h. The surface elemental compositions, morphologies, and crystal structures of the cycled electrodes were investigated through X-ray photoelectron spectroscopy (XPS, PHI5600, Physical Electronics), time-of-flight secondary-ion mass spectrometry (TOF-SIMS), scanning electron microscopy (SEM, SU 8020), transmission electron microscopy (TEM, JEM-2100 plus), and X-ray diffraction (XRD, Ultima IV). To study the inhibition of HF by additives, 50 uL of water were added to 5 mL of STD, STD-Mg, STD-Ca, and STD-Sr and then we stored the four electrolytes for 15 days at 25 °C before19F and 31P nuclear magnetic resonance spectroscopy (NMR, Advance 400, Bruker) was performed. To examine the effects of the MgHPO4, CaHPO4, and SrHPO4 additives on the inhibition of Mn/Ni dissolution in LNMO materials, we put fresh LNMO (150 mg) powders into STD, STD-Mg, STD-Ca, and STD-Sr (10 mL) electrolytes and then we sealed it in an oven at 60 °C and stored it for 25 days. The content of Mn/Ni dissolved in the electrolyte was tested through inductively coupled plasma optical-emission spectroscopy (ICP-OES, Agilent, USA).

The highest molecular-occupied orbital (HOMO) and lowest molecular-unoccupied orbital (LUMO) energies of all additives and solvent molecules were calculated according to the density functional theory (DFT) with the B3LYP/6-311 + + G(d) basis set for all the elements. The solvent environment was simulated using the SMD model, and the dielectric constant of mixed solvents was set to 20.5. The reaction energies of all of the additives and solvent molecules with HF were also calculated using the same method.

Data availability

The data are available from the corresponding author upon reasonable request.

References

Yin, X. et al. China’s transportation energy consumption and CO2 emissions from a global perspective. Energy Policy 82, 233–248 (2015).

Ren, G., Ma, G. & Cong, N. Review of electrical energy storage system for vehicular applications. Renewable Sust. Energy Rev. 41, 225–236 (2015).

Choi, S. & Wang, G. Advanced lithium-ion batteries for practical applications: Technology, development, and future perspectives. Adv Mater Technol 3, 1700376–1700396 (2018).

Wu, F., Maier, J. & Yu, Y. Guidelines and trends for next-generation rechargeable lithium and lithium-ion batteries. Chem. Soc. Rev. 49, 1569–1614 (2020).

Huang, Y. et al. Lithium manganese spinel cathodes for lithium-ion batteries. Adv. Eng. Mater. 11, 2000997 (2021).

Zhang, K. et al. Modulation of physical and chemical connections between SiOx and carbon for high-performance lithium-ion batteries. Energy Mater. 4, 400043 (2024).

Wang, R. et al. Highly fluorinated co-solvent enabling ether electrolyte for high-voltage lithium-ion batteries with graphite anode. Energy Mater. 3, 300040 (2023).

Liang, G., Peterson, V. K., See, K. W., Guo, Z. & Pang, W. K. Developing high-voltage spinel LiNi0.5Mn1.5O4 cathodes for high-energy-density lithium-ion batteries: Current achievements and future prospects. J. Mater. Chem. A 8, 15373–15398 (2020).

Ye, C. et al. Converting detrimental HF in electrolytes into a highly fluorinated interphase on cathodes. J. Mater. Chem. A 6, 17642–17652 (2018).

Chen, H. et al. Enhanced cycling stability of high-voltage lithium metal batteries with a trifunctional electrolyte additive. J. Mater. Chem. A 8, 22054–22064 (2020).

Wang, W. et al. Stable cycling of high-voltage lithium-metal batteries enabled by high-concentration FEC-based electrolyte. ACS Appl. Mater. Interfaces 12, 22901–22909 (2020).

Ha, S. et al. Using a lithium bis(oxalato) borate additive to improve electrochemical; performance of high-voltage spinel LiNi0.5Mn1.5O4 cathodes at 60 °C. Electrochim. Acta 104, 170–177 (2013).

Dong, Y. et al. Improving the performance at elevated temperature of high voltage graphite/LiNi0.5Mn1.5O4 Cells with added lithium catechol dimethyl borate. J. Electrochem. Soc. 164, A128–A136 (2016).

Dong, Y. et al. Effect of lithium borate additives on cathode film formation in LiNi0.5Mn1.5O4/Li cells. ACS Appl. Mater. Interfaces 9, 20467–20475 (2017).

Zhao, D. et al. New insight into the mechanism of LiPO2F2 on the interface of high-voltage cathode LiNi0.5Mn1.5O4 with truncated octahedral structure. Appl. Surf. Sci. 49, 595–606 (2019).

Zhu, Y. et al. Diethyl(thiophen-2-ylmethyl)phosphonate: A novel multifunctional electrolyte additive for high voltage batteries dagger. J. Mater. Chem. A 6, 10990–11004 (2018).

Kim, J. et al. Lithium bis(trimethylsilyl) phosphate as a novel bifunctional additive for high-voltage LiNi0.5Mn1.5O4/graphite lithium-ion batteries. ACS Appl. Mater. Interfaces 13, 22351–22360 (2021).

Bolloju, S., Chiou, C. Y., Vikramaditya, T. & Lee, J. T. (Pentafluorophenyl) diphenylphosphine as a dual-functional electrolyte additive for LiNi0.5Mn1.5O4 cathodes in high-voltage lithium-ion batteries. Electrochim. Acta 299, 663–671 (2019).

Li, C., Wu, S., Qiu, Y. & Lu, D. Phosphorus-containing C12H27O4P as functional electrolyte additives for high-voltage LiNi0.5Mn1.5O4/Graphite Li-ion batteries with excellent electrochemical performance. Adv. Mater. Interfaces 8, 2001588 (2021).

Yang, X. et al. High-voltage lithium-ion capacitors enabled by a multifunctional phosphite electrolyte additive. Energy Storage Mater. 46, 431–442 (2022).

Lu, D. et al. Using triallyl phosphate as electrolyte additive to stabilize electrode–electrolyte interface of LiNi0.5Mn1.5O4/graphite high voltage lithium-ion cells. ACS Appl. Energy Mater. 5, 13600–13609 (2022).

Zhao, D. et al. Improvement of interfacial stability for LiNi0.5Mn1.5O4 cathode: Insight into the effect and mechanism of additive with special structure. Energy Technol. 6, 2450–2460 (2018).

Huang, Y. et al. Modifying the cathode–electrolyte interphase by sulfone-based additive to enhance the electrochemical performance of LiNi0.5Mn1.5O4. ACS Appl. Energy Mater. 5, 639–647 (2021).

Wang, T. et al. Impact of triethyl borate on the performance of 5 V spinel/graphite lithium-ion batteries. ACS Appl. Energy Mater. 5, 7346–7355 (2022).

Huang, T., Zheng, X., Pan, Y., Li, Q. & Wu, M. Effect of tributyl borate on electrochemical performance at an elevated temperature of high-voltage LiNi0.5Mn1.5O4 cathode. ACS Appl. Mater. Interfaces 11, 26872–26879 (2019).

Yue, H. et al. Boron additive passivated carbonate electrolytes for stable cycling of 5 V lithium–metal batteries. J. Mater. Chem. A 7, 594–602 (2019).

Chen, Y. et al. An electrolyte additive with boron-nitrogen-oxygen alkyl group enabled stable cycling for high voltage LiNi0.5Mn1.5O4 cathode in lithium-ion battery. J. Power Sources 477, 228473 (2020).

Lee, T. et al. Tris (pentafluorophenyl) silane as an electrolyte additive for 5 V LiNi0.5Mn1.5O4 positive electrode. J. Electrochem. Soc. 163, A898 (2016).

Tu, W. et al. Trimethylsilylcyclopentadiene as a novel electrolyte additive for high temperature application of lithium nickel manganese oxide cathode. J. Power Sources 364, 23–32 (2017).

Lee, T. et al. A bifunctional electrolyte additive for high-voltage LiNi0.5Mn1.5O4 positive electrodes. ACS Appl. Mater. Interfaces 11, 11306–11316 (2019).

Li, Y. et al. Stabilized high-voltage cathodes via an F-rich and Si-containing electrolyte additive. ACS Appl. Mater. Interfaces 12, 28169–28178 (2020).

Dong, Y., Demeaux, J., Zhang, Y. & Lucht, B. L. Improving the performance of graphite/LiNi0.5Mn1.5O4 cells with added N, N-dimethylformamide sulfur trioxide complex. J. Electrochem. Soc. 164, A3182 (2017).

Wang, X. et al. Adiponitrile as lithium-ion battery electrolyte additive: A positive and peculiar effect on high-voltage systems. ACS Appl. Energy Mater. 1, 5347–5354 (2018).

Liu, J. et al. Fluorinated phosphazene derivative–a promising electrolyte additive for high voltage lithium ion batteries: from electrochemical performance to corrosion mechanism. Nano Energy 46, 404–414 (2018).

Yue, H. et al. Artificial interface derived from diphenyl ether additive for high-voltage LiNi0.5Mn1.5O4 cathode. ChemElectroChem 5, 1509–1515 (2018).

Shang, H. et al. Improving the cyclic stability of LiNi0.5Mn1.5O4 at high cut off voltage by using pyrene as a novel additive. Energy Technol. 8, 2000671 (2020).

Tan, C. et al. Enhancing the electrochemical performance of a high-voltage LiNi0.5Mn1.5O4 cathode in a carbonate-based electrolyte with a novel and low-cost functional additive. Chem. Eur. J. 26, 12233–12241 (2020).

Tan, C. et al. Rescue the cycle life of LiNi0.5Mn1.5O4 cathode on high voltage via glyceryl triacetate as the multifunction additive. Sep. Purif. Technol. 314, 123608 (2023).

Guo, J. et al. Flavone as a novel multifunctional electrolyte additive to improve the cycle performance of high-voltage LiNi0.5Mn1.5O4 batteries. Appl. Surf. Sci. 616, 156534 (2023).

Liu, J., Zhou, L., Yu, W. & Yu, A. Effect of fluoroethylene carbonate as an electrolyte solvent in the LiNi0.5Mn1.5O4/Li4Ti5O1.2 cell. J. Alloys Compd. 812, 152064 (2020).

Xia, L. et al. Fluorinated electrolytes for Li-ion batteries: the lithium difluoro (oxalato) borate additive for stabilizing the solid electrolyte interphase. ACS Omega 2, 8741–8750 (2017).

Piao, N. et al. Nonflammable all-fluorinated electrolytes enabling high-power and long-life LiNi0.5Mn1.5O4/Li4Ti5O1.2 lithium-ion batteries. Nano Energy 105, 108040 (2023).

Xue, L., Ueno, K., Lee, S. Y. & Angell, C. A. Enhanced performance of sulfone-based electrolytes at lithium-ion battery electrodes, including the LiNi0.5Mn1.5O4 high voltage cathode. J. Power Sources 262, 123–128 (2014).

Jia, H. et al. Sulfone-based electrolytes for high energy density lithium-ion batteries. J. Power Sources 527, 231171 (2022).

Zou, Z., Xu, H., Zhang, H., Tang, Y. & Cui, G. Electrolyte therapy for improving the performance of LiNi0.5Mn1.5O4 cathodes assembled lithium–ion batteries. ACS Appl. Mater. Interfaces 12, 21368–21385 (2020).

Xia, L., Miao, H., Zhang, C., Chen, G. & Yuan, J. Recent advances in non-aqueous liquid electrolytes containing fluorinated compounds for high energy density lithium-ion batteries. Energy Storage Mater. 38, 542–570 (2021).

Jo, M., Park, S. H. & Lee, H. NaH2PO4 as an electrolyte additive for enhanced thermal stability of LiNi0.8Co0.1Mn0.1O2/graphite batteries. J. Electrochem. Soc. 167, 130502 (2020).

Jo, M., Park, S. H. & Lee, H. Effects of a sodium phosphate electrolyte additive on elevated temperature performance of spinel lithium manganese oxide cathodes. Materials 14, 4670 (2021).

Mu, J. et al. Effect of lithium-containing inorganic phosphate additives in stabilization of carbonate-based electrolyte for 5 V LiNi0.5Mn1.5O4-based lithium-ion batteries. J. Energy Storage 96, 112538 (2024).

Beltrop, K. et al. Triphenylphosphine oxide as highly effective electrolyte additive for graphite/NMC811 lithium-ion cells. Chem. Mater. 30, 2726–2741 (2018).

Duan, K. et al. Synergistic inorganic–organic dual-additive electrolytes enable practical high-voltage lithium-ion batteries. ACS Appl. Mater. Interfaces 14, 10447–10456 (2022).

Lee, S. et al. Toward the sustainable lithium metal batteries with a new electrolyte solvation chemistry. Adv. Eng. Mater. 10, 2000567 (2020).

Rong, H. et al. A novel imidazole-based electrolyte additive for improved electrochemical performance at elevated temperature of high-voltage LiNi0.5Mn1.5O4 cathodes. J. Power Sources 329, 586–593 (2016).

Li, X. et al. Constructing a stable interface film on both cathode and anode via a novel electrolyte additive for high performance LiNi0.8Co0.1Mn0.1O2/graphite pouch cell. J. Power Sources 596, 234055 (2024).

Li, G. et al. Constructing a low-impedance interface on a high-voltage LiNi0.8Co0.1Mn0.1O2 cathode with 2,4,6-triphenyl boroxine as a film forming electrolyte additive for li-ion batteries. ACS Appl. Mater. Interfaces 12, 37013–37026 (2020).

Acknowledgements

This work was supported by the Research Foundation of China University of Petroleum-Beijing at Karamay (No. XQZX20240023); “333 Talent Project’’ of Hebei Province (C20231023) and High-level talents nurturing and funding project of Hebei Academy of Sciences (2024G04); Key R&D Plan of Karamay (No.2024zdyf0009); Karamay Innovation Environment Construction Plan (Innovative Talents) Project, (2024hjcxrc0029, 20212022hjcxrc0013, and 2024hjcxrc0055); National Natural Science Foundation of China (Grant No. 52104053); Special Fund for Central Government to Guide Local Science and Technology Development (No. ZYYD2023A08); Prefecture Science Foundation of Xinjiang Uygur Autonomous Region (No. 2022D01F40); Natural Science Foundation of Xinjiang Uygur Autonomous Region (No. 2022D01A126); Xinjiang Tianshan Innovation Team (NO. 2022TSYCTD0002).

Author information

Authors and Affiliations

Contributions

A.J.W. conceived and designed the experiments, performed experimental measurements and analyses, and wrote the manuscript. Y.Q.Y. performed experimental measurements and analyses, and wrote the manuscript; J.P.M. prepared the electrolytes and performed some experimental measurements. R.H. performed some characterization analyses. X.H. L. performed some characterization analyses. H.P. Z. performed some characterization analyses. Z.F. L. revise the manuscript. S.S.W. revise the manuscript. Y. Z. revise the manuscript. S.X.M. performed characterization analyses and revise the manuscript. All authors discussed the results and contributed to data analysis.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wei, A., Yang, Y., Mu, J. et al. Enhancing the electrochemical performance of high-voltage LiNi0.5Mn1.5O4 batteries with a multifunctional inorganic MgHPO4 electrolyte additive. Sci Rep 15, 6186 (2025). https://doi.org/10.1038/s41598-025-90702-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-90702-z