Abstract

To provide a theoretical basis for the development of water hazard prevention schemes for roof sandstone, this study systematically conducts uniaxial compression, acoustic emission, scanning electron microscopy-energy dispersive spectroscopy (SEM-EDS), and X-ray diffraction (XRD) tests on the thick water-bearing sandstone at depths of 623–943 m in the Luohe Formation of the Binchang Mining Area, investigating its mechanical properties and the mechanisms of micro-damage evolution under uniaxial compression.The results indicate that with the increase in water content, the elastic modulus, strength, peak strain, and brittleness index of sandstone decrease. Dry sandstone primarily undergoes shear failure, while water-saturated sandstone mainly experiences a combination of tensile and shear failure. The cumulative ring count of acoustic emission in water-saturated sandstone decreases with increasing water content, and the damage evolution can be divided into three stages: the initial damage stage, the stable damage development stage, and the rapid damage increase stage. The damage variable of water-saturated sandstone increases with the rise in water content. The uniaxial compression fracture characteristics of dry and saturated sandstone include intergranular and transgranular fractures, primarily exhibiting brittle failure. In dry sandstone, the contents of Si, Fe, Ca, Na and Al are relatively high, while in water-saturated sandstone, these contents decrease, but the Carbon(C) content significantly increases. The average grain size of saturated sandstone is smaller than that of dry sandstone, and the strength of sandstone decreases with the reduction in grain size.The main components of sandstone include feldspar, calcite, muscovite, and quartz, among these, quartz endows the sandstone with higher strength, and the strength of the sandstone decreases with a reduction in the quartz content.

Similar content being viewed by others

Introduction

Fossil fuels have played an indispensable role in driving societal development. Their safe and efficient development and utilization are of paramount significance in effectively alleviating the predicament of energy shortages1,2.In China’s energy structure, coal plays a pivotal role, with its consumption share remaining above 50% for a long period, reaching 55.3% in 20233. It is evident that the status of coal as a cornerstone of China’s energy security is unlikely to change in the short term4,5. With the deepening implementation of China’s “Belt and Road” initiative and the shift of coal production focus to the western regions, the development of coal resources in Western China has become a key task in ensuring national energy security6. The Ordos Basin is an important coal-bearing basin in China, with its Jurassic coal resources accounting for 31.9% of the nation’s total7. The Jurassic coal seams are generally covered by sandstone (or loose sand layers) aquifers of different periods8. During coal mining, the release of ground stress leads to significant changes in the roof structure, gradually forming the “three zones” structure of the caving zone, the fracture zone, and the bending subsidence zone. As the rock layers in the caving zone become unstable and collapse, the fracture zone develops through-going fractures, and the rock layers in the bending subsidence zone bend and break, the coal seam gradually connects with the aquifer, allowing water to infiltrate into the mining space along the damaged areas, thereby inducing roof water hazards. The uniaxial compression test is an important method for studying the mechanical properties of rocks under complex stress conditions and can simulate the fracturing and micro-damage processes of water-bearing sandstone under stress release conditions in the mining field. In-depth research on the mechanical behavior and micro-damage mechanism of water-bearing sandstone under uniaxial compression conditions is of significant scientific importance for understanding the formation process of the “three zones” and further preventing and controlling roof water hazards.

Scholars both domestically and internationally have conducted extensive research on the mechanical properties and micro-damage mechanisms of water-bearing sandstone under uniaxial compression tests. Sun et al.9 demonstrated that the uniaxial compressive strength and elastic modulus of sandstone exhibit an exponential decline with increasing water content. This finding aligns with the research by Zhang et al.10, who observed that the compressive strength and elastic modulus of saturated sandstone are significantly reduced compared to dry sandstone, with an increase in Poisson’s ratio. Additionally, the variation in acoustic emission energy is highly correlated with the degree of damage, especially during the elastic deformation phase of saturated sandstone, where the total acoustic emission energy is markedly decreased. Further research indicates that the presence of water weakens the mechanical properties of sandstone. Zhang et al.11 found that with increasing water saturation, the compressive strength and elastic modulus of sandstone significantly decrease, and the acoustic emission energy correspondingly diminishes. Dang et al.12 pointed out that the peak stress, elastic modulus, and brittleness index of sandstone decrease with increasing water content, while the peak strain increases, indicating a trend of weakened mechanical performance. Moreover, Zheng et al.13 experimentally showed that the softening coefficient and brittleness coefficient of rocks under different water saturation states have a certain relationship with water content.Teng et al.14 discovered that the peak strain of saturated sandstone is 32% higher than that of dry sandstone, and its energy accumulation is three to five times that of dry sandstone. Saturated sandstone has a longer compaction stage, a shorter elastic stage, and an extended plastic stage, but its strength is significantly lower than that of dry sandstone. Similarly, Lu et al.15 noted through uniaxial compression tests that the uniaxial compressive strength and elastic modulus of saturated sandstone decreased by 38.9% and 48.5%, respectively. Yao et al.16 demonstrated that in the dry state, the peak acoustic emission count of sandstone corresponds to the stress peak, but as water content increases, the peak acoustic emission count lags behind the stress peak, showing a “delay” phenomenon. Duan et al.17 also indicated that with increasing water content, the peak strength and elastic modulus of sandstone decrease, and the peak strain increases. Li et al.18 further noted that increasing water content significantly reduces the peak strength and elastic modulus of weakly cemented sandstone, with little effect on peak strain, while plasticity gradually increases. Studies by Zhao et al.19 and Chen et al.20 also support this trend, showing that with increasing water content, the compressive strength, elastic modulus, and energy of acoustic emission events of sandstone all significantly decrease. The water immersion treatment experiment of ore pillar rock samples indicates that the longer the immersion time, the more significant the decrease in the mechanical properties of sandstone, exhibiting a negative exponential decay characteristic. Furthermore, Luo et al.21 and Fan et al.22 confirmed through compression tests of sandstone under water immersion that the pore structure and macroscopic mechanical properties of sandstone change significantly after water immersion, characterized by an increase in the number of pores, enlargement of pore size, and this deterioration of microstructure is closely related to the degradation of mechanical properties.

Undoubtedly, numerous achievements have been made by domestic and international scholars in the study of the mechanical properties of water-bearing sandstone. However, there are still some deficiencies. Firstly, previous studies have mostly focused on the macroscopic mechanical properties of water-bearing sandstone, with relatively insufficient research on microstructural changes and the joint analysis of macroscopic and microscopic aspects. Moreover, in previous studies, the changes of different mineral components under water-bearing conditions and their impacts on the mechanical properties of sandstone have not been deeply explored.

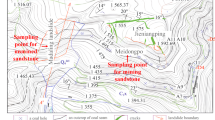

Therefore, this study takes the thick water-rich sandstone from 623 m to 943 m deep in the Luohe Formation of the Binchang mining area as the research object. It comprehensively uses uniaxial compression tests, acoustic emission tests, scanning electron microscopy (SEM), and energy-dispersive spectroscopy (EDS) to systematically study the mechanical characteristics and damage mechanisms of water-bearing sandstone from both macroscopic and microscopic perspectives. Furthermore, X-ray diffraction (XRD) and SEM-EDS tests are employed to reveal the changes of mineral components in sandstone under water-bearing conditions, with the expectation of providing a scientific basis for the formulation of roof water hazard prevention and control plans.

Experimental methods

Sample Preparation for testing

Uniaxial compression and acoustic emission testing

(1) Sample preparation: ①According to the ISRM standard, the test samples are usually cylindrical specimens with a diameter of 50 mm and a height of 100 ~ 125 mm, and the unevenness error of the two ends is strictly controlled within ± 0.02mm23. ②Based on the “Standard for Test Methods of Engineering Rock Mass” (GB/T50266-2013), the preparation method of the dried specimen is as follows: Place the standard rock specimen in an oven and dry it for 24 h at a temperature of 105–110 °C. Subsequently, remove the specimen from the oven and place it in a desiccator to cool to room temperature, and finally weigh the mass of the dried specimen, with a weighing accuracy of 0.01 g. To more effectively reduce the influence of temperature on the mechanical properties of the specimen, the oven temperature was adjusted to 65 °C in this study, and the oven is a 101–1 A type ventilated electric thermostatic drying oven (Fig. 1). The specific steps are as follows: Through coring, cutting, grinding, drying (drying for more than 24 h at a temperature of 65 °C), and weighing (with a weighing accuracy of 0.01 g, until the weight remains unchanged), the final sandstone standard specimen with a diameter of 50 mm and a height of 100 mm is prepared, and the parallelism error of the two ends of each specimen is less than 0.02 mm, and the surface of the specimen is intact, with no visible cracks to the naked eye (Fig. 2).

(2) Preparation of Sandstone Specimens with Different Water Contents: ①The mass of the dried specimen is denoted as mdry; ②Using the ZYB-II vacuum pressure saturation device (Fig. 3), the sandstone is subjected to vacuum and then pressurized with water to achieve saturation. The weight of the saturated sandstone is measured and recorded as msat; ③The water content of the sandstone is calculated using the formula: (msat-mdry)/mdry; ④The above experimental steps are repeated to obtain multiple sets of saturated water content measurements, establishing an effective experimental range for the sandstone’s saturated water content, which is determined to be between 9.5% and 11.0%; ⑤Based on the effective water content range of the sandstone, the specific water contents for the test sandstone are determined to be 0%, 5%, and 10%. When the water content reaches 10%, the sandstone specimens are considered to be saturated by default. The dried sandstone was vacuumed and then pressurized with water using the ZYB-II vacuum pressure saturation machine (Fig. 3) to achieve saturation. Subsequently, the saturated sandstone was placed in a 101–1 A type ventilated electric thermostatic drying oven and slowly dried at a temperature of 65℃, with continuous monitoring until the requirements were met, in order to prepare sandstone specimens with a water content of 5%.

-

(3)

Sample grouping and numbering: Sandstone samples themselves have considerable variability. To minimize the influence of the inherent variability of the samples on the test results, the following measures were taken: ①In the sample selection stage, we eliminated as far as possible samples with visible defects and structural inhomogeneity to ensure the quality and homogeneity of the samples; ②We tried to select samples with similar densities for testing. Finally, nine sandstone samples were selected for the test, and the uniaxial compression specimens of sandstone with water contents of 0%, 5%, and 10% were numbered as SU0-1, SU0-2, SU0-3, SU5-1, SU5-2, SU5-3, SU10-1, SU10-2, and SU10-3, respectively. The specific data are shown in Table 1 below.

Scanning electron microscopy (SEM) and X-ray energy dispersive spectroscopy (EDS) testing

During Scanning Electron Microscopy (SEM) and Energy-Dispersive Spectroscopy (EDS) analyses, in accordance with the “Microbeam Analysis—Identification of Authigenic Clay Minerals in Sedimentary Rocks by Scanning Electron Microscopy and Energy-Dispersive Spectroscopy” (GB/T1736-2013), sandstone block samples were prepared with a diameter not exceeding 10 mm and with distinct representative fresh fracture surfaces for analysis.

Since it is very difficult to directly prepare sandstone with a water content of 5% through natural soaking, the sandstone samples with a water content of 5% in this experiment were obtained by saturating the sandstone and then slowly drying it while monitoring in real time. When conducting the scanning electron microscopy (SEM) experiment, the samples must be in a dry state. Therefore, the sandstone samples with a water content of 5% used for SEM are the same as the saturated sandstone samples, both of which are obtained by drying from a saturated state. Thus, in this experiment, SEM tests were only performed on sandstone samples in dry and saturated states.

Dry and saturated sandstone samples were prepared in triplicate for parallel testing, labeled sequentially from left to right as SM0-1, SM0-2, SM0-3, SM10-1, SM10-2, and SM10-3, as shown in Fig. 4.

X-ray diffraction test

During the X-ray Diffraction (XRD) test, the blocky sandstone samples are subjected to a series of processes including crushing, grinding, and sieving, ultimately resulting in the selection of powder finer than 350 mesh (approximately 40 μm). This powder is then placed into a glass slide, compacted with a blade, and prepared as XRD test samples. As shown in Fig. 5, from left to right, they are labeled as Sample 1, Sample 2, and Sample 3.

The experiment was conducted using the Bruker X-ray diffractometer D8 at the Key Laboratory of Organic Polymer Optoelectronic Materials, Xijing University (Fig. 6). The main steps of the XRD test analysis include: ①Sample loading; ②Setting the instrument parameters with a Start Angle of 5°, a Stop Angle of 100°, operating current I = 40 A, and operating voltage V = 40 kV, with a dwell time of 0.2s per step, totaling 9298 steps and a total time of 1917.2s; ③Initiating the test and obtaining the scanning results; ④Qualitative analysis, using the Jade software(link of software:https://mp.weixin.qq.com/s/JTadYVuKmFp1xcy3fAjbqw;version number: MDI Jade 6) to conduct a combined whole-pattern and single-peak search method for the qualitative analysis of the sandstone’s mineral phases; ⑤Quantitative analysis, employing the Rietveld full-pattern fitting refinement method (using FullProf software).

Experimental setup and methods

Uniaxial compression and acoustic emission testing

The uniaxial compression and acoustic emission tests were conducted using the MTS-2000 microcomputer-controlled electro-hydraulic servo universal testing machine from the Shaanxi Key Laboratory of Safety and Durability of Concrete Structures at Xijing University, and the AEwin system manufactured by the American company Physical Acoustics Corporation (PAC) (Fig. 7). (1) The MTS-2000 microcomputer-controlled electro-hydraulic servo universal testing machine was used to apply axial displacement loading at a rate of 0.002 mm/s until the sandstone specimens were damaged; (2) The AE system emitted high-frequency pulse signals through probes and received signals reflected back from the target. A total of six acoustic emission channels were equipped to collect signals in this test, with preamplifiers and threshold values set at 40dB, and the acoustic emission sampling frequency was 1 MHz.

Scanning electron microscopy (SEM) and X-ray energy dispersive spectroscopy (EDS) testing

The SEM-EDS testing was conducted using the high-resolution electron scanning microscope - EVO10 (Fig. 8), in conjunction with the Oxford X-Max 20 20 square detector (Fig. 9) at the Key Laboratory of Organic Polymer Optoelectronic Materials, Xijing University. During the testing process: ①The prepared samples were adhered to the sample stage using conductive adhesive, ensuring that the analysis surface was parallel to the surface of the sample stage; ②The samples were then sputter-coated with gold; ③At various magnifications (employing a strategy that started with low magnification and gradually increased), the scanning electron microscope was used to locate the target area on the surface to be tested, capturing SEM images; ④Suitable points were selected for EDS spectral analysis.

Experimental results and analysis

Mechanical properties of sandstone under uniaxial compression at different water contents

Three types of sandstone with different water contents (0%, 5%, and 10%) were selected for uniaxial compression tests. The stress-strain curves for these three types of sandstone are shown in Fig. 10, and the specific mechanical parameters are listed in Table 2. The axial peak strain is denoted by the symbol εmax with the unit of %, and the average axial peak strain is denoted by εavg with the unit of %. The elastic modulus is denoted by the symbol E with the unit of GPa, and the average elastic modulus is denoted by \(\:\stackrel{-}{E}\) with the unit of GPa. The strength is denoted by the symbol σmax with the unit of MPa, and the average strength is denoted by σavg with the unit of MPa.

Analysis of deformation characteristics

From Fig. 10, it can be observed that the uniaxial compression deformation process of each specimen essentially goes through four stages, taking the stress-strain curve of specimen ⑤ as an example: I. Sandstone pore closure stage (0-a), during which the pores in the sandstone specimen are gradually compressed, the axial stress increases slowly with the axial strain, and the curve takes on a concave shape; II. Elastic deformation stage (a-b), in this stage, the relationship between stress and strain exhibits a linear characteristic, conforming to Hooke’s Law. III. Plastic yielding stage (b-c), as internal micro-cracks gradually develop, the sandstone enters the plastic yielding stage, characterized by the tangent modulus on the curve approaching zero. The curve slightly bulges upwards in this stage, reflecting the material’s initiation of plastic deformation; IV. Peak failure stage (c-d), when the specimen reaches its ultimate strength, the stress drops sharply, and the curve shows a vertical descent, indicating that the sandstone specimen undergoes brittle failure and complete failure, with the specimen rapidly disintegrating, which is a typical brittle characteristic. Stress-strain curves of specimens ①③⑥⑦⑧⑨ are consistent with the deformation characteristics of ⑤, while specimens ②④ show strain-strain curves that are consistent with the deformation characteristics of ⑤ in stages I,II,III, but stage IV exhibits a stepwise drop.

By analyzing the average peak strain (εavg), elastic modulus (E), average elastic modulus (\(\:\stackrel{-}{E}\)) and Fig. 11 in Table 2 for different water contents, it can be observed that as the water content increases, both the εavg and \(\:\stackrel{-}{E}\) of the sandstone decrease. The εavg of sandstone with 5% water content is reduced by 4.55% compared to that of dry sandstone, and εavg of sandstone with 10% water content is reduced by 7.95% compared to dry sandstone. The E of dry sandstone samples ranges from 6.62 to 6.88 GPa, with an average of 6.81 GPa. For sandstone samples with 5% water content, the E ranges from 5.62 to 6.52 GPa, with an average of 6.22 GPa. For sandstone samples with 10% water content, the E ranges from 3.75 to 5.34 GPa, with an average of 4.77 GPa. The \(\:\stackrel{-}{E}\) of sandstone with 5% water content is reduced by 8.67% compared to dry sandstone, and the \(\:\stackrel{-}{E}\) of sandstone with 10% water content is reduced by 29.96% compared to dry sandstone. The analysis suggests that the internal presence of numerous closed fractures in the sandstone samples is a contributing factor. The E tends to increase with the friction factor of the sandstone fracture surfaces. However, when the friction factor is high, the fracture surfaces become difficult to slide, and the sliding friction factor is related to the sliding speed and roughness. In saturated conditions, the internal water in the sandstone acts as a lubricant, reducing the friction coefficient on the crack surfaces, which in turn lowers the difficulty of sliding and leads to a decrease in E24,25,26,27.

Analysis of strength characteristics

Analysis of the maximum strength (σmax) and average strength (σavg) of sandstone under different water content conditions in Table 2 reveals the following: (a) The σmax range of dry sandstone samples is 35.30 to 44.13 MPa, with an average value of 40.82 MPa; (b) The σmax range of sandstone samples with a water content of 5% is 6.22 to 38.45 MPa, with an average value of 33.49 MPa, which is a 17.94% reduction compared to dry sandstone; (c) The σmax range of sandstone samples with a water content of 10% is 21.24 to 31.91 MPa, with an average value of 27.07 MPa, which is a 33.68% reduction compared to dry sandstone. Figure 12 shows that the σavgdecreases with increasing water content. The reasons for this are analyzed as follows: (a) During the process of water immersion and saturation, a series of complex physical and chemical reactions occur in the sandstone. Water present in the micropores or cracks of the sandstone reduces surface free energy, thereby promoting further crack propagation and reducing the strength of the rock. Elements in the rock undergo chemical reactions in water, leading to the dissolution of minerals within the sandstone, or after dissolution, they may re-deposit in other areas. This also results in a reduction of sandstone strength28,29,30; (b) Sandstone contains a large number of pores, in the wet samples (sandstone with 5% water content), pore water pressure mainly comes from the gravity and capillary action of the pore water. Since the pores are not fully saturated, the pore water pressure is relatively low and unevenly distributed. When external loads act on the rock, the pore water may not be able to be drained in time, thus generating a certain amount of pore water pressure in local areas. In the fully saturated samples, the pore water pressure is significantly higher and more evenly distributed. Since the pores are completely filled with water, the pore water cannot be drained when external loads act on the rock, resulting in higher pore water pressure.The existence of this pore pressure reduces the stress between rock particles, thereby weakening the strength of the rock and leading to a reduction in the σmaxof the sandstone31.

Brittleness and ductility analysis

(1) Brittleness Index: Brittleness refers to the characteristic of a material to fail under a small amount of plastic deformation, and is commonly represented by the brittleness index B. Based on the uniaxial compression test of rock, the brittleness evaluation method32 is used, and its expression is as follows:

In the formula, B is the brittleness index of the sandstone;σci is the crack initiation stress in MPa; σcd is the crack damage stress in MPa; σmax is the peak strength in MPa; σr is the residual stress in MPa;ε1ci is the axial strain at crack initiation in %; ε1cd is the axial strain at crack damage in %; εmax is the peak strain of the sandstone in %; εr is the residual axial strain in %, as shown in Fig. 13; \(\:\overline{B}\) is the average brittleness index.

From Table 3; Fig. 14, it can be seen that the \(\:\overline{B}\) of sandstone decreases with the increase of water content. Specifically, for dry sandstone, the brittleness index B ranges from 0.998 to 0.999, with an average brittleness index \(\:\overline{B}\) of 0.999. For sandstone with a water content of 5%, the brittleness index B ranges from 0.996 to 0.999, with an average brittleness index \(\:\overline{B}\) of 0.998, which is a 0.1% decrease compared to the average brittleness index \(\:\overline{B}\) of dry sandstone. For sandstone with a water content of 10%, the brittleness index B ranges from 0.994 to 0.997, with an average brittleness index \(\:\overline{B}\) of 0.996, representing a 0.3% decrease compared to the average brittleness index \(\:\overline{B}\) of dry sandstone. The decrease in the \(\:\overline{B}\) implies that as the water content increases, the rock undergoes more plastic deformation before failure.

-

(2)

From an engineering perspective, following the conventional classification based on the εmax in uniaxial compression tests, where failure is considered brittle when εmax is less than 1%, brittle-ductile when εmax is between 1% and 5%, and ductile when εmaxis greater than 5%33, the εmax of sandstone with different water contents in this experiment all fall within the range of 0.70–0.96% (Table 2), thus the overall failure mechanism is characterized as brittle failure.

Analysis of failure characteristics

The failure characteristics of sandstone with different water contents in uniaxial compression tests are shown in Fig. 15. The failure characteristics of dry sandstone samples (0% water content) are primarily shear failures (Fig. 15(a), 15(b), and 15(c)). Specifically, before failure, the dry samples typically exhibit large pieces falling off at the top (Fig. 15(a)), forming a “Y”-shaped shear failure. This is followed by single-plane shear failure (Fig. 15(b) and 15(c)). The reason for this is the pronounced brittleness of dry sandstone, which leads to a relatively rapid failure process. The crack propagation mainly occurs along the principal shear plane, creating a distinct failure surface. The characteristic of this brittle failure is the large width of the cracks, which quickly penetrate through the sample, leading to rapid failure.

Sandstone samples with water contents of 5% and 10% exhibit a combination of tensile and shear failure characteristics. Specifically, some samples display tensile failure (Fig. 15(e) and 15(h)), characterized by a main crack that runs through the entire specimen and is parallel to the vertical axis. This form of failure indicates that the rock experienced concentrated tensile stress during compression, leading to crack propagation in the vertical direction. Additionally, mixed shear and tensile failures are observed, with some water-saturated sandstone samples still showing “Y”-shaped shear failures, but with a more complex distribution of cracks. The cracks not only propagate along the main shear plane but may also generate secondary cracks (Fig. 15(d), 15(f), 15(g), and 15(i)). This is due to the presence of free water in the internal pores and micro-cracks of the sandstone when the water content increases. When subjected to external forces, the free water cannot be expelled in time, resulting in pore pressure. This pore pressure reduces the effective stress between particles, decreases the shear strength, and can even generate tensile stress at the tips of micro-cracks, leading to splitting failure in the rock34.

Acoustic emission characteristics of sandstone under uniaxial compression at different water contents

The stress, ring count, cumulative ring count, and damage variable changes over time during the uniaxial compression and acoustic emission tests of sandstone with three different water contents were used to study the characteristics of acoustic emission parameters during the deformation and fracturing process of the rock samples.

Analysis of the evolutionary characteristics of stress, ring count, cumulative ring count, and damage variable

The acoustic emission ring count feature reflects the intensity and frequency of acoustic emission events, which is an important parameter for analyzing the internal damage evolution and failure process of rocks35. The damage variable Dacan be expressed as36:

in the formula, N0 is the cumulative ring count when the rock body is completely damaged without any prior damage, and Nt is the cumulative ring count of the rock body at the time of loading.

The damage variables for the three types of sandstone with different water contents under uniaxial compression were calculated using the above formula. The changes in acoustic emission ring count, cumulative ring count, and damage variable over time during the uniaxial compression test of the three types of water-saturated sandstone were used to study the characteristics of acoustic emission parameters during the deformation and failure process of the rock samples. The stress, ring count, cumulative ring count, and damage variable changes over time for sandstone with different water contents are shown in Fig. 16.

From Fig. 16, the following observations can be made: ① Relationship between stress and ring count: The peak ring counts for both dry and water-saturated sandstone are concentrated near the peak stress, indicating that during the failure stage, internal cracks in the rock rapidly extend and generate high-frequency acoustic emission signals. Several distinct stress drops can also be observed on the stress curve, each accompanied by a significant increase in ring count, indicating that crack propagation leads to local damage, which in turn triggers a sudden decrease in stress. ② Relationship between stress and cumulative ring count: As stress increases, crack propagation accelerates, and the cumulative ring count exhibits exponential growth. Particularly near the peak stress, crack propagation reaches its maximum rate, causing a sudden increase in acoustic emission signals. After the sandstone fails, stress drops sharply, and the ring count also decreases. However, residual ring counts remain after failure, indicating significant deformation activity within the sandstone, possibly due to further crack propagation and the sliding of small particles. ③ Acoustic emission characteristics at low load stages: At lower load stages, micro-cracks and pores within the sandstone gradually close, resulting in less acoustic emission activity and lower ring counts. This is because during the crack closure process, less energy is released, and some acoustic emission signals do not have sufficient energy to exceed the detection threshold and are therefore filtered out. However, due to the heterogeneity of sandstone, local weak planes may fail preferentially, leading to the premature appearance of signals with high ring counts, as shown in Fig. 16(a), 16(c), 16(f), and 16(h). ④ Relationship between cumulative ring count and damage variable: The cumulative ring count and damage variable curves are consistent. Based on the slope changes of the time and damage variable curves, the damage evolution process of sandstone with different water contents under uniaxial compression can be divided into three stages: (a) Initial damage stage (G1), which is the compaction stage of sandstone. In this stage, some damage has already occurred within the sandstone of all three water contents, with damage development being relatively gentle and damage variables generally at low values. This is because the original fissures within the sandstone are compacted, and sandstone particles exhibit relative slippage, resulting in relatively minor damage. However, due to the heterogeneity of sandstone, some internal weak layers within the sandstone begin to fail under small loads in the early loading stage, causing the damage variable curve to develop more rapidly in the early G1 stage, as represented by Fig. 16(a), 16(c), 16(f), and 16(i); (b) Stable damage development stage (G2), in which, with the continuous increase of stress, sandstone enters the elastic deformation stage, crack expansion is relatively stable, new cracks gradually appear, acoustic emission signals are relatively frequent but not intense, and damage values increase steadily. The growth rate of the damage value-time curve in the stable damage development stage is significantly higher compared to the initial damage stage; (c) Rapid damage increase stage (G3), where G3 is the stage of rapid crack expansion and unstable development. In this stage, the internal stress of the sandstone reaches its ultimate bearing capacity, cracks quickly penetrate, leading to massive damage, and both the number of acoustic emission events and damage values increase sharply. The cumulative ring count in this stage shows exponential growth, and the damage curve has a slope close to vertical, indicating rapid crack expansion.

Relationship between different water contents and cumulative ring count, damage variable

Relationship between different water contents and cumulative ring count: A comparison between dry sandstone and sandstone with 5% and 10% water content shows that the cumulative ring count for water-saturated sandstone is significantly lower than that of dry sandstone under uniaxial compression. Specifically, the cumulative ring count for dry sandstone under uniaxial compression ranges from 6.0693 million to 6.3345 million instances, with an average of 6.164 million instances. For sandstone with 5% water content, the cumulative ring count ranges from 2.2294 million to 2.9098 million instances, with an average of 2.5139 million instances. For sandstone with 10% water content, the cumulative ring count ranges from 1.5306 million to 2.4385 million instances, with an average of 1.9051 million instances. As shown in Fig. 17, the average cumulative ring count decreases with increasing water content. The analysis suggests that the presence of water in the pores of sandstone weakens the bonding strength between sandstone particles, reducing the strength of the crystals and the bonding strength between them, which in turn lowers the energy required for sandstone failure, directly manifesting as a significantly reduced cumulative ring count during the failure of saturated sandstone, further indicating the significant impact of water on sandstone.

Relationship between different water contents and damage variable: In the initial stage of damage, the damage variable of dry sandstone is relatively low. For saturated sandstone, the initial damage degree is higher compared to dry sandstone. Before the sandstone reaches the failure stage, the damage variables for 0% water content sandstone are 0.821, 0.431, and 0.831, with an average of 0.694; for sandstone with 5% water content, the damage degrees are 0.843, 0.913, and 0.931, with an average of 0.896; for sandstone with 10% water content, the damage degrees are 0.910, 0.953, and 0.902, with an average of 0.922. Before the failure stage, the damage degree of dry sandstone is much lower than that of water-saturated sandstone. Compared to dry sandstone, the damage degree of sandstone with 5% water content has increased by 29.1%, but it is still at a relatively low level. The damage degree of sandstone with 10% water content has increased by 32.9%. Figure 17 shows that the damage variable increases with the increase of water content. The analysis suggests that the failure of sandstone is due to the continuous expansion and interconnection of internal native fissures under external load, eventually forming a fracture surface that penetrates the rock mass. In the case of water-saturated sandstone, water enters the pores and native fissures of the sandstone, and the lubricating and moistening effect of water reduces the frictional resistance between sandstone particles, lowering the ability of internal weak layers to resist slippage.

In summary, the damage variable of dry sandstone is relatively low in the early stages of uniaxial compression, and it increases dramatically during the failure stage, leading to sudden failure. However, with the increase of water content, the initial damage variable of sandstone increases, and the damage variable during the failure stage is much lower compared to dry sandstone. This is consistent with the brittleness index mentioned earlier; the addition of water significantly reduces the brittleness index of sandstone, thereby reducing the probability of sudden failure.

Relationship between RA-AF values and fracture failure

As two crucial parameters of acoustic emission (AE), the RA (Rise Time/Amplitude) and AF (Average Frequency) values can characterize the types of internal cracks in materials. The RA value is calculated by dividing the rise time of the AE signal by its amplitude, with units of ms/V−1. The AF value is determined by dividing the number of AE counts exceeding a threshold by the duration of the AE hit, with units of kHz. Generally, low AF values and high RA values indicate the formation or development of shear cracks, while high AF values and low RA values suggest the formation or development of tensile cracks37.

The RA-AF values can characterize the crack propagation modes in rock masses. In Fig. 18, the slope of the dividing line is defined as k. When AF/RA > k, the crack exhibits tensile failure characteristics, whereas when AF/RA < k, the crack exhibits shear failure characteristics. According to the classification methods presented in References38and39, the value of k was determined to be 400 through moment tensor inversion.

Representative samples of sandstone with different water contents were selected for analysis of the relationship between RA-AF values and crack failure modes. The relationship between RA-AF values and crack failure modes in sandstone samples with different water contents is shown in Fig. 19. Figure 19(a) presents the RA-AF value distribution for sample SU0-3. The RA values range from 0 to 792.44ms/V−1, and AF values range from 0 to 5 kHz. Most data points are concentrated in the region where RA < 200ms/V−1 and AF < 1 kHz, below the dividing line, indicating shear failure. This is consistent with the shear failure characteristic observed in the rock sample in the upper right corner of the figure, which shows a distinct oblique shear crack. Figure 19(b) shows the RA-AF value distribution for sample SU5-1. The RA values range from 0 to 46.64ms/V−1, and AF values range from 0 to 4 kHz. Most data points are concentrated in the region where RA < 20ms/V−1 and AF < 1 kHz, on the dividing line, indicating a mixed mode of shear and tensile failure. This corresponds to the mixed shear and tensile failure characteristic observed in the rock sample in the upper right corner of the figure, which shows spalling and irregular cracks. Figure 19(c) presents the RA-AF value distribution for sample SU10-1. The RA values range from 0 to 1086.03ms/V−1, and AF values range from 0.02 to 59.69 kHz. The data points are more dispersed, distributed on both sides of the dividing line, indicating a mixed mode of shear and tensile failure. This is consistent with the mixed shear and tensile failure characteristic observed in the rock sample in the upper right corner of the figure, which shows cracks propagating in multiple directions.

Characteristics of scanning electron microscopy (SEM) on the fracture surfaces of water-saturated sandstone under uniaxial compression

The scanning electron microscopy (SEM) test results of sandstone with water contents of 0% and 10% were used to analyze the micromorphological characteristics and fracture mechanisms of sandstone.

Analysis of micromorphological characteristics and fracture mechanisms of dry and saturated sandstone under uniaxial compression fracture surfaces

Figure 20presents the SEM scanning results of sandstone with different water contents, from which the microfeatures of the fracture surfaces can be observed, including intergranular fracture, transgranular fracture, cleavage steps, river patterns, dimples, and slip separation. The majority of these microfeatures are intergranular fracture, cleavage steps, and river patterns, which further indicate that the failure mode of the three types of sandstone is brittle failure40.

In the microfeatures, intergranular fracture indicates that under compressive load, the lubricating effect of water accelerates the propagation of cracks along weak interfaces (grain boundaries); transgranular fracture shows significant stress concentration, indicating that the internal destruction of rock grains occurs in high-stress areas; both intergranular and transgranular fractures reflect the brittle characteristics of sandstone, which coincide with the macroscopic failure characteristics of sandstone (such as sudden brittle failure and rapid energy release). They are also consistent with the high ring counts and cumulative ring count peaks observed in acoustic emission tests, especially during the G3 stage when cracks expand unstablely, leading to a sharp increase in acoustic emission signals, indicating rapid internal rock fracture. The rapid crack expansion of cleavage steps and river patterns is manifested as linear or stepped features on the fracture surface. The propagation path of cracks can also be observed, especially under high stress, where cracks rapidly expand along weak planes in the crystal structure. These rapid crack expansion characteristics correspond to the brittle failure behavior of water-saturated sandstone and are also consistent with the significant increase in ring counts at the stress peak in acoustic emission tests, further reflecting the rapid expansion and massive destruction of cracks, especially during the G3 stage when the crack expansion is no longer local but penetrates the entire rock mass, leading to brittle fracture. Local ductile characteristics such as slip separation and dimples occur at the edges or interfaces of some grains, where slip separation reflects the relative sliding between particles under the lubricating action of water, and dimples indicate local ductile deformation, corresponding to the G1 and G2 stages in the damage evolution curve. In these two stages, cracks expand gradually and stably, with acoustic emission signals increasing gradually, indicating a mild initial crack expansion phase with local ductile behavior, especially at high water contents.

Analysis of the impact of water content on the micromorphological features of sandstone fracture surfaces

Figures 21 and 22 clearly show the differences in the micromorphology of the fracture surfaces between dry and saturated sandstone under uniaxial compression. Under dry conditions, the development of internal mineral grain fractures is more pronounced (intergranular fracture), with less attached rock debris within the grain fractures and larger debris volumes. The extension trajectory of the fractures is clear and easily identifiable, forming distinct fracture paths. The fracture surfaces of the dry rock samples are angular with distinct edges and can clearly distinguish the protrusions and depressions of the fracture surfaces. There is a certain amount of cementing material at the fracture, forming a relatively stable structural feature with the surrounding minerals, and the surface has some small pores and cracks, with a relatively dense structure. In contrast, the saturated samples have less cementing material, with exposed and peeled mineral grains, and the development and expansion of grain-to-grain fractures and pores. The fractures between grains tend to penetrate, leading to the development of both transgranular and intergranular fractures, with multiple transgranular fractures cutting through grains at local positions, and intergranular fractures converging and penetrating. After the sandstone is saturated with water, the cementing material is dissolved, the grain pores enlarge, and the size of the pores significantly increases. At the same time, the cementing structure between mineral grains is severely damaged around the cracks and on the surface of the mineral grains.

Mineral element analysis of sandstone fracture surfaces

EDS scans were performed on the fracture surfaces of uniaxial compression specimens with water contents of 0% and 10%. The scanning locations are shown in Fig. 23, and the atomic number proportions at the fracture surfaces of dry and 10% water-saturated sandstone are shown in Fig. 24.

From Fig. 24, it can be observed that the main elements in sandstone include O, Si, Fe, Ca, Na, Al, C, and Mg. In dry sandstone, the content of elements such as silicon (Si), iron (Fe), calcium (Ca), sodium (Na) and Aluminum (Al) is relatively high, indicating that the main minerals in sandstone, such as quartz, hematite, calcite, feldspar, and kaolinite, maintain a relatively intact structure. Compared to sandstone at 0% moisture content, the content of these elements in sandstone at 10% moisture content is lower, while the atomic mass fraction of carbon (C) is significantly higher than in the 0% moisture content sandstone. This is primarily due to the higher solubility of calcite in water, especially in water containing carbon dioxide, where calcium carbonate reacts with water and carbon dioxide to form soluble calcium bicarbonate, leading to an increase in the content of carbon elements and the deterioration of the rock41.Due to the increased content of carbon (C) elements, the overall molecular mass of the sandstone has increased. Meanwhile, the content of calcium (Ca) elements remains unchanged, resulting in a decrease in the mass fraction of Ca. Feldspar, which contains sodium (Na), is difficult to react with water under normal temperature and pressure conditions, but due to the pressurized saturation of sandstone, feldspar can react with water under high pressure, undergoing hydrolysis to form soluble minerals, resulting in the destruction of the mineral structure42. Additionally, sandstone contains a large number of Si and O atoms, and water can significantly weaken the strength of quartz crystals, especially at the crack tips, where water molecules replace Si-O bonds through hydrogen bonding, promoting crack propagation and thus reducing the strength of sandstone43,44,45.

Relationship between sandstone grain size and strength

The analysis process of the relationship between grain size and strength of sandstone is shown in Fig. 25. Specifically, secondary electron images are first imported into ImageJ(link of software:https://imagej.net/ij/download.html;version number: ImageJ bundled with 64-bit Java 8). Then, the scale is calibrated by converting the pixel-based secondary electron images into micrometers (µm) based on a known dimension in the image. Finally, the grains within the rock are marked, measured, and statistically analyzed using the ROI Manager command.

The marking of dry sandstone grains is shown in Fig. 26. The statistical results indicate that the maximum grain diameter is 460.71 μm, the minimum is 122.48 μm, and the average is 241.74 μm. The marking of saturated sandstone grains is shown in Fig. 27. The statistical results show that the maximum grain diameter is 406.57 μm, the minimum is 58.34 μm, and the average is 173.69 μm. It is evident that the average grain size of saturated sandstone is smaller than that of dry sandstone. Moreover, the strength of saturated sandstone is lower than that of dry sandstone. This suggests that the strength of the rock decreases with the reduction in grain size, which is consistent with the findings reported in the literature46.

Mineral component analysis of sandstone based on X-ray diffraction

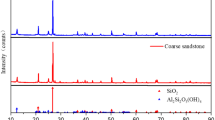

The mineral composition of sandstone was analyzed using the results from the XRD tests of three dried sandstone samples.

Procedure for quantitative mineral phase analysis of sandstone

Based on the XRD analysis results, the preliminary identification of the mineral phases in sandstone was achieved using phase retrieval technology. Subsequently, the scanning electron microscopy-energy dispersive spectroscopy (SEM-EDS) analysis results were integrated for accurate qualitative analysis of the sandstone mineral categories. Further quantification of the mineral composition was conducted using the Rietveld refinement technique (Fig. 28). The specific analytical steps are as follows: ① The original XRD scan data were processed using PowDLL Converter and subsequently opened with Jade software; ② Full-spectrum and single-peak unconditional searches were conducted based on the characteristics of the diffraction peaks to determine the range of mineral phases; ③ Integrating the SEM-EDS elemental analysis results for sandstone, accurate qualitative mineral identification results were obtained; ④ Rietveld refinement was performed on the qualitative identification results (importing the crystal structure information file, the cif file, into Fullprof software(link of software:https://mp.weixin.qq.com/s/sc6xxr51pPrlxi3eBFwPuw;version number: FP_Suite 64bits) to generate a pcr file, and then refining the graph, structural parameters (atomic coordinates, occupancy, and temperature factors), background, zero point, etc., within the Fullprof environment until the Rwp (weighted residual factor) met the requirements, after which other mineral phases were added one by one); ⑤ Based on the phase relationships from the refinement results (the order of mineral component contents obtained from the initial refinement) and the refinement sequence, as well as the precision requirements for Rwp, it was determined whether a second refinement was necessary; ⑥ The second refinement involved adjusting the refinement sequence according to the mineral phase proportion order from the previous refinement, from most to least, until the required precision was met; ⑦ After obtaining the final refinement results, the data were imported into Origin software(link of software:https://mp.weixin.qq.com/s/oD3o-4q5gQ4PWhRAvWlEcg;version number: Origin 2021) for plotting the refinement results and statistical analysis of the mineral content.

Phase analysis of different sandstone samples

The study of the phases and their contents in sandstone samples (three specimens) was conducted using X-ray diffraction (XRD) technology and Rietveld refinement technique. The types of phases and refinement results for the three sandstone specimens are shown in Fig. 29, and the phase contents and their average percentage results for the three sandstone specimens are presented in Table 4.

In the refinement result plots of the sandstone samples (Fig. 29(b), 29(d), and 29(f)), the red line represents the observed pattern (obs), the black line represents the calculated pattern (calc), and the blue line represents the difference plot (diff). The difference plots for the majority of the samples are generally flat, with only occasional minor peak-like fluctuations at certain positions, indicating a good fit, that is, a high degree of match between the calculated and observed patterns. Additionally, the refinement in this study uses the R-factor, specifically Rwp (weighted residual factor), as an indicator of the quality of the refinement results. It is generally accepted that a lower R-factor indicates a better refinement outcome. When the Rwp is around 10%, the refinement results can be considered reliable47.

As shown in Table 4, the types and contents of the phases in the sandstone are as follows: feldspar (25.91%), calcite (20.33%), muscovite (28.71%), quartz (18.45%), kaolinite (0.82%), talc (5.33%), and hematite (0.45%).

Relationship between quartz content and the strength of sandstone

Quartz endows sandstone with high strength48. X-ray diffraction (XRD) tests on dry sandstone further confirmed that the mineral containing silicon (Si) is quartz. Combining the analysis of Si-O bonds in Sect. 3.3.3 and Fig. 24, it was found that after saturation, the mass of silicon elements in sandstone decreased, leading to a reduction in quartz content, which in turn caused a decrease in sandstone strength.

Conclusions

Based on the study of the uniaxial compressive mechanical properties and micro-damage mechanisms of water-saturated sandstone, the following conclusions were drawn:

(1) With the increase in water content, the elastic modulus, strength, peak strain, and brittleness index of sandstone decrease, indicating a trend of weakening mechanical performance; the failure characteristics of dry sandstone specimens are primarily shear failure, while those of water-saturated sandstone specimens are mainly mixed tensile and shear failure.

(2) The cumulative ring count of acoustic emission in water-saturated sandstone decreases with the increase in water content; the damage evolution process can be divided into the initial damage stage, stable damage development stage, and rapid damage increase stage, with the damage variable in water-saturated sandstone increasing with water content.

(3) The micro-morphological characteristics of the fracture surfaces of dry and saturated sandstone under uniaxial compression include intergranular fracture, transgranular fracture, cleavage steps, river patterns, dimples, and slip separation, with most micro-features being intergranular fracture, cleavage steps, and river patterns, thus further indicating that the failure mode of the three types of sandstone is brittle failure.

(4) The content of elements such as silicon (Si), iron (Fe), calcium (Ca), sodium (Na) and Aluminum (Al)in dry sandstone is relatively high, while in sandstone with 10% water content, these elements are lower in content, and the carbon (C) element content is significantly higher than in sandstone with 0% water content.

(5) The average grain size of saturated sandstone (173.69 μm) is smaller than that of dry sandstone (241.74 μm), and the strength of sandstone decreases with the reduction in grain size.

(6) The major minerals in the sandstone include feldspar (25.91%), calcite (20.33%), muscovite (28.71%), and quartz (18.45%). Among these, quartz endows the sandstone with higher strength, and the strength of the sandstone decreases with a reduction in the quartz content.

Credit authorship contribution statement.

Kaide Liu: Writing – review & editing, Writing-original draft, Funding acquisition, Formal analysis, Data curation, Conceptualization. Songxin Zhao: Writing – review & editing, Software, Project administration, Formal analysis, Conceptualization. Diao Lu: Writing – original draft, Data curation, Software, Conceptualization. Wenping Yue: Supervision, Conceptualization. Chaowei Sun: Investigation, Conceptualization. Yu Xia: Software, Project administration, Investigation.

Data availability

All data generated or analyzed during this study are included in the published paper. The detailed data could be supplied on demand after corresponding author.

References

Li, Q. et al. Wellhead stability during development process of hydrate reservoir in the Northern South China Sea: evolution and mechanism[J]. Processes 13 (1), 40 (2024).

Li, Q. et al. The crack propagation behaviour of CO2 fracturing fluid in unconventional low permeability reservoirs: factor analysis and mechanism Revelation[J]. Processes 13 (1), 159 (2025).

National Bureau of Statistics.Statistical. Bulletin on nationaeconomic and social development of the People’s Republic of China in 2022 [EB/OL].(2024-02-29)[2024-04-01].

Bi, Y. et al. Study on the Characteristics of Soil Moisture Infiltration and Evaporation in Coal Mining Subsidence Area of Coal Mines in Northern Shaanxi51839–849 (Journal of China University of Mining & Technology, 2022). 5.

Yuan, L. et al. The concept, model and reserve forecast of green coal resources in China. J. China Univ. Min. Technol. 47 (1), 1–8 (2018).

Miao, S. et al. Effects of confining pressure on failure mechanism of porous and weakly cemented rock and compaction-damage constitutive model. J. China Univ. Min. Technol. 52 (2), 229–240 (2023).

Wang, S. & Ming Coal Accumulation Patterns and Coal Resource Assessment in the Ordos Basin (China Coal Industry Publishing House, 1996).

Dong, S. et al. Causes and Prevention Technologies of Typical Roof Water Hazards in Coal Seams of the Ordos Basin (Science, 2021).

Sun, X. et al. Experimental study on creep mechanical properties of sandstone with different water contents in Wanfu coal mine. Rock. Soil. Mech. 44 (03), 624–636 (2023).

Zhang, Y. et al. Mechanical properties and acoustic emission characteristics of sandstone under dry and saturated conditions during compression failure. Coal Geol. Explor. 50 (02), 98–105 (2022).

Zhang, C. et al. The characteristics of uniaxial compression failure and weakening mechanism of sandstone under the influence of water saturation. J. China Univ. Min. Technol., 1–15 [2024-10-22].

Dang, Y. et al. Evolution characteristics of energy and damage in rock materials under different water contents. High. Press. Phys. 37 (03), 62–71 (2023).

Zheng, W. et al. Study on the influence pattern of water content on rock charge induced signals. Rock. Soil. Mech. 43 (3), 659–668 (2022).

Teng, T. et al. Experimental and theoretical study on the compression characteristics of dry/water-saturated sandstone under different deformation rates. Arab. J. Geosci. 13, 1–10 (2020).

Lu, Y. et al. Experimental study of the influence of water and temperature on the mechanical behavior of mudstone and sandstone. Bull. Eng. Geol. Environ. 76, 645–660 (2017).

Yao, Q. et al. Strength deterioration and acoustic emission characteristics of water-bearing sandstone in uniaxial compressive experiment. J. Min. Saf. Eng. 30 (5), 717–722 (2013).

Duan, T. et al. Mechanical properties of sandstone under uniaxial compression and damage assessment using the P-wave velocity method at different water contents. Coal Geol. Explor. 47 (04), 153–158 (2019).

Li, H. et al. The influence of water content on the mechanical properties of weakly cemented sandstone. J. Min. Strata Control Eng. 3 (04), 60–66 (2021).

Zhao, K. et al. Effect of water content on the failure pattern and acoustic emission characteristics of red sandstone. Int. J. Rock Mech. Min. Sci. 142, 104709 (2021).

Chen, J. et al. Progressive failure characteristics and damage constitutive model of rock samples under water immersion conditions. J. China Coal Soc., 1–19 [2024-10-22].

Luo, Z. et al. Research on the Influence of Moisture Condition on the Mechanical Properties and Microstructure of Sandstone. Shock and Vibration, 2021. (2021).

Fan, L. et al. Stress-Water coupling effects on failure of sandstone based on Real-Time CT technology. Rock Mech. Rock Eng. 56 (6), 4329–4341 (2023).

Yang, P. et al. Real-time porosity inversion of rock based on the ultrasonic velocity and its compression-damage coupled model under triaxial compression. Sci. Rep. 14, 29252 (2024).

Xia, K. et al. Research progress on the dynamic mechanical response of deep rock under Fluid-Solid coupling. J. China Coal Soc. 49 (01), 454–478 (2024).

Tang, C. et al. Study on the particle disintegration characteristics and microscopic mechanism of red sandstone under Dry-Wet cycling. Mater. Rep. 37 (S2), 278–282 (2023).

Chen, G. et al. Mechanical properties and damage characteristics of Coal-Rock composites under Water-Rock interaction. Coal Sci. Technol. 51 (04), 37–46 (2023).

Feng, F. et al. Experimental study on the failure characteristics of natural and saturated sandstone under true triaxial Unloading-Dynamic disturbance. Chin. J. Rock Mechan. Eng. 41 (11), 2240–2253 (2022).

Yang, Z. et al. Water absorption characteristics and Micro-Evolutionary patterns of Strongly-Moderately weathered siliceous slates in Water-Rich environments. J. Min. Strata Control Eng. 6 (01), 141–152 (2024).

Gou, B. et al. Influence of supercritical CO_2 on the mechanical properties of dense carbonate rocks. J. Southwest. Petroleum Univ. (Science Technol. Edition). 46 (02), 65–76 (2024).

Zhang, J. et al. Water-Rock (Soil) chemical action in the formation of soft interlayers in red bed accumulations. People’s Yangtze River. 54 (12), 142–146 (2023).

Cheng, J. et al. Research on the control technology of floor heaving in deep structurally stressed and Water-Rich soft rock roadways based on blasting unloading. Coal Sci. Technol. 50 (07), 117–126 (2022).

Asemi, F. et al. A new rock brittleness index based on crack initiation and crack damage stress thresholds. Int. J. Geomech. 24 (5), 040240741–040240712 (2024).

Liu, K. et al. Study on cleavage and uniaxial compression tests considering the effect of bedding direction in coal rock. Chin. J. Rock Mechan. Eng. 32 (2), 308–316 (2013).

Yao, Q. et al. Direct shear characteristics and acoustic emission features of sandy mudstone under the influence of water content. J. China Coal Soc. 46 (09), 2910–2922 (2021).

Zhou, L. et al. Acoustic emission and damage evolution characteristics of thermally damaged granite under triaxial compression creep failure. J. Cent. South. Univ. (Science Technology). 54 (06), 2360–2369 (2023).

Shen, P. et al. A damage mechanics based on the constitutive model for strain-softening rocks. Eng. Fract. Mech., 216. (2019).

Zhou, Y. et al. Identification of cracking characteristics of limestone under uniaxial compression condition using acoustic emission and GMM[J]. Water Resour. Hydropower Eng. 2019, 50(11):131–140 .

Gan, Y. Research on Parameter Characterization of Rock Fracturing and Optimizing of Locating Methods of AE Monitoring in Underground Engineering [D]. Beijing: University of Science and Technology Beijing, 2020。.

Li, Y. et al. Acoustic emission RA-AF characteristics of different stratification coal during failure process. Coal Mine Saf. 53 (01), 37–43 (2022).

Liang, Z. et al. Triaxial compression and Micro-Fracture mechanism of yellow sandstone after High-Temperature effects. Sci. Technol. Eng. 21 (24), 10430–10439 (2021).

Ma, C. et al. Dissolution and precipitation of calcite in different water environments. Chin. Karst. 42 (01), 29–39 (2023).

Xue, W. et al. Feldspar dissolution mechanism in clastic rocks and its contribution to diagenesis. Complex. Oil Gas Reservoirs. 8 (01), 1–6 (2015).

Griggs, D. et al. Quartz: anomalous weakness of synthetic crystals. Science, 147(3655), 292–294 .

Atkinson, B. et al. The theory of subcritical crack growth with applications to minerals and rocks. J. Geophys. Research: Solid Earth, 92(B7), 8783–8794 .

Dunning, J. et al. Water in quartz at high pressure: the effect of water fugacity on dislocation mobility. J. Geophys. Research: Solid Earth. B2, 1175–1182 (90).

Lakirouhani, A. et al. The influence of grain size on the physical parameters, tensile and compressive strength of dolomite rock samples. J. Civil Eng. Manage., 26(8), 789–799 .

Huang, J. et al. Polycrystalline Material X-ray Diffraction - Experimental Principles, Methods, and Applications (Metallurgical Industry, 2012).

Lakirouhani, A. et al. Physical and mechanical properties of sandstones from Southern Zanjan, north-western Iran. Baltica, 35(1), 23–36 .

Acknowledgements

This work is supported by The National Nature Science Foundation of China (No.52104222, No.51909224), the Natural Science Basic Research Program of Shaanxi (2021JLM-48, 2020JQ-920, 2019JM-182), and the Special Fund for the Launch of Scientific Research in Xijing University (XJ18T04). The authors would like to express sincere thanks to the reviewers for their thorough reviews and valuable advice.

Author information

Authors and Affiliations

Contributions

K. L.: Writing – review & editing, Writing-original draft, Funding acquisition, Formal analysis, Data curation, Conceptualization. S. Z.: Writing – review & editing, Software, Project administration, Formal analysis, Conceptualization. D. L.: Writing – original draft, Data curation, Software, Conceptualization. W. Y.: Supervision, Conceptualization. C. S.: Investigation, Conceptualization. Y. X.: Software, Project administration, Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, K., Zhao, S., Diao, L. et al. Research on the mechanical properties and micro damage mechanism of water bearing sandstone under uniaxial compression. Sci Rep 15, 7320 (2025). https://doi.org/10.1038/s41598-025-91736-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-91736-z