Abstract

A novel foldable model is used for extending the constitutive relations of a cylindrical pressure vessel composed of the copper matrix cylinders reinforced with three-dimensional nanofillers named as graphene origami. Deformability is accounted based on the shear deformable kinematic model using the first order shear deformation theory. The overall material characteristics are evaluated using the Halpin–Tsai micromechanical models and rule of mixture. The governing equations are derived using the virtual work principle. Nanofiller characteristics dependent results are obtained using the analytical method. The results show an enhancement in the deformation and stress components with an enhancement in the foldability parameter and thermal loads as well as decrease in volume fraction.

Similar content being viewed by others

Introduction

Graphene origami is introduced as novel reinforcement for application in the copper matrix. Furthermore, the origami shapes can be used in biomedical applications such as reported in DNA format1,2,3,4. The graphene origami as a novel nanostructure is produced using the hydrogenation from the two-dimensional graphene sheets and nanoplatelets. The hydrogenation process can be used to arrive at three-dimensional graphene sheets known as graphene origami. A brief visual description of hydrogenation process is presented in Fig. 1 based on Reference5.

The schematic figure of a graphene origami5.

The copper material can be used as matrix or coverage in the composite reinforced structures and materials6,7. The graphene origami as a novel reinforcement can be used in the mechanical elements in the plate8 and shell configuration9. Choi et al.4 developed application of origami nanostructures in the DNA form using the microbeads4. The mechanical behavior of auxetic metamaterials and graphene origami in various structural elements and configurations was illustrated in the recent references10,11,12,13,14.

Pressure vessels are used in the various situations as a reservoir or container of pressurized gas or liquid. Analysis of a pressurized pressure vessel is necessary for design of this equipment to arrive an optimized sketch and design. Stress and deformation analysis of pressure vessels are the important requirements for a pressure vessel designer to check necessary criteria. Application of novel materials for the pressure vessels leads to an innovative design strategy. The nanocomposite and nanofillers are recently used for manufacturing the various technical equipment specially for the pressure vessels. The 3D nanofillers are introduced as a novel material with controllable and tuneable material characteristics. These materials are named as graphene origami that are made from hydrogenation of two dimensional graphene sheets with controllable folding characteristics. The graphene origami is used as a controllable material in which the thermal loads are used an effective parameter for changing the material properties. The experimental and statistical methods are used for estimation of the overall material properties of graphene origami enabled copper matrix materials.

Liu et al.15 presented a numerical investigation on the improvement of the mechanical behavior and responses of the nanocomposite sandwich plate using a differential quadrature approach. Molecular dynamic and moving least square approaches were developed for estimation of the overall material properties and extending the mesh free approach. Song et al.16 extended a lower order shear deformable model for investigating the bending and buckling responses of the multi-layered composite plate, where the overall material characteristics were evaluated using the micromechanical-based models. Zghal et al.17 studied effect of a higher order shearing kinematic model for investigating the nonlinear responses of the nanotube reinforced shell with various distributions and functionalities. After presentation of convergence study, an investigation on the impact of various patterns of reinforcement and its amount on the responses was provided. Feng et al.18 presented an analytical work for investigating the impact of geometric nonlinearity and graphene nanoplatelets patterns on the large deflection bending results of the nanocomposite reinforced beam using the micromechanical model and Ritz method. They discussed on the impact of various nanofillers dispersion and its effect on the overall stiffness of the nanocomposite beam. The copper matrix based composite materials and structures are used for special purpose in structural elements and analyses19,20,21,22,23. Meng et al.24 extended a novel process for conversion of two dimensional graphene sheets structure to three dimensional structures through a folding process where a chemical process including hydrogenation was used. Continuum-based formulation as well as molecular dynamic simulation were extended in order to evaluate Miura-ori effective properties. Programmability and tuneability of the constituent materials were explained with changes of important parameters. Characteristics of graphene origami based composite metamaterial through a hydrogenation process was illustrated by Guo et al.25. They concluded on the effect of various dispersion of folded microstructures and thermal loads on the overall material properties of composite structure. Effect of characteristics of folded structure was examined on the wave dispersion characteristics and general behavior of enabled structure. Murari et al.26 used a Timoshenko framework for investigating the vibrational behavior of enabled metamaterial nanocomposite beam reinforced with folded nanomaterials where the reinforcements were dispersed with a layerwise pattern along the thickness direction. Differential quadrature numerical method was extended for investigating the impact of foldability characteristics as well as content and dispersion patterns of folded graphene on the dynamic responses. Importance and application of folded composite structures were developed in the wave dispersion problems in a Timoshenko beam rested on an elastic foundation by Yang et al.27. Importance of these materials in reflecting an extended response and providing a wide range of dynamic responses with major tuneability in terms of temperature and foldability was explained in detail. Furthermore, an overview on the effect of wave number and various patterns of nanofillers was presented. Fan and Shen28 defined characteristics and importance of graphene origami as a metamaterial with solid phase in micro scales. It was confirmed that the overall material properties of graphene origami inside a copper matric reflects a general anisotropic property and a negative Poisson’s ratio. Furthermore, temperature dependent material properties of those materials was explained in detail. Zhao et al.29 presented an atomistic overview on the new metamaterials with negative Poisson’s ratio using a programmable manufacturing process. In order to overcome the serious conditions of some auxetic materials due to local exceed deformations or high loading failures, the graphene origami was metamaterials was introduced with excellent tuneability.

Chien et al.30 presented a four variable kinematic based formulation in order to present deformation, stability and free vibration analyses of graphene nanoplatelets reinforced plate using the NURBS-based formulation. The various homogenization and mixture rules were employed for investigating the overall material properties of the nanocomposite structure. A curvilinear-based kinematic model was employed for static and dynamic analysis of the graphene nanoplatelet reinforced double curved shell by Wang et al.31, in which the overall material properties were evaluated using the micromechanical models in the Halpin–Tsai format and rule of mixture for various material properties. Bakamal et al.32 employed finite element approach in hierarchical format for investigating the impact of carbon nanotube reinforcement on the various analyses of the nanocomposite plate including buckling, vibrational characteristics and static bending responses. The main novelty of the paper was accounting the impact of van der Waals interaction on the assumed responses. Bouderba et al.33 investigated impact of thermal and mechanical loads on the static results of shear deformable modeled graded plates resting on non-uniform foundation. Higher order deformability was accounted for the displacement field using a novel shape function in order to apply more accurate variation in shear strain components. Hoang et al.34 applied a novel three-dimensional theory in quasi form for transient analysis of a graphene nanoplatelets reinforced composite plate subjected to liquid medium. After derivation of the governing motion equations, the artificial neural network was applied to investigate impact of various parameters such as graphene content and various distributions on the natural frequencies responses. Ansari et al.35 investigated the impact of geometric nonlinearity on the static responses of the graphene nanoplatelets reinforced composite plate with cutout of various shapes. The porosity was accounted for the material distribution and the Gaussian random-field was applied for investigating the effective material characteristics. The problem was analyzed and solved using the variational form of differential quadrature method and finite element formulation. Safarpour et al.36 investigated impact of thermal loads and various foundation characteristics on the vibrational and bending responses of the higher deformable nanocomposite plate using the computational method of generalized differential quadrature method. Sensitivity of the responses with changes of graphene nanoplatelets characteristics and foundation parameter was presented using the parametric analysis.

Tian et al.37 studied dynamic crushing behavior and energy absorption of hybrid auxetic metamaterial inspired by Islamic motif art. Zhao et al.38 investigated the impact of trapezoidal shape of the plate on the static/bending responses of graphene nanoplatelets reinforced nanocomposite plate with various distributions of porosity. The solution procedure was developed using finite element approach in which the Halpin–Tsai micromechanical model was applied for estimation of the effective material properties. A parametric investigation on the impact of various distributions and graphene amount was presented. Ahmadi et al.39 developed a multi scale finite element approach for vibrational and stability responses of nanocomposite plate enriched by carbon nanotubes. They modeled the chemical interactions using some mathematical modeling. García-Macías et al.40 employed some novel models for investigating the impact of agglomeration characteristics of carbon nanotubes on the structural static/dynamic responses of the nanocomposite plate. The sensitivity of the responses was accounted on the static/dynamic responses of the nanocomposite plate. Liu et al.41 studied effect of shear phenomenon on the analytical solution of a corrugated plate made of composite materials. They discussed on the selection of the best configuration of the reinforcement on the dynamic/static responses. Cong et al.42 studied buckling characteristics of a pressurized circular cylindrical shell reinforced with carbon fiber in various configurations.

Wang et al.43 extended the Chebyshev–Ritz based method in order to present the numerical results for static bending analysis of the graphene nanoplatelets reinforced nanocomposite plate using the virtual work principle. They discussed on the impact of graphene nanoplatelets distribution and amount as well as nanofiller characteristics on the deformation characteristics of the nanocomposite plate. Stability-based analysis of the carbon nanotube and carbon fiber reinforced nanocomposite plate was studied using an adopted size-capturing theory by Luo et al.44 based on the Hamilton principle. After constituting the behavioral relations using the homogenization schemes, the numerical results were explored using the analytical approach in order to trace the impact of the filler and nano scale characteristics on the stability characteristics. Jafari Mehrabadi et al.45 investigated impact of straight and inclined carbon nanotubes on the stability responses of the nanocomposite plate subjected to uniaxial/biaxial loading based on Mindlin’s plate as well as first order shear defomation theories and Hamilton’s principle. A large parametric analysis for investigating the impact of the reinforcement characteristics was provided in detail. Sun et al.46 investigated impact of different combination of the boundary conditions on the vibrational analysis of the composite plate reinforced with nano scale reinforcement in nanotube and nanofiller configurations.

Peng et al.47 developed Navier’s technique for free vibration analysis of a sandwich plate integrated with two nanocomposite reinforced composite plate, where the homogenization scheme was applied based on Eshelby Mori Tanaka scheme. Wang48 presented a review paper on the nanocomposite structures and materials and its application in novel structures and systems. They discussed on the impact of various size-capturing theories and homogenization schemes for analysis of the nanocomposite structures and systems. He et al.49 presented an analytical work for investigating the bending responses of nanocomposite sandwich circular and annular plate using the hybrid modeling and theories. The solution was provided using the state space version of the differential quadrature method. A comprehensive investigation on the singular point was provided in the analysis. Liu et al.50 studied bending and free vibration responses of a spherical shell reinforced with various distributions of graphene nanoplatelets subjected to mechanical loads using a general three dimensional elasticity solution method. Wang et al.51 used the Eshelby-Mori–Tanaka methodology for investigating the thermal and mechanical dynamic behavior of the nanocomposite sandwich plate subjected to thermomechanical loads. The pre thermal and mechanical loads were accounted in the external work expression using the constitutive relations. The kinematic modeling was accounted based on the higher order modeling. Miaofen et al.52 provided a detailed dynamic/stability analysis on the nanocomposite plate enriched by carbon nanotubes using a refined version of shear deformation theory in order to satisfy zero out of plane shear strains. Authors used the homogenization scheme for providing the overall material properties with changes of the material characteristics. Mehar and Panda53 prepared a computer simulation-based analysis as well as computer package analysis on the stress and deformation analysis of the nancarbon reinforced nanocomposite plate. The results were evaluated using the theoretical, numerical and experimental analyses and the efficiency of them has been evaluated with changes of various parameters. Shen54 employed a novel mathematical method for investigating the nonlinear behavior of a nanocomposite plate reinforced with single walled carbon nanotubes. The results were provided based on new version of perturbation technique with considering von Karman version of nonlinear strain components. a detailed parametric analysis on the impact of thermal loads and reinforcement content was performed.

In order to capture impact of the micro size in micro systems and structures, the modified couple stress-based formulation was employed for nonlinear static/dynamic analysis of the nanocomposite porous layers by Tao et al.55. The time-varying solution was provide using Newmark integration method. The isogeometric analysis was provided for investigating the numerical analysis.

The advanced materials and composite structures are used in the structural elements for high level analysis and investigations56,57,58. In order to present a more accurate analysis, Hou et al.59 developed a stretchable model for dynamic analysis of graphene origami reinforced sport plate. Structural response of a fiber reinforced sandwich double skin steel annular shells subjected to higher gradient temperature loading by Dong et al.60. Jin et al.61 studied interaction of foldability and thermal loads on the bending results of a higher order shell reinforced with graphene origami. Ma et al.62 studied the impact of micro scale parameters on the static and dynamic results of a microplate using the strain gradient theory. Yu et al.63 presented a study for investigating the simultaneous impact of multi field loading and graphene origami characteristics on the responses of sandwich composite reinforced curved beam. Huang et al.64 developed a new mathematical solution for investigating the impact of various boundary conditions on the bending responses of golf club cylindrical shell. Some important works on the impact of graphene origami in advanced structures and systems can be observed in the literature65,66,67,68. Adab and Arefi et al.69 illustrated a large parametric analysis for investigating the impact of various characteristics of graphene nanoplatelets on the bending analysis of composite truncated conical porous shell using a shear deformable model. An investigation on the convergence of the results with changes of layer’s number was presented. Furthermore, the size dependent analysis was carefully discusses using the nonlocal elasticity theory.

A more range of negative values for Poisson’s ration and higher values for elasticity modulus was reported through this experimental work. Some experimental works were suggested for preparation and characterization of graphene based nanocomposite structures. For example, Guo et al.70 reported details of two experimental works regarding preparation of SiO2 nanocomposites with graphene sheets using the hydrothermal reaction. Du et al.71 extended a single step operation for application of carbon fibers as reinforcement in a folded structure using graphene origami. Some analytical approaches were developed for providing upper and lower limits of out of plane and in plane compressive strengths. Various characteristics such as failure modes, history of deformation and compressive strengths of manufactures composite structure were computed using theoretical, numerical and experimental analyses72,73. There are some important works on the modeling and material science of graphene and origami materials in the literature74,75,76,77. Application of auxetic metamaterials with negative Poisson’s ratio in sensor and actuator application was developed in a review paper by Ren et al.78. Furthermore, the new production method such as additive manufacturing process was developed by Kolken and Zadpoor79 for application in biomedical equipments, soft robotics and electronics in micro/nano scale. The material properties and strength characteristics of the graphene origami auxetic metamaterials were explained for application in energy systems and structure by Han et al.80. Some experimental and numerical simulation were developed by the researchers81,82 for analysis of the mechanical and thermal properties of the auxetic metamaterials. Application of auxetic metamaterials for application in energy dissipation and improvement of fracture and shear modulus of the structures made of them was developed by Zhang et al.83. A novel property of the auxetic metamaterials is its application for the structure with controllability of the material properties. A new work for proposal of a new material with tuneability of thermal expansion parameter was explained by Ho et al.84. Another work85 on the application of graphene origami in a rotationally loaded nanomotor was explained in the literature.

Yue et al.86 presented a review works about the adsorption as well as photo catalyst application of nano and carbon active particles. Bai et al.87 studied temperature dependent behaviors of metal un-saturated soils using solution of the coupled nonlinear contaminant-heat-moisture equations. Bai et al.88 developed some thermo-mechanical operations to arrive at some more efficient nanocomposite materials with enhanced material properties and energy absorption capacity. Bai et al.89 developed a novel efficient thermo-mechanical operation for production of microporous materials and structures with high absorption capacity using a higher order kinetic model. Bai et al.90 developed an efficient production experimental method to arrive at a new material with negative transfer for application in transmission systems. Wang et al.91 studied effect of higher speed rotating velocity and fiber reinforcement on the vibration and buckling results of disks in micro scale. Ma et al.92 studied bending and vibration analyses of the sandwich microplates using the modified strain gradient theory. Zha93 studied effect of temperature dependent material properties on the low velocity impact analysis of a micro beam reinforced with novel nanofillers. Ray94 presented an elasticity formulation for analysis of doubly curved shells composed of antisymmetric composite layers. Wang 95 studied the influence of magnetic loads on the drift characteristics of a velometer. Arefi et al.96 extended a numerical method for bending analysis of thick doubly curved shell made of functionally graded materials. Arefi et al. 97 studied effect of an initial thermal load on the stress and displacement analysis of the smart shells. A dynamic-based formulation using the improved kinematic relations was developed for natural frequency responses of a double curved shell by Arefi98. Effect of initial electromagnetic potentials was studied on the vibrational characteristics of microstructures by Zhang et al.99. Nguyen and Phan100 studied nonlinear vibration analysis of a porous plate made of bi directionally functionally graded materials through a nonlinear kinematic model using an isogeometric analysis. Shen et al.101 investigated impact of thickness-stretching phenomenon on the static bending responses of composite beam rested on the on-parameter elastic foundation. The formulation was completed using a higher order theory without any need to shear stress correction factor. Zhao et al.102 investigated impact of an energy sink in nonlinear form on the vibrational results of a system of double beam structural element. Wang et al.103 studied effect of thermal stress on the bending results of a multi-layered plates with a reliability focus made of functionally graded materials. Namvar et al.106 developed a novel metamaterial-based structure for application in energy absorption applications with improved mechanical properties. They presented mechanical properties of 4D-printed mechanical metamaterials using the computational models (ABAQUS software). Shirzad et al.107 presented the experimental and numerical analyses for investigating the mechanical properties of poly scaffolds using the 3D printing. They presented optimized physical, mechanical and biological properties of 3D truss architecture tissue scaffolds with different pore geometries.

Author developed a detailed review study and literature survey to confirm novelty and uniqueness of the present study. It is deduced that there is no available published work to study the deformation, strain and stress analysis of a pressurized cylindrical shell composed of the copper matric matrix reinforced with graphene origami enabled metamaterials. The proposed model uses the overall material characteristic relations to show impact of thermal loads, foldability parameter and volume fraction of the graphene origami reinforcement on the deformation analysis of reinforced structure. The foldable and shear deformable models are extended for development of the constitutive and kinematic relations. The virtual work principle is used for derivation of the governing equations. The shell is subjected to mechanical and thermal loads while is resting on the Pasternak’s foundation. The analytical solution is used to obtain the parametric analysis investigating impact of affecting parameters on the static responses of the reinforced shell.

Mathematical modeling

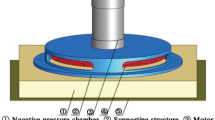

This section develops the required relations and equations for static bending analysis of a pressurized cylindrical shell composed of a copper matrix enriched with a novel type of three dimensional nanofillers named as graphene origami (Fig. 2). The governing equations are analytically derived using the virtual work principle and the constitutive relations are extended using the three-dimensional Hooke’s law in cylindrical coordinate and overall material properties reported in the literature experimental and theoretical works. The shear deformable model for development of the kinematic relations are expressed as follows:

where there are two axial \({\mathfrak{U}}_{\mathcal{X}}\) and transverse \({\mathfrak{U}}_{\mathcal{Z}}\) displacement components as linear function of thickness coordinate. Furthermore, middle surface displacement and rotation components are denoted with \(\mathfrak{U},\mathcalligra{w},{\mathfrak{Y}}_{x},{\mathfrak{Y}}_{\mathcal{Z}}\), respectively. Using the linear strain–displacement relations gives the strain components in the following form:

The virtual work principle is used to derive the governing equations as follows:

Substitution of the variation of strain components into the variation of strain energy gives:

Using Eq. (4), one can re-derive the strain energy variation in the resultant form as:

where:

A simpler form of the strain energy variation can be derived using the integration by part as follows:

One can arrive at final governing equations using the computation of the external works due to pre-thermal and mechanical loads initially applied on the shell as well as Pasternak’s foundation in the following form:

where \({F}_{f}\) denotes as Pasternak’s foundation force that is analytically expressed as:

Using the minimization of the total potential energy and rearranging the variables, one can arrive at the governing equations as follows:

In order to complete the governing equations, one should develop the constitutive relations in the cylindrical coordinate with accounting the thermal strain and overall material properties derived from the literature works. The constitutive relations are developed as:

In order to finalize constitutive relations, it is necessary to use the overall material characteristics in the following form67:

in which, \({V}_{G.O}=\frac{{W}_{G.O}}{{W}_{G.O}+\frac{{\rho }_{Gr}}{{\rho }_{Cu}}\left(1-{W}_{G.O}\right)}\),

Using the stress relations from Eq. (11) and regarding the overall material properties from Eq. (12), one can derive the expressions for the effective force and moments as follows:

The integration constants defined in Eq. (15) are computed as

in which \(\lambda =\frac{{E}_{eff}}{\left(1+{\nu }_{eff}\right)\left(1-2{\nu }_{eff}\right)}\). Substitution of resultant of force and moment into governing equations of motion gives:

Solution

The analytical solution of the governing equations as derived in Eq. (15) can be presented using the trigonometric functions in order to satisfy the necessary boundary conditions. The analytical solution is assumed as follows:

Substitution of the Eq. (16) into the Eq. (15) gives an algebraic system in known format as \(\left[\mathcal{K}\right]\left\{{\mathbb{X}}\right\}=\left\{{\mathbb{F}}\right\}\) where \(\left\{{\mathbb{X}}\right\}={\left\{{\mathbb{U}}_{m},{\mathbb{W}}_{m},{\mathfrak{V}}_{m},{\mathfrak{W}}_{m}\right\}}^{T}\) ,\(\left[\mathcal{K}\right]\) is stiffness matrix and \(\left\{{\mathbb{F}}\right\}\) is force matric as a function of pressure and thermal loading.

Results and discussion

After derivation of the governing equations and suggestion of a solution for the governing equations, it is time to present the numerical results including, displacement, strain and stress components along the thickness direction with changes of important input parameters such as thermal loading, graphene origami content and foldability parameters.

A verified test is presented to confirm our formulation and numerical results. Listed in Table 1 is a comparative study with available results of literature. This comparison verified our formulation and solution procedure.

The input parameters including material properties of copper matrix and graphene reinforcement are assumed as \(E_{{Cu}} = 65.79\;{\text{GPa}},E_{{Gr}} = 929.57\;{\text{GPa}},\,\)\(\vartheta _{{Cu}} = 0.387,\vartheta \;_{{Gr}} = 0.22,\) \(\alpha _{{Cu}} = 16.51 \times 10^{{ - 6}} \frac{1}{{K^{O} }},\vartheta _{{Gr}} = - 3.98 \times 10^{{ - 6}} \frac{1}{{K^{O} }},l_{{Gr}} = 83.76 \times 10^{{ - 10}} \;{\text{m}},t_{{Gr}} = 3.4 \times 10^{{ - 10}} \;{\text{m}}\).

Figure 3 shows the effect of foldability parameter on the radial dependent variation of strain components (axial, circumferential and shear strain components). The results show an increase in circumferential and shear strain components with an enhancement in foldability parameter. Furthermore, the maximum and minimum strain components are observed at outer and inner surfaces.

Figure 4 presents variation in axial, circumferential, radial and shear stress components with an enhancement in foldability parameter at various radial surfaces. It is deduced that the all stress components are decreased with an enhancement in the foldability parameter. In addition, it is deduced that the maximum and minimum stress components are occurred at outer and inner surfaces.

Figure 5a,b show variation in axial and transverse displacements with an enhancement in the foldability parameter of the graphene origami for various radial surfaces. The results show an increase in both displacements with an enhancement in the foldability parameter. In addition, it is deduced that the both displacements reach to maximum value at outer surface.

Figure 6 shows variation in various strain components with an enhancement in the graphene origami content at various radial coordinates. It is deduced a decrease in strain components with an improvement in the graphene origami content.

Figure 7a,b show variation in dimensionless axial and transverse deflections along the thickness direction with an improvement in graphene origami content. The results show a decrease in both displacements with an enhancement in the graphene origami content. Furthermore, it is deduced that the transverse deflection is slightly changed along the thickness direction and consequently one can ignore the changes of this component along the thickness direction.

Figure 8a–d show variation in axial, circumferential shear and radial strain components along the thickness direction for various thermal loading. A significant increase in all strain components is observed with an enhancement in thermal load. Furthermore, one can arrive at minimum and maximum strain components at outer and inner surfaces.

Figure 9 shows a variation in radial, circumferential and shear stress components with changes of thermal loading at various radial surfaces. It is observed a significant enhancement in the various stress components with an enhancement in thermal loading. Furthermore, with an advance in the radial coordinate, one can arrive a decrease in all stress components.

Figure 10 shows variation in axial and transverse displacements with an enhancement in thermal loading at various radial surfaces. The results show a considerable change in the transverse displacement along the thickness direction.

Conclusions

The new foldable and shear deformable models were extended in this paper for static deformation, strain and stress analyses of the graphene origami reinforced copper matrix cylindrical pressure vessel subjected to thermal and mechanical loads. The governing equations were derived using the virtual work principle in terms of two axial and radial displacements and rotation components. The solution procedure was extended using the trigonometric functions in order to satisfy simply supported boundary conditions. The numerical results are presented to investigate impact of significant parameters of the material characteristics such as graphene origami content and foldability and thermal loading along thickness direction. The deformation characteristics of the nanocomposite reinforced shell are presented along the thickness direction with changes of the significant parameters of the shell. The main conclusions of this analytical work are listed as follows:

An investigation on the impact of thermal loads indicates that the stress, strain and deformation components are significantly increased with an enhancement in the thermal loads because of an increase in thermal strain and deformation.

The results were presented with changes of various radial coordinate, in which the maximum and minimum stress and strain components were occurred at outer and inner surfaces.

Foldability parameter during hydrogenation process was used for control of the material characteristics of the nanocomposite shell. It is deduced that the strain and stress components are significantly increased with an enhancement in the folding characteristics because of a decrease in structural stiffness.

Graphene origami content is used as a parameter for control of deformation and stress. It is deduced that the stress, strain and deformation components are decreased with an enhancement in the graphene origami content.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Oh, C. Y. et al. DNA origami drives gene expression in a human cell culture system. Sci. Rep. 14, 27364. https://doi.org/10.1038/s41598-024-78399-y (2024).

Shah, S. I. H. & Lim, S. Bioinspired DNA origami quasi-yagi helical antenna with beam direction and beamwidth switching capability. Sci. Rep. 9, 14312. https://doi.org/10.1038/s41598-019-50893-8 (2019).

Wakayama, T. et al. Skyrmion engineering with origami. Sci. Rep. 14, 21673. https://doi.org/10.1038/s41598-024-71566-1 (2024).

Choi, Y. et al. A new reporter design based on DNA origami nanostructures for quantification of short oligonucleotides using microbeads. Sci. Rep. 9, 4769. https://doi.org/10.1038/s41598-019-41136-x (2019).

Vali, H. & Arefi, M. Extension of a novel higher order modeling to the vibration responses of sandwich graphene origami cylindrical panel. Archiv. Civ. Mech. Eng 23, 268. https://doi.org/10.1007/s43452-023-00797-2 (2023).

Wang, Y. et al. Enhanced local CO coverage on Cu quantum dots for boosting electrocatalytic CO2 reduction to ethylene. Adv. Funct. Mater. https://doi.org/10.1002/adfm.202417764.Closed20250113 (2024).

Zhang, M. et al. Cold-sprayed Cu matrix composite coatings with core-shell structured Co@WC reinforcements on Q235 steel. Surf. Interfaces 56, 105577. https://doi.org/10.1016/j.surfin.2024.105577 (2025).

Wang, W., Zhang, J., Habibi, M. & Albaijan, I. Stretchable-thickness model for dynamic responses of graphene origami reinforced badminton sport plate. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2024.2373976 (2024).

Zhang, Q., Xie, M., Zhou, D., Habibi, M. & Khorami, M. Bending responses of graphene nanoplatelets reinforced sandwich cylindrical micro panel with piezoelectric layers. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2024.2385008 (2024).

Gimenez-Pinto, V. et al. Modeling out-of-plane actuation in thin-film nematic polymer networks: From chiral ribbons to auto-origami boxes via twist and topology. Sci. Rep. 7, 45370. https://doi.org/10.1038/srep45370 (2017).

Kamrava, S. et al. Origami-based cellular metamaterial with auxetic, bistable, and self-locking properties. Sci. Rep. 7, 46046. https://doi.org/10.1038/srep46046 (2017).

Wang, F. et al. Folding to curved surfaces: A generalized design method and mechanics of origami-based cylindrical structures. Sci. Rep. 6, 33312. https://doi.org/10.1038/srep33312 (2016).

Liu, X., Gattas, J. & Chen, Y. One-DOF superimposed rigid origami with multiple states. Sci. Rep. 6, 36883. https://doi.org/10.1038/srep36883 (2016).

Lv, C. et al. Origami based mechanical metamaterials. Sci. Rep. 4, 5979. https://doi.org/10.1038/srep05979 (2014).

Liu, H. et al. A comprehensive mathematical simulation of the composite size-dependent rotary 3D microsystem via two-dimensional generalized differential quadrature method. Eng. Comput. 38(5), 4181–4196. https://doi.org/10.1007/s00366-021-01419-2 (2022).

Song, M., Yang, J. & Kitipornchai, S. Bending and buckling analyses of functionally graded polymer composite plates reinforced with graphene nanoplatelets. Compos. Part B Eng. 134, 106–113. https://doi.org/10.1016/j.compositesb.2017.09.043 (2018).

Zghal, S., Frikha, A. & Dammak, F. Non-linear bending analysis of nanocomposites reinforced by graphene-nanotubes with finite shell element and membrane enhancement. Eng. Struct. 158, 95–109. https://doi.org/10.1016/j.engstruct.2017.12.017 (2018).

Feng, C., Kitipornchai, S. & Yang, J. Nonlinear bending of polymer nanocomposite beams reinforced with non-uniformly distributed graphene platelets (GPLs). Compos. Part B Eng. 110, 132–140. https://doi.org/10.1016/j.compositesb.2016.11.024 (2017).

Zhang, M. et al. Cold sprayed Cu-coated AlN reinforced copper matrix composite coatings with improved tribological and anticorrosion properties. Surf. Coat. Technol. 496, 131666. https://doi.org/10.1016/j.surfcoat.2024.131666 (2025).

Feng, G. et al. Novel (Ni, Mn) co-doping CuFe5O8 black ceramic pigment with pinning strengthen effect in high-temperature black zirconia ceramic application. Ceram. Int. https://doi.org/10.1016/j.ceramint.2024.12.186 (2024).

Ding, H. & Zhou, J. Well-posedness of solutions for a class of quasilinear wave equations with strong damping and logarithmic nonlinearity. Stud. Appl. Math. 149(2), 441–486. https://doi.org/10.1111/sapm.12498 (2022).

Xie, Z., You, W., Wong, P. K., Li, W. & Zhao, J. Fuzzy robust non-fragile control for nonlinear active suspension systems with time varying actuator delay. Proc. Instit. Mech. Eng. Part D J. Automob. Eng. 238(1), 46–62. https://doi.org/10.1177/09544070221125528 (2024).

Zhang, Y. et al. Bagasse-based porous flower-like MoS2/carbon composites for efficient microwave absorption. Carbon Lett. https://doi.org/10.1007/s42823-024-00832-z (2024).

Meng, F. et al. Negative Poisson’s ratio in graphene Miura origami. Mech. Mater. 155, 103774. https://doi.org/10.1016/j.mechmat.2021.103774 (2021).

Guo, L., Zhao, S., Guo, Y., Yang, J. & Kitipornchai, S. Bandgaps in functionally graded phononic crystals containing graphene origami-enabled metamaterials. Int. J. Mech. Sci. 240, 107956. https://doi.org/10.1016/j.ijmecsci.2022.107956 (2023).

Murari, B., Zhao, S., Zhang, Y., Ke, L. & Yang, J. Vibrational characteristics of functionally graded graphene origami- enabled auxetic metamaterial beams with variable thickness in fluid. Eng. Struct. 277, 115440. https://doi.org/10.1016/j.engstruct.2022.115440 (2023).

Yang, C. et al. Transfer learning-based crashworthiness prediction for the composite structure of a subway vehicle. Int. J. Mech. Sci. 248, 108244. https://doi.org/10.1016/j.ijmecsci.2023.108244 (2023).

Fan, Y. & Shen, H.-S. Non-symmetric stiffness of origami-graphene metamaterial plates. Compos. Struct. 297, 115974. https://doi.org/10.1016/j.compstruct.2022.115974 (2022).

Zhao, S., Zhang, Y., Zhang, Y., Yang, J. & Kitipornchai, S. Graphene origami-enabled auxetic metallic metamaterials: An atomistic insight. Int. J. Mech. Sci. 212, 106814. https://doi.org/10.1016/j.ijmecsci.2021.106814 (2021).

Thai, C. H., Ferreira, A. J. M., Tran, T. D. & Phung-Van, P. Free vibration, buckling and bending analyses of multilayer functionally graded graphene nanoplatelets reinforced composite plates using the NURBS formulation. Compos. Struct. 220, 749–759. https://doi.org/10.1016/j.compstruct.2019.03.100 (2019).

Wang, A., Chen, H., Hao, Y. & Zhang, W. Vibration and bending behavior of functionally graded nanocomposite doubly-curved shallow shells reinforced by graphene nanoplatelets. Results Phys. 9, 550–559. https://doi.org/10.1016/j.rinp.2018.02.062 (2018).

Bakamal, A., Ansari, R. & Hassanzadeh-Aghdam, M. K. Computational analysis of the effects of carbon nanotubes on the bending, buckling, and vibration characteristics of carbon fabric/polymer hybrid nanocomposite plates. J Braz. Soc. Mech. Sci. Eng. 43, 61. https://doi.org/10.1007/s40430-020-02792-7 (2021).

Bouderba, B., Hamza Madjid, B. & Pham, D. T. Bending analysis of P-FGM plates resting on nonuniform elastic foundations and subjected to thermo-mechanical loading. Cogent Eng. https://doi.org/10.1080/23311916.2022.2108576 (2022).

Hoang, V. N. V., Shi, P., Toledo, L. & Vu, H. Free vibration analysis of nanocomposite plate in contact with fluid using a novel quasi-3D shear deformation theory and artificial neural network. Mech. Based Des. Struct. Mach. https://doi.org/10.1080/15397734.2024.2373265 (2024).

Ansari, R., Hassani, R., Gholami, R. & Rouhi, H. Nonlinear bending analysis of arbitrary-shaped porous nanocomposite plates using a novel numerical approach. Int. J. Non-Linear Mech. 126, 103556. https://doi.org/10.1016/j.ijnonlinmec.2020.103556 (2020).

Safarpour, M., Forooghi, A., Dimitri, R. & Tornabene, F. Theoretical and numerical solution for the bending and frequency response of graphene reinforced nanocomposite rectangular plates. Appl. Sci. 11, 6331. https://doi.org/10.3390/app11146331 (2021).

Tian, R. et al. Dynamic crushing behavior and energy absorption of hybrid auxetic metamaterial inspired by Islamic motif art. Appl. Math. Mech. Eng. Ed. 44(3), 345–362. https://doi.org/10.1007/s10483-023-2962-9 (2023).

Zhao, Z., Feng, C., Wang, Y. & Yang, J. Bending and vibration analysis of functionally graded trapezoidal nanocomposite plates reinforced with graphene nanoplatelets (GPLs). Compos. Struct. 180, 799–808. https://doi.org/10.1016/j.compstruct.2017.08.044 (2017).

Ahmadi, M., Ansari, R. & Rouhi, H. Multi-scale bending, buckling and vibration analyses of carbon fiber/carbon nanotube-reinforced polymer nanocomposite plates with various shapes. Phys. E Low Dimens. Syst. Nanostruct. 93, 17–25. https://doi.org/10.1016/j.physe.2017.05.009 (2017).

García-Macías, E., Rodríguez-Tembleque, L. & Sáez, A. Bending and free vibration analysis of functionally graded graphene vs. carbon nanotube reinforced composite plates. Compos. Struct. 186, 123–138. https://doi.org/10.1016/j.compstruct.2017.11.076 (2018).

Liu, Y. et al. Analytical model for corrugated rolling of composite plates considering the shear effect. J. Manuf. Process. 134, 1069–1081. https://doi.org/10.1016/j.jmapro.2025.01.025 (2025).

Cong, F. et al. Buckling analysis of moderately thick carbon fiber composite cylindrical shells under hydrostatic pressure. Appl. Ocean Res. 153, 104272. https://doi.org/10.1016/j.apor.2024.104272 (2024).

Wang, Y., Xie, K., Fu, T. & Shi, C. Bending and elastic vibration of a novel functionally graded polymer nanocomposite beam reinforced by graphene nanoplatelets. Nanomaterials 9, 1690. https://doi.org/10.3390/nano9121690 (2019).

Luo, Y. et al. Novel multidimensional composite development for aging resistance of sbs-modified asphalt by attaching zinc oxide on expanded vermiculite. Energy Fuels 38(17), 16772–16781. https://doi.org/10.1021/acs.energyfuels.4c02685.Closed20250113 (2024).

Jafari Mehrabadi, S., Sobhani Aragh, B., Khoshkhahesh, V. & Taherpour, A. Mechanical buckling of nanocomposite rectangular plate reinforced by aligned and straight single-walled carbon nanotubes. Compos. Part B Eng. 43(4), 2031–2040. https://doi.org/10.1016/j.compositesb.2012.01.067 (2012).

Sun, B.-L. et al. Ultrahigh-strength textile fiber-supported schiff base copper complexes for photocatalytic degradation of methyl orange. ACS Appl. Polym. Mater. 6(21), 13077–13088. https://doi.org/10.1021/acsapm.4c02009 (2024).

Peng, S. et al. Laboratory investigation of the effects of blanket defect size on initiation of backward erosion piping. J. Geotech. Geoenviron. Eng. 150(10), 4024095. https://doi.org/10.1061/JGGEFK.GTENG-11976 (2024).

Wang, Z., Yuan, Y., Zhang, S., Lin, Y. & Tan, J. A multi-state fusion informer integrating transfer learning for metal tube bending early wrinkling prediction. Appl. Soft Comput. 151, 110991. https://doi.org/10.1016/j.asoc.2023.110991 (2024).

He, X., Ding, J., Habibi, M., Safarpour, H. & Safarpour, M. Non-polynomial framework for bending responses of the multi-scale hybrid laminated nanocomposite reinforced circular/annular plate. Thin Walled Struct. 166, 108019. https://doi.org/10.1016/j.tws.2021.108019 (2021).

Liu, D., Zhou, Y. & Zhu, J. On the free vibration and bending analysis of functionally graded nanocomposite spherical shells reinforced with graphene nanoplatelets: Three-dimensional elasticity solutions. Eng. Struct. 226, 111376. https://doi.org/10.1016/j.engstruct.2020.111376 (2021).

Wang, Z. et al. Towards high-accuracy axial springback: Mesh-based simulation of metal tube bending via geometry/process-integrated graph neural networks. Expert Syst. Appl. 255, 124577. https://doi.org/10.1016/j.eswa.2024.124577 (2024).

Miaofen, L., Youmin, L., Tianyang, W., Fulei, C. & Zhike, P. Adaptive synchronous demodulation transform with application to analyzing multicomponent signals for machinery fault diagnostics. Mech. Syst. Signal Process. 191, 110208. https://doi.org/10.1016/j.ymssp.2023.110208 (2023).

Mehar, K. & Panda, S. K. Elastic bending and stress analysis of carbon nanotube-reinforced composite plate: Experimental, numerical, and simulation. Adv. Polym. Technol. 37(6), 1643–1657. https://doi.org/10.1002/adv.21821 (2018).

Shen, H.-S. Nonlinear bending of functionally graded carbon nanotube-reinforced composite plates in thermal environments. Compos. Struct. 91(1), 9–19. https://doi.org/10.1016/j.compstruct.2009.04.026 (2009).

Tao, C. & Dai, T. Modified couple stress-based nonlinear static bending and transient responses of size-dependent sandwich microplates with graphene nanocomposite and porous layers. Thin Walled Struct. 171, 108704. https://doi.org/10.1016/j.tws.2021.108704 (2022).

Wang, X., Zhang, Y., Wen, M. & Mang, H. A. A simple hybrid linear and nonlinear interpolation finite element for the adaptive Cracking Elements Method. Finite Elements Anal. Design 244, 104295. https://doi.org/10.1016/j.finel.2024.104295 (2025).

Liu, J., Xie, Z., Gao, J., Hu, Y. & Zhao, J. Failure characteristics of the active-passive damping in the functionally graded piezoelectric layers-magnetorheological elastomer sandwich structure. Int. J. Mech. Sci. 215, 106944. https://doi.org/10.1016/j.ijmecsci.2021.106944 (2022).

Chu, S., Lin, M., Li, D., Lin, R. & Xiao, S. Adaptive reward shaping based reinforcement learning for docking control of autonomous underwater vehicles. Ocean Eng. 318, 120139. https://doi.org/10.1016/j.oceaneng.2024.120139 (2025).

Hou, T. et al. Numerical investigation of cavitation induced noise and noise reduction mechanism for the leading-edge protuberances. Appl. Ocean Res. 154, 104361. https://doi.org/10.1016/j.apor.2024.104361 (2025).

Dong, J. F. et al. Investigating the structural behaviour of double-skin steel tubes filled with basalt fibre reinforced recycled aggregate concrete under high temperature. J. Build. Eng. 100, 111782. https://doi.org/10.1016/j.jobe.2025.111782 (2025).

Jin, Z., Huo, W., Habibi, M. & Albaijan, I. Thermo-foldable bending analysis of tunable shells using a higher-order modeling. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2024.2369263 (2024).

Ma, B., Chen, K. Y., Habibi, M. & Albaijan, I. Static/dynamic analyses of sandwich micro-plate based on modified strain gradient theory. Mech. Adv. Mater. Struct. 31(23), 5760–5767. https://doi.org/10.1080/15376494.2023.2219453 (2023).

Yu, C., Lin, P., Wu, Z., Habibi, M. & Zhang, W. Multi-load effect on the deformation analysis of composite nano reinforced origami sandwich panel. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2024.2367015 (2024).

Huang, J., Pan, Z., Yang, S., Habibi, M. & Safa, M. Bending-based solution methodology using eigenvalue-eigenvector approach for analysis of foldable reinforced Golf Clubs cylindrical shell. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2024.2378372 (2024).

Zhiqiang, S. et al. Application of a folded nanostructure reinforcement for the pole vault curved shell. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2024.2375368 (2024).

Zainul, R. et al. Levy-type based bending formulation of a G-Ori reinforced plate. J. Vib. Eng. Technol. https://doi.org/10.1007/s42417-024-01517-7 (2024).

Yang, N., Zou, Y. & Arefi, M. Bending results of graphene origami reinforced doubly curved shell. Def. Technol. 35, 198–210. https://doi.org/10.1016/j.dt.2023.11.017 (2024).

Arefi, M. & Zenkour, A. M. Thermo-electro-magneto-mechanical bending behavior of size-dependent sandwich piezomagnetic nanoplates. Mech. Res. Commun. 84, 27–42. https://doi.org/10.1016/j.mechrescom.2017.06.002 (2017).

Adab, N. & Arefi, M. Vibrational behavior of truncated conical porous GPL-reinforced sandwich micro/nano-shells. Eng. Comput. https://doi.org/10.1007/s00366-021-01580-8 (2022).

Guo, R. et al. SiO2@Graphene composite materials obtained through different methods used as substrate materials. Silicon 11, 1261–1266. https://doi.org/10.1007/s12633-018-0058-z (2019).

Du, Y., Keller, T., Song, C., Wu, L. & Xiong, J. Origami-inspired carbon fiber-reinforced composite sandwich materials—Fabrication and mechanical behavior. Compos. Sci. Technol. 205, 108667. https://doi.org/10.1016/j.compscitech.2021.108667 (2021).

Arefi, M. Analysis of wave in a functionally graded magneto-electro-elastic nano-rod using nonlocal elasticity model subjected to electric and magnetic potentials. Acta Mech. 227, 2529–2542. https://doi.org/10.1007/s00707-016-1584-7 (2016).

Arefi, M. & Zenkour, A. M. Free vibration, wave propagation and tension analyses of a sandwich micro/nano rod subjected to electric potential using strain gradient theory. Mater. Res. Exp. 3(11), 115704. https://doi.org/10.1088/2053-1591/3/11/115704 (2016).

Long, X. et al. Review of uniqueness challenge in inverse analysis of nanoindentation. J. Manuf. Process. 131, 1897–1916. https://doi.org/10.1016/j.jmapro.2024.10.005 (2024).

Meng, X., Zhang, B., Cao, F. & Liao, Y. Effectiveness of measures on natural gas pipelines for mitigating the influence of DC ground current. IEEE Trans. Power Deliv. 39(4), 2414–2423. https://doi.org/10.1109/TPWRD.2024.3406826 (2024).

Arefi, M. & Mohammad-Rezaei Bidgoli, E. Electro-elastic displacement and stress analysis of the piezoelectric doubly curved shells resting on Winkler’s foundation subjected to applied voltage. Mech. Adv. Mater. Struc. 26(23), 1981–1994. https://doi.org/10.1080/15376494.2018.1455937 (2019).

Arefi, M. & Kiani, M. Magneto-electro-mechanical bending analysis of three-layered exponentially graded microplate with piezomagnetic face-sheets resting on Pasternak’s foundation via MCST. Mech. Adv. Mater. Struc. 27(5), 383–395. https://doi.org/10.1080/15376494.2018.1473538 (2020).

Ren, X., Das, R., Tran, P., Ngo, T. D. & Xie, Y. M. Auxetic metamaterials and structures: A review. Smart Mater. Struct 27(2), 023001. https://doi.org/10.1088/1361-665X/aaa61c (2018).

Kolken, H. M. A. & Zadpoor, A. A. Auxetic mechanical metamaterials. RSC Adv. 7, 5111–5129. https://doi.org/10.1039/C6RA27333E (2017).

Han, D. et al. Lightweight auxetic metamaterials: Design and characteristic study. Compos. Struct. 293, 115706. https://doi.org/10.1016/j.compstruct.2022.115706 (2022).

Shi, X., Li, J. & Habibi, M. On the statics and dynamics of an electro-thermo-mechanically porous GPLRC nanoshell conveying fluid flow. Mech. Based. Des. Struct. Mach. 50(6), 2147–2183. https://doi.org/10.1080/15397734.2020.1772088 (2022).

Chen, F., Chen, J., Duan, R., Habibi, M. & Khadimallah, M. A. Investigation on dynamic stability and aeroelastic characteristics of composite curved pipes with any yawed angle. Compos. Struct. 284, 115195. https://doi.org/10.1016/j.compstruct.2022.115195 (2022).

Zhang, Y. et al. Design and analysis of an auxetic metamaterial with tuneable stiffness. Compos. Struct. 281, 114997. https://doi.org/10.1016/j.compstruct.2021.114997 (2022).

Ho, D. T., Park, H. S., Kim, S. Y. & Schwingenschlögl, U. Graphene origami with highly tunable coefficient of thermal expansion. ACS Nano 14(7), 8969–8974. https://doi.org/10.1021/acsnano.0c03791 (2020).

Cai, K., Sun, S., Shi, J. & Qin, Q.-H. Carbon-nanotube nanomotor driven by graphene origami. Phys. Rev. Appl. 15, 054017. https://doi.org/10.1103/PhysRevApplied.15.054017 (2021).

Yue, X. et al. Mitigation of indoor air pollution: A review of recent advances in adsorption materials and catalytic oxidation. J. Hazard. Mater. 405, 124138. https://doi.org/10.1016/j.jhazmat.2020.124138 (2021).

Bai, B., Chen, J., Zhang, B., Chen, L. & Zong, Y. The solidification of heavy metal Pb2+-contaminated soil by enzyme-induced calcium carbonate precipitation combined with biochar. Biochem. Eng. J. 212, 109496 (2024).

Bai, B., Wu, H., Zhou, R., Wu, N. & Zhang, B. A granular thermodynamic framework-based coupled multiphase-substance flow model considering temperature driving effect. J. Rock Mech. Geotech. Eng. https://doi.org/10.1016/j.jrmge.2024.11.017 (2025).

Bai, B., Wu, H., Nie, Q., Liu, J. & Jia, X. Granular thermodynamic migration model suitable for high-alkalinity red mud filtrates and test verification. Int. J. Numer. Anal. Methods Geomech. https://doi.org/10.1002/nag.3946 (2025).

Bai, B., Chen, J., Bai, F., Nie, Q. & Jia, X. Corrosion effect of acid/alkali on cementitious red mud-fly ash materials containing heavy metal residues. Environ. Technol. Innov. 33, 103485 (2024).

Wang, Z., Shuiqin, Y., Xiao, Z. & Habibi, M. Frequency and buckling responses of a high-speed rotating fiber metal laminated cantilevered microdisk. Mech. Adv. Mater. Struct. 29(10), 1475–1488. https://doi.org/10.1080/15376494.2020.1824284 (2022).

Ma, B., Chen, K.-Y., Habibi, M. & Albaijan, I. Static/dynamic analyses of sandwich micro-plate based on modified strain gradient theory. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2023.2219453 (2023).

Zha, J. & Zhang, Z. Reversible negative compressibility metamaterials inspired by Braess’s Paradox. Smart Mater. Struct. 33(7), 075036. https://doi.org/10.1088/1361-665X/ad59e6 (2024).

Ray, M. C. Exact solutions of elasticity theories for static analysis of doubly curved antisymmetric angle-ply composite shells. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2023.2246223 (2023).

Wang, Z., Wang, S., Wang, X. & Luo, X. Permanent magnet-based superficial flow velometer with ultralow output Drift. IEEE Trans. Instrum. Meas. 72, 1–12. https://doi.org/10.1109/TIM.2023.3304692 (2023).

Arefi, M., Mohammad-Rezaei Bidgoli, E. & Civalek, O. Bending response of FG composite doubly curved nanoshells with thickness stretching via higher-order sinusoidal shear theory. Mech. Based Des. Struct. Mach. 50(7), 2350–2378. https://doi.org/10.1080/15397734.2020.1777157 (2022).

Arefi, M., Faegh, R. K. & Loghman, A. The effect of axially variable thermal and mechanical loads on the 2D thermoelastic response of FG cylindrical shell. J. Therm. Stress. 39(12), 1539–1559. https://doi.org/10.1080/01495739.2016.1217178 (2016).

Arefi, M. Plus Nonlocal free vibration analysis of a doubly curved piezoelectric nano shell. Steel Compos. Struct. Int. J. 27(4), 479–493. https://doi.org/10.12989/scs.2018.27.4.479 (2018).

Zhang, M., Jiang, X. & Arefi, M. Dynamic formulation of a sandwich microshell considering modified couple stress and thickness-stretching. Eur. Phys. J. Plus 138(3), 227. https://doi.org/10.1140/epjp/s13360-023-03753-4 (2023).

Nguyen, N. V. & Phan, D.-H. Nonlinear free vibration of bi-directional functionally graded porous plates. Thin Walled Struct. 192, 111198. https://doi.org/10.1016/j.tws.2023.111198 (2023).

Shen, Z., Dong, R., Li, J., Su, Y. & Long, X. Determination of gradient residual stress for elastoplastic materials by nanoindentation. J. Manuf. Process. 109, 359–366. https://doi.org/10.1016/j.jmapro.2023.10.030 (2024).

Zhao, Y., Guo, F., Sun, Y. & Shi, Q. Modeling and vibration analyzing of a double-beam system with a coupling nonlinear energy sink. Nonlinear Dyn. 112(11), 9043–9061. https://doi.org/10.1007/s11071-024-09551-6 (2024).

Wang, C., Song, Z. & Fan, H. Novel evidence theory-based reliability analysis of functionally graded plate considering thermal stress behavior. Aerosp. Sci. Technol. 146, 108936. https://doi.org/10.1016/j.ast.2024.108936 (2024).

Jabbari, M., Sohrabpour, S. & Eslami, M. R. Mechanical and thermal stresses in a functionally graded hollow cylinder due to radially symmetric loads. Int. J. Press. Vessels Pip. 79, 493–497 (2002).

Arefi, M., Abbasi, A. R. & Vaziri Sereshk, M. R. Two-dimensional thermoelastic analysis of FG cylindrical shell resting on the Pasternak foundation subjected to mechanical and thermal loads based on FSDT formulation. J. Therm. Stress. 39(5), 554–570. https://doi.org/10.1080/01495739.2016.1158607 (2016).

Namvar, N., Zolfagharian, A., Vakili-Tahami, F. & Bodaghi, M. Reversible energy absorption of elasto-plastic auxetic, hexagonal, and AuxHex structures fabricated by FDM 4D printing. Smart Mater. Struct. 31(5), 055021 (2022).

Shirzad, M., Zolfagharian, A., Matbouei, A. & Bodaghi, M. Design, evaluation, and optimization of 3D printed truss scaffolds for bone tissue engineering. J. Mech. Behav. Biomed. Mater. 120, 104594 (2021).

Acknowledgements

This paper was received support by the funding project: Guangzhou electric power design institute Co., Ltd. technology project CG2800062001849528. All authors would like to express their gratitude to Guangzhou electric power design institute Co., Ltd. for providing data support and application cases, especially grateful to this company for providing support for the experimental conditions.

Author information

Authors and Affiliations

Contributions

The role of each author is expressed as follows: X Ying: Fundamental relations, Derivation, A Yunzhu: Software, writing draft, revising, Y. Qige: Fundamental relations, Derivation, L Kai: Conceptualization, Writing draft, Mostafa Habibi: Coding and Software, Literature review, Tang Xingjia: Software, writing draft, revising L. Yongji: Conceptualization, Writing draft,

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ying, X., Yunzhu, A., Qige, Y. et al. A novel foldable metamaterial for application in the pipeline pressure vessel with a static deformation, strain and stress analysis. Sci Rep 15, 9680 (2025). https://doi.org/10.1038/s41598-025-93302-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-93302-z

Keywords

This article is cited by

-

On propagation analysis of flexural waves in functionally graded poroelastic biocomposite higher-order beams

Acta Mechanica (2025)

-

A Systematic Study of the Structural, Electronic and Optical Properties of 3d, 4d and 5d Binary Transition Metal Arsenides TMAs2 (TM = Fe, Ru, Os)

Brazilian Journal of Physics (2025)