Abstract

Emerging non-volatile memristor-based devices with resistive switching (RS) materials are being widely researched as promising contenders for the next generation of data storage and neuromorphic technologies. Titanium nitride (TiNx) is a common industry-friendly electrode system for RS; however, the precise TiNx properties required for optimum RS performance is still lacking. Herein, using ion-assisted DC magnetron sputtering, we demonstrate the key importance not only of engineering the TiNx bottom electrodes to be dense, smooth, and conductive, but also understoichiometric in N. With these properties, RS in HfO2-based memristive devices is shown to be optimised for TiN0.96. These devices have switching voltages ≤ ±1 V with promising device-to-device uniformity, endurance, memory window of ~40, and multiple non-volatile intermediate conductance levels. This study highlights the importance of precise tuning of TiNx bottom electrodes to achieve robust performance of oxide resistive switching materials.

Similar content being viewed by others

Introduction

The pace of digital innovation in cloud storage and computation, artificial intelligence (AI) chips, medicine, security, electric vehicles, telecommunication, robotics, Internet of Things, entertainment, and wearable devices critically depends on expanding the power of processing and storing data. Although enhancing the performance of memory and processing units has always been the centre of attention, the huge energy consumption of these rapidly growing technologies demands further immediate actions1. In this context, advanced non-volatile memories are urgently needed not only to fabricate faster and high-performance devices but also to significantly reduce their current huge energy consumption.

While 3-terminal semiconductor-based transistors have already reached their fabrication limitations and are not adequately efficient for advanced memories, 2-terminal insulating(oxide)-based devices are gaining considerable attention as the next generation of data storage technologies and neuro-electronics2,3. Oxide-based non-volatile memories such as resistive random-access memories, phase change memories, ferroelectric random-access memories, and spin-dependent magnetoresistive random-access memories are emerging data storage technologies and being globally explored. In particular, energy-efficient resistive switching (RS) memory devices that also have switching characteristics similar to synapses in the human brain are attractive due to their simple structure (an insulating oxide thin film is sandwiched between two electrodes), easy-to-fabricate process, complementary metal-oxide-semiconductor (CMOS) compatibility, low power consumption (≤ 4 pJ), large scalability (≤ 5 nm), ultrafast switching speeds (~10 ns), high endurance (≥ 106 cycles), good ON/OFF ratios (≥ 10), and multilevel storage capability4,5. They are also essential for fast-AI-processing ‘compute-in-memory’ devices that provide promising solutions for overcoming the challenges of conventional von Neumann computers6,7,8.

During the last decade, massive efforts have been devoted to exploring various switchable electronic materials (e.g. high-k dielectrics like HfO29) for emerging non-volatile memories, enhancing their performance, and understanding their switching mechanisms2,10,11,12,13. However, in addition to the switching layer, the functionality of these nano-scale devices also depends on their electrodes and interfaces, particularly the interface between the switching layer and the bottom electrode, which typically doubles as the substrate for the switching layer. Regarding the electrodes, sputter-deposited titanium nitrides (TiNx) are extensively used in CMOS technologies and especially in the emerging memory devices14. TiNx has a wide compositional range (0.6 ≤ N/Ti ≤ 1.2) and large free-carrier concentration, providing a unique combination of physical and chemical properties15,16. As an electrode material, properties such as nanostructure, density, surface roughness, electrical resistivity, composition, grain size, and crystal orientation can significantly influence the device's performance. For example, the surface roughness of the TiNx bottom electrodes induces a considerable local electric-field increase at the interface that results in asymmetric electrical behaviour, leakage current, and reliability degradation17,18,19. In addition, surface convex protrusions are also thermodynamically favourable sites for defect nucleation, local chemical nonuniformity, and changing trap states20 that can directly affect the device-to-device uniformity of the memory devices. The electrical resistivity of TiN, which can be widely tuned by changing the film nanostructure, is another important parameter that changes electronic transport properties and the overall initial resistance of RS memory devices, potentially causing uncontrolled electroforming processes and hard breakdowns21. It is also reported that changing the TiNx crystal orientation influences the work function, leading to fluctuations in threshold voltage22.

However, there are few systematic studies about the impacts of structural and physical properties of TiNx bottom electrodes and their interfaces on the RS device performance. Here, we thoroughly investigate the roles of three key magnetron sputtering parameters of TiNx: substrate bias (Vs), N2-gas flow rate (\({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\)), and substrate temperature (Ts) on the properties of TiNx thin films and the switching performance of TiNx/Ba-doped HfO2 (BHO)/W memristive devices. BHO was chosen as an advanced amorphous oxide RS material that shows promising RS performance, which details of this material system are discussed in ref. 23. For optimising the oxide RS performance, we demonstrate the necessity to engineer not only highly dense, ultra-smooth, and conductive TiNx, but also for the TiNx to be deficient in N. The study also has significant applicability to other oxide RS materials.

Results and discussion

Device performance

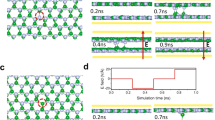

Figure 1a, b shows the representative current–voltage (I–V) curves of the TiNx/BHO/W devices fabricated on the TiNx bottom electrodes grown by ion-assisted direct current (DC) magnetron sputtering at Vs = −100 V under the optimised \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) condition of 1 sccm at Ts = room temperature and 400 °C. All devices were subjected to a voltage sweep of 0 → +VSET → −VRESET → 0 applied at the top electrode and showed SET voltages < 2 V, in good agreement with our previous results from the same devices grown on Nb:SrTiO323. We note that for most memristors, the forming voltage is higher than the SET voltage, which can lead to unstable RS and undesired extra energy consumption. In our devices, on the other hand, the forming voltages are not required to be larger than the SET voltages, which is based on our previous work and attributed to the careful engineering of the BHO nanostructure23. We demonstrated that Ba addition suppresses the HfO2 crystallisation and changes the concentration and coordination of oxygen, leading to an easier formation of conductive channels inside BHO; hence, enabling the filament formation at low voltages. We also revealed that the filaments are not metallic and should be comprised of oxygen vacancies. While the focus of this work is to properly engineer the TiN bottom electrodes, a brief analysis of the I–V curves with the best switching behaviour shown in Fig. 1b is provided in Figs. S1–S3 in the supplementary material. The devices with TiNx grown under the same deposition conditions, but without applying substrate bias (Vs = floating), show initial ohmic I–V responses without any hysteretic effect (Fig. 1c) or undergo abrupt current increases during SET processes (positive voltage application), which is a typical indication of filament formation, and then suddenly experience hard breakdowns, see Fig. 1d.

I–V curves of Si(001)/a-SiO2/TiNx/BHO/W devices with the TiNx bottom electrodes grown at a Ts = no external substrate heating and b Ts = 400 °C both with Vs = −100 V, and at c Ts = no external substrate heating and d Ts = 400 °C both with Vs = floating. \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) was 1 sccm for all four different deposition conditions. The voltage-sweep scheme follows: 0 → +V (VSET) → 0 → −V (VRESET) → 0, which is also indicated by numbered arrows in b. The forming process required for some devices is indicated by the 1* arrow in b. The forming voltage is not higher than subsequent switching voltages. Each panel consists of multiple I–V curves acquired from each device. The inset in a illustrates the schematic device structure and electrical measurement geometry.

The key trend observed in the I–V plots of the devices with TiNx grown at all combinations of variables studied (Vs, \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\), and Ts), shown in Fig. S4, is that the memory window (low-resistance-state LRS to high-resistance-state HRS ratios) in those devices that exhibit hysteretic effects increases by decreasing \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) from 10 to 1 sccm, independent of Ts. Figs. 1 and S4 also show the typical initial cycle-to-cycle variability of devices based on all TiN deposition conditions. There is no clear trend in the current levels of the devices as a function of \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\), except for those with TiNx sputter-deposited at Vs = −100 V and Ts = 400 °C, Fig. S4g–i, where the overall current clearly decreases by decreasing \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) from 2.4 × 10−4 to 9.6 × 10−5 to 1.1 × 10−5 A for HRS at −0.1 V.

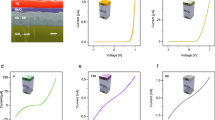

Figure 2 shows the results of further electrical measurements carried out on the TiNx/BHO/W devices with TiNx sputter-deposited at Vs = −100 V, \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) = 1 sccm, and Ts = 400 °C, i.e. the devices from Fig. 1b. These devices exhibit optimised RS performance as determined by comparing all data in Fig. S4. I–V curves for 25 different devices are compared in Fig. 2a, indicating reproducible I–V characteristics with a switching voltage ≤ 1 V. The LRS and HRS distributions of these devices, shown in Fig. 2b, reveal excellent device-to-device uniformity with a consistent memory window > 10. In addition, the robustness of the materials combination was also confirmed by the endurance data in Fig. 2c. Figure 2d shows the switching currents at the positive and negative switching voltages as a function of the W top-electrode diameter (dTE). The applied switching voltages were 1.0 and −1.0 V for all device sizes. These data are obtained from the I–V curves of at least 25 different devices for each dTE, and the error bars are the standard deviations across all devices of the same dTE. None of current states (thus, resistance states) shows any significant change as a function of dTE. This is typically considered as a reliable indication for the filamentary-dominated RS, where most likely only one dominant filament controls the resistance state10.

a 2nd I–V loops of 25 different devices. b LRS and HRS data of 25 different devices (read at −0.1 V). c Pulsed endurance data was measured by applying ±3.0 V pulses with read pulses of −1.0 V. Note that the BHO layer was deposited with increased oxygen partial pressure; hence, the different current and voltage levels. Data shown in a–c were obtained from devices with W top-electrode diameter dTE = 100 μm. d Switching currents at 1.0 and −1.0 V for the devices with dTE = 25, 50, and 100 μm. Grey diamonds are the measured data, and red circles with error bars are the average and standard deviation. e Multilevel retention data. All states are from the same device programmed by consecutive cumulative set voltages from 0.5 to 1.0 V with increments of 0.01 mV (read at −0.05 V). f, g Zoomed-in regions indicated in e. All data were obtained from devices with the TiNx bottom electrodes sputter-deposited at Vs = −100 V, \({P}_{{{{{\rm{N}}}}}_{2}}\) = 1 sccm, and Ts = 400 °C.

These devices can be also programmed to multiple intermediate conductance states. Figure 2e reveals the stability of 50 intermediate states in the same device measured with cumulative set voltage increments of 0.01 mV, starting from 0.5 V. No state decay is observed for any of these levels during > 600 s measured, which demonstrates the formation of stable filaments with increasing strengths as the conductance increases. Figure 2f, g is zoomed-in regions marked in Fig. 2e. The difference in noise levels can be attributed to the relatively larger current fluctuations for weaker filaments in relation to the overall current passing through the filament. We note that the non-linearity in the state distribution in Fig. 2e is common for filamentary devices and can be accommodated by the appropriate encoding of the programming voltage24. However, since the core of this research is to optimise the TiN bottom electrodes, we do not further optimise this as it goes beyond the scope of the work and just take these results as a good demonstration that our devices successfully show multiple conductance states, which are essential for memristive-based neuromorphic devices.

Microstructure and physical properties of TiNx

To understand the key reasons for the different I–V behaviour shown in Figs. 1 and S4, Fig. 3 compares the cross-sectional transmission electron microscopy (TEM) and scanning TEM (STEM) micrographs of the devices with the two most contrasting I–V plots of Fig. 1b, c. These devices have the TiNx bottom electrodes grown at: (i) Vs = −100 V and Ts = 400 °C (optimum RS performance) and (ii) Vs = floating and Ts = no external substrate heating (poor RS performance). The TiNx layer in the optimum performance device consists of a dense columnar microstructure with no visible porosity or open column boundaries. It also has a sharp and highly flat interface, see Fig. 3a, b. The TiNx columns continuously grow along the [001] direction without a significant change in their width, shown in Fig. 3c. In addition, the BHO layer in this device is highly dense and uniform with smooth interfaces. Such TiNx microstructures, which represent Zone II in the structure zone models25, can be obtained by employing ion irradiation during the thin-film growth with average ion energies Ei > ~60 eV. In this ion-energy regime, the dominant growth mechanisms are subplantation and recoil creation induced by knock-on atomic displacement events that result in sufficiently high atomic mobility inside the bulk TiNx and the formation of dense microstructures with large column widths. A detailed discussion is provided in the supplementary material, Fig. S5.

Cross-sectional STEM and bright-field and dark-field TEM images of the Si(001)/a-SiO2/TiNx/BHO/W devices with TiNx bottom electrodes sputter-deposited at a–c Vs = −100 V and Ts = 400 °C, and d–f Vs = floating and Ts = no external substrate heating. For both cases, \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) = 1 sccm.

The TiNx layer for the poor performance device has columnar grains of TiNx with non-uniform conical column-tops with valley-to-peak distance of ~9 nm (Fig. 3d), indicating a high surface roughness. A large network of inter- and intra-columnar porosities is also visible, appearing as bright regions that are mostly elongated from the substrate towards the surface, see Fig. 3e. A competitive growth is observed from the dark-field TEM image (Fig. 3f) where fine grains are formed initially near the substrate up to a thickness of ~10 nm, with fewer larger V-shaped columnar grains remaining near the film surface. Critically, this rough columnar TiNx microstructure carries through to the BHO layer, making it highly porous. We note that no TiON thin layer is detected at the TiNx/BHO interface. Such porous TiNx microstructures, which correspond to zones I and T in structure zone models25, typically form under a kinetically-limited competitive growth following a random grain nucleation. Their significantly rough faceted columns and porous microstructures are mainly attributed to a highly restricted anisotropic adatom surface diffusion, classified as a hit-and-stick or ballistic deposition regime. These results agree with X-ray photoelectron spectroscopy (XPS) data shown in Fig. S6 that demonstrate the presence of oxygen and Ti–O–N and Ti–O bonds in porous TiNx.

It is known that increasing Ts considerably promotes adatom surface migration26 that can eliminate porosities and surface mounds during the growth process, resulting in thin-film densification and surface smoothening27. This growth temperature is typically ≥ 700 °C for TiN28. However, we highlight that the TiNx/BHO/W devices fabricated on TiNx sputter-deposited at Ts = 800 °C (and different \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\)) without applying substrate bias (Vs = floating) do not show any hysteretic I–V loops, see Fig. S7. This indicates that high growth temperatures alone cannot provide the optimum TiNx performance for RS.

The atomic force microscopy (AFM)-determined surface topographies of the TiNx thin films sputter-deposited at different Vs, \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\), and Ts conditions are shown in Fig. S8. The surface topographies consist of typical nodular grains of various sizes. For different \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) and Ts, the TiNx layers grown by ion-assisted DC magnetron sputtering at Vs = −100 V have much more uniform, smoother surfaces than those sputter-deposited at floating substrate bias. The X-ray diffraction (XRD) θ–2θ scans of the TiNx thin films grown with the different sputtering variables studied are shown in Fig. S9. The films crystallise in a cubic structure (Fm-3m, 225) with [111] and [200] crystal orientations present in different intensities. For the device with the optimum RS conditions, the dominant TiNx orientation is [200], which can explain why the films are smoother, i.e. the surfaces of [111] oriented grains are more faceted, and they pack less efficiently. More analysis of the XRD data in relation to the film orientation is discussed in Fig. S9.

Having established that highly dense and smooth TiNx bottom electrodes are essential to achieve optimum RS behaviour in an exemplar switching oxide system, we now explore the influence of TiNx electrical properties and compositions on RS behaviour. Figure 4a shows the LRS/HRS ratios of all devices as a function of the TiNx electrical resistivity. All TiNx/BHO/W devices with the low-density, rough TiNx bottom electrodes have high resistivity, mostly due to large conducting-electron scattering and quantum-mechanical electron tunnelling effects29,30,31,32, and thus, do not show any RS effects (LRS/HRS ratios = 1). However, the devices fabricated on the dense, smooth TiNx layers have resistivity values ≤ ~1.1 × 10−7 Ω.m and exhibit memristive performance (LRS/HRS ratios > ~3). This demonstrates that low resistivity is required for the TiNx bottom electrodes to enable memristive behaviour.

a, b LRS/HRS ratios of the TiNx/BHO/W devices as a function of the electrical resistivity of their TiNx bottom electrodes. c Surface roughness, d density, and e oxygen and f hydrogen contents of the TiNx thin films sputter-deposited at \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) = 1, 5, and 10 sccm, Ts = no external substrate heating and 400 °C, and Vs = floating and −100 V plotted versus TiNx electrical resistivity.

Figure 4b reveals a correlation between the device memory window and the TiNx resistivity. For devices fabricated on TiNx with N/Ti ratios ≥ 0.99, the memory window steadily increases from ~3 to ~10 by decreasing the TiNx resistivity from ~1.1 × 10−7 to ~0.5 × 10−7 Ω.m. The device fabricated on TiNx with the lowest resistivity (~0.3 × 10−7 Ω.m) and a N/Ti ratio of 0.96 (sputter-deposited at Vs = −100 V, \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) = 1 sccm, and Ts = 400 °C) has the largest memory window (~40). This indicates that N deficiency is an important factor for achieving the widest memory window. The presence of a sufficiently high concentration of N vacancies in the understoichiometric TiN0.96 lattice facilitates oxygen exchange at the TiN0.96/BHO interface. Thus, the N-deficient TiN0.96 thin films play an important role in the RS process33,34. The large memory window for the devices with TiN0.96 can be explained by N vacancies that act as the reservoir and supplier of oxygen ions34, allowing to control of the filament during the electric-field applications. This leads to stable and robust RS performance. This is similar to amorphous TiON thin layers that typically form at the interface between TiNx and oxide switching films and behave as an oxygen reservoir35,36,37,38,39,40.

Overall, all layers grown by ion-assisted DC magnetron sputtering have significantly denser nanostructures and smoother surfaces than those deposited at floating substrate bias, see Fig. 4c, d. Further details of the TiNx roughness, density, composition, and resistivity data in relation to Vs are discussed in Figs. S5, S10 and S11.

Measuring the oxygen and hydrogen concentrations after exposing the TiNx thin films to air is an indirect method that similar to direct approaches like TEM can be used for assessing the layer densification41,42. After air exposure, light elements like oxygen and hydrogen readily penetrate into the porosities and open column boundaries and result in high concentrations of these elements in porous films. However, the light-element concentrations, especially oxygen, in dense thin films mainly result from their incorporation during the growth process in the vacuum chamber rather than air exposure28. Fig. 4e, f shows high oxygen (~12–20 at.%) and hydrogen (~1–4 at.%) concentrations in the TiNx thin films sputter-deposited at Vs = floating, indicating that these layers are highly porous, in agreement with the cross-section TEM data in Fig. 3d–f. In contrast, the TiNx layers grown by ion-assisted magnetron sputtering at Vs = −100 V contain much lower oxygen (~0.4–2.8 at.%) and hydrogen (≤ ~0.5 at.%, 0 at.% for most layers) contents, proving that these layers have highly dense nanostructures, as also demonstrated by X-ray reflectivity (XRR)-determined TiNx densities in Fig. 4d.

Conclusions

A systematic study was undertaken on the factors that lead to optimised RS performance in amorphous HfO2-based memristors fabricated on sputter-deposited TiNx thin films. Memristive behaviour was observed only for devices with highly dense, smooth, and conductive TiNx bottom electrodes grown by ion-assisted DC magnetron sputtering. An important crucial factor for achieving the highest RS performance was the presence of N vacancies in TiNx. The optimised TiN0.96 layer was obtained at a growth condition with a substrate biasing of −100 V, N2/Ar gas ratio of 5%, and substrate temperature of 400 °C. The devices with the TiN0.96 bottom electrodes have switching voltages ≤ ±1 V and show a large memory window (~40) together with promising device-to-device uniformity, endurance, and multiple non-volatile intermediate conductance levels. This research reveals the importance of precise engineering of TiNx bottom electrodes for achieving robust memristive performance. The findings have broad applicability to wide-ranging oxides for non-volatile memory devices.

Methods

TiNx thin films were grown by DC magnetron sputtering from a 5.08-cm (2-inch) Ti target in a reactive nitrogen atmosphere on Si(001) and Si(001) with a 200-μm-thick amorphous SiO2 top layer (Si(001)/a-SiO2) substrates. The substrates were sequentially cleaned in acetone and isopropyl alcohol and thereafter mounted on a substrate holder at the top of the growth chamber. The substrate holder, whose surface normal has a tilt angle with respect to the Ti target positioned at the bottom of the growth chamber, rotated with a speed of 20 rpm during the film growth. The Si(001) substrates were used for compositional and thickness measurements, while the Si(001)/a-SiO2 substrates were employed for structural and electrical studies. The system base pressure was < 8.0 × 10−8 Torr (1.0 × 10−5 Pa). Prior to each deposition, the Ti target was pre-sputtered in a pure Ar atmosphere under a closed shutter for 1800 s.

For all TiNx depositions, the Ar gas flow rate, total deposition pressure, and Ti-target power were maintained constant at 20 sccm, 2 mTorr, and 140 W, respectively. The total deposition pressure was kept as low as possible at 2 mTorr to minimise the thermalisation of sputter-ejected Ti atoms, occurring due to collisions with Ar atoms in the bulk plasma, and hence, the formation of porous microstructures. For the different TiNx growth conditions, substrate bias (Vs), N2-gas flow rate (\({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\)), and substrate temperature (Ts) were varied. The N2-gas flow rate was increased from \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) = 1 to 5 to 10 sccm, providing a N2/Ar gas ratio of 5%, 25%, and 50%, respectively. Three substrate temperatures were explored: Ts = no external heating, 400 °C (compatible with CMOS processing), and 800 °C (to provide a high adatom surface mobility during growth that typically results in the formation of dense microstructures). In addition, two different substrate bias voltages were applied: Vs = −10 V (floating bias) and −100 V (radio-frequency bias). The deposition time for each condition was adjusted in order to grow all TiNx layers with an average thickness of ~700 Å. This thickness range was chosen to minimise the shadowing effect, which originates from the limited mobility of low-energy, sputter-ejected atoms on the growing surface that leads to a preferential facet growth and consequently, an increase in the surface roughness with increasing film thickness43,44.

Two sets of samples were prepared. The first set was TiNx thin films sputter-deposited for the purpose of characterising their compositions, microstructures, and electrical resistivities. The second set was TiNx/BHO/W devices fabricated to determine the impact of different TiNx bottom electrodes on RS performance. The BHO thin films (as the switching layers) with an average thickness of ~200 Å were deposited by pulsed laser deposition, with growth conditions detailed in ref. 23. ~100-Å-thick W top electrodes were grown following a typical lift-off process by DC magnetron sputtering. A positive UV photoresist (AZ 4533) was first spin-coated on the BHO surface. Thereafter, the sample was baked at 110 °C for 2 min and exposed to UV light for ~11.5 s through a photolithography mask. The resist was then developed by an AZ351B developer. After that, the samples were coated with W. The resist lift-off was carried out by submersing the samples into ethanol for ~900 s, followed by a low-frequency sonication.

The crystal structures and orientations of the TiNx thin films grown on the Si(001)/a-SiO2 substrates (first set of samples) were determined from XRD scans using a PANalytical Empyrean high-resolution X-ray diffractometer operated at 45 kV and 40 mA with a Cu Kα source (λ = 1.5406 Å). The surface topographies and roughness of these samples were obtained using an Agilent AFM from scanning areas of 2 × 2 μm2. Electrical resistivity values were determined by measuring the sheet resistances of the films with a four-point-probe Jandel RM3000 station and then multiplying these resistance values by the film thicknesses. The elemental compositions of TiNx grown on the Si(001) substrates were determined by time-of-flight elastic recoil detection analysis using a 36-MeV 127I8+ probe beam in a 5-MV 15SDH-2 tandem accelerator45. XRR scans carried out in the PANalytical Empyrean high-resolution X-ray diffractometer were used to determine the average thickness, roughness, and density of each film. The nanostructure of these devices was further studied by TEM and STEM using a Talos F200X G2 TEM operated at 200 kV. Cross-sectional TEM specimens were prepared by mechanical polishing, followed by Ar+ ion milling at 5 keV on both sides of each sample during rotation in a Gatan ion miller. The ion energy was reduced to 2.5 keV during the final step of sample thinning.

XPS was used to analyse Ti 2p, N 1 s, and O 1 s core-level spectra of the TiNx thin films sputter-deposited at (i) Vs = −100 V and Ts = 400 °C and (ii) Vs = floating and Ts = no external substrate heating (for both cases, \({{{{\rm{P}}}}}_{{{{{\rm{N}}}}}_{2}}\) = 1 sccm). Analyses were performed in a Thermo Scientific Escalab 250Xi instrument with monochromatic Al Kα radiation (hν = 1486.6 eV) after an Ar ion surface sputter-etching process carried out to remove the native surface oxide layers. To minimise the destructive effects of the sputter-etching process on XPS core levels, we used a beam of Ar ions with ultra-low energies (200 eV). The core levels were obtained from 500 × 500 μm2 regions located in the centre of 2 × 2 mm2 sputter-etched areas. The binding energies of the spectra were calibrated against their Fermi edge cut-offs.

The RS performance of the TiNx/BHO/W devices (second set of the samples) was obtained using a computer-controlled Keysight B2912A46 connected to a probe station. The measurements were carried out on at least 15 different devices with W top electrode diameters of 100 µm for all samples with different TiNx bottom electrodes, and this was increased to at least 25 different devices with W top electrode diameters of 25, 50, and 100 μm for the samples with memristive characteristics. At least five I–V cycles were measured on each device.

Data availability

All data generated or analysed during this study are included in this published article and its supplementary material file.

Change history

05 May 2025

The graphic abstract was missing from this article and has now been added.

References

Jones, N. How to stop data centres from gobbling up the world’s electricity. Nature 561, 163–166 (2018).

Lanza, M. et al. Memristive technologies for data storage, computation, encryption, and radio-frequency communication. Science 376, eabj9979 (2022).

Roldán, J. B. et al. Variability in resistive memories. Adv. Intell. Syst. 5, 2200338 (2023).

Ielmini, D. & Waser, R. Resistive Switching: From Fundamentals of Nanoionic Redox Processes to Memristive Device Applications (John Wiley and Sons, 2016).

Zidan, M. A., Strachan, J. P. & Lu, W. D. The future of electronics based on memristive systems. Nat. Electron. 1, 22–29 (2018).

Ielmini, D. & Wong, H. S. P. In-memory computing with resistive switching devices. Nat. Electron. 1, 333–343 (2018).

Christensen, D. V. et al. 2022 roadmap on neuromorphic computing and engineering. Neuromorphic Comput. Eng. 2, 022501 (2022).

Park, J. et al. Multi-level, forming and filament free, bulk switching trilayer RRAM for neuromorphic computing at the edge. Nat. Commun. 15, 3492 (2024).

Banerjee, W., Kashir, A. & Kamba, S. Hafnium oxide (HfO2)—a multifunctional oxide: a review on the prospect and challenges of hafnium oxide in resistive switching and ferroelectric memories. Small 18, 2107575 (2022).

Dittmann, R., Menzel, S. & Waser, R. Nanoionic memristive phenomena in metal oxides: the valence change mechanism. Adv. Phys. 70, 155–349 (2021).

Sun, G., Zhao, J., Poremba, M., Xu, C. & Xie, Y. Memory that never forgets: emerging nonvolatile memory and the implication for architecture design. Natl. Sci. Rev. 5, 577–592 (2017).

Vasilopoulou, M. et al. Neuromorphic computing based on halide perovskites. Nat. Electron. 6, 949–962 (2023).

Wang, H. et al. 2D ferroic materials for non-volatile memory applications. Adv. Mater. 2305044. https://doi.org/10.1002/adma.202305044 (2023).

Kuesters, K. H. et al. New materials in memory development sub 50 nm: trends in flash and DRAM. Adv. Eng. Mater. 11, 241–248 (2009).

Zhou, Y., Guo, W. & Li, T. A review on transition metal nitrides as electrode materials for supercapacitors. Ceram. Int. 45, 21062–21076 (2019).

Mascaretti, L. et al. Plasmonic titanium nitride nanomaterials prepared by physical vapor deposition methods. Nanotechnology 34, 502003 (2023).

Liang, H. et al. Thickness dependent microstructural and electrical properties of TiN thin films prepared by DC reactive magnetron sputtering. Ceram. Int. 42, 2642–2647 (2016).

Gaillard, N., Pinzelli, L., Gros-Jean, M. & Bsiesy, A. In situ electric field simulation in metal/insulator/metal capacitors. Appl. Phys. Lett. 89, https://doi.org/10.1063/1.2357891 (2006).

Molina, J. et al. Influence of the surface roughness of the bottom electrode on the resistive-switching characteristics of Al/Al2O3/Al and Al/Al2O3/W structures fabricated on glass at 300°C. Microelectron. Reliab. 54, 2747–2753 (2014).

Gerritsen, S. H. et al. Surface smoothing by atomic layer deposition and etching for the fabrication of nanodevices. ACS Appl. Nano Mater. 5, 18116–18126 (2022).

Lee, C. B. et al. Effects of metal electrodes on the resistive memory switching property of NiO thin films. Appl. Phys. Lett. 93, https://doi.org/10.1063/1.2967194 (2008).

Li, Y. & Cheng, H. W. Random work-function-induced threshold voltage fluctuation in metal-gate MOS devices by Monte Carlo simulation. IEEE Trans. Semicond. Manuf. 25, 266–271 (2011).

Hellenbrand, M. et al. Thin film design of amorphous hafnium oxide nanocomposites enabling strong interfacial resistive switching uniformity. Sci. Adv. 9, eadg1946 (2023).

Hellenbrand, M. & MacManus-Driscoll, J. Multi-level resistive switching in hafnium-oxide-based devices for neuromorphic computing. Nano Converg. 10, 44 (2023).

Mahieu, S., Ghekiere, P., Depla, D. & De Gryse, R. Biaxial alignment in sputter deposited thin films. Thin Solid Films 515, 1229–1249 (2006).

Patsalas, P. et al. Conductive nitrides: growth principles, optical and electronic properties, and their perspectives in photonics and plasmonics. Mater. Sci. Eng. R Rep. 123, 1–55 (2018).

Michely, T. & Krug, J. Islands, Mounds and Atoms https://doi.org/10.1007/978-3-642-18672-1 (Springer Science and Business Media, 2012).

Greczynski, G., Petrov, I., Greene, J. E. & Hultman, L. Paradigm shift in thin-film growth by magnetron sputtering: from gas-ion to metal-ion irradiation of the growing film. J. Vac. Sci. Technol. A 37, 060801 (2019).

Patsalas, P. & Logothetidis, S. Optical, electronic, and transport properties of nanocrystalline titanium nitride thin films. J. Appl. Phys. 90, 4725–4734 (2001).

Patsalas, P. & Logothetidis, S. Interface properties and structural evolution of TiN/Si and TiN/GaN heterostructures. J. Appl. Phys. 93, 989–998 (2003).

Mayadas, A. F. & Shatzkes, M. Electrical-resistivity model for polycrystalline films: the case of arbitrary reflection at external surfaces. Phys. Rev. B 1, 1382–1389 (1970).

Soffer, S. B. Statistical model for the size effect in electrical conduction. J. Appl. Phys. 38, 1710–1715 (1967).

Yong, Z. et al. Tuning oxygen vacancies and resistive switching properties in ultra-thin HfO2 RRAM via TiN bottom electrode and interface engineering. Appl. Surf. Sci. 551, 149386 (2021).

Bradley, S. R., McKenna, K. P. & Shluger, A. L. The behaviour of oxygen at metal electrodes in HfO2 based resistive switching devices. Microelectron. Eng. 109, 346–350 (2013).

Bianchi, S. et al. A self-adaptive hardware with resistive switching synapses for experience-based neurocomputing. Nat. Commun. 14, 1565 (2023).

Celano, U. et al. Direct probing of the dielectric scavenging-layer interface in oxide filamentary-based valence change memory. ACS Appl. Mater. Interfaces 9, 10820–10824 (2017).

Su, T. Y. et al. Tunable defect engineering in TiON thin films by multi-step sputtering processes: from a Schottky diode to resistive switching memory. J. Mater. Chem. C 5, 6319–6327 (2017).

Baek, K. et al. In situ TEM observation on the interface-type resistive switching by electrochemical redox reactions at a TiN/PCMO interface. Nanoscale 9, 582–593 (2017).

Morgan, K. A. et al. Effect of stoichiometry of TiN electrode on the switching behavior of TiN/HfOx/TiN structures for resistive RAM. MRS Online Proc. Libr. 1631, 301 (2014).

Ma, Y. et al. Exchange of ions across the TiN/TaOx interface during electroformation of TaOx-based resistive switching devices. ACS Appl. Mater. Interfaces 12, 27378–27385 (2020).

Li, X. et al. Dense, single-phase, hard, and stress-free Ti0.32Al0.63W0.05N films grown by magnetron sputtering with dramatically reduced energy consumption. Sci. Rep. 12, 2166 (2022).

Bakhit, B. et al. Microstructure, mechanical, and corrosion properties of Zr1-xCrxBy diboride alloy thin films grown by hybrid high power impulse/DC magnetron co-sputtering. Appl. Surf. Sci. 591, 153164 (2022).

Petrov, I., Barna, P. B., Hultman, L. & Greene, J. E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 21, S117–S128 (2003).

Patsalas, P., Gravalidis, C. & Logothetidis, S. Surface kinetics and subplantation phenomena affecting the texture, morphology, stress, and growth evolution of titanium nitride films. J. Appl. Phys. 96, 6234–6246 (2004).

Bakhit, B. et al. Systematic compositional analysis of sputter-deposited boron-containing thin films. J. Vac. Sci. Technol. A 39, 063408 (2021).

Hellenbrand, M. Keysight B2912 Memristor characterisation. https://doi.org/10.17863/CAM.109318 (Apollo—University of Cambridge Repository, 2024).

Acknowledgements

B.B. acknowledges the financial support from Swedish Research Council VR, grant numbers 2019-00191 (for the accelerator-based ion-technological centre in tandem accelerator laboratory in Uppsala University, Sweden) and 2021-00357, CAPE BlueSky Research Award 2022, and Energy IRC Small Grant award for Knowledge Exchange and Impact from the Higher Education Innovation Fund (HEIF). J.L.M.-D. acknowledges support from the Royal Academy of Engineering Chair in Emerging Technologies, grant number CIET1819_24. J.L.M.-D., M.H. and B.B. acknowledge the EU-H2020-ERC-ADG grant and EROS, grant number 882929. The TEM/STEM effort at Purdue University was supported by the U.S. National Science Foundation (DMREF-2323752).

Author information

Authors and Affiliations

Contributions

B.B.: conceptualisation (lead), data curation (lead), methodology (lead), formal analysis (lead), investigation (lead), validation (lead), visualisation (lead), resources (lead), funding acquisition (lead), project administration (lead), supervision (equal), writing—original draft (lead), writing—review and editing (lead). M.H.: data curation (supporting—electrical measurements), methodology (supporting—BHO deposition and electrical measurements), formal analysis (supporting—electrical data), investigation (supporting—BHO depositions and electrical measurements), validation (supporting), visualisation (supporting), software (lead), writing—review and editing (supporting). B.K.T.: investigation (supporting—TEM data acquisition) and writing—review and editing (supporting). A.C.: investigation (supporting—TEM sample preparation) and writing—review and editing (supporting). P.P. and S.K.: validation (supporting), visualisation (supporting), resources (supporting), writing—review and editing (supporting). H.W.: investigation (supporting—TEM data acquisition), validation (supporting), visualisation (supporting), resources (supporting), writing—review and editing (supporting). A.J.F.: validation (supporting), visualisation (supporting), resources (supporting), project administration (supporting), supervision (equal), writing—review and editing (supporting). J.L.M.-D.: validation (supporting), visualisation (supporting), resources (supporting), project administration (supporting), supervision (equal), writing—review and editing (supporting).

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Shimul Kanti Nath, Mrinal K. Hota and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Aldo Isidori.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bakhit, B., Hellenbrand, M., Tsai, B.K. et al. Enhanced non-volatile resistive switching performance through ion-assisted magnetron sputtering of TiN bottom electrodes. Commun Mater 6, 77 (2025). https://doi.org/10.1038/s43246-025-00798-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-025-00798-z