Abstract

The logarithmic spiral is observed as a common pattern in several living beings across kingdoms and species. Some examples include fern shoots, prehensile tails, and soft appendages like octopus arms and elephant trunks. In the latter cases, spiraling is also used for grasping. Motivated by how this strategy simplifies behavior into kinematic primitives and combines them to develop smart grasping movements, this work focuses on the elephant trunk, which is more deeply investigated in the literature. We present a soft arm combined with a rigid robotic arm to replicate elephant grasping capabilities. In our system, the rigid arm ensures positioning and orientation, mimicking the role of the elephant’s head, while the soft manipulator reproduces trunk motion primitives of bending and twisting under proper actuation patterns. The synergy between rigid and soft components replicates 9 distinct elephant grasping strategies, enabling adaptation to various object shapes and sizes while reducing control complexity.

Similar content being viewed by others

Introduction

In nature, logarithmic spirals are commonly observed in biological structures, combining remarkable esthetic appeal with functional efficiency. A logarithmic spiral is defined as a plane curve that originated from a fixed point, known as the pole, such that every arc between this point and any other on the curve remains geometrically similar to the whole1. The polar equation for a logarithmic spiral is:

where r is the radius, θ is the polar angle, and a and b are real constants. The spiral expands logarithmically with θ, resulting in an ever-widening curve without bounds. This pattern is a recurring motif across various prehensile appendages, such as the tails of chameleons and seahorses, the trunks of elephants, and even the human hand and arm2,3. These structures not only exhibit logarithmic spiral geometries in their static configurations but also leverage the dynamic properties of these spirals during grasping and manipulation tasks.

Static logarithmic spirals are evident in the resting morphology of many prehensile appendages. For example, animals often store their appendages in spiral configurations, tightly wrapping each segment to optimize space usage. This compact form could be an efficient way to conserve energy and maintain readiness for rapid deployment. In contrast, dynamic spirals emerge during the prehension process, where the inward propagation of curvature plays a key role in anchoring objects and transporting them securely. This behavior, particularly observed in the elephant trunk4, demonstrates a proximal propagation of curvature during grasping and its reversal during releasing. Such a motion strategy ensures efficient object handling, facilitating secure capture, transportation, and precise placement.

Elephant trunks exhibit remarkable versatility while maintaining a high force capacity. This is enabled by the activation of approximately 90,000 muscle fascicles5, which work in coordination to produce complex behaviors. They are arranged in a muscular hydrostat, comprising of longitudinal, transverse and oblique muscles, which keeps constant volume during contractions6. In principle, a muscular hydrostat like the trunk could exhibit a virtually infinite number of degrees of freedom. However, to simplify control for specific tasks, elephants have evolved strategies that involve identifying the most efficient kinematic primitives and combining them in finite configurations to address diverse scenarios4.

A typical point-to-point grasp by elephants can be decomposed into four main phases of motion: reaching, prehension, transport, and release 4, see in Fig. 1e. During the reaching phase, the elephant moves its head to adjust its orientation and elongates its trunk to fetch the target object. In the subsequent phases of prehension, transport, and release, the elephant trunk relies on three primary deformation methods—bending, twisting, and extension—to manipulate objects. The trunk bending, twisting, and extension are induced by curvature, torsion, and longitudinal strain, respectively, which are achieved through the activation of specific muscle groups. These motion primitives can be combined in different configurations to enable versatile grasping strategies. Through empirical observation of African elephant grasping behavior in controlled experiments, 17 distinct strategies were summarized in 4 for grasping objects of varying sizes, shapes, and weights by integrating these fundamental primitives with precise head orientation and movement.

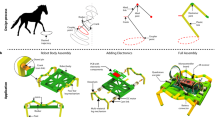

a An overview of the proposed hybrid system compared to typical elephant motions. The system comprises a Franka Emika Panda robotic arm and a cable-driven soft continuum manipulator with a trunk-tip gripper. Three typical configurations are present: twisting when lowering the head, bending with the head up, and resting under gravity. b The exploded view of the motor housing demonstrates the detailed placement of the actuators. c The rotation of the steering gear allows the trunk-tip gripper to open and close. d, e The schematic graph of the point-to-point elephant grasping procedure, including reaching, prehension, transport, and release phases (the real trunk demonstration images are adapted from the video in ref. 4). During the reaching phase, the primary deformation is elongation, which facilitates an extended reach. During prehension, small objects are grasped through an open-and-close motion of the trunk tip, while larger objects exceeding the capacity of the trunk-tip are wrapped using the trunk body, achieved through bending and/or twisting, depending on the object’s position. In the transport phase, a curvature propagation would occur towards the proximal end to secure the object by inward bending. Finally, during the releasing phase, an opposite curvature propagation assists in releasing the object at the target ___location.

Inspired by these biological phenomena, this work presents a novel synergy between soft and rigid robotic systems to replicate the grasping strategies observed in African elephants from a high-level behavioral perspective (Fig. 1a). The rigid component, a Franka Emika Panda robot arm, is analogous to the elephant’s head, providing precise positioning and orientation within the workspace during the reaching phase. The soft manipulator in our hybrid system is designed to reproduce the motion primitives of an elephant trunk by a special actuation mode. By the cooperation of the synergy, the hybrid system is capable of replicating 9 grasping strategies out of the total 17 described, such as tip grip, distal wrap in the horizontal plane, or trunk “kick” with objects in various sizes and shapes.

It has been demonstrated that coordinating the degrees of freedom (DoFs) of the rigid skeleton with those of the soft trunk enhances the smoothness of overall shape planning7. While there has been an initial attempt to study the theoretical framework of the synergy between rigid and soft robotic hydrostats—particularly from a cognitive and neural control perspective7,8—the physical implementations remain scarce. Although the few existing studies demonstrate physical implementations and offer insights from a control perspective9,10,11, they fall short of providing high-level strategy-oriented approaches to coordination and manipulation. It is important to note that, in our context, a hybrid system refers specifically to a composition of a rigid skeleton coupled with a hyper-redundant continuum arm rather than an integrated structure of rigid and soft materials (e.g., bones and muscles) forming a single component.

In our soft manipulator, a symmetric three-cable configuration is specially arranged to achieve motion primitives in elephants inspired by their muscle group configuration5. One cable is positioned dorsally to mimic the dorsal longitudinal muscle of the trunk, inducing an upward bending motion when activated. The other two cables are placed ventrally to represent the symmetric ventral muscle groups. Equal activation of the ventral cables produces inward bending, while differential activation enables twisting. By actuating the respective cables in specific proportions, guided by our analytical model, the manipulator is capable of executing bending and twisting motions of varying shapes, mimicking the elephant trunk’s motion primitives.

By applying the geometrical concept of the logarithmic spiral to the design, bending motions can be propagated gradually from the distal to proximal sections, due to the proportionally decreasing of both joint geometry and the corresponding bending stiffness along the manipulator. The curvature initiates at the tip and extends dynamically as more proximal regions curl, which closely resembles the curvature propagation observed in an elephant trunk during prehension and transportation.

Inspired by the multifunctionality of the elephant trunk body and trunk tip, we present a novel integration of a continuum manipulator and an end-effector gripper, each capable of independently executing grasping tasks. Current research often focuses on mounting grippers on soft or rigid robots, relying solely on the end-effector for grasping12,13,14 or exclusively using the soft arm for grasping15,16. While these approaches achieve certain levels of functionality, they lack the synergistic integration of both elements, limiting their adaptability and efficiency in diverse tasks.

Most existing soft robotic arms are restricted to planar motions17,18,19. Designs capable of achieving versatile configurations in three-dimensional (3D) space typically rely on multi-section architectures20,21,22, which require numerous actuators, significantly increasing control complexity. Alternatively, some single-section designs23 exhibit rich configuration spaces but lack grasping capabilities, limiting their practical applications. In contrast, our work adopts a different approach by developing a single-section cable-driven soft manipulator capable of full 3D motion and grasping.

To enable diverse bending and twisting configurations in our soft manipulator, we develop a novel length-based forward kinematic model that leverages the mathematical properties of the logarithmic spiral. These kinematic primitives serve as the foundation for executing complex grasping tasks when combined with the rigid robot arm. While the logarithmic-spiral-based concept was first proposed in ref. 15, their friction-based model24 was restricted to 2D motion, making it unsuitable for omnidirectional grasping. Traditional length-based modeling approaches, such as piecewise constant curvature methods25, are not well-suited for cone-shaped robots. Adaptations for variable-curvature designs26 offer improved flexibility but are complex to derive. Alternative modeling techniques, such as beam theories—including Cosserat rod theory27,28—and finite element methods (FEM)29, provide higher accuracy by analyzing forces and deformations. However, these methods demand significantly greater computational resources, making them less practical for real-time applications. In contrast, our approach balances mathematical simplicity with functional precision, enabling efficient modeling of the manipulator’s 3D configurations.

By integrating logarithmic spiral-based geometry and kinematic modeling, the proposed design overcomes the limitations of previous works, enabling a versatile configuration space and robust grasping capabilities. Combined with the rigid robot arm, the hybrid system achieves the precision, adaptability, and dexterity necessary to handle objects of varying sizes, shapes, and weights. These capabilities are demonstrated through a series of validation experiments.

Results

Our contributions can be summarized as follows:

-

1.

Drawing inspiration from the logarithmic spiral patterns observed in animal prehensile appendages, we identify a set of geometry constraint parameters that can be consistently applied to both a soft continuum manipulator and its end-effector gripper. This unified parameterization enables both components to achieve spiral-based grasping. Furthermore, we analyze the advantages of these spiral patterns in biological systems and demonstrate their relevance in robotic design.

-

2.

We establish a novel cable-driven actuation pattern for the soft manipulator to achieve bending and twisting, inspired by the functionality of the trunk muscles, which generate kinematic primitives. A novel length-based forward kinematic model is further proposed to describe the different configurations of these primitives, in which the model accuracy is validated via a set of experiments.

-

3.

We integrate the soft manipulator with a rigid robot arm to create a hybrid synergy that can achieve a wider range of configurations, effectively replicating 9 distinct grasping strategies observed in African elephant behaviors.

In this section, we first present an overview of the design and modeling of our robotic system in Section Soft Manipulator Design, followed by an overview and validation of our forward kinematic model in Section Forward Kinematic Model. The reproduction of elephant grasping strategies is shown in Section Reproducing Elephant Grasping Strategies with the Hybrid System and recorded in the supplementary video. More technical details of our work are postponed to Section Methods.

Soft Manipulator Design

In this section, we first explain how to determine optimal parameters in the logarithmic spiral and then transform the obtained spiral curve into the real prototype. We describe the logarithmic spiral in the Cartesian coordinate as:

As θ increases from negative to positive infinity, the curve will spiral outward from the origin in cycles. We position two logarithmic spirals with the same parameters together and scale one of them by scaling factor k:

These two contour spirals would form an enclosed area, as shown in Fig. 2a. The colored area enclosed by the two contour spirals determines half of the main body of our manipulator, and a rotation around one contour spiral constitutes the whole manipulator, as shown in Fig. 2e. The body shapes vary under different parameters. First, we list three design principles to determine the optimal parameters:

Three sprials at different scales formed by varying (a). the scale factor a, (b). the growth parameter b, (c). The compactness parameter k, (d). The discrete parameter Δθ. (e). The optimal parameters are selected for the geometry constraint of our soft manipulator and its end-effector gripper. f The final dimensions of our soft manipulator. g, h The qualitative comparison of bending and twisting between the analytical model (above) and prototype (below) under the same actuation amount in different angles to the gravity directions.

Principle 1

The design shall keep compact.

Principle 2

The grasping range of the trunk body and trunk tip gripper shall be overlapped to eliminate ungraspable sizes.

Principle 3

The soft prototype shall match the rigid robot arm.

As illustrated in Fig. 2, the key parameters exert different influences on the resulting spiral shapes. A brief overview is provided here, with detailed derivations deferred to Section Methods.

Figure 2a illustrates how a determines the scale of the spiral, which would subsequently decide the manipulator size. When a increases, the overall size of the spiral increases. A proper a can be decided via Principle 3.

Figure 2b illustrates how b affects the growth rate of the spiral. The larger the value of b, the faster the curve decays towards the origin. If the full length of curve is kept constant, a reduction in b leads to a smaller area in the center of the spiral (orange line in Fig. 2e), with a smaller width of the end section (blue line in Fig. 2e). The width of the smallest section imposes a constraint on the maximum allowable size of the mounted end-effector gripper, while the central encirclement area of the spiral determines the minimum size of a graspable object of the trunk body. Thus, a larger b reduces the grasping range of the end-gripper while benefiting that of the trunk manipulator. A tradeoff of b to fulfill Principle 2 is necessary to improve the overall graspable range and reduce the difficulty of small-scale fabrication.

k determines the degree of compactness of the spiral. An appropriate value of k (the yellow spiral in Fig. 2c) enables the spiral to curl tightly in successive loops without gaps, which is crucial for Principle 1.

Δθ defines the amount of discretization of the spiral. We compare different values of Δθ in Fig. 2d. The discrete level is restricted by the trade-off of the prototype dexterity and the fabrication difficulty. A more continuous prototype would be more flexible yet more difficult to fabricate. Empirically, the Δθ has been determined as 30∘ for the trunk body, while the tip gripper exhibits a higher degree of discretion of Δθ = 60∘, as shown in Fig. 2e. While the tip gripper is designed to be mounted at the distal end of the trunk manipulator, its design inspiration is drawn not from the elephant trunk but from human fingers. Prior studies 2,3,30 have demonstrated strong correlations between human fingers and logarithmic spirals, both in terms of anatomical structure and motion trajectories. To maintain design consistency, we therefore adopt human fingers as the reference model for the gripper. Specifically, the spiral for the finger design is constructed using the golden ratio, b = 0.61830.

Figure 2e demonstrates how we transform the spiral geometry to the prototype. Additionally, each section of the manipulator is wrapped with wrinkled silicon shells. The ratio of the sizes of the adjacent sections remains constant. This proportion lays the foundation for developing the forward kinematic model. The graspable range of the trunk main body spans objects with cross-sectional widths between 267mm and 33mm15. The maximum theoretical payload of 4.89kg is achieved when grasping objects with a cross-sectional width of 33mm15. The tip gripper is capable of grasping objects with a maximum cross-sectional width of approximately 40mm, resulting in a 7mm overlapping range with the trunk body. It should be noted that this payload estimation considers only the soft manipulator. In practice, the overall payload capacity of the hybrid system may be further constrained by the payload limits of the supporting robot arm at 3kg.

Forward Kinematic Model

This section provides an overview of the forward kinematic model, with detailed derivations deferred to Section Reproducing Elephant Grasping Strategies with the Hybrid System.

The manipulator’s elastic joints are designed as cylindrical components with radii that decrease progressively according to a fixed scaling ratio kp = 0.9196. This proportional reduction in joint geometry leads to a corresponding distribution of decreasing bending stiffness along the manipulator. As a result, when the actuation cables are tightened, the curling motion initiates at the tip and propagates toward the base. To establish the forward kinematic model, we make the following two assumptions:

Assumption 1

Each link of the manipulator is treated as a rigid body.

Assumption 2

The joints are assumed to allow bending deformation, while torsional effects are neglected.

The joint dimensions are significantly smaller than the link radius, allowing the manipulator to be modeled by a joint-link configuration similar to that of rigid robots. When the cable is actuated, while the links are undeformed, the joints rotate due to the large passive material deformations. These deformations are constrained by the geometric of the links, which impose rotation limits of 30∘ at each joint.

Resting under gravity

We start with analyzing the initial resting state of the manipulator. In the absence of actuation, if the manipulator base adopts an initial inclination angle, each section will bend under the influence of gravity. The material stiffness of the joints provides resistance to this bending, resulting in a shape model that describes the manipulator’s configuration at various inclination angles. This static shape serves as the baseline for further modeling under cable actuation. Notably, the influence of gravity allows the soft manipulator to achieve a more diverse range of configurations. When gravity is considered, the same actuation input induces different shape configurations depending on the orientation of the manipulator’s base relative to the gravitational field. This highlights the importance of incorporating gravitational effects into the model to capture the manipulator’s true behavior and expand its functional range.

Bending

Bending deformation is affected by the cable actuation amount, the manipulator’s geometry and material properties. When a single cable is shortened by a specified amount, the resulting length change is distributed across all sections of the manipulator, inducing corresponding joint rotations. To accommodate the deformation, the other two cables must be passively relaxed. By analyzing the system’s geometry, material stiffness, and torque balance, the relationships governing length distribution between adjacent sections and the associated rotation angles can be calculated. The same methodology applies when both ventral-side cables are equally shortened while the remaining dorsal cable is relaxed, resulting in symmetrical bending of the manipulator. This approach enables the accurate prediction of the manipulator’s shape in response to a given actuation input. Detailed derivations are described in Section Reproducing Elephant Grasping Strategies with the Hybrid System.

Twisting

Twisting deformation is introduced by applying a different amount of actuation in the second cable based on the existed actuation of the first cable. To model this behavior, we propose the following assumption:

Assumption 3

The actuation of the second active cable does not alter the distribution relationships established by the initial cable.

Under this assumption, the second cable’s action is treated as a further rotation of the joint around a specific axis defined by the initial cable’s actuation amount. This approach enables the calculation of joint angles under two-cable actuation, capturing the twisting effect induced by differential cable tensions. The section geometry imposes constraints on the manipulator’s deformation by limiting the twisting angle depending on the state of the first cable. If the distributed cable length causes a joint to reach its limit, the excess cable length is reallocated to subsequent joints. This redistribution ensures smooth and continuous deformation while respecting geometric and material constraints. Detailed procedures for handling these limits are described in Algorithm 1 and Algorithm 2, presented in Section Reproducing Elephant Grasping Strategies with the Hybrid System.

Model Validation

We evaluate the manipulator’s performance in replicating predefined shapes predicted by the forward kinematic model. We utilize an OptiTrack motion capture system equipped with 17 cameras to track the manipulator’s shape changes under different cable actuation and gravity directions. The evaluation process involves quantitative and qualitative assessments of the manipulator’s ability to conform to target geometries.

The validation focused on two behaviors central to elephant trunk motion: bending and resting under gravity. Three reflective markers are affixed to the lower edge of each section, forming rigid body coordinate frames along the manipulator’s backbone, as shown in Fig. 3a. Actuation commands were sent to the GM6020 motors via the RoboMaster Development Board to selectively tighten or relax the cables embedded in the manipulator. Once the manipulator reached static equilibrium, its shape was recorded, and the 3D positions of the rigid body frames were stored and aligned with the model output using a rigid-body transformation. The position deviation was calculated at each frame of the backbone, and the Root Mean Square Error (RMSE) was used as the primary accuracy metric. The detailed systematic evaluation is described in Section Model Validation via Motion Capture System.

a Schematic graph of the motion capture validation experiment setup for the model. b The visualization of the motion capture results in the vertical plane for different bending shapes, and the quantitative result shows the averaged error along shapes (c) and sections (d). e The visualization of the motion capture results in the resting shapes under different gravity angles, and the quantitative result shows the averaged error along shapes (f) and sections (g).

Bending: We evaluate the entire bending process from the initial state—when the manipulator is fully extended— to the fully wrapped state in the vertical gravity direction. The qualitative and quantitative results are shown in Figs. 2g and 3b, respectively. In Fig. 3b, we select five frames among the 26 discrete bending steps. Quantitatively, the average RMSE value for all sections across all steps was 10.41mm, with the largest deviation being 32.14mm. Figure 3c shows how the absolute error distribution changes as the shape of the manipulator changes with each step. Figure 2d shows the absolute error distribution of each section across the 27 shapes captured by the motion capture system.

Deformation under gravity: To validate the accuracy of the gravity model, we allow the manipulator to hang naturally at tilt angles of 0∘, 45∘, 90∘, 135∘, with respect to the gravity direction. The qualitative and quantitative results are shown in Figs. 2h and 3e, respectively. Quantitative analysis revealed RMSE values of 5.48mm, 10.57mm, 10.45mm, and 19.86mm for the respective tilt angles. The positional error distributions are further illustrated using box plots in Fig. 3f, g, offering insights from directional and sectional perspectives, respectively. These results demonstrate the model’s effectiveness at smaller tilt angles, with increasing deviations observed at larger angles due to cumulative material deformation and gravitational effects.

The results demonstrated a fairly consistent match between the experimental and theoretical profiles. The minor deviations observed could be attributed to slight variations in the material’s elastic properties and random errors introduced during the fabrication process. Further details about the potential sources of error that could affect the accuracy of our model validation results are discussed in Section V-E. These findings validate the manipulator’s capacity to mimic bending behaviors, showcasing its potential for adaptive and gravity-compliant tasks.

Reproducing Elephant Grasping Strategies with the Hybrid System

To evaluate the capability of our hybrid robotic system to reproduce the grasping strategies of elephants, we conducted a series of experiments inspired by the behaviors documented in ref. 4. Our experiments utilized the same geometric objects as those used by Dagenais et al. for real elephants. These objects provided a standardized basis for comparing the performance of our robotic system with that of a real elephant. Objects were placed at various distances and orientations within the robot’s workspace to test the system’s ability to perform diverse prehension tasks.

Our hybrid system successfully replicated 9 out of the 17 grasping strategies. Fig. 4 summarizes the qualitative results of our experiments and also the actuation methodology utilized to form the shape required to execute the grasping strategy. We refer the reader to our supplementary video for a complete demonstration of the grasping strategies.

The listed strategy and elephant demonstration are derived from studies in ref. 4. Key shapes with different actuation patterns are determined from the study and pre-defined by the forward kinematic model. The snapshots of our prototype demonstration showcase the successful prehension and transportation of geometric objects of various sizes. A full video demonstration can be seen in the supplementary files.

Strategy Breakdown

If we break down the elephant strategy in Fig. 1 further, we find that the variations primarily occur during the prehension stage, which is also the most complex of the four steps. Broadly speaking, the prehension phase involves a preparatory action, followed by one of two distinct modes, depending on the characteristics of the target object: trunk tip prehension or trunk-body prehension.

-

1.

Preparatory Action: When objects are positioned beyond direct reach or oriented in a manner unsuitable for immediate grasping, elephants typically perform a preparatory action to reposition the item. A trunk ‘kick’ or sweeping motion (strategies 8 and 9 in Fig. 4) is usually executed to roll or push the object toward a more accessible ___location. This strategy is commonly employed for small or lightweight objects and requires fine control of the distal trunk and trunk tip to maintain precision. Additionally, elephants would also press objects against the ground with their trunk to stabilize them before grasping.

-

2.

Trunk Tip Prehension: For small and light objects, elephants utilize the trunk tip to perform pinching, gripping and/or suction, with the direction from the top or the side determined by the target pose. Pinching (strategy 2 in Fig. 4) is typically for thin and slender objects, involving minimal contact—analogous to using fingertips in humans. Gripping (strategy 3 in Fig. 4) is used for objects with similar shapes but slightly larger sizes, where the entire “palm” of the trunk tip wraps tightly around the object. In the case of granular materials (e.g., a pile of peanuts) or smooth, flat objects (e.g., a piece of glass), elephants often combine suction with gripping to facilitate effective prehension.

-

3.

Trunk Body: When interacting with larger, heavier, or irregularly shaped objects, elephants engage the entire trunk body during prehension. The strategy employed is determined by the object’s position (i.e., whether it is suspended or resting on a surface). In the case of suspended objects, bending serves as the primary deformation mode. During bending (strategy 1 in Fig. 4), the trunk wraps around the object within the vertical plane, ensuring a secure grasp. This method is particularly effective for cylindrical or bulky items. Conversely, when the object’s base is in contact with the ground, twisting becomes essential (strategies 4, 5, and 6 in Fig. 4). A purely upward or inward bend would induce trunk encirclement in the vertical plane, which may impede effective grasping due to interference with the ground. By applying a twist, the curvature direction gradually transitions from the vertical plane to the oblique plane and finally to the horizontal plane, enabling the trunk to encircle the object from the side. This strategy is particularly effective for objects with a broad or flat base situated on a surface. In addition, elephants occasionally rely on their tusks or forelimbs to aid in the manipulation and handling of particularly large or heavy items.

During the transport phase, bending remains the dominant deformation mode. The inward curvature propagates further from the distal end to the proximal sections, mimicking the behavior of an elephant trunk. For trunk tip prehension mode, a distal flip is frequently used to secure the object after lifting. This facilitates secure transportation by engaging larger volumes of the manipulator for stabilization and enhancing grip strength for heavier or bulkier objects.

Throughout the prehension and transport processes, elephants modulate their trunk stiffness to accommodate varying object loads. This is achieved via localized multi-axial muscular contractions. Similarly, our soft manipulator modulates stiffness through tendon antagonism. The manipulator can maintain its shape by dynamically adjusting opposing tensions in the dorsal and ventral cables while achieving secure prehension and stable transportation.

During the releasing phase, a curvature propagation in the opposite direction occurs, transporting the object from the proximal end toward the tip of the trunk and finally letting go at the desired target point.

Grasping Fruits of Different Sizes and Masses

To evaluate the real-world applicability of our hybrid system, we conduct experiments grasping fruits of varying sizes, masses, and surface textures. Our soft manipulator’s motion primitives and compliant structure allow it to adapt to the shape of the fruit and execute a grasping strategy that minimizes damage to the fruit, outperforming rigid grippers. As illustrated in Fig. 5, our soft manipulator employs strategies such as tip pinch or grip for delicate fruits (cherries and blueberries), horizontal distal wrap for an apple placed on the table, and distal twist or full trunk wrap for larger fruits. Our system handles fruits from 10g (a blueberry) to 1kg (a coconut), bridging the gap between fully soft robots (with limited payloads) and industrial arms (overly rigid for delicate tasks).

Fruits used (from left to right): blueberry, cherry, apple, mango, a bunch of grapes, a bunch of bananas, pineapple, and coconut. The manipulator could not securely grasp a coconut due to the shifting center of gravity (CG) caused by the liquid inside the fruit. The soft manipulator’s inability to resist torsional twists during dynamic CG shifts led to grip loss.

Results and Observations

The experiments demonstrate the ability of the soft manipulator to reproduce the motion primitives of an elephant trunk effectively. Figure 4 highlights the qualitative success of each replicated strategy, while the actuation patterns show the versatility of the manipulator’s cable-driven mechanism. Notably, the logarithmic spiral design enables dynamic bending propagation, ensuring the manipulator could adapt its shape in response to the object’s shape and position. Figure 5 showcases the adaptability of our soft manipulator to object geometry and fragility. However, our soft manipulator could not securely grasp a coconut due to the shifting center of gravity (CG) caused by the liquid inside the fruit, which reveals a design limitation in our soft manipulator. As the actuation system of our soft manipulator only consists of longitudinal cables, stiffness regulation can only be executed in the sagittal plane. Therefore, our soft manipulator’s inability to resist torsional twists during dynamic CG shifts led to grip loss. Further discussions on future research directions to improve our hardware design are postponed to Section Discussion.

Discussion

The logarithmic spiral serves as an effective design reference, as it is a recurring pattern observed not only in elephants but also across various prehensile appendages in different species. This pattern is evident in anatomical structures30, motion trajectories2, and muscle morphologies15. Combined with its mathematical properties and observed behaviors in nature, we hypothesize that the logarithmic spiral offers significant advantages for prehension, both biologically and in engineered systems.

From an engineering perspective, the logarithmic spiral contributes to enhanced grasping ranges while simplifying the design, fabrication, and modeling of robotic systems. First, the self-similarity inherent to the logarithmic spiral makes it a scalable design principle, applicable across different size scales. Prior research15 has demonstrated that grasping capabilities remain consistent across meter-scale to millimeter-scale designs, highlighting its cross-scale adaptability. Second, the tapering geometry constrained by the logarithmic spiral supports a broader curvature range, improving grasping adaptability. This is because a uniform activation in longitudinal muscles (or equivalent actuation mechanisms) leads to increased local curvature as the cross-sectional radius decreases23. In other words, the more pronounced the tapering, the greater the grasping precision and adaptability. Third, the fixed ratio of geometric dimensions from proximal to distal sections unifies the design, enabling modular fabrication. A single-unit design can be scaled up or down systematically for adjacent sections, reducing complexity in manufacturing while maintaining functionality.

However, there are limitations to the application of the logarithmic spiral in robotic systems. This study primarily focuses on replicating grasping behaviors observed in elephants, while other trunk movement patterns fall outside the scope of this work. For instance, elephants exhibit behaviors such as forming pseudo-joints for sideways reaching or actuating only distal segments while keeping proximal sections rigid. These movements involve complex biomechanical strategies that extend beyond the capabilities of a logarithmic spiral-based manipulator. Consequently, while the logarithmic spiral serves as a robust framework for grasping, it represents only a subset of the full behavioral repertoire of elephant trunk movements.

The results presented in this study demonstrate the effectiveness of the proposed soft-rigid hybrid robotic system in replicating key grasping strategies inspired by the elephant. The system successfully reproduced 9 out of the 17 documented strategies, showcasing its ability to adapt to objects of varying shapes, sizes, and orientations. This work showcases the first implementation of a logarithmic-spiral-based soft manipulator integrated with a rigid robotic arm, effectively leveraging the strengths of both components. The rigid arm provides precise positioning and support, while the cable-driven soft manipulator achieves complex motion primitives such as bending, twisting, and tip grasping. The experimental validation highlights the versatility of the system and underscores the advantages of the logarithmic spiral geometry in enabling dynamic bending propagation and controlling complex manipulator shapes with minimal actuation inputs. The forward kinematic model developed for the manipulator further contributed to this achievement by enabling precise control of the manipulator’s motion primitives, validated through experimental results.

While our experiments demonstrate the manipulator’s ability to perform predefined grasping strategies, the system lacks adaptability to novel objects and dynamic tasks. This is partly due to the reliance on predefined actuation models in this work rather than on a more flexible learning-based framework.

Several grasping strategies commonly employed by elephants could not be replicated, revealing key limitations of our current design and motivating future improvements. For instance, elephants use suction to grasp granular, smooth, or flat objects—a capability absent from our system, which lacks mechanisms for generating or controlling suction forces. This limitation could be addressed by incorporating a miniature suction cup at the trunk tip, actuated pneumatically.

Additionally, elephants often stabilize irregular objects by pressing them against the ground prior to grasping. Our system’s reliance on position control simplifies actuation but restricts the ability to regulate interaction forces. Executing such a strategy would require an accurate model relating motor torques—used to modulate manipulator stiffness—to the vertical contact forces applied to the object, which is not currently available in our framework.

Another limitation lies in the inability to leverage other body parts or environmental support during manipulation. Elephants often use their tusks, forelimbs, or brace their trunks against surfaces to aid in grasping large or heavy objects. Our system, comprising a single manipulator and a rigid arm, lacks this versatility. While we demonstrated a simple open-loop example of using ground relief for tip-assisted grasping (strategy 7 in Fig. 4), the design lacks tactile feedback or compliance modulation necessary for more robust interaction. Future work will incorporate tactile sensors and a hybrid impedance-force control scheme that combines real-time feedback from force sensors on the rigid arm with cable tension feedback.

Finally, the current cable-driven architecture provides limited torsional resistance, resulting in instability when manipulating heavy objects that exhibit dynamic mass redistribution, as observed in the failed coconut grasping attempt (Section Grasping Fruits of Different Sizes and Masses). Enhancing torsional stiffness through helical cable routing or antagonistic actuators, along with real-time cable tension control based on force-torque feedback to detect shifts in the object’s center of gravity, represents a promising direction for improving manipulation stability.

Beyond improving the hardware design, a more intelligent grasping system based on a deep learning framework could be developed and tested in unstructured environments involving irregularly shaped objects and dynamic disturbances. Real-time object detection and tracking of objects is important for the dynamic planning of grasping trajectories and executing grasping strategies. Improving the shape sensing and proprioception capabilities of our soft manipulator will also make it easier to collect data and train deep learning models.

Methods

In this section, we delve into the details of the method and experiments. Firstly, we provide the method to derive the key parameters in the logarithmic spiral in design (Determining the Optimal Parameters of the Logarithmic Spiral). Next, we introduce the fabrication details of the hybrid system (Hardware Fabrication), followed by a thorough derivation of the forward kinematic model (Kinematic Model). Lastly, we illustrate the procedure for the motion capture experiment (Model Validation via Motion Capture System) and analyze the possible sources of error (Measuring Sources of Error).

Determining the Optimal Parameters of the Logarithmic Spiral

The starting and ending angle of the spiral contours is set as \(\theta \in (\frac{\pi }{2},\frac{7\pi }{2})\), with the discrete angle Δθ = 30∘. The radius of the base section of the trunk manipulator Rsoft = AB shall match the radius of the last link of the rigid robot arm Rrigid as shown in Fig. 6a. From Fig. 6a, it can be derived that:

a Schematic graph of the spiral with optimal parameters. b A two-section arm hangs freely with a incline anlge θ0 under gravity. Notably, only the upper half of the body is shown here and in (c) for simplification. c The generalization of force equilibrium to multiple sections. d Bending deformation. The points A, B, C, D, E, G represent the positions of the holes where the cables run through, while the colored lines represent cables. Axis1 is obtained by transforming the vector EG to pass through point E. When tightening cable ABCD, the section on the right would rotate around Axis1. When a series of sections rotate around their own axis (which is parallel with each other), a bending effect is induced where all the joint rotation angles are in the same plane. e Twisting deformation. On top of the bending effect, if the second cable FG is subsequently tightened, in order to maintain the length of ABCD, the section on the right would rotate along Axis2, which is defined by the vector BE. When a series of sections rotate around their own axis (which is not parallel with each other), a twist is induced where the joint rotation angles would not be in the same plane.

To keep the spiral compact, the outer contour of the trunk body shall fit closely with each successive loop when curled. The most compact shape is achieved when the structure aligns precisely between the inner and outer loops of the original spiral, where AC = CD, as shown in Fig. 6a. According to the geometry, let the y coordinate of PointA be yinside, PointD’s as youtside, while PointC’s as yk, k can be expressed as follows:

The tip gripper is responsible for grasping small objects. To satisfy the requirement in Principle 2, the maximum effective graspable size of the tip gripper shall be larger than the minimum graspable size of the trunk main body, which means their grasping ranges shall overlap. This is determined by the value of parameter b and the finger geometry.

Referring to Fig. 6a, the width of the tip gripper base is GH, which is equal to the diameter of the robotic arm’s end section. The minimum graspable size for the soft arm main body is the distance between the two points in the inner circle HJ. If the maximum effective graspable size of the tip gripper is m times bigger than the gripper base, we establish that:

Analyzing the finger geometry, we empirically determined the m = 1.53. Combining equation (6),(7),(8), we get:

Based on these three principles, the parameters of the logarithmic spiral were uniquely determined to constrain the robot geometry, which supports the subsequent fabrication and modeling process.

Hardware Fabrication

As shown in Figure 1a, the hybrid system consists of a Franka Emika Panda robot arm, a motor housing, a spiral-based soft manipulator, a set of wrinkled silicone shells, and a tip gripper with three fingers.

Based on the spiral parameters determined in subsection Determining the Optimal Parameters of the Logarithmic Spiral, the enclosed quadrilateral area between two contour spirals can be rotated around the central axis to form each section of the soft arm main body.

The prototype is 3D-printed with thermoplastic polyurethane (TPU) 95A with Bambu X1-Carbon Printer. 20% of the periphery is cut off and replaced by a wrinkled silicone shell to increase friction. This is inspired by skin patterns observed in real elephants31. Wrinkles are designed by randomly distributing horizontal cuts on the mold. The shell is then fabricated via molding of Smooth-On Ecoflex™ 00-30 silicone.

The tip gripper is also 3D printed. The three fingers are symmetrically distributed at the end of the robot arm at an interval of 120∘. Compared with the two-finger gripper, a three-finger configuration possesses a more stable grasping ability. A rotating mortise is designed on the base of the gripper to connect with the tip of the robot arm.

Serving as the connection between the rigid and soft components, the motor housing contains the actuation mechanisms, which include three GM6020 motors and a DS-929MG steering gear. These actuators regulate the tension of the ultra-high molecular weight polyethylene cables (UHMWPE) that run through the manipulator. Three GM6020s are distributed symmetrically at intervals of 120∘, controlling three individual cables running through the peripheral of the soft manipulator. Winders are installed in the motor driver, and each cable can be wound around each winder to tighten and relax without idling.

The tip gripper, on the other hand, is actuated by the DS-929MG servo motor, which is connected to two UHMWPE cables that are braided with three strands. The cables run from the central axis of the motor housing through the cavity in the soft arm’s central backbone. When approaching the end-effector, the cables split into three strands, and each group of strands goes through the dorsal and ventral sides of the three fingers, respectively. Referring to figure 1, two groups of cable are respectively tied on both sides of a double-arm-connector that connects to the steering gear. By rotating clockwise and anti-clockwise, one group of cables would be tightened while the other group would be relaxed. With this arrangement, three fingers can be actuated together for opening and closing by two groups of cables.

Kinematic Model

In this section, we establish the forward kinematic model in three steps. Firstly, we analyze the gravitational forces acting on the manipulator when the base section of the soft manipulator is at an oblique angle. Secondly, we actively actuate a single cable to induce a bend. Lastly, based on the single cable actuation model, an additional second cable is tightened by a different length to induce a twist.

Resting Under Gravity

The soft arm is mounted on a 7-DoF rigid robot. As the end-effector pose of the rigid arm changes, it will form an initial inclination angle relative to the original vertical plane. Therefore, the same cable actuation could induce different shape configurations because of gravity. This necessitates analyzing the resting state of the soft arm under the influence of gravity with respect to the initial inclination angle of the base.

We define the initial static state as the set of joint angles in each section when the soft arm passively hangs downward under gravity without any cable actuation. θ0 is defined as the angle between the central axis of the soft arm and the horizontal line shown in Fig. 6b.

According to the equation of elementary beam theory, the relationship between an applied bending moment M, Young’s Modulus E (E = 16.9MPa for our soft manipulator), the second moment of area I, and the resulting curvature κ of the beam can be described as equation (10):

The gravitational force exerted on each joint induces a moment M and a curvature κ. Taking the case of a two-section-arm as an example, as shown in Fig. 6b, given the mass and center of gravity (CG) of the first and second section, the gravitational moment of the second section about joint1 (shown in blue rectangle) can be expressed \({m}_{1}g{a}_{1}{K}_{c}\cos ({\theta }_{0}+{\theta }_{1})\), where Kc is a constant representing the ___location of CG on the trapezoid base. Thus, if a certain tilt angle θ0 is given, θ1 can be calculated by:

When there are N joints in total (Fig. 6c, N = 17 in our case), when considering jointn, we can effectively treat the remaining N − n sections as one entire part, and derive its gravitational moment about jointn. Subtracting and simplifying two adjacent equations as (12), the joint bending angles θ1 ~ θN can be solved.

Each joint has a maximum rotation limit of Δθ = 30∘. If gravity causes the joint to reach this limit under a certain tilt angle (which generally happens in the first joint), these two adjacent sections would be treated as a rigid body. Therefore, the gravity torque equation shall be updated. Taken joint1 as an example, if θ1 = 30∘, the remaining 16 joints θ2 ~ θ17 can be obtained by the remaining 16 equations.

Finally, the joint angle θ1−θ17 can be used to determine the cable length in the resting state, preparing for the subsequent calculation under cable actuation.

Bending

Since each cable runs through the manipulator from the tip to the base, if one cable is shortened by the amount of ΔX, it would affect the cable length in every single section by Δx. Since every section and joint is kp = 0.9196 times the former one, we can derive the relationship of ΔX and Δx. Consequently, the core solution for establishing this single-segment length-based kinematic model is to assign proper cable length to each joint based on the special geometry of the logarithmic spiral when a certain amount of cable actuation is given.

As Fig. 6d shows, when actuated, the cable lengths AB and CD stay constant within the section, while the cable length between BC changes. Thus, the main purpose is to derive how the changing length of a certain cable D1 would affect the cable length xi = BC between each joint.

According to equation (10), if we regard each joint as a small cylinder, when the joint deforms, the backbone of the small cylinder can be approximately regarded as an arc with a constant length L. Thus, the second moment of area of the joint I and the curvature κ can be described as:

According to the logarithmic-spiral proportionality, \({r}_{i}={{k}_{p}r}_{i-1}\), \({L}_{i}={{k}_{p}L}_{i-1}\). We assume the torque relationship between each section empirically as:

Substitute equation (13), (14), (15) into equation (10), the joint rotation described in Δθi can be determined. To establish relations between joint angles θ and cable length X, the cosine theorem can be applied as:

Where Rhole = BE = CE, X = BC. The current joint angle θ is the difference between the initial angle and the rotation angle θ = θinitial − Δθ, while the current cable length X is the difference between initial length and the changing length: X = Xinitial − Δx:

The ratio portioni can be calculated to distribute the input total cable length L and distribute Li to each joint as:

Utilizing the calculated portioni, Algorithm. 1 computes the final joint pose given the desired length change for a particular cable:

Algorithm 1

Calculate length distribution for bending

Input: D = the length change for a cable

Output: length distribution

Definitions:

• n: The total section number of the manipulator.

• \({\bf{limitation}}\,{{\bf{L}}}^{{\prime} }\) : The cable length between each section when the joint is not bending.

1: \(portion(i)=\frac{\Delta {X}_{i}}{\sum \Delta {X}_{i}}\)

2: for i = n: 1 do

3: distributeLength(i) = portion(i)*D

4: if \(distributeLength(i)\le limitation{L}^{{\prime} }(i)\) then

5: \(newLength(i)=limitation{L}^{{\prime} }(i)-distributeLength(i)\)

6: else

7: newLength(i) = 0

8: assign the additional length to the rest of the joints

9: end if

10: end for

11: calculate joint pose via newLength

Since the bending movement would only be performed in planes, the shape of the trunk can be determined by the rotation angles Δθi of the joints via transformation matrix described in equation (18) below, where the x-direction is set along the trunk body:

Twisting

A twist is induced by actively tightening the second cable by a different length on top of the actuation length of the first cable.

When the second cable is actuated, the rotation axis of the affected sections changes. The gradual change in the rotation axis causes the manipulator to rotate progressively out of the initial plane, resulting in a twist effect as shown in Fig. 6e.

We model the influence of the two cables in a sequential manner. Firstly, tightening the first cable by a length D1 induces a bend in a specific plane. At this stage, some distal joints may reach their maximum allowable angles while others remain within their limits. Subsequently, when the second cable is tightened by an additional length D2, joints that have already reached their limits remain unaffected due to the constraint imposed by the first cable. The second actuation thus affects only those joints with remaining rotational capacity. Each section rotates about its specific axis, following the same distribution principle described in Equation (17).

Consequently, we can approximately regard the groups of maximally rotated sections as rigid bodies and calculate the rotation of the rest of the sections. The detailed process is demonstrated in Algorithm 2.

Algorithm 2

Calculate joint pose for twisting

Input: D1 = the length change for tendon1, D2 = the length change for tendon2

Output: Joint pose

Definitions:

• n: The total section number of the manipulator

1: calculate originalL2 after D1 is pulled via Algorithm1

2: find the joint indice m where all joints after reaching maximum bending angles

3: \(portion(i)=\frac{{x}_{i}}{\mathop{\sum }\nolimits_{i = 1}^{n}{x}_{i}}\)

4: for i = n: 1 do

5: if i > m then

6: newL2(i) = originalL2(i)

7: else

8: find the rotation axis for each single joint

9: find the maximum rotation angle \(\theta \max (i)\) when two links collide

10: find the maximum length change \(D2\max (i)\) via \(\theta \max (i)\)

11: distributeL2(i) = portion(i)*D2

12: if \(distributeL2(i)\le D2\max (i)\) then

13: newL2(i) = originalL2(i) − distributeL2(i)

14: else

15: \(newL2(i)=D2\max (i)\)

16: assign the additional length to the rest of the joints

17: end if

18: end if

19: end for

20: calculate new joint pose via newL2(i)

Model Validation via Motion Capture System

Bending

For each trial, one cable running through a vertex of the trunk was incrementally tightened while the other two cables were relaxed. The tightening process was conducted in 26 steps, with each step shortening the length of the active cable by 5mm. The lengths by which the other two cables were relaxed at each step were computed using Algorithm 1, ensuring the manipulator reproduced the target shape as closely as possible.

Resting under gravity

To validate the ability of our soft manipulator to replicate the bending behavior of an elephant trunk at rest under gravity, we measure its deformation at various base angles. The manipulator was securely mounted on an adjustable-angle wedge mounting plate, allowing precise control of the base rotation angle. The plate was configured to tilt the manipulator to angles of 0∘, 45∘, 90∘, and 135∘ relative to the vertical axis. In each configuration, the cables running through the vertices of the manipulator were left relaxed, enabling the manipulator to bend freely under its weight until a static equilibrium shape was reached.

The captured data included the positions of the 15 rigid body frames, allowing precise reconstruction of the manipulator’s backbone shape. All data were saved in CSV format for post-processing and analysis. The recorded bending profiles were then compared to theoretical predictions from the physics model described in Section Kinematic Model.

Measuring Sources of Error

Two main sources of error could affect the accuracy of the data captured using the motion capture system.

Material Elasticity

A systematic source of error in our experiments arose from the elasticity of the material used to 3D-print the soft manipulator, which violated the assumption that each link behaves as a rigid body without deformation. This elasticity introduced residual slack in the cables during actuation. To account for this error, we fully wrapped the manipulator and measured the residual slack in each cable. These measurements were then used to compute compensation factors for the cable lengths, enabling adjustments to the tightening and relaxing steps. By compensating for material deformation, we improved the accuracy of the manipulator’s motion and alignment with the theoretical forward kinematic model.

The total measured slack in the cable (Lslack) was determined by fully wrapping the manipulator and recording the excess cable length required to achieve the desired shape. This slack was then evenly distributed across the total number of tightening steps (Nsteps), resulting in a stepwise compensation factor for each cable:

To ensure progressive correction, we incorporated the compensation factor into each step of cable tightening, such that the adjusted tightening length at step i was computed as

where ΔLi is the theoretical length based on our analytical model. This linear scaling of the compensation factor with the step index ensures that the cumulative slack is systematically offset as the manipulator bends further.

Material Deformation and 3D Printing Quality

The 3D-printed manipulator, fabricated using TPU, exhibited slight asymmetries due to the material’s high liquidity during the printing process. TPU tends to spread before solidifying, and under the influence of gravity, the printed structure may develop minor deformations. These asymmetries caused the manipulator to deflect slightly to one side during actuation. To account for the random error that could be introduced into the results due to this defect, we conducted our bending experiment 2 times and took the average of each rigid body marker position at each step.

Data availability

All supplementary data for this paper is provided in https://doi.org/10.5281/zenodo.15278644.

Code availability

The MATLAB code for the forward kinematic model of our soft manipulator can be found at: https://github.com/ziyao-hhs/Grasping-by-Spiraling.

References

Thomson, J. A. On growth and form (1917).

Gupta, A. et al. The motion path of the digits. J. Hand Surg. 23, 1038–1042 (1998).

Littler, J. W. On the adaptability of man’s hand (with reference to the equiangular curve). Hand 5, 187–191 (1973).

Dagenais, P., Hensman, S., Haechler, V. & Milinkovitch, M. C. Elephants evolved strategies reducing the biomechanical complexity of their trunk. Curr. Biol. 31, 4727–4737 (2021).

Longren, L. L. et al. Dense reconstruction of elephant trunk musculature. Curr. Biol. 33, 4713–4720 (2023).

Kier, W. M. The diversity of hydrostatic skeletons. J. Exp. Biol. 215, 1247–1257 (2012).

Morasso, P. Neural simulation of actions for serpentine robots. Biomimetics 9, 416 (2024).

Morasso, P. A computational model of hybrid trunk-like robots for synergy formation in anticipation of physical interaction. Biomimetics 10, 21 (2025).

Uppalapati, N. K. et al. A berry picking robot with a hybrid soft-rigid arm: Design and task space control. In Robotics: Science and Systems, 95 (2020).

Peng, R., Wang, Y., Lu, M. & Lu, P. A dexterous and compliant aerial continuum manipulator for cluttered and constrained environments. Nat. Commun. 16, 889 (2025).

Koe, K. et al. Learning-based position and orientation control of a hybrid rigid-soft arm manipulator. Journal of Mechanisms and Robotics 1–14 (2025).

Jiang, H. et al. Hierarchical control of soft manipulators towards unstructured interactions. Int. J. Robot. Res. 40, 411–434 (2021).

Ruotolo, W., Brouwer, D. & Cutkosky, M. R. From grasping to manipulation with gecko-inspired adhesives on a multifinger gripper. Sci. Robot. 6, eabi9773 (2021).

Xie, Z. et al. Octopus-inspired sensorized soft arm for environmental interaction. Sci. Robot. 8, eadh7852 (2023).

Wang, Z., Freris, N. M. & Wei, X. Spirobs: Logarithmic spiral-shaped robots for versatile grasping across scales. Device (2024).

McMahan, W. et al. Field trials and testing of the octarm continuum manipulator. In Proceedings 2006 IEEE International Conference on Robotics and Automation, 2006. ICRA 2006., 2336–2341 (IEEE, 2006).

Zhang, J. et al. In situ reconfigurable continuum robot with varying curvature enabled by programmable tensegrity building blocks. Adv. Intell. Syst. 5, 2300048 (2023).

Liu, Y., Ge, Z., Yang, S., Walker, I. D. & Ju, Z. Elephant’s trunk robot: An extremely versatile under-actuated continuum robot driven by a single motor. J. Mechanisms Robot. 11, 051008 (2019).

Katzschmann, R. K., Marchese, A. D. & Rus, D. Autonomous object manipulation using a soft planar grasping manipulator. Soft Robot. 2, 155–164 (2015).

Hannan, M. & Walker, I. The’elephant trunk’manipulator, design and implementation. In 2001 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. Proceedings (Cat. No. 01TH8556), vol. 1, 14–19 (IEEE, 2001).

Zhou, P. et al. Design and kinematic of a dexterous bioinspired elephant trunk robot with variable diameter. Bioinspiration Biomim. 17, 046016 (2022).

Guan, Q., Sun, J., Liu, Y., Wereley, N. M. & Leng, J. Novel bending and helical extensile/contractile pneumatic artificial muscles inspired by elephant trunk. Soft Robot. 7, 597–614 (2020).

Kaczmarski, B. et al. Minimal design of the elephant trunk as an active filament. Phys. Rev. Lett. 132, 248402 (2024).

Wang, Z. & Freris, N. M. Exploiting frictional effects to reproduce octopus-like reaching movements with a cable-driven spiral robot. In 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft), 537–542 (IEEE, 2024).

Webster III, R. J. & Jones, B. A. Design and kinematic modeling of constant curvature continuum robots: A review. Int. J. Robot. Res. 29, 1661–1683 (2010).

Mahl, T., Hildebrandt, A. & Sawodny, O. A variable curvature continuum kinematics for kinematic control of the bionic handling assistant. IEEE Trans. Robot. 30, 935–949 (2014).

Alessi, C. et al. Rod models in continuum and soft robot control: a review. arXiv preprint arXiv:2407.05886 (2024).

Alkayas, A. Y. et al. Soft synergies: Model order reduction of hybrid soft-rigid robots via optimal strain parameterization. IEEE Trans. Robot. 41, 1118–1137 (2024).

Wu, K., Zheng, G. & Zhang, J. Fem-based trajectory tracking control of a soft trunk robot. Robot. Autonomous Syst. 150, 103961 (2022).

Hutchison, A. L. & Hutchison, R. L. Fibonacci, littler, and the hand: a brief review. Hand 5, 364–368 (2010).

Schulz, A. K. et al. Elephants develop wrinkles through both form and function. R. Soc. Open Sci. 11, 240851 (2024).

Acknowledgements

The authors are grateful to Dr. Li Yangfan and Dr. Lu Dingjie for their insightful discussions and helpful suggestions that greatly contributed to the development of this paper. This research is supported by the National Research Foundation (NRF), Prime Minister’s Office, Singapore under its Campus for Research Excellence and Technological Enterprise (CREATE) programme. The Mens, Manus, and Machina (M3S) is an interdisciplinary research group (IRG) of the Singapore MIT Alliance for Research and Technology (SMART) centre. This research is also supported by A*STAR, Singapore, through the Italy-Singapore collaborative project ``DESTRO - Dextrous, strong yet soft robots" (C.L.).

Author information

Authors and Affiliations

Contributions

H.H. and H.W. conceived and designed the study. C.F. investigated the optimal parameters in the logarithmic spiral. H.H. and C.F. established the forward kinematic model and designed the hardware. M.Y. and R.X. developed the embedded control system for the soft manipulator. H.W. integrated the control of the soft and rigid components into one system. H.H., H.W., M.Y., and R.X. completed the motion capture validation experiment. H.H., H.W., C.F., M.Y. reproduced the demonstration of elephant grasping strategies. Y.Z. provided insights on hardware prototyping and gave constructive advice for this work. Z.W. provided design and fabrication advice for the soft manipulator prototype. H.H., W.H., C.F., and F.Y. analyzed the data and drafted the manuscript. J.L., C.L., and M.A. supervised and revised the research. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Huang, H., Wang, H., Fang, C. et al. Grasping by spiraling: reproducing elephant movements with rigid-soft robot synergy. npj Robot 3, 18 (2025). https://doi.org/10.1038/s44182-025-00038-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44182-025-00038-z