Abstract

Dense and crack-free eutectic Al16.2Co30.3Cr9.7Fe10.4Ni30.7W2.2C0.6 multi-principal element alloy (MPEA) was additively manufactured using powder bed fusion-laser beam (PBF-LB). The MPEA powders were produced by gas atomization using an in-house laboratory scale gas atomizer. PBF-LB parameters were optimized by exploring laser powers ranging from 200 to 350 W, and scan speeds varying from 300 to 1800 mm/s. The as-fabricated alloy exhibited a two-phase eutectic microstructure with alternating FCC and BCC phases interspersed by cellular dendrites. This unique nano-scale microstructure exhibited remarkable tensile strength, yield strength, and elongation of ~1.6 GPa, ~1.3 GPa, and ~10%, respectively. These are comparable to those reported for transition metal high entropy and/or multi-principal element alloys fabricated using either PBF-LB or traditional processing methods, underscoring the potential of this novel eutectic MPEA produced by additive manufacturing technology for engineering applications where stainless steels and Ni-base superalloys dominate.

Similar content being viewed by others

Introduction

The laser-material interaction in powder bed fusion-laser based (PBF-LB) enables rapid cooling and steep thermal gradients with micron-scale interaction volumes1. This unique thermo-kinetic environment yields refined grain size decorated with sub-grain dislocation structures2 and solute segregation, which are distinct characteristics of metallic alloys produced by PBF-LB additive manufacturing (AM)3. However, not all alloys developed for traditional manufacturing processes demonstrate good printability, e.g., crack-free structure of high relative density4. Critical engineering components produced by PBF-LB still rely on existing alloys designed and developed for traditional materials processing techniques and thus calls for newly designed alloys specifically tailored for PBF-LB. High entropy or multi-principal element alloys (HEAs or MPEAs) have been widely regarded as promising classes of alloys due to their high temperature stability with entropic contribution (-TS) to lower the free energy, sluggish diffusion kinetics5, and softening resistance at high temperatures6. All of these are desirable characteristics for engineering components additively manufactured for service in high temperature applications.

Cast single phase BCC-type MPEAs have high strength but low plasticity/ductility, while FCC-type MPEAs lacks strength but exhibit a great deal of plasticity7,8. The balance of strength and ductility can be expected in alloys containing both phases. Eutectic variants designated as eutectic multi-principal elelement alloys (EMPEAs) belonging to the MPEA family overcome the strength-ductility limit by combining both phases into an eutectic microstructure of alternating FCC and BCC9,10. Literature concerning castability and microstructure of eutectic HEAs via traditional processes have highlighted their promising mechanical properties owing to the pseudo-eutectic lamellar microstructures8,11. The microstructures observed in EMPEAs combine the strong solid solution properties of the BCC phase for high strength with the FCC phase for improved ductility. While the micro-scale alternating lamellae of cast EMPEAs exhibit good mechanical properties9, nano-scale lamellae of near-equiatomic AlCoCrFeNi2.1 produced by PBF-LB have been reported to exhibit excellent tensile properties12. To date, only a few EMPEAs have been reported to possess promising tensile behavior when produced by PBF-LB13,14,15,16.

Alloy compositions near the eutectic reaction have demonstrated good printability with low susceptibility to cracking during rapid solidification17,18,19; therefore, a modified version of Al18Co30Cr10Fe10Ni30W2 EMPEA11 was chosen so that a pseudo-eutectic reaction consisting of FCC and BCC phases would occur upon solidification during PBF-LB. Al18Co30Cr10Fe10Ni30W2 have demonstrated good castability and possess good tensile strength as high as 1266.5 MPa and elongation as much as 20.3%20. However, the rapid solidification environment in PBF-LB could promote solidification cracks notably observed in some traditional alloys that are considered weldable4,21. Therefore, the modified alloy should have a narrow equilibrium solidification range, i.e., freezing range for reduced cracking susceptibility and a stable two-phase microstructure ranging from the intermediate temperatures to the eutectic temperature.

ThermoCalc version 2024b with the TCNI12 database was used to explore the pseudo-binary phase diagram of Alx(Co30Cr10Fe10W2Ni48-x) as presented in Fig. 1. The modified version of Al18Co30Cr10Fe10Ni30W2 was investigated to evaluate the effectiveness of PBF-LB processing on microstructure and mechanical properties. Figure 1 shows that two phases consisting of FCC and B2 should exist just below the eutectic reaction at ~16.5 at% Al for Al16.5Co30Cr10Fe10Ni31.5W2. This alloy should demonstrate good printability imparted by the low freezing range associated with the pseudo-eutectic reaction. Excellent mechanical properties should be provided by the hard BCC phase without significant reductions in ductility provided by ductile FCC phase. Moreover, the alternating FCC and B2 phases achieved by the predicted eutectic reaction potentially maximizes the number of phase boundaries enabled by the microstructural refinement available from PBF-LB. Therefore, the results reported here focus on exploring the printability of pseudo-eutectic Al16.5Co30Cr10Fe10Ni31.5W2 to extend the list of alloys suitable for PBF-LB with excellent printability and mechanical properties in the as-built condition.

Results

Gas atomized powders

The particle size distribution of the gas-atomized powders is presented in Fig. 2a and its composition is reported in Table 1. Use of the graphite hold crucible introduced minor amounts of C into the alloy powders produced, and therefore, the present alloy will be referred to as Al16.2Co30.3Cr9.7Fe10.4Ni30.7W2.2C0.6. Corresponding D10, D50, and D90 were 24.85 μm, 59.79 μm, and 100.5 μm, respectively. The inset in Fig. 2a shows the low magnification backscatter electron (BSE) micrograph of the as-atomized powders. A mix of spherical and irregularly shaped particles was observed, without any significant satellites on the surface. Despite the presence of some irregularly shaped particles, the powders exhibit excellent flowability and spreadability during PBF-LB, likely attributed to their high density and minimal satellites. The BSE micrograph shown in Fig. 2b reveals the two-phase microstructure characterized by distinct light and dark regions corresponding to FCC and BCC, respectively, which agrees with that reported in the literature11. The well-defined microstructure observed on the surface of the powders suggests negligible oxidation occurred during gas-atomization. Cross sectional micrograph shown in Fig. 2c further highlights the microstructure, displaying dark regions of coarse dendrites interspersed with fine lamellar eutectic structures.

Microstructure and phase constituents of PBF-LB specimens

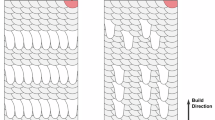

Figure 3 showcases representative optical micrographs of the as-built PBF-LB specimens. Low scan speeds (e.g., high energy input) yielded characteristic spherical, keyhole (KH) pores while higher scan speeds (e.g., low energy input) yielded non-spherical, lack-of-fusion flaws. Cracking of any size-scale was not observed in any of the samples. By utilizing a laser power of 200 W, a well-defined processing window at scan speeds ranging from 500 to 700 mm/s produced near full-density specimens. At 350 W power, a notably larger processing window that yielded near full density specimens was observed for scan speeds ranging from 800 to 1400 mm/s. The density of each sample is tabulated in Table 2. The specimen produced using a laser power of 350 W and a scan speed of 1000 mm/s yielded the highest relative density of 99.98%. Due to its exceptional density, this combination of PBF-LB parameters was chosen for further microstructural analysis and mechanical properties evaluations in this study.

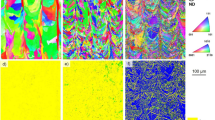

X-ray diffraction (XRD) patterns in Fig. 4 show that two phases exist in the powders and as-built alloy. No preferred orientation along the [001] direction was observed even though the [001] direction have been frequently reported as the preferred growth direction for cubic crystals produced by PBF-LB. Instead, the FCC (111) diffraction peak measured at 43.5° was the most prominent, followed by the less pronounced BCC (110) peak observed at 44.6°. As such, the orientation relationship between the FCC and BCC phases maintains a Kurdjumov-Sachs type orientation i.e., <111>FCC//<110>BCC to minimize the interfacial energy.

As shown in Fig. 5a and Fig. 5b, the as-built microstructure consisted of fine cellular dendrites and lamellar eutectics. The BSE micrograph presented in Fig. 5a features a melt pool boundary decorated by relatively coarse BCC phase. In other regions, numerous cellular dendrites intermixed with off-eutectic lamellae of alternating FCC and BCC were observed as presented in Fig. 5b. The alternating FCC and BCC phases had respective thicknesses (λ) of approximately λFCC ≈ 250 nm and λBCC ≈ 100 nm; much finer lamellar thicknesses as compared to ~1 μm lamellae observed for the cast EMPEAs8,11. The high solidification rate inherent to the PBF-LB process have effectively refined the lamellar thicknesses. Figure 5c provides a high-angle annular dark field (HAADF) transmission electron microscope (TEM) micrograph of the alternating FCC and BCC phases obtained from the off-eutectic region. Since the backscatter electron micrographs provide sufficient contrast between the FCC and BCC phases, image analysis has been carried out to quantify the area fraction of each phase to corroborate to the phase quantification obtained by XRD. Quantitative XRD analysis indicates that the as-built samples consist of ~24 vol% BCC which is similar to the 25.7 ± 2.5% BCC obtained by image analysis. These are lower than the 47.5 vol% BCC determined for the powders presumably due to the difference in cooling rate and supersaturation in primary FCC phase.

Compositions of FCC and BCC phases determined by X-ray energy dispersive spectroscopy (XEDS) on TEM are reported in Table 3, and they indicated that the concentration of Al in the FCC is ~11.29 ± 0.57 at%, while that in BCC is ~20.46 ± 1.46 at%. As presented in Fig. 6, the dark BCC phase is decorated with numerous nano-scale precipitates ~10 nm in diameter. The XEDS elemental distribution maps from the area outlined by the yellow square show that these precipitates are enriched with Cr and W. These precipitates could correspond to two possible types of secondary phases with the first being (Cr,W)-rich μ phase, observed in refractory containing MPEAs22,23 and Ni- and/or Co-based superalloys24, and the second being carbides. The introduction of carbon reported in Table 1 may favor the formation Cr,W-rich carbides in the form of M6C25 or M7C326 at intermediate temperatures. These carbides may be precipitated during successive reheating of the non-equilibrium microstructure. Bright W-rich precipitates were also reported by Ren et al.27 for as-built Al18Co20Cr10Fe10Ni40W2 but they were not identified in this study. However, the overall ductility of the alloy did not decrease27,28 even though the W-rich precipitates coarsened at high temperatures; therefore, phase identification in post annealed microstructures will be examined in a future investigation.

Mechanical behavior

Room temperature tensile tests were conducted on three specimens additively manufactured using a laser power of 350 W and a scan speed of 1000 mm/s. The engineering stress-strain plots of three different tensile specimens presented in Fig. 7 indicate that all tensile specimens exhibited remarkably consistent behavior under uniaxial tension. The Young’s modulus, yield strength, tensile strength, and elongation at fracture were determined to be 202.7 ± 0.9 GPa, 1265 ± 9.53 MPa, 1563 ± 13.12 MPa, and 9.77 ± 0.44%, respectively. Interestingly, post uniform elongation is absent. This alloy demonstrated exceptional tensile strength, surpassing that of additively manufactured Al18Co30Cr10Fe10Ni32 with yield and tensile strengths of 1064.3 MPa and 1368.6 MPa, respectively15, which already outperformed CoCrFeNi29, CoCrFeNiMn30, and Al0.3CoCrFeNi31 alloys with yield strengths below 1 GPa. Compared to other EMPEAs characterized with more defined lamellar microstructures, the yield strength is similar to that reported by Guo et al.13 for AlCoCrFeNi2.1 (1210 ± 23 MPa) but slightly lower than 1333 ± 38 MPa reported by Ren et al.12 for nano-lamellar AlCoCrFeNi2.1. Yu et al.28 reported lower yield strength but more comparable tensile strengths for the as-built Al18Co10Cr10Fe10Ni30W2; however, the present alloy offers ~50% greater ductility. Furthermore, its performance rivals that of precipitation-strengthened IN718 produced via PBF-LB, which achieves yield and tensile strengths of up to 1245 MPa and 1640 MPa, respectively2.

Discussion

This investigation purely focuses on the most basic processing strategies such as power and speed at constant hatch spacing and slice thickness to provide the most fundamental documentation of the laser-material interaction. Without relying on other processing strategies such as border, contour, and remelting, the printability of an alloy can only be influenced by the most basic processing parameters, and is therefore acceptable to consider the excellent printability of the present alloy. Large tensile specimens 84 mm (see Fig. 10 in “Method”) in length was printed without any printability concerns such as cracking or delamination. Rather than machining tensile bars to shape from a printed block, the tensile specimens in this investigation were printed to near net shape and lightly ground to remove geometrical inconsistencies on the surface prior to tensile testing. The excellent printability is further supported by the engineering stress-strain curve provided in Fig. 6 which highlights the extremely consistent tensile behavior across multiple tensile samples.

The EMPEA examined in this study exhibited excellent printability with a wide PBF-LB processing window i.e., wide range of power and scan speed combination. This can be attributed to the low freezing range associated with the eutectic reaction predicted by the pseudo-binary phase diagram shown in Fig. 1. XRD phase quantification revealed that the respective volume percent of FCC and BCC in the as-built specimen was ~0.76 and 0.24. The large volume fraction of FCC would be favorable to plasticity and ultimately contribute to the global ductility. Furthermore, the measured phase fractions agree with calculated phase fractions of 0.74 for FCC and 0.26 for BCC at ~1327 °C obtained via TCNI12 database in Thermocalc™ version 2024b. This highlights the far from equilibrium phenomena during PBF-LB, in which the nucleation and growth of the BCC phase during cooling was largely suppressed by rapid solidification. In other words, the fraction of FCC and BCC in the as-built condition mimics the respective fractions obtainable at high temperatures just below the eutectic equilibrium rather than that obtained for a matrix containing a higher fraction of BCC obtained by slower cooling to room temperature as shown by the powder diffraction in Fig. 4.

Parts produced by PBF-LB are primarily characterized by a dominant cellular dendritic microstructure1,3,15. The microstructure in the present alloy consists of cellular dendrites and off-eutectic lamellae. Under rapid solidification conditions, solidification morphologies may not reflect the typical lamellar characteristics of a eutectic alloy. Instead, the cellular dendritic and off-eutectic microstructure is directly related to the temperature gradient (\(G\)) and the solidification velocity (\(V\)) of the solid-liquid interface. The planar growth of the solidifying interface would become unstable, and the cellular morphology would develop when the ratio of the eutectic freezing range (\(\varDelta {T}_{e}\)) and the diffusion coefficient of the solute in liquid (\({D}_{L}\)) is greater than or equal to the ratio of \(G\) and \(V\). The criterion for planar growth instability is expressed by32:

In Al containing HEAs, the fraction of BCC is sensitively influenced by the concentration of Al in the alloy33. Table 3 reports that the BCC phase is enriched in Al, while depleted in FCC. Therefore, it is reasonable to consider that the diffusion or distribution of Al in the liquid during solidification influences the fraction of BCC, which would influence the as-built microstructure. Phase constituents of the solidified microstructure can then be explored through the pseudo-ternary Ni-Al-(Co, Cr, Fe, W) behavior inferred from the pseudo-binary phase diagram presented in Fig. 1. Unlike conventional simple binary eutectic alloys with a two-phase equilibrium just below the near zero eutectic freezing range (\(\varDelta {T}_{e}=\) 0 K), the alloy examined in this study must solidify through a eutectic freezing range of approximately \(\varDelta {T}_{e}=\) 5 K where the three-phase equilibrium (L + FCC + BCC) exist. During PBF-LB, \(G\) is typically in the order of 105–107 K/m, and \(V\) in the range of 0.1–2 m/s34,35. Assuming \({D}_{L}\) in the range of 10−8–10−9 m2/s 36,37,38, and \(\varDelta {T}_{e}\,=\,\,\) 5 K, the ratio \(\varDelta {T}_{e}/{D}_{L}\) can range from 5 \(\times \,\)108 Ks/m2 to 5 \(\times\) 109 Ks/m2. The ratio \(G/V\) can range from 5 \(\times \,\)105 Ks/m2 to 1 \(\times \,\)107 Ks/m2, both of which are lower than \(\varDelta {T}_{e}/{D}_{L}\) and thus, based on Eq. (1), the criteria for stable, non-planar, cellular dendritic formation is satisfied, as highlighted in Fig. 5. These estimations only give a simple explanation of the solidification conditions, since repeated re-melting could drastically change the local temperature gradient, and therefore, the local solidification conditions.

Interstitial carbon in MPEAs have been reported to provide FCC stabilization at sufficiently high levels, therefore, the C introduced during gas atomization for the present alloy may affect the eutectic phase distribution of the as-built specimen. For equiatomic BCC AlCoFeNi, the addition of 0.5 at% C demonstrated some FCC stabilization39, and for AlCoCrFeNi with at least 2 at% C40. A carbon concentration of 0.64 at% reported in Table 1 for the alloy investigated is just above the 0.5 at% for observed stabilization of FCC in AlCoFeNi, but insufficient for AlCoCrFeNi. To examine the effects of C on FCC phase stabilization, the calculated phase fractions presented in Fig. 8 compares the fraction of FCC with and without 0.64 at% C. The calculated FCC phase fraction with and without added C is 0.749 and 0.743, respectively, upon eutectic solidification, therefore, the measured C concentration has negligible effects on the eutectic phase distribution of the as-built EMPEA.

As shown in Fig. 5c and Fig. 6, the absence of secondary phases in FCC suggests that there is a higher solubility for C in the FCC phase, compared to the BCC phase. Complete solubility of up to 1.21 at% C in FCC CoCrFeNi has been reported41. This level of carbon incorporation can enhance strength through interstitial hardening of the FCC matrix. For instance, Lin et al.42 reported yield and tensile strengths of 552 and 706 MPa, respectively, for CoCrFeNi alloy (0.06 at% C reported). Zhou et al.41 reported yield and tensile strengths of 630 and 776 MPa, respectively, for an CoCrFeNi with 1.21 at% C. Both studies reported similar grain sizes, and under the assumption of comparable dislocation densities, comparison suggests that interstitial hardening from 1.21 at% C leads to ~14% and 10% increases in yield and tensile strength, respectively. The current study reports a carbon content of 0.64 at%, which is expected to make a smaller contribution to strengthening. The tensile properties obtained for Al16.2Co30.3Cr9.7Fe10.4Ni30.7W2.2C0.6, therefore, should be comparable to Al16.5Co30Cr10Fe10Ni31.5W2.

The ultra-high tensile strength of PBF-LB EMPEA can be understood based on microstructure observed in this study along with those reported in the literature. For cast alloys, it has been demonstrated that BCC type HEAs are much stronger than FCC type HEAs7. The strength of as-built FCC and BCC phases should also follow. Therefore, the strain partitioning between FCC and BCC during deformation must be different. During initial stages of tensile deformation, both phases will co-deform elastically until the onset of plasticity for the softer FCC phase. As the FCC phase plastically deforms, the phase boundary constraints imposed by neighboring BCC phases prevent it from deforming freely. Here, strain continuity must occur, and it must occur under said boundary constraints. As dislocations are generated during deformation, strain gradients accommodated by geometrically necessary dislocations have been observed in the FCC phase along the phase boundaries43. Plastic strain would continue to build in the FCC phase as deformation progresses until the neighboring BCC phase begins to plastically deform27. The continued deformation generates high dislocation pile-ups27 until dislocation slip transfer occurs across the phase boundary into the BCC lamellae44. Combined with phase boundary constraints, reduced dislocation movement leads to increased strengthening of the softer FCC in the eutectic microstructure, which is now stronger than the stand-alone FCC only matrix. Concurrently, dislocation entanglement produced by residual stresses in PBF-LB may also add to the strength of the alloy. Strain gradients may also exist along intergranular BCC boundaries that could ultimately contribute to the global yield strength. Compared to traditional cast EHEA20, the nanoscale microstructure and refined grain size obtained via PBF-LB maximizes the number of phase boundaries available in the overall matrix, and thereby contribute to the ultra-high tensile strength of this alloy.

While the present alloy contains 76.3% FCC, the measured tensile ductility is only ~10%. Large fractions of ductile FCC can act as dislocation storage for increased ductility by allowing dislocations to glide across the FCC matrix. For the BCC matrix, slip does not occur as easily. As dislocations glide across the BCC lamellae, nano-scale precipitates shown in Fig. 6 would further impede dislocation movement. The dislocation pinning provided by nano-scale precipitates would contribute to the increase of global strength, but at the cost of dislocation movement in the already brittle BCC matrix.

A non-equiatomic eutectic multi-principal element alloy with a nominal composition, Al16.2Co30.3Cr9.7Fe10.4Ni30.7W2.2C0.6, consisting of FCC and BCC phases was successfully gas-atomized to produce alloy powders with exceptional printability for powder bed fusion-laser beam. Al16.2Co30.3Cr9.7Fe10.4Ni30.7W2.2C0.6 offered a broad PBF-LB processing window for achieving high relative densities. Densities exceeding 99.9% were achieved using a laser power of 350 W and laser scan speeds as low as 800 mm/s to as high as 1200 mm/s. Rapid solidification through PBF-LB produced nano-scale microstructure characterized by a mix of fine cellular dendrites and off-eutectic fine lamellae. Based on phase diagram calculations and experimental results, alloy design strategy with minimum freezing range have resulted in crack-free samples produced by PBF-LB. The presence of 0.64 at% C in the gas-atomized powders had negligible effects on the eutectic phase distribution, i.e., FCC and BCC, in the PBF-LB Al16.2Co30.3Cr9.7Fe10.4Ni30.7W2.2C0.6 alloy. The non-equiatomic MPEA with a two-phase microstructure produced by PBF-LB exhibited exceptional yield and tensile strength as high as 1265 ± 9.53 MPa and 1563 ± 13.12 MPa, respectively.

Methods

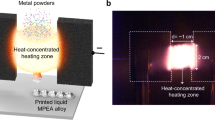

Gas atomization

Pre-alloyed cast-and-homogenized rods were used as charge materials for gas atomization using an in-house, double-induction gas atomizer. Alloy charges were melted under ultra-high purity Argon (99.99%) shrouding in an alumina crucible heated by an induction furnace. For accurate temperature measurements, melt temperature was monitored by using an OptrisTM PI 1 M infrared camera system. The alloy charge was superheated to ~1800 °C and subsequently poured into a graphite hold crucible pre-heated to ~1100 °C. An alumina atomization nozzle with orifice diameter of 4.5 mm was attached to the bottom of the graphite crucible. The molten liquid was allowed to flow through the atomization nozzle via gravity and atomized using ultra-high purity Argon flow pressure pre-set to 3 MPa. Gas atomized powders were mechanically sieved using industry standard No. 200 (75 μm) sieve compatible with a Ro-TapTM mechanical shaker to obtain a particle size distribution suitable for PBF-LB. The particle size distribution of the sieved powders was examined using a laser diffraction particle size analyzer (Beckman Coulter LSTM 13320).

Phase identification and quantification

Phase identification of gas atomized powders and PBF-LB samples was carried out using a PANalytical EmpyreanTM X-ray diffractometer (XRD) equipped with a Cu Kα radiation source operating at 45 kV and 40 mA. XRD patterns were acquired with a step size of 0.03° and a dwell time of 120 s. All XRD patterns were analyzed using the PANalytical Highscore Plus software including phase quantification by Rietveld refinement45. XRD patterns were refined using \({Fm}\bar{3}m\) and \({Im}\bar{3}m\) space groups. The fitting method employed the pseudo-Voigt function by first changing the global parameters such as background, scale factors, zero-shift, and sample offset. Then, structural parameters such as atomic coordinates, site occupancies, lattice parameters, and extinction were appropriately refined. Asymmetry, preferred orientation, isothermal parameters, and profile shape were also finetuned for good refinement. Fitting quality was evaluated by computing the goodness of fit (\({GOF}\)), a ratio of the weighted profile R-factor (\({R}_{{wp}}\)) and the expected R-factor (\({R}_{\exp }\)), expressed as \({GOF}={R}_{{wp}}^{2}/{R}_{\exp }^{2}\). The GOF value approaches 1, indicating a perfect fit46. In this study, fitting sequences yielding a GOF less than 4 were considered acceptable, consistent with practice reported in the open literature for most metallic alloys. Additionally, each fitted profile was visually inspected to ensure the quality and reliability of the results.

For cross-sectional examination, powders were cold mounted in epoxy resin and metallographically polished to 1 µm diamond. Both surface and cross-sectional microstructure were examined using a ZeissTM Ultra 55 field emission scanning electron microscope (FESEM) equipped with an X-ray energy dispersive spectroscopy (XEDS) detector. Detailed chemical composition analysis of the powders was performed by using inductively coupled plasma optical emission spectroscopy (ICP-OES) and combustion following ASTM E1479 and ASTM E1019, respectively.

Powder bed fusion-laser beam

Sieved powders were employed for PBF-LB using a SLM 125HL system equipped with a single continuous wave IPG Yb fiber laser capable of producing a laser spot size of ~70 μm at 400 W power. Initially, cubic specimens with dimensions of 8 × 8 × 8 mm3 were fabricated on a stainless steel 316 L substrate pre-heated to 100 °C. The build chamber was purged with ultra-high purity Argon until the oxygen concentration was less than 0.05%. All cubic specimens were fabricated on 3 mm tall, 200 μm thin wall support structures with 0.8 mm spacing between each wall. Supports were printed using laser power, scan speed, and slice thickness of 200 W, 700 mm/s, and 60 μm, respectively. Based on previous PBF-LB processing optimization studies1,3, laser powers of 350 W and 200 W were established as sufficient starting-point for high and low laser powers to document the processing-microstructure relationship in PBF-LB. In this study, hatch spacing and slice thickness were held constant at 120 μm and 30 μm, respectively, while scan speeds were systematically varied to document the formation of keyhole pores and lack-of-fusion flaws.

Microstructural characterization and quantification

All as-built specimens were cross-sectioned using a slow speed diamond saw according to the representative schematic shown in Fig. 9a and Fig. 9b for microstructural analysis and quantification of relative density by image analysis. The cross-sectioned surfaces were cold mounted in epoxy resin prior to metallographic preparation. Specimens were then ground using SiC paper and polished using a polishing pad covered with 1 μm diamond paste. A final polishing step was performed using 0.05 μm colloidal silica suspension. Optical micrographs of polished specimens were obtained using a Nikon Metaphot optical microscope at a 50× magnification.

To determine the relative density with statistical confidence, a total of 5 optical micrographs were acquired per specimen according to the schematic shown in Fig. 9c. Since relative density determined by image analysis corroborate well to that measured by Archimedes principle in our previous investigations1,3,4, relative densities in this investigation were quantified only by image analysis via ImageJ (National Institutes of Health). In addition to FESEM and XEDS, detailed microstructural examination was carried out by a FEITM Tecnai F30 TEM, operating at 300 kV. The system is equipped with an XEDS detector and a FischioneTM HAADF detector. TEM samples were prepared using a FEITM TEM 200 focused ion beam system using in-situ lift-out method.

Mechanical testing

Based on relative density determined by image analysis, an optimal processing parameter set consisting of 350 W and a scan speed of 1000 mm/s was used to build tensile bars with dimensions pursuant of ASTM E8/E8M as presented in Fig. 10. Tensile bars were printed onto the build substrate without supports and removed using wire electric discharge machining without stress relieving. Tensile testing was carried out for three specimens to determine the average and standard deviation. All surfaces were ground to 1200 grit finish prior to tensile testing in their as-built condition. Room temperature tensile tests were conducted using a MTSTM Landmark 370 machine under a strain rate of 1 × 10−3 s−1. An MTSTM extensometer was used to measure the axial elongation. The quasi-static tensile tests were conducted perpendicular to the build direction.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Hyer, H. et al. Understanding the laser powder bed fusion of AlSi10Mg alloy. Metallogr. Microstruct. Anal. 9, 484–502 (2020).

Gallmeyer, T. G. et al. Knowledge of process-structure-property relationships to engineer better heat treatments for laser powder bed fusion additive manufactured Inconel 718. Addit. Manuf. 31, 100977 (2020).

Huynh, T. et al. Microstructural development in Inconel 718 nickel-based superalloy additively manufactured by laser powder bed fusion. Metallogr. Microstruct. Anal. 11, 88–107 (2022).

Mehta, A. et al. Additive manufacturing and mechanical properties of the dense and crack free Zr-modified aluminum alloy 6061 fabricated by the laser-powder bed fusion. Addit. Manuf. 41, 101966 (2021).

Tsai, K.-Y., Tsai, M.-H. & Yeh, J.-W. Sluggish diffusion in co–cr–fe–mn–ni high-entropy alloys. Acta Mater. 61, 4887–4897 (2013).

Hsu, C.-Y. et al. On the superior hot hardness and softening resistance of AlCoCrxFeMo0. 5Ni high-entropy alloys. Mater. Sci. Eng.: A 528, 3581–3588 (2011).

Joseph, J., Stanford, N., Hodgson, P. & Fabijanic, D. M. Understanding the mechanical behaviour and the large strength/ductility differences between FCC and BCC AlxCoCrFeNi high entropy alloys. J. Alloy. Compd. 726, 885–895 (2017).

Yang, Z. et al. Enhancing the mechanical properties of casting eutectic high entropy alloys with Mo addition. Appl. Phys. A 125, 1–6 (2019).

Lu, Y. et al. A promising new class of high-temperature alloys: eutectic high-entropy alloys. Sci. Rep. 4, 6200 (2014).

Huo, W. et al. Microstructure and properties of novel CoCrFeNiTax eutectic high-entropy alloys. J. Alloy. Compd. 735, 897–904 (2018).

Wu, Q. et al. A casting eutectic high entropy alloy with superior strength-ductility combination. Mater. Lett. 253, 268–271 (2019).

Ren, J. et al. Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing. Nature 608, 62–68 (2022).

Guo, Y. et al. New insight into tailorable eutectic high entropy alloys with remarkable strength–ductility synergy and ample shaping freedom fabricated using laser powder bed fusion. Addit. Manuf. 60, 103257 (2022).

Luo, S., Wang, Z., Nagaumi, H. & Wu, Z. Tailoring the microstructure and mechanical property of additively manufactured AlCrCuFeNi3. 0 high-entropy alloy through heat treatment. Mater. Sci. Eng. A 844, 143192 (2022).

Mehta, A. et al. Additive manufacturing of Al18Co30Cr10Fe10Ni32 high entropy alloy by gas atomization and laser powder bed fusion. Mater. Lett. 350, 134942 (2023).

Yang, F. et al. Ultra strong and ductile eutectic high entropy alloy fabricated by selective laser melting. J. Mater. Sci. Technol. 106, 128–132 (2022).

DebRoy, T. et al. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 92, 112–224 (2018).

Hyer, H. et al. Composition-dependent solidification cracking of aluminum-silicon alloys during laser powder bed fusion. Acta Mater. 208, 116698 (2021).

Zhou, L. et al. Laser powder bed fusion of Al–10 wt% Ce alloys: microstructure and tensile property. J. Mater. Sci. 55, 14611–14625 (2020).

Wu, Q. et al. Uncovering the eutectics design by machine learning in the Al–Co–Cr–Fe–Ni high entropy system. Acta Mater. 182, 278–286 (2020).

Zhou, L. et al. Microstructure and mechanical properties of Zr-modified aluminum alloy 5083 manufactured by laser powder bed fusion. Addit. Manuf. 28, 485–496 (2019).

Fan, A.-C., Li, J.-H. & Tsai, M.-H. On the phase constituents of three CoCrFeNiX (X= Cr, Mo, W) high-entropy alloys after prolonged annealing. Mater. Chem. Phys. 276, 125431 (2022).

Niu, Z. et al. Microstructure, mechanical properties and corrosion resistance of CoCrFeNiWx (x= 0, 0.2, 0.5) high entropy alloys. Intermetallics 112, 106550 (2019).

William, C. H., Chester, T. & Norman, S. S. Superalloys 2: High-Temperature Materials for Aerospace and Industrial Power (John Wiley & Sons, 1987).

Zhang, L. et al. Designing eutectic high-entropy alloys containing nonmetallic elements. Adv. Eng. Mater. 24, 2200486 (2022).

Shun, T.-T. & Du, Y.-C. Age hardening of the Al0. 3CoCrFeNiC0. 1 high entropy alloy. J. Alloy. Compd. 478, 269–272 (2009).

Ren, J. et al. Deformation mechanisms in an additively manufactured dual-phase eutectic high-entropy alloy. Acta Mater. 257, 119179 (2023).

Yu, Y. et al. Tuning of the mechanical properties of a laser powder bed fused eutectic high entropy alloy Ni30Co30Cr10Fe10Al18W2 through heat treatment. Mater. Sci. Eng.: A 918, 147469 (2024).

Chen, Y., Li, B., Chen, B. & Xuan, F. High-cycle fatigue induced twinning in CoCrFeNi high-entropy alloy processed by laser powder bed fusion additive manufacturing. Addit. Manuf. 61, 103319 (2023).

Zhu, Z. et al. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scr. Mater. 154, 20–24 (2018).

Peng, H. et al. Additive manufacturing of Al0. 3CoCrFeNi high-entropy alloy by powder feeding laser melting deposition. J. Alloy. Compd. 862, 158286 (2021).

Kurz, W. & Fisher, D. Dendrite growth in eutectic alloys: the coupled zone. Int. Met. Rev. 24, 177–204 (1979).

Wang, W.-R. et al. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26, 44–51 (2012).

Hooper, P. A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 22, 548–559 (2018).

Chouhan, A., Mädler, L. & Ellendt, N. Modeling of rapid solidification in Laser Powder Bed Fusion processes. Comput. Mater. Sci. 238, 112918 (2024).

Ahmed, T. et al. Interdiffusion and thermotransport in Ni–Al liquid alloys. Philos. Mag. 98, 2221–2246 (2018).

Horbach, J. et al. Self-diffusion and interdiffusion in Al 80 Ni 20 melts: simulation and experiment. Phys. Rev. B 75, 174304 (2007).

Gäumann, M., Bezençon, C., Canalis, P. & Kurz, W. Single-crystal laser deposition of superalloys: processing–microstructure maps. Acta Mater. 49, 1051–1062 (2001).

Fan, J. et al. Improved the microstructure and mechanical properties of AlFeCoNi high-entropy alloy by carbon addition. Mater. Sci. Eng. A 728, 30–39 (2018).

Qin, G. et al. Grain refinement and FCC phase formation in AlCoCrFeNi high entropy alloys by the addition of carbon. Materialia 6, 100259 (2019).

Zhou, R. et al. Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting. Intermetallics 94, 165–171 (2018).

Lin, D. et al. A strong, ductile, high-entropy FeCoCrNi alloy with fine grains fabricated via additive manufacturing and a single cold deformation and annealing cycle. Addit. Manuf. 36, 101591 (2020).

Wu, X. & Zhu, Y. Heterogeneous materials: a new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 5, 527–532 (2017).

Zhu, Y. et al. Enabling stronger eutectic high-entropy alloys with larger ductility by 3D printed directional lamellae. Addit. Manuf. 39, 101901 (2021).

Young, R. A. The Rietveld Method Vol. 5 (International Union of Crystallography, 1993).

McCusker, L., Von Dreele, R., Cox, D., Louër, D. & Scardi, P. Rietveld refinement guidelines. Appl. Crystallogr. 32, 36–50 (1999).

Acknowledgements

This research article was sponsored by the Office of Naval Research Grant (N00014-21-1-2660). The views, opinions, and conclusions made in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Office of Naval Research or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein.

Author information

Authors and Affiliations

Contributions

T.H.: Methodology, Investigation, Validation, Formal analysis, Visualization, Writing—Original Draft. K.G.: Investigation, Methodology, Validation. T.O.: Validation, Review. A.H.: Funding, Validation, Conceptualization, Supervision. M.K.: Investigation, Validation. Y.S.: Investigation, Visualization, Supervision, Funding acquisition, Conceptualization, Writing—Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Huynh, T., Graydon, K., Olson, T. et al. High strength eutectic multi-principal element alloy additively manufactured by powder bed fusion-laser beam. npj Adv. Manuf. 2, 23 (2025). https://doi.org/10.1038/s44334-025-00035-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44334-025-00035-y