Abstract

The study pertains to preparing value added frozen yoghurt through use of orange peel powder (OPP). The quality aspects of medium-fat (6.0% fat) frozen yoghurt prepared using OPP at three levels (1.5, 2.5, 3.5% as T1, T2 and T3 respectively) was studied. Frozen yoghurt was prepared by freezing blend of fermented yoghurt base with ice cream mix (25:75 w/w); other ingredients were sugar, stabilizer-emulsifier and orange crush. Inclusion of OPP in frozen yoghurt impacted the orange flavour favorably and enriched product with β-carotene and dietary fiber. The control product (TC) was prepared in similar manner, avoiding OPP. As the level of OPP was raised in formulation, there was a marked increase in the protein, carbohydrate, ash and total solids when compared with TC. Presence of OPP markedly affected the acidity, viscosity, overrun and melting resistance of the product; maximum overrun was associated with TC. Product T3 had the maximum acidity and viscosity; T2 had maximum total sensory score. It is recommended to prepare medium-fat frozen yoghurt utilizing 2.5% OPP along with orange crush as flavouring. Such inclusion of peel solids enriched the product with β-carotene and dietary fiber, contributed to stabilization of product and enhanced the products sensory acceptance.

Similar content being viewed by others

Introduction

Citrus is a major fruit crop that is largely grown and consumed all over the world. Citrus fruits are in demand for their excellent flavour, taste, aroma, and they confer health benefits1. According to the world crop production statistics of the FAO STAT-2022, 157.3 million tons (MT) of citrus fruit were produced in 2020. India stands in the top five citrus-producing countries; Brazil, China, United States and Mexico are the first four rankers. India produced 13.32 MT of citrus fruit in 2019. As per FAO-2020 report, approximately 40.0% of waste (peel, seeds and pomace) from citrus fruit is generated in India per annum2. According to the Ministry of Food Processing Industries (MoFPI), the estimated total fruit losses including citrus fruit in India was 12.0 MT in 2019. This amounted to ₹ 440.0 crores in value terms3.

The fruit waste is comprised of peel, pomace and seeds which are rich in phytochemicals, over and above the phenolic compounds, dietary fibers, and other bioactive compounds4. The citrus industry generates peel and seed residues amounting to about 50.0% of the whole fruit5. Such discarding of residues from citrus industry leads to great loss of valuable phytochemicals; serious management problems from an economic and ecological point of view are also faced. To address these problems, the recovery of residues represents a promising solution. The valorization of citrus by-products enables affording better remuneration to the fruit producers and helps in valorizing specific components i.e. hesperidin and naringin of orange peel—exerting antioxidant, anti-inflammatory and antimicrobial (against pathogens) activities6.

Fruit peels are excellent natural sources of phenolic compounds, minerals, vitamins and fiber7. Among fruit peels, citrus peel is a richer source of polyphenolic compounds; their concentration is higher than in edible portion of fruit6. The adoption of advanced technological means aids in preserving the nutritive and nutraceutical virtues of fruit peels and improves their sensory acceptance; environmental issues are tackled too. Osmotic dehydration in sugar solution, coupled with vacuum tray drying is one option to produce high-quality fruit peel products such as orange-peel powder (OPP). Such palatable transformed peel products can serve as valued additive in several foods viz., ice cream, frozen yoghurt, Bhapa dahi (steamed concentrated yoghurt, usually sweetened), baked goods, etc.8,9,10,11. To extend the shelf stability of fruit peels, it is desirable to reduce their moisture content to ≤ 8.0%12. Drying conditions should be such that the food value and flavor components are appreciably retained13.

Yoghurt contains live lactic acid bacteria (LAB) that can favorably contribute to regulated body weight gain and reduce the incidence of type 2 diabetes via modulation of the gut microbiota14. Ice cream is one of the world’s leading dairy product and a highly delectable and refreshing product; frozen yoghurt is one of its versions15. Amalgamation of yoghurt and ice cream produces frozen yoghurt that can provide a healthier alternative (owing to lower fat content) to usual ice cream; with subtle acidity and viable LAB too16.

Frozen yoghurt is a fermented frozen dairy dessert that combines the physical qualities of ice cream with the sensory, nutritional and therapeutic benefits of fermented milk. Frozen yoghurt is obtained by processing the ice cream mix, followed by blending the yoghurt base with ice cream mix; subsequent steps include ageing, flavour and colour addition, prior to freezing in a batch/continuous ice cream freezer17. The recommended pH and acidity of frozen yoghurt are 3.45–4.65 and 0.78–1.20% lactic acid (LA) respectively16,17. Frozen yoghurt can be produced through fermentation of an ice cream mix (i.e. direct acidification method) with LAB (i.e. cultures of Streptococcus thermophilus and Lactobacillus delbrueckii ssp. bulgaricus). Another method involves blending yoghurt base with an ice cream mix (i.e. indirect acidification method) as mentioned earlier18.

Though frozen yoghurt is associated with desired nutritive value and therapeutic virtues, they often lack in natural antioxidants and fiber. Consumers demand has switched to food choices which supplies the basic nutrients and contribute towards health improvement. Functional foods can be conventional, modified or may contain functional ingredient(s) containing adequate amounts of natural bioactive substances, prebiotics, probiotics, etc.19.

Fiber enriched frozen yoghurt can be developed through incorporation of fruit peels, transformed into a palatable form, and can be included in dry (powder) state too. Such awareness amongst consumers regarding the positive features of fruit peels has led to the growing demand for the incorporation of novel fibers into foods. The fruit peels that have been attempted as a valued additive in frozen yoghurt include red dragon fruit20, apple9 and pomegranate21. The use of citrus peel in ice cream and frozen yoghurt has been documented in literature8,10,11. Among various fruit peels, orange peel has the potential to be used as the preferred additive (i.e. marmalade being one classic example), in addition to exerting pharmacological effects. Besides this, fruit peels originating from apple, banana, mango and grapefruit have also found application as a valued additive in ice cream22.

Utilization of byproduct such as orange-peel solids in frozen yoghurt can lead to waste reduction and promote agri-sustainability. These aspects are particularly significant in today's environmentally conscious society. Incorporating orange peel solids in frozen yoghurt, especially reduced-fat products would possibly serve as a fat substitute, contribute to flavor (orange fruit) and confer nutrients and phytochemicals, making the product healthier and highly appealing to the consumers. The starchy material and fiber content of orange peels can potentially modify the texture of frozen yoghurt favorably, especially the mouthfeel and creaminess.

Considering all the aforementioned aspects, the study was undertaken to evaluate use of OPP as an adjunct flavouring in medium-fat frozen yoghurt and evaluate its impact on the proximate composition, physico-chemical characteristics and sensory acceptability of frozen yoghurt. The focus was laid on the enrichment of the product with peel components (viz. β-carotene, fiber), the sensory quality and feasibility of using such additive in the resultant product.

Materials and methods

Materials

Mixed milk (cow and buffalo milk; 4.6% fat, 8.6% MSNF) and cream (42.0% fat) required for standardization were procured from Vidya Dairy, Anand (Gujarat), India. 'Sagar' brand skim milk powder (SMP) was used as the source of milk solids non-fat (MSNF). Cane sugar of' Madhur' brand was procured from local market at Anand, India. Pectin (High methoxy type) and carrageenan (RM-1576) were obtained from HiMedia, Mumbai, while Glycerol Mono Stearate (GMS) was procured from Loba Chemie, Mumbai. The orange colour of 'Blossom’ brand was obtained from Raunak Enterprises, Mumbai. Fresh oranges of Valencia variety (Citrus sinensis cv. Valencia) were sourced from Dev Exotica, Anand, India. Orange crush was obtained from Mapro Foods Pvt. Ltd., Panchgani (Maharashtra). Delvo DSL direct set lyophilized yoghurt starter culture RST—776 was sourced from DSM Food Specialties. The cane sugar and oranges used in this study complied with the national guidelines and legislation of India.

Equipment

The equipment used were (i) Homogenizer of M/s. Goma Engineering Pvt. Ltd., Mumbai, (ii) Batch ice cream freezer (8.0 L/batch) of M/s. Pal Engineers, Ahmedabad, (iii) Blast tunnel hardener of M/s. Pal Engineers, Ahmedabad, Gujarat, India (iv) Vacuum tray dryer of M/s. Perfect Engineering and Allied Works Pvt. Ltd., Vadodara, Gujarat, India and the appliance used was Brookfield viscometer (Model—LVDV—II + P, DV II + Pro Viscometer) from IGene Labserve, New Delhi (LMDV-100 model).

Methods

Preparation of orange peel powder

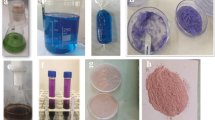

Fresh oranges were washed and peeled. The peel was cut into strips [4.00 × 1.0 × 0.3 cm: length × width × height]. The peel strips were subjected to blanching (77 °C for 2–5 min; peel: water of 1:2 w/v) in potable water in order to arrest the undesirable changes brought about by inherent peel enzymes32. The blanched peel strips were soaked in sodium bicarbonate (NaHCO3) solution (2.0% strength) for 3–4 min at 95 °C in order to mute bitterness and make the peels palatable12. Such treated peel strips were subjected to osmotic dehydration by submerging them in sugar syrup (50°Brix, 50 °C, for 4 h) and later freed from adhering syrup. The osmotically dehydrated peels were subjected to drying (45 ± 2 °C for 8 h; 670 mm of Hg column vacuum) in a vacuum tray drier. The dried orange peel pieces (on an average 7.21% moisture) were milled in a food processor and sieved through 35 No. U.S. stainless steel sieve to obtain powder with particle size ≤ 500 µm. The photograph of OPP is shown in Fig. 1.

Preparation of yoghurt base

The weighed quantities of milk, skim milk and SMP required for a batch of 1.0 kg mix base (2.5% fat, 12.5% MSNF) were mixed, heated to 63 °C prior to homogenization (13.79 MPa and 3.45 MPa in first and second stages respectively) and subsequently heated at 90 °C/15 min., followed by cooling to 40 °C. Starter culture (Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus, 1:1 v/v, designated as ST and LB hereafter) was added at the rate of 7.0 g/100 L milk and the milk incubated at 40 ± 2 °C till 0.57–0.60% LA of yoghurt mass was reached. On reaching this acidity, the mass was cooled to 4 ± 2 °C.

Preparation of ice cream mix

The quantities of milk, cream, SMP, sucrose, stabilizer-emulsifier required for preparing a batch of 3.0 kg ice cream mix was computed using serum point method. Mixing the ingredients led to basic ice cream mix having 7.43% fat, 12.50% MSNF, 21.50% sucrose, 0.27% stabilizer blend (pectin: carrageenan, 8:1 w/w) and 0.20% emulsifier (GMS). The mix pre-heated to 68 °C was homogenized (13.79 MPa and 3.4 MPa) and subsequently pasteurized at 80 °C/5.0 min. The pasteurized mixes were cooled to 4 ± 2 °C and aged overnight (12 h).

Preparation of frozen yoghurt

The aged ice cream mix base was mixed with cooled (4 °C) plain, unsweetened yoghurt base in 75:25 (w/w) proportion. Three batches of frozen yoghurt (6.0% fat) were prepared as follows: (a) TC—control utilizing 9.0% by weight of orange crush and 16.0% sugar, (b) T1—1.5% OPP, (c) T2—2.5% OPP, and (d) T3—3.5% OPP; the latter three samples (viz., b,c,d) were added with 9.0% of orange crush and 16.0% sugar by weight of blended mix. OPP was added just prior to mix pasteurization. The orange colour, prepared in previously boiled and cooled potable water, was added (1.4 mL/kg mix) to the blended mix, prior to freezing. The orange crush, in cooled (4 ± 2 °C) condition, was incorporated into the partly frozen mix. The ice cream mix-yoghurt base blend was frozen in a batch ice cream freezer, drawn into individual packages, which were subsequently subjected to hardening in a blast tunnel hardener operated at − 23 °C for 2 h. The hardened frozen yoghurt was kept in a deep freeze cabinet (M/s Blue Star, Thane, India) maintained at − 18 ± 2 °C. The photographs of the frozen yoghurt samples are depicted in Fig. 2.

Analysis

Orange peel powder

The OPP was analyzed for moisture, ash and total carbohydrates23. The crude fiber (European Community No. 152, 2009) and β-carotene (by HPLC–UV method) content of OPP were analyzed by Centre of Analysis and learning in Livestock and Food (CALF) laboratory, Anand, Gujarat, India. HPLC analysis was conducted using the method described by Chiosa et al.31. The analyses were carried out on an HPLC (Agilent), model LC 1100 series, equipped with a degasser, an auto-sampler automatic injector, a high-pressure pump, and a UV/visible detector at multiple wavelengths. The mobile phase was acetonitrile-tetrahydrofuran-methanol-ammonium-acetate (68, 4% (v:v): Tetrahydrofuran [THF] 22.0% (v:v): 6.8% (v:v): 2.8% (v:v) (1% (w:v)). The detection wavelength was set at 450 nm with a flow rate of 1.5 ml/min.

Yoghurt

Yoghurt was analyzed for moisture, fat, titratable acidity (TA) and ash using standard method24.

Frozen yoghurt

The frozen yoghurt samples were analyzed for total solids (TS), protein and ash25. The fat content was determined using method as suggested by BIS24. The total carbohydrate content was obtained by difference. The analysis for crude fiber and β-carotene content of frozen yoghurt was carried out at CALF laboratory, Anand, India.

Physico-chemical properties of frozen yoghurt

The aged mix containing appropriate dosage of flavoring matter (i.e. orange crush) was analyzed for viscosity at 20 °C using a Brookfield viscometer using RV spindle set (No. 63) operated at 100 rpm26. The TA of the mix base was determined using standard method24. The melting resistance and overrun of frozen yoghurt were determined using the method of Muse and Hartel26 and Marshall et al.16 respectively.

Sensory scoring of frozen yoghurt

A panel of 12 judges, comprising faculty members of the SMC College of Dairy Science, Anand, India performed sensory evaluation of frozen yogurts in accordance with relevant guidelines and regulations. All experimental sensory protocols were followed as suggested by the American Dairy Science Association, and informed consent was obtained from all judges. The judges were initially screened based on ‘Duo-Trio’ and ‘Triangle tests’. The frozen yoghurts were served in High impact polystyrene (HIPS) cups (150 ml capacity) and served at − 13 ± 1 °C temperature. Four-digit random codes were assigned to each sample, which were scored for the pertinent sensory attributes according to American Dairy Science Association score card16. Such score card was pertaining to ice cream.

Statistical analysis

The data obtained from duplicate samples of frozen yoghurt, obtained in four replications, were subjected to statistical analysis using Completely Randomized Design; testing was carried out at 5.0% level of significance27.

Ethical approval

A panel of 12 judges, comprising of faculty members of the college, performed sensory evaluation of frozen yogurts in accordance with relevant guidelines and regulations. All experimental sensory protocols were followed as suggested by the American Dairy Science Association, and informed consent was obtained from all subjects.

Results and discussion

Four batches of orange flavoured frozen yoghurt were prepared using orange crush (62.0% total soluble solids, TSS) @ 9.0% by weight of ice cream-yoghurt base mix; OPP was used at levels of 1.5, 2.5 and 3.5% as flavour adjunct (product designated as T1, T2 and T3 respectively). Control product (TC) was prepared, omitting OPP. OPP had 7.21% moisture, 65.67% total carbohydrates, 4.10% crude fiber, 3.51% ash and 77.40 µg of β-carotene per 100 g (Table 1). The proximate composition of yoghurt is shown in Table 1.

Composition of frozen yoghurt as affected by the presence or absence of peel solids

The inclusion of OPP at three levels in frozen yoghurt formulation had a significant (p < 0.05) effect on the protein, total carbohydrates, ash and TS content; fat content remained unaffected. Till to date, Food Safety and Standards Authority of India (FSSAI) has not promulgated any specifications for frozen yoghurt. Nevertheless, the experimental and control frozen yoghurts conformed to the compositional requirements of frozen yoghurt as framed by Kenya Bureau of Standards28.

The protein (4.32–4.77%), total carbohydrates (24.29–25.44%), ash (1.04–1.19%) and TS (35.80–37.60%) content of experimental frozen yoghurts increased significantly (p < 0.05) with an increase in the level of OPP. Nevertheless, the protein content of sample T3 (3.5% OPP) was statistically at par with that of T2 (2.5% OPP); such values of protein were, however, significantly (p < 0.05) higher when compared with the protein of samples Tc and T1. With respect to ash content, sample T3 had the highest value (i.e. 1.19%), which differed significantly (p < 0.05) from the ash content of the remaining three samples. The noted increase in the TS of frozen yoghurts containing incremental higher levels of OPP could be attributed to the contribution of TS from peel solids in the mix formulation. In a similar fashion, the innate carbohydrates, protein and ash content of OPP contributed to the pertinent constituents of the resultant frozen yoghurts. Similar findings of an increase in the protein, carbohydrates and ash content of orange ice creams have been reported by8 and Chandgude10 who utilized OPP at varying (i.e. 1.5–3.5%) levels.

Haghani et al.15 reported an increase in the TS (i.e. from 34.60 to 36.50%) of probiotic ice cream upon addition of Cornelian Cherry Peel Extract (CCPE) powder at levels ranging from 3.0 to 9.0%; control product tested 33.40% TS. In another study, Chandgude10 reported that medium-fat (6.00%) orange ice cream containing 1.5, 2.5 and 3.5% OPP had 39.71, 40.63 and 41.55% TS respectively.

The presence of OPP at varying levels in frozen yoghurt had a significant effect (p < 0.05) on the β-carotene and crude fiber content. As the level of OPP in the product formulation was raised, the aforementioned components of frozen yoghurts demonstrated a linear increase. Such an increase in the β-carotene content of frozen yoghurt could be attributed to the β-carotene supplied by OPP, over and above that contributed by orange crush. β-carotene is a functional component; it plays a role as an antioxidant or reductant, depending on the reaction conditions6. The frozen yoghurt samples T1, T2 and T3 had crude fiber content of 2.69, 4.37 and 5.13% (dry basis) respectively, as against 1.29% (dry basis) in control Tc. This indicated enrichment of frozen yoghurt with both β-carotene and fiber on utilization of OPP in product formulation.

Dissanayaka et al.18 reported an increase in the fiber content of frozen yoghurt when utilizing 15.0% jackfruit pulp. The fiber content of control and experimental frozen yoghurt was 1.99 and 15.83% respectively. Frozen yoghurt made using 25.0% red dragon peel (RDP) extract led to an increase in the crude fiber content of product by 23.08% over that of control. In another study, orange ice cream incorporated with 8.0% candied orange peel (moisture 37.03%, ash 2.16% and β-carotene 71.50 µg/100 g) led to an increase in the β-carotene content by 94.32% when compared with control product10.

Physico-chemical properties of frozen yoghurt as affected by presence or absence of peel solids

The physico-chemical properties of frozen yoghurt, in presence or absence of OPP, are depicted in Table 2. The rate of usage of OPP exerted a significant (p < 0.05) influence on the viscosity and TA of the mix, as well as on the melting rate and overrun of the resultant frozen yoghurts.

The TA of frozen yoghurts ranged from 0.43 to 0.51% LA. The incorporation of OPP in frozen yoghurts (viz., T1, T2 and T3) led to a significant (p < 0.05) increase in the TA of the products. Such an increase in the TA of mixes could be as a result of the contribution of ascorbic acid, caffeic acid and other phenolic acids from the orange peel solids29. A similar result with regard to an increase in the TA of orange ice cream has been reported by Ananthakumar et al.8 and Chandgude10 when utilizing OPP at levels of 1.5 to 3.5%. In another study, an increase in TA of vanilla flavoured frozen yoghurt has been reported when utilizing pomegranate peel powder (PPP) extract @ 25–100%21. Ismail et al.22 reported an increase in the TA from 0.27 to 0.29% LA in case of ice cream (Doum fruit syrup was used as flavouring) incorporating PPP at 1.0 to 2.0% level; the control product had 0.21% LA.

The viscosity of the frozen yoghurt mixes increased significantly (p < 0.05) in the presence of OPP. The highest viscosity (i.e. 410.69 cP) was noted for the mix containing 3.5% OPP(T3); followed by mix with 2.5% OPP (361.63 cP; T2), 1.5% OPP (307.00 cP; T1) and control (Tc; 140.74 cP). In general, the viscosity of mixes beyond some specific value tends to pose problem in achieving the desired overrun in frozen dairy delicacies16. In the ensuing paragraph, the impairment in the overrun of frozen yoghurts containing OPP at varying levels will corroborate the above fact. Similar result for enhancement in the viscosity of mixes have been reported by Tawfek21 when preparing frozen yoghurt utilizing 2.5–10.0% PPP extract. A similar trend of viscosity increase has been reported by Chandgude10 and Ananthakumar et al.8 when utilizing OPP at levels of 1.5–3.5% in producing orange ice cream.

The overrun associated with frozen yoghurt usually tends to be lower than is usually associated with ice cream (i.e. 85.0–100.0% overrun). The overrun in frozen yoghurt reported in the literature ranged from 42.50–63.70%16,21. As anticipated, there was a decline in the overrun of frozen yoghurts containing incremental higher levels of OPP. The marked rise in the viscosity of frozen yoghurt base mixes incorporating OPP must have hindered the ease of air incorporation during the whipping stage (Table 2), leading to such an impairment in the overrun. Similar findings of impairment in the overrun in orange ice cream have been reported by Chandgude10, when utilizing OPP at levels of 1.5 to 3.5%; the overrun of ice creams containing OPP ranged from 49.26 to 60.10% only.

Likewise, impairment in the overrun of low-fat (4.0% fat) ice cream has been reported by Hafids et al.30 when RDP puree was used at levels of 6.0–12.0% and by Ismail et al.22 for ice cream containing 0.25–0.50% PPP. The overrun (47.46–53.53%) of ice cream containing CCPE (14.8% TSS) was lower than that of control product (56.56%) owing to greater viscosity of the former base mix15.

Besides overrun, melting resistance is also an important quality index of frozen yoghurt. Table 2 reveals that at 1 h period, sample TC as well as samples T1, T2 and T3 recorded melting rates of 64.56, 60.10, 54.50 and 49.26 g respectively. The melting resistance of experimental frozen yoghurt samples improved in presence of OPP. The causative factor for such an improvement in the melting resistance was possibly due to the inherent pectin contained in orange peel, as well as the contribution of TS by such peel solids7. Haghani et al.15 reported increased melting resistance of vanilla ice cream when using cherry peel at 3.0–6.0% as food additive.

Sensory quality of frozen yoghurts as affected by presence or absence of peel solids

The results presented in Table 3 represent the influence of OPP, attempted at three levels, on the various sensory quality and scores of frozen yoghurts. Except for colour scores, other sensory scores [viz. flavour, body and texture (BT), melting quality] remained unaffected by the varying level of OPP used in the preparation of frozen yoghurts. The sensory scores of frozen yoghurts T1 (1.5% OPP) and T2 (2.5% OPP) were statistically alike with respect to flavour, BT, melting quality and total sensory scores. Sample T3 had the least scores for all the above attributes, except for melting quality. In most cases, samples T3 and T1 were at par with each other, while samples Tc and T2 differed significantly (p < 0.05) from each other with respect to flavour and total score. In some cases, sample T3 was criticized for eliciting ‘chalky’ mouthfeel. Such impaired mouthfeel could be due to the compromised solubility of peel powder, since the level used was highest. Consequently, sample T3 was moderately ‘heavy and soggy’ bodied, possibly due to the presence of highest TS (i.e. 37.60%) and least overrun (i.e. 51.58%). The above findings revealed superiority of frozen yoghurt utilizing 2.5% OPP as flavour adjunct over other two usage levels.

The sensory score for melting quality was statistically alike when frozen yoghurt samples T2 and T3 as well as T1 and TC were compared with each other; the former two products had significantly (p < 0.05) superior melting quality scores when compared with that of TC (Table 3). The presence of OPP at specific usage level contributed to the innate pectin which led to increased melting resistance of the resultant frozen yoghurts, with consequent improved melting quality scores. Similar findings have been reported regarding the melting rate by Chandgude10 on incorporating OPP at levels of 1.5–3.5% by weight in producing orange-flavoured ice cream; the author recommended using 2.5% OPP.

The sensory scores of frozen yoghurts of the present investigation are in conformity with the findings of Haghani et al.15 pertaining to cherry ice cream supplemented with CCPE at levels of 3.0–9.0% by weight; level exceeding 6.0% was not recommended. Likewise, Chandgude10 recommended use of 2.5% OPP in producing orange ice cream based on use of orange crush as the flavouring matter. Such fruit ice cream had superior sensory scores compared to product made utilizing other levels (viz., 1.5, 3.5%) of OPP and even the control product. Ananthakumar et al.8 also reported an improvement in the flavour, body and texture and total sensory scores of experimental orange ice cream containing 2.5% OPP over those of control product.

Conclusions

The study was aimed to assess the impact of incorporating OPP as flavor adjunct in the formulation of frozen yoghurt to add value to the product through enriching the product with β-carotene and fiber. The inclusion of OPP positively influenced the sensory scores of medium-fat frozen yoghurt. Incorporation of such fruit peel solids resulted in frozen yoghurt having pleasingly intense orange flavor, eliciting refreshing experience and at the same time enriched the product with β-carotene and fiber. The presence of OPP in frozen yoghurt led to improved viscosity of mix, culminating in improved melting resistance in the product. The only parameter getting impaired was the overrun of product. Considering sensory scores and proximate composition, a level of 2.5% OPP is recommended in producing value-added frozen yoghurt when using orange crush as the primary flavouring matter at usage level of 9.0% by weight.

Data availability

All data generated during this research study has been included in the manuscript in tabulated form.

Abbreviations

- CCPE:

-

Cornelian cherry peel extract

- COP:

-

Candied orange peel

- CRD:

-

Completely randomized design

- FY:

-

Frozen yoghurt

- GMS:

-

Glycerol mono stearate

- HIPS:

-

High impact polystyrene

- LA:

-

Lactic acid

- LAB:

-

Lactic acid bacteria

- MoFPI:

-

Ministry of Food Processing Industries

- MSNF:

-

Milk solids non-fat

- MT:

-

Million tonnes

- OPP:

-

Orange peel powder

- PPP:

-

Pomegranate peel powder

- RDP:

-

Red dragon peel

- SMP:

-

Skim milk powder

- TSS:

-

Total soluble solids

References

Goldenberg, L., Yaniv, Y., Porat, R. & Carmi, N. Mandarin fruit quality: A review. J. Sci. Food Agric. 98, 18–26 (2018).

Suri, S., Singh, A. & Nema, P. K. Recent advances in valorization of citrus fruits processing waste: A way forward towards environmental sustainability. Food Sci. Biotechnol. 30, 1–26 (2021).

Plazzotta, S., Manzocco, L. & Nicoli, M. C. Fruit and vegetable waste management and the challenge of fresh-cut salad. Trends Food Sci. Technol. 63, 51–59 (2017).

Nirmal, N. P. et al. Valorization of fruit waste for bioactive compounds and their applications in the food industry. Foods 12(3), 556–562 (2023).

Magalhaes, D., Vilas-Boas, A. A., Teixeira, P. & Pintado, M. Functional ingredients and additives from lemon by-products and their applications in food preservation: A review. Foods 12(5), 1–29 (2023).

Rafiq, S. et al. Citrus peel as a source of functional ingredient: A review. J. Saudi Soc. Agric. Sci. 17(4), 351–358 (2018).

Suleria, H. A., Barrow, C. J. & Dunshea, F. R. Screening and characterization of phenolic compounds and their antioxidant capacity in different fruit peels. Foods 9(9), 1206S (2020).

Ananthakumar, K. V., Dhanalakshmi, B. & Pugazhenthi, T. R. Quality evaluation of orange peel (Flavedo) incorporated ice cream. Indian J. Anim. Res. 48(4), 1–4 (2019).

Ahmad, I. et al. Effect of polyphenol from apple peel extract on the survival of probiotics in yoghurt ice cream. Int. J. Food Sci. Technol. 55(6), 2580–2588 (2020).

El-Rahman, A., Darwish, S., Megali, H. K., El-Hakim, A. & Hassan, I. Characterization of β-carotene extracted from orange peels and its use as a natural colorant and antioxidant in ice cream. Egypt. J. Food Sci. 47(2), 173–185 (2019).

Adil, S., Jana, A. H., Mehta, B. M. & Darji, V. B. Value addition to frozen yoghurt through the use of orange peel solids as flavour adjunct. Int. J. Dairy Technol. 76(2), 371–380 (2023).

Pinzon, M. K., Cortes-Rodriguez, M. & Rodríguez-Sandoval, E. Effect of drying conditions on the physical properties of impregnated orange peel. Braz. J. Chem. Eng. 30(3), 667–676 (2013).

Jeong, B. G. et al. Antioxidative properties of machine-drip tea prepared with Citrus fruit peels are affected by the type of fruit and drying method. Foods 11(14), 2094S. https://doi.org/10.3390/foods11142094 (2022).

Le Roy, C. I. et al. Yoghurt consumption is associated with changes in the composition of the human gut microbiome and metabolome. BMC Microbiol. https://doi.org/10.1186/s12866-021-02364-2 (2022).

Haghani, S. et al. Application of Cornelian cherry (Cornus mas L.) peel in probiotic ice cream: Functionality and viability during storage. Antioxidants 10(11), 1777 (2021).

Marshall, R. T., Goff, H. D. & Hartel, R. W. Analyzing frozen desserts. In Ice Cream 7th edn (eds Goff, H. D. & Hartel, R. W.) 403–435 (Springer, 2013). https://doi.org/10.1007/978-1-4614-6096-1_14.

Nofal, T. G., El-Gammal, O. E. I. & Abo-Zaid, E. M. Improving characteristics of frozen yogurt enriched with loquat leaves extract. New Valley J. Agric. Sci. 3(7), 624–641 (2023).

Dissanayaka, T. M., Gimhani, K. H. & Champa, W. A. Evaluation of nutritional, physico-chemical and sensory properties of jackfruit (Artocarpus heterophyllus) incorporated frozen yoghurt. Int. J. Sci. Res. 9(6), 627–632 (2019).

Chhikara, N. & Panghal, A. Overview of functional foods. In Functional Foods 1st edn (eds Chhikara, N. et al.) 1–20 (Wiley, 2022).

Analianasari, A. & Apriyani, M. Characteristics of frozen yoghurt enriched with red dragon fruit skin extracts (Hylocereus polyrhizus). J. Phys. Conf. Ser. 953(1), 012036. https://doi.org/10.1088/1742-6596/953/1/012036 (2018).

Tawfek, M. A. Properties of low-fat bio-frozen yoghurt fortified with extract and powder of pomegranate peel (Punicaganatum L.). Egypt. J. Food Sci. 49(2), 261–270 (2021).

Ismail, H. A., Hameed, A. M., Refaey, M. M., Sayqal, A. & Aly, A. A. Rheological, physio-chemical and organoleptic characteristics of ice cream enriched with Doum syrup and pomegranate peel. Arab. J. Chem. 13(10), 7346–7356 (2020).

Ranganna, S. Handbook of Analysis and Quality Control for Fruit and Vegetable Products. 2nd edn, 25th reprint, 9–12 (Tata Mc Graw Hill, 2018).

BIS, Handbook of Food Analysis, SP: 18 (Part XI - Dairy Products). Bureau of Indian Standards (BIS), Manak Bhavan, 32–33 (1989).

FSSAI, Manual of Methods of Analysis of Foods. Milk and milk products. Food Safety and Standards Authority of India (Ministry of Health and Family Welfare, Government of India, New Delhi, 2016).

Muse, M. R. & Hartel, R. W. Ice cream structural elements that affect melting rate and hardness. J. Dairy Sci. 87(1), 01–10 (2004).

Steel, R. G. D. & Torrie, J. H. Analysis of Variance - I: The one-way classification. In Principles and Procedure of Statistics - A Biometrical Approach, 2nd edn. 137–167 (Mc-Graw Hill, 1980).

DKS-1517, Dairy based desserts and ice mixes – Specification. https://members.wto.org/crnattachments/2018/TBT/KEN/18_0858_00_e.pdf. Accessed 2018.

Goraya, R. K. & Bajwa, U. Enhancing the functional properties and nutritional quality of ice cream with processed amla (Indian gooseberry). J. Food Sci. Technol. 52(12), 7861–7871 (2015).

Hafids, S., Rahmi, S. L. & Chairunisah, A. R. Study of low-fat ice cream with the substitution of super red dragon (Hylocereus costaricensis) fruit peel. Indones. J. Sci. Technol. 3(1), 23–28 (2019).

Chiosa, V., Mandravel, C., Kleinjans, J. C. & Moonen, E. Determination of β-carotene concentration in orange and apple juice and in vitamin supplemented drinks. In Analele Universită Ńii din Bucureşti – Chimie, Anul XIV (Serienouă), Vol. I–II, 253–258 (2005).

Magangana, T. P. et al. Blanching pre-treatment promotes high yields, bioactive compounds, antioxidants, enzyme inactivation and antibacterial activity of ‘wonderful’ pomegranate peel extracts at three different harvest maturities. Antioxidants 10(7), 1–25 (2021).

Acknowledgements

Authors are thankful to Mr. Pravin Singh, Key Account Manager, DSM Food Specialties Ltd., Anand, India for providing ‘Delvo DSL Direct set lyophilized starter cultures RST—776’ used in the present study.

Funding

This research was carried out at SMC College of Dairy Science, Anand, India with financial support from Education Department, Gujarat State under the ‘ScHeme Of Developing High quality research’.

Author information

Authors and Affiliations

Contributions

S.A. designed and conducted the experiments, analyzed the data, and wrote the manuscript; J.A.H. conceived the research and aided in refining the design and editing the manuscript; M.B.M. contributed to the physico-chemical analyses of ingredients and final products; A.B. assisted in the conduct of experiment and the writing of manuscripts; and A.S. and B.R. helped in the statistical analysis of data and in preparing the tables and figures.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Adil, S., Jana, A.H., Mehta, B.M. et al. Value addition to dietetic frozen yoghurt through use of fruit peel solids. Sci Rep 14, 18743 (2024). https://doi.org/10.1038/s41598-024-69762-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-69762-0