Abstract

This study investigates the impact of varying compositions of AlxInyGazN barrier layers on the performance of AlxInyGazN/GaN Metal-Insulator-Semiconductor High Electron Mobility Transistors (MISHEMTs) using Sentaurus TCAD simulation. By systematically increasing the compositions of Al and In and decreasing the Ga composition of the AlxInyGazN layer, we maintained the lattice-matched conditions with GaN and explored the effects of compositions on channel charge, drain current, and threshold voltages. Under the lattice-matching conditions, it was shown that the AlxInyGazN barrier with higher Al/In and lower Ga exhibited significantly enhanced channel charges and drain current while making threshold voltages more negative. Additionally, the influence of AlxInyGazN layer thickness was studied. Subsequently, we analyzed the electrical characteristics of AlxInyGazN/GaN MISHEMT based on systematically changing the compositions of each group III element. The lattice mismatch-related piezoelectric polarization was also taken into consideration. Our results indicate that total polarization increases as Al composition increases; however, the total polarization decreases as In composition increases. Notably, the change in total polarization looked slightly stronger by varying In composition compared to Al. Furthermore, we compared the charge density and band structures of MISHEMT heterostructures with and without the AlN spacer layer. The inclusion of an AlN spacer layer was found to enhance carrier confinement and reduce the dependence of charge density on composition due to the presence of large polarization between the barrier layer and channel layer. These findings highlight the importance of precise material composition control in optimizing MISHEMT performance.

Similar content being viewed by others

Introduction

Gallium Nitride (GaN) and its alloys have emerged as promising materials for high-power and high-frequency device applications due to their exceptional properties, such as wide bandgap (3.4 eV), high critical electric field (3.3 MV cm− 1), high electron mobility (1200 cm2 V− 1 cm− 1), high saturation drift velocity (2.5 × 107 cm s− 1), and high thermal conductivity (210 W m− 1 K− 1), making it an excellent candidate for operating in harsh conditions1. Among GaN-based devices, high electron mobility transistors (HEMTs) are particularly popular due to the high carrier mobility of two-dimensional electron gas (2DEG) based conducting channels formed by polarization-induced charges at the heterojunction such as AlGaN/GaN2. In GaN-based heterostructure, polarization effects play a crucial role in device operation. Spontaneous polarization arises from the intrinsic crystal polarity of the asymmetric wurtzite crystal structure, while piezoelectric polarization is induced by the strain resulting from lattice mismatch between different materials in heterostructures3,4. The discontinuity of spontaneous polarization at interfaces, along with piezoelectric polarization, leads to the accumulation of electrons at the interface. This results in the formation of 2DEG with high carrier concentration and mobility, which directly affects device performance.

Increasing the Al composition in the AlGaN barrier layer enhances the 2DEG sheet carrier density, thereby improving device performance in high-power and high-frequency applications5,6. However, a significant increase in Al composition leads to a deterioration in 2DEG electron mobility due to the larger lattice mismatch between the AlGaN and GaN layers, which introduces more defects and traps layers7. To overcome this issue, the AlxInyGazN barrier layer has been explored as an alternative to AlGaN. AlxInyGazN can alleviate miscibility problems while maintaining the lattice-matched conditions with GaN through a suitable Al/In- ratio8,9. Compared to AlGaN, the AlxInyGazN barrier layer offers higher spontaneous polarization, resulting in a larger conduction band offset (ΔEc) with smaller barrier layer thickness, leading to better electron confinement and much higher 2DEG charge density (> 1.5 × 1013 cm2 V s− 1)10. Moreover, AlxInyGazN offers the flexibility to adjust its bandgap and lattice constant independently by adjusting the Al, In, and Ga compositions11. In addition, in AlxInyGazN barrier layers, these polarization effects can be modulated by adjusting the compositional ratios of group III elements, providing additional degrees of freedom in device design.

Given the aforementioned advantages of AlxInyGazN over AlGaN, a comprehensive understanding of its underlying physics is essential. In this study, we conduct a systematic study using Sentaurus TCAD simulation to evaluate the influence of various AlxInyGazN compositions on the key device parameters such as drain current, sheet charge density, threshold voltage, and total polarization in AlxInyGazN/GaN MISHEMTs. The effects of varying each group III element on total polarization and the resulting sheet charge density are demonstrated. We also perform a detailed analysis of the polarization mechanisms and compare MISHEMT structures with and without an AlN spacer layer to understand its impact on carrier confinement and polarization, which are discussed and highlighted.

Simulation set-up of AlxInyGazN/GaN MISHEMT

Device structure

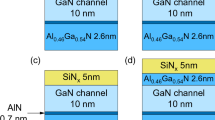

The cross-sectional view of the AlxInyGazN/GaN MISHEMT structure used in the study is depicted in Fig. 1. Sentaurus TCAD simulation tools were used for the study, and the developed model was validated against published experimental data12. The device heterostructure consists of a Si substrate, a 400 nm AlN seed layer, a 1.8 μm AlGaN buffer layer, a 1.8 μm GaN buffer layer, a 300 nm GaN Channel, 1 nm AlN spacer layer, a 6 nm Al0.63In0.04Ga0.33N barrier layer, a 1 nm GaN cap layer, and 25 nm SiN dielectric. The device’s gate-to-source distance (LSG) is 3 μm, and the gate-to-drain distance (LGD) is 19 μm. In this study, the gate contact is modeled as a Schottky contact, while the drain and source contacts are ohmic. The GaN channel is usually undoped to ensure less scattering and increase mobility. The AlN spacer layer between the barrier and channel layers has been reported to reduce alloy scattering and interface roughness, thereby increasing the 2DEG carrier density13,14.

Simulation models

To achieve maximum accuracy, we incorporated various physical models as described below. This study considers the drift-diffusion model (DD) for the device transport. The continuity and Poisson equations for both electrons and holes are solved numerically in a self-consistent manner. The Poisson equation is solved using an anisotropic model, which accounts for the anisotropic dielectric properties of the materials. Fermi statistics models are used to calculate electron density in degenerate cases due to high 2DEG channel electron density. The surface roughness scattering effects are included in the simulation by activating the constant mobility and Lombardi models, as the spacer is undoped15. In addition, high field saturation and doping-dependent mobility models are considered. The high field saturation model includes three sub-models: the actual mobility model, the velocity saturation model, and the driving force model. Furthermore, several critical physical models, such as barrier tunneling and thermionic emission models to calculate the thermionic current, recombination-generation models, the Fermi-Dirac model, and bandgap narrowing, are also considered in the simulation. Schottky-read hall (SRH), Auger, and radiative recombination models are included in the recombination analysis. Moreover, in our simulation, both spontaneous and piezoelectric polarization effects are incorporated through a comprehensive polarization model that includes stress effects. Spontaneous polarization is modeled based on the intrinsic polarization parameters of binary nitrides (AlN, GaN, InN), with composition-dependent factors applied for the quaternary AlxInyGazN barrier layer. Piezoelectric polarization is calculated dynamically based on the strain state arising from the lattice mismatch between layers, using the piezoelectric tensor elements specific to each material. Additionally, a position-dependent stress model is incorporated into the simulation to account for the effects of spatially varying strain across heterojunctions, which is essential for the accurate calculation of piezoelectric polarization. Newton’s numerical method is used to solve these physical models16.

Simulation parameters

High-density interface traps, ranging from 1010 to 1014 cm− 2eV− 1, can be present at the dielectric/III-nitride interface due to structural damage, defects from oxidation, and dangling bonds17,18. These traps are introduced due to structural damage, defects from oxidation, dangling bonds, and other factors. Moreover, the deposition process and post-deposition annealing significantly influence the density of interface traps19,20. These defects create energy levels within the band structure that function as donor traps21 Moreover, some studies suggest that these traps play an important role in affecting 2DEG density22,23,24. Additionally, acceptor traps are considered in the buffer region, as buffer layers are typically doped with p-type dopants like carbon, iron, and others to enhance resistivity25,26,27. In this study, the selection of the interface donor concentration, bulk acceptor concentration, and their associated energy levels is based on ranges established in prior literature and adjusted in accordance with the fits to experimental data11,23,28,29,30,31,32. Nonlocal electron tunneling is enabled by utilizing a low tunneling mass of 0.001 times the rest electron mass (mο) to simulate the source and drain ohmic contacts32. The parameters used for calibrating the simulation data with experimental data are listed in Table 1. Interfacial charges and traps at the dielectric/III-nitride interface (passivation/top layer) play a crucial role in determining the performance of III-nitride-based HEMTs. Donor-like interface traps contribute to the 2DEG formation by supplying additional electrons, while acceptor-like buffer traps primarily influence the buffer resistivity and leakage currents. Our simulation results show that variation in the interface trap density affects the threshold voltage and maximum drain current. Specifically, increasing the donor interface trap density from 1 × 1013 cm−2 to 5 × 1013 cm−2 results in a threshold voltage shift of approximately − 0.2 V and an increase in maximum drain current by 37.31%. These findings are consistent with the referenced experimental data29.

The comparison of DC on-state characteristics between simulated and experimental results of the AlxInyGazN/GaN MISHEMT is shown in Fig. 2. The Al and In compositions used for calibration match those of the experimental device. Fig. 2(a) compares the input characteristic (IDS-VGS) at VDS=20 V. Fig. 2(b) compares the output characteristic (IDS-VDS) for VGS ranging from 1 V to VGS=−11 V, with a step size of 2 V. As seen in Fig. 2, the simulated results show good agreement with the experimental data. In this study, we started our AlxInyGazN/GaN MISHEMT simulation using a lattice-matched AlxInyGazN barrier layer. The lattice-matching condition was maintained by increasing the In and Al compositions while simultaneously decreasing the Ga content. Then, we systematically varied the compositions of each group III element in the AlxInyGazN layer, with the corresponding compositions and lattice constants depicted in Fig. 3.

Comparison of the simulated and experimental12 on-state DC characteristics (a) IDS-VGS and (b) IDS-VDS.

Simulation results and discussion

Lattice matched AlxInyGazN/GaN MISHEMT

The significant advantage of quaternary group III-nitride is that its lattice constant and bandgap energy can be adjusted independently, depending on the molar fractions of group III elements. The lattice constant and the bandgap are calculated using Vegard’s law, which depends on the values of x, y, and z, where x represents Al composition, y represents In composition, and z (where z = 1−x−y) represents the Ga composition. The equation to calculate the lattice constant of AlxInyGazN is given by:

where aAlN, aInN and aGaN are the lattice constants of AlN, InN, and GaN, respectively. Similarly, the bandgap of AlxInyGazN is the sum of the binary semiconductor’s bandgap, i.e., the bandgap of GaN, InN, and AlN, with appropriate bowing parameters33,34. The equation of the bandgap of AlxInyGazN is given by35

where, \(\:{E}_{g,AlN},{\:E}_{g,InN}\:and{\:E}_{g,GaN}\)are the bandgaps of AlN, GaN and InN, respectively, and \(\:{b}_{AlGaN}\), \(\:{b}_{AlInN}\), and \(\:{b}_{InGaN}\) are the bowing parameters of AlGaN, AlInN, and InGaN, respectively36. The relationship between the bandgap and lattice constant of AlxInyGazN as a function of Al and In compositions is shown in Fig. 4. Fig. 4(a) shows the lattice constant values, and Fig. 4(b) shows the bandgap of AlxInyGazN as a function of Al and In composition. Fig. 4(a) is plotted based on Eq. (1), while Fig. 4(b) is plotted through simulation. A similar correlation between lattice constant and bandgap as a function of Al and In compositions has been previously reported37.

For our study (as shown in Fig. 3), three pairs of Al and In compositions are considered for AlxInyGazN barrier layer with lattice-matched conditions with GaN, where the lattice constant a0 of AlxInyGazN is 3.186 Å. The three selected AlxInyGazN compositions are Al0.4In0.09Ga0.51N, Al0.5In0.11Ga0.39N, and Al0.6In0.13Ga0.27N, based on37,38. The structural dimensions of the MISHEMT remain the same as the structure shown in Fig. 1. Fig. 5 compares the on-state DC characteristics of the three lattice-matched AlxInyGazN barrier layers. Fig. 5(a) compares the corresponding transfer characteristics, and Fig. 5(b) compares the output characteristics. As seen in Figs. 5(a) and (b), the drain current (ID) increases as Al and In compositions increase and the Ga composition decreases. The bandgap of the barrier layer increases with higher Al content, with measured bandgaps of 4.1 eV, 4.3 eV, and 4.5 eV for Al0.4In0.09Ga0.51N, Al0.5In0.11Ga0.39N, and Al0.6In0.13Ga0.27N, respectively. Under lattice-matched conditions, the polarization effect considered for the barrier layer is only spontaneous polarization in this study. The spontaneous polarization difference (ΔPs) between AlxInyGazN barrier and the GaN channel becomes larger for samples with higher Al compositions. Moreover, the conduction band offset (ΔEc) between the AlxInyGazN barrier and GaN channel increases with the increase in the bandgap (i.e. higher Al composition). The enlarged ΔEc induces a deeper quantum well for 2DEG confinement. Hence, the larger the polarization-induced charge and the deeper quantum well depth for 2DEG, the larger the 2DEG sheet charge density (ns).

Deeper quantum wells offer significant advantages for device performance by enhancing carrier confinement. The deeper potential well at the heterojunction interface more effectively confines the 2DEG, accommodates more sub-bands within the channel region, and minimizes electron spillover. This improved confinement directly results in a higher ns at the heterojunction, leading to increased ID, as shown in our simulations (Fig. 5). Additionally, inadequate carrier confinement can make devices more susceptible to short channel effects (SCEs) and current collapse, both of which seriously deteriorate reliability39,40. Moreover, a deeper quantum well suppresses carrier leakage due to thermal excitations41. The improved thermal stability is particularly important for high-power applications, where device temperature can fluctuate significantly during operation. The ID can be quantified with a 2DEG sheet charge in a quantum well using the relation42:

where w is the device’s width, and VDrift denotes the electron drift velocity. Based on this relationship, we conclude that a deeper 2DEG quantum well results in a larger ns, which subsequently leads to an increased ID and a more negative threshold voltage (VTH).

In addition, we analyzed the device performance with respect to barrier thickness. The variation in ns, VTH, and ID, for barrier thicknesses ranging from 4 nm to 10 nm are shown in Fig. 6. Figs. 6(a)-(c) compare the ns (at VG=0 V and VD=0 V), VTH, and ID (at VG=1 V and VD=20 V), respectively, as the barrier thickness aries from 4 nm to 10 nm for the GaN MISHEMT with three lattice-matched AlxInyGazN barrier layers. As the barrier thickness increases, the triangular quantum well channel becomes deeper. Consequently, the ns of the 2DEG increases as shown in Fig. 6(d). As the quantum confinement enhances, electron accumulation at the channel region increases at zero gate bias, resulting in more negative VTH and larger ID.

Comparison of the performances of lattice-matched AlxInyGazN barrier layer for different barrier thicknesses (a) Sheet charge density at VG = 0 V and VD = 0 V, (b) Threshold voltage, (c) Drain current at VG = 1 V and VD = 20 V, and (d) Conduction band comparison for 4 types of barrier thickness: 4 nm, 6 nm, 8 nm, and 10 nm (inset: 2DEG quantum wells comparison).

Systematic variation of Al/In/Ga ratios

Without the AlN spacer layer

To understand the effect of various compositions of group III elements on the performance of AlxInyGazN/GaN MISHEMT, we performed a systematic analysis of the compositional effect on the various performances of the device. In this study, Al, In, and Ga compositions were chosen based on three different lattice constant values: 3.167 Å, 3.186 Å, and 3.211 Å. Relative to the lattice constant of GaN Channel (3.186 Å), the AlxInyGazN barrier layer with a lattice constant of 3.167 Å induces compressive stress on GaN channel, while the AlxInyGazN barrier layer with a lattice constant of 3.211 Å induces a tensile stress. The Al composition was fixed at three compositions: 0.4, 0.5, and 0.6, and the In and Ga compositions were adjusted accordingly based on the corresponding lattice constants, as shown in Fig. 3.

It was stated previously that ns is mainly induced by the polarization difference between the AlxInyGazN barrier and GaN channel. The total polarization of AlxInyGazN layer (\(\:{P}_{{Al}_{x}{In}_{y}{Ga}_{z}N}\)) is given by

where \(\:{P}_{sp}\left({Al}_{x}{In}_{y}{Ga}_{z}N\right)\) and \(\:{P}_{pz}\left({Al}_{x}{In}_{y}{Ga}_{z}N\right)\) represent the spontaneous and piezoelectric polarization components, respectively. \(\:{P}_{pz}\left({Al}_{x}{In}_{y}{Ga}_{z}N\right)\) is the weighted sum of the piezoelectric polarizations of the binary III-nitride components. The piezoelectric polarization of the binary component is calculated by using basal strain, η(x, y,z). The \(\:{P}_{pz}\left({Al}_{x}{In}_{y}{Ga}_{z}N\right)\) and \(\:{P}_{sp}\left({Al}_{x}{In}_{y}{Ga}_{z}N\right)\) are given by Eqs. (5) and (6)43,44:

where \(\:{b}_{AlGaN},\:{b}_{InGaN},\:and\:{b}_{AlInN}\) are the bowing parameters for the respective ternary components.

In this study, the polarization effects were calculated using a stress model that determines the complete polarization in tensor without simplifying assumptions:

where dij presents the piezoelectric coefficient (cm/V), and \(\:\sigma\:\) represents the stress tensor (Pa) which is composed of in-plane stress, vertical stress, and shear stress components. The crystal system and the stress system employed in the simulation define \(\:{P}_{sp}\), dij and\(\:\:\sigma\:\). The lattice mismatch results in in-plane stress components, while the vertical and the sheer stress components ontribute to in-plane piezoelectric polarization, resulting in charge density and potential variations. In our study, the reference point for stress was set inside the buffer layer, ensuring a completely relaxed buffer layer.

The 3D plots of the simulated ID, ns, 2DEG density, and VTH, as functions of Al and In compositions in the AlxInyGazN barrier layer are shown in Figs. 7(a)-(d). The ID is measured at VG= 1 V and VD= 20 V. Total polarization and the conduction band energy for different barrier compositions are shown in Figs. 7(e) and (f), respectively. For each Al composition (0.4, 0.5, and 0.6), the In composition is varied from 0.03 to 0.19 in steps of 0.02. In Figs. 7(a)-(d), the dotted line represents the lattice-matched condition: values above the line represent compressive stress, and those below the line represents tensile stress. At a fixed Al composition, increasing the In composition increases the total polarization due to transition from compressive to tensile (as the lattice constant increases), as seen in Fig. 7(e). Consequently, ns and ID decrease with increasing In content (shown in Figs. 7(a) and (b)). Conversely, at constant In content, as Al composition increases, the total polarization increases (Fig. 7(e)). For example, at a fix In composition of 0.19, the increase in total polarization is from 3.19 × 10− 6 C/cm2 to 5.23 × 10− 6 C/cm2 as Al composition increases from 0.4 to 0.6. At a fix Al composition of about 0.4, the total polarization increases from 3.19 × 10− 6 C/cm2 to 6.16 × 10− 6 C/cm2 as In composition decreases from 0.19 to 0.03. This indicates that In composition has a slightly stronger influence on total polarization compared to Al.

3D plot comparison of AlxInyGazN MISHEMT without AlN spacer layer characteristics as a function of Al and In composition, (a) Drain current at VG = 1 V and VD = 20 V, (b) sheet charge density (ns) at VG = 0 V and VD = 0 V, (c) 2DEG electron density, (d) Threshold Voltage, (e) Total Polarization, and (f) Conduction band bending for various Al and In compositions, for each Al composition, the In composition is increased from 0.03 to 0.19 with an increment of 0.02.

Furthermore, as the Al composition increases, both the bandgap and ΔEc increase, shown in Fig. 4(b) and Fig. 7(f). The VTH of the III-V GaN HEMT depends on ΔEc, Schottky barrier height\(\:{\:(\phi}_{b})\), and the dielectric constant (\(\:\epsilon\:\)), and is given by45:

where \(\:q\) is the electric charge and d is the barrier layer thickness. The increase in σ(x) and \(\:\varDelta\:{E}_{c}\) as the polarization increases results in a reduction of VTH46. Therefore, VTH becomes more negative as Al compositions increase and In composition decreases, as shown in Fig. 7(d). Devices under compressive stress conditions exhibit a higher VTH compareded to those under tensile stress conditions.

With AlN spacer layer

In this section, we study the effect of varying Al and In compositions on the performance of the AlxInyGazN/GaN MISHEMT with an AlN spacer layer. As in previous study, we conducted a systematic analysis of the compositional effect on the various characteristics of the device. The device parameters and physics models used are identical to those in the previous section except for the inclusion of the AlN spacer layer. The Al and In compositions used for both structures are also the same. Figs. 8(a)-(d) present 3D plots of the simulated ID, ns, 2DEG charge density, and VTH, as functions of Al and In composition. The total polarization and conduction band energy comparison of the device for different barrier compositions are shown in Figs. 8(e) and (f), respectively. For both Figures, for each Al composition (0.4, 0.5, and 0.6), the In composition increases from 0.03 to 0.19 with an increment of 0.02. Similar to the structure without the AlN spacer, the device with an AlN spacer layer exhibits similar improvement in ID, ns, and polarization with increasing Al composition and decreasing In composition. The major advantage of the device with an AlN spacer layer over one without an AlN spacer layer lies in the larger carrier confinement. The larger bandgap of the AlN layer leads to a more significant conduction band offset from the fermi level, resulting in more negative VTH and larger carrier confinement, ultimately leading to a larger ID than the device without an AlN spacer layer, as observed by comparing Figs. 7(a) and (d) with Figs. 8(a) and (d).

3D plot comparison of AlxInyGazN MISHEMT with AlN spacer layer characteristics as a function of Al and In composition, (a) Drain current at VG=1 V and VD=20 V, (b) sheet charge density (ns) at VG = 0 V and VD = 0 V, (c) 2DEG electron density, (d) Threshold Voltage, (e) Total polarization, and (f) Conduction band bending for various Al and In compositions, for each Al composition, the In composition is increased from 0.03 to 0.19 with an increment of 0.02.

Based on our simulation, we summarized that the increase of the Al composition enhances the polarization charges, bandgap offset, and quantum confinement of 2DEG. However, for a constant Al composition, as In composition increases, the bandgap decreases, as well as total polarization decreases, as do the electrical performances (Figs. 7(e) and 8(e)).

Comparison between with and without AlN spacer layer

Previously, we presented 3D plots comparing ns as a function of Al and In compositions for MISHEMTs without and with an AlN spacer layer in Figs. 7(b) and 8(b), respectively. The range of ns of the MISHEMT without an AlN spacer layer is approximately 3.78 × 107 cm−2 to 1.28 × 1013 cm− 2, while for the MISHEMT with an AlN spacer layer, it ranges from 4.25 × 1012 cm− 2 to 1.38 × 1013 cm− 2, as shown in Figs. 7(b) and 8(b), respectively. By comparing the ns plots of both the devices (Figs. 7(b) and 8(b)), it is evident that ns trends to saturate at the upper corner of the plots, corresponding to high Al and low In compositions. The saturation of ns for MISHEMT with AlN spacer occurred earlier at lower Al and higher In compositions, and the final saturated ns value for AlxInyGazN at x = 0.6 and y = 0.07 is slightly higher. For example, at 0.6 Al composition, for the device with AlN spacer layer, ns changes from 1.19 × 1013 cm− 2 to 1.38 × 1013 cm− 2 as In/Ga composition changes from 0.19/0.21 to 0.03/0.37, similarly at 0.03 In composition, as Al composition increases from 0.4 to 0.6, ns changes from 1.35 × 1013 cm− 2 to 1.38 × 1013 cm− 2, as shown in Fig. 8 (b). On the other hand, for the device without an AlN spacer layer, at 0.6 Al composition as In/Ga composition changes from 0.19/0.21 to 0.03/0.37, ns increases from 5.72 × 1012 cm− 2 to 1.28 × 1013 cm− 2 and at 0.03 In composition as Al composition increases from 0.4 to 0.6, ns increases from 9.59 × 1012 cm− 2 to 1.28 × 1013 cm− 2 as shown in Fig. 7(b). The trends of ns variation with respect to group III element compositions reflect the band offset at the 2DEG channel region. On comparing the total polarization of without and with AlN spacer shown in Figs. 7(e) and 8(e), we observed that the total polarization remains nearly the same for both with and without the ALN spacer. Although the total polarization of the AlxInyGazN barrier and GaN channel are almost the same for both the devices without or with the AlN spacer, the MISHEMT with AlN spacer shows a deeper quantum well at the GaN channel region, as shown in Fig. 9. We suspect that the additional electric field induced by the polarization of the AlN spacer contributes to the difference in ns between the two devices.

On comparing Figs. 7 and 8, the MISHEMT with AlN spacer shows much higher ID at VG=0 and more negative VTH in regions with saturated ns. Fig. 9 compares the band structures of both devices using an Al0.63In0.04Ga0.33N barrier layer. As seen in the figure, the AlN spacer layer introduces significant band discontinuity at the GaN channel interface, resulting in a slightly deeper quantum well that enhances the confinement of the 2DEG47. For MISHEMT with an AlN spacer layer, the quantum well depth is about 0.396 eV below the Fermi level, compared to 0.385 eV for the device without an AlN spacer. The deeper quantum well results in higher ns and more negative VTH for the MISHEMT with an AlN spacer than the MISHEMT without an AlN spacer.

Furthermore, we conducted 2DEG channel mobility trends depending on device structures and barrier compositions. For devices with an AlN spacer layer, the calculated mobility consistently remains at approximately 1724 cm2V− 1s− 1 under zero-bias conditions for all Al and In compositions in the barrier layer. In contrast, for structures without the AlN spacer, the mobility exhibits the following trends: (a) With a fixed In composition of 0.03 and varying Al content, the mobility slightly decreases from 1579 to 1575 cm2V− 1s− 1 as the Al composition increases from 0.4 to 0.6. (b) With a fixed Al composition of 0.6 and varying In content, the mobility initially increases from 1575 to 1580 cm2V− 1s− 1 as the In composition increases from 0.03 to 0.13 but then declines to 1569 cm2V− 1s− 1 when the In composition is further increased to 0.19. The enhanced 2DEG mobility in devices with the AlN spacer layer is primarily attributed to reduced alloy scattering at the interface. This improvement arises because the AlN spacer forms a binary/binary interface with the GaN channel, rather than the quaternary/binary interface observed in structures without the spacer. Additionally, the AlN layer contributes a larger conduction band offset48,49. For devices without the AlN spacer layer, the slight decrease in mobility with increasing Al content is likely due to enhanced alloy disorder scattering50. The initial increase in mobility with increasing In content can be attributed to reduced lattice mismatch with GaN when In content is properly balanced with Al content (specifically, Al0.6In0.13GaN represents a lattice-matched barrier layer condition), which improves interface quality and reduces scattering. However, excessive In incorporation beyond this optimal point leads to compositional fluctuations, leading to degrade mobility.

While our study demonstrates the benefits of including an AlN spacer layer in enhancing 2DEG confinement and carrier density, there are critical trade-offs to be considered. Recent literature51 indicates that increasing AlN spacer thickness (e.g. from 0.7 nm to 1.5 nm) enhances sheet carrier density but may also degrade mobility due to increased interface roughness. Moreover, achieving high-quality and precise compositional control of the AlN spacer layer poseses fabrication challenges. The presence of gallium during growth can result in the formation of an Al-rich AlGaN layer instead of pure AlN, leading to reduced spontaneous polarization, altered interface characteristics, and diminished 2DEG mobility52,53. Additionally, while the spacer enhances carrier confinement, it may increase source/drain resistance if the device is not optimized, potentially affecting high-frequency performance54. These considerations highlight the need for a well-balanced device design when incorporating an AlN spacer layer in MISHEMT structures.

Conclusion

In this work, we conducted a comprehensive investigation of the compositional effects of AlxInyGazN barrier layers on the performance of AlxInyGazN/GaN MISHEMTs, focusing on drain current, 2DEG density, threshold voltage, and total polarization, using Sentaurus TCAD simulation. AlxInyGazN barrier with various group III element compositions, based on three lattice constant values representing different stress states, namely 3.167 Å (compressive stress), 3.186 Å (lattice matched), and 3.211 Å (tensile stress) were considered. The simulation results indicate that, regardless of the lattice constant value of AlxInyGazN, the higher Al composition in the barrier layer leads to larger spontaneous polarization, larger bandgap differences, larger conduction band offset, and deeper quantum well for 2DEG confinement. This, in turn, results in a larger sheet carrier density, more negative threshold voltage and increased drain current. Similarly, increasing the AlxInyGazN barrier layer thickness enhances carrier confinement, leading to a deeper quantum well. However, as In composition increases, the bandgap and total polarization decrease, thus resulting in the opposite effect as that of Al composition.Furthermore, by comparing AlxInyGazN/GaN MISHEMT with and without an AlN spacer layer, we observed that the presence of larger polarization of the AlN spacer significantly influences device performance. The systematic variation of AlxInyGazN compositions highlights the critical role of polarization differences at the channel interface and conduction band bending in the 2DEG region.

Our comprehensive investigation of AlInGaN/GaN MISHEMTs provides significant contributions to both cutting-edge research and industry practices in GaN device technology through several key advancements. By systematically quantifying the impact of Al, In, and Ga compositions on device behavior, we address a critical knowledge gap necessary for optimal device design. Our findings demonstrate that quaternary AlInGaN barriers can simultaneously achieve higher polarization and maintain lattice-matching with GaN by adjusting the ratios of group III elements. This provides a practical solution to the trade-off between polarization and crystal quality that constrains conventional AlGaN/GaN devices. The detailed analysis of the barrier thickness effect on 2DEG formation provides a design guideline for device scaling. The distinct impacts of Al and In compositions on total polarization offer new possibilities for engineering control of the 2DEG in the channel. Additionally, our comparative analysis regarding the incorporation of AlN spacer layers identifies the strategy to enhance carrier confinement and mobility in next-generation power and RF applications. These insights directly support semiconductor manufacturers in developing device structures with optimal performance for specific application requirements.

However, several key factors may influence the reliability of AlInGaN/GaN HEMTs: 1) Lattice-matching between the quaternary barrier layer with GaN channel can minimize interface mechanical stress and reduce defect generation; (2) Higher Al content may increase interface roughness since higher growth temperature may be required; 3) Higher In content (> 10%) may experience compositional instabilities at elevated temperatures due to segregation of In. Although these reliability concerns were not directly investigated in this work, they represent important trade-offs between performance enhancement and device lifetime that should be addressed in future experimental studies. For future work, we also plan to scale down the channel length of the AlInGaN/GaN MISHEMT, calibrate it with experimental RF devices, and investigate their RF and DC characteristics.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Vetury, R., Zhang, N. Q., Keller, S. & Mishra, U. K. The impact of surface States on the DC and RF characteristics of AlGaN/GaN hfets. IEEE Trans. Electron. Devices. 48 (3), 560–566 (2001).

Koley, G. & Spencer, M. G. On the origin of the two-dimensional electron gas at the algan∕ GaN heterostructure interface. Applied Phys. Letters, 86, 4, (2005).

Yu, E. T., Dang, X. Z., Asbeck, P. M., Lau, S. S. & Sullivan, G. J. Spontaneous and piezoelectric polarization effects in III–V nitride heterostructures. J. Vacuum Sci. Technol. B: Microelectron. Nanometer Struct. Process. Meas. Phenom. 17 (4), 1742–1749 (1999).

Bernardini, F. Spontaneous and Piezoelectric Polarization: Basic Theory vs. Practical Recipes, in Nitride Semiconductor Devices: Principles and Simulation, pp. 49–68. (2007).

Wu, Y. F. et al. High Al-content AlGaN/GaN modfets for ultrahigh performance. IEEE Electron Device Lett. 19 (2), 50–53 (1998).

Zhou, X. et al. Impact of bulk traps in GaN buffer on the gate-lag transient characteristics of AlGaN/GaN HEMTs, Solid-State Electronics, vol. 100, pp. 15–19, /10/01/ 2014. (2014).

Cao, Y. & Jena, D. High-mobility window for two-dimensional electron gases at ultrathin aln∕ GaN heterojunctions. Applied Phys. Letters, 90, 18, (2007).

Takayama, T., Yuri, M., Itoh, K., Baba, T. & Harris, J. S. Jr Analysis of phase-separation region in wurtzite group III nitride quaternary material system using modified valence force field model, Journal of Crystal Growth, vol. 222, no. 1, pp. 29–37, /01/01/ 2001. (2001).

Matsuoka, T. Calculation of unstable mixing region in wurtzite In1 – x–yGaxAlyN. Appl. Phys. Lett. 71 (1), 105–106 (1997).

Medjdoub, F. et al. High electron mobility in high-polarization sub-10 Nm barrier thickness InAlGaN/GaN heterostructure. Applied Phys. Express, 8, 10, p. 101001, 2015/09/16 2015.

Khan, M. A. et al. Lattice and energy band engineering in AlInGaN/GaN heterostructures. Appl. Phys. Lett. 76 (9), 1161–1163 (2000).

Weng, Y. C. et al. High current density and low Ron quaternary InAlGaN MIS-HEMT on Si for power applications. ECS J. Solid State Sci. Technology, 12, 7, p. 075003, 2023/07/13 2023.

Wosko, M., Paszkiewicz, B., Paszkiewicz, R. & Tlaczala, M. Influence of AlN spacer on the properties of AlGaN/AlN/GaN heterostructures. Optica Appl. 43 (1), 61–66 (2013).

Antoszewski, J. et al. Scattering mechanisms limiting two-dimensional electron gas mobility in al 0.25 Ga 0.75 n/gan modulation-doped field-effect transistors. J. Appl. Phys. 87 (8), 3900–3904 (2000).

Lombardi, C., Manzini, S., Saporito, A. & Vanzi, M. A physically based mobility model for numerical simulation of nonplanar devices. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 7 (11), 1164–1171 (1988).

Gassoumi, M., Helali, A., Maaref, H. & Gassoumi, M. DC and RF characteristics optimization of AlGaN/GaN/BGaN/GaN/Si HEMT for microwave-power and high temperature application. Results Phys. 12, 302–306 (2019). 2019/03/01/.

Dammann, M. et al. Reliability and degradation mechanism of AlGaN/GaN HEMTs for next generation mobile communication systems. Microelectron. Reliab. 49 (5), 474–477 (2009). 2009/05/01/.

Lu, X., Yu, K., Jiang, H., Zhang, A. & Lau, K. M. Study of interface traps in AlGaN/GaN mishemts using LPCVD SiNx as gate dielectric. IEEE Trans. Electron. Devices. 64 (3), 824–831 (2017).

Eller, B. S., Yang, J. & Nemanich, R. J. Electronic surface and dielectric interface States on GaN and AlGaN. Journal Vacuum Sci. & Technol. A, 31, 5, (2013).

Long, R. D. & McIntyre, P. C. Surface preparation and deposited gate oxides for gallium nitride based metal oxide semiconductor devices, Materials, vol. 5, no. 7, pp. 1297–1335, (2012).

Karmalkar, S., Shur, M. S. & Gaska, R. GaN-based Power High electron Mobility Transistors Edpp. 173–213 (World Scientific, 2003).

Jogai, B. Influence of surface States on the two-dimensional electron gas in AlGaN/GaN heterojunction field-effect transistors. J. Appl. Phys. 93 (3), 1631–1635 (2003).

Longobardi, G. et al. Impact of donor traps on the 2DEG and electrical behavior of AlGaN/GaN MISFETs, vol. 35, no. 1, pp. 27–29, (2013).

Ibbetson, J. P. et al. Polarization effects, surface States, and the source of electrons in AlGaN/GaN heterostructure field effect transistors. Appl. Phys. Lett. 77 (2), 250–252 (2000).

Klein, P. B. et al. Investigation of traps producing current collapse in AlGaN/GaN high electron mobility transistors. Electron. Lett. 37 (10), 1 (2001).

Saito, W. et al. Effect of buffer layer structure on drain leakage current and current collapse phenomena in high-voltage GaN-HEMTs. IEEE Trans. Electron. Devices. 56 (7), 1371–1376 (2009).

Silvestri, M., Uren, M. J. & Kuball, M. Iron-induced deep-level acceptor center in GaN/AlGaN high electron mobility transistors: energy level and cross section. Applied Phys. Letters, 102, 7, (2013).

Vigneshwara Raja, P., Nallatamby, J. C., DasGupta, N. & DasGupta, A. Trapping effects on AlGaN/GaN HEMT characteristics. Solid State Electron. 176, 107929 (2021). 2021/02/01/.

Wu, T. L. et al. Correlation of interface States/border traps and threshold voltage shift on AlGaN/GaN metal-insulator-semiconductor high-electron-mobility transistors. Applied Phys. Letters, 107, 9, (2015).

Mukherjee, K., Darracq, F., Curutchet, A., Malbert, N. & Labat, N. TCAD simulation capabilities towards gate leakage current analysis of advanced AlGaN/GaN HEMT devices. Microelectronics Reliability, vol. 76–77, pp. 350–356, (2017). 2017/09/01/.

Kwak, H. T. et al. Operational improvement of AlGaN/GaN high electron mobility transistor by an inner field-plate structure. Appl. Sci. 8 (6), 974 (2018).

Sentaurus, T. C. A. D. Device User Guide, vol. Version T-2022.03, (2022).

Shrestha, N. M. et al. Design and simulation of high performance lattice matched double barrier normally off AlInGaN/GaN HEMTs. IEEE J. Electron. Devices Soc. 8, 873–878 (2020).

Zine-eddine, T., Zahra, H. & Zitouni, M. Design and analysis of 10 Nm T-gate enhancement-mode MOS-HEMT for high power microwave applications. J. Science: Adv. Mater. Devices. 4 (1), 180–187 (2019).

Sakalauskas, E. et al. Dielectric function and optical properties of quaternary AlInGaN alloys. J. Appl. Phys. 110 (1), 013102 (2011).

Gorczyca, I., Suski, T., Christensen, N. E. & Svane, A. Band gap bowing in quaternary nitride semiconducting alloys. Applied Phys. Letters, 98, 24, (2011).

Tao, H. et al. Enhanced performance of N-polar AlGaN-based ultraviolet Light-Emitting diodes with Lattice-matched AlInGaN insertion in n-AlGaN layer. IEEE Photonics Journal, (2023).

Rahbardar Mojaver, H., Gosselin, J. L. & Valizadeh, P. Use of a bilayer lattice-matched AlInGaN barrier for improving the channel carrier confinement of enhancement-mode AlInGaN/GaN hetero-structure field-effect transistors. J. Appl. Phys. 121 (24), 244502 (2017).

Lee, D. S. et al. 300-ghz Inaln/gan Hemts with Ingan back barrier. IEEE Electron Device Lett. 32 (11), 1525–1527 (2011).

Chen, L. et al. Effect of InGaN Channel on Radio-Frequency Performance in High-Electron-Mobility Transistors with an InAlGaN Barrier, physica status solidi (a), vol. 219, no. 14, p. 2200024, 2022/07/01 2022.

Soh, C. B. et al. Influence of composition pulling effect on the two-dimensional electron gas formed at AlyInxGa1 – x–yN∕GaN interface. J. Appl. Phys. 98 (10), 103704 (2005).

Baskaran, S. et al. Modeling of 2DEG sheet carrier density and DC characteristics in spacer based AlGaN/AlN/GaN HEMT devices. Superlattices Microstruct. 64, 470–482 (2013).

Godwinraj, D., Pardeshi, H., Pati, S. K., Mohankumar, N. & Sarkar, C. K. Polarization based charge density drain current and small-signal model for nano-scale AlInGaN/AlN/GaN HEMT devices. Superlattices Microstruct. 54, 188–203 (2013). 2013/02/01/.

Ambacher, O. et al. Pyroelectric properties of al (In) GaN/GaN hetero-and quantum well structures. J. Phys.: Condens. Matter. 14 (13), 3399 (2002).

Wang, Z., Zhang, B., Chen, W., Li, Z., Closed-Form, A. & Charge control model for the threshold voltage of Depletion- and Enhancement-Mode AlGaN/GaN devices. IEEE Trans. Electron. Devices. 60 (5), 1607–1612 (2013).

Rahman, S., Othman, N. A. F., Hatta, S. W. M. & Soin, N. Optimization of graded AlInN/AlN/GaN HEMT device performance based on quaternary back barrier for high power application. ECS J. Solid State Sci. Technol. 6 (12), P805 (2017).

Jena, K., Swain, R. & Lenka, T. R. Impact of AlN spacer on analog performance of Lattice-Matched AlInN/AlN/GaN MOSHEMT. J. Electron. Mater. 45, 2172–2177 (2016).

Shen, L. et al. AlGaN/AlN/GaN high-power microwave HEMT. IEEE Electron Device Lett. 22 (10), 457–459 (2001).

Roensch, S. et al. Impact of AlN Spacer on electron Mobility of AlGaN/AlN/GaN Structures on Silicon, vol. 740, pp. 502–505 : Trans Tech Publ.

Li, Y. Theoretical Investigation on Electron Mobility in AlInGaN/InGaN Heterostructures, physica status solidi (b), vol. 256, no. 3, p. 1800704, 2019/03/01 2019.

Piotrowicz, C. et al. Influence of AlGaN n-type doping and AlN thickness on the two-dimensional electron gas density (ns) and resistance (R2DEG), Solid-State Electronics, vol. 201, p. 108594, /03/01/ 2023. (2023).

Li, H. et al. Unintentional gallium incorporation in AlN and its impact on the electrical properties of GaN/AlN and GaN/AlN/AlGaN heterostructures. Semicond. Sci. Technol. 30 (5), 055015 (2015).

Dai, S. et al. Unintentional incorporation of Ga in the nominal AlN spacer of AlInGaN/AlN/GaN heterostructure. Journal Phys. D: Appl. Physics, 51, 3, p. 035102, 2017/12/27 2018.

Nanjo, T. et al. Enhancement of drain current by an AlN spacer layer insertion in AlGaN/GaN high-electron-mobility transistors with Si-ion-implanted source/drain contacts. Jpn. J. Appl. Phys. 50, 064101 (2011).

Acknowledgements

The author would like to express sincere gratitude to Prof. Girish Pahwa for his invaluable support and guidance. His insightful explanations and in-depth understanding of semiconductor device physics greatly contributed to the technical aspects of this work. His mentorship has significantly enhanced my comprehension of the subject matter.

Funding

This work was partly supported by the National Science and Technology Council, Taiwan, under Grant NSTC 112-2622-E-A49-012-, 112-2622-8-A49-020-.

Author information

Authors and Affiliations

Contributions

CL and CHL performed conceptualization; CL did methodology; CHL and HCK approved validation; CL conducted investigation; CL drafted writing—original draft preparation; CL, CCT, and CHL prepared writing—review and editing: HCK and CHL did funding acquisition: EYC, CHL and HCK analyzed supervision. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Langpoklakpam, C., Tu, CC., Chang, E.Y. et al. The characteristics and polarization effects in AlInGaN barrier GaN MISHEMT with various compositions of group III elements. Sci Rep 15, 22970 (2025). https://doi.org/10.1038/s41598-025-02995-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-02995-9