Abstract

In this research, a novel reservoir stimulation scheme combining impermeable artificial barriers and high-conductivity artificial fractures was introduced for gas hydrate extraction from clayey silt deposits, and the injection-production performance was numerically investigated using hydrates at the Shenhu SH2 site as the typical case scenario. The results indicated that impermeable barriers effectively addressed the challenges including boundary water intrusion, decomposition gas leakage, and injected hot fluid loss. Especially, artificial barriers and fractures exert a synergistic stimulation effect of “1 + 1 > 2”. The average gas production rate increased logarithmically as fracture conductivity increased, whereas the gas-to-water ratio and energy ratio, presented an opposite trend. The impact of injection pressure and production pressure on productivity was limited relative to hot water temperature, whereas low-temperature and low-pressure injection were more conducive to water control and energy utilization. Furthermore, parameter optimization based on multivariate nonlinear models suggested that commercial productivity and the Class II development standard for offshore gas reservoirs were expected to be achieved. Therefore, the combination of artificial fractures and impermeable boundaries is promising for clayey silt hydrate reservoir stimulation, offering a viable development mode for marine challenging hydrate.

Similar content being viewed by others

Introduction

Natural gas hydrate (NGH) is a cage-like crystalline compound composed of gas molecules (mainly CH4) and water molecules widely deposited in submarine sediments and permafrost regions1. Due to its vast reserves and clean combustion, NGH is considered a promising energy source that will play a pivotal role in the future energy supply and climate environment2.

Since the 1980s, countries including the United States, Russia, Japan, China, India, and South Korea have recognized the huge potential of NGH and therefore have conducted several resource surveys and research projects3. Nevertheless, the vast majority of NGH is stored in weak/unconsolidated sediments on the seafloor, and its commercial production faces technical challenges such as deep-sea drilling4,5,6, wellbore stabilization7, sand production8, gas leakage9,10, and seafloor slide11, which greatly limit the commercialization process12,13. Particularly, most NGH deposits are characterized by high thermodynamic stability, low initial temperatures, low reservoir permeability, and lack of impermeable boundary layers, which are termed challenging hydrates because of greater extraction difficulty14. The NGH in the Shenhu Area of the South China Sea is hosted in low-permeability clayey silt deposits with permeable boundary layers, which are the main type of challenging hydrate. However, significant advances have been made in the trial production of Shenhu hydrates indicating that gas recovery from this challenging deposit is viable15.

The premise of hydrate extraction is to break its equilibrium and release methane gas from the water molecule cages, with viable ways including depressurization, thermal stimulation, gas displacement, and chemical inhibitors3. Of these, depressurization combined with thermal fluid injection is widely considered to be highly potential, especially for sandy deposits with high permeability16. However, it may be not promising for gas recovery from clayey silt deposits. First, the extremely low effective reservoir permeability severely inhibits fluid flow and pressure–temperature transmission, resulting in a limited well control area17,18,19,20. Second, the permeable cover exacerbates interlayer contradictions, such as ineffective pressure relief due to boundary water intrusion, weak stimulation due to massive injected heat losses, and methane leakage due to the escape of decomposed gases to the overburden21,22,23. Especially the environmental problems caused by gas leakage induced by NGH dissociation have become a growing concern recently. Skarke et al.10 pointed out that methane emissions from permeable seafloor may be an important input of atmospheric methane. Pillsbury et al.24 observed methane bubbles released from the seafloor at the western Atlantic margin. McGinnis et al. (2006), Zhang et al. (2015), and Brown et al. (2016) suggest that methane releases induced by future-scaled NGH development could affect the global carbon cycle and exacerbate the greenhouse effect9,25,26. Consequently, exploring the safe and efficient extraction method of challenging hydrates has become a hot topic.

To enhance the production potential of challenging hydrates, various development modes involving hydraulic fracturing and horizontal wells techniques have been proposed, as depicted in Table 1. These studies have demonstrated the effectiveness of reservoir stimulation techniques in enhancing productivity through extensive numerical simulations27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43. Particularly, hydraulic fracturing shows attractive potential as it dramatically improves the mass and heat transfer efficiency within the NGH deposits. However, little attention has been paid to boundary water intrusion, methane leakage, and injection heat loss. Given the low strength and weak consolidated characteristics of NH deposits, hydraulic fracturing may disrupt the integrity of the seabed, and the uncontrolled NGH dissociation it induces may increase the risk of gas leakage. E.g., in the Shenhu hydrate simulation, more than 15,000 m3 of gas escaped into the permeable boundary layers under a unit horizontal well section43. Additionally, considerable injected heat loss and boundary water intrusion were observed, which was detrimental to energy utilization and water control.

Water intrusion is a common issue in reservoirs containing marginal or bottom water44. Currently, the primary solution is creating impermeable artificial barriers using sealing and plugging materials, such as cement, to cut off the hydraulic connection between the reservoir and the aquifer45,46,47,48,49. This water control concept can be integrated into NGH development. Moreover, artificial barriers also increase the resistance to hot water and gas migration to the permeable cover layers, which may be promising for the safe and efficient extraction of marine NGH.

This study proposed a novel reservoir stimulation method, including the use of high-conductivity artificial fractures to improve reservoir mass and heat transfer efficiency and the use of impermeable artificial barriers to address boundary water intrusion, decomposition gas escape, and injected heat loss. Furthermore, the injection-production behavior was numerically investigated with challenging Shenhu hydrates at the SH2 site as a case study, and the influences of key parameters were analyzed. Therefore, compared with previous similar studies, the proposed mode comprehensively considers gas–water production, gas leakage, and energy utilization, and is expected to provide new insights for the safe and efficient exploitation of challenging hydrates.

Numerical modeling

Wellbore-reservoir model

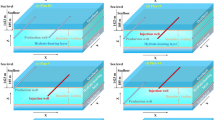

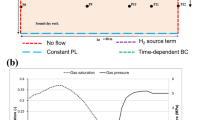

The clayey silt NGH deposit at the Shenhu SH2 site, in the South China Sea, is taken as a case study. The hydrate-bearing layer (HBL) is located 185 m below the seafloor (mbsf), with a thickness of 0–44 m, and 40 m is taken here for modeling50. To accurately simulate reservoir temperature–pressure transfer, the thicknesses of the overlayer (OL) and underlayer (UL) are set to be 80 m. A three-spot horizontal well pattern was used36,37,39,40, wherein all horizontal well sections were located in the middle of the reservoir with a well spacing of 100 m. In addition, reservoir properties are assumed to be homogeneous along the well axis, and thus only a unit horizontal well section was modeled. As a result, the model size was 200 m × 200 m × 1 m, as depicted in Fig. 1.

Reservoir stimulation scheme

The reservoir stimulation consists of 2 processes: fracturing the HBL and sealing the permeable OL and UL, with a feasible scheme given as follows.

First, one horizontal artificial fracture is created between wells by hydraulic fracturing technology (Fig. 1), which has been commonly used to improve inter-well heat and mass transfer efficiency36,37,38. It should be noted that, although NGH deposition has the characteristics of low strength and weak/unconsolidated, several researches have proved that hydraulic fractures can be generated from the sample scale51,52,53,54,55. Nevertheless, due to the complex and uncertain geostress state of deep-sea sedimentary laye, fracture morphology cannot be determined yet. Here, referring to previous studies29,36,37,43,56, it is assumed that a horizontal fracture is formed with a fracture half-length of 100 m and fracture width of 0.01 m.

Second, chemical sealing and plugging techniques were employed to create impermeable horizontal artificial barriers at the top and bottom of the HBL (Fig. 1). As early as 1962, this idea of creating horizontal barriers for controlling water coning was proposed49. Subsequently, a variety of chemical water shutoff agents was developed, such as gel and polymer, thus making it feasible to create large artificial barriers with the processes of “injection, migration, plugging, and stabilization”44,46,48. E.g., Bai et al.45 achieved “long-distance, long-lasting” profile control in oil reservoirs using in-situ generation of dispersed gel particles under reservoir conditions.

After the artificial barriers and fractures were built, production was initiated using depressurization and hot water injection, as depicted in Fig. 1. Referring to previous studies, the intermediate wells inject thermostatic hot water at a constant injection pressure, whereas the lateral wells produce at a constant bottom-hole pressure36,37,38. It should be noted that wellbore stability was not considered in this study. Given that hydraulic fracturing may disrupt the integrity of the formation, in particular, hydrate dissociation can further weaken the formation strength and induce issues such as fracture closure and submarine landslide. All of these pose significant challenges to wellbore stabilization. These geomechanical issues need to be addressed in further research.

Generalization of the artificial barrier and the fracture

The artificial barriers and fractures were generalized as porous media. The thickness of the artificial barrier was assumed to be 1 m, and there was no fluid flow. In addition, the fluid flow in the artificial fractures followed the continuous multiphase Darcy’s law:

The relative permeabilities model in Ref.57 is employed:

The aqueous phase pressure is described as:

Gas–water capillary pressure is given by Ref.58:

The diffusive mass flux in the gas phase is calculated by:

Gas tortuosity is given by Ref.59:

The diffusive mass fluxes of water vapor and methane gas satisfy the following relationship:

Numerical code and initial conditions

TOUGH + HYDRATE (T + H), specially developed for the simulation of methane hydrate deposition systems, was adopted because of its internationally recognized reliability60,61. Furthermore, T + H has been widely used in the production performance evaluation of Shenhu hydrates, demonstrating its superior mine-scale simulation capability19,62,63.

Given the connectivity of pore water in permeable deposits, the reservoir pressure is calculated from the hydrostatic pressure gradient, as follows.

Reservoir temperature is derived by the geothermal gradients, as follows.

Model parameters are listed in Table 2.

Model validation

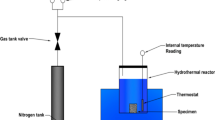

The reliability of the reservoir model was confirmed using the field data from Shenhu second test site, as shown in Fig. 2. The reservoir properties in the validation model were consistent with the test site15, and the production pressure of the horizontal well was 3 MPa. It was reported that the cumulative gas production (VG) for 30 days was 861,400 m3 at the optimal horizontal well section length of 250–300 m, while the same amount of gas was produced at a horizontal well section length of 260 m in our simulation. As a result, the simulation results match the field test data, proving the effectiveness of the reservoir model.

Simulation scheme

Table 3 shows the detailed simulation cases. First, the stimulation potential of artificial fractures and/or artificial barriers was evaluated, with the NGH reservoir without stimulation as the base case. Then, the sensitivity of fracture conductivity (CF), hot water temperature (TI), injection pressure (PI), and production pressure (PP) were examined to obtain optimal plans.

Evaluation of production performance

NGH decomposition behavior was evaluated by the gas release rate from NGH dissociation (QH, m3/d) and the NGH decomposition rate (RH) defined by:

When RH is 1, it signifies the complete decomposition of the hydrate. The corresponding time was identified as the hydrate decomposition cycle (THD, days).

Gas production behavior was analyzed by gas production rate (QG, m3/d), cumulative gas production (VG, m3), and gas recovery ratio (RE) defined by:

RG value of 1 means that the gas contained in the NGH reservoir is completely recovered. Thus, the corresponding time was defined as the gas recovery cycle (TGR, days).

Water production behavior was analyzed by the gas–water ratio (RGW) defined by:

Energy output to input was defined as the energy ratio (RE) to evaluate the economy of the system as follows64:

Referring to the production index of offshore water-driven reservoirs, an RG of 0.85 indicates that the secondary development standard has reached65. Therefore, the average QG, RGW, and RE at RG of 0.85 were used for evaluating production performance.

Result analysis

The effect of artificial fracture and impermeable barriers

Figure 3 shows the production performance of the un- and reconstructed NGH reservoir. In case 1, QH exhibits four phases including rise, fall, stabilization, and decay (Fig. 3a). This variation could be elucidated by the reservoir physical field distribution depicted in Figs. 4, 5, 6, and 7. During the initial phase, the increase in the hot water wave area enhanced QH (Fig. 4a), reaching a peak value of 100 m3/d at 360 days. After that, the injection pressure was released (Fig. 5a–c), and a considerable amount of hot water flowed into permeable covers (Figs. 4b). Thus, the thermal stimulation effect diminished, resulting in a decrease in QH, and eventually stabilized at 40–60 m3/d. With the advancement of the thermal decomposition front (Figs. 4a–c), the inter-well NGH was gradually decomposed (Figs. 6a–c). At 4000 days, the inter-well NGH was nearly completely decomposed, forming a high-seepage channel. The subsequent water flooding of the producing wells (known as the thermal breakthrough) and the decreasing amounts of NGH led to a dramatic decline in QH. In Case 2, the variation of QH shows a steady period before the thermal breakthrough (~ 2880 days) and a subsequent decay phase. The mechanics for this is that the impermeable barrier maintains high injection pressure (Figs. 4d–f), and also, hot water loss (Figs. 5d–f) and gas escape (Figs. 7a–f) are successfully addressed. As a result, NGH decomposition efficiency was greatly improved (Figs. 6a–f), and the thermal breakthrough time was shortened from 4000 to 2880 days.

In Case 3, QH rose for a short time and then dropped sharply. The mechanics for this phenomenon is that hot water primarily flowed along the high-conductivity fracture (Fig. 4g–i), which increased the hot water wave area and thus greatly improved the NGH decomposition efficiency (Figs. 6a–i). However, this also led to a premature thermal breakthrough (~ 360 days) that released the injection pressure (Figs. 5g–i). Subsequently, QR decreased as the NGH decomposition front gradually moved away from the fracture (Figs. 7g–i). It is noteworthy that, while the fracture enhanced inter-well fluid flow efficiency, it can not effectively prevent methane leakage (Figs. 7g–i), a finding consistent with previous studies40,42,43. In Case 4, the change in QH, as well as the evolution of reservoir temperature- (Figs. 4g–l), pressure- (Figs. 5g–l), and NGH distributions (Figs. 6g–l) are comparable to those observed in Case 3. One difference is that no gas escaped (Fig. 7g–l), demonstrating the necessity of reconstructing the permeable cover.

As shown in Fig. 3b, the change in QG for Cases 1 and 2 is similar. During the first 1400 days, QG was at a low level (15–25 m3/d) as thermal decomposition gas had not yet been transported to the production wells (Figs. 7a–f). Subsequently, as more and more gas was recovered, QG gradually increased and peaked at 73 and 100 m3/d in Cases 1 and 2, respectively, indicating that the presence of artificial barriers improved the displacement efficiency. After that, QG gradually decayed due to the thermal breakthrough. In Cases 3 and 4, since the fracture greatly enhanced NGH decomposition efficiency and provided high-conductivity channels for gas recovery (Fig. 7g–l), QG increased dramatically and stabilized at 105–125 and 130–175 m3/d, respectively. Hence, gas production is maximized when both the HBL and cover are reconstructed.

As shown in Fig. 3c, the THD for both Case 1 and Case 2 is approximately 4700 days, suggesting that artificial barriers have a limited effect on NGH decomposition. Whereas in Cases 3 and 4, THD is shortened to 2100 days, indicating that fracturing is an effective method for improving the NGH decomposition efficiency. Similarly, the TGR for Case 1 is over 5760 days (Fig. 3d), whereas it is shortened to 5500, 4440, and 2800 days for Cases 2–4, respectively. This indicates that both artificial barriers and fractures are beneficial for gas recovery. Additionally, the final Vg in Case 3 is 23.99 × 104 m3, lower than the 24.27 × 104 m3 in Cases 2 and 4. This indicated that 2800 m3 of gas escaped into the cover in Case 3 (Fig. 7g–i). Consequently, artificial boundaries are critical for the safe and efficient extraction of challenging hydrates.

As depicted in Fig. 3e, the change in RGW in Case 1 shows two phases of decrease and then increases with the minimum value of 5.83, representing the thermal decomposition gas transported to the production well. However, in Case 2, RGW shows an increase and then a decrease with a peak value of 30.06, corresponding to the thermal breakthrough time. The final RGW in Case 2 is 25.10, 15.36 higher than that in Case 1. This suggested that artificial barriers effectively impeded boundary water intrusion. In Case 3, the decreasing trend in RGW indicated that the artificial fracture enhanced the water yield more significantly, relative to gas production, resulting in the lowest final RGW of 6.71. In Case 4, the change in RGW is similar to that in Case 2, with a final value of 16.24. This value is increased by 178% and 142% relative to those of Cases 1 and 3, respectively.

The final RE for Cases 1 and 3 is 0.91 and 0.76, respectively, indicating that not feasible in terms of energy utilization. This is consistent with previous findings that thermal-based hydrate dissociation was inefficient as a lot of injected heat was wasted on non-productive sinks (the grains of the porous media and the native water)66. For the case in this study, heat loss caused by permeable boundaries is also an important factor. The final RE for Cases 2 and 4 is enhanced to 2.94 and 1.68, respectively, indicating that the use of impermeable barriers greatly improves the feasibility of heat injection for NGH extraction. Notably, the energy evaluation in this study is relatively harsh, and RE could be further improved if the deeper (and possibly more saline) geothermal water from the same ___location can be used. This is a potential direction for further plan optimization.

Overall, artificial barriers are favorable for water control and energy utilization, but have a limited enhancement in gas production; artificial fractures can substantially improve extraction efficiency, but would also induce high water yield. Consequently, simultaneous reconstruction of the reservoir and cover could obtain ideal production performance.

Influence of fracture conductivity

Figure 8 depicts the production performance at different CF values. As can be seen from Fig. 8a, NGH decomposition efficiency increases as CF increases. When CF increased from 1 to 10 D cm, the peak value of QH increased from 100 to 194 m3/d, 1.20–2.33 times higher than that of Case 1. The mechanism responsible for this is that high-conductivity fractures are more favorable for inter-well heat and mass transfer. When CF was increased to 50 D·cm, initial QD was greatly improved (\(>\) 300 m3/d) and then decreased sharply due to the premature thermal breakthrough. Furthermore, there was almost no variation in QH when CF was further increased to 100 D·cm. This indicated that the hot water flow rate in the fracture was too high to allow sufficient heat exchange with the reservoir, resulting in an ineffective increased injection.

The changes in QG in Fig. 8b are similar to those in QD. As can be seen, the initial QG increased from 38 to more than 300 m3/d as CF increased from 1 to 100 D·cm, 3.83–40.3 times higher than that of Case 1. In particular, the thermal decomposition gas could be recovered efficiently at the initial production stage when CF reached 10 D·cm. The THD is 3570, 2450, 2080, 1768, and 1730 days at CF of 1, 5, 10, 50, and 100 D·cm, respectively (Fig. 8a, c). The reduction is 1110, 2230, 2600, 2912, and 2950 days, respectively, in comparison to the no-fracture scenario (4680 days). Similarly, the TGR is 4360, 3195, 2800, 2355, and 2270 days at CF of 1, 5, 10, 50, and 100 D·cm, respectively (Fig. 8b,d). The reduction is 1210, 2375, 2770, 3215, and 3300 days, respectively, in comparison to the no-fracture scenario (5570 days). As a result, increasing CF is conductive to NGH decomposition and gas recovery, but the enhancement gradually decreases.

The final RGW decreased from 22.74 to 2.89 as CF increased from 1 to 100 D·cm (Fig. 8e), indicating that the increase in CF was more significant in increasing water yield relative to the enhancement of gas production. Similarly, the final RE decreased from 2.68 to 0.34 as CF increased from 1 to 100 D·cm (Fig. 8f). Overall, artificial fractures greatly improved extraction efficiency, and CF values of 1–10 D·cm are recommended.

It is important to note that the current sensitivity analysis on CF is relatively ideal due to the lack of referenceable engineering cases. In fact, it may be challenging to keep fractures open given the weak/unconsolidated characteristics of NGH deposits, especially after hydrate there dissociation, which plays a cementing role. That is, CF may decay as production proceeds, even to reach the intrinsic permeability of the hydrate-free deposits. Consequently, future attention should be paid to the effect of fracture closure on production performance.

Influence of injection pressure

Figure 9 shows the production performance at different PI values. As can be seen, PI mainly affected the initial QH (Fig. 9a) and QG (Fig. 9b). This is because the increase in PI improved the fluid flow rate in the fracture and shortened the thermal breakthrough time. As PI increased from 17 to 22 MPa, THD was reduced from 2340 to 1960 days (Fig. 9c), and TGR was reduced from 3250 to 2520 days (Fig. 9d). This indicated that a high PI was conducive to NGH decomposition and gas recovery, while the enhancement was not pronounced. The final RGW decreased from 17.87 to 12.61 (Fig. 9e), and the final RE decreased from 2.13 to 1.49 (Fig. 9f) as PI increased from 17 to 22 MPa. This suggested that an increase in PI was detrimental to water control and energy utilization, as inducing more severe water flooding. Overall, a low-pressure injection is recommended.

Influence of hot water temperature

Figure 10 shows the production performance at different TI values. It can be seen that increasing TI is conducive to NGH extraction because of the increased heat transfer efficiency. When TI increased from 40 to 90 °C, the peak value of QH increased from 114 to 212 m3/d (Fig. 10a), the maximum QG increased from 100 to 127 m3/d (Fig. 10b), THD reduced from 2700 to 1615 days (Fig. 10c), and TGR reduced from 3380 to 2230 days (Fig. 10d). The influence of TI on the final RGW was very limited (Fig. 10e), whereas its impact on RE was pronounced. Specifically, an increase in TI from 40 to 90 °C resulted in a notable decline in RE, from 3.12 to 0.94 (Fig. 10f). Overall, moderate TI is recommended to balance gas recovery and energy utilization.

Influence of production pressure

Figure 11 shows the production performance at different PP values. PP mainly improved QH and QG in the first 300 days, as lower PP promoted NGH decomposition around the production wells (Fig. 11a,b). When PP increased from 3 to 6 MPa, THD increased from 1830 to 2340 days (Fig. 11c), and TGR increased from 2550 to 3020 days (Fig. 11d). Thus, the improvement in extraction efficiency by lowering PP was limited. In addition, the influence of PP on RGW and RE diminished as production progressed and hardly affected the final RGW and RE (Figs. 11e,f). As a result, a low PP value is suggested at the initial production stage.

Discussion

Synergistic effects of artificial fractures and impermeable barriers

Figure 12 shows the average QG, RGW, and RE at RG of 0.85 for different simulation cases. The average QG increases by 9 and 52 m3/d for Cases 2 and 3, respectively, relative to Case 1, whereas their sum is lower than the enhancement of 89 m3/d in Case 4 (Fig. 12a). This demonstrates that the artificial fracture and artificial barriers have a synergistic stimulation of “1 + 1 > 2”. Additionally, the average QG increases with the increases of CF, PI, and TI and the decreases of PP. The RGW for Cases 2 and 4 are 2.50 and 2.00 times higher than those for Cases 1 and 3 (Fig. 12b), respectively, suggesting that boundary water intrusion is effectively addressed by artificial barriers. This finding is critical for improving the production performance of challenging hydrates. RGW decreases with increasing CF and PI but is almost unaffected by TI and PP. In addition, the change in RE is similar to the change in RGW, except that TI has a significant effect on RE (Fig. 12c).

Development plan optimization

The one-factor fitting results of average QG, RGW, and RE at RG of 0.85 are shown in Fig. 13. The CF is logarithmically correlated with average QG, RGW, and RE (Figs. 13a–c), while PI and PP are linearly correlated with them (Figs. 13d–f,j–l). For TI, its relationship with average QG, RGW, and RE is presented as linear, quadratic, and exponential, respectively (Figs. 13g–i).

Based on the results of the single factor analysis, further multivariate nonlinear regression analysis was carried out, as shown in Table 4. The multiple R-squared (R2) were higher than 0.97 and all the fitted parameters were significant, indicating the reliability of the fitted equations. Notably, TI and PP are not significant to RGW, and PP is not significant to RE.

The fitted multiple regression equations can be used to predict production performance and optimize engineering parameters, as shown in Fig. 14.

When CF is 10 D·cm and PP is 4.5 MPa, QG, RE, and RGW versus injection parameters are plotted in Figs. 14a–c. Assuming that the target average QG of the unit horizontal well section reaches 100 m3/d (a horizontal well length of 500 m can reach the commercial gas production threshold of 50,000 m3/d16) and finally RE of 2.0, respectively, the satisfying zone of PI and TI are presented in Fig. 14d. When TI is 50 °C, the corresponding interval of values of PI is 16.15–21.6 MPa. Consequently, commercial development is possible by using the proposed plan.

Conclusions

This study proposes a novel reservoir stimulation scheme combining artificial fractures and artificial barriers for marine challenging hydrates and numerically investigates the production potential with Shenhu hydrates as a case study.

-

1.

The proposed reservoir stimulation scheme effectively addresses boundary water intrusion, gas escape, and thermal fluid loss faced by challenging hydrate extraction, while obtaining considerable productivity, gas-to-water ratio, and energy ratio, providing a promising development mode for the safe and efficient development of challenging hydrates.

-

2.

Although extraction efficiency improves greatly with fracture conductivity increases, premature thermal breakthroughs are detrimental to water control and energy utilization. Particularly, when the fracture conductivity is increased to a certain level, its effect on productivity is no longer significant and is not economically viable in terms of energy utilization. Consequently, the extent of reservoir reconstruction for challenging hydrates is not as great as it could be.

-

3.

Increasing hot water temperature improves extraction efficiency greatly but decreases the energy ratio; whereas injection and production pressures have a limited effect on productivity, and high injection pressures are not conducive to water control and energy utilization. As a result, moderate hot water temperature and low injection pressure are recommended here.

-

4.

Commercial production of hydrates from marine clayey silt deposits with artificial fractures and impermeable barriers is possible. Moreover, impermeable barriers are indispensable for improving the injection-production performance, especially for deposits with fractures, as uncontrolled hydrate dissociation exacerbates the risk of gas leakage. Consequently, future implementation of hydraulic fracturing in hydrate trail sites requires fine control of fracture morphology.

The present research initially demonstrates the effectiveness of the proposed reservoir stimulation method for marine challenging hydrate extraction. However, the setup of impermeable barriers and artificial fractures in the model was relatively ideal, and geomechanical issues such as closure of fractures, failure of barriers, as well as wellbore stability were not considered. In addition, as a case study, sensitivity analysis of parameters such as rock properties was not carried out. Given that the particular physicomechanical properties of NGH deposition and the geomechanical problems induced by its exploitation are one of the global focuses. Therefore, a comprehensive consideration of the above issues and a combination of physical and numerical simulations are needed in the future to further demonstrate the feasibility of the proposed development mode.

Data availability

Data used in this study are available from the corresponding author by request.

Abbreviations

- NGH:

-

Natural gas hydrate

- OL:

-

Overlayer

- HBL:

-

Hydrate-bearing layer

- UL:

-

Underlayer

- \(F\) :

-

Darcy flux (kg/m2)

- \(k\) :

-

Intrinsic permeability of sediment (m2)

- \({k}_{r}\) :

-

Relative permeability (m2)

- \(\rho\) :

-

Density (kg/m3)

- \(\mu\) :

-

Fluid viscosity (Pa s)

- \(S\) :

-

Saturation (dimensionless)

- \(P\) :

-

Pressure (Pa)

- \(\mathbf{g}\) :

-

Gravitational acceleration (m/s2)

- \(X\) :

-

Mass fraction (dimensionless)

- \(b\) :

-

Klinkenberg b-factor accounting for gas slippage effects (Pa)

- \(\mathbf{J}\) :

-

Diffusive mass flux (kg/(m2 s))

- \({S}_{ir}\) :

-

Irreducible saturation (dimensionless)

- \(n\) :

-

Permeability reduction exponent (dimensionless)

- \({P}_{cGW}\) :

-

Gas–water capillary pressure (Pa)

- \({P}_{0}\) :

-

Initial pressure (Pa)

- \(\vartheta\) :

-

Pore structure index (dimensionless)

- \(\tau\) :

-

Tortuosity (dimensionless)

- \(D\) :

-

Multicomponent molecular diffusion coefficient (dimensionless)

- \(\phi\) :

-

Porosity (dimensionless)

- \({P}_{res}\) :

-

Reservoir pressure (Pa)

- \({P}_{atm}\) :

-

Atmospheric pressure (Pa)

- \(Z\) :

-

Distance from the seafloor to sea level (m)

- \({h}_{mbsf}\) :

-

Meter below the seafloor (m)

- \({T}_{res}\) :

-

Reservoir temperature (°C)

- \({T}_{sf}\) :

-

Seafloor temperature (°C)

- \(\Delta T\) :

-

Geothermal gradient (°C/m)

- Superscript \(\kappa\) :

-

Components \(w\) (water) or \(m\) (methane)

- Subscript \(A\) :

-

Aqueous phase

- Subscript \(G\) :

-

Gaseous phase

- \({\text{Q}}_{\text{H}}\) :

-

CH4 release rate from NGH dissociation (m3/d)

- \({\text{R}}_{\text{H}}\) :

-

NGH decomposition ratio (dimensionless)

- \({\text{m}}_{\text{dec}}\) :

-

Decomposed NGH mass (kg)

- \({\text{m}}_{\text{ori}}\) :

-

Origin NGH mass in the reservoir (kg)

- \({\text{Q}}_{\text{G}}\) :

-

Gas production rate (m3/d)

- \({\text{V}}_{\text{G}}\) :

-

Cumulative gas production (m3)

- \({\text{R}}_{\text{G}}\) :

-

Gas recovery ratio (dimensionless)

- \({\text{R}}_{\text{GW}}\) :

-

Gas-to-water ratio (dimensionless)

- \({\text{V}}_{\text{W}}\) :

-

Cumulative water production (m3)

- \({\text{R}}_{\text{E}}\) :

-

Energy ratio (dimensionless)

- \({\text{M}}_{\text{gas}}\) :

-

Combustion enthalpy of CH4 under standard conditions (J)

- \({\text{C}}_{\text{W}}\) :

-

Specific heat of water (J/(kg °C))

- \({\text{M}}_{\text{inj}}\) :

-

Mass of injected water (kg)

- \({\text{T}}_{\text{I}}\) :

-

Hot water temperature (°C)

- \({\text{T}}_{0}\) :

-

Initial water temperature (°C)

- \({\text{C}}_{\text{F}}\) :

-

Fracture conductivity (D cm)

- \({\text{P}}_{\text{I}}\) :

-

Injection pressure (MPa)

- \({\text{P}}_{\text{P}}\) :

-

Production pressure (MPa)

References

Klauda, J. B. & Sandler, S. I. Global distribution of methane hydrate in ocean sediment. Energy Fuels 19, 459–470. https://doi.org/10.1021/ef049798o (2005).

Makogon, Y. F. Natural gas hydrates-a promising source of energy. J. Nat. Gas Sci. Eng. 2, 49–59. https://doi.org/10.1016/j.jngse.2009.12.004 (2010).

Li, X. et al. Investigation into gas production from natural gas hydrate: A review. Appl. Energy 172, 286–322. https://doi.org/10.1016/j.apenergy.2016.03.101 (2016).

Gizatullin, R., Dvoynikov, M., Romanova, N. & Nikitin, V. Drilling in gas hydrates: Managing gas appearance risks. Energies 16, 2387. https://doi.org/10.3390/en16052387 (2023).

Khurshid, I., Lee, K. J. & Choe, J. Analyses of thermal disturbance in drilling deep and high temperature formations. Energy Sour. Part A: Recovery Util. Environ Effects 35, 1487–1497. https://doi.org/10.1080/15567036.2010.529562 (2013).

Chen, H. et al. Research on the formation and plugging risk of gas hydrate in a deepwater drilling wellbore: A case study. Processes 11, 488. https://doi.org/10.3390/pr11020488 (2023).

Khurshid, I., Lee, K.-j., Bahk, J.-j. & Choe, J. In Paper Presented at the Offshore Technology Conference, Houston, Texas, USA, May 2010.

Chong, Z. R., Yang, S. H. B., Babu, P., Linga, P. & Li, X. Review of natural gas hydrates as an energy resource: Prospects and challenges. Appl. Energy 162, 1633–1652. https://doi.org/10.1016/j.apenergy.2014.12.061 (2016).

Zhang, Y. & Zhai, W.-D. Shallow-ocean methane leakage and degassing to the atmosphere: Triggered by offshore oil-gas and methane hydrate explorations. Front. Mar. Sci. https://doi.org/10.3389/fmars.2015.00034 (2015).

Skarke, A., Ruppel, C., Kodis, M., Brothers, D. & Lobecker, E. Widespread methane leakage from the sea floor on the northern US Atlantic margin. Nat. Geosci. 7, 657–661. https://doi.org/10.1038/ngeo2232 (2014).

Kayen, R. E. & Lee, H. J. Pleistocene slope instability of gas hydrate-laden sediment on the Beaufort sea margin. Mar. Geotechnol. 10, 125–141. https://doi.org/10.1080/10641199109379886 (1991).

Moridis, G. J. et al. Toward production from gas hydrates: Current status, assessment of resources, and simulation-based evaluation of technology and potential. SPE Reserv. Eval. Eng. 12, 745–771. https://doi.org/10.2118/114163-pa (2009).

Moridis, G. J. J. et al. Challenges, uncertainties, and issues facing gas production from gas-hydrate deposits. SPE Reserv. Eval. Eng. 14, 76–112. https://doi.org/10.2118/131792-pa (2011).

Moridis, G. J., Reagan, M. T., Boyle, K. L. & Zhang, K. Evaluation of the gas production potential of some particularly challenging types of oceanic hydrate deposits. Transp. Porous Media 90, 269–299. https://doi.org/10.1007/s11242-011-9762-5 (2011).

Ye, J. et al. The second natural gas hydrate production test in the South China Sea. China Geol. 3, 197–209. https://doi.org/10.31035/cg2020043 (2020).

Consortium, M. R. http://www.mh21japan.gr.jp/mh21wp/wp-content/uploads/mh21form2017_doc01.pdf. (2017).

Wang, B. et al. Influence of intrinsic permeability of reservoir rocks on gas recovery from hydrate deposits via a combined depressurization and thermal stimulation approach. Appl. Energy 229, 858–871. https://doi.org/10.1016/j.apenergy.2018.08.056 (2018).

Feng, J., Wang, Y. & Li, X. Entropy generation analysis of hydrate dissociation by depressurization with horizontal well in different scales of hydrate reservoirs. Energy 125, 62–71. https://doi.org/10.1016/j.energy.2017.02.104 (2017).

Su, Z., He, Y., Wu, N., Zhang, K. & Moridis, G. J. Evaluation on gas production potential from laminar hydrate deposits in Shenhu Area of South China Sea through depressurization using vertical wells. J. Pet. Sci. Eng. 86–87, 87–98. https://doi.org/10.1016/j.petrol.2012.03.008 (2012).

Ahmadi, G., Ji, C. & Smith, D. H. Production of natural gas from methane hydrate by a constant downhole pressure well. Energy Convers. Manag. 48, 2053–2068. https://doi.org/10.1016/j.enconman.2007.01.015 (2007).

Gao, Y., Yang, M., Zheng, J. & Chen, B. Production characteristics of two class water-excess methane hydrate deposits during depressurization. Fuel 232, 99–107. https://doi.org/10.1016/j.fuel.2018.05.137 (2018).

Sun, J. et al. Numerical simulation of gas production from hydrate-bearing sediments in the Shenhu area by depressurising: The effect of burden permeability. J. Unconv. Oil Gas Resour. 12, 23–33. https://doi.org/10.1016/j.juogr.2015.08.003 (2015).

Bhade, P. & Phirani, J. Effect of geological layers on hydrate dissociation in natural gas hydrate reservoirs. J. Nat. Gas Sci. Eng. 26, 1549–1560. https://doi.org/10.1016/j.jngse.2015.05.016 (2015).

Pillsbury, L. & Weber, T. C. Fate of methane gas bubbles emitted from the seafloor along the Western Atlantic Margin as observed by active sonar. J. Acoust. Soc. Am. 137, 2361–2361. https://doi.org/10.1121/1.4920575 (2015).

McGinnis, D. F., Greinert, J., Artemov, Y., Beaubien, S. E. & Wüest, A. Fate of rising methane bubbles in stratified waters: How much methane reaches the atmosphere?. J. Geophys. Res. https://doi.org/10.1029/2005jc003183 (2006).

Brown, P. et al. Impacts and effects of ocean warming on carbon management including methane hydrates. In Explaining Ocean Warming: Causes, Scale, Effects and Consequences. https://doi.org/10.1201/b18442-10 (2016).

Chen, C. et al. Simulation study on the effect of fracturing technology on the production efficiency of natural gas hydrate. Energies 10, 1241. https://doi.org/10.3390/en10081241 (2017).

Feng, Y. et al. Enhancement of gas production from methane hydrate reservoirs by the combination of hydraulic fracturing and depressurization method. Energy Convers. Manag. 184, 194–204. https://doi.org/10.1016/j.enconman.2019.01.050 (2019).

Sun, J. et al. Gas production from a silty hydrate reservoir in the South China Sea using hydraulic fracturing: A numerical simulation. Energy Sci. Eng. 7, 1106–1122. https://doi.org/10.1002/ese3.353 (2019).

Yu, T., Guan, G., Wang, D., Song, Y. & Abudula, A. Gas production enhancement from a multilayered hydrate reservoir in the South China Sea by hydraulic fracturing. Energy & Fuels 35, 12104–12118. https://doi.org/10.1021/acs.energyfuels.1c01785 (2021).

Lv, T. et al. Numerical evaluation of long-term depressurization production of a multilayer gas hydrate reservoir and its hydraulic fracturing applications. Energy & Fuels 36, 3154–3168. https://doi.org/10.1021/acs.energyfuels.1c04017 (2022).

Feng, Y. et al. Numerical analysis of gas production from layered methane hydrate reservoirs by depressurization. Energy 166, 1106–1119. https://doi.org/10.1016/j.energy.2018.10.184 (2019).

Yin, F. et al. Numerical investigation on the long-term production behavior of horizontal well at the gas hydrate production site in South China Sea. Appl. Energy 311, 118603. https://doi.org/10.1016/j.apenergy.2022.118603 (2022).

Jin, G. et al. Enhancement of gas production from low-permeability hydrate by radially branched horizontal well: Shenhu Area, South China Sea. Energy 253, 124129. https://doi.org/10.1016/j.energy.2022.124129 (2022).

Yu, T., Guan, G., Abudula, A. & Wang, D. 3D investigation of the effects of multiple-well systems on methane hydrate production in a low-permeability reservoir. J. Nat. Gas Sci. Eng. 76, 103213. https://doi.org/10.1016/j.jngse.2020.103213 (2020).

Zhong, X. et al. Evaluation of the gas production enhancement effect of hydraulic fracturing on combining depressurization with thermal stimulation from challenging ocean hydrate reservoirs. J. Nat. Gas Sci. Eng. 83, 103621. https://doi.org/10.1016/j.jngse.2020.103621 (2020).

Chen, C. et al. Research on the influence of injection-production parameters on challenging natural gas hydrate exploitation using depressurization combined with thermal injection stimulated by hydraulic fracturing. Energy & Fuels 35, 15589–15606. https://doi.org/10.1021/acs.energyfuels.1c02134 (2021).

Ju, X. et al. Gas production from hot water circulation through hydraulic fractures in methane hydrate-bearing sediments: THC-coupled simulation of production mechanisms. Energy & Fuels 34, 4448–4465. https://doi.org/10.1021/acs.energyfuels.0c00241 (2020).

Zhong, X. et al. Fracture network stimulation effect on hydrate development by depressurization combined with thermal stimulation using injection-production well patterns. Energy 228, 120601. https://doi.org/10.1016/j.energy.2021.120601 (2021).

Zhong, X. et al. Commercial production potential evaluation of injection-production mode for CH-Bk hydrate reservoir and investigation of its stimulated potential by fracture network. Energy 239, 122113. https://doi.org/10.1016/j.energy.2021.122113 (2022).

Nie, S., Li, J., Liu, K., Zhong, X. & Wang, Y. Numerical evaluation of commingled production potential of marine multilayered gas hydrate reservoirs using fractured horizontal wells and thermal fluid injection. J. Mar. Sci. Eng. 12, 365. https://doi.org/10.3390/jmse12030365 (2024).

Nie, S. et al. Numerical simulation of a new methodology to exploit challenging marine hydrate reservoirs without impermeable boundaries. J. Nat. Gas Sci. Eng. 96, 104249. https://doi.org/10.1016/j.jngse.2021.104249 (2021).

Nie, S. et al. Numerical evaluation of a novel development mode for challenging oceanic gas hydrates considering methane leakage. Sustainability 14, 14460. https://doi.org/10.3390/su142114460 (2022).

Guo, P. et al. Chemical water shutoff agents and their plugging mechanism for gas reservoirs: A review and prospects. J. Nat. Gas Sci. Eng. 104, 104658. https://doi.org/10.1016/j.jngse.2022.104658 (2022).

Bai, Y., Pu, W., Jin, X., Shen, C. & Ren, H. Review of the micro and Macro mechanisms of gel-based plugging agents for enhancing oil recovery of unconventional water flooding oil reservoirs. J. Mol. Liq. 399, 124318. https://doi.org/10.1016/j.molliq.2024.124318 (2024).

Liu, K., Zhu, W. & Pan, B. Laboratory evaluation on oil-soluble resin as selective water shut-off agent in water control fracturing for low-permeability hydrocarbon reservoirs with bottom aquifer. Geoenergy Sci. Eng. 225, 211672. https://doi.org/10.1016/j.geoen.2023.211672 (2023).

Tang, M. et al. Experimental investigation on plugging performance of nanospheres in low-permeability reservoir with bottom water. Adv. Geo-Energy Res. 6, 95–103. https://doi.org/10.46690/ager.2022.02.02 (2022).

Yue, P., Du, Z., Chen, X. & Liang, B. The critical rate of horizontal wells in bottom-water reservoirs with an impermeable barrier. Pet. Sci. 9, 223–229. https://doi.org/10.1007/s12182-012-0202-0 (2012).

Karp, J. C., Lowe, D. K. & Marusov, N. Horizontal barriers for controlling water coning. J. Pet. Technol. 14, 783–790. https://doi.org/10.2118/153-pa (1962).

Wu, N. et al. Gas hydrate system of Shenhu Area, Northern South China Sea: Geochemical results. J. Geol. Res. 1–10, 2011. https://doi.org/10.1155/2011/370298 (2011).

Too, J. L., Cheng, A., Khoo, B. C., Palmer, A. & Linga, P. Hydraulic fracturing in a penny-shaped crack. Part II: Testing the frackability of methane hydrate-bearing sand. J. Nat. Gas Sci. Eng. 52, 619–628. https://doi.org/10.1016/j.jngse.2018.01.046 (2018).

Zhang, W. et al. Experimental study of hydraulic fracture initiation and propagation in highly saturated methane-hydrate-bearing sands. J. Nat. Gas Sci. Eng. 79, 103338. https://doi.org/10.1016/j.jngse.2020.103338 (2020).

Ma, X., Jiang, D., Sun, Y. & Li, S. Experimental study on hydraulic fracturing behavior of frozen clayey silt and hydrate-bearing clayey silt. Fuel 322, 124366. https://doi.org/10.1016/j.fuel.2022.124366 (2022).

Nie, S. S., Zhong, X. P., Song, J., Tu, G. G. & Chen, C. Experimental study on hydraulic fracturing in clayey-silty hydrate-bearing sediments and fracability evaluation based on multilayer perceptron-analytic hierarchy process. J. Nat. Gas Sci. Eng. 106, 104735. https://doi.org/10.1016/j.jngse.2022.104735 (2022).

Nie, S. et al. Research on hydraulic fracture propagation patterns in multilayered gas hydrate reservoirs using a three-dimensional XFEM-based cohesive zone method. Energy & Fuels 38, 5106–5123. https://doi.org/10.1021/acs.energyfuels.3c05015 (2024).

Ma, X., Sun, Y., Guo, W., Jia, R. & Li, B. Numerical simulation of horizontal well hydraulic fracturing technology for gas production from hydrate reservoir. Appl. Ocean Res. 112, 102674. https://doi.org/10.1016/j.apor.2021.102674 (2021).

Stone, H. L. Probability model for estimating three-phase relative permeability. J. Pet. Technol. 22, 214–218. https://doi.org/10.2118/2116-pa (1970).

van Genuchten, M. T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 44, 892–898. https://doi.org/10.2136/sssaj1980.03615995004400050002x (1980).

Millington, R. J. & Quirk, J. P. Permeability of porous solids. Trans. Faraday Soc. 57, 1200. https://doi.org/10.1039/tf9615701200 (1961).

Moridis, G. J. Numerical studies of gas production from methane hydrates. SPE J. 8, 359–370. https://doi.org/10.2118/87330-pa (2003).

Moridis, G., Kowalsky, M. & Pruess, K. TOUGH+ Hydrate V1. 0 User’s Manual. Report LBNL-0149E. Lawrence Berkeley National Laboratory, Berkeley, CA. (2008).

Li, G., Moridis, G. J., Zhang, K. & Li, X. Evaluation of gas production potential from marine gas hydrate deposits in Shenhu Area of South China Sea. Energy & Fuels 24, 6018–6033. https://doi.org/10.1021/ef100930m (2010).

Li, G., Moridis, G. J., Zhang, K. & Li, X.-S. The use of huff and puff method in a single horizontal well in gas production from marine gas hydrate deposits in the Shenhu Area of South China Sea. J. Pet. Sci. Eng. 77, 49–68. https://doi.org/10.1016/j.petrol.2011.02.009 (2011).

Feng, J.-C., Wang, Y., Li, X.-S., Li, G. & Zhang, Y. Three dimensional experimental and numerical investigations into hydrate dissociation in sandy reservoir with dual horizontal wells. Energy 90, 836–845. https://doi.org/10.1016/j.energy.2015.07.110 (2015).

Li, Z. Basic Theory and Technology Of Waterflooding Oilfield Development 68–70 (Science Press Beijing, 2019).

Moridis, G. J. & Reagan, M. T. Strategies for gas production from oceanic class 3 hydrate accumulations. Offshore Technology Conference, Houston, Texas, U.S.A., April 2007. https://doi.org/10.4043/18865-MS (2007).

Acknowledgements

This work was funded by project ZR2024QD212 supported by Shandong Provincial Natural Science Foundation and project QN2024286 supported by Science Research Project of Hebei Education Department.

Author information

Authors and Affiliations

Contributions

S.N. and Y.H. proposed the methodology; K.L. and K.X. conducted the investigation; X.Z. and Y.W. developed the numerical model; S.N. and Y.H. analyzed the results; and J.S. and J.L. collected the data. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Nie, S., Liu, K., Zhong, X. et al. Numerical investigation of production performance of challenging gas hydrates from deposits with artificial fractures and impermeable barriers. Sci Rep 15, 5361 (2025). https://doi.org/10.1038/s41598-025-87460-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-87460-3