Abstract

The synthesis of multi-carbon (C2+) fuels via electrocatalytic reduction of CO, H2O using renewable electricity, represents a significant stride in sustainable energy storage and carbon recycling. The foremost challenge in this field is the production of extended-chain carbon compounds (Cn, n ≥ 3), wherein elevated *CO coverage (θco) and its subsequent multiple-step coupling are both critical. Notwithstanding, there exists a “seesaw” dynamic between intensifying *CO adsorption to augment θco and surmounting the C-C coupling barrier, which have not been simultaneously realized within a singular catalyst yet. Here, we introduce a facilely synthesized lattice-strain-stabilized nitrogen-doped Cu (LSN-Cu) with abundant defect sites and robust nitrogen integration. The low-coordination sites enhance θco and concurrently, the compressive strain substantially fortifies nitrogen dopants on the catalyst surface, promoting C-C coupling activity. The n-propanol formation on the LSN-Cu electrode exhibits a 54% faradaic efficiency and a 29% half-cell energy efficiency. Moreover, within a membrane electrode assembly setup, a stable n-propanol electrosynthesis over 180 h at a total current density of 300 mA cm−2 is obtained.

Similar content being viewed by others

Introduction

The electrochemical reduction reaction of carbon dioxide and carbon monoxide (CO2/CORR), powered by renewable energy, has surfaced as an efficacious strategy for carbon cycle management1,2,3. Multi-carbon compounds (C2+), such as ethylene4, acetate5, ethanol6, and n-propanol7, are highly prized for their substantial energy density and wide-ranging applications. Cu-based catalysts have shown promising CO adsorption strength, facilitating efficient C–C coupling and the generation of C2+ chemicals8. Despite considerable advancements in converting CO to C2 products for industrial use, achieving elevated selectivity and reaction rates for extended-chain carbon products (Cn, n ≥ 3) remains a formidable challenge9,10. The synthesis of C3 compounds on Cu surfaces is hindered by suboptimal Faradaic efficiency (FEs < 50%), energy efficiency (EEs < 25%), and long-period stability7,11,12,13,14,15,16,17,18,19,20.

A critical factor in producing extended-chain carbon compounds is enhancing *CO coverage (θco) on catalyst surfaces, thus promoting the coupling with *C2 intermediates4,7,19,21,22. Surface defects like steps, stacking faults (SFs), and grain boundaries (GBs) have proven effective in increasing *CO adsorption, thereby raising its surface coverage16,20,23,24. However, excessive *CO adsorption can inhibit C–C coupling, leading to the hydrogen evolution reaction (HER) as a counterproductive side reaction, which restricts selectivity improvements in C3 production, especially at higher overpotentials5,25. Thus, catalyst design faces the task of increasing surface θco while ensuring efficient C–C coupling for CO-to-C3 conversion, especially at high electrolysis rates (>100 mA cm−2)26,27,28.

Heteroatom engineering, including non-metallic doping (nitrogen (N)29, sulfur (S)30, fluorine (F)31,32, chlorine (Cl)33, etc.) has been explored for modulating the chemical state32, introducing vacancies30,34, and modifying *CO adsorption29 on metal sites to enhance C–C coupling35,36,37, while suppressing HER competition. Introducing non-metallic dopants onto a defect-rich surface may thus promote C–C coupling under high *CO coverage, conducive to the formation of longer-chain carbon compounds. Nonetheless, these non-metallic atoms tend to be unstable and are gradually removed under electrochemical conditions38,39, leading to a metallic Cu and a significant decline in catalytic activity. Notably, N dopants on Cu-based catalysts have demonstrated relatively high stability35,40, remaining intact under CO2/CORR conditions due to their strong metal-N bond energies41,42. However, catalyst stability is still insufficient (<10 h) for industrial applications13,29,34, as N atoms gradually vanish, leading to structural collapse.

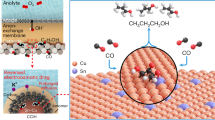

Recently, lattice strain has been identified as a direct factor in oxygen deficiency in transition metal-based catalysts. Specifically, compressive strain can mitigate the formation of oxygen vacancies43. Therefore, we propose that an appropriate lattice strain may stabilize N dopants, thereby augmenting its stability in catalysts. To this end, we have developed a facile synthesis of a lattice strain-stabilized nitrogen-doped Cu (LSN-Cu) catalyst via N2 plasma treatment on CuO surfaces, followed by an electroreduction step. This plasma treatment, previously reported40,42,44, introduces defect sites, compressive lattice strain, and surface nitrogen doping spontaneously. These low-coordinated defect sites on the LSN-Cu surface enhance *CO adsorption, leading to increased θco. Concurrently, the compressive lattice-strain-stabilized N dopant bolsters C–C coupling capability, significantly boosting the likelihood of carbon chain elongation under heightened θco, and thus ensuring optimal C3 formation and elevated stability. Utilizing the LSN-Cu catalyst, we achieved a FEn-propanol of 54 ± 3%, a n-propanol half-cell EE of 29%, and a 71 ± 7 mA cm−2 partial current density for n-propanol production. Furthermore, in a membrane electrode assembly (MEA) setting, we sustained stable electrochemical n-propanol synthesis for 180 h at a current density of 300 mA cm−2.

Results

Synthesis and characterization of the N-CuOx pre-catalyst

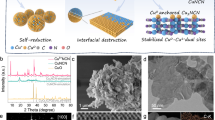

The initial synthesis of CuO nanosheets (Supplementary Fig. 1) was followed by N2 plasma treatment to yield N-doped CuO (N-CuOx) precursors. The treatment durations, 600, 900, and 1200 s, were varied for comparison and labeled as N-CuOx-s, N-CuOx, and N-CuOx-l, respectively. X-ray diffraction (XRD) analysis of these precursors revealed that the fundamental CuO lattice structure remained intact post-treatment (Fig. 1a). An increase in plasma treatment duration led to a marginal shift in the XRD diffraction peaks at ~35.4° (aligned with the (002) plane of CuO) towards higher angles, indicating slight lattice contraction in the N-CuOx samples. Concurrently, a decrease in the intensity ratio of the 35.4° (CuO(002)) to 38.6° (CuO(111)) peaks from 5.4 to 3.2 was observed (Supplementary Fig. 2), suggesting that plasma treatment may disrupt the flake structure of CuO particles. The Raman spectroscopy of the N-CuOx samples showed a blue shift compared to pristine CuO, corroborating lattice shrinkage as indicated by XRD (Fig. 1b)45. Scanning electron microscopy (SEM) imaging revealed surface and edge roughening of CuO nanosheets after plasma treatment (Supplementary Fig. 3), further affirming the structural disintegration consistent with XRD results. Transmission electron microscopy (TEM) and high-resolution TEM (HRTEM) images, alongside selected area electron diffraction (SAED) patterns, demonstrated a transformation from a single crystal to a polycrystalline structure in the CuO nanosheets during plasma treatment (Fig. 1c–h, Supplementary Figs. 4, 5). This change is attributed to the development of stacking faults (SFs) and grain boundaries (GBs). Notably, the presence of a Cu2O phase in the N-CuOx samples was evident in SAED patterns (Fig. 1g). HRTEM imaging of N-CuOx revealed lattice fringe spacings of 0.24 and 0.20 nm, corresponding to the Cu2O(111) and Cu2O(200) planes, respectively (Fig. 1h), signifying that the Cu2O phase predominantly emerges on the N-CuOx surface. The lattice spacings in N-CuOx were slightly compressed compared to those in pristine Cu2O. Energy dispersive X-ray spectroscopy (EDX) elemental mapping showed an even distribution of Cu, O, and N elements on the N-CuOx surface, indicating successful incorporation of N atoms from the plasma treatment (Fig. 1i). High-resolution X-ray photoelectron spectroscopy (XPS) analysis further confirmed N atom integration into the CuO lattice and the emergence of Cu+ species on the N-CuOx surface (Supplementary Fig. 6). These results align with EDX and SAED findings. Crystallographic geometric phase analysis (GPA), based on high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images, was performed to evaluate surface lattice strain on the N-CuOx surface (Supplementary Fig. 7)46. GPA analyses revealed an even distribution of axial strain (ɛxx) of ~4% across the N-CuOx surface, with shear strain (ɛxy) predominantly along the SFs, reaching up to 4%. This indicates that shear strain occurs primarily along SFs, while axial strain originates from lattice compression.

a XRD patterns of the N-CuOx and CuO samples and the partial magnification of the corresponding diffraction peaks of the (002) facets in XRD patterns. b The Raman spectra of N-CuOx and CuO samples. c, e TEM images of the CuO particles (c) and corresponding SAED pattern (d), Scale bar 50 nm (c), 5 1/nm (d). e HRTEM images of the CuO particles. Scale bar, 20 nm. f, g TEM images of the N-CuOx particles (f) and corresponding SAED pattern (g), Scale bar, 50 nm (f), 5 1/nm (g). h HRTEM images of the N-CuOx-900 particles. Scale bar, 20 nm. i STEM images and corresponding EDS elemental mapping images of the N-CuOx. Scale bar, 100 nm. Source data are provided as a Source Data file.

X-ray absorption spectroscopy (XAS) provided insights into the electronic structure and coordination environment of the N-CuOx samples. Cu K-edge X-ray absorption near-edge structure (XANES) exhibited a lower energy level shift in the absorption edge with increasing plasma treatment, indicative of Cu+ species formation during N2 plasma treatment (Supplementary Fig. 8a). Extended X-ray absorption fine structure (EXAFS) spectra and fitting analysis (Supplementary Figs. 8b, 9, and Supplementary Table 1)47 revealed a reduction in the coordination number of Cu-O/N from 3.8 to 3.4 and a decrease in bond lengths of Cu–Cu and Cu–O/N paths, signifying oxygen vacancy formation and lattice contraction. Wavelet-transform (WT)-EXAFS analysis at the Cu K-edge indicated that the WT maximum of the Cu–O/N path in the N-CuOx (4.7 Å−1) has a lower k-value compared to the CuO (5.1 Å−1) (Supplementary Fig. 10), suggesting that nitrogen doping alters the electronic structure within the N-CuOx samples48,49.

Formation and characterization of the LSN-Cu catalyst

The LSN-Cu catalyst, derived from N-CuOx precursors via an in-situ electroreduction process in a CO gas environment at −0.43 V versus the reversible hydrogen electrode (RHE), underwent a substantial transition from the CuO lattice to a Cu-based lattice, as revealed by XRD analysis (Supplementary Fig. 11). This transition was highlighted by the distinct resolution of the (111) and (200) planes, characteristic of Cu. SEM and TEM investigations confirmed that GBs and SFs, introduced by plasma treatment, were retained in the LSN-Cu samples post-lattice reorganization (Fig. 2a and Supplementary Figs. 12, 13). HRTEM images and corresponding SAED patterns disclosed the coexistence of Cu+ and Cu0 regions within the LSN-Cu, identifiable by lattice fringe spacings corresponding to the Cu2O(111), Cu2O(200), Cu(111), and Cu(200) planes (Fig. 2b, c). In contrast, the CuO precursor predominantly displayed only Cu(200) and Cu(111) planes (Supplementary Fig. 14), indicating transformation to a pristine Cu catalyst. HAADF-STEM imaging revealed a ~4% decrease in the Cu(200) plane spacing in the LSN-Cu catalyst compared to pristine Cu, suggesting a compression strain on the LSN-Cu surface (Supplementary Fig. 15). HAADF-based GPA showed the persistence of both axial strain (ɛxx) and shear strain (ɛxy) across the LSN-Cu surfaces, with average strains of about 4%, while negligible lattice strain was observed in the pristine Cu sample (Fig. 2d). EDX elemental mapping confirmed a uniform distribution of Cu, O, and N elements across the LSN-Cu catalyst, indicating stabilization of the N and O atoms (Supplementary Fig. 16). XPS analysis provided insights into the local electronic structure of the LSN-Cu catalyst (Fig. 2e and Supplementary Fig. 17). The surface nitrogen content, quantified at about 4.9%, showed N 1s binding energy peaks indicative of lattice nitrogen atoms and nitrogen vacancies at approximately 398 and 400 eV, respectively34. This differs from the singular peak near 398 eV on the N-CuOx sample, suggesting partial depletion of N atoms and formation of N vacancies during the CORR. However, the presence of a lattice N atoms peak (~398 eV) in LSN-Cu suggests the incorporation of nitrogen as lattice atoms, implying stable N doping in the Cu2O lattice during the CORR. Comparative GPA and XPS analysis of post-CORR N-CuOx-s and N-CuOx-l samples (now the LSN-Cu-s and LSN-Cu-l) revealed average lattice strains of approximately 2% and 6%, respectively (Supplementary Fig. 18). Notably, nitrogen content in the LSN-Cu (4.9%) was significantly higher than in the LSN-Cu-s (2.1%) and the LSN-Cu-l (2.8%), suggesting that optimal lattice strain might stabilize nitrogen dopants during CORR (Supplementary Table 2).

a, b TEM images of the LSN-Cu particles (a) and corresponding SAED pattern (b), Scale bar, 200 nm (a), 5 1/nm (b). c HRTEM images of the LSN-Cu particles. Scale bar, 2 nm. d Atomic resolved-HRTEM image and the corresponding GPA simulations for shear strain (ɛxy) and axial strain (ɛxx) analyses of the pristine Cu and LSN-Cu catalysts. Scale bar, 1 nm. e High-resolution N 1s spectra of the LSN-Cu catalyst. The spectra of the Cu catalyst were listed for comparison. f The operando Fourier-transformed Cu K-edge EXAFS k2χ of the LSN-Cu catalyst under the CORR. g The formation energies of oxygen vacancies on the N-doped and pristine Cu2O/Cu surface with different lattice compression (0%, 2%, 4%, and 6%), inset, the N-doped Cu2O/Cu interfaces model. Orange, red, and purple spheres represent Cu, O, and N atoms, respectively. Source data are provided as a Source Data file.

Operando XAS analysis at −0.53 V (vs. RHE) provided insights into the charge state and coordination environment of the LSN-Cu samples during CORR. Quick-scanning XAS (QXAS) and linear combination analysis (LCA) showed a partial reduction of Cu2+ species in N-CuOx to Cu0 and Cu+ states within the initial 10 min (Supplementary Fig. 19a) to form the LSN-Cu catalyst50. The LSN-Cu maintained a stable oxidation state predominantly featuring Cu+ species, in contrast to the rapid transition of the CuO sample to metallic Cu (Supplementary Fig. 19b). LCA results based on operando Cu K-edge XANES spectra revealed average oxidation states of the LSN-Cu-s, the LSN-Cu, and the LSN-Cu-l as 0.13 ± 0.01, 0.27 ± 0.01, and 0.18 ± 0.01 during CORR, respectively (Supplementary Fig. 20a–d). The LSN-Cu with 4% compressive strain exhibited the highest concentration of Cu+ species (Supplementary Fig. 20e), suggesting an optimal compressive strain stabilizes the Cu2O lattice and preserves stable N doping. To assess the impact of lattice strain on Cu2O lattice stabilization, QXAS tests on argon plasma-treated CuO (Ar-CuOx) were conducted. The Ar-CuOx sample, undergoing CORR, transformed into a lattice-strained Cu (LS-Cu) catalyst with a surface structure and compressive strain similar to the LSN-Cu (Supplementary Fig. 21) but without nitrogen atom incorporation. QXAS analysis on LS-Cu samples (LS-Cu, LS-Cu-s, and LS-Cu-l) revealed a similar trend in Cu reduction, with an initial increase followed by a decrease in Cu+ species concentration (Supplementary Fig. 22a–c). The LS-Cu sample demonstrated the slowest Cu+ reduction rate, suggesting that optimal lattice strain can prevent loss of N and O atoms and facilitate Cu2O lattice stabilization (Supplementary Fig. 22d). Moreover, operando EXAFS analysis on the LSN-Cu, the LS-Cu, and the Cu samples (Fig. 2f, Supplementary Figs. 23, 24, Supplementary Tables 3, 4)47 revealed bond lengths in the LSN-Cu indicative of Cu–O/N and Cu–Cu pathways, in contrast to the sole Cu–Cu pathway observed in the LS-Cu and the Cu samples. Morlet WT-EXAFS patterns supported these findings, showing features of the Cu–O/N shell in LSN-Cu distinct from the Cu catalyst (Supplementary Figs. 25 and 26).

To more comprehensively understand the impact of lattice compressive strain on the stabilization of the Cu2O lattice and subsequent preservation of nitrogen dopants, density functional theory (DFT) simulations were meticulously performed. DFT reveals that the formation energies of oxygen vacancies (Vo) are significantly increased under conditions of compressive strain, both on the pristine Cu2O/Cu surface and the nitrogen-doped Cu2O/Cu surface (Supplementary Fig. 27 and Supplementary data 1). This increase in formation energies is most pronounced at a compressive strain of 4% applied to the model surface, where the Vo formation energies peak (Fig. 2g). The elevated formation energies under these conditions imply an enhanced resistance to oxygen removal from the reactive surface, thereby contributing to the stabilization of the Cu2O lattice to preserve the nitrogen dopants. Consequently, it can be deduced that an optimal lattice strain, specifically at 4%, can effectively modulate oxophilicity on the nitrogen-doped Cu surface. This modulation significantly augments the stability of nitrogen atoms as integral components of the lattice structure, thereby surpassing the stability of dissociative nitrogen species29.

CO adsorption and C–C coupling on the LSN-Cu Catalyst

We carried out the temperature-programmed desorption of CO (CO-TPD) test to evaluate the CO adsorption ability of the LSN-Cu, LS-Cu and Cu samples (Fig. 3a). The main desorption peaks for the LSN-Cu (460, 520 °C), and for the LS-Cu (399, 492 °C) obviously occur at higher temperatures than that of the Cu sample (303, 379 °C), suggesting stronger *CO bindings on both the LSN-Cu and LS-Cu sample.

a CO-TPD profile of the LSN-Cu and the Cu catalysts. b–d Operando Raman spectra of the LSN-Cu (b), LS-Cu (c), and the Cu (d) samples under CORR. e Peak frequencies of LFB of C ≡ O stretch as a function of applied potential. The straight lines represent the linear fitting results, of which the slopes represent the Stark tuning rates. f Normalized v(CO–CO) peak area (with the v(CO–CO)/(HFB + LFB) as a function) of applied potential for different studied catalysts. The potential is presented with a 70% iR correction. Source data are provided as a Source Data file.

To further understand the role of the LSN-Cu catalyst plays in CO adsorption and C–C coupling, we performed operando Raman measurements under CORR conditions. The bands located at ~283 and ~363 cm−1 are associated with the frustrated rotation and the stretching of *CO on Cu sites14,51, respectively. We observed a blueshift of the Cu–CO stretching band on the LSN-Cu and LS-Cu catalysts, as compared with that on the Cu surface (Supplementary Fig. 28), indicating a stronger binding of *CO on the LSN-Cu and LS-Cu surface, as the CO-TPD results. Besides, the bands observed in the 1950–2100 cm−1 range arising from the stretching of C ≡ O were observed to split into two distinct peaks, a low-frequency band (LFB) located at ~2030 cm–1 and a high-frequency band (HFB) at ~2070 cm–1, arise from the *CO adsorbed on the terrace and step sites52,53,54, respectively (Fig. 3b–d). Furthermore, it is worth noting that an additional band at ~1990 cm–1 was observed, which can be attributed to the interaction among *CO intermediates (vco–co), based on the DFT calculations and previous literature (Supplementary Table 5)33,55,56. A differential response in the electrochemical vibrational Stark effect of the intermediate *CO band was observed among the three catalyst types. Figure 3e illustrates that all electrodes experienced a redshift of the LFB band at more negative potentials, with the LSN-Cu exhibiting the most significant Stark tuning slopes (73.8 cm−1 V−1 in the range of −0.48 to −0.69 V versus RHE). This suggests an intensified interaction between *CO and the catalyst surface, leading to higher *CO coverage57. It has been reported that at elevated *CO coverages, adsorption tends to occur preferentially on step sites26. Consequently, the HFB ratio (HFB/(HFB + LFB)) in the *CO adsorption bands is also an essential indicator for assessing *CO coverage on defect-rich nitride/oxide-derived Cu catalysts (Supplementary Fig. 29). Both the LSN-Cu and LS-Cu catalysts demonstrated significantly higher HFB ratios compared to the Cu sample, which can be ascribed to the creation of low-coordinated defect sites (GBs and SFs) enhancing *CO binding and thus increasing surface *CO coverage. It can be observed that the HFP ratio on the LS-Cu sample is slightly higher than that on the LSN-Cu, within the potential range of −0.53 to −0.58 V (vs. RHE). However, a consistently high HFB ratio above −0.58 V was exclusively observed for the LSN-Cu sample. This indicates that the LSN-Cu surface stabilizes the low-coordinated defect sites induced by plasma treatment, resulting in a sustained high *CO coverage across various applied potentials7. Moreover, the vco–co bands (at ~1990 cm–1) provide direct insights into the CO–CO coupling ability of the catalysts. Normalized integrated peak areas (Fig. 3f) reveal that the LSN-Cu catalyst displays significantly enhanced CO dimerization capability across all examined potentials. In contrast, the LS-Cu catalyst exhibits slightly diminished CO–CO coupling ability compared to the CuO sample, likely due to the increased *CO adsorption strength on the LS-Cu surface, which potentially impedes CO–CO couplings7,28. These observations underscore that the low-coordinated defect sites formed through plasma treatments facilitate *CO adsorption, maintaining high *CO coverage on the catalyst surface. The incorporation of nitrogen notably aids in enhancing CO dimerization capabilities.

To confirm the n-propanol formation mechanism on the LSN-Cu catalyst, we conducted operando electrochemical attenuated total reflection surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS) under CORR conditions. As shown in Supplementary Fig. 30, peaks in the range of 2000–2100 cm−1, associated with *CO adsorption58, split into two bands: the low-frequency band (LFB) at ~2025–2058 cm−1 and the high-frequency band (HFB) at ~2060–2083 cm−1. The *CO-HFB on the LSN-Cu catalyst is more abundant and located at a higher wavenumber range (~2071–2083 cm−1) compared to that on the Cu catalyst (~2061–2065 cm−1). Additionally, the stack turning effect of the LFB bands on the LSN-Cu is significantly larger, indicating higher *CO coverage on the defect-rich LSN-Cu surface, consistent with the operando Raman results (Fig. 3e). In the range of 1150–1700 cm−1, we observed two peaks around 1230 and 1589 cm−1, attributed to the C–O–H and C=O stretching modes of the hydrogenated CO dimer (*COCOH)59,60, respectively. The ATR-SEIRAS spectra show that *COCOH occurs at −0.50 V (vs. RHE) on the LSN-Cu catalyst. In contrast, the *COCOH peaks are much weaker on the Cu catalyst and appear at more negative potentials (−0.7 V vs. RHE). This indicates that *COCOH is more strongly and stably preserved on the LSN-Cu at applied potentials, which aligns with the superior CO-to-n-propanol selectivity of the LSN-Cu catalyst. Another peak at ~1161 cm−1 was also observed on the catalysts, which is more intense on the LSN-Cu sample than on the Cu sample. This suggests that *CO on the LSN-Cu surface more favorably undergoes hydrogenation to form *COH60,61, a key species for *COCOH formation, potentially promoting C–C coupling through the *CO–*COH pathway. The peak assignments are also confirmed by our DFT calculations (Supplementary Table 5). Additionally, peaks of bidentate carbonate (b-CO32−, at ~1366 cm−1), monodentate carbonate (m-CO32−, at ~1536 and ~1296 cm−1), H2O* (at ~1636 cm−1), and bicarbonate (HCO3−, at ~1430 cm−1)62 were also observed. The presence of carbonate and bicarbonate is due to the dissolution of carbon dioxide from the atmosphere into the alkaline solution (1 M KOH)63.

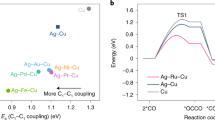

To further understand the enhanced n-propanol proficiency on the LSN-Cu surface, DFT calculations were performed on the nitrogen-doped Cu/Cu2O (N-Cu/Cu2O with a 4% compression strain), Cu(111), and Cu(211) surfaces. The Cu(211) surface was chosen to explore the influence of defect-rich areas7, similar to the LS-Cu catalyst in this study, which features low-coordinated Cu sites akin to GBs and SFs. We initially focused on the adsorption of *CO on these surfaces (Fig. 4a–c). The adsorption-free energies of *CO were −0.08 eV on N-Cu/Cu2O and −0.12 eV on Cu(211), both stronger than the 0.04 eV observed on Cu(111). Thus, the defect sites on N-Cu/Cu2O and Cu(211) surfaces significantly enhance *CO adsorption, increasing θco, in alignment with our Raman spectroscopy and CO-TPD results (Fig. 3a, e, and Supplementary Fig. 28).

a–c Adsorption configurations and adsorption energies (ΔGads) of *CO at N-Cu/Cu2O (a), Cu(211) (b), and Cu(111) (c) surfaces. d and e Gibbs free energy evolution for *COCOH and *COCOHCO intermediates formation on the N-Cu/Cu2O (d) and Cu(211) (e) at 0 V (versus SHE) through *COH (orange) and *CO–*CO (purple) pathways. Orange, gray, red, and purple spheres in a–c represent Cu, C, O, and N atoms, respectively. Source data are provided as a Source Data file.

Subsequently, we assessed the formation energies of *COCOH and *COCOHCO, intermediates commonly proposed for C2 and C3 product formation and also evidenced by our operando ATR-SEIRAS results64,65 (Fig. 4d, e and Supplementary Figs. 31–33). We explored two pathways for *COCOH formation: the hydrogenation of *CO to *COH followed by C–C coupling to form *COCOH, and a direct *CO dimerization to *COCO, followed by hydrogenation to *COCOH66,67,68. Ultimately, *COCOH transforms into *COCOHCO58. The influence of water was also analyzed using an implicit solvent model, which demonstrated that water does not significantly alter CORR trends in our system, as depicted in Supplementary Fig. 34. The critical steps in the C3 pathway involve hydrogenation of *CO and *COCO, besides transition from *COCOH to *COCOHCO. The key intermediates, including *COH, *COCO, *COCOH, and *COCOHCO are stabilized by surface interactions, with C atoms bonded to the Cu surface66.

In results, Cu(211), with ΔG values of 1.61 eV for *CO to *COH and 1.75 eV for *COCOH to *COCOHCO, poses more challenging conditions for the formation of both C2 and C3 intermediates compared to Cu(111), where ΔG values are 0.98 and 1.05 eV, respectively (Fig. 4e and Supplementary Figs. 32, 33). This is consistent with our experimental findings that excessive *CO adsorption on the LS-Cu inhibits C–C coupling (Fig. 3f). Conversely, the ΔG values on the N-Cu/Cu2O surface are significantly lower, at 0.83 eV for *CO to *COH and 0.91 eV for *COCOH to *COCOHCO (Fig. 4d and Supplementary Fig. 31). This indicates that nitrogen doping substantially enhances C–C coupling, which is in line with the ATR-SEIRAS analysis, where the *COH formation is promoted and the *COCOH species are more stable for the subsequently CO–C2 step to generate the C3 products. This finding confirms that, with defect engineering, the LSN-Cu catalyst effectively integrates enhanced C–C coupling capabilities to increase *CO adsorption and thereby θco, significantly promoting C3 formation.

The CORR performance on the LSN-Cu catalyst

The CO-to-n-propanol conversion performance was evaluated using a potentiostatic flow-cell reactor. The LSN-Cu samples (LSN-Cu, LSN-Cu-s, and LSN-Cu-l) were employed as catalysts, while 1 M KOH served as the electrolyte. In comparison, we observed a volcano-type correlation between the n-propanol selectivity, partial current density, and surface lattice strain (Supplementary Figs. 35–37 and Supplementary Table 6). The peak performance was achieved with LSN-Cu, where 4% surface strain on, and 4.9% N atoms contained (Supplementary Table 2). Figure 5a illustrates the FEs of C2+ products during the CORR on the LSN-Cu across the potential range of −0.43 to −0.67 V (vs. RHE). Notably, we observed the production of n-propanol, with a peak FE value of 54 ± 3% occurring at −0.53 V. The n-propanol production achieved a high current density of 71 ± 7 mA cm−2 (Supplementary Fig. 36), representing a significant advancement compared to other state-of-the-art n-propanol-selective catalysts that have been reported7,11,12,13,14,15,16,17,18,19,20. Our electrosynthesis of n-propanol from CO using the LSN-Cu catalyst exhibited a half-cell energy efficiency (EE) of 29 ± 1% (Supplementary Fig. 38). In contrast, the major products on both the LS-Cu and the Cu samples were C2 species such as ethanol, acetate, and ethylene (Supplementary Figs. 39, 40 and Supplementary Table 7). Furthermore, the FEs of n-propanol at −0.55 V were measured to be 28 ± 1% and 14 ± 1% on the LS-Cu and the Cu electrodes, respectively (Fig. 5b). The n-propanol FE on the LSN-Cu catalyst showed a remarkable 1.9-fold and 3.9-fold improvement, respectively, compared to the LS-Cu and the Cu electrodes. It is worth noting that the hydrogen evolution reaction (HER) followed the order of LS-Cu > Cu > LSN-Cu across almost all investigated potentials. This trend was accompanied by a decrease in the total FEs of C2+ products in the same order. This correlation is consistent with the Raman and DFT findings (Figs. 3f, 4e and Supplementary Figs. 32, 33), wherein the LS-Cu catalyst, characterized by increased defect-sites, exhibits enhanced surface *CO coverage, promoting the formation of C3 species through branching pathways from C2. However, the strong binding of *CO hinders the C–C coupling, intensifying the HER. Conversely, the lattice strain-stabilized N doping in the LSN-Cu, is known to be advantageous for C–C coupling, indicating good HER inhibition capability and facilitating C3 formation.

a CORR products distribution under different potentials for the LSN-Cu electrodes, the potential is with a 70% iR correction. b CORR products distribution under −0.53 V vs. RHE on different catalysts. c Comparison of this work with state-of-the-art CORR electrocatalysts, including n-propanol current density, n-propanol FE, n-propanol production rate, stability, and n-propanol EE among all CORR products. d Continuous 180 h measurement using a 5 cm2 MEA electrolyzer at a total current of 1.5 A in 1 M KOH. e The N K-edge XANES spectra of the LSN-Cu before and after 180 h MEA measurement. Error bars in a, b correspond to the standard deviation of at least three independent measurements. Source data are provided as a Source Data file.

Partial current densities were additionally normalized to the electrochemically active surface areas (ECSAs)2, demonstrating an even higher intrinsic activity towards n-propanol on the LSN-Cu catalyst compared to those both on the LS-Cu and the Cu samples (Supplementary Fig. 41 and Supplementary Table 8). This suggests that the improved CO-to-n-propanol activity on the LSN-Cu catalyst cannot be attributed to differences in particle size and surface area.

To exclude the participation of dissolved carbon dioxide in C2+ production, we replaced the CO flow with an argon flow during the CORR measurement, and measured the product distribution (Supplementary Fig. 42). As a result, only H2 was detected, with no trace of carbon-based products. This confirms that the C2+ products in our work are exclusively generated from CO reduction. The 13CO isotopic labeling experiments were also performed to trace the carbon source. As illustrated in Supplementary Fig. 43, the two peaks at 0.85 and 0.65 ppm correspond to the protons in the -CH3 group of n-propanol coupled with 13C nuclei, while the peak at 0.75 ppm is absent. This clearly indicates that the carbon source of n-propanol in our study originates from 13CO (Supplementary Note 3)69.

Furthermore, the LSN-Cu electrocatalyst demonstrated remarkable operational stability in a 5 cm2, two-electrode MEA electrolyzer, with a continuous CORR operation for 180 h at a high total current density of 300 mA cm−2 (Fig. 5d). The applied full-cell voltage was ~2.61 V, maintaining a stable n-propanol FE of around 35%. The LSN-Cu catalyst exhibited the highest n-propanol FE of 42%, together with a full-cell energy efficiency (EE) of 17%. The n-propanol partial current reached 630 mA at a current density of 136 mA cm−2. TEM, HADDF-STEM, and corresponding GPA simulations on the post-reaction electrode reveal that the LSN-Cu catalyst retains its structure after a long-period operation with stable defects and compressive strain on the surface (Supplementary Fig. 44). Besides, XANES analysis at the N K-edge demonstrates the preservation of nitrogen coordination, highlighting the stabilizing effect of lattice strain on nitrogen-doped Cu sites (Fig. 5e). Notably, the LSN-Cu catalyst surpassed all previously reported catalysts in terms of n-propanol Faradaic efficiency, n-propanol current density, n-propanol production rate, stability, and half-cell energy efficiency in CORR products (Fig. 5c and Supplementary Table 9)7,11,12,13,14,15,16,17,18,19,20.

Discussion

In conclusion, our study presents a groundbreaking synthesis of the LSN-Cu catalyst via a facial N2 plasma treatment, tailored for enhanced CO electroreduction to n-propanol. The defect-rich structure on the catalyst significantly elevates the surface *CO coverage, crucial for facilitating extended carbon-chain formation through the coupling between *C2 intermediates and an additional *CO. Meanwhile, the lattice compressive strain stabilizes nitrogen doping, markedly improving the C–C coupling efficiency. This synergy between enhanced *CO coverage and improved C–C coupling has been shown to effectively balance the dynamics between *CO adsorption and C–C coupling ability, leading to increased n-propanol production. Our findings not only contribute to the understanding of selective catalysis for C3 compounds but also pave the way for future developments in the synthesis of longer carbon-chain compounds.

Methods

Chemicals

Copper chloride dehydrate (99.99%) was purchased from Macklin. Nano-carbon black (99.5%) was purchased from Aladdin. Potassium hydroxide (≥85.0%), sodium hydroxide (≥96.0%), and methanol (≥99.5%) were purchased from the Sinopharm Chemical Reagent Company. Ethanol (≥99.7%) was purchased from General Reagent. Cu NPs (25 nm, 99.0%), CuO (99.0%), and Cu2O (99.0%) were purchased from Sigma-Aldrich. The Nafion solution (Dupont, D-520 dispersion, 5% w/w in water, and 1-propanol) was purchased from Alfa Aesar. Freudenberg H23C9 and H14C9 gas diffusion layer (GDL) and Sigracet 39BC GDL were purchased from the Fuel Cell Store. A hydroxide exchange membrane FAB-PK-130 was purchased from Fumatech. An anion exchange membrane X37-FA was purchased from Sustainion. All chemicals, including precursors, solvents, hydrophobic agents, and ionomers, unless otherwise stated, were used without further purification.

Preparation of the CuO nanopowders

The CuO nanopowders were synthesized via a refined solvothermal method. Initially, 1.02 g of Copper (II) chloride dihydrate (6.0 mmol) and 50 mg of nano-carbon black were dissolved in 30 ml of 2 M sodium hydroxide solution and stirred for 30 min at room temperature. This mixture was then transferred to a 50 ml Teflon-lined stainless-steel autoclave and subjected to solvothermal treatment at 130 °C for 12 h. Post-treatment, the product underwent centrifugation with deionized water and ethanol, each thrice, for purification. Finally, the CuO nanopowders were dried in a vacuum oven at 80 °C for 6 h, yielding a high-purity product.

Preparation of gas diffusion electrodes (GDEs)

In the fabrication of gas diffusion electrodes (GDE) utilizing the nitrogen-doped CuOx (N-CuOx) pre-catalyst, a catalyst ink was prepared by homogeneously mixing 5 mg of CuO nanopowders with 1 ml of methanol and 30 μl of Nafion solution, followed by sonication to ensure uniform dispersion. This slurry was then carefully applied onto a 2 cm × 2 cm gas diffusion layer (GDL) using a drip-coating technique. The coated GDL was subsequently placed in the chamber of an atmospheric plasma-enhanced cleaning machine. During the plasma treatment process, a plasma ball was generated above the sample, maintained at a microwave power of 500–600 W. The plasma comprised ultra-high purity Argon (Ar, 99.999%) and Nitrogen (N2, 99.999%), with constant pressure and flow rates. The exposure time to the plasma was meticulously controlled to ensure the sample temperature did not exceed 150 °C. This exposure resulted in a color change of the samples, indicative of the plasma’s effect. For comparative purposes, electrodes with the CuO pre-catalyst were also prepared using a similar procedure, excluding the plasma treatment. All subsequent preparation steps were identical to those used for the N-CuOx pre-catalyst GDEs.

The prepared GDEs were electrochemically activated by running them for 900 s in a CO gas environment (20 ml min−1) at −0.43 V (versus reversible hydrogen electrode, RHE) in 1 M KOH solution at 25 °C. This activation ensured that the pre-catalysts were fully electro-reduced to a stable state, suitable for CORR catalysis, as indicated by the achievement of a stable current density.

The electrode potentials were rescaled to the RHE reference by the following equation:

And the potential is presented with a 70% iR correction. The uncompensated solution resistances (RΩ) were measured by extrapolating the electrochemical impedance semi-circle to the high-frequency end, which was ca. 3.5 ± 0.1 Ω for each electrode in 1 M KOH.

Structural characterization

Scanning electron microscopy (SEM) analysis was conducted on a Hitachi FE-SEM S-4800, operated at an accelerating voltage of 1.0 kV, providing detailed surface morphology insights. high-resolution transmission electron microscopy (HRTEM) images were captured using a JEOL JEM-2100F transmission electron microscope, functioning at 200 kV. Scanning transmission electron microscopy (STEM) investigations were performed on two sophisticated instruments: an FEI Titan Cubed 60-300, operating at a high accelerating voltage of 300 kV, and a JEOL ARM-200F equipped with a cold field emission gun and a CEOS-corrected Cs probe, at an operating voltage of 200 kV. These STEM analyses were complemented by high-resolution energy dispersive X-ray spectroscopy (EDX) utilizing a state-of-the-art super-X detector, enabling precise elemental analysis. X-ray photoelectron spectroscopy (XPS) was carried out on a PHI 5700 ESCA system, employing Al Kα X-ray radiation (1486.6 eV) for excitation. Powder X-ray diffraction (XRD) patterns were acquired using a MiniFlex600 instrument, operating in Bragg–Brentano mode. The instrument was configured with a 0.02° divergence and a scan rate of 0.1° s−1. The surface strain was quantified by HAADF-STEM images with Strain++ software70, utilizing geometric phase analysis (GPA) to map the strain71. The color spectrum in the strain maps ranges from negative (compressive) to positive (tensile) strain values.

Operando X-ray absorption fine spectroscopy (XAFS)

Operando Cu K-edge X-ray absorption fine structure (XAFS) measurements were executed at the 1W1B beamline of the Beijing Synchrotron Radiation Facility (BSRF), China. These measurements utilized the Quick XAFS (QXAFS) technique, spanning an energy range from 8.8 to 9.2 keV, with a detailed focus on the near-edge region using a fine step size of 0.5 eV. This approach, conducted in fluorescence mode, allowed for an efficient collection of spectra, with each QXAFS spectrum requiring ~40 s (30 s for data acquisition and 10 s for detector repositioning).

The study involved the use of an LSN-Cu-loaded gas diffusion electrode (GDE), identical to the one used in electrochemical assessments. This GDE underwent a chronoamperometry process at a potential of −0.53 V (vs. RHE) within a custom-built flow-cell type reactor (Supplementary Fig. 45b). This setup was akin to that used in preference measurements, with the sole variation being the replacement of the outer surface of the gas chamber with Kapton tape. The reactor system comprised a Hg/HgO reference electrode in 1 M KOH, a Fe–S/Ni foam electrode as the anode, and a Fumatech FAB-PK-130 anion exchange membrane. The electrolyte was 1 M KOH solution, and CO (99.99% purity, Air France) was continuously supplied to the gas chamber for CORR studies. XAS data processing was conducted using Athena and Artemis software within the IFEFFIT package suite. And the potential is presented with a 70% iR correction. The uncompensated solution resistances (RΩ) were measured by extrapolating the electrochemical impedance semi-circle to the high-frequency end, which was ca. 3.5 ± 0.1 Ω for each electrode in 1 M KOH.

The Fe–S/Ni foam electrodes were fabricated using a solvothermal method. The process began with ultrasonication of Fe–S/Ni foam in a mixture of acid, H2O, and ethanol. A solution containing 4.87 g of Ferric chloride hexahydrate and 7.21 g of sodium sulfide nonahydrate, dissolved in 300 ml of deionized water, was stirred for 2 h at room temperature. Subsequently, this mixture, along with the pre-treated Ni foam, was transferred to a 50 ml Teflon-lined stainless-steel autoclave for solvothermal treatment at 150 °C for 13.5 h. Following this, the sample was centrifuged three times with deionized water and then dried in a vacuum oven at 60 °C for 12 h.

For comparative purposes, ex-situ Cu K-edge XAFS measurements were carried out on commercial Cu nanoparticles (NPs) and CuO powders. These reference samples were prepared by uniformly distributing the powders on a strip of 3 M tape, ensuring a standardized approach for comparative XAFS analysis.

Operando surface-enhanced Raman spectroscopy (SERS)

Operando SERS measurements were expertly conducted using a Horiba Scientific Xplora Raman Microscope, equipped with a water immersion objective (×100) and utilizing a 633 nm laser (numerical aperture, NA = 1.0; working distance, WD = 2.0 mm; LUMPLFLN-60X/W; Olympus Inc., Waltham, MA) and a flow-cell type reactor (Supplementary Fig. 46). Each Raman spectrum was meticulously acquired over a integration time of 5 s, with an averaging of 10 scans to ensure data accuracy and repeatability. The acquired spectra were subsequently analyzed and processed utilizing LabSpec 6.0 software, providing detailed insights into molecular interactions and structural changes.

For these measurements, the same working electrode previously utilized for electrochemical performance evaluation was employed. This ensured consistency in the experimental conditions and comparability of the results. The electrochemical setup was complemented by an Ag/AgCl reference electrode in 3 M KCl and a graphite rod as the counter electrode. A 1 M KOH aqueous solution served as the electrolyte, maintaining an optimal environment for electrochemical reactions.

During the SERS experiments, CO gas was continuously supplied to the gas chamber, ensuring a stable and controlled environment for the assessment of catalytic processes under realistic operational conditions. This operando approach enables the direct observation and analysis of electrocatalytic phenomena, providing valuable insights into the mechanisms and efficiency of the catalysts under study. The potentials in Raman measurements were converted to values with reference to RHE using the equation:

where the pH value of the 1 M KOH aqueous solution in this work is 13.6 ± 0.1. And the potential is presented with a 70% iR correction. The uncompensated solution resistances (RΩ) were measured by extrapolating the electrochemical impedance semi-circle to the high-frequency end, which was ca. 3.5 ± 0.1 Ω for each electrode in 1 M KOH.

Temperature programed desorption (TPD)

GDEs, identical to those used in electrochemical measurements, were subjected to a chronoamperometry process at −0.53 V (vs. RHE) and subsequently dried in a vacuum oven. Following this, both the catalyst and gas diffusion layer (GDL) components of the samples were meticulously ground into a fine powder to facilitate CO desorption measurements. To isolate the specific contribution of the GDL support, a parallel CO desorption assessment was conducted on ground GDL samples under identical conditions.

For the CO adsorption studies, a sophisticated TPD apparatus equipped with a thermal conductive detector (AutoChem II 2920) was employed. The catalysts underwent a degassing process at 100 °C under a continuous flow of Argon (Ar) gas, effectively removing any pre-adsorbed gases from the catalyst surface. This process lasted for 1 h, ensuring thorough preparation of the catalysts for subsequent CO adsorption. Following degassing, CO gas was introduced to the system, allowing for ample adsorption onto the catalysts. Excess CO was then purged using Argon.

The TPD sequence was initiated under a steady Ar flow at a constant velocity, facilitating the transport of desorbed CO molecules to the detector. This methodology provided a detailed understanding of CO adsorption and desorption dynamics on the catalyst surfaces, crucial for elucidating their catalytic behavior and efficiency in electrochemical processes.

Operando attenuated total reflection surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS)

ATR-SEIRAS measurements were conducted using a Bruker INVENIO infrared spectrophotometer equipped with a built-in mercury cadmium telluride (MCT) detector. Various Cu-based catalysts coated on an Au/Si substrate were used as the working electrode, with a Hg/HgO electrode and a graphite rod serving as the reference and counter electrodes, respectively (Supplementary Fig. 47a). The Au/Si substrate was prepared as follows: a hemicylindrical Si prism was purchased from IRUBIS GmbH. The Au film on the reflecting plane of the Si prism (Au/Si substrate) was prepared using a two-step wet process: First, the reflecting plane of the Si prism was mechanically polished with 1.0, 0.3, and 0.05 µm Al2O3 powder, sonicated in acetone and water, respectively, soaked in piranha solution, and thoroughly rinsed with Milli-Q water (18.2 MΩ cm). The reflecting plane was then immersed in a 40% NH4F solution for 1.5 min to terminate the Si surface with hydrogen, and subsequently immersed in a plating solution containing 0.015 M HAuCl4, 0.15 M Na2SO3, 0.05 M Na2S2O3, and 0.05 M NH4Cl at 60 °C for 3 min to deposit the Au film.

ATR-SEIRAS spectra were acquired at a resolution of 4 cm−1 using unpolarized IR radiation at an incidence angle of ~70°. The electrolyte was 0.1 M KOH, saturated with CO or purged with Ar gas during the experiment. The electrode potential was held at an open circuit potential (OCP), and a background spectrum was recorded. All spectra are presented in absorbance units as −log(I/I0), where I and I0 represent the intensities of the reflected radiation of the sample and the background spectrum, respectively. The electrode potential was varied from −0.40 to −0.75 V vs. RHE, in a stepwise manner. Concurrently, infrared spectra were recorded with a time resolution of 30 s per spectrum at a spectral resolution of 4 cm−1. The potential is presented with a 70% iR correction. The uncompensated solution resistances (RΩ) were measured by extrapolating the electrochemical impedance semi-circle to the high-frequency end, which was ca. 7.5 ± 0.3 Ω for each electrode in 0.1 M KOH.

Operando differential electrochemical mass spectroscopy (DEMS)

The DEMS experiments were conducted in a custom-designed cell (Supplementary Fig. 47b). A cold trap, cooled with dry ice, was installed between the vacuum chamber and the electrochemical cell to trap water vapor during the experiments and protect the mass spectrometer. Platinum wire and a Hg/HgO electrode were used as the counter electrode and reference electrode, respectively. The working electrode consisted of an Au film sputtered onto a hydrophobic polytetrafluoroethylene membrane, with the catalyst ink airbrushed onto the Au film and dried at ambient temperature before the DEMS experiments. Due to the pressure difference, the online-generated products were drawn downward into the vacuum chamber and subsequently detected by the mass spectrometer. The experiments were performed in 1 M KOH, with the electrolyte saturated by CO bubbling prior to the electrochemical measurements. The catalysts were subjected to cyclic voltammetry (CV) cycles from 0 to −0.9 V (vs. RHE) with no iR correction, at a scan rate of 5 mV s−¹, while the mass signals of the products were recorded.

Electrochemical measurements

In the absence of specific conditions, the CORR performance of various catalysts was systematically evaluated at a standard temperature of 25 °C using a flow cell setup (Supplementary Fig. 45a). This configuration encompassed a gas chamber, a cathodic chamber, and an anodic chamber. The prepared working electrode was strategically positioned between the gas and cathodic chambers, ensuring that the catalyst-coated side faced the cathodic chamber, which had a geometrically active surface area of 1 cm2. For electrochemical consistency, a Fe–S/Ni foam electrode and a Hg/HgO electrode, filled with 1 M KOH, were utilized as the counter and reference electrodes, respectively.

Separation of the cathode and anode chambers was achieved using an Anion exchange membrane (AEM, Supplementary Fig. 48), specifically the Fumatech FAB-PK-130 (110–140 μm). The Fumatech FAB-PK-130 membranes were activated for 12 h in 1 M KOH at room temperature before use. This configuration was carefully assembled with the combined catalyst and diffusion layer, the AEM, and the nickel anode, all held in place using PolyTetraFluoroEthylene (PTFE) spacers. This design facilitated the introduction of alkaline electrolytes into the interstitial spaces between the anode and the membrane, as well as between the membrane and the cathode. The electrolyte flow was regulated at 10 ml min−1 using a peristaltic pump.

To maintain a consistent and controlled environment, CO gas (99.99% purity, Air France) was supplied to the gas chamber at a constant rate of 20 ml min−1, managed by an Alicat Scientific mass flow controller. The actual flow rate within the system was accurately determined using a bubble flowmeter located at the outlet of the cathodic chamber. This comprehensive setup ensured precise control over the experimental conditions, vital for the reliable assessment of CORR catalytic performance. Potentials are presented with 70% iR corrections. The uncompensated solution resistances (RΩ) were measured by extrapolating the electrochemical impedance semi-circle to the high-frequency end, which was ca. 3.5 ± 0.1 Ω for each electrode in 1 M KOH.

Membrane electrode assembly (MEA) electrolysis experiments were conducted at a controlled temperature of 25 °C, employing a custom-built CO electrolyzer with a 5 cm2 reaction area. A specially prepared gas-diffusion electrode (GDE), measuring 2.0 cm× 2.5 cm, functioned as the cathode. To prevent short-circuiting, a PTFE insulator sheet featuring a 5 cm2 window, was strategically affixed to the cathode. Adjacent to this setup, a pre-treated sustainion membrane (X37-FA, 50 μm) was aligned with a Fe–S/Ni foam electrode of identical dimensions. The X37-FA membranes were activated for 12 h in 1 M KOH at room temperature before use. The anolyte, consisting of a 1 M KOH aqueous solution, was continuously circulated at a flow rate of 30 ml min−1 using a pump.

On the cathodic side, CO gas at a flow rate of 40 ml min−1, humidified using deionized (DI) water, was introduced into the cathode chamber. Gas products were collected and analyzed via an in-line gas chromatograph equipped with a cold trap. Given the crossover of liquid products, the Faradaic efficiencies (FEs) of these products were computed based on the total amount collected at both anode and cathode.

All CO reduction experiments were conducted using an Autolab PGSTAT302N electrochemical workstation, complemented with a 10 A current booster. Reactions were sustained for a minimum of 300 s before product collection to ensure complete electro-reduction of the pre-catalysts to stable CORR catalysts. Gas chromatographs (Agilent Technologies 7890B and Shanghai Ramiin GC 2060), equipped with thermal conductivity (TCD) and flame ionization (FID) detectors, quantified the gaseous products. These were sampled from both the gas chamber’s outlet and the cathode chamber for enhanced accuracy. Liquid products were examined offline via ¹H nuclear magnetic resonance (NMR) analysis (AVANCE III HD 400 MHz), with Dimethyl sulfoxide (Sigma, 99.99%) added as an internal standard. The ¹H spectra were acquired using water suppression through a pre-saturation technique. FEs of liquid products were calculated based on the total amount collected from both anode and cathode chambers, taking into account the crossover of liquids. After obtaining the n-propanol concentration of each sample from NMR quantification, FEn-propanol was calculated based on the following equation:

where i is the stabilized total current during electrolysis measurements.

Electrochemical active surface area (ECSA) calculation

The ECSAs of catalysts were calculated based on their electrical double-layer capacitor (Cdl), which were obtained from CV plots in a narrow non-Faradaic potential window from 0.14 to 0.20 V (vs. RHE) with no iR correction. The measured capacitive current densities at 0.17 V were plotted as a function of scan rate, and the slope of the linear fit was calculated as Cdl. The specific capacitance was found to be 29 μF cm−2, and the ECSA of the catalyst is calculated from the following equation:

The intrinsic activity was revealed by normalizing the current to the ECSA to exclude the effect of surface area on catalytic performance. The ECSA values of the catalysts are listed in Supplementary Table 8.

Cathodic energy efficiency (EE) calculation

Cathodic EE is calculated assuming the overpotential of anodic oxygen evolution reaction to be zero, which is calculated as follows:

where E is the applied potential; FEn-propanol is the measured Faradaic efficiency of n-propanol; En-propanol is the thermodynamic potential of the CO-to-n-propanol process, i.e., 0.20 V. This potential is presented with a 70% iR correction. The uncompensated solution resistances (RΩ) were measured by extrapolating the electrochemical impedance semi-circle to the high-frequency end, which was ca. 3.5 ± 0.1 Ω for each electrode in 1 M KOH.

Full-cell EE calculation

Similar to cathodic energy EE, full-cell EE is calculated as follows:

where Ecell is the measured cell voltage at a given current density, FEn-propanol is the measured Faradaic efficiency of n-propanol; En-propanol is the thermodynamic potential of the CO-to-propanol process, i.e., 0.20 V.

DFT calculations

The simulations were conducted utilizing the framework of density functional theory (DFT), employing the Perdew–Burke–Ernzerhof (PBE) density functional72, as implemented in the Quantum Espresso ab initio simulation package73. For wavefunction and electron density representation, a plane wave basis set was used, with kinetic energy and charge density cutoffs set at 40 and 240 Ry, respectively. The core electron regions and core–valence interactions were described through Vanderbilt ultrasoft pseudopotentials74. Three models were chosen to represent the Cu0 surface, the Cu0/Cu+ surface, and the N-doped Cu0/Cu+ surface, as shown in Supplementary Fig. 27. The Cu0 surface was constructed by a three-layer 4 × 4 Cu(111) surface. The Cu0/Cu+ surface was constructed by reducing one-quarter of a three-layer 2 × 2 Cu2O(111) surface, which is replaced by the Cu(111) surface. The N-doped Cu0/Cu+ surface was constructed by substituting an N atom for an O atom in the Cu0/Cu+ surface75. The oxygen formation energy was computed as follows:

The adsorption energies for the OCCO* and OCCOCO* species were calculated using the following equation:

where the Esurf represents the adsorption energy of the pristine surface, the Esurf+ads denote the energy of the surface with the adsorbate, the Esurf+Ovac corresponds to the surface energy with an oxygen vacancy, and the ECO is the energy of an adsorbed *CO molecule.

Data availability

The data that support the conclusions of this study are available within the paper and its supplementary information files or from the corresponding authors upon request (B.Z. and W.G.). Source data are provided with this paper.

References

Sheng, H. & Liu, C. Spatial decoupling boosts CO2 electro-biofixation. Nat. Catal. 5, 357–358 (2022).

Li, C. W., Ciston, J. & Kanan, M. W. Electroreduction of carbon monoxide to liquid fuel on oxide-derived nanocrystalline copper. Nature 508, 504–507 (2014).

Bushuyev, O. S. et al. What should we make with CO2 and how can we make it? Joule 2, 825–832 (2018).

Li, J. et al. Constraining CO coverage on copper promotes high-efficiency ethylene electroproduction. Nat. Catal. 2, 1124–1131 (2019).

Ji, Y. et al. Selective CO-to-acetate electroreduction via intermediate adsorption tuning on ordered Cu–Pd sites. Nat. Catal. 5, 251–258 (2022).

Li, J. et al. Enhanced multi-carbon alcohol electroproduction from CO via modulated hydrogen adsorption. Nat. Commun. 11, 3685 (2020).

Niu, W. et al. Pb-rich Cu grain boundary sites for selective CO-to-n-propanol electroconversion. Nat. Commun. 14, 4882 (2023).

Wang, G. et al. Electrocatalysis for CO2 conversion: from fundamentals to value-added products. Chem. Soc. Rev. 50, 4993–5061 (2021).

Calvinho, K. U. D. et al. Surface hydrides on Fe2P electrocatalyst reduce CO2 at low overpotential: steering selectivity to ethylene glycol. J. Am. Chem. Soc. 143, 21275–21285 (2021).

Raaijman, S. J., Schellekens, M. P., Corbett, P. J. & Koper, M. T. M. High-pressure CO electroreduction at silver produces ethanol and propanol. Angew. Chem. Int. Ed. 60, 21732–21736 (2021).

Qi, K. et al. Unlocking direct CO2 electrolysis to C3 products via electrolyte supersaturation. Nat. Catal. 6, 319–331 (2023).

Wu, G. et al. Selective electroreduction of CO2 to n‐propanol in two‐step tandem catalytic system. Adv. Energy Mater. 12, 2202054 (2022).

Phong Duong, H. et al. Silver and copper nitride cooperate for CO electroreduction to propanol. Angew. Chem. Int. Ed. 62, e202310788 (2023).

Wang, X. et al. Efficient electrosynthesis of n-propanol from carbon monoxide using a Ag–Ru–Cu catalyst. Nat. Energy 7, 170–176 (2022).

Liu, J. et al. Directing the architecture of surface-clean Cu2O for CO electroreduction. J. Am. Chem. Soc. 144, 12410–12420 (2022).

Gu, Z. et al. Efficient electrocatalytic CO2 reduction to C2+ alcohols at defect-site-rich Cu surface. Joule 5, 429–440 (2021).

Wang, X. et al. Efficient upgrading of CO to C3 fuel using asymmetric C–C coupling active sites. Nat. Commun. 10, 5186 (2019).

Pang, Y. et al. Efficient electrocatalytic conversion of carbon monoxide to propanol using fragmented copper. Nat. Catal. 2, 251–258 (2019).

Zhuang, T.-T. et al. Copper nanocavities confine intermediates for efficient electrosynthesis of C3 alcohol fuels from carbon monoxide. Nat. Catal. 1, 946–951 (2018).

Li, J. et al. Copper adparticle enabled selective electrosynthesis of n-propanol. Nat. Commun. 9, 4614 (2018).

Chen, C. et al. Highly efficient electroreduction of CO2 to C2+ alcohols on heterogeneous dual active sites. Angew. Chem. Int. Ed. 59, 16459–16464 (2020).

O’Mara, P. B. et al. Cascade reactions in nanozymes: spatially separated active sites inside Ag-core–porous-Cu-shell nanoparticles for multistep carbon dioxide reduction to higher organic molecules. J. Am. Chem. Soc. 141, 14093–14097 (2019).

Lu, X. K., Lu, B., Li, H., Lim, K. & Seitz, L. C. Stabilization of undercoordinated Cu sites in strontium copper oxides for enhanced formation of C2+ products in electrochemical CO2 reduction. ACS Catal. 12, 6663–6671 (2022).

Sang, J. et al. A reconstructed Cu2P2O7 catalyst for selective CO2 electroreduction to multicarbon products. Angew. Chem. Int. Ed. 61, e202114238 (2022).

Jia, L. et al. Phase-dependent electrocatalytic CO2 reduction on Pd3Bi nanocrystals. Angew. Chem. Int. Ed. 60, 21741–21745 (2021).

Wei, P. et al. Coverage-driven selectivity switch from ethylene to acetate in high-rate CO2/CO electrolysis. Nat. Nanotechnol. 18, 299–306 (2023).

Wakerley, D. et al. Gas diffusion electrodes, reactor designs and key metrics of low-temperature CO2 electrolysers. Nat. Energy 7, 130–143 (2022).

Yan, S. et al. High-power CO2-to-C2 electroreduction on Ga-spaced, square-like Cu sites. J. Am. Chem. Soc. 145, 26374–26382 (2023).

Zheng, M. et al. Electrocatalytic CO2-to-C2+ with ampere-level current on heteroatom-engineered copper via tuning *CO intermediate coverage. J. Am. Chem. Soc. 144, 14936–14944 (2022).

Peng, C. et al. Double sulfur vacancies by lithium tuning enhance CO2 electroreduction to n-propanol. Nat. Commun. 12, 1580 (2021).

Peng, C. et al. Surface Co-modification of halide anions and potassium cations promotes high-rate CO2-to-ethanol electrosynthesis. Adv. Mater. 34, e2204476 (2022).

Ma, W. et al. Electrocatalytic reduction of CO2 to ethylene and ethanol through hydrogen-assisted C–C coupling over fluorine-modified copper. Nat. Catal. 3, 478–487 (2020).

Yang, P. P. et al. Highly enhanced chloride adsorption mediates efficient neutral CO2 electroreduction over a dual-phase copper catalyst. J. Am. Chem. Soc. 145, 8714–8725 (2023).

Peng, C. et al. Lithiation-enabled high-density nitrogen vacancies electrocatalyze CO2 to C2 products. Adv. Mater. 33, e2103150 (2021).

Chen, P. et al. Efficient electrocatalytic reduction of CO2 to ethane over nitrogen-doped Fe2O3. J. Am.Chem. Soc. 144, 14769–14777 (2022).

Xia, W. et al. Adjacent copper single atoms promote C–C coupling in electrochemical CO2 reduction for the efficient conversion of ethanol. J. Am. Chem. Soc. 145, 17253–17264 (2023).

Feng, J. et al. Modulating adsorbed hydrogen drives electrochemical CO2-to-C2 products. Nat. Commun. 14, 4615 (2023).

Lum, Y. & Ager, J. W. Stability of residual oxides in oxide‐derived copper catalysts for electrochemical CO2 reduction investigated with 18O labeling. Angew. Chem. Int. Ed. 57, 551–554 (2017).

Lee, S. Y. et al. Mixed copper states in anodized Cu electrocatalyst for stable and selective ethylene production from CO2 reduction. J. Am. Chem. Soc. 140, 8681–8689 (2018).

Park, D. G. et al. Increasing CO binding energy and defects by preserving Cu oxidation state via O2-plasma-assisted N doping on CuO enables high C2+ selectivity and long-term stability in electrochemical CO2 reduction. ACS Catal. 13, 9222–9233 (2023).

Ye, T.-N. et al. Vacancy-enabled N2 activation for ammonia synthesis on an Ni-loaded catalyst. Nature 583, 391–395 (2020).

Zhou, Y. et al. Predicted stable high-pressure phases of copper-nitrogen compounds. J. Phys.: Condens. Matter 34, 025401 (2021).

Liu, X. et al. Uncovering the effect of lattice strain and oxygen deficiency on electrocatalytic activity of Perovskite cobaltite thin films. Adv. Sci. 6, 1801898 (2019).

Zhang, Y. et al. 3D Porous hierarchical nickel–molybdenum nitrides synthesized by RF plasma as highly active and stable hydrogen‐evolution‐reaction electrocatalysts. Adv. Energy Mater. 6, 1600221 (2016).

Wang, Z., Pischedda, V., Saxena, S. K. & Lazor, P. X-ray diffraction and Raman spectroscopic study of nanocrystalline CuO under pressures. Solid State Commun. 121, 275–279 (2002).

Hao, S. et al. Torsion strained iridium oxide for efficient acidic water oxidation in proton exchange membrane electrolyzers. Nat. Nanotechnol. 16, 1371–1377 (2021).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Xie, L. et al. Pauling-type adsorption of O2 induced electrocatalytic singlet oxygen production on N-CuO for organic pollutants degradation. Nat. Commun. 13, 5560 (2022).

Sun, Y. et al. Nitrogen-doped cobalt diselenide with cubic phase maintained for enhanced alkaline hydrogen evolution. Angew. Chem. Int. Ed. 60, 21575–21582 (2021).

Timoshenko, J. et al. Steering the structure and selectivity of CO2 electroreduction catalysts by potential pulses. Nat. Catal. 5, 259–267 (2022).

Wang, X. et al. Efficient electrically powered CO2-to-ethanol via suppression of deoxygenation. Nat. Energy 5, 478–486 (2020).

Gunathunge, C. M. et al. Spectroscopic observation of reversible surface reconstruction of copper electrodes under CO2 reduction. J. Phys. Chem. C 121, 12337–12344 (2017).

Gunathunge, C. M., Li, J., Li, X., Hong, J. J. & Waegele, M. M. Revealing the predominant surface facets of rough Cu electrodes under electrochemical conditions. ACS Catal. 10, 6908–6923 (2020).

Malkani, A. S., Dunwell, M. & Xu, B. Operando spectroscopic investigations of copper and oxide-derived copper catalysts for electrochemical CO reduction. ACS Catal. 9, 474–478 (2018).

Niu, Z. Z. et al. Hierarchical copper with inherent hydrophobicity mitigates electrode flooding for high-rate CO2 electroreduction to multicarbon products. J. Am. Chem. Soc. 143, 8011–8021 (2021).

Iijima, G., Inomata, T., Yamaguchi, H., Ito, M. & Masuda, H. Role of a hydroxide layer on Cu electrodes in electrochemical CO2 reduction. ACS Catal 9, 6305–6319 (2019).

Li, J., Li, X., Gunathunge, C. M. & Waegele, M. M. Hydrogen bonding steers the product selectivity of electrocatalytic CO reduction. Proc. Natl Acad. Sci. USA. 116, 9220–9229 (2019).

Zhu, S., Jiang, B., Cai, W. B. & Shao, M. Direct observation on reaction intermediates and the role of bicarbonate anions in CO2 electrochemical reduction reaction on Cu surfaces. J. Am. Chem. Soc. 139, 15664–15667 (2017).

Kim, Y. et al. Time-resolved observation of C–C coupling intermediates on Cu electrodes for selective electrochemical CO2 reduction. Energy Environm. Sci. 13, 4301–4311 (2020).

Geng, Q. et al. Revolutionizing CO2 electrolysis: fluent gas transportation within hydrophobic porous Cu2O. J. Am. Chem. Soc. 146, 10599–10607 (2024).

Pérez‐Gallent, E., Figueiredo, M. C., Calle‐Vallejo, F. & Koper, M. T. M. Spectroscopic observation of a hydrogenated CO dimer intermediate during CO reduction on Cu(100) electrodes. Angew. Chem. Int. Ed. 56, 3621–3624 (2017).

Yu, Y., He, Y., Yan, P., Wang, S. & Dong, F. Boosted C–C coupling with Cu–Ag alloy sub-nanoclusters for CO2-to-C2H4 photosynthesis. Proc. Natl Acad. Sci. USA 120, e2307320120 (2023).

Wang, X. et al. Site-selective protonation enables efficient carbon monoxide electroreduction to acetate. Nat. Commun. 15, 616 (2024).

Yang, K. D., Lee, C. W., Jin, K., Im, S. W. & Nam, K. T. Current status and bioinspired perspective of electrochemical conversion of CO2 to a long-chain hydrocarbon. J. Phys. Chem. Lett. 8, 538–545 (2017).

Kortlever, R., Shen, J., Schouten, K. J., Calle-Vallejo, F. & Koper, M. T. Catalysts and reaction pathways for the electrochemical reduction of carbon dioxide. J. Phys. Chem. Lett. 6, 4073–4082 (2015).

Xiao, H., Cheng, T., Goddard, W. A. & Sundararaman, R. Mechanistic explanation of the pH dependence and onset potentials for hydrocarbon products from electrochemical reduction of CO on Cu (111). J. Am. Chem. Soc. 138, 483–486 (2016).

Wang, P. et al. Boosting electrocatalytic CO2-to-ethanol production via asymmetric C–C coupling. Nat. Commun. 13, 3754 (2022).

Li, H. et al. C2+ Selectivity for CO2 electroreduction on oxidized Cu-based catalysts. J. Am. Chem. Soc. 145, 14335–14344 (2023).

Cai, Y. et al. Self-pressurizing nanoscale capsule catalysts for CO2 electroreduction to acetate or propanol. Nat. Synth. 3, 891–902 (2024).

Ma, W. et al. Copper lattice tension boosts full-cell CO electrolysis to multi-carbon olefins and oxygenates. Chem 9, 2161–2177 (2023).

Hytch, M. J., Snoeck, E. & Kilaas, R. Quantitative measurement of displacement and strain Þelds from HREM micrographs. Ultramicroscopy 74, 131–146 (1998).

Perdew, J. P., Ernzerhof, M. & Burke, K. Rationale for mixing exact exchange with density functional approximations. J. Chem. Phys. 105, 9982–9985 (1996).

Giannozzi, P. et al. QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys.: Condens. Matter 21, 395502 (2009).

Garrity, K. F., Bennett, J. W., Rabe, K. M. & Vanderbilt, D. Pseudopotentials for high-throughput DFT calculations. Comput. Mater. Sci. 81, 446–452 (2014).

Xiao, H., Goddard, W. A., Cheng, T. & Liu, Y. Cu metal embedded in oxidized matrix catalyst to promote CO2 activation and CO dimerization for electrochemical reduction of CO2. Proc. Natl Acad. Sci. USA 114, 6685–6688 (2017).

Acknowledgements

This work was supported by NSFC (22279019 [B.Z.]), STCSM (21DZ1207102 [B.Z.], 21DZ1207103 [B.Z.]) and National Key Research and Development Program of China (Grant 2022YFA1503101 [Y.L.]). This work has also benefited from the 1W1B Beamline at Being Synchrotron Radiation Facility (BSRF) and the authors thank Prof. Lirong Zheng (Institute of High Energy Physics, Chinese Academy of Sciences) for the assistance in the XAS measurements. The authors thank Prof. Jun Li (Shanghai Jiao Tong University) and Prof. Fengwang Li (The University of Sydney) for constructive comments and suggestions. The authors also thank Mr. Feng Zhang (Linglu Instruments (Shanghai) Co., Ltd.), Ms. Wenwei Mao (Linglu Instruments (Shanghai) Co., Ltd.), Prof. Xiaodong Zhuang (Shanghai Jiao Tong University) and Dr. Pengfei Shi (Shanghai Jiao Tong University) for assistance in the operando DEMS experiments.

Author information

Authors and Affiliations

Contributions

B.Z. and W.G. supervised the project. W.N. conceived the idea and carried out most of the experiments. J.F. and Y.L. carried out the DFT calculations. W.N. and J.C. performed the XAS measurements. W.N. analyzed the XAS data. L.D. and L.Z. contributed to the TEM and STEM characterization. W.N. and H.L. performed the ex-situ and operando Raman measurements. W.N., J.F, W.G., Y.L., and B.Z. co-wrote the manuscript. J.C. assisted with the data analyses, discussions, and provided suggestions on the experimental operations. All authors discussed the results and assisted during manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Niu, W., Feng, J., Chen, J. et al. High-efficiency C3 electrosynthesis on a lattice-strain-stabilized nitrogen-doped Cu surface. Nat Commun 15, 7070 (2024). https://doi.org/10.1038/s41467-024-51478-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-51478-4