Abstract

Polymer gels have been widely used in flexible electronics, soft machines and impact protection materials. Conventional gels usually suffer from the inherent conflict between stiffness and toughness, severely hampering their applications. This work proposes a facile yet versatile strategy to break through this trade-off via the synergistic effect of crystal-___domain cross-linking and chelation cross-linking, without the need for specific structure design or adding other reinforcements. Both effects are proven to boost the mechanical performance of the originally weak gel, and result in a stiff and tough conductive gel, achieving significant enhancements in elastic modulus and toughness by up to 366-, and 104-folds, respectively. The resultant gel achieves coordinatively enhanced stiffness (110.26 MPa) and toughness (219.93 MJ m−3), reconciling the challenging trade-off between them. In addition, the presented strategy is found generalizable to a variety of metal ions and polymers, offering a promising way to expand the applicability of gels.

Similar content being viewed by others

Introduction

The design and construction of polymeric gels for promising applications in the fields of tissue engineering1, energy storage2, soft robots3 and flexible electronics4 have attracted intensive attention. Because of the inherent softness and stretchability of conventional synthetic polymer, gels based on poly(vinyl alcohol) (PVA)5, polyacrylamides (PAM)6, poly(acrylic acid) (PAA)7, and polydimethylsiloxane (PDMS)8 are paving the way toward versatile application scenario. For example, Zhang et al. reported a class of ultra-stretching, soft, and self-adhesive polymeric gel to wearable electronics for high-quality physiological signal monitoring9. Among these, little attention has been paid to impact-resistant protective materials from polymeric gels, when it comes to discussing practical applications (head impact protection device, ballistic armor, back protectors, safety barriers, etc.) where long service life, high loading capability and/or impact tolerance are highly demanded, because they are normally soft and fragile10. Effective strategies to improve their mechanical properties are urgently needed. Meanwhile, gels also need to fulfill further requirements, such as a wide working temperature range (−80°C–25°C), fracture resistance (> 250 kJ m–2), good ionic conductivity (> 0.1 S m−1), etc., in order to function under critical conditions11. Therefore, the preparation of stiff and tough conductive polymeric gels with multifunctional properties still represents a challenge for existing material systems.

In recent years significant breakthroughs have been achieved in the stiffening and toughening of gel materials mainly include molecular engineering and micro/nano structural engineering. The former includes the preparation of homogeneous gel materials by multiple networks (double-network and interpenetrating polymer network)12, dynamic interactions (hydrogen bonds, coordination bonds)13, designed molecular structures14, developing novel cross-linkers (chemical and physical)15, and others16, resulting in the sufficiently enhanced mechanical behavior of gel materials. However, the irreversibility of covalent networks and the poor mechanical strength of dynamic bonds limit the molecular engineering of strong gels. The latter includes the construction of anisotropic micro–nano structures by in situ methods such as directional freezing17, pre-stretching18 and mechanical training19, whereas these methods always involve complicated and multi-step preparation routes. In addition, enhanced microregions of gels are introduced by phase-separation and nanocomposites20, salting-out treatment21, which improve the strength and toughness in the counterpart of a homogeneous network. However, the deformability of gels is sacrificed. The method is unfavorable in terms of cost and energy consumption. The stiffness and toughness of gels prepared by the above strategies fails to fully trigger their deformation-resisting and energy-dissipating capacities, leaving it still challenging to reconcile the inherent trade-off between stiffness and toughness. Therefore, the development of a universal strategy for constructing both high stiff and tough with multifunctional gels is imperative.

The advent of deep eutectic solvents (DESs) offers a great opportunity to the above challenges22. In general, DESs is a mixture of multiple components formed under hydrogen bonding and possess low freezing point (Supplementary Table 1), low vapor pressure and high-electrical conductivity (Supplementary Table 2). Moreover, DESs have some characteristics similar to ionic liquids (ILs) such as tunability, thermal/chemical stability and wide electrochemical window23. Additionally, DESs have significant advantages over ILs such as low cost, green, and facile preparation24. Therefore, DESs is becoming a favorable medium for building gels in extreme environments. However, the defects in mechanical properties, such as low stiffness (< 10 MPa) and poor toughness (< 20 MJ m−3), remain current obstacles for functional improvements and applications.

The stiffness and toughness of networked gel materials largely depend on the characteristics, number density, and spatial distribution of cross-linking points25. Based on this, designing robust yet dynamic cross-linking domains (e.g., crystalline domains, micellar microspheres, and folded protein domains) and incorporating dynamic energy dissipation mechanisms are keys to creating gels with both high stiffness and toughness26. In detail, at the initial deformation stage, all robust cross-linking domains behave as high-energy barriers to minimize the network mobility, bonds in dynamic energy dissipation domains randomly broke to absorb energy, significantly increasing the initial elastic modulus; at the larger deformation stage, the adaptive disentanglement of all robust cross-linking domains within homogeneous networks effectively dissipates energy until sample failure, and bonds in dynamic and reversible energy dissipation domains can withstand strain attributed to the reduction of cross-linking density, both serving as a continuous source of toughening.

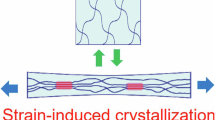

Based on the above considerations, here we demonstrate a synergy of homogeneous distribution yet high number density of robust crystalline domains by phase separation and dynamic cross-linked network created by a large number of metal coordination sites, simultaneously tuning network structure, enhancing stiffness and toughness, and offering functions. In detail, a simple solvent exchange method was applied to convert weak PVA-carboxymethyl cellulose (CMC) composite gels to both stiff and tough gels in a deep eutectic solvent containing metal ions (DESs-M). Crucially, the rational regulation of noncovalent interactions and, thereby, the conformation of polymer chains via solvent exchange can lead to homogeneous distribution and robust crystalline domains for meanwhile dynamic and reversible physical cross-linked domains induced by the metal coordination sites, achieving rigid phase and soft phase. As expected, the as-prepared gel collectively renders good stiffness (110.26 MPa) and toughness (219.93 MJ m−3) to balance the inverse relation of those two. In addition, it is universal and directly applicable to DESs-M liquid containing different metal ions and polymers, offering a promising direction for stiff and tough polymeric gels or other soft materials.

Results

Stiffening while simultaneously toughening polymeric gels with a homogenized dense network cross-linked by strong and tunable domains was constructed via a synergy of phase separation and ion complexation, which is schematically illustrated in Fig. 1a. Firstly, the ChCl, urea and DESs-Ca were characterized by 1H and 13C nuclear magnetic resonance (NMR), indicating that the DESs-Ca liquid was successfully prepared (Supplementary Fig. 1). The intensity of active hydrogens on ChCl decreases with the addition of urea and hydrogen bonds peak shifts to low ppm (5.69–5.61 ppm), indicating the formation of hydrogen bonds between the O-H group of ChCl and the -C = O group of urea (Supplementary Fig. 2a), as stated in Fig. 1a. Considering that urea in the DESs-Ca prepared with ChCl undergoes decomposition when heated above 80 °C for prolonged periods, it may have an impact on the dissolution of CaCl2 in the DESs-Ca liquid. We continued to melt and heat the DESs-Ca liquid at 130 °C for 24 h, and take the heated DESs-Ca sample (heating for 24 h) for 1H NMR and 13C NMR measurement, as shown in Supplementary Figs. 2b, c. After heating for 24 h, there is almost no difference between the spectrum of DESs-Ca (heating for 24 h) and DESs-Ca liquid, and the DESs-Ca liquid is still clear and transparent with no precipitation, indicating that it has almost no effect on the dissolution of CaCl2 in the DESs-Ca liquid. We further discuss the properties of the deep eutectic solvents (DESs-Ca) after adding CaCl2. The interactions between CaCl2 and DESs were initially reflected by the zero-shear viscosity of the DESs-Ca liquid. Noticeably, the DES-Ca liquid (33.14 Pa s) exhibited a higher viscosity than the DESs (0.79 Pa s) (Supplementary Fig. 3a), which indicates the effect of metal ions on the DESs. Also, because of the addition of Ca2+, the thermal decomposition temperature (Td) of DESs-Ca liquid was 174 °C, which was much higher than that of the DESs (Td = 154 °C) (Supplementary Fig. 3b). The results show that a large number of metal ions can further improve the thermal stability of the DESs-Ca liquid. Furthermore, we evaluated the stability of the DESs-Ca liquid. As shown in Supplementary Fig. 3c, after 6 months, DESs-Ca is still clear and transparent, indicating its excellent stability.

a Schematic illustration of the consecutive preparation process of PVA/CMC composite gel (FTD-C) by the synergy strategy. b Contrasting mechanical properties of the FT and FTD-C gel. c Optical images of the flexible, strong and tough FTD-C gel, which can be used to carry a 10 kg bucket of water in a small piece. Data are presented as mean ± standard deviation (n = 3 independent samples).

To implement our design, PVA and CMC were chosen as a model system for constructing composite gel. PVA has regulable conformation and aggregation state, as well as tunable crystallinity, while the CMC chains can be physically cross-linked by multivalent cations. In brief, PVA and CMC were first dissolved in water (which is a good solvent for PVA and CMC) to obtain a homogeneous solution in a solvated state, eliminating intra- and interpolymeric noncovalent interactions. Then, the PVA/CMC polymer solution was poured into Teflon mold and frozen at −20 °C for 24 h. With freezing, the PVA/CMC was fixed in a specific shape macroscopically and the polymer chains were prepacked microscopically to facilitate the subsequent aggregation by solvent exchange to form a bulk gel. The freezing also ensured that the gel block had a flat surface and was morphologically intact after solvent exchange. As shown in Supplementary Fig. 4, instead of forming a smooth and flat bulk gel, the aggregates of PVA/CMC (without prior freezing) partially dispersed and presented an uneven surface of the gel, when the solution state PVA/CMC was directly immersed into DESs-Ca liquid. On the contrary, with freezing, a dense flat bulk gel was formed. This was attributed to the polymer chains prepacking, as they were squeezed between the growing ice crystals during the freezing process27. During the subsequent solvent exchange process, a homogeneously and densely cross-linked PVA/CMC gel was constructed through solvent exchanging from a good solvent (e.g., water) to a relatively poorest one (e.g., DESs-Ca liquid) (Supplementary Fig. 5), a well-established route for regulating noncovalent interactions28 and thereby favoring extended polymer conformations to homogenize networks. In terms of specific details, this process is attributed to the synergistic effects of phase separation and ion complexation, where phase separation occurs with PVA chains shrinking considerably and consequently forming crystalline domains owing to the immiscibility of DESs-Ca liquid with PVA, and the ion complexation is mainly attributed to the interaction between carboxyl groups on CMC and Ca2+, which strongly promoted the aggregation and coordinated the cross-linking of the chains, further increasing the cross-linking density of PVA/CMC network. Finally, through solvent exchange, the synergy between phase separation and ion complexation afforded a stiff and tough gel with chain entanglements and high crystallinity. The final mass content of polymers in the gel is 84.7 ± 3 wt%, among which PVA is 78.8 ± 3 wt%, and CMC is 5.9 ± 3 wt%. The water content in the final gel is about 4.3 ± 3 wt%. Moreover, the molar ratio of choline chloride to urea in the gel was 1:1.95, which was roughly consistent with the composition of DESs-Ca (1:2) used in the solvent-exchange stage, as proved by 1H NMR spectrum (Supplementary Fig. 6).

We first studied the influence of the polymer concentration on the gel in the DESs-Ca liquid with a fixed molar concentration of 1.0 M Ca2+. The solutions with PVA concentration of 15.0 wt% were first prepared, followed by tuning the concentration of the CMC (from 0 to 2.0 wt%). A series of gels with different mechanical properties were obtained. Gels processed by the synergy of phase separation and ion complexation are denoted by x-y-M, where x, y, and M represent the initial mass fraction of PVA and CMC in water solution, and the type of metal ions, respectively. As shown in Supplementary Fig. 8, 15-1.5-Ca gel showed the highest toughness of 84.48 MJ m−3 with the largest tensile stress of 19.27 MPa. As we fixed the concentration of the CMC (1.5 wt%) and increased the mass fraction of the PVA from 10.0 to 20.0 wt%, the tensile stress of gel raised from 5.01 to 29.42 MPa, the elastic modulus changed from 8.19 to 54.82 MPa, and the toughness changed from 11.13 to 129.66 MJ m−3, respectively (Supplementary Fig. 9). The results might be attributed to the fact that the increased PVA strengthened polymer–polymer interactions, induced strong crystallization to form a denser network structure in 20-1.5-Ca. On the other side, we further studied the effect of Ca2+ concentration in the DESs-Ca liquid on the mechanical properties. As depicted in Supplementary Fig. 10, the tensile strength, elastic modulus, and toughness of the 20-1.5-Ca gel increased simultaneously with the concentration of Ca2+. Of note, when 1.3 M of Ca2+ was added, the DESs-Ca liquid began to appear cloudy, indicating that the concentration of calcium ions in the DESs-Ca liquid has reached oversaturation (Supplementary Fig. 11). Therefore, the concentration of the Ca2+ was set to be 1.0 M in further studies.

Driven by the synergetic integration of the phase separation and ion complexation, a homogeneous and robust physical cross-linking network could be established, and the obtained PVA/CMC gel (20-1.5-Ca) exhibited good flexibility (Supplementary Fig. 12) yet high strength, as well as used to pull up two buckets weighing up to 10 kg in only a small piece (8*2*0.05 cm) (Fig. 1c). The excellent flexibility, stiffness, and toughness of PVA/CMC gel were mainly attributed to its homogeneous phase-separated structure and resultant synergistic effects. First, we verify the importance of the slow solvent exchange process for the generation of synergistic effects. The gel produced by dissolving PVA and CMC in a mixture of water and DESs-Ca liquid followed by evaporating the water to the same composition as the 20-1.5-Ca gel (denoted as FTD-C) is named FTE gel. As depicted in Supplementary Fig. 13, the opaque FTE gel has a tensile strength of 12.7 MPa and a tensile strain of 6, indicating its mechanical properties are much smaller than those of FTD-C gel. Furthermore, the FTE gel also exhibits a relatively low elastic modulus of 15.47 MPa and toughness of 49.15 MJ m−3, compared with FTD-C gel. This result confirmed the importance of the slow diffusion of DESs-Ca liquid replacing the water in the solvent exchange process. Also, to further elucidate the effects of the solvent exchange process on the morphology and crystallinity of gels, we have designed controlled experiments and prepared other three types of gels: a) once freeze-thawed hydrogel, without phase separation and Ca2+ complexation, (as a common method for preparing PVA/CMC hydrogel, denoted as FT), b) once freeze-soaked hydrogel, soaking the frozen PVA/CMC in the 1.0 M Ca2+ aqueous solutions, with Ca2+ complexation but no phase separation, denoted as FT-C, and c) gel with only DESs as the substituted solvent, with phase separation but no Ca2+ complexation (denoted as FTD), for comparison with FTD-C gel.

Control experiments verify that the synergetic effect of the phase separation and Ca2+ complexation effectively densify the network structure, facilitate the strong aggregation and polymer crystallization, and evoke the enhancement of all-around mechanical properties of the network gel. Considerably high elastic modulus of 54.82 MPa is attained without sacrificing the ductility (fracture strain of 720%) when the CMC/PVA hydrogel is replaced in DESs-Ca liquid, which is approximately 36600% that of the FT gel (Fig. 1b) and rivals a large number of state-of-the-art tough gels (Supplementary Fig. 14). Meanwhile, the toughness and tensile strength of the FTD-C gel outperform the FT gel by 10400% and 2900%, respectively, opening the opportunity for fabricating high-performance and durable soft materials at low cost for usage in multitude circumstances, including soft body armor, robotics, and flexible electronics, etc.

The four PVA/CMC gels (including FT, FT-C, FTD, and FTD-C) were tested to demonstrate the enhancement of our synergy strategy on mechanical properties. Firstly, their typical stress–strain curves were plotted in Fig. 2a. Due to the synergistic effects of phase separation and ion complexation, FTD-C gel exhibited overwhelming enhanced tensile strength up to 29.45 MPa. This strength was 162% that of FTD gel (18.20 MPa), 3385% that of FT-C gel (0.87 MPa), and 2916% that of FT gel (1.01 MPa), as shown in Fig. 2b. It was noteworthy that the tensile strength of FT-C gel was less than that of FT gel. This performance might be attributed to the salting-in effect of CaCl2 on PVA polymer chains, which can soften the tough hydrogels slowly29. On average, as illustrated in Fig. 2c, the FTD-C gel also exhibited a high elastic modulus of 54.82 MPa and superb toughness of 129.66 MJ m−3, two order of magnitude higher than those before solvent-exchange. Compressing measurements (Supplementary Fig. 15) were also performed and exhibited similar enhancement trend, whereby FTD-C gel presented good toughness with 5660% higher compressive stress, 18800% higher compressive modulus and 8985% higher toughness than the FT gel, respectively, indicating the essential roles of crystalline domains generated by phase separation and coordination bonds by ion complexation.

a Tensile stress-strain curve of the gels. b Strain and tensile strength of the gels. c Elastic modulus and toughness of the gels. d Sequential loading-unloading tensile tests without interval and (e) the corresponding calculated total and dissipated energy and hysteresis ratio of the FTD-C gel under different strains. f The mechanical performances of FTD-C gel in the state-of-the-art toughness–modulus diagram together with results from previously reported high-performance gels and elastomers (TOR, COR elastomer55, PVA-ANF56, C-G-P CN57, PCL-PNAGA58, SPM59, PRC60, Hybrid DN61, Alg62-PVA-Zn2+, FT-EtFe-V63, DES-PVA2064, SEWA25-1203048, PAAm-PAA20, PVA-CA65, UiO-6666, P(MEA-co-IBA)67, TN-EAMAMA68, HA-PVA17, P(MAAm-co-MAAc)69, P(DMAA-co-MAAc)70, PAAm-I-MBAm71). The yellow dashed line indicated the trade-off between toughness and stiffness for the current state-of-the-art hydrogels (Γ = 862490 kN3/2 m−2 × E−1/2). The FTD-C gel in this work surpassed this limit and simultaneously achieved high stiffness and toughness. g The proposed deformation mechanism of highly stiff and tough FTD-C gels. Data are presented as mean ± standard deviation (n = 3 independent samples).

We further investigated the energy dissipation of the FTD-C gel subjected to prolonged cyclic loads. Upon cyclic loading with increased tensile strain without intervals between cycles, the corresponding dissipated energy per unit volume significantly improved from 7.05 to 24.38 MJ m−3 when the tensile strain increased from 1 to 6, providing efficient energy dissipation to toughen the FTD-C gel (Fig. 2d). The ratio of the integrated area of the hysteresis to that of the loading curve (Supplementary Fig. 16), i.e., hysteresis ratio (hr)30, is 83.52% in the first cycle, and in the subsequent five cycles, showing a larger hr of 87.90% (Fig. 2e). While, for the FT, FT-C gels, the loading curve almost overlaps with the unloading curve in the previous cycle, but for the FTD gel, the loading curve of the following cycle is significantly higher than the unloading curve of the previous cycle (Supplementary Fig. 17), justifying that the phase separation-caused physical interactions in the gel networks. Supplementary Fig. 18 shows hr of each cycle at different strains for FT, FT-C, FTD gels. The FTD gel exhibits the largest hr of 83.91% among them, whereas still lower than hr of the FTD-C gel (87.90%), indicating ionic complexation further enhances the efficient energy dissipation to toughen the gels. In addition, mechanical hysteresis of FTD-C was observed in cyclic stretching with a fixed tensile strain of 3.0 (Supplementary Fig. 19d). The energy dissipated in the 1st cycle was 37.55 MJ m−3, 652% and 2030% the dissipated energy in the 2nd (5.76 MJ m−3) and 10th (1.85 MJ m−3) cycle, respectively, which demonstrated that the sacrificial bonds (primarily coordination bonds and reversible hydrogen bonds) in FTD-C gel broke during deformation. After 10 cycles of stretching, the maximum stress still maintained a high level (8.27 MPa), manifesting the structural stability of these partially damaged cross-linking points within the homogeneous networks, therefore effectively avoiding material failure caused by stress concentration during repeated deformation. Supplementary Fig. 20 shows the hr of consecutive cyclic tensile tests of the gels to the same strain for the FT, FT-C, FTD, FTD-C gel. For, FTD-C, a very large hr up to 94.5% is observed in the first cycle to the strain of 300%, and high hr values were observed in the subsequent cycles, with a high hr of 63.0% even in the 10th cycle (Supplementary Fig. 20d). While, for the FT gel, hr is 54.4% in the first cycle, but in the subsequent cycles, its loading and unloading curves almost overlap (Supplementary Fig. 19a), showing a low hr of 9.2% in the 10th cycle. This observation suggests that the FTD-C gel possesses a more effective energy-dissipation mechanism. Additionally, Mullins’ effect is evident during cyclic loading, and the compressive strength exhibited negligible changes, maintaining 93% of its original value after ten loading cycles at a fixed tensile strain of 0.5. This observation further underscores the structural stability of the FTD-C gel within its homogeneous network (Supplementary Fig. 21).

It is well established that elastomers and gels typically exhibit a trade-off between stiffness and toughness, as described by the Lake–Thomas model (Γ ∼ E−1/2), indicating a performance limit for the current state-of-the-art gels31. In the PVA/CMC composite gel, the high number density of crystalline domains caused by phase separation and reversible dynamic coordination bonds caused by ion complexation enhances the stiffness of its homogenized network without inducing brittleness, having effectively circumvented this challenging trade-off observed in water-free elastomers (Fig. 2f). Without surprise, the FT, FT-C, and FTD gels exhibited much lower modulus of 0.15 MPa, 0.19 MPa and 23.97 MPa and fracture energy of 2.46 kJ m−2, 1.44 kJ m−2 and 84.25 kJ m−2, respectively. These values are well below the upper limit seen in the toughness-versus-stiffness diagram (Fig. 2c and f). The key to reconciling the stiffness–toughness conflict lies in the synergistic combination of uniformly distributed robust crystalline domains and reversible dynamic ion complexation domains. This combination fully activates both the deformation-resisting and energy-dissipating capacities of the cross-linking points in the network. The crystalline domains and metal coordination bonds in the FTD-C gel are not rigid but are instead dynamic and adaptable. Upon deformation, the metal coordination bonds in soft domains begin to fracture gradually, dissipating energy and subsequently reforming to withstand further strain. At the same time, the robust crystalline domains remain intact at the initial stage, preventing significant network deformation. As the deformation progresses, these crystalline domains gradually unravel, facilitating ongoing energy dissipation. This mechanism enables the gel to achieve a rare combination of superb stiffness and toughness, thus effectively addressing the mechanical properties trade-off (Fig. 2g).

To assess the influence of loading rate on mechanical properties of the FTD-C gel, we further performed the uniaxial tensile test of the FTD-C gels using different loading rates from 5 to 80 mm min−1, as shown in Fig. 3a. When the loading rate was increased from 5 to 80 mm min−1, the tensile strength of the FTD-C gels increased from 20.84 to 43.51 MPa, whereas the tensile strain remained nearly unchanged. Additionally, the elastic modulus and toughness of the FTD-C gel followed a similar trend as the loading rate increased, and reached maximum values of 110.26 MPa and 219.93 MJ m−3, respectively, at 80 mm min−1 (Fig. 3b). Based on this, we performed two-dimensional wide-angle X-ray scattering (2D WAXS) analysis on two samples with loading rates of 5 mm min−1 and 80 mm min−1. As illustrated in Supplementary Fig. 22a and 22b, the ellipsoidal WAXS pattern of FTD-C gels indicated a noticeable orientation of crystalline domains through stretch-induced alignment. In addition, the WAXS results showed a significant increase in the crystallinity of the samples after increasing the loading rate (Supplementary Fig. 22c). As shown in Supplementary Fig. 22d and 22e, the FTD-C gel displayed two obvious diffraction peas at 2θ = 19.7° and 40.3°, which corresponds to the typical reflection plane of (101) and (102) in semicrystalline PVA32. As a result (Supplementary Fig. 22f), the FTD-C gel (80 mm min−1) showed a higher crystallinity of 34.30% compared with 25.15% of FTD-C gel (5 mm min−1). This result shows that the amorphous polymer chain segments are arranged more closely and orderly due to the applied force during the stretching process, that is stretching-induced long-range molecular chains improve the ordering of the amorphous phase33, which may be the reason for the enhancement of mechanical properties with increasing loading rate34. In addition, FTD-C gel also demonstrated excellent mechanical stability and durability as shown by the multiple tensile cycle tests, in which apparent overlapping curves were observed after a hysteresis loop in the 1000th cycle (Fig. 3c), and slight plastic deformation of the gel is observed, and no crack is detected over 10000 stretching-and-contracting cycles (Supplementary Fig. 23). Since the deep eutectic solvents are hydrophilic, we tried to explore the effect of moisture on the mechanical properties of the FTD-C gel. As shown in Supplementary Fig. 24, the mechanical properties of the FTD-C with different water content (2.3%−16.6%) were assessed to reveal the effect of moisture. The higher water content led to the omnidirectional decrease of the tensile strength, elastic modulus, and toughness. It is worth noting that when the water content of the FTD-C gel reaches equilibrium at 16.6%, the tensile strength, elastic modulus, and toughness of the gel are 23.5 MPa, 35.6 MPa and 102.7 MJ m−3, respectively, and the mechanical properties of the FTD-C gel still remain at a relatively high level.

a Tensile stress-strain curves of the FTD-C gel with different loading rates. b Elastic modulus and toughness of the FTD-C gel with different loading rates. c Cyclic stretching curve of FTD-C gel for over 10,000 cycles at a predeterminate strain of 50%. d Experimental determination of fracture energy. e The FTD-C gel containing the notch was stretched to 7 times its initial length. f Schematic diagram of the crack resistance of a material. g Γ of various materials versus energy dissipation density, W. The slopes shown by the dotted lines reflect the size of the energy dissipation zone of different materials. h–i Comparison of the prepared FTD-C gels: (h) toughness vs ultimate tensile stress, and (i) elastic modulus vs ultimate tensile stress (microphase separation72, mechanical training73, phase separation20, ion-induced and salting-out62, solvent-exchange and salting-out65, solvent-exchange and wet-annealing48, freeze-casting and salting-out17, anisotropic densification and ionic cross-linking74, coordinated supramolecular solvents50, solvent-replacement64, solution annealing and dual cross-linking75, nanofibrils-filled76). Data are presented as mean ± standard deviation (n = 3 independent samples).

Currently, the fatigue and fracture of materials primarily stem from the catastrophic growth of cracks caused by stress concentration at the crack tip35. Therefore, the service life of gels partly depends on their ability to resist crack propagation. To validate the impact of the synergetic combination of phase separation and ion complexation on resistance to crack propagation, gel specimens containing unilateral notches were stretched uniaxially and their fracture energy \(\varGamma={HW}({\lambda }_{c})\) was calculated according to the method introduced by Rivlin and Thomas36. As shown in Fig. 3d, to adapt the method to measure the fracture energy of a stretchable gel, we separately tested two samples of the same gel. One sample was unnotched, and the other sample was notched. The fracture energy was determined to be 2.46 kJ m−2 for FT, 1.44 kJ m−2 for FT-C, 84.25 kJ m−2 for FTD and 393.87 kJ m−2 for FTD-C as the synergistic effects enhancement progressed (Supplementary Fig. 25). The fracture toughness of 393.87 kJ m–2 is achieved by the FTD-C gel, which is two orders of magnitude that of the FT gel. The increase in fracture energy could be attributed to the fact that the synergistic-enhanced strategy significantly induced the formation and growth of crystalline domains and dynamic ion complexation domains, resulting in a much higher energy requirement per unit area for breaking domains compared to breaking amorphous polymer chains37. Photographs during the test evidently show the contrasting crack resistance of the FT, FT-C, FTD, and FTD-C gel. At a strain of 250%, FT gel has been completely pulled apart, and the crack grows intensively in the FT-C and FTD gels while it is pinned in the FTD-C gel (Supplementary Fig. 26). As shown in Fig. 3e, when we cut a notch into the FTD-C gel and then pulled it to a stretch of 7, the notch was dramatically blunted and remained stable. Furthermore, the toughening mechanism of the FTD-C gel can be explained by the recent work on tough soft materials38, which has demonstrated that the material’s crack resistance (or fracture toughness, Γ) follows a simple relation: \(\varGamma=W{l}_{{{{\rm{T}}}}}\). In this equation, ƖT (m) represents the size of the energy dissipation zone, and W (J m–3) indicates the energy dissipation density (Fig. 3f). In this work, both the fracture energy (Γ) and the work required to rupture (W) were determined through mechanical testing, allowing for the calculation of ƖT values for the different gels. The results show that the four gels possess close ƖT values: 1.87 mm for FT, 1.35 mm for FT-C, 1.04 mm for FTD, and 1.07 mm for FTD-C gel. However, there is a notable difference in their energy dissipation densities. Specifically, the W of the FTD-C gel (129.66 MJ m–3) is 2 orders of magnitude higher than that of the FT gel (1.25 MJ m–3). This significant difference explains why the FTD-C gel exhibits superior crack resistance. In simpler terms, the FTD-C gel requires a much higher amount of energy to fracture a unit volume compared to the FT gel. As a result, cracks cannot propagate in the FTD-C gel unless the applied energy surpasses the threshold. This finding highlights the critical role of the synergistic strategy in enhancing the toughness of the originally weaker FT gel. The force transfer length or the size of the energy dissipation zone of a material is usually expressed by a plot of fracture energy, Γ, versus the work to rupture, W39. The slope of the plot reflects the size of the energy dissipation zone, ƖT, according to Equation \(\varGamma=W{l}_{{{{\rm{T}}}}}\). Here, we show the plot of Г versus W for various material systems, from soft to rigid in Fig. 3g. It is obvious that the FTD-C gel can achieve energy dissipation zones of about 1 mm, which is larger than most common material system40,41,42.

Different from the traditional polymeric materials which suffer from the inherent conflict between stiffness and toughness, FTD-C gel achieves coordinatively enhanced stiffness (54.82–110.26 MPa) and toughness (129.67–220.54 MJ m−3), reconciling the challenging trade-off between them. The ultimate toughness and ultimate elastic modulus far surpassed the values of the reported nanofibrils-filled ionogels, phase-separation ionogels, mechanical training hydrogels, solvent-exchange gels, and other representative tough ionogels and hydrogels (Fig. 3h, i). This was attributed to the synergistic stiffening and toughening effects, across homogeneous distribution and high number density of robust crystalline domains via phase separation and dynamic ion complexation domains via Ca2+ complexation. It was also worth noting that many gels were prepared with complex engineering (freeze-casting, pre-stretching−salting-out fixation, triple networks, etc) to achieve stiffening and toughening. Having prepared a simple approach to solvent exchange in this study, our proposed synergetic strategy could achieve an unusual combination of impressive stiffness and toughness, which can be further applied to more intricate material systems for even enhanced mechanical properties.

Crucial to the combination of high modulus and toughness on FTD-C gels is the synergetic integration of high number density of crystalline domains and dynamic cross-linking domains. To understand the synergistic effects, we conducted a series of characterizations for comparing the microstructures of FT, FT-C, FTD, and FTD-C gels. The scanning electron microscopy (SEM) images of the different gels after freeze drying are shown in Supplementary Fig. 27. FT gel showed a homogeneously dispersed network, whereas the large uneven aggregates were discovered in FT-C gel. After the composite gel underwent solvent exchange, the morphology changed drastically. Polymer-rich phases become visible in the SEM images, and FTD-C gel displayed a more homogeneous and dense morphology than FTD gel.

To reveal the densified network structural characteristics after solvent exchange, we further measured the crystalline structures of the resultant FT, FT-C, FTD, and FTD-C in gel state. The diffraction patterns of FT and FT-C gel displayed two halos centered at 2θ ≈ 28 and 41°, signifying its amorphous character43 (Supplementary Fig. 28). As demonstrated in Fig. 4a, the diffraction peak at 2θ = 19.6°, originated from the typical reflection plane of (101) in semicrystalline PVA, exhibits an abrupt intensification after solvent replacement with the liquid DESs-Ca, indicating a rise in crystallinity. It is worth noting that the signal of FT-C gel became blunter, nearly disappearing, which might be attributed to the salting-in effect of CaCl2 on PVA polymer chains, inducing relaxation of polymer chains, which is different from the multivalent cation-induced coordination interaction44. Moreover, small peaks at 2θ = 23.1°, attributed to the (200) plane of the PVA crystalline structure, which is absent in the FT and FT-C gel, come into being after solvent exchange. As shown in Fig. 4b and Supplementary Fig. 29, the FT-C gel with salting-in effect showed negligible crystalline peaks, and low crystallinity of around 0.76%. On distinct contrast, after solvent exchanging with the liquid DESs-Ca, the crystallinities sharply increased to ~58.26%, suggesting the substantial increasement of crystallinity in the FTD-C gel by the solvent exchange-induced phase separation effect.

a XRD profiles of the FT, FT-C, FTD and FTD-C gel. b Calculated crystallinities of the FT, FT-C, FTD and FTD-C gel. c Representative SAXS profiles of the FT, FT-C, FTD and FTD-C gel. d The corresponding estimated average size of crystalline domains (D) and average distance between adjacent crystalline domains (L) of the FT, FT-C, FTD and FTD-C gel. The insets illustrated that the average size of crystalline domains remained largely the same, whereas the average distance between adjacent crystalline domains decreased owing to the generation of a large number of new crystalline domains during the solvent exchange. The data bits in the hollow circular ring are estimated data. e ATR-FTIR spectra for the FT, FT-C, FTD and FTD-C gel. f Ca 2p of the FTD and FTD-C gel. g O 1 s of the FTD and FTD-C gel. h AFM phase image of the FTD-C gel.

By identifying the half-width of the maximum diffraction peak β, the average size of crystalline domains D can be approximately estimated using Scherrer’s equation D = kλ/ (β cos θ), where k is a dimensionless shape factor varying with the actual shape of the crystalline ___domain, λ is the wavelength of X-ray diffraction, and θ is the Bragg angle. Here, β is identified after fitting the WAXS profiles of gels (Supplementary Fig. 30), and the dimensionless shape factor k is set as 1, approximating the spherical shape of the crystalline domains45. As shown in Fig. 4d, the average size of crystalline domains was found to remain largely the same by using different preparation methods, implying that the substantially increased crystallinity during solvent exchange can be only attributed to the increase of the number density rather than the size of individual crystalline domains. Additionally, we further conducted SAXS measurements on the FT, FT-C, FTD, and FTD-C gels to measure the scattering intensity I (q) versus the scattering vector q. As shown in Fig. 4c, there is no peak in the plot of the intensity versus the scattering vector q for the FT-C gel, which implies negligible interference between adjacent crystalline domains. For the FT gel, there is a slight shoulder shown in the intensity curve, which indicates stronger interference between adjacent domains. The average distance between adjacent crystalline domains L can be estimated from the critical vector corresponding to the peak intensity qmax, following the Bragg expression46. The average distance between adjacent crystalline domains L decreased from 18.47 to 11.03 nm after phase separation and ion complexation, consistent with the crystallinity results (Fig. 4d). The increase in the crystallinity coupled with the decrease in the distance between adjacent crystalline domains supported the structural reinforcement and densification of the FTD-C gel networks.

Subsequently, the attenuated total reflection Fourier transform infrared (ATR-FTIR) spectroscopy was used to investigate the hydrogen bonding between polymers within the gels. Compared to PVA, the FTD-C gel containing CMC showed new absorption peaks at 1675 and 1617 cm−1 (Supplementary Fig. 31), which were assigned to the stretching vibration of the C = O and C = C47. Besides, the absorption bands at 3436 cm−1 attributed to the asymmetric stretching of a N−H group in primary amide of urea and 3429 cm−1 attributed to the vibrational stretching of a O–H group of CMC shift to 3358 cm−1. These shift indicate the formation of hydrogen bonds between the NH2 group of urea, O–H group of CMC and the O−H group of PVA30. As shown in Fig. 4e, a peak fitting method was performed on the stretching vibration of O-H from 3000 to 3700 cm–1, where the peak at 3210 cm–1 was attributed to the PVA–PVA interactions46. The contribution of the hydrogen bonding between PVA was quantified by calculating the area ratio of the peak at 3210 cm–1 to the sum area of the stretching vibration of O–H (Supplementary Fig. 32). The area ratio was determined to be 30.8%, 28.1%, 33.3% and 36.2% for FT, FT-C, FTD and FTD-C gel, respectively, implying that the hydrogen bonding of PVA–PVA was more profound in FTD-C gel. This trend was consistent with the crystallinity results, which supported the structural densification of the FTD-C gel networks. In addition, as shown in Supplementary Fig. 33, the absorption peaks of 1143 cm−1 representing C-O of PVA related to the formation of crystalline ___domain48, and the FTD-C gel exhibited the maximum peak intensity, suggesting that the solvent exchange with liquid DESs-Ca formed more crystalline domains. Supplementary Fig. 34 shows that the peak reflecting the symmetric stretching vibration of the −COO– group gradually shifts from 1446 to 1476 cm–1 using liquid DESs-Ca for substitution, which is powerful evidence of the formation of strong interaction with Ca2+ forming a carboxyl-Ca2+ complex during the solvent exchange process49. The pH value of DESs-Ca liquid before and after solution exchange was around 7, which showed that the pH value of the solution exchange process had little effect on the formation of coordinated Ca2+ with −COO– group. Supplementary Fig. 35a plotted the endothermal peaks of the glass transition (highlighted as Tg) and melting (Tm) of the FTD and FTD-C gel. The glass transition of the FTD-C gel occurred at ≈71 °C, showing low and broad endothermal peaks. The distinct endotherm melting peak could be observed at ≈182 °C. The gel has since melted. Also, because of the addition of Ca2+, the thermal decomposition temperature (Td) of FTD-C gel was 212 °C, which was much higher than that of the FTD gel (Td = 181 °C) (Supplementary Fig. 35b). The results show that a large amount of added metal ions can further improve the thermal stability of the FTD-C gel50.

Moreover, as illustrated in Supplementary Fig. 36, the XPS peaks corresponding to the element Ca 2p were clearly observed in FTD-C gel and two broad characteristic peaks at 399.82 and 402.52 eV for O = C-NH2 and -N+, respectively, appear in the FTD-C gel, which is not shown by the FT-C gel, indicating the successful solvent exchange within the liquid DESs-Ca. Also, two typical peaks of Ca 2p1/2 and Ca 2p3/2 at 351.07 eV and 347.41 eV, respectively, appear in the FTD-C gel, which is not shown by the FTD gel (Fig. 4f). Meanwhile, the -C-OH and −C = O peaks in FTD-C gel shifted to higher binding energy (from 532.45 to 532.55 eV and from 531.81 to 531.97 eV, respectively) compared with FTD gel (Fig. 4g). These results verify the strong coordination interactions51 between the −COO– and Ca2+. On the other hand, in the XPS spectra of O 1 s (Supplementary Fig. 37), the shift of the −C = O peak from 531.97 of FT to 531.81 eV of FTD gel further confirmed the formation of the hydrogen bond among polymer chains52, which is roughly consistent with the results of ATR-FTIR test.

It is worth noting that the prepared FT, FT-C, FTD, FTD-C gel exhibited different transparency. As shown in Supplementary Fig. 38, the transmittance of FTD-C gel was as high as 87.12% but decreased to 60.42% of FTD gel, 23.71% of FT-C gel, 1.86% of FT gel. It is generally accepted that the uniform distribution of crystals with regular structure provides PVA gel with good transmittance, owing to the fact that they can reduce the occurrence of light scattering and improve the optical transmittance of the gel by enhancing light refraction53. We believed that the improved transmittance in FTD-C gel was attributed to the formation of a more uniform internal polymer network with denser crystal structures as illustrated in Fig. 4b, d.

To further validate the phase-separation structure of the FTD-C gel with the exchange of a relatively good solvent (H2O) with an extremely poor solvent (DESs-Ca), atomic force microscopy (AFM) was employed to obtain phase images of the composite after solvent exchange. In Fig. 4h, the bright areas indicate regions of relatively high modulus (PVA-concentrated phase of crystalline domains), and dark areas correspond to regions of relatively low modulus (PVA-dilute phase of amorphous domains)54. FTD-C gel had a homogeneous phase-separated structure with a length scale much smaller than the wavelength of visible light, which contributed to the transparency and toughness of the composite. On the contrast, the phase-separation structure of FTD gel exhibited a significant decrease in homogeneousness (Supplementary Fig. 39), which is also reflected in its transparency and mechanical properties both decreasing.

The excellent mechanical properties and energy dissipation ability of FTD-C gel make it exhibit extraordinary impact resistance. To characterize the impact performance of FTD-C gel, we carried out falling ball experiments at different heights under the protection of FTD-C gel (Supplementary Fig. 40). As shown in Fig. 5a and Supplementary Movie 1, FTD-C gel was used as safeguard to protect glasses from impact. Glass with a size of 100 mm × 100 mm × 2.5 mm was covered with FTD-C gel with a size of 70 mm × 70 mm × 3.5 mm, and then impacted by a steel ball of 115 g falling from a height of 70 cm. As a control experiment, the glass was exposed and directly impacted by a steel ball of 115 g falling from a height of 35 cm (Fig. 5b and Supplementary Movie 2). Only the glass protected by FTD-C gel maintained integrity (Supplementary Fig. 41), while the glass exposed shattered after impact. In addition, to more intuitively demonstrate the excellent impact resistance ability of the FTD-C gel, an apparatus for the falling steel ball (115 g) impact test was constructed. When the steel ball fell on the FTD-C gel suspended on the rubber gasket from a distance of 130 cm, the gel could fully support the steel ball without punctured (Supplementary Fig. 42 and Movie 3). These results indicate that the FTD-C has a good cushioning effect and impact resistance, making it very promising for protecting fragile items in daily life.

Benefiting from the inherent low freezing point of DESs-Ca, the FTD-C gel also exhibited good anti-freezing performances. The freezing temperature was measured by differential scanning calorimetry (DSC) to highlight the anti-freezing ability. As shown in Supplementary Fig. 43, two sharp peaks located at −22.5 °C and −29.8 °C as the freezing point of free water and CaCl2 aqueous solution were observed for FT and FT-C gel, while no exothermic peak appeared even at −80.0 °C for FTD-C gel. In addition, the prepared FTD-C gel also exhibited good ionic conductivity of ~0.15 S m−1 because of the characteristics of DESs-Ca liquid in the polymer network (Supplementary Fig. 44). Supplementary Fig. 45 simultaneously compares the ionic conductivity and tensile stress of the FTD-C gels in this work and numerous advanced conductive gels. The FTD-C gels in this work are located in the rightmost area of the plot, indicating that they possess higher tensile stress to some previously reported conductive gels while preserving competitive ionic conductivity. Therefore, based on the excellent impact resistance and good conductivity, the FTD-C gel provided a promising design idea for the future development of sensors that can be used to detect impact signals.

According to the reinforcing mechanism of FTD-C gel, we propose that the synergistic method of phase separation and ion complexation is a universal strategy to convert the preformed homogeneous hydrogels into stiff and tough eutectogel. To validate this hypothesis, we chose other monovalent and multivalent cations salts to prepare different DESs-M liquid, namely DESs-Li, DESs-Zn, DESs-Fe, and also fabricated the FTD-Li, FTD-Zn, FTD-Fe gels with excellent mechanical properties and good ionic conductivity (Figs. 6a–c and Supplementary Fig. 46). It’s worth noting that the gels prepared with multivalent cations exhibited different reinforcement behaviors. With the concentration of CMC in the gel increased from 0 to 2.0 wt%, both FTD-Zn and FTD-Fe greatly increased toughness and stiffness of the gels, whereas the mechanical properties of FTD-Li gel had remained almost unchanged. This kind of enhancement behavior is similar to the results reported in previous literature44, and proves that the DESs-M liquid containing multivalent cations efficiently complies with this strategy. Moreover, we envisioned using other water-soluble polymers as backbones to create eutectogels for further evaluating the universality of this strategy. Physical eutectogels from κ-Carrageenan, PVA/SA (sodium alginate), PAAm, and gelatin were prepared through the synergistic strategy (Figs. 6d–f and Supplementary Fig. 47 and 48). As shown in Supplementary Fig. 49, the FTD-C gels showed a good all-around performance, like elastic modulus increased for κ-Carrageenan (9.05 MPa), PVA/SA (sodium alginate) (57.25 MPa), PAAm (120.41 MPa), and gelatin (120.02 MPa), which overwhelmingly exceeded their constituents FT gel, κ-Carrageenan (0.36 MPa), PVA/SA (sodium alginate) (0.11 MPa), PAAm (not yet fully gelled), and gelatin (0.07 MPa). These results implied that the synergistic strengthening and toughening strategy can be applied to other polymers and DESs-M, and would greatly promote the development of these materials with all-round properties for high-performance applications.

a Tensile stress-strain curves of FTD-Li gel. b Tensile stress-strain curves of FTD-Zn gel. c Tensile stress-strain curves of FTD-Fe gel. d Tensile stress-strain curves of FT (black), FTD-C (red) composed of κ-Carrageenan. e Tensile stress-strain curves of FT (black), FTD-C (red) composed of PVA/SA. f Tensile stress–strain curves of FT (black), FTD-C (red) composed of PAAm.

In the scheme of solvent exchange for preparing the FTD-C gel, this should consider the challenges of homogeneous diffusion imposed by the geometry and size of the materials prepared, which affects the time-consuming of the solvent exchange process and the volume of DESs-Ca required. This shows that the solvent exchange method still has certain limitations, which are also reflected in other works34,35. In the follow-up work, further research can be carried out on the exchange solvent volume, solvent exchange speed, solvent diffusion effect, etc., to seek shorter processing time and less solvent consumption.

Discussion

In this study, polymer network structure was adjusted to prepare both stiff and tough gels (FTD-M) via the synergy of homogeneous distribution and high number density of robust crystalline domains by phase separation and dynamic cross-linked network created by metal coordination sites. In detail, we first have synthesized a deep eutectic solvent containing various metal ions (DESs-M), and then a facile and universal solvent-exchange method was used to achieved an unusual combination of mechanical properties. The obtained FTD-C gel exhibited impressive stiffness (110.26 MPa), high toughness (219.93 MJ m−3) and strength (43.51 MPa), which effectively circumvented the long-standing incompatibility between stiffness and toughness. Furthermore, the gel also demonstrated good cushioning effect, impact resistance, wide temperature-tolerance and conductivity.

Considering that the aforementioned design principle is based on generic polymer networks, it should be applicable to imparting competitive mechanical performance to other soft materials comprised of polymer networks, thereby extending their scope of applications, such as tissue engineering, vibration absorbers, soft robotics, and smart wearable devices.

Methods

Preparation of liquid deep eutectic solvents-metal (DESs-M)

DESs-Ca was taken as an example. DESs were made by stirring a mixture containing choline chloride (200.0 g) and urea (172.0 g) in a molar ratio of 1:2 at a temperature condition (90 °C) for 1 h, and a homogenous and transparent solution was obtained. Then, 1 M anhydrous CaCl2 was added into deep eutectic solvents under at 130 °C under stirring until being completely dissolved. Finally, a clear, transparent, and homogeneous target liquid obtained. As with the above preparation, by varying the concentration and type of cationic salt added, we can prepare different DESs-M liquid. The obtained liquids were labeled as DESs-Li, DESs-Zn, and DESs-Fe, respectively.

Preparation of FT and FT-C gel

6.0 g of PVA powder was firstly added into 23.55 g of deionized water under vigorous stirring at 90 °C until the clear PVA aqueous solutions formed. Then 0.45 g CMC was added into the PVA solution with stirring for 2 h until the clear PVA/CMC aqueous solutions formed with mass fraction of 20 wt% PVA, 1.5 wt% CMC. After defoaming, the transparent solutions were poured into Teflon mold (9 × 5 × 0.4 cm) and frozen at −20 °C for 12 h. After freezing, the samples were thawed at room temperature (~25−30 °C) and then the resulting gels were denoted as FT gel. Frozen blocks can be obtained by demolding the samples using a hydraulic press with designed compression dies. Then the frozen blocks were submerged in 500 mL of 1 M CaCl2 solution at room temperature for 24 h to create the gel. Every 12 h, the CaCl2 solution was changed with new CaCl2 solution. And the resulting gels were denoted as FT-C gel.

Preparation of FTD and FTD-C gel

6.0 g of PVA powder was firstly added into 23.55 g of deionized water under vigorous stirring at 90 °C until the clear PVA aqueous solutions formed. Then 0.45 g CMC was added into the PVA solution with stirring for 2 h until the clear PVA/CMC aqueous solutions formed with mass fraction of 20 wt% PVA, 1.5 wt% CMC. After defoaming, the transparent solutions were poured into Teflon mold (9 x 5 x 0.4 cm) and frozen at −20 °C for 12 h. Then the frozen samples were submerged in 500 mL of DESs-Ca liquid at room temperature for 24 h to create the DESs-Ca gel. For DESs-Ca, every 12 h, the DESs-Ca was changed with fresh DESs-Ca to ensure that the water content in the final gel reached a certain equilibrium (See Supplementary Fig. 7 for more details). And the resulting gels were denoted as FTD-C. The final mass content of polymers in FTD-C gel is 84.7 ± 3 wt%. Among them, PVA is 78.8 ± 3 wt%, CMC is 5.9 ± 3 wt%. The water content in the final gel is about 4.3 ± 3 wt%. The FTD gel was fabricated using the same method and mole concentration as the DESs-Ca gel by altering the liquid DESs-Ca to DESs.

Preparation of FTE gel

As mentioned above, the mass content of components in FTD-C gel is 84.7 ± 3 wt% polymers, 4.3 ± 3 wt% water and 11% ± 3 wt% DESs-Ca liquid. 6.0 g of PVA powder was firstly added into a mixed solution of 22.71 g deionized water and 0.84 g DESs-Ca liquid under vigorous stirring at 90 °C until the clear PVA aqueous solutions formed. Then 0.45 g CMC was added into the PVA solution with stirring until the PVA/CMC aqueous solutions to form with mass fraction of 20 wt% PVA and 1.5 wt% CMC. After defoaming, the solutions were poured into Teflon mold (9 × 5 × 0.4 cm) and were frozen at −20 °C for 12 h. After freezing, the samples were thawed at room temperature (~25–30 °C) followed by evaporating the water to the same composition (4.3 ± 3 wt%), and the gel is named as FTE gel.

Effect of moisture on FTD-C gel mechanical properties

The samples were prepared and exposed to the external environment for different times until the FTD-C gel reached moisture equilibrium (about 3 days). Then a series of FTD-C gels with different water contents were obtained.

Determination of solvent composition ratio in FTD-C gel

The solvent in the FTD-C gel was dialyzed (Mw cutoff 3500) against distilled water (5 days) and freeze-dried to obtain DESs. Then the freeze-dried DESs were redissolved using DMSO-d6 solvent for 1H NMR analysis.

Preparation of gels with other water-soluble polymers

κ-Carrageenan

1.5 g of κ-Carrageenan powder was firstly added into 28.5 g of deionized water under vigorous stirring at 90 °C until the clear κ-Carrageenan aqueous solutions formed. Then the transparent solutions were poured into Teflon mold (9*5*0.4 cm) and was frozen at −20 °C for 12 h. After freezing, the frozen samples were thawed at room temperature (~25–30 °C) and then the resulting gels were denoted as FT gels. Similar to the previous steps, the frozen samples were submerged in DESs-Ca liquid at room temperature for 24 h to create the FTD-C gels.

PVA/SA

4.5 g of PVA powder was firstly added into 24.6 g of deionized water under vigorous stirring at 90 °C until the clear PVA aqueous solutions formed. Then 0.9 g SA was added into the PVA solution with stirring until the homogeneous PVA/SA aqueous. After defoaming, the transparent solutions were poured into Teflon mold (9 × 5 × 0.4 cm) and was frozen at −20 °C for 12 h. After freezing, the frozen samples were thawed at room temperature (~25–30 °C) and then the resulting gels were denoted as FT gels. Similar to the previous steps, the frozen samples were submerged in DESs-Ca liquid at room temperature for 24 h to create the FTD-C gels.

Gelatin

6.0 g of gelatin powder was firstly added into 24.0 g of deionized water under vigorous stirring at 90 °C until the clear gelatin aqueous solutions formed. After defoaming, the transparent solutions were poured into Teflon mold (9 × 5 × 0.4 cm) and frozen at −20 °C for 12 h. After freezing, the frozen samples were thawed at room temperature (~25–30 °C) and then the resulting gels were denoted as FT gels. Similar to the previous steps, the frozen samples were submerged in DESs-Ca liquid at room temperature for 24 h to create the FTD-C gels.

PAAm

4.5 g of AAm, 0.09 g of APS were added into 25.5 g of deionized water under vigorous stirring at room temperature until the clear AAm aqueous solutions formed. Then the resulting solution was poured into Teflon mold at 60 °C for 3 h to free radical polymerization. The samples after polymerization were frozen at −20 °C for 12 h. After freezing, the frozen samples were thawed at room temperature (~25–30 °C) and then the resulting gels were denoted as FT gels. Similar to the previous steps, the frozen samples were submerged in DESs-Ca liquid at room temperature for 24 h to create the FTD-C gels.

Data availability

The data supporting the findings of this study are included in the main text, Supplementary Information, and Source Data file. Additional data are available from the corresponding author upon request. Source data are provided in this paper.

References

Khuu, N., Kheiri, S. & Kumacheva, E. Structurally anisotropic hydrogels for tissue engineering. Trends Chem. 3, 1002–1026 (2021).

Zhang, W., Feng, P., Chen, J., Sun, Z. & Zhao, B. Electrically conductive hydrogels for flexible energy storage systems. Prog. Polym. Sci. 88, 220–240 (2019).

Shen, Z., Zhu, X., Majidi, C. & Gu, G. Cutaneous ionogel mechanoreceptors for soft machines, physiological sensing, and amputee prostheses. Adv. Mater. 33, 2102069 (2021).

Zhang, J. et al. High-performance triboelectric nanogenerator based on chitin for mechanical-energy harvesting and self-powered sensing. Carbohydr. Polym. 291, 119586 (2022).

Zhao, L. et al. A Multifunctional, self-healing, self-adhesive, and conductive sodium alginate/poly(vinyl alcohol) composite hydrogel as a flexible strain sensor. ACS Appl. Mater. Interfaces 13, 11344–11355 (2021).

Yang, Z. et al. Highly stretchable, adhesive, biocompatible, and antibacterial hydrogel dressings for wound healing. Adv. Sci. 8, 2003627 (2021).

Zhang, X. et al. Tough liquid-free ionic conductive elastomers with robust adhesion and self-healing properties for ionotronic devices. Adv. Funct. Mater. 34, 2307400 (2023).

Mo, F. et al. A highly stable and durable capacitive strain sensor based on dynamically super-tough hydro/organo-gels. Adv. Funct. Mater. 31, 2010830 (2021).

Zhang, J., Hu, Y., Zhang, L., Zhou, J. & Lu, A. Transparent, ultra-stretching, tough, adhesive carboxyethyl chitin/polyacrylamide hydrogel toward high-performance soft electronics. Nano-Micro Lett. 15, 8 (2023).

Xu, L. et al. A transparent, highly stretchable, solvent-resistant, recyclable multifunctional ionogel with underwater self-healing and adhesion for reliable strain sensors. Adv. Mater. 33, 2105306 (2021).

Han, L. et al. Mussel-inspired adhesive and conductive hydrogel with long-lasting moisture and extreme temperature tolerance. Adv. Funct. Mater. 28, 1704195 (2018).

Matsuda, T., Kawakami, R., Namba, R., Nakajima, T. & Gong, J. P. Mechanoresponsive self-growing hydrogels inspired by muscle training. Science 363, 504 (2019).

Han, Z. L. et al. A versatile hydrogel network-repairing strategy achieved by the covalent-like hydrogen bond interaction. Sci. Adv. 8, eab15066 (2022).

Zhang, H. J. et al. Tough physical double-network hydrogels based on amphiphilic triblock copolymers. Adv. Mater. 28, 4884–4890 (2016).

Freedman, B. R. et al. Degradable and removable tough adhesive hydrogels. Adv. Mater. 33, 2008553 (2021).

Liu, C. et al. Tough hydrogels with rapid self-reinforcement. Science 372, 1078 (2021).

Hua, M. T. et al. Strong tough hydrogels via the synergy of freeze-casting and salting out. Nature 590, 594 (2021).

Wu, L. et al. Natural-wood-inspired ultrastrong anisotropic hybrid hydrogels targeting artificial tendons or ligaments. ACS Nano 17, 13522–13532 (2023).

Lin, S. T., Liu, J., Liu, X. Y. & Zhao, X. H. Muscle-like fatigue-resistant hydrogels by mechanical training. Proc. Natl Acad. Sci. USA 116, 10244–10249 (2019).

Wang, M. X. et al. Tough and stretchable ionogels by in situ phase separation. Nat. Mater. 21, 359 (2022).

He, Q. Y., Huang, Y. & Wang, S. Y. Hofmeister effect-assisted one step fabrication of ductile and strong gelatin hydrogels. Adv. Funct. Mater. 28, 1705069 (2018).

Carriazo, D., Serrano, M. C., Gutiérrez, M. C., Ferrer, M. L. & del Monte, F. Deep-eutectic solvents playing multiple roles in the synthesis of polymers and related materials. Chem. Soc. Rev. 41, 4996–5014 (2012).

Hansen, B. B. et al. Deep eutectic solvents: a review of fundamentals and applications. Chem. Rev. 121, 1232–1285 (2021).

Gu, C. A. et al. A full-device autonomous self-healing stretchable soft battery from self-bonded eutectogels. Adv. Mater. 35, 2208392 (2023).

Zhao, X. H. Multi-scale multi-mechanism design of tough hydrogels: building dissipation into stretchy networks. Soft Matter 10, 672–687 (2014).

Kamata, H., Akagi, Y., Kayasuga-Kariya, Y., Chung, U. & Sakai, T. Nonswellable” hydrogel without mechanical hysteresis. Science 343, 873–875 (2014).

Handorf, A. M., Zhou, Y. X., Halanski, M. A. & Li, W. J. Tissue stiffness dictates development, homeostasis, and disease progression. Organogenesis 11, 1–15 (2015).

Xu, L. J. et al. A solvent-exchange strategy to regulate noncovalent interactions for strong and antiswelling hydrogels. Adv. Mater. 32, 2004579 (2020).

Yu, H. C. et al. Reversibly transforming a highly swollen polyelectrolyte hydrogel to an extremely tough one and its application as a tubular grasper. Adv. Mater. 32, 2005171 (2020).

Wu, Y. Q., Shi, Y. Q. & Wang, H. L. Urea as a hydrogen bond producer for fabricating mechanically very strong hydrogels. Macromolecules 56, 4491–4502 (2023).

Li, M. X. et al. Superstretchable, yet stiff, fatigue-resistant ligament-like elastomers. Nat. Commun. 13, 2279 (2022).

Peng, M., Xiao, G., Tang, X. & Zhou, Y. Hydrogen-bonding assembly of rigid-Rod Poly(p-sulfophenylene terephthalamide) and flexible-chain poly(vinyl alcohol) for transparent, strong, and tough molecular composites. Macromolecules 47, 8411–8419 (2014).

Zhang, Y., Kou, K., Pan, C., Li, Z. & Ji, T. Effect of tensile rates on thermal and mechanical properties of porous PTFE composites. J. Appl. Polym. Sci. 136, 48175 (2019).

Li, W. Z. et al. Supramolecular Ionogels tougher than Metals. Adv. Mater. 35, 2301383 (2023).

Tang, N. et al. Evolutionary reinforcement of polymer networks: a stepwise-enhanced strategy for ultrarobust eutectogels. Adv. Mater. 36, 2309576 (2023).

Rivlin, R. & Thomas, A. G. Rupture of rubber. I. characteristic energy for tearing. J. Polym. Sci. 10, 291–318 (1953).

Lin, S. T. et al. Anti-fatigue-fracture hydrogels. Sci. Adv. 5, eaau8528 (2019).

Cui, W. et al. Fiber-reinforced viscoelastomers show extraordinary crack resistance that exceeds metals. Adv. Mater. 32, 1907180 (2020).

Mazínová I., Florian P. Materials Selection in Mechanical Design. In: 54th International Conference of Machine-Design-Departments) 145, 10–12 (2013).

Kmetty, A., Bárány, T. & Karger-Kocsis, J. Self-reinforced polymeric materials: A review. Prog. Polym. Sci. 35, 1288–1310 (2010).

Ritchie, R. O. The conflicts between strength and toughness. Nat. Mater. 10, 817–822 (2011).

Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014).

Ricciardi, R. et al. Structural organization of poly(vinyl alcohol) hydrogels obtained by freezing and thawing techniques:: a SANS study. Chem. Mater. 17, 1183–1189 (2005).

Yang, C. H. et al. Strengthening alginate/polyacrylamide hydrogels using various multivalent cations. ACS Appl. Mater. interfaces 5, 10418–10422 (2013).

Otsuka, E. et al. Effects of preparation temperature on swelling and mechanical properties of PVA cast gels. Soft Matter 8, 8129–8136 (2012).

Zhang, R. et al. Stretch-induced complexation reaction between poly(vinyl alcohol) and iodine: an in situ synchrotron radiation small- and wide-angle X-ray scattering study. Soft Matter 14, 2535–2546 (2018).

Bai, Z. et al. A solvent regulated hydrogen bond crosslinking strategy to prepare robust hydrogel paint for oil/water separation. Adv. Funct. Mater. 31, 2104701 (2021).

Wu, Y. C. et al. Solvent-exchange-assisted wet annealing: a new strategy for superstrong, tough, stretchable, and anti-fatigue hydrogels. Adv. Mater. 35, 2210624 (2023).

Priyadarshi, R., Kumar, B. & Rhim, J.-W. Green and facile synthesis of carboxymethylcellulose/ZnO nanocomposite hydrogels crosslinked with Zn2+ ions. Int. J. Biol. Macromolecules 162, 229–235 (2020).

Li, L. et al. Ultra-tough and recyclable ionogels constructed by coordinated supramolecular solvents. Angew. Chem.-Int. Ed. 61, e202212512 (2022).

Yang, X. et al. In-situ encapsulation and construction of Lac@ HOFs/hydrogel composite for enhancing laccase stability and azo dyes decolorization efficiency. Carbohydr. Polym. 320, 121157 (2023).

Lin, X. et al. Polyphenol-driving assembly for constructing chitin-polyphenol-metal hydrogel as wound dressing. Carbohydr. Polym. 290, 119444 (2022).

Hou, Y. et al. Preparation of PVA hydrogel with high-transparence and investigations of its transparent mechanism. Rsc Adv. 5, 24023–24030 (2015).

Wan, H., Wu, B., Hou, L. & Wu, P. Amphibious Polymer Materials with High Strength and Superb Toughness in Various Aquatic and Atmospheric Environments. Adv. Mater. 36, 2307290 (2023).

Rylski, A. K. et al. Polymeric multimaterials by photochemical patterning of crystallinity. Science 378, 211–215 (2022).

Xu, L., Zhao, X., Xu, C. & Kotov, N. A. Water-rich biomimetic composites with abiotic self-organizing nanofiber network. Adv. Mater. 30, 1703343 (2018).

Xu, L. et al. Conjoined-network rendered stiff and tough hydrogels from biogenic molecules. Sci. Adv. 5, eaau3442 (2019).

Zhang, Q. et al. 3D printed high-strength supramolecular polymer hydrogel-cushioned radially and circumferentially oriented meniscus substitute. Adv. Funct. Mater. 32, 2200360 (2022).

Yan, X. et al. Quadruple H-bonding cross-linked supramolecular polymeric materials as substrates for stretchable, antitearing, and self-healable thin film electrodes. J. Am. Chem. Soc. 140, 5280–5289 (2018).

Gotoh, H. et al. Optically transparent, high-toughness elastomer using a polyrotaxane cross-linker as a molecular pulley. Sci. Adv. 4, eaat7629 (2018).

Matsuda, T., Nakajima, T. & Gong, J. P. Fabrication of tough and stretchable hybrid double-network elastomers using ionic dissociation of polyelectrolyte in nonaqueous media. Chem. Mater. 31, 3766–3776 (2019).

Cui, W. et al. Strong tough conductive hydrogels via the synergy of ion-induced cross-linking and salting-out. Adv. Funct. Mater. 32, 2204823 (2022).

Dong, X. et al. Strong and tough conductive organo‐hydrogels via freeze‐casting assisted solution substitution. Adv. Funct. Mater. 32, 2203610 (2022).

Zhang, H., Tang, N., Yu, X., Li, M.-H. & Hu, J. Strong and tough physical eutectogels regulated by the spatiotemporal expression of non-covalent interactions. Adv. Funct. Mater. 32, 2206305 (2022).

Xu, L., Qiao, Y. & Qiu, D. Coordinatively stiffen and toughen hydrogels with adaptable crystal-___domain cross-linking. Adv. Mater. 35, 2209913 (2023).

Xia, Q. et al. Metal-organic framework (MOF) facilitated highly stretchable and fatigue-resistant ionogels for recyclable sensors. Mater. Horiz. 9, 2881–2892 (2022).

Yiming, B. et al. Ambiently and Mechanically Stable Ionogels for Soft Ionotronics. Adv. Funct. Mater. 31, 2102773 (2021).

Ducrot, E., Chen, Y. L., Bulters, M., Sijbesma, R. P. & Creton, C. Toughening elastomers with sacrificial bonds and watching them break. Science 344, 186–189 (2014).

Wang, Y. J. et al. Ultrastiff and tough supramolecular hydrogels with a dense and robust hydrogen bond network. Chem. Mater. 31, 1430–1440 (2019).

Hu, X., Vatankhah-Varnoosfaderani, M., Zhou, J., Li, Q. & Sheiko, S. S. Weak hydrogen bonding enables hard, strong, tough, and elastic hydrogels. Adv. Mater. 27, 6899 (2015).

Rauner, N., Meuris, M., Zoric, M. & Tiller, J. C. Enzymatic mineralization generates ultrastiff and tough hydrogels with tunable mechanics. Nature 543, 407 (2017).

Wu, J. et al. Strong and ultra-tough supramolecular hydrogel enabled by strain-induced microphase separation. Adv. Funct. Mater. 33, 2210395 (2023).

Luo, C. et al. Super-strong, nonswellable, and biocompatible hydrogels inspired by human tendons. ACS Appl. Mater. Interfaces 14, 2638–2649 (2022).

Lin, X. et al. Anisotropic hybrid hydrogels constructed via the noncovalent assembly for biomimetic tissue scaffold. Adv. Funct. Mater. 32, 2112685 (2022).

Wei, P. et al. Strong and tough cellulose hydrogels via solution annealing and dual cross-LInking. Small 19, 2301204 (2023).

Ye, Y., Zhang, Y., Chen, Y., Han, X. & Jiang, F. Cellulose nanofibrils enhanced, strong, stretchable, freezing-tolerant ionic conductive organohydrogel for multi-functional sensors. Adv. Funct. Mater. 30, 2003430 (2020).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51973166) to A.L., the Key Research and Development Program of Hubei Province (2020BCA079) to A.L., and the Large-scale Instrument and Equipment Sharing Foundation of Wuhan University to A.L.

Author information

Authors and Affiliations

Contributions

J.Z. (Jipeng Zhang) conceived the study, performed the experiments, conducted data analyzes and wrote the manuscript. M.Z., and H.W. provided related drawing supports for this study. J.Z. (Jinping Zhou), and A.L. conceived, supervised the study and revised the manuscript. All authors have agreed with the manuscript for publication.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Jun Fu, Josue D. Mota-Morales and the other, anonymous, reviewer for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, J., Zhang, M., Wan, H. et al. Coordinatively stiffen and toughen polymeric gels via the synergy of crystal-___domain cross-linking and chelation cross-linking. Nat Commun 16, 320 (2025). https://doi.org/10.1038/s41467-024-55245-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-55245-3